Patents

Literature

104results about How to "Fast cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

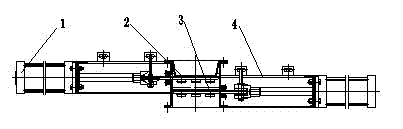

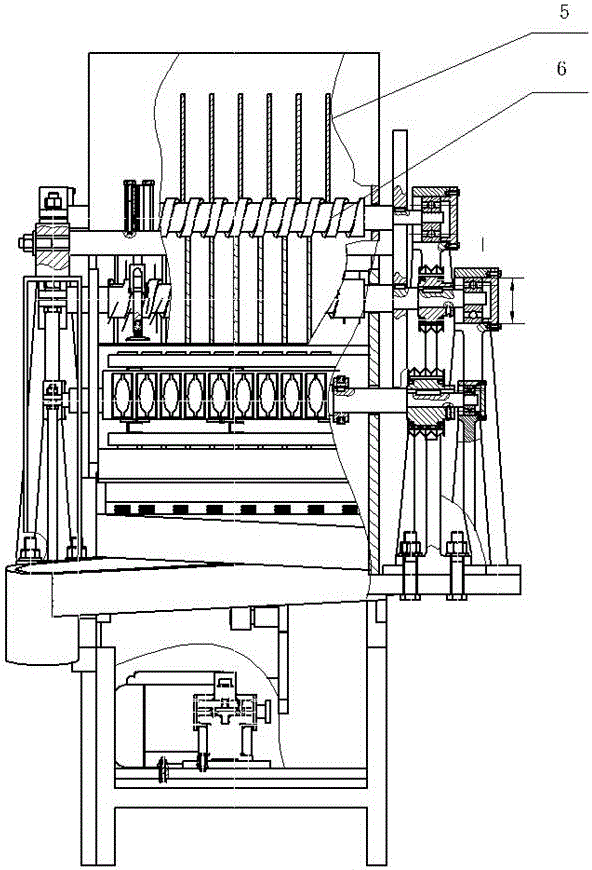

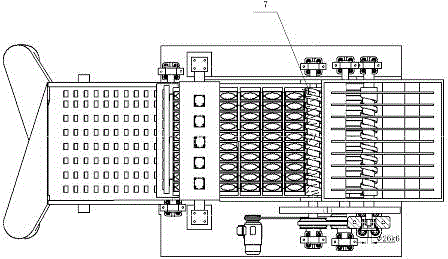

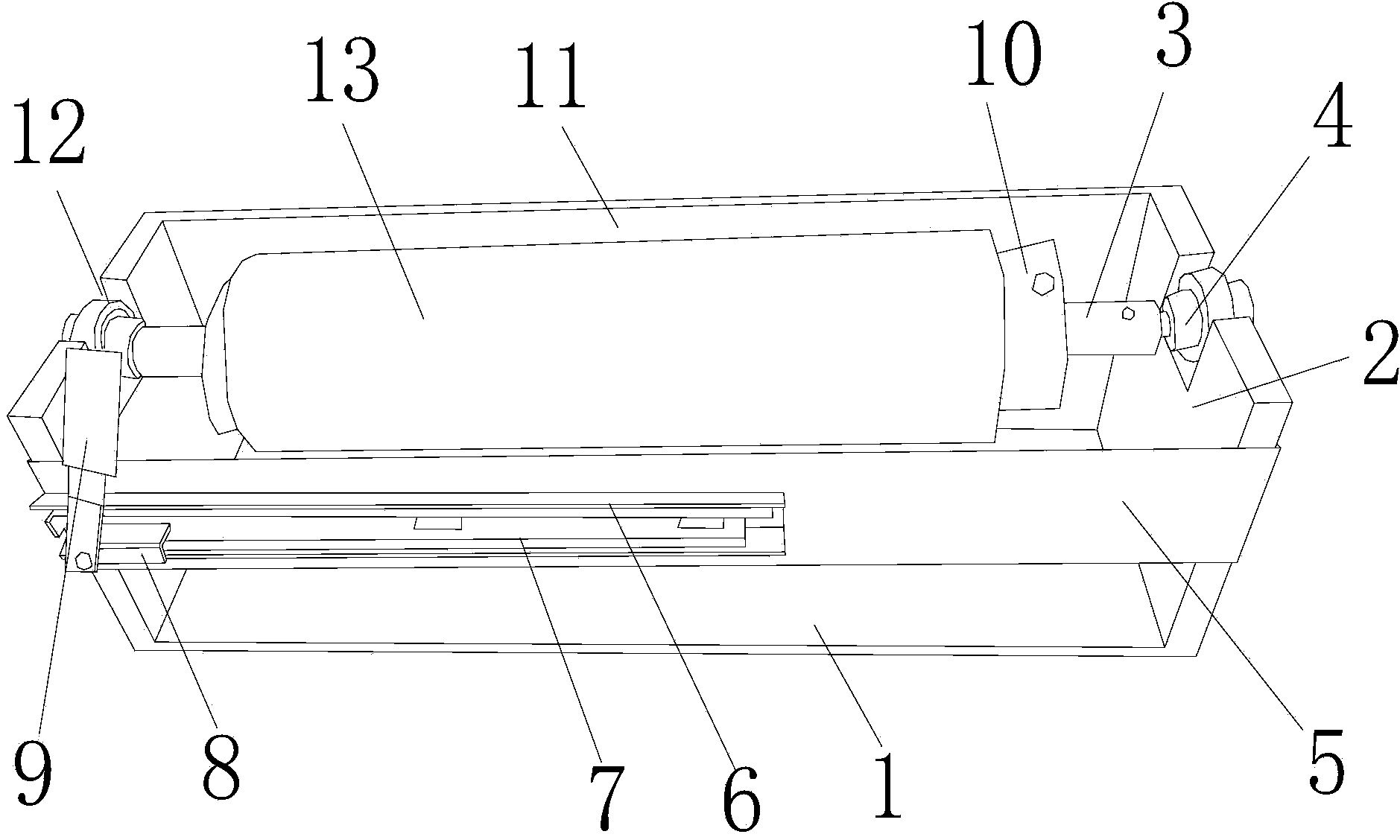

EVA film hob cutting device of thin-film solar cell

InactiveCN101823268ACompact structureLarge operating spaceMetal working apparatusDrive shaftMachining

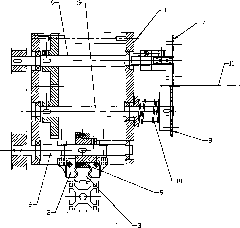

The invention relates to a part of a thin-film solar cell manufacturing device, in particular to an EVA film hob cutting device of a thin-film solar cell. The EVA film hob cutting device comprises a knife rest which is used for installing a cutting knife, wherein the bottom of the knife rest is fixedly connected with a slide block, the slide block is mutually matched and positioned with a fixed linear guide track under the slide block, the slide block and the knife rest can move along the linear guide track, an upper knife shaft, a lower knife shaft and a rubber wheel shaft are arranged on the knife rest, one of the upper knife shaft, the lower knife shaft and the rubber wheel shaft is a driving shaft driven by an electric motor, the other two shafts are synchronously driven by the driving shaft through a driving mechanism, the ends of the same sides of the upper knife shaft and the lower knife shaft are respectively provided with an upper hob and a lower hob which can rotate along the upper knife shaft and the lower knife shaft, the edges of the upper hob and the lower hob are provided with interlaced and bonded parts, at least one rubber rolling wheel is arranged on the rubber wheel shaft, and the bottom of the rubber rolling wheel is pressed on the top surface of the linear guide track. The EVA film hob cutting device can automatically cut an EVA film of a thin-film solar cell and has high automation degree and high machining precision.

Owner:镇江市博锐自动化科技有限公司

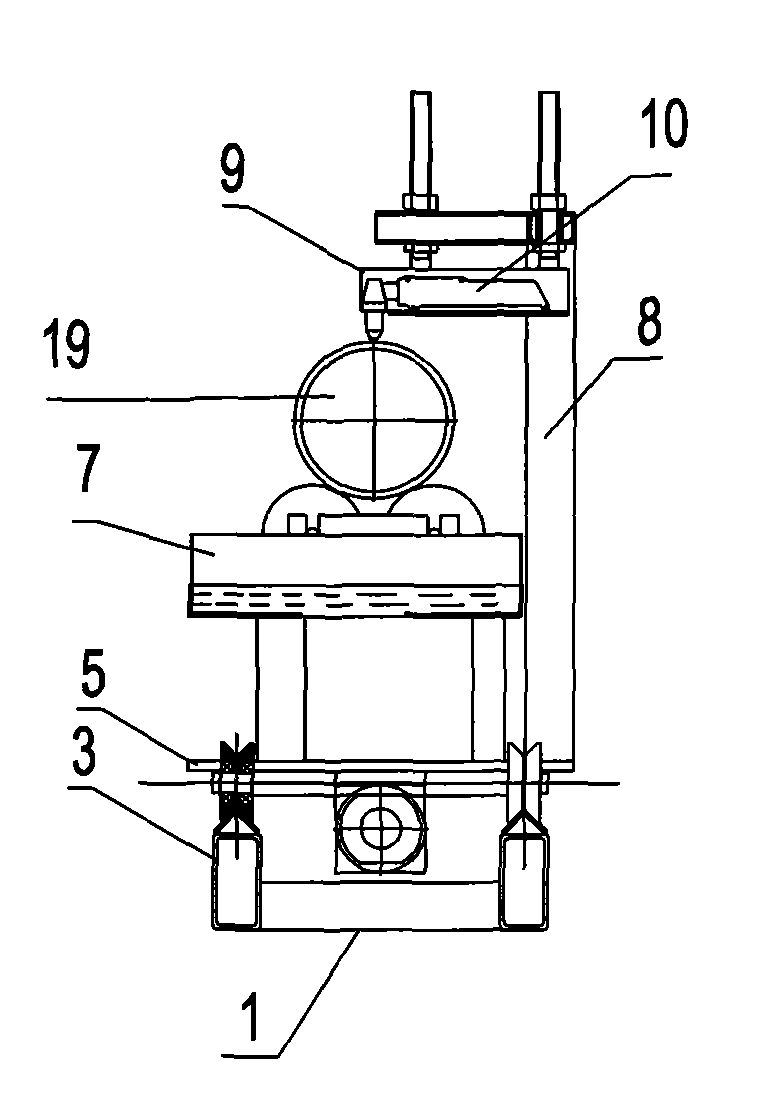

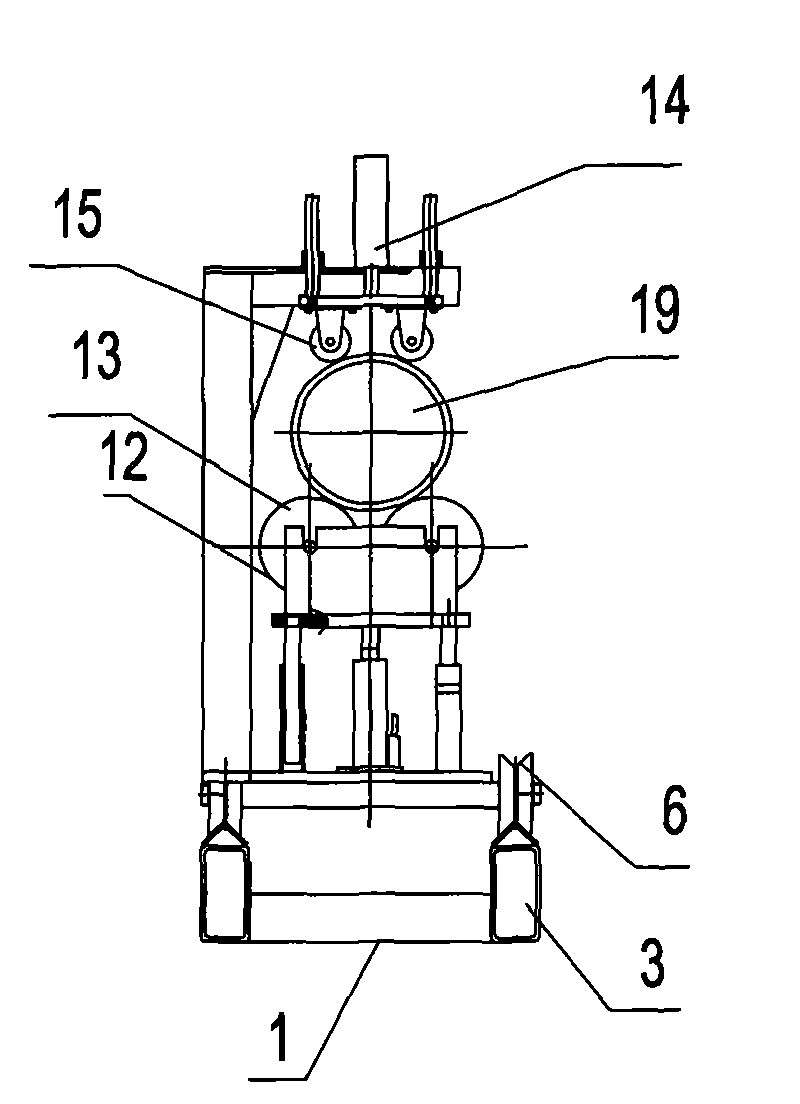

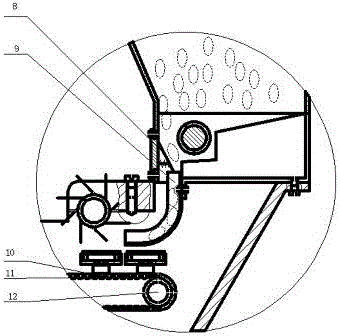

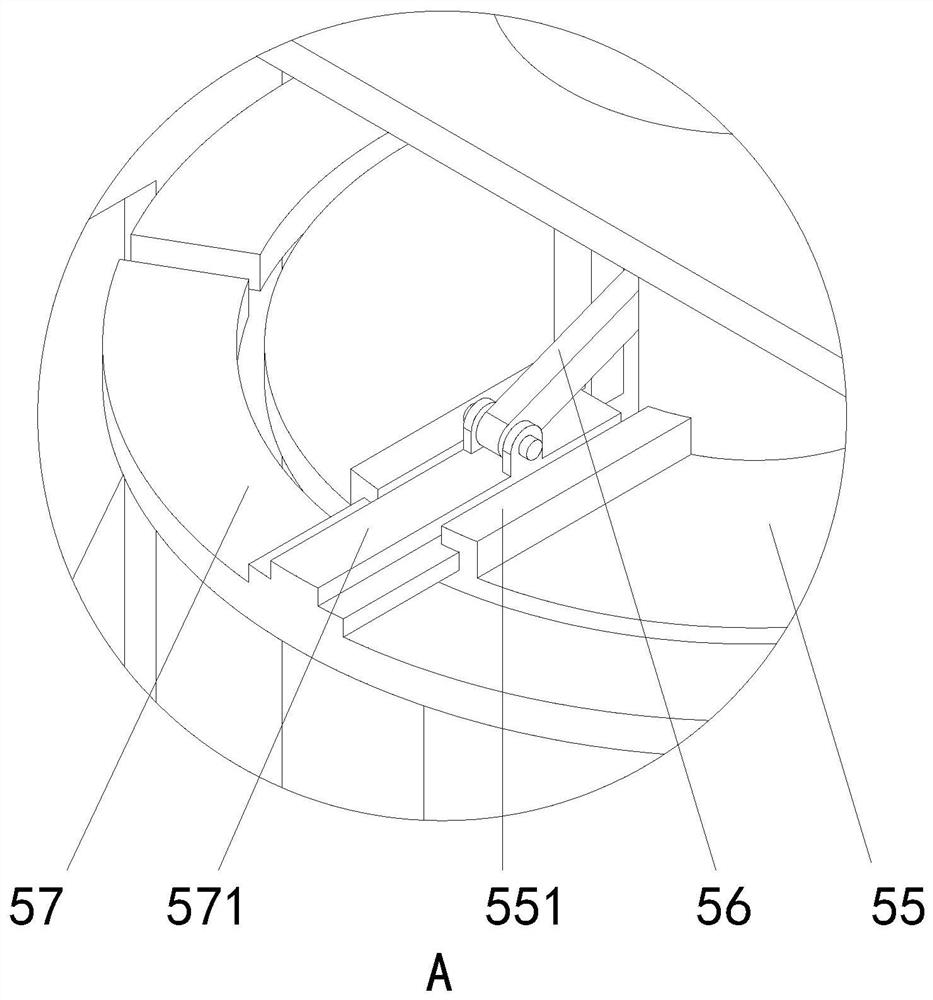

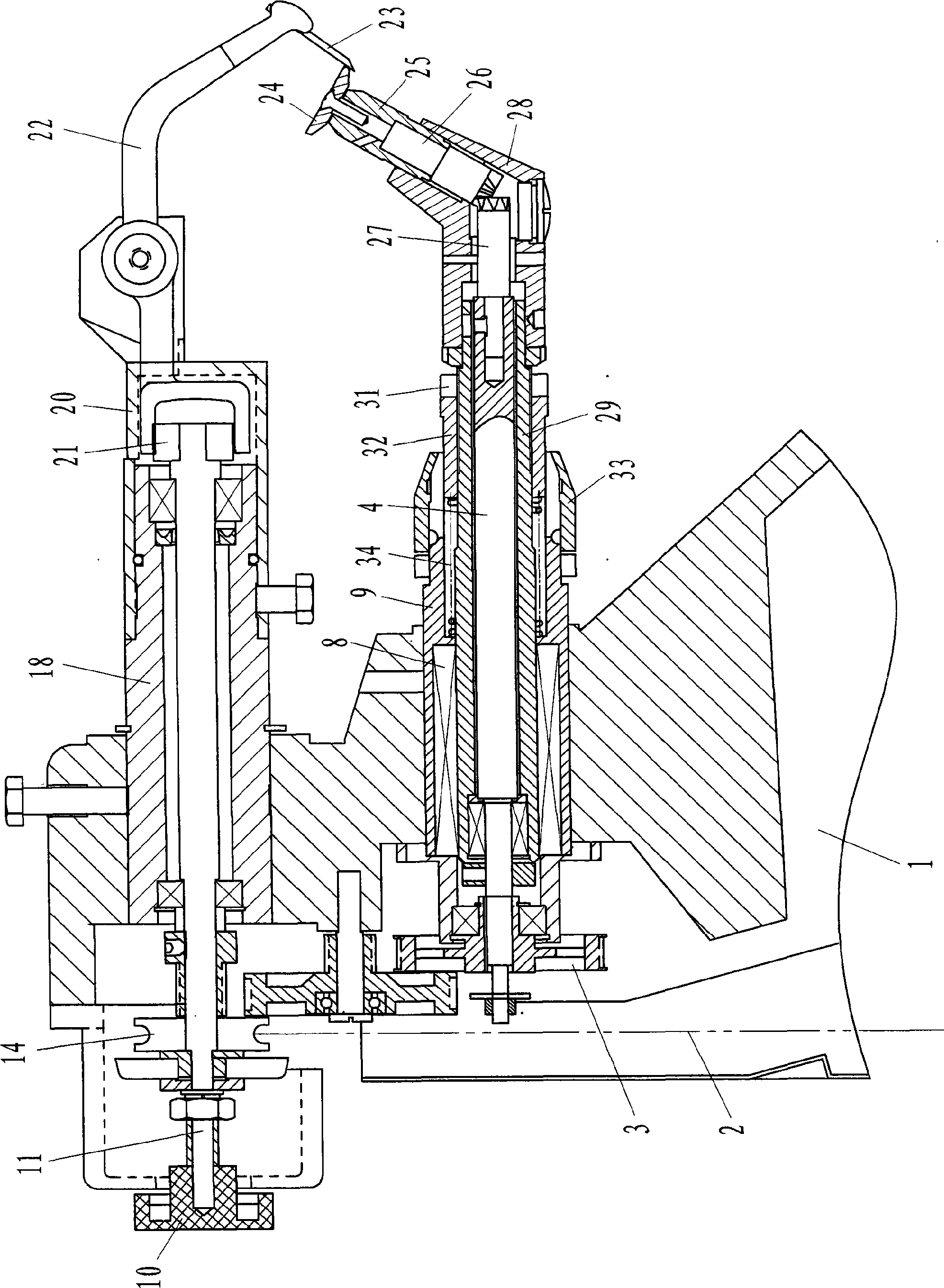

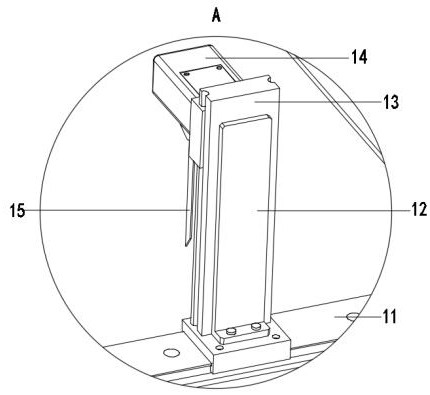

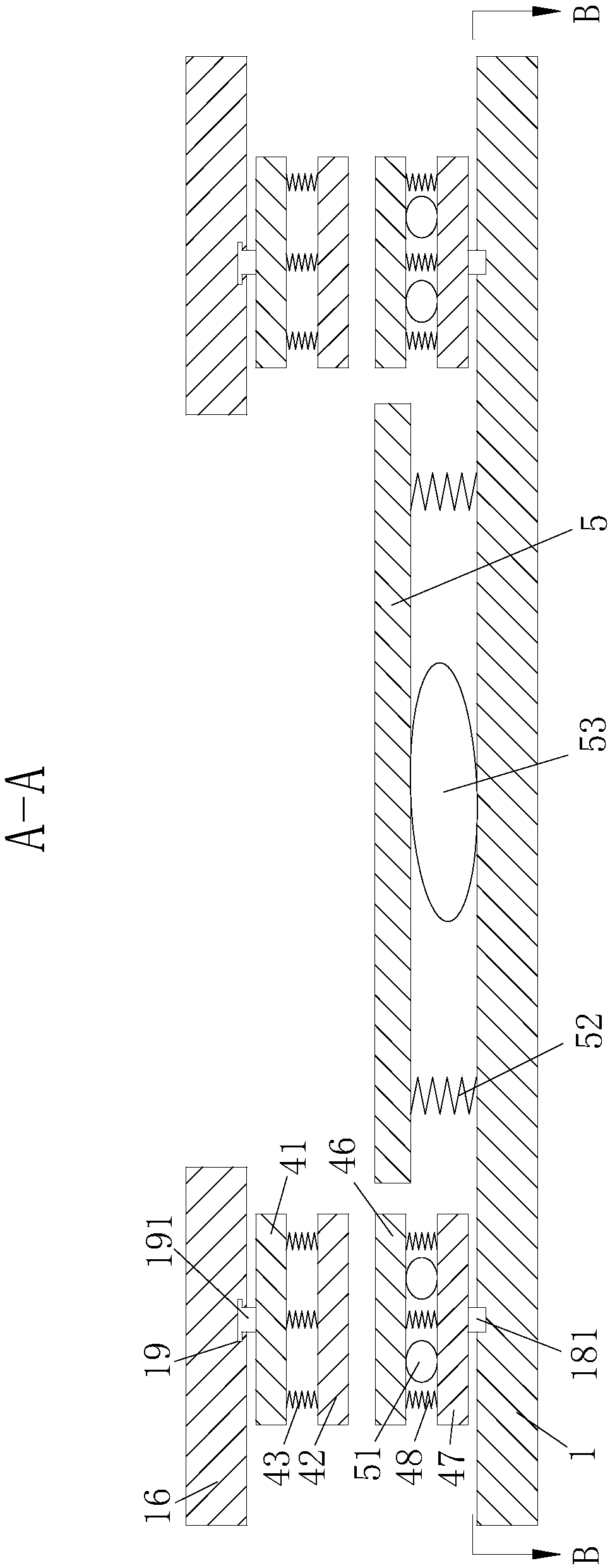

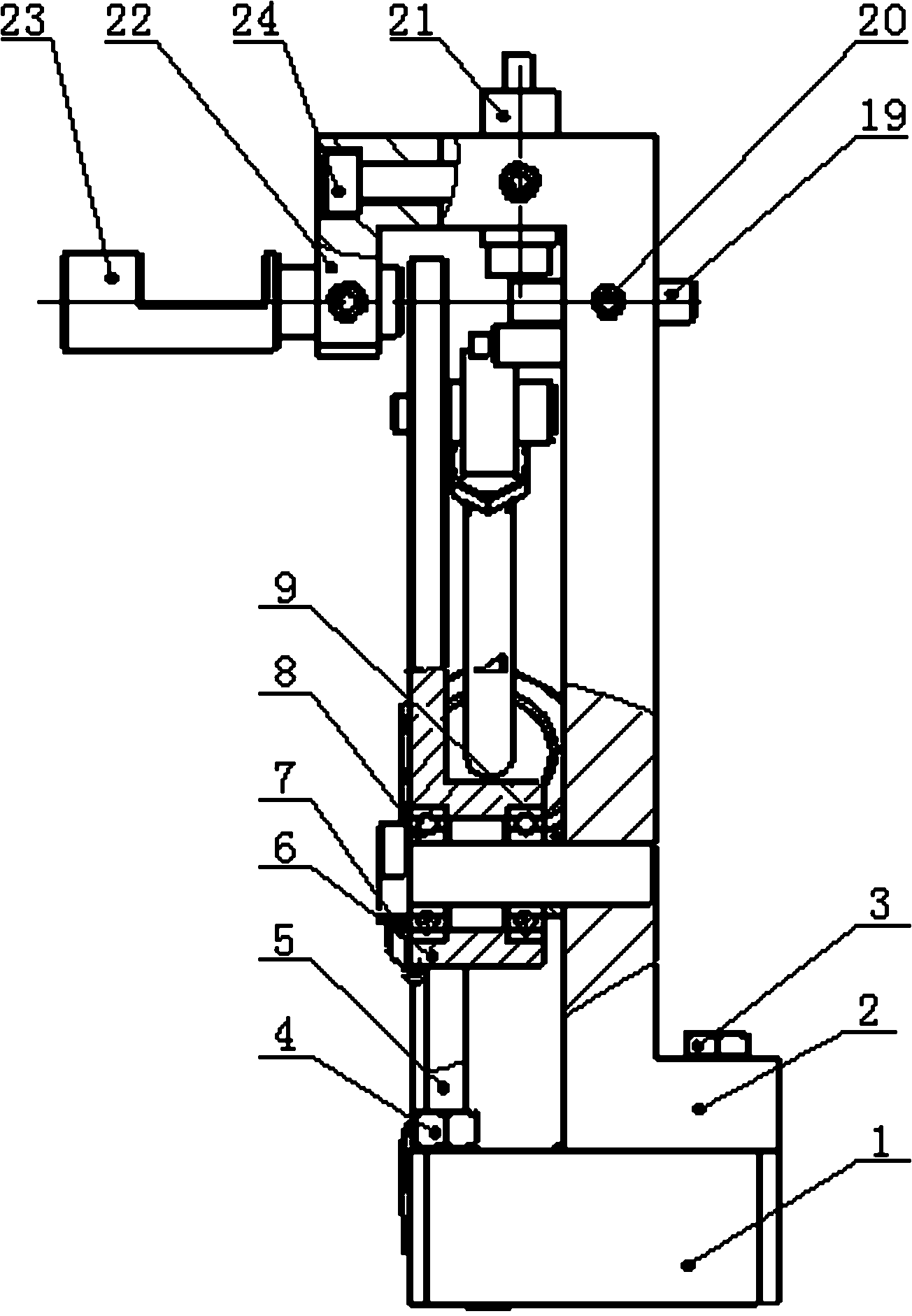

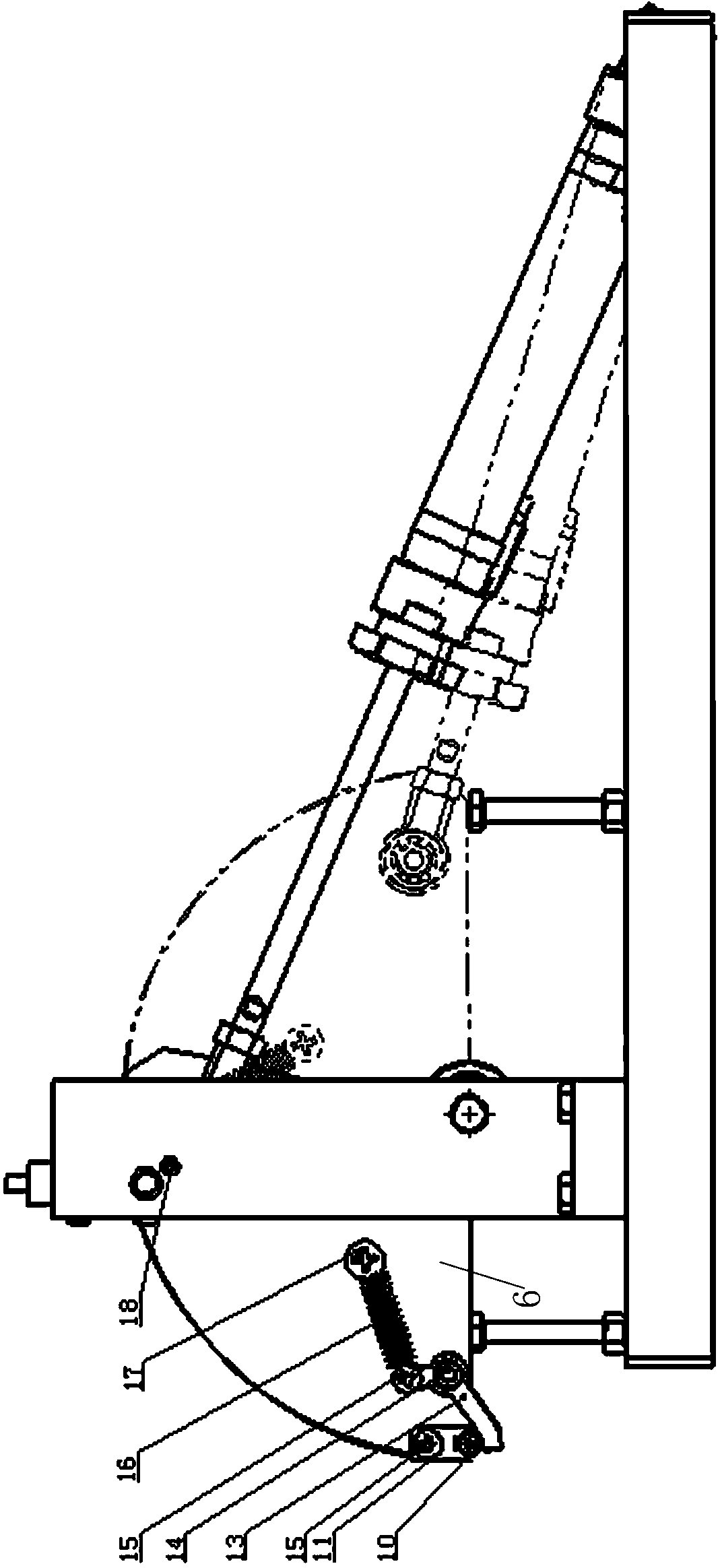

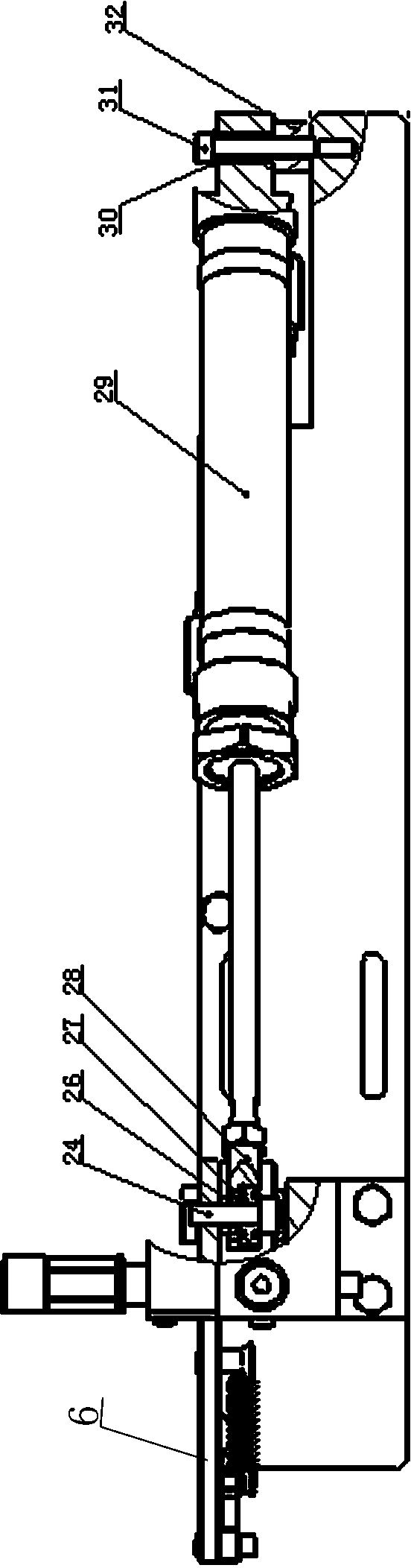

Plasma automatic unloading machine and using method thereof

ActiveCN102029465APrevent jumpingGuaranteed stabilityWelding/cutting auxillary devicesAuxillary welding devicesPhysical hard workAir cylinder Press

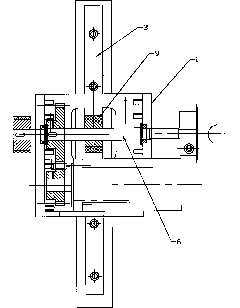

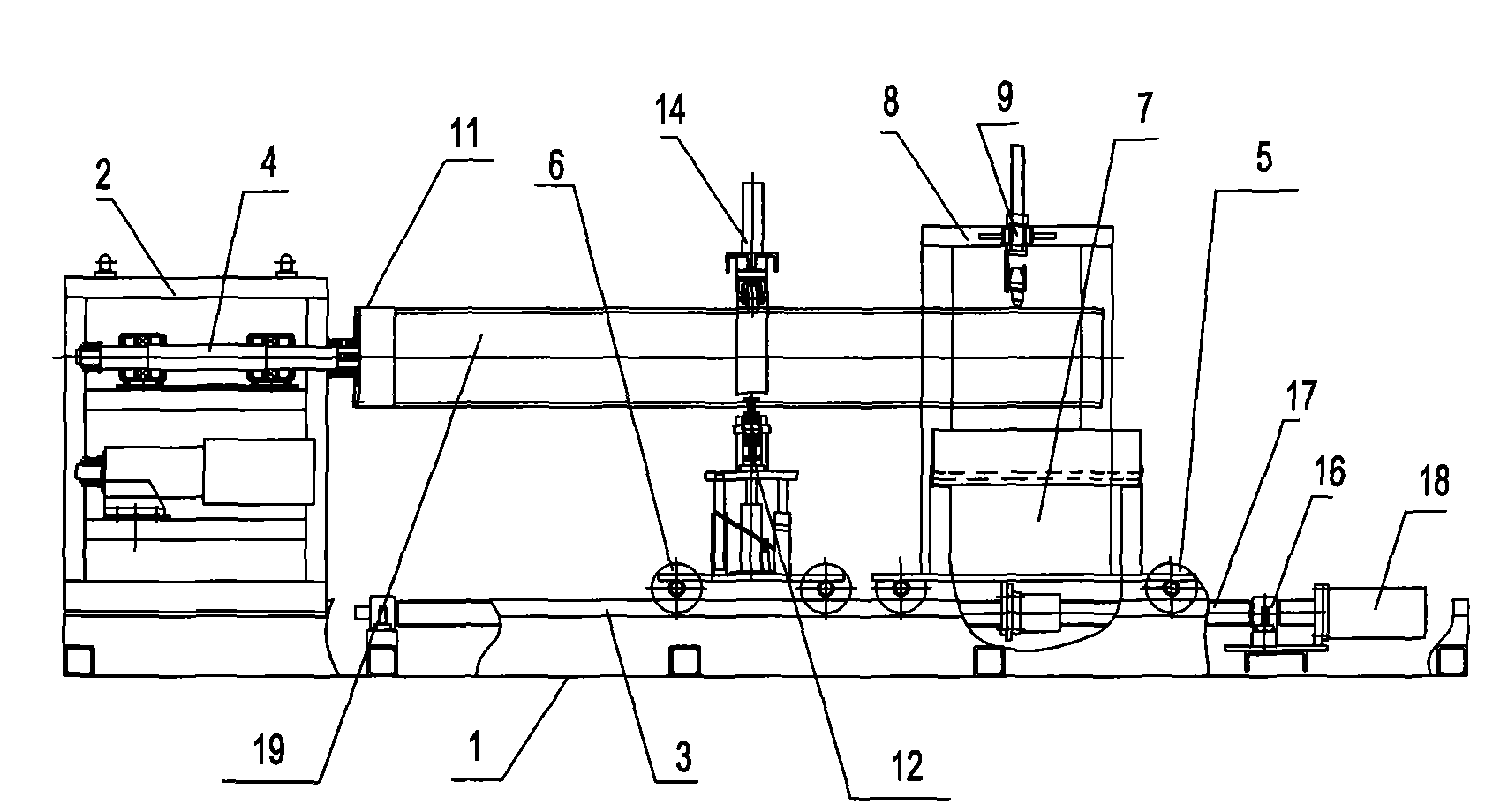

The invention discloses a plasma automatic unloading machine and a using method thereof. The unloading machine comprises an unloading machine base, wherein a rotator box component and a rail component are fixedly arranged on the base; a stainless steel tube material rotating main shaft is arranged in the rotary box component, and a three-claw chuck is arranged on one end of the main shaft; two sets of trolley components are arranged on the rail component, a material receiving box component is arranged on the tail trolley component, an upright post component is arranged on the material receiving box component, a cutting component is arranged on the upright post component, and a plasma cutting gun is arranged on the cutting component; and a supporting roller component is arranged on the middle trolley component, a supporting roller is arranged on the supporting roller component, an air cylinder pressing component is arranged on the supporting roller component, and a pressing wheel is arranged on the air cylinder pressing component. The device can continuously and automatically cut the stainless steel tube material into the required tube materials according to the length of a drawing, so that unloading time is greatly shortened, efficiency is improved, cost is reduced greatly, and the labor of operators is reduced.

Owner:BEIJNG HINEN HITECH PETROLEUM TECH DEV

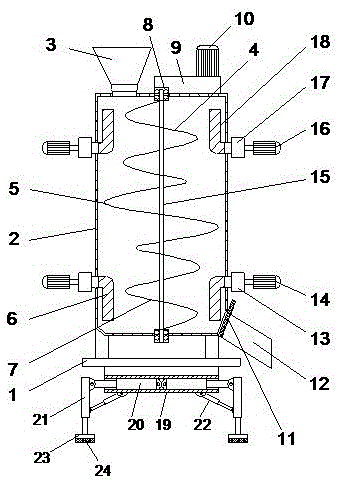

Stable supporting type building stirrer

InactiveCN105582832AImprove stabilityStir wellRotary stirring mixersTransportation and packagingHydraulic cylinderBaseboard

A stable supporting type building stirrer comprises a stirring container, a supporting frame, a feed inlet and a discharge outlet, wherein the supporting frame is fixedly installed on the bottom of the stirring container, the supporting frame is arranged on a supporting guide rail, first hydraulic cylinders are symmetrically arranged inside the supporting guide rail, the end of a piston rod of each first hydraulic cylinder is connected with one end of a corresponding second hydraulic cylinder, a third hydraulic cylinder is arranged between each second hydraulic cylinder and the supporting guide rail, and the end of a piston rod of each second hydraulic cylinder is connected with a corresponding baseboard; the feed inlet is formed in the left side of the top of the stirring container, a feed hopper is arranged above the feed inlet, the discharge outlet is formed in the right side of the bottom of the stirring container, a discharging electromagnetic valve is arranged on the discharge outlet, and a rotary shaft is installed in the middle inside the stirring container through a bearing. Stirring efficiency is high, construction cost is reduced, stirring is uniform, slipping during working of equipment is avoided, and supporting stability is high.

Owner:黄斌

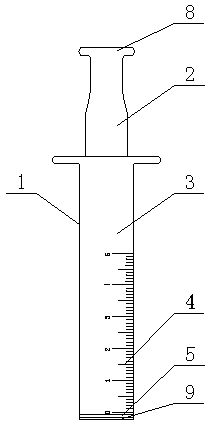

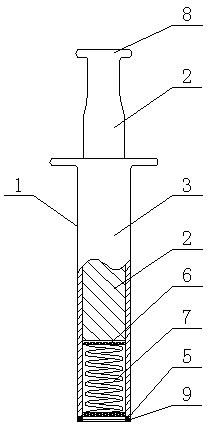

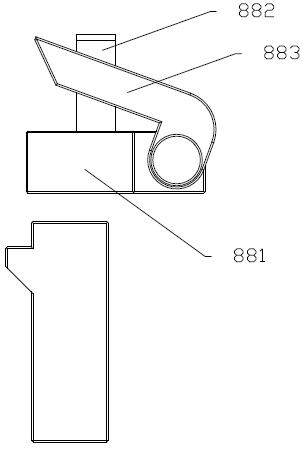

Pork tenderness detection sampler

ActiveCN103954473AGuaranteed accuracyIncrease usage intensityWithdrawing sample devicesAssistive device/technologyBiochemical engineering

The invention belongs to the technical field of auxiliary equipment for pork quality detection, and particularly relates to a pork tenderness detection sampler. The pork tenderness detection sampler comprises a sampler main body, wherein the sampler main body comprises a shear knife cylinder and a push rod, the shear knife cylinder is a hollow cylinder body, the upper and lower ends are open, scales are arranged at the lower part of the outer surface of the shear knife cylinder, a shear knife is fixedly arranged on the bottom surface of the shear knife cylinder, the shear knife is an annular knife, and the inside diameter of the annular knife is equal to the inside diameter of the shear knife cylinder; the outside diameter of the push rod is equal to the inside diameter of the shear knife cylinder, the push rod can move back and forth in the shear knife cylinder, and a spring assembly is fixedly arranged on the bottom surface of the push rod in the vertical direction. The pork tenderness detection sampler provided by the invention is simple and easy to use, economical and convenient, easy to carry and capable of being used for quickly and accurately sampling to improve the detection accuracy, so that the pork tenderness detection sampler is especially suitable for large-scale research and industrial production detection.

Owner:INST OF ANIMAL SCI & VETERINARY MEDICINE SHANDONG ACADEMY OF AGRI SCI

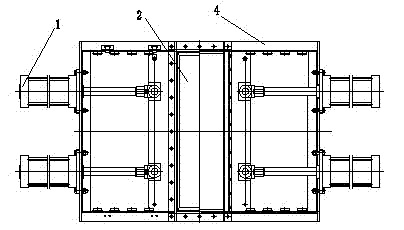

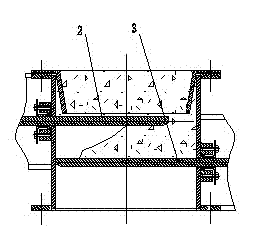

Pneumatic gate valve for feeding of roll squeezer

ActiveCN102364175AGuaranteed uptimeMaterial cut offOperating means/releasing devices for valvesSlide valveTwo layerGate valve

The invention relates to improvement on a pneumatic gate valve structure for feeding of a roll squeezer. A pneumatic gate valve for feeding of the roll squeezer comprises a shell provided with a feed port, wherein a gate valve and a driving cylinder for driving the gate valve to move are arranged on the shell; and the pneumatic gate valve for feeding of the roll squeezer is characterized in that the gate valve comprises at least two layers of valve plates which are vertically arranged. The pneumatic gate valve for feeding of the roll squeezer has the advantages that: 1) a plurality of layers of valve plates are arranged; when materials are required to be cut off, each valve plate moves; and most of the materials are blocked by the valve plate of the upper layer, so that even though the valve plate of the upper layer is blocked by the materials, the valve plate of the lower layer can be closed smoothly to cut off the materials; and 2) in order to provide the compactness and the material cut-off effect of a device, a valve plate 1 and a valve plate 2 are vertically arranged and move oppositely, so that when the materials are cut off, the opening end of the valve plate 2 of the lower layer is blocked by the valve plate of the upper layer and cannot be blocked by the materials; therefore, the materials are cut off quickly and conveniently and the normal running of the roll squeezer is ensured.

Owner:JIANGSU HENGYUAN INT ENG CO LTD

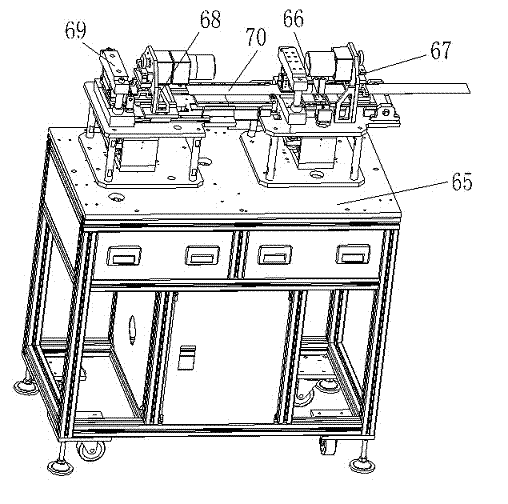

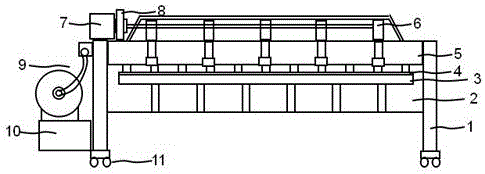

Light-absorbing-piece cutting machine

InactiveCN103112026AEasy to limitGuaranteed qualityMetal working apparatusWebs handlingEngineeringMechanical engineering

The invention discloses a light-absorbing-piece cutting machine. The light-absorbing-piece cutting machine comprises a working table and is characterized by further comprising a limiting mechanism, a delivery mechanism, a piece pressing mechanism, a feeding mechanism and a cutting mechanism, wherein the delivery mechanism which is used for conveying light absorbing pieces to the piece pressing mechanism is installed beside the working table, the limiting mechanism which is used for limiting conveying positions of the light absorbing pieces is installed at the rear end of the piece pressing mechanism, the feeding mechanism which is used for delivering the light absorbing pieces to the cutting mechanism is installed at the rear end of the limiting mechanism, and the cutting mechanism is installed at the rear end of the feeding mechanism. The light-absorbing-piece cutting machine is simple in structure, and good in cutting effect.

Owner:KUNSHAN FOR EASIER AUTOMATION TECH

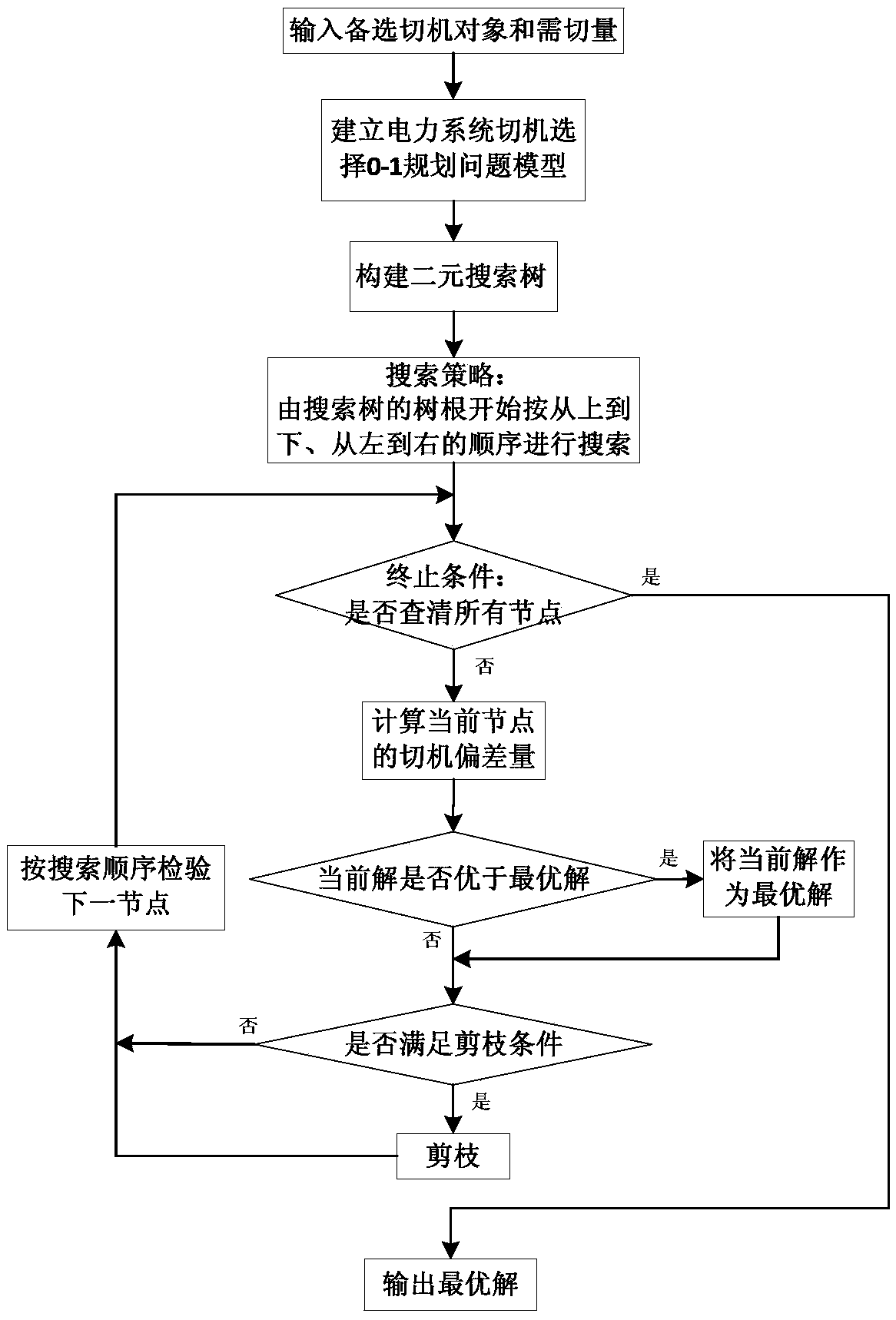

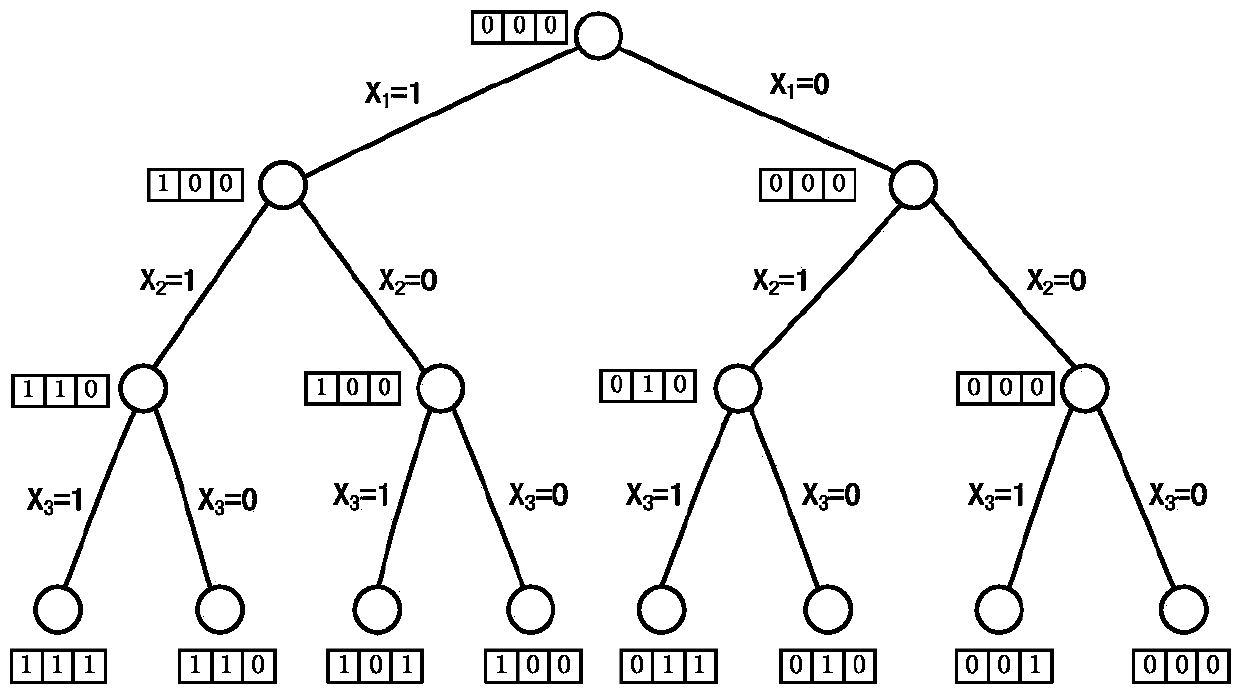

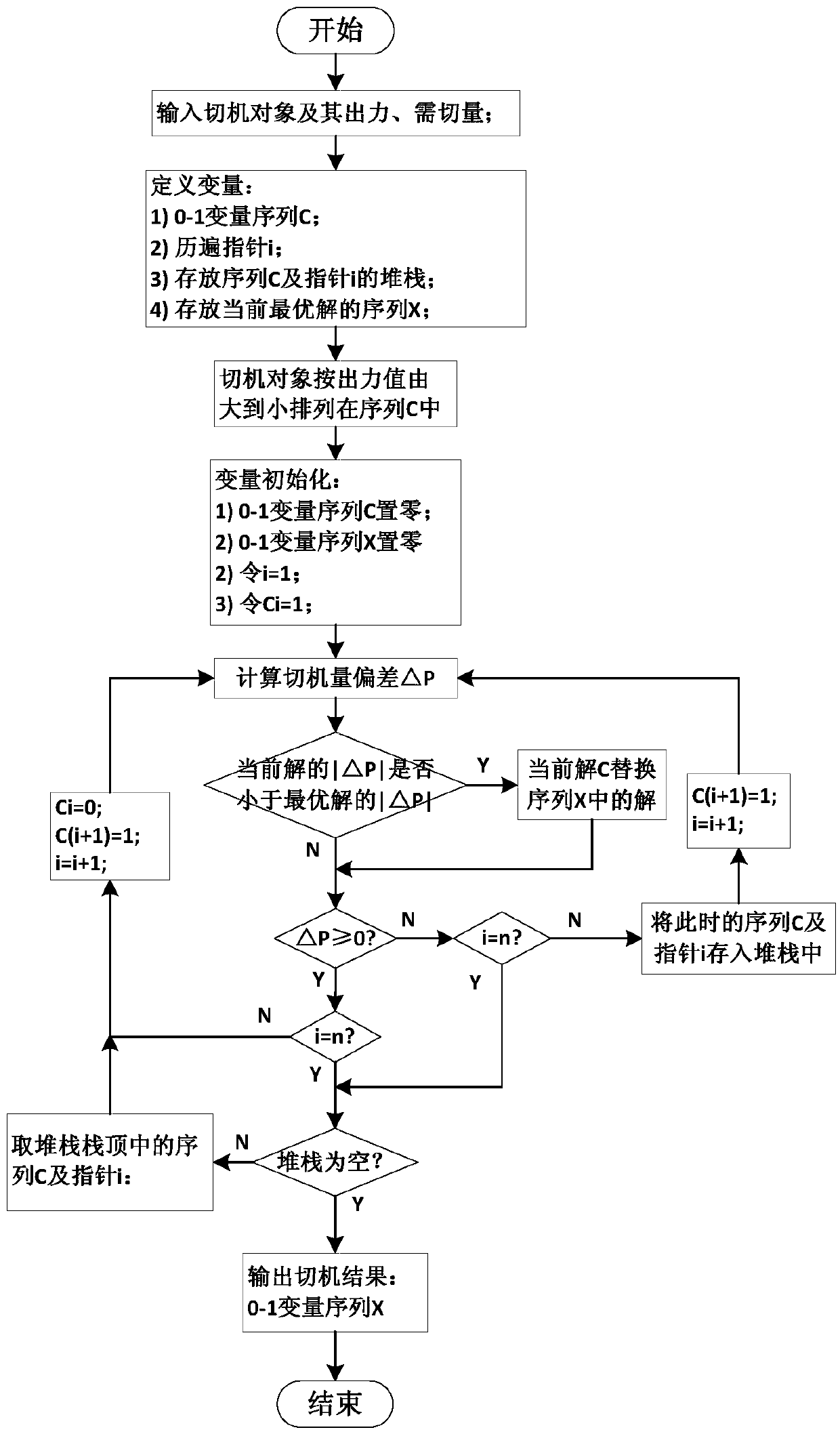

Electric power system optimized generator tripping method based on implicit enumeration method

ActiveCN105515054AReduce computing timeOptimal Cutting MachineData processing applicationsSingle network parallel feeding arrangementsPower gridAlgorithm

The invention discloses an electric power system optimized generator tripping method based on an implicit enumeration method. An optimized generator tripping problem is a typical 0-1 planning problem. In the process that the implicit enumeration method is applied to solving the optimized generator tripping problem, firstly, according to an input alternative generator tripping object and the needed generator tripping amount, an electric power system generator tripping selection 0-1 planning problem model is established, and a corresponding binary search tree is established; then, a search strategy, a pruning strategy and a terminal strategy of the optimized generator tripping problem are solved according to the implicit enumeration method, search is performed along the binary search tree, and search ceaselessly approaches to an optimal solution; when the requirements of a terminal criterion are met, the solving process is completed. By means of the optimized generator tripping method based on the implicit enumeration method, on one hand, the optimal calculation time of a device is shortened, and fast generator tripping is achieved; on the other hand, optimal generator tripping is achieved, and safe and stable running of a power grid is guaranteed.

Owner:NR ELECTRIC CO LTD +1

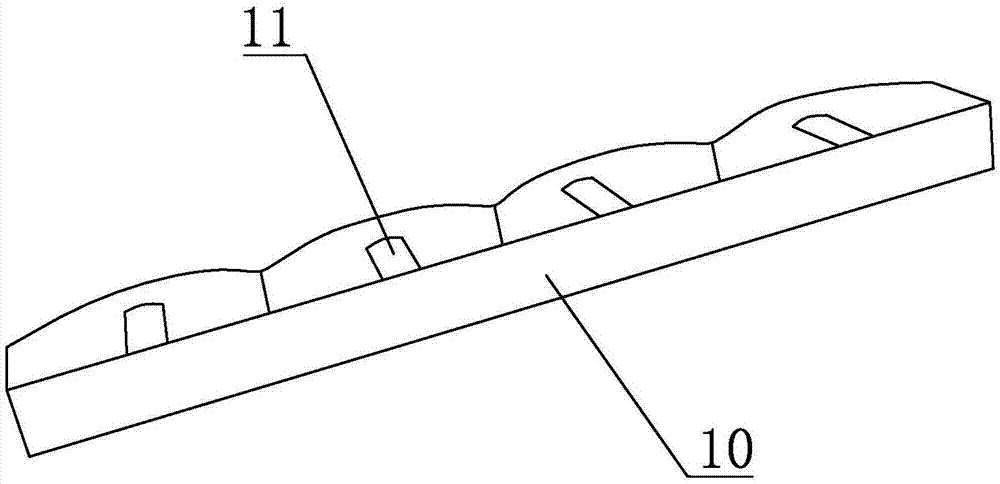

Areca nut slicing mechanism and slicing method

ActiveCN105904493AImprove quality and efficiencyIncrease productivityMetal working apparatusSlide plateAreca

Provided are an areca nut slicing mechanism and slicing method. The areca nut slicing mechanism comprises a vibration screen, an areca template, an air cylinder, a V-shaped collector hopper, a partition plate, a spiral rubber roller, a brush roller, a spring baffle, a U-shaped sliding plate, a rubber skin layer, a synchronous belt and the like, wherein the partition plate is welded in the V-shaped collector hopper; the spiral rubber roller penetrates through the V-shaped collector hopper under the support of a bearing and a bearing block; the spring baffle is installed on the front portion of the V-shaped collector hopper; the U-shaped sliding plate is installed below the V-shaped collector hopper through a bolt; the areca template is installed on the rubber skin layer (10) of the synchronous belt; the air cylinder is connected with a suction cup through a T-shaped rod, and a spring is installed on the suction cup through a bolt; and a cutter clamped by an n-shaped clamp is arranged inside the suction cup and used for slicing areca nuts. After the areca nuts are sliced, areca slices and seeds fall into the vibration screen under the turning action of the synchronous belt, so that vibrating screening is completed, and preparations are made for the next procedure.

Owner:CHANGSHA UNIVERSITY

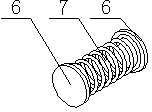

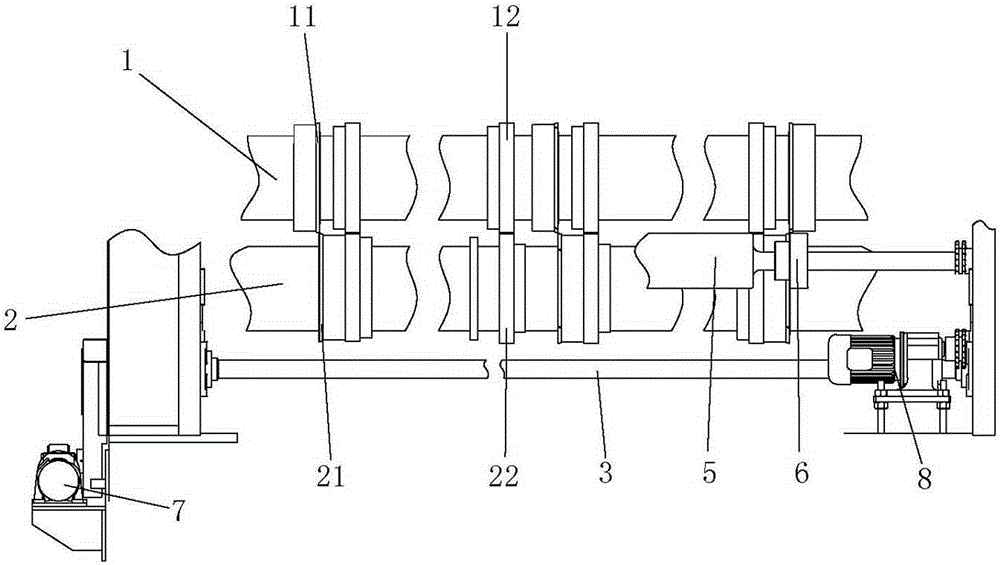

Slitting mill

The invention relates to a slitting mill, and belongs to the technical field of thin plate cutters. The slitting mill comprises an upper roller and a lower roller, and further comprises at least two upper ring cutters arranged on the upper roller and rotating with the upper roller, and at least two lower ring cutters arranged on the lower roller and rotating with the lower roller, wherein the upper roller and the lower roller are both rollers actively rotating; and each upper ring cutter and the corresponding lower ring cutter are opposite in edges to form a cutter set. Through mutual fit between the ring cutters mounted on the upper roller and the lower roller, the slitting mill can realize longitudinal cutting of various plates, can perform fixed-width treatment for the plates, can cut copper foil substrates, paper substrates, aluminum substrates and the like, and has the advantages of quick cutting speed and good cutting effect.

Owner:浙江安浦科技有限公司

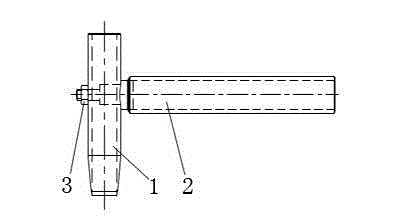

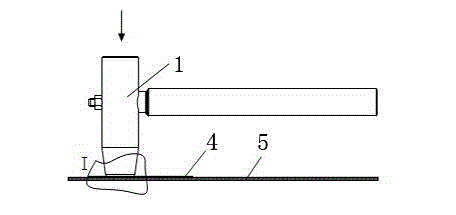

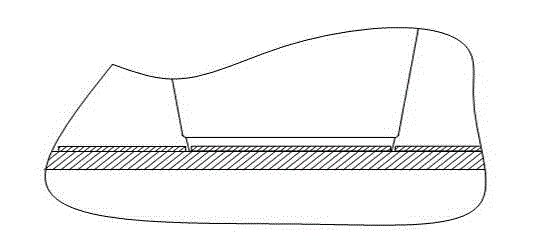

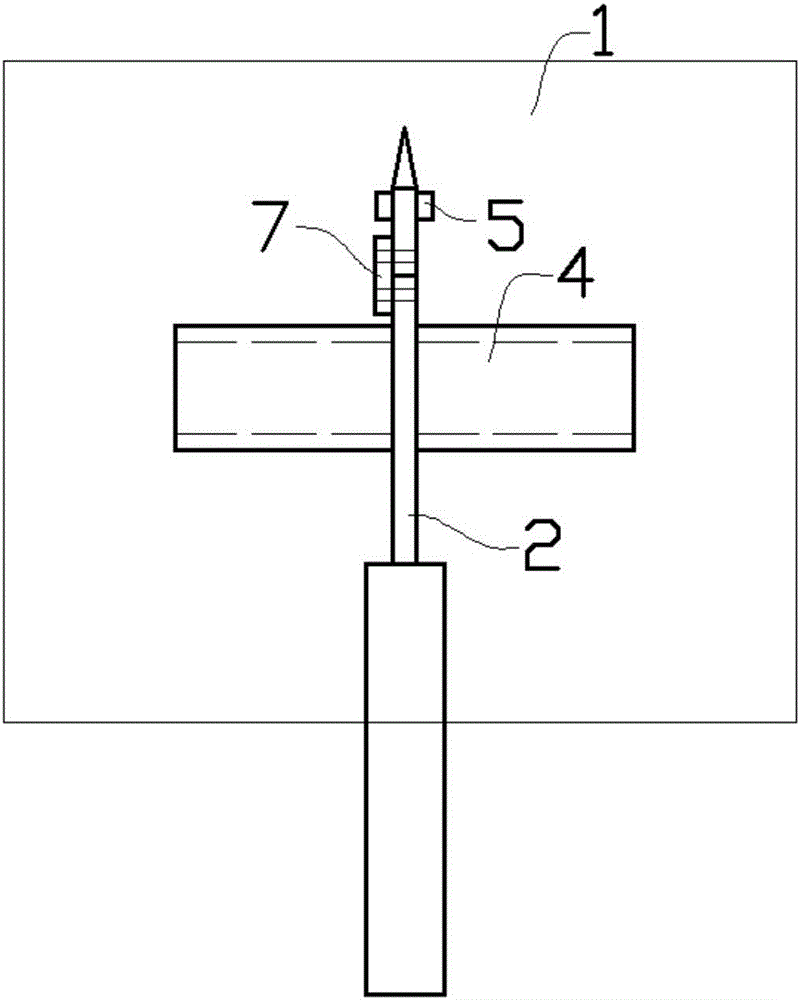

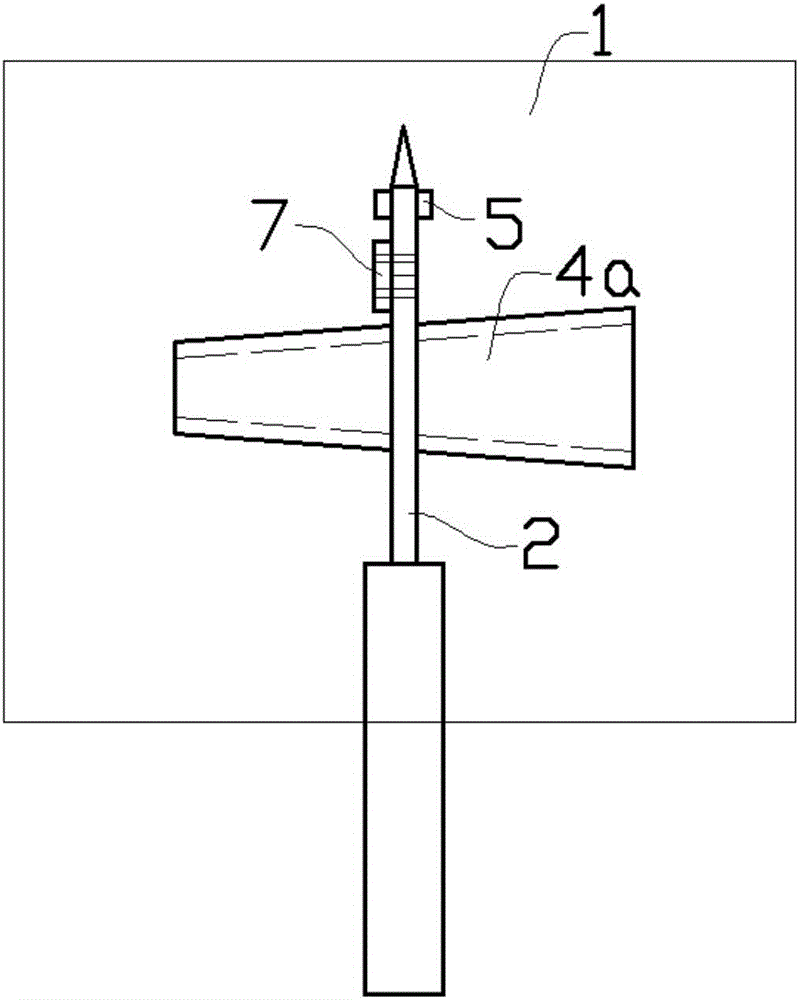

Self-adhesive sticker rapid blanking process

InactiveCN102941600AIncrease the feeding speedReduce weightMetal working apparatusEngineeringMechanical engineering

The invention relates to a self-adhesive sticker rapid blanking process, and belongs to the technical field of transformer production. The technical scheme is that a blanking hammer is used for manufacturing self-adhesive stickers and is composed of punch (1) installed on a handle (2). The punch is in a hollow structure, and the end portion is provided with a closed cutting edge. A self -adhesive paper (4) is placed on a rubber mat (5), hammered by the blanking hammer and cut by the sealed cutting edge of the end portion of the punch to be manufactured into a self-adhesive sticker with a shape in accordance with that of the closed cutting edge of the end portion of the punch. Shapes and sizes of closed cutting edges of punches are variant, self-adhesive stickers with different shapes and sizes are matched with the closed cutting edges of the punches with different shapes and sizes, only different punches are needed to be changed, and then different self-adhesive stickers can be manufactured. The self-adhesive sticker rapid blanking process has the advantages that the operation is simple and convenient, the blanking speed is fast, and the shaping is regular. Besides, the punches have multiple specifications and can be changed at any time, so that the operation program is simplified, and the cost is reduced.

Owner:BAODING TIANWEI GRP CO LTD

Cutting device used for towel belt

ActiveCN105133282AImprove processing efficiencyFast cuttingSevering textilesEngineeringMechanical engineering

The invention discloses cutting device used for a towel belt. The cutting device comprises a feeding frame used for conveying the towel belt and a platen. An installation frame is fixed to the feeding frame. A pressing strip which can move up and down and can press the towel belt on the platen is arranged on the installation frame. A cutting groove is formed in the platen. A cutter motor which can slide is arranged below the platen and provided with a cutter which can rotate. The cutter is located in the cutter groove. According to the cutting device, the towel belt is fixed through the pressing strip, the cutter which can rotate conducts cutting along the cutter groove, full-automatic and rapid cutting of the towel belt can be achieved and the towel processing efficiency can be improved.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

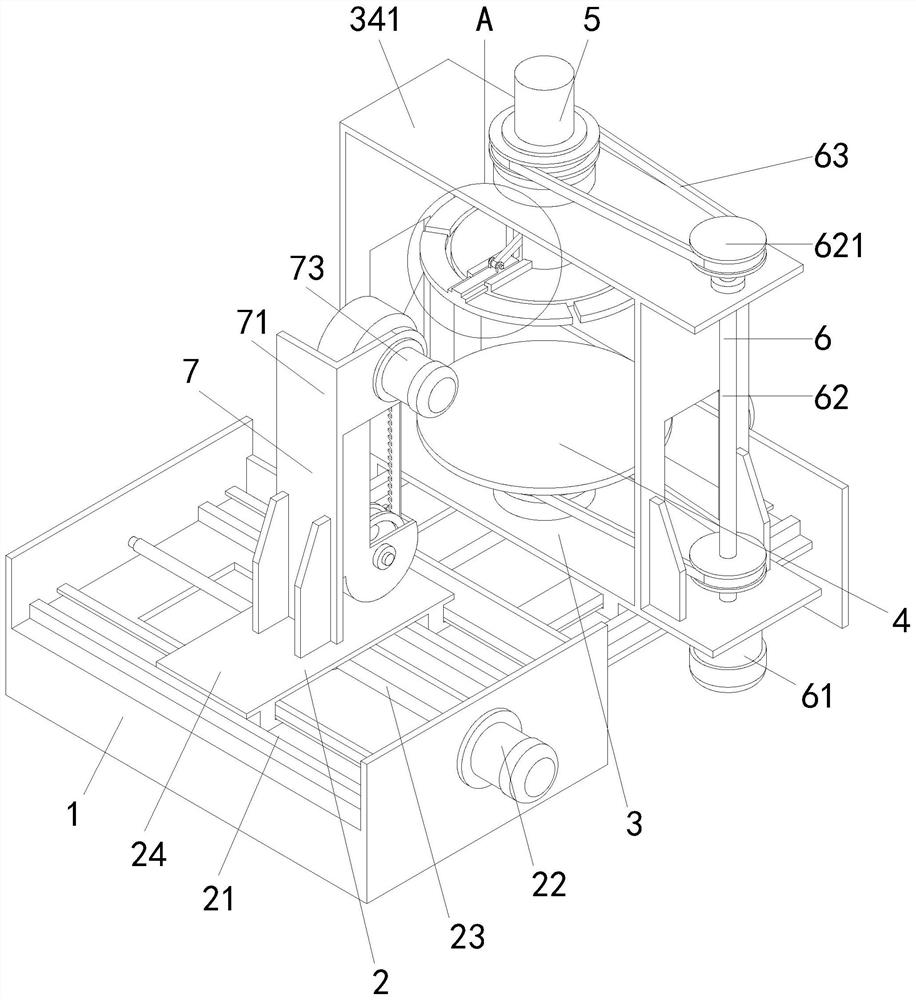

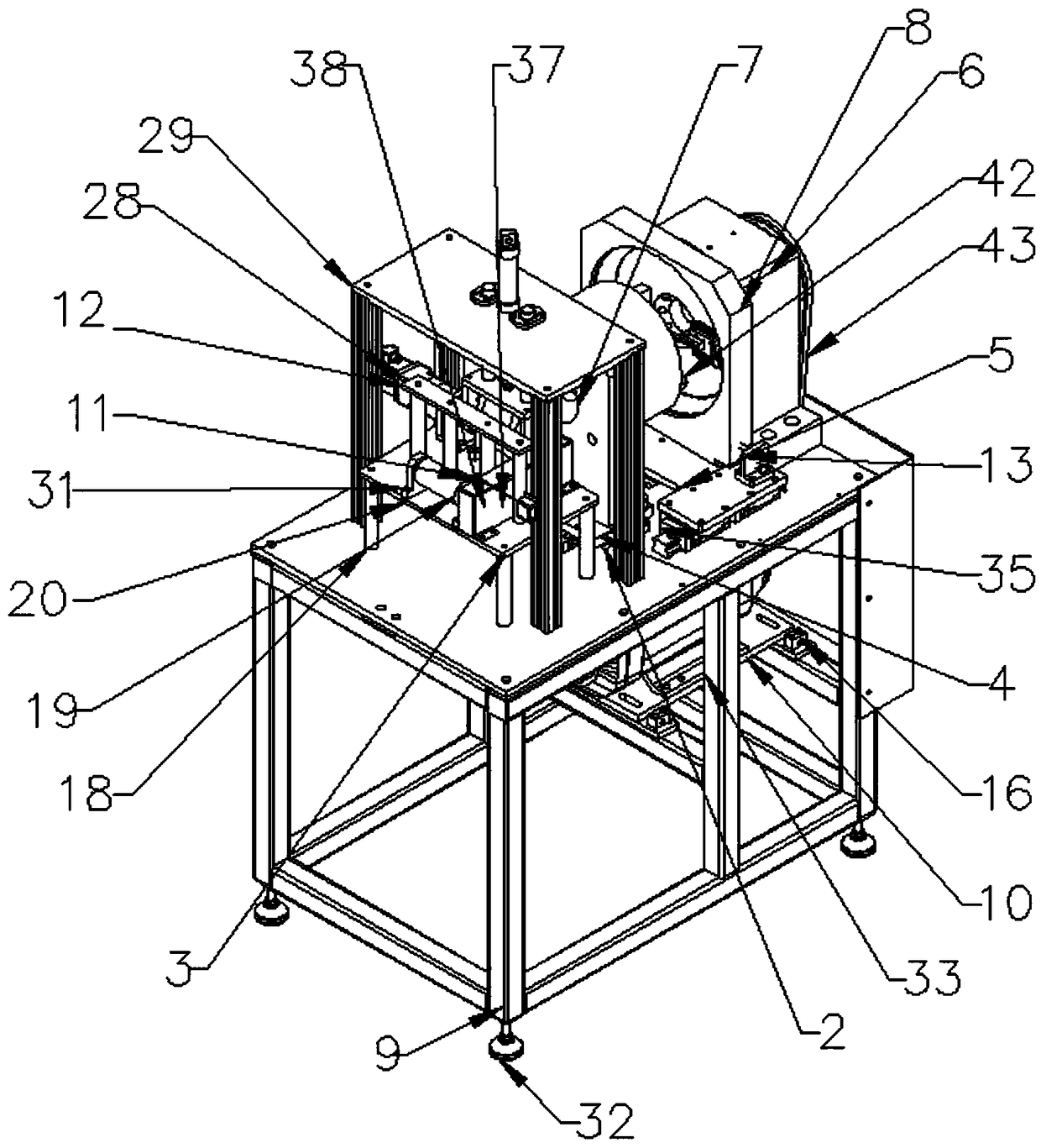

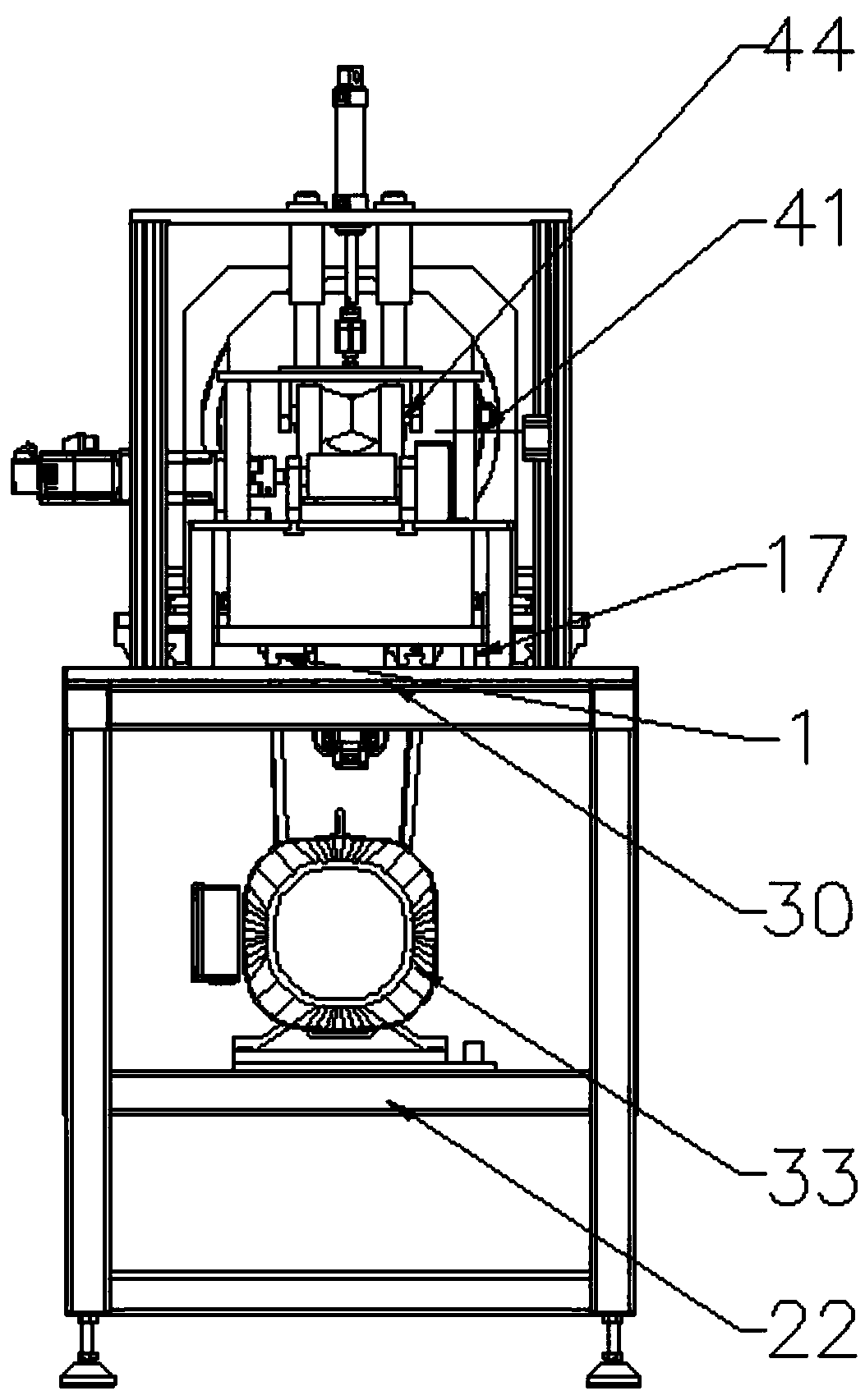

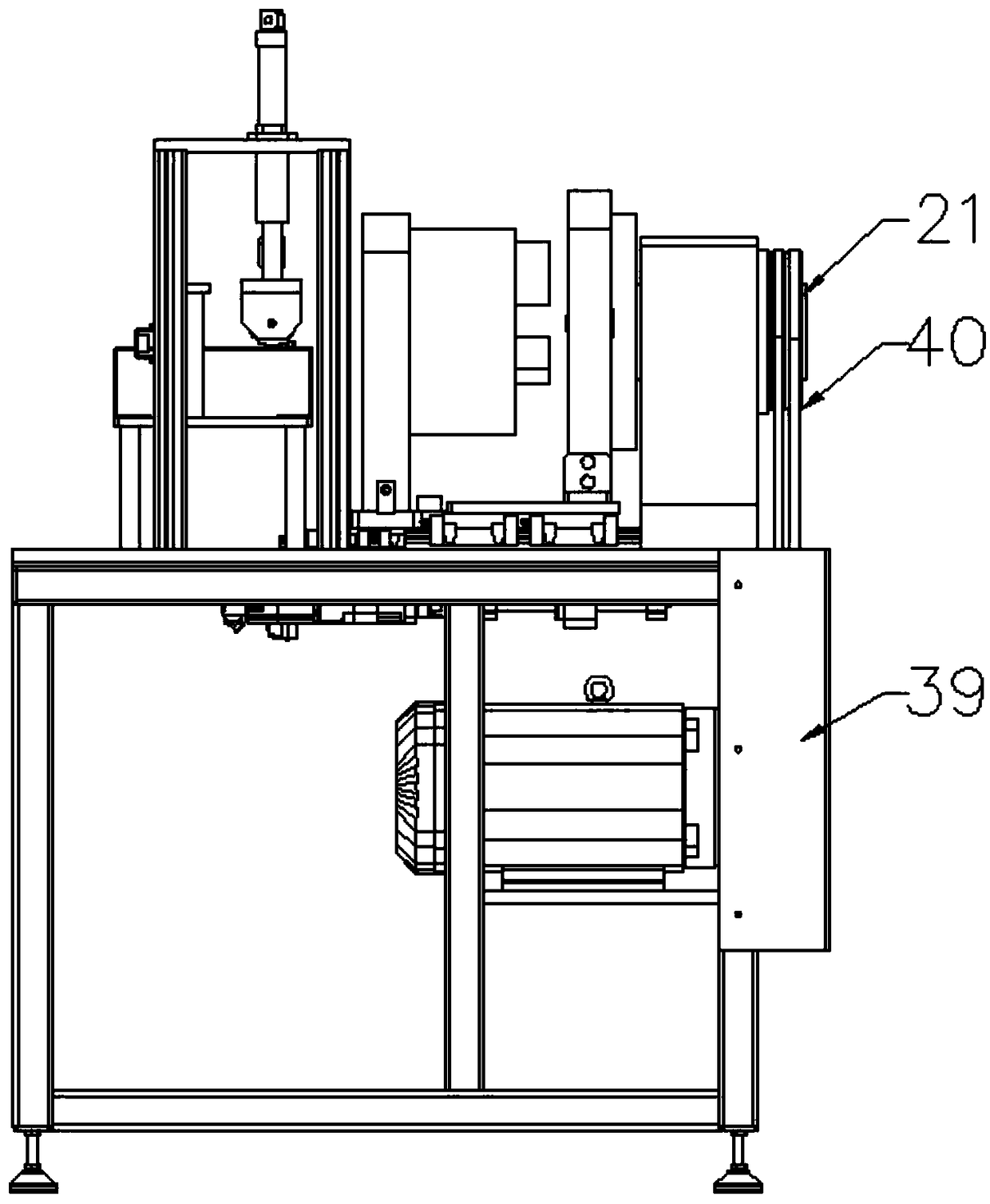

Reinforced hard corrugated board die-cutting machine

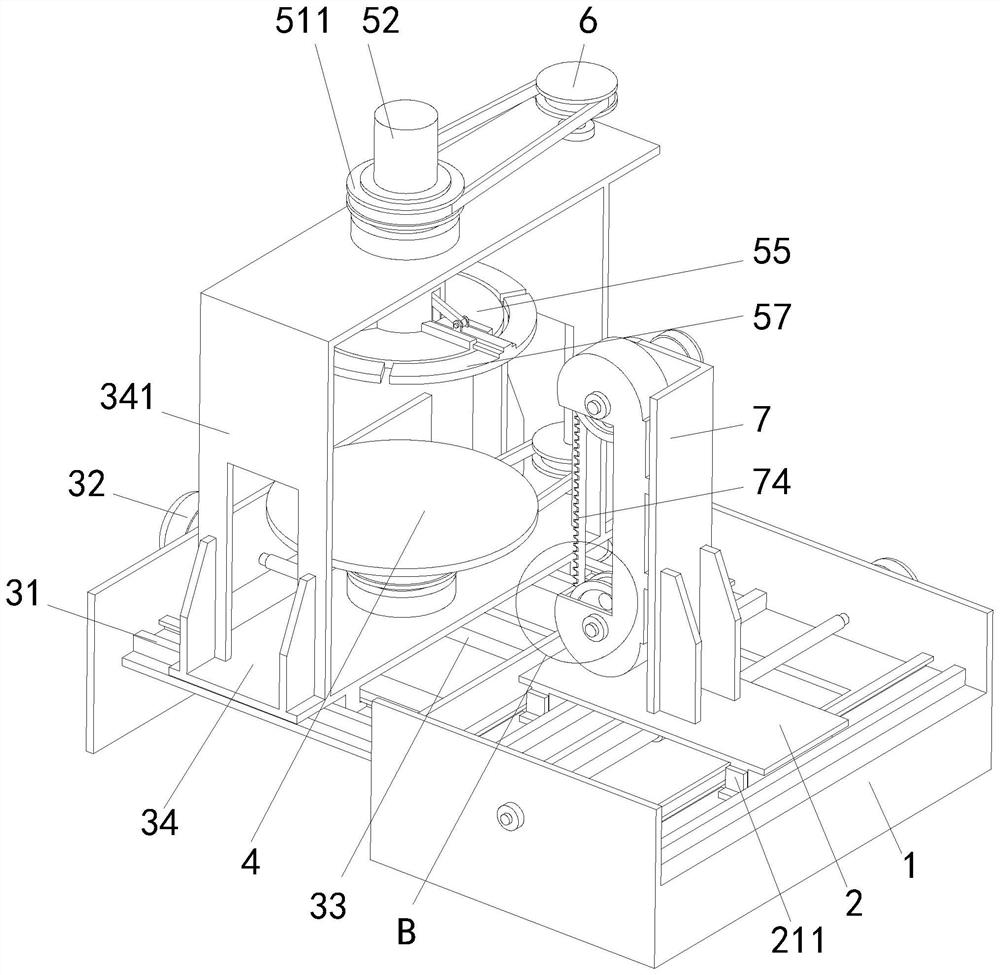

InactiveCN112621857ASimple structureEasy maintenanceMetal working apparatusStructural engineeringMachining

The invention relates to a reinforced hard corrugated board die-cutting machine. The reinforced hard corrugated board die-cutting machine comprises a base table, a cutting carry mechanism, a radius adjusting mechanism, a rotary bearing platform, a pressing mechanism, a synchronous rotary driving mechanism and a cutting device. The pressing mechanism comprises a rotating cylinder, a lifting air cylinder, a stroke frame, an adjusting air cylinder, a center pressing disc, a connecting rod and a pressing ring. The die-cutting machine can be used for cutting machining of corrugated boards of circular structures, the circular corrugated boards of the same diameter size can be cut and formed in a standardized mode after adjustment is completed, the uniformity of the quality of cut finished products is guaranteed, batched cutting machining can be rapidly completed, the operation is easy, the production efficiency is high, and in addition, the die-cutting machine is simple in overall structure, low in equipment cost input and convenient to maintain and repair in the later period.

Owner:何欣悦

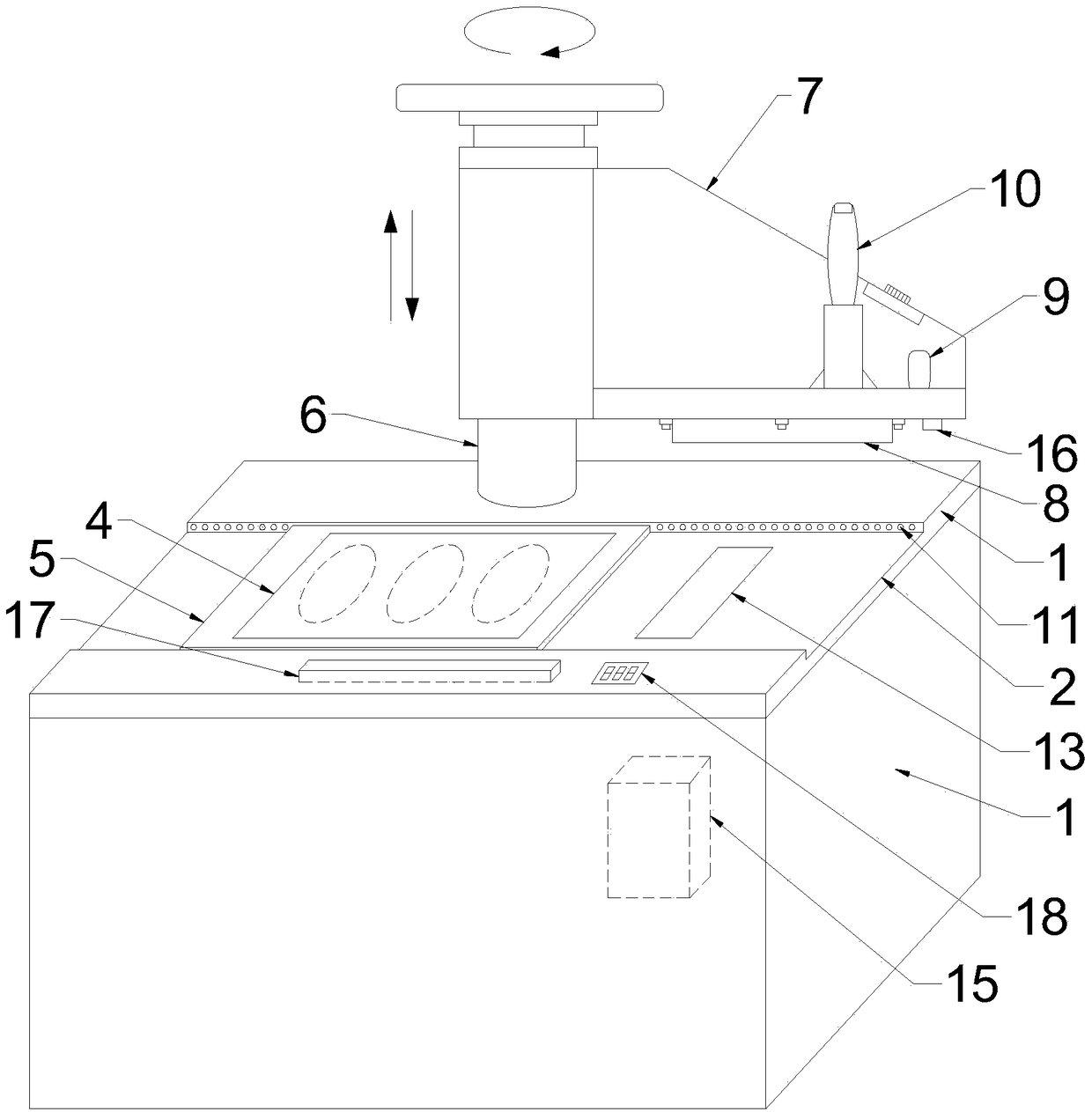

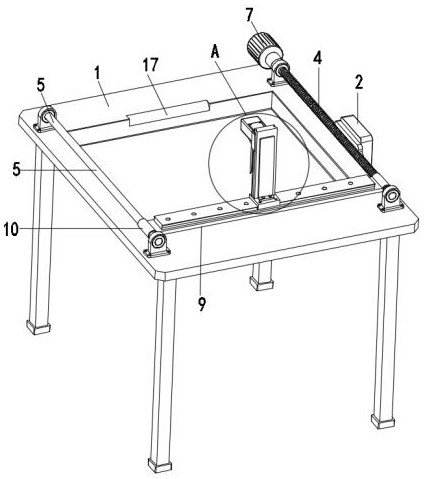

Feeding platform of swing arm type cutting machine

PendingCN108890772AAvoid adjustmentAvoid smoothingMetal working apparatusEngineeringMechanical engineering

The invention provides a feeding platform of a swing arm type cutting machine, includes a horizontal table located at the upper end of the body of the swing arm cutter, a transverse feeding groove isarranged on the work table, the feeding groove penetrates from the left end of the work table to the right end of the work table, a pressing plate for placing sheets to be cut is embedded in the feeding groove, the width of the pressing plate is matched with the width of the feeding groove, and the pressing plate can be translated transversely along the feeding groove; A mounting groove is arranged on the work table, a column is arranged in the mounting groove, a swing arm is arranged on the column, the swing arm can rotate around the column and make lifting motion, a cutting die is arranged at the bottom of the swing arm, and a cutting switch and a handle are arranged on the upper side of the swing arm. The invention has high feeding efficiency and low labor intensity.

Owner:YANCHENGSHI YUZHENG PRECISION MACHINE

Edge trimmer

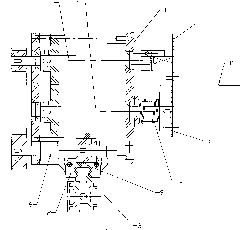

The invention relates to an edge trimmer for solving the technical problems that that handwork is difficult to cut a sheet material into a complex concave curve. A mainshaft of the edge trimmer is arranged inside a mainshaft seat by a bearing; the inside of a tool post seat of the mainshaft seat is provided with an eccentric wheel; the eccentric wheel is connected to the outer end of the mainshaft; a tool post rocking ram is arranged on the tool post seat through the bearing; the base part of the tool post rocking arm and the eccentric wheel are in sliding arrangement; the end part of the tool post rocking arm is provided with an upper blade; a lower transmission shaft is arranged inside a sliding shaft through the bearing, and the sliding shaft is arranged inside a linear bearing seat through a linear bearing, so that the sliding shaft can only do linear motion in the axial direction and cannot rotate; the inside of a steering gear seat at outer end of the sliding shaft is provided with a shaft end steering gear component and a blade steering gear component which are engaged with each other; the shaft end steering gear component is connected with the outer end of a lower transmission shaft; and the end part of the blade steering gear component is provided with a lower rotatory blade. The upper blade driven by the mainshaft cuts the lower rotatory blade driven by the lower transmission shaft to complete the cutting and side trimming of a workpiece.

Owner:冯建兵

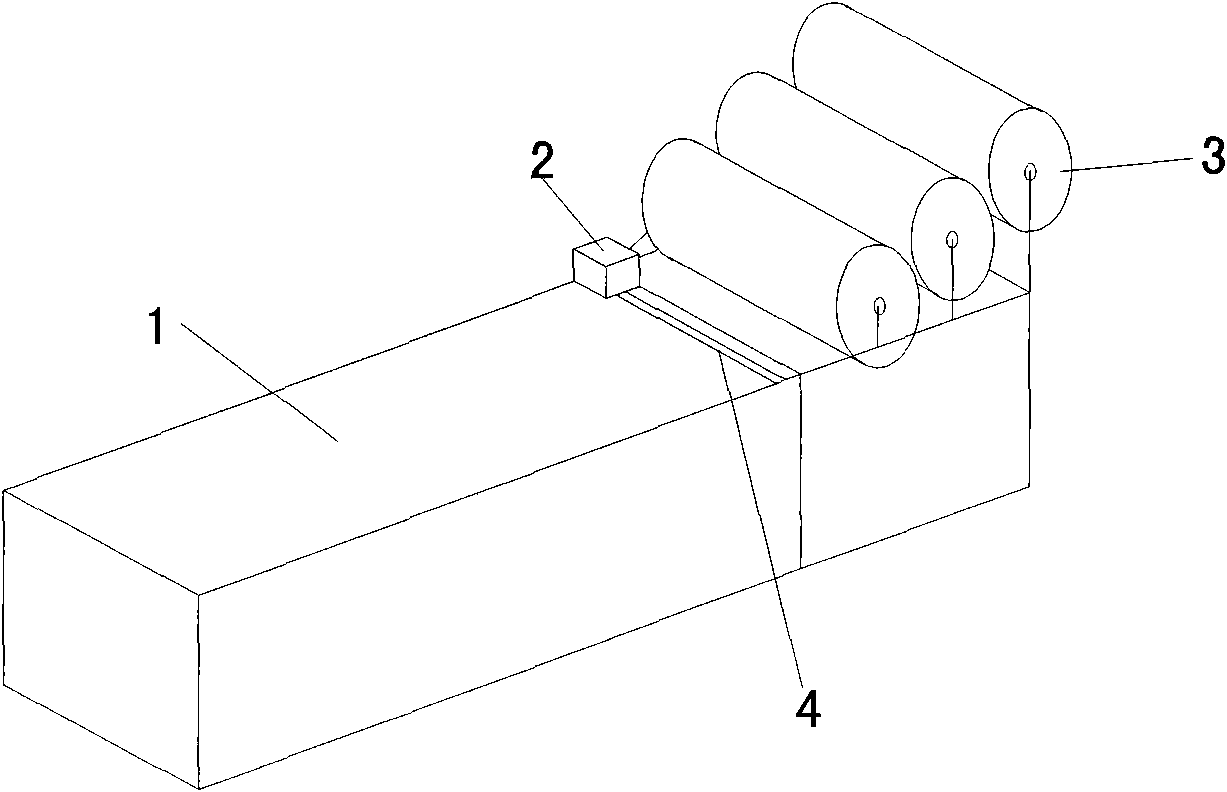

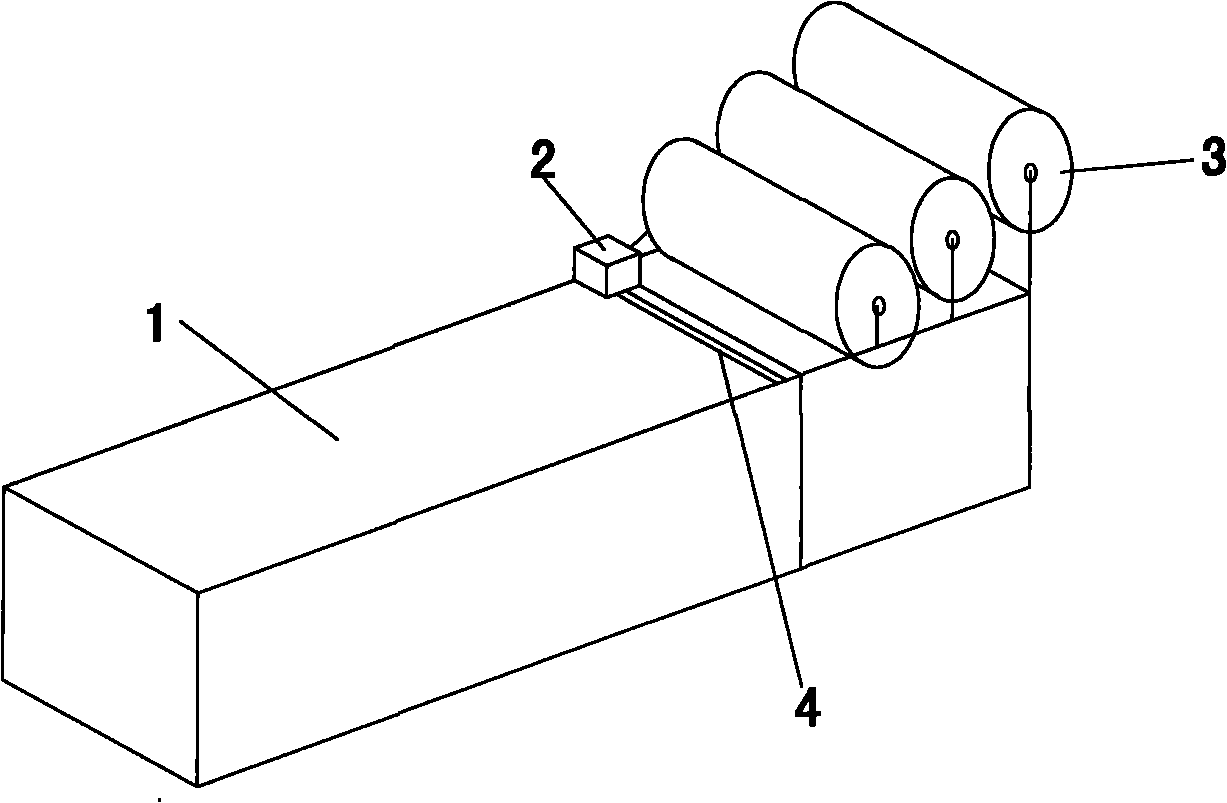

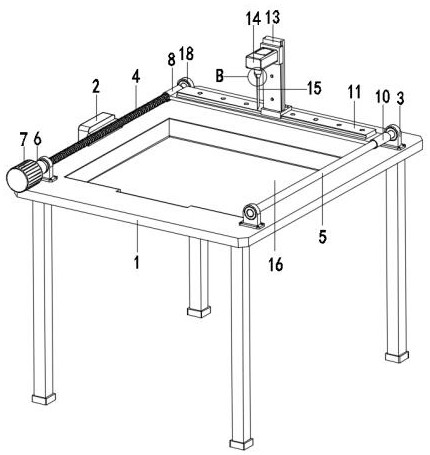

Ethylene vinyl acetate (EVA) cutting equipment

The invention provides ethylene vinyl acetate (EVA) cutting equipment, which comprises a workbench, and a cutting machine and a material rack which are arranged on the workbench, wherein an aluminum alloy rail is erected on the workbench; the cutting machine is a movable linear cutting machine, and is erected on the aluminum alloy rail to move along the aluminum alloy rail; one end of the aluminum alloy rail is rotationally connected with the workbench through a rotating mechanism; and the material rack comprises three brackets with different heights which can accommodate three rolls of EVA for simultaneous discharging and cutting. By the EVA cutting equipment, the cutting speed is greatly improved, the cutting precision is high, the waste of materials can be reduced, the operation is simple and convenient, labor force is reduced, operators are prevented from contacting the blades, and industrial accidents in the cutting process are prevented.

Owner:SHANGHAI SOLAR ENERGY S&T

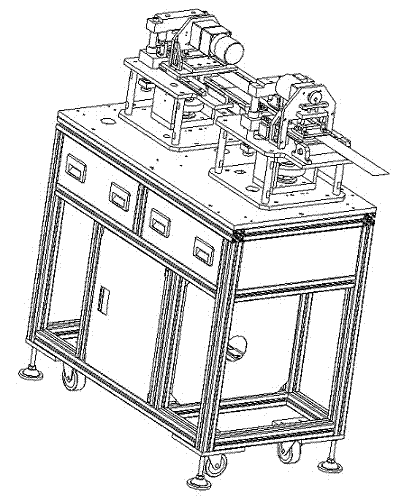

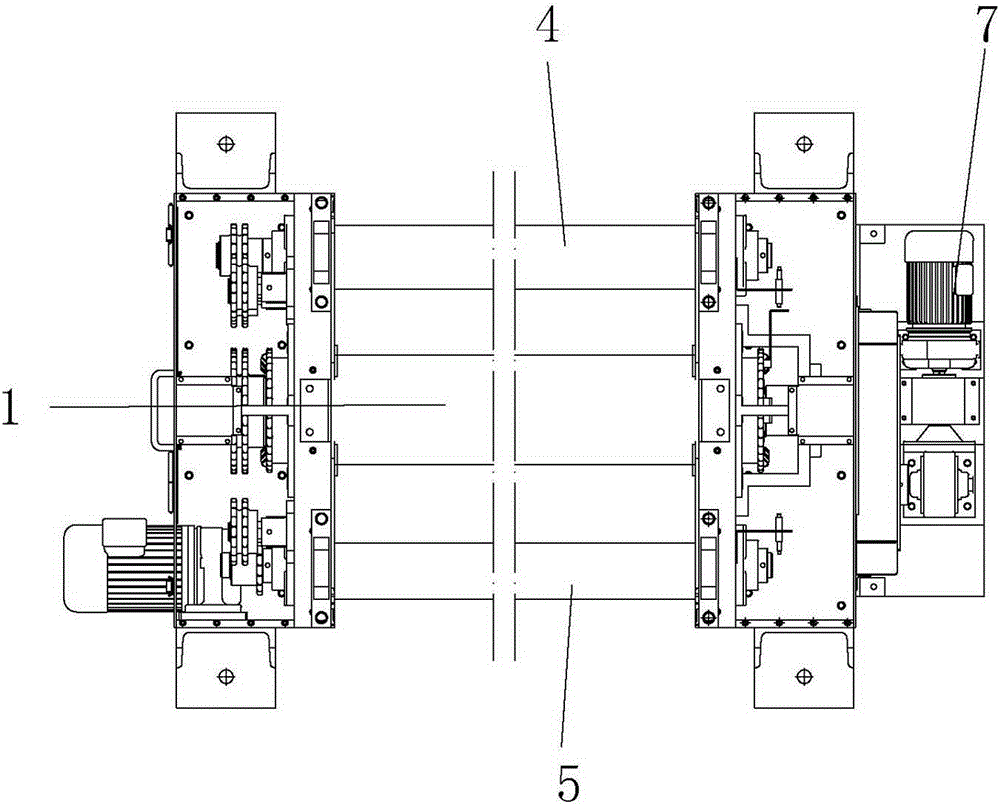

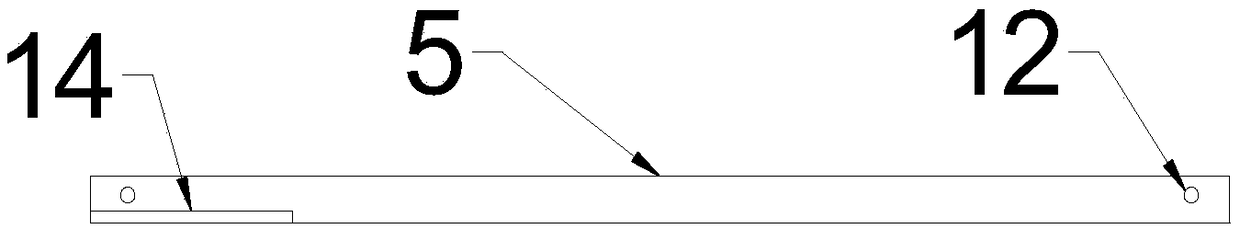

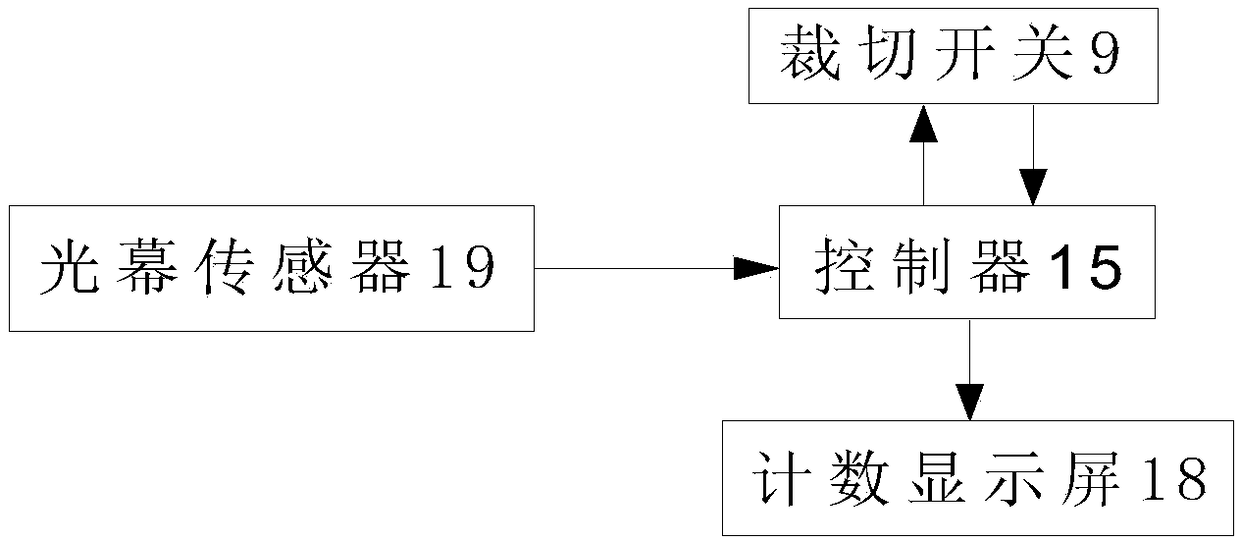

Automatic ribbon cutting device and method

ActiveCN113954164AEasy to manufactureIncreased durabilityMetal working apparatusStructural engineeringMechanical engineering

The invention discloses an automatic ribbon cutting device and method, and belongs to the field of automatic cutting. The automatic ribbon cutting device comprises a base plate, a left movable cutting unit, a full-sheet ribbon, a right movable cutting unit, a movable plate, a guide rail, a pushing air cylinder, a guide block seat, a guide block and a pressing mechanism. The left movable cutting unit and the guide rail are installed on the base plate, the movable plate is installed on the guide rail, the right movable cutting unit is installed on the movable plate, the pushing air cylinder is arranged on the left side face of the movable plate, and the guide block seat is installed on the portion, between the left movable cutting unit and the right movable cutting unit, of the base plate; and the guide block is arranged on the guide block seat, the pressing mechanism is arranged above the guide block, and the full-sheet ribbon is placed between the guide block and the pressing mechanism. By means of the cutting device and method, automatic one-by-one induction counting can be achieved, and when the quality requirement of a notch is met, a single ribbon in the full-sheet ribbon is automatically cut and automatically falls into a stock bin to be temporarily stored for subsequent packaging use.

Owner:东莞市八九十智能科技有限公司

Device for cutting multilayer cloth by one time with high efficiency

InactiveCN107503105AEnsure consistencyFast cuttingSevering textilesHigh volume manufacturingEngineering

The invention discloses a high-efficiency one-time cutting device for multi-layer cloth, which includes a frame and a pressing plate. Guide rods are arranged at both ends of the frame, and the two ends of the pressing plate are respectively fixed on the guide rods and can pass through the top of the guide rods. The height is adjusted by the nuts and the wheels at both ends of the pressure plate. The guide rods are driven up and down by the drive devices at both ends of the frame. The lower parts of the guide rods at both ends are connected by connecting rods. There is a backing plate; a die-cutting edge made according to the design requirements of the cloth is arranged under the pressing plate. Press the die cutting blade under the pressure plate to cut hundreds of pieces of fabric at one time. The cutting speed is fast and the efficiency is high. It is suitable for mass production, greatly improving the processing efficiency and greatly increasing the output. It not only reduces the labor intensity. , but also save labor costs.

Owner:李俊强

Magnetic adsorption type geometric cutting device

InactiveCN105839385AEasy to cut outNeat knife marksSevering textilesEngineeringMechanical engineering

The invention provides a magnetic adsorption geometric cutting device, which includes a magnetic plate and a cutting knife. The magnetic plate is placed horizontally, and its upper part is covered with an iron metal plate. The front part of the cutting knife is designed as a blade, and the rear part Designed as a knife handle, the blade position at the front of the cutting knife is equipped with a guide roller that can rotate on its own axis in the horizontal direction. The guide roller is made of iron material, and the lower end of the guide roller is lower than the lower part of the blade when the blade is placed horizontally position, the upper part of the front edge of the blade is equipped with an adsorption block of iron material. The device can conveniently cut the fabric in a straight line or an arc, and the cutting size is more accurate and the cutting speed is faster.

Owner:RUIAN AOYA CLOTHING CO LTD

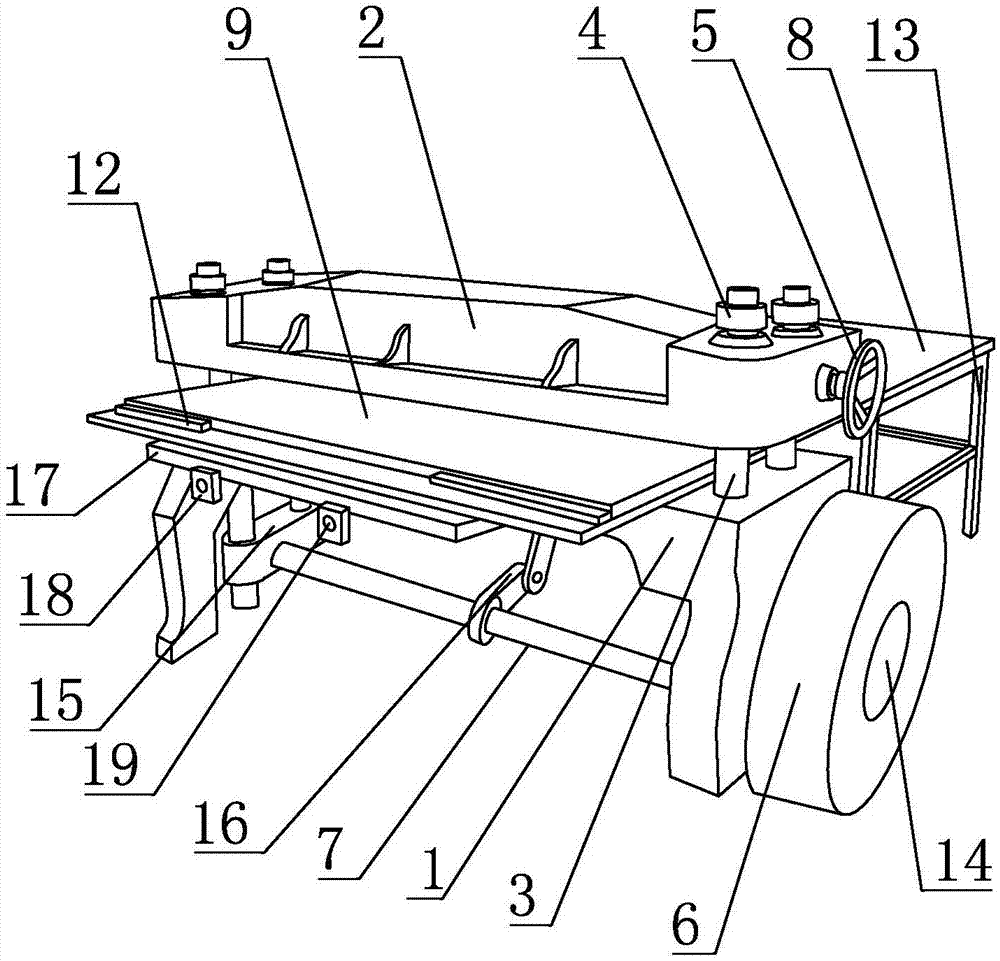

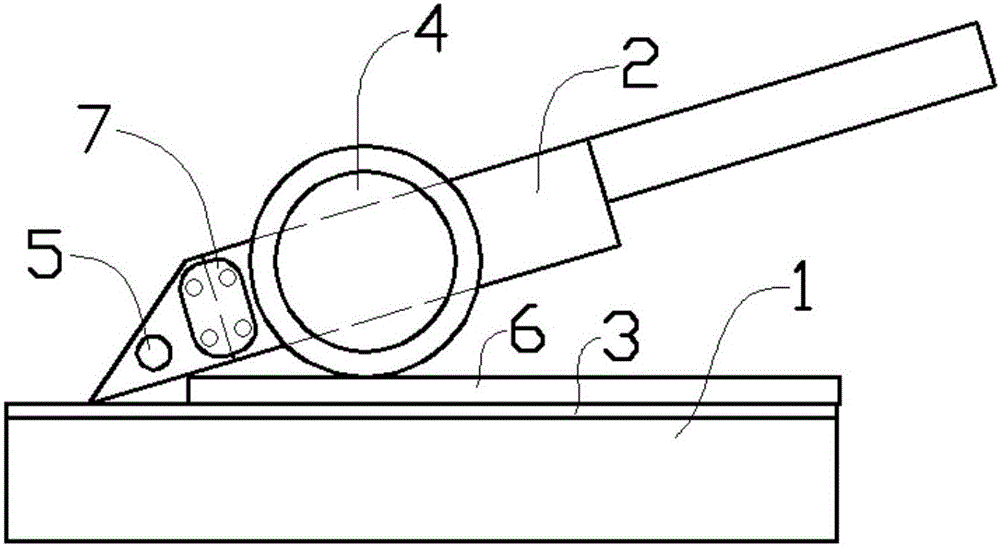

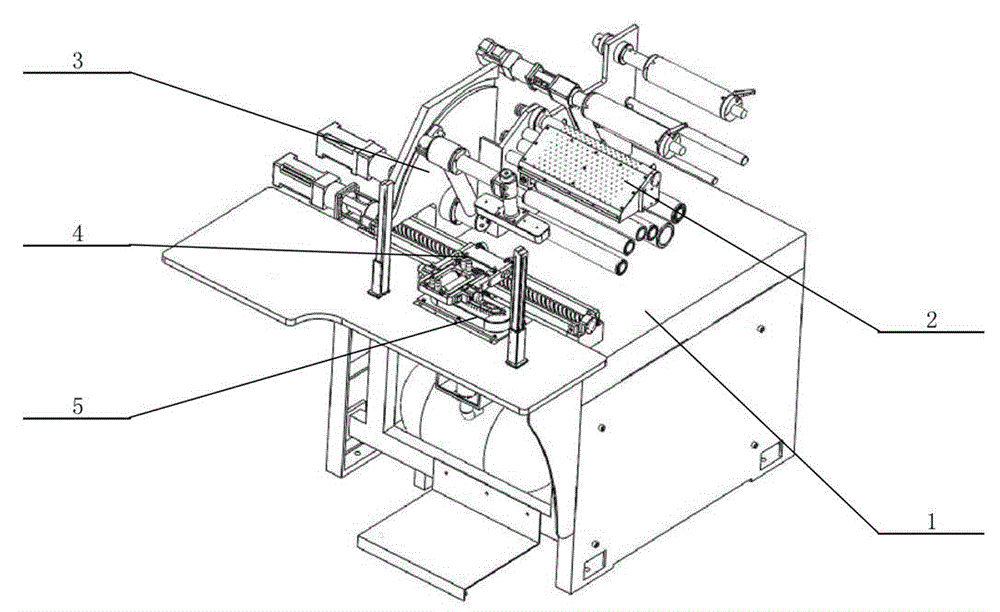

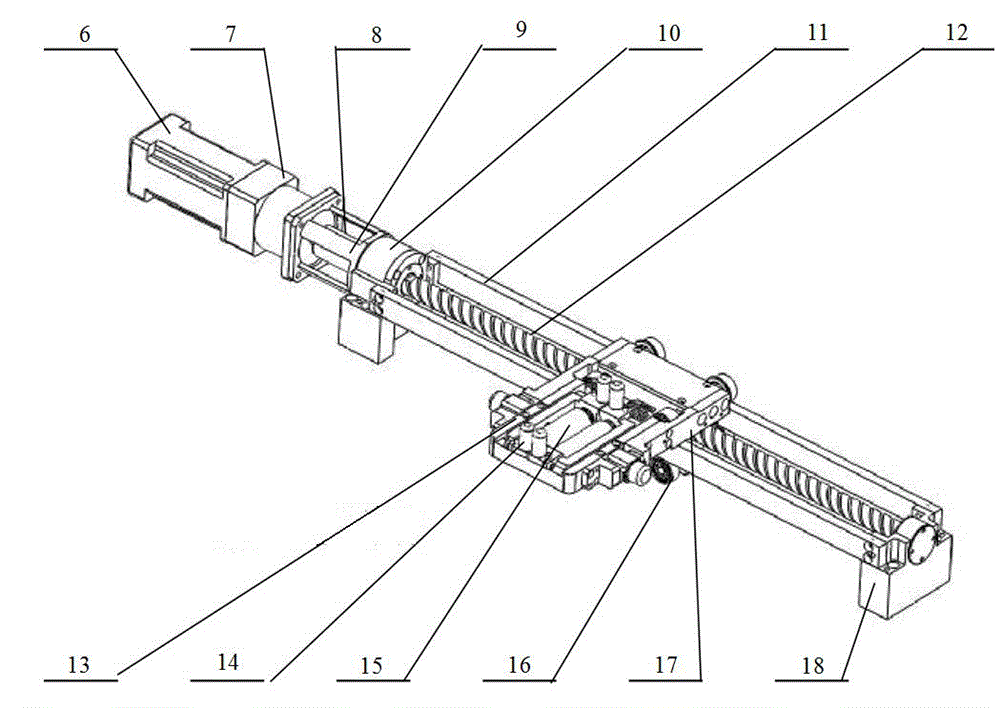

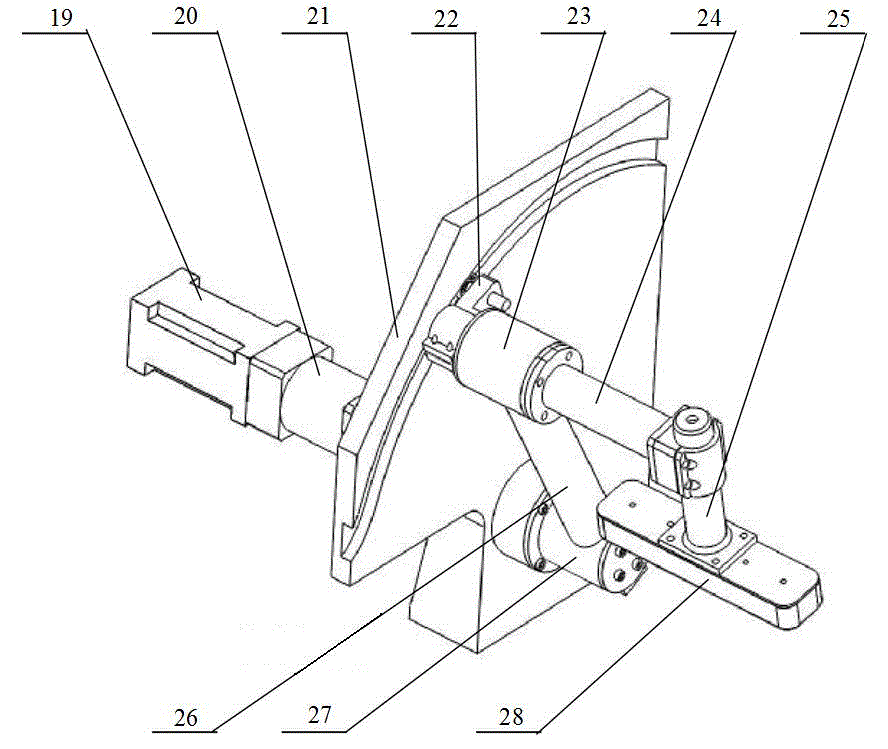

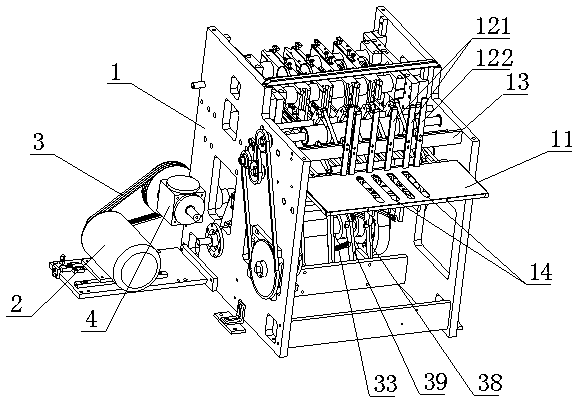

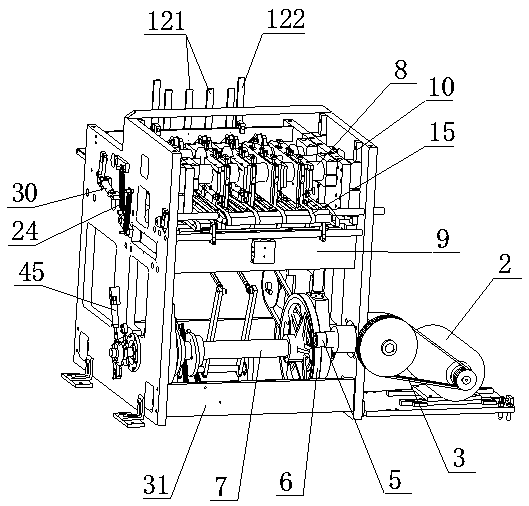

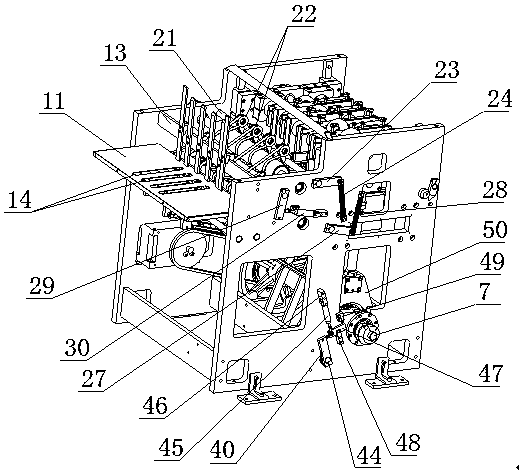

Cigar coat forming machine

The invention discloses a cigar coat forming machine, which is characterized in that a rolling mechanism (4), a sheet moving mechanism (3), a take-up mechanism (2) and a cutting mold mechanism (5) are mounted on a base (1), wherein the rolling mechanism (4) is mounted above the cutting mold mechanism (5); the sheet moving mechanism (3) is mounted behind the cutting mold mechanism (5); the take-up mechanism (2) is mounted behind the sheet moving mechanism (3); and the cutting mold mechanism (5), the rolling mechanism (4), the sheet moving mechanism (3) and the take-up mechanism (2) are connected with a control mechanism to constitute the cigar coat forming machine. The cigar coat forming machine is reasonable in structure, flexible in operation and reliable in running; and the cutting speed is high, the cutting is in good trim, the form of cut cigar coats is uniform, the control precision is high, automatic manufacture of the cigar coats is achieved, and the work efficiency is high.

Owner:徐彬

Protective film cutting device

InactiveCN104070548AReduce uneven croppingAvoid wastingMetal working apparatusTectorial membraneEngineering

The invention discloses a protective film cutting device. The protective film cutting device comprises a base plate and two side plates which are located on the bilateral sides of the base plate respectively. The protective film cutting device is characterized by also comprising a rotating shaft, bearings, a front panel, a sliding rail frame, a sliding rail, a sliding block and a cutter; each side plate is provided with a gap; the inner wall of each gap is provided with a clamping groove; each bearing is arranged in each gap through the corresponding clamping groove; the rotating shaft is detachably arranged between the two bearings; the front portions of the two side plates are provided with the front panel; the front surface of the front panel is provided with the sliding rail frame which is provided with the sliding rail; the sliding rail is provided with the sliding block which can slide along the sliding rail; the cutter is hinged to the front surface of the sliding block. According to the protective film cutting device, the structure is simple, the use is convenient, the rapid positioning can be achieved, the machining frequency can be improved, the non-uniform cutting of protective films can be reduced, the lamination yield can be improved, and the use cost can be reduced.

Owner:XINGWEI COMP KUNSHAN

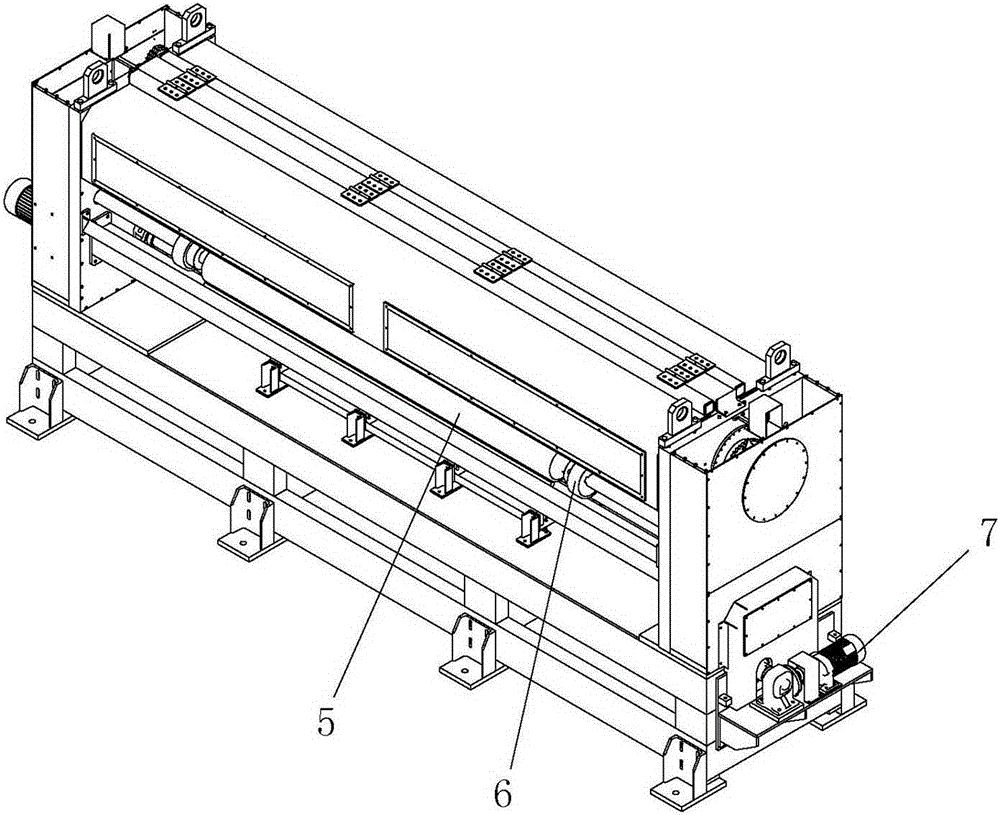

Book cutting machine

PendingCN110303547AReduce labor intensityFast cuttingMetal working apparatusMechanical equipmentEngineering

The invention relates to the technical field of book cutting mechanical equipment, in particular to a book cutting machine. The book cutting machine comprises a cutting machine body, a driving motor,a reverser, a guide rail transmission rod and a sliding block transmission rod, wherein the driving motor and the reverser are fixed outside the cutting machine body, and the driving motor drives a driving gear in the reverser to rotate through a driving belt, so that the driving gear is meshed with a driven gear. According to the book cutting machine, a plurality of combined book bodies to be cutcan be placed at a time, and the integral feeding of a single combined book body can be realized in the cutting process; and the positioning operation can be realized before cutting, so that the labor intensity of workers is reduced, the cutting speed is greatly increased, the cutting and positioning are accurate, the maintenance is convenient, and the device is suitable for popularization and application.

Owner:上海殷烁机械设备有限公司

Cutting device for expandable polystyrene package

The invention relates to the technical field of a cutting device, in particular to a cutting device for an expandable polystyrene package. The cutting device for the expandable polystyrene package comprises a machine frame and a controller, wherein support seats are fixedly arranged on the machine frame; a screw rod is rotationally connected between the support seats at one side; a guide rod is rotationally connected between the support seats at the other side; one end of the screw rod is fixedly connected with a servo motor through a shaft coupler; at the same time, a threaded tube is screwedonto the screw rod; the threaded tube is fixedly connected with a connecting plate; the connecting plate is fixedly connected with a guide tube; a first linear module is fixedly connected to the topsurface of the connecting plate; a support plate is screwed onto a slide block of the first linear module; a second linear module is fixedly arranged on the inner side surface of the support plate; aheating device is fixedly arranged on a slide block of the second linear module; a cutter is fixedly arranged on the bottom surface of the heating device; and a placing region for expandable polystyrene plates is formed on the top surface of the machine frame from top to bottom. The cutting device for the expandable polystyrene package has the advantages that the cutting speed is high; the efficiency is high; in addition, the quality of the product is improved; and the efficient production is facilitated.

Owner:佛山市顺德区嘉美立包装有限公司

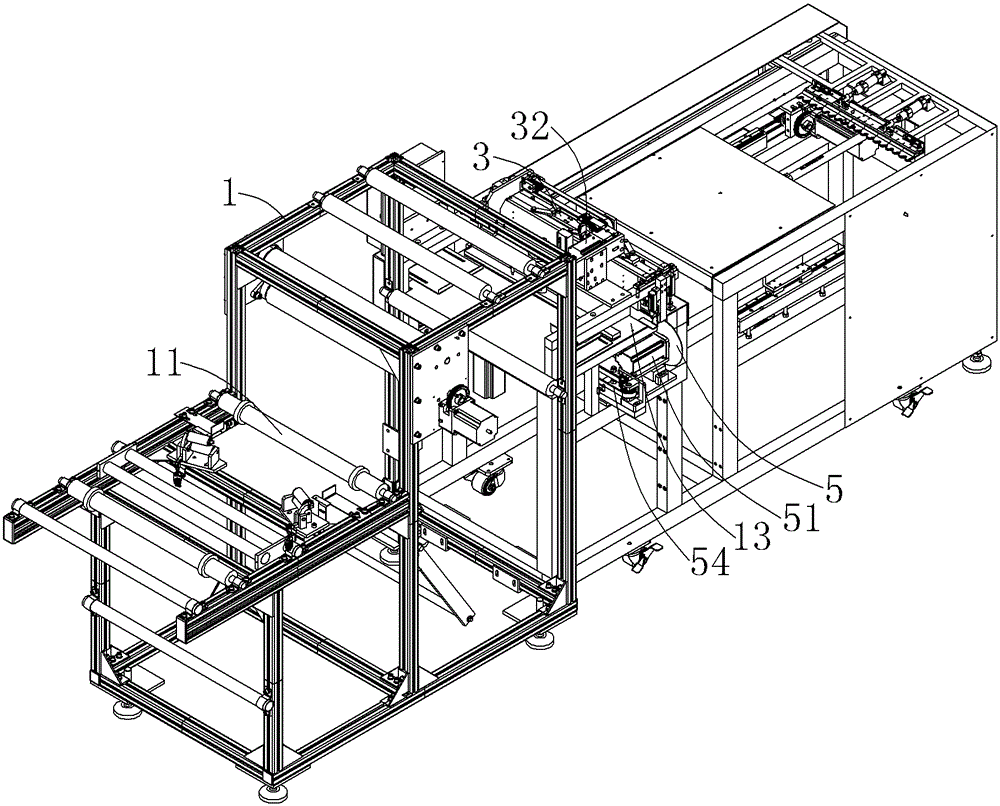

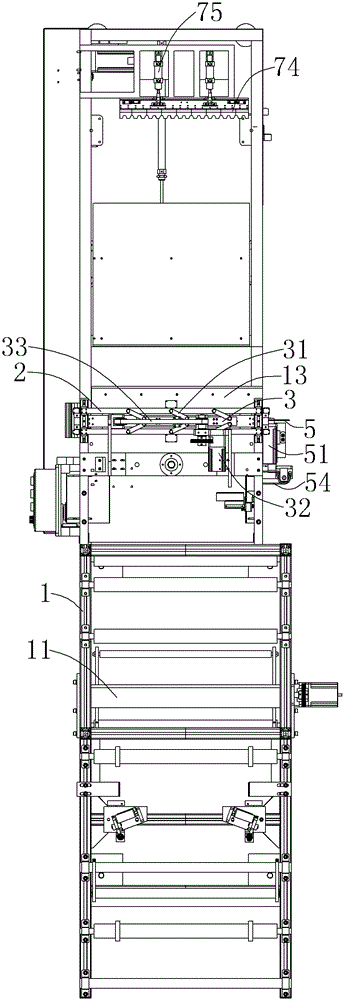

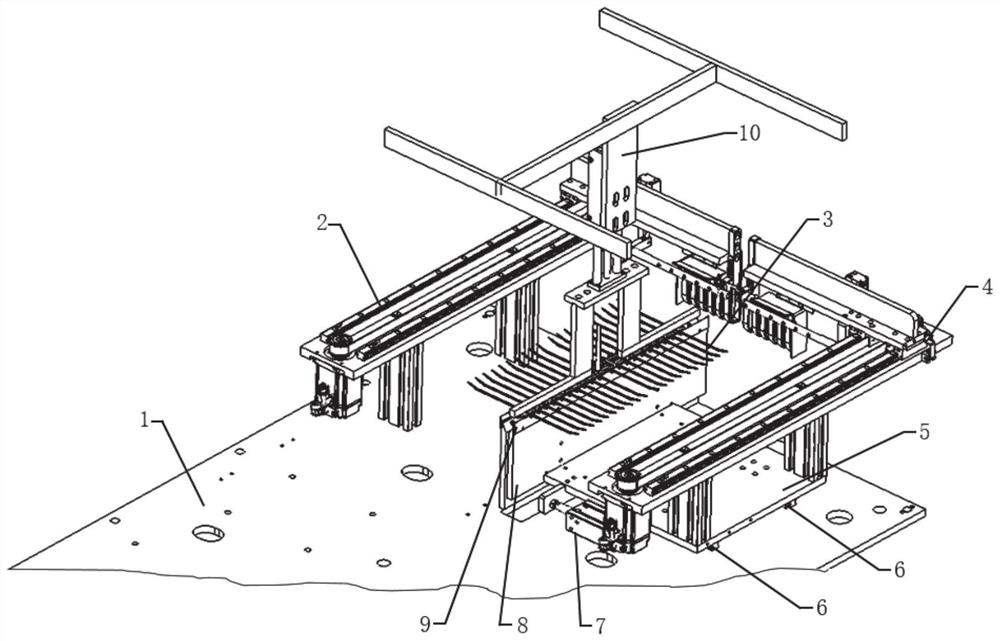

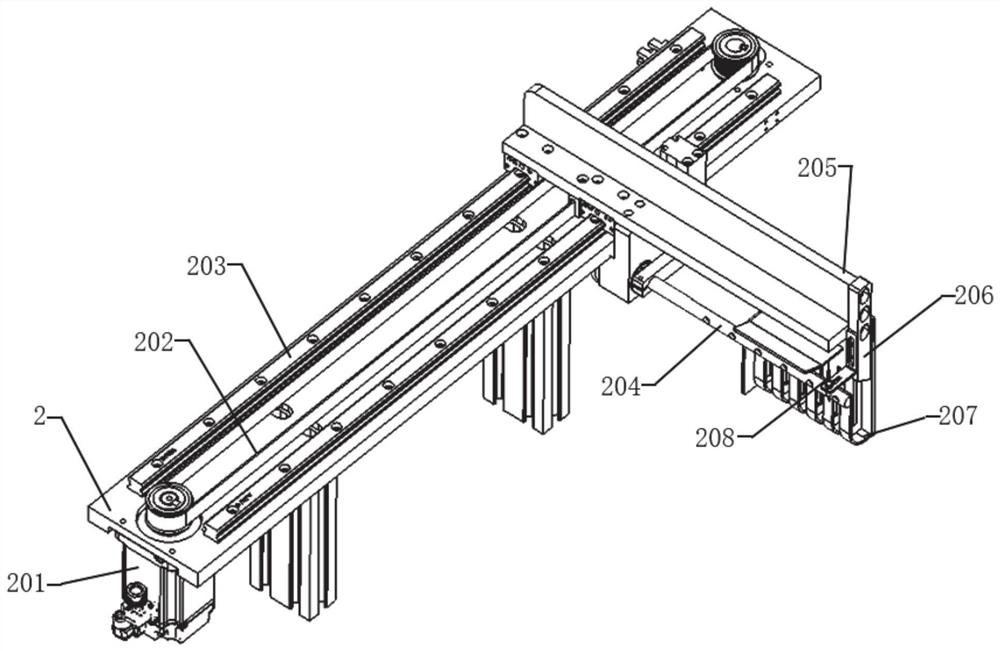

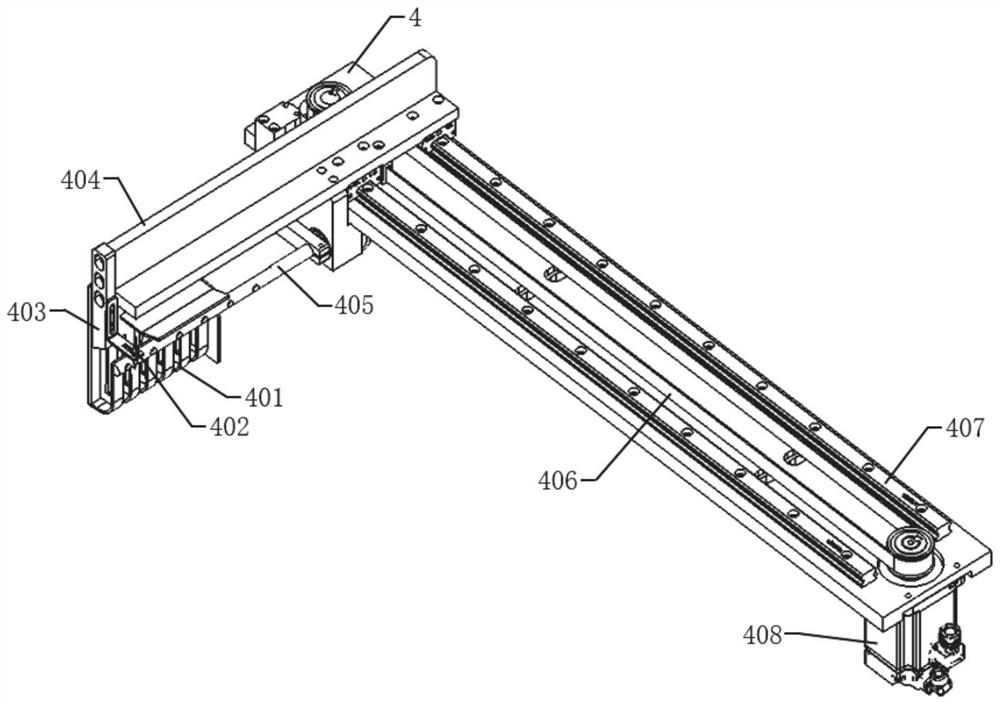

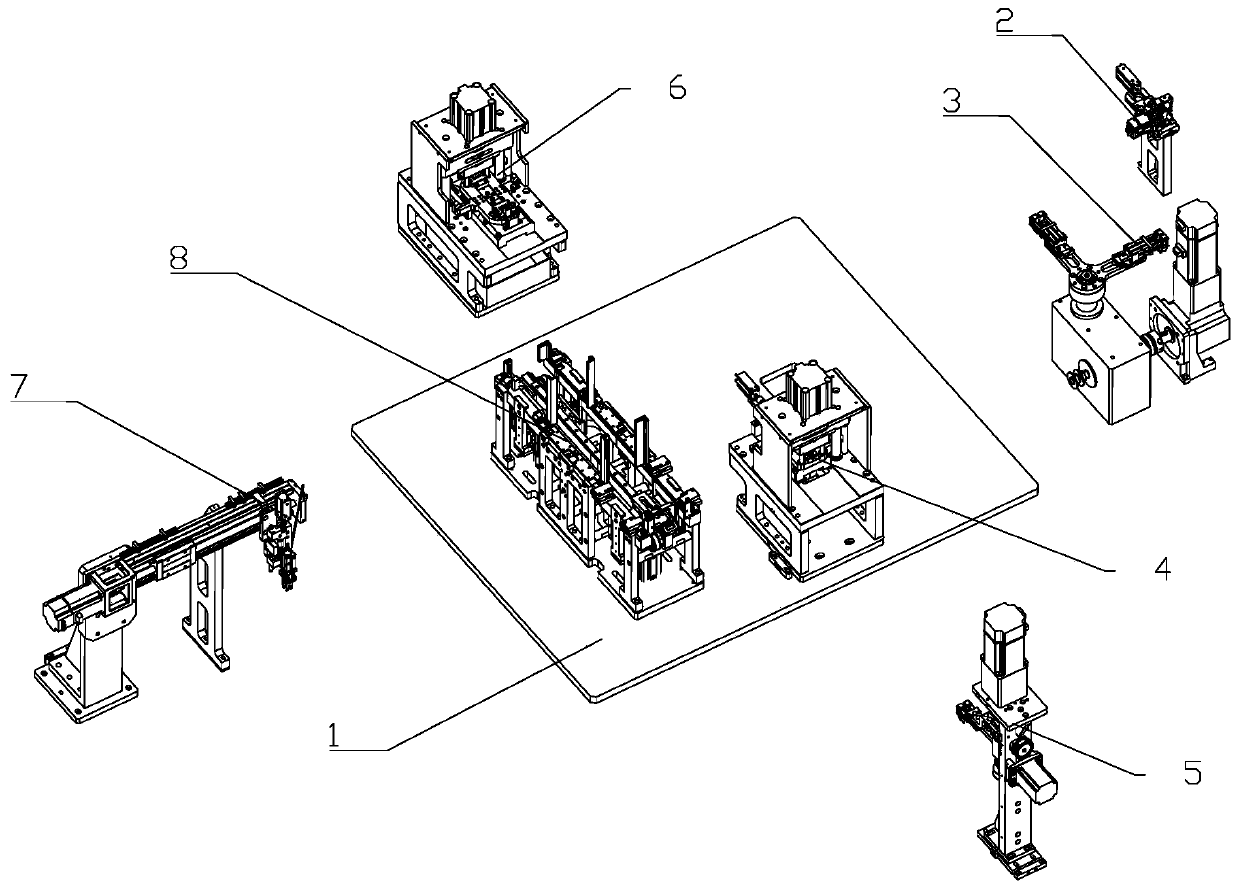

Automatic tray filling device of electronic chip tray filling machine

ActiveCN111086875AImprove transfer efficiencyGuaranteed one-way traversabilityConveyorsStacking articlesComputer hardwareElectronic chip

The invention relates to the technical field of electronic chip production. An automatic tray filling device of an electronic chip tray filling machine comprises a base, limiting stand columns, a transmission assembly, a fixture assembly, a tray taking assembly, a tray stacking assembly, a first lock catch assembly and a second lock catch assembly; the base is fixedly arranged on a rack, the limiting stand columns are arranged at the upper end of the base, the base is correspondingly provided with an empty material tray taking station, a tray arranging station and a full stacked material traystation, and the empty material tray taking station and the full stacked material tray station are each correspondingly provided with the four limiting stand columns; the tray taking assembly corresponds to the empty material tray taking station, and the tray stacking assembly corresponds to the full stacked material tray station; the transmission assembly is installed on the base, and the fixtureassembly is installed at the output end of the transmission assembly; and the first lock catch assembly and the second lock catch assembly are installed on the base, the first lock catch assembly corresponds to the empty material tray taking station, and the second lock catch assembly corresponds to the full stacked material tray station. The automatic tray filling device of the electronic chip tray filling machine has the advantages that material tray taking is precise, moving is efficient, the tray stacking success rate is high, and stacking automation is achieved.

Owner:浙江优众新材料科技有限公司 +2

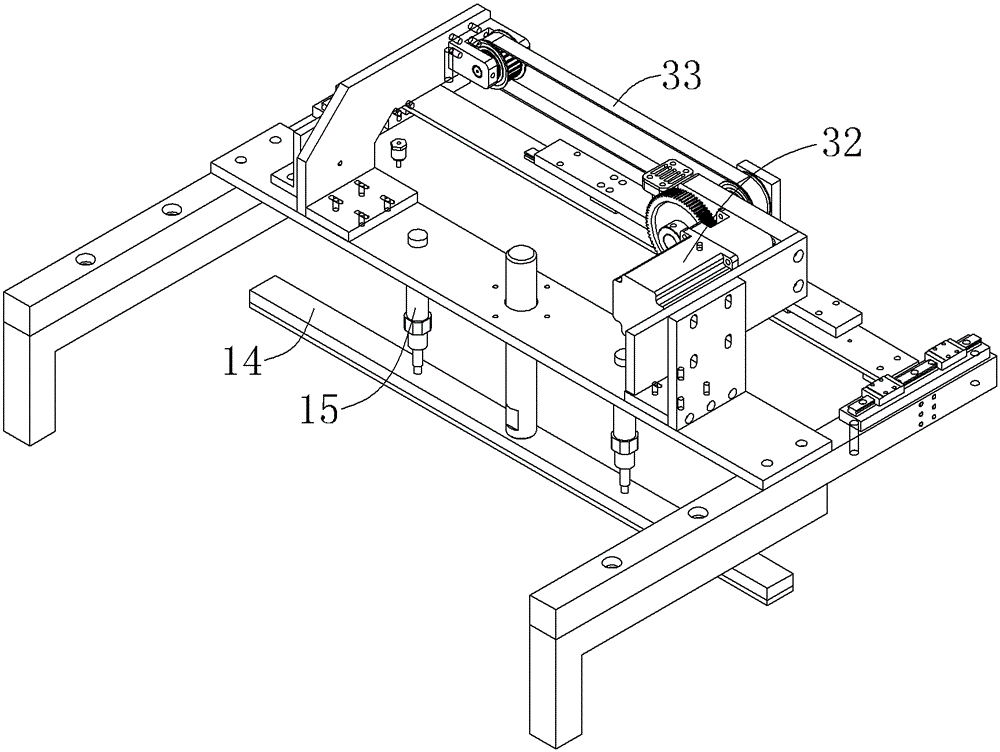

Automatic spreading and cutting machine for rubber inner tube base plate

InactiveCN107891457AAccurate sizingAccurate cut to lengthMetal working apparatusWebs handlingStructural engineeringIndustrial engineering

The invention provides an automatic spreading and cutting machine for a rubber inner tube base plate. According to the automatic spreading and cutting machine, a belt wheel is arranged on a power machine, the belt wheel is in transmission connection with a roller belt wheel arranged at a base plate roller through a belt, the base plate roller is arranged on a roller support, and the other side ofthe base plate roller is provided with a base plate spreading rolling roller through a cutting frame; and a travel switch is arranged at the position, adjacent to the outer side of the base plate spreading rolling roller, of the cutting frame, and a cutting knife is arranged at the position, on the outer side of the travel switch, of the cutting frame; and the cutting knife is arranged on a cutting shaft, the cutting shaft is arranged on an upper cross beam of the cutting frame, and the cutting shaft can rotate for cutting. According to the automatic spreading and cutting machine, the rubberinner tube base plate is automatically unwound and is automatically cut in a fixed size, so that cutting of the base plate is automatically carried out, and the machine has the advantages that sizingis accurate, the edge is smooth, and the spreading and cutting speed is high; and the machine is suitable for being used as the machine for automatically spreading of the rubber inner tube base plate.

Owner:CHAOYANG HUAXING WANDA TIRE

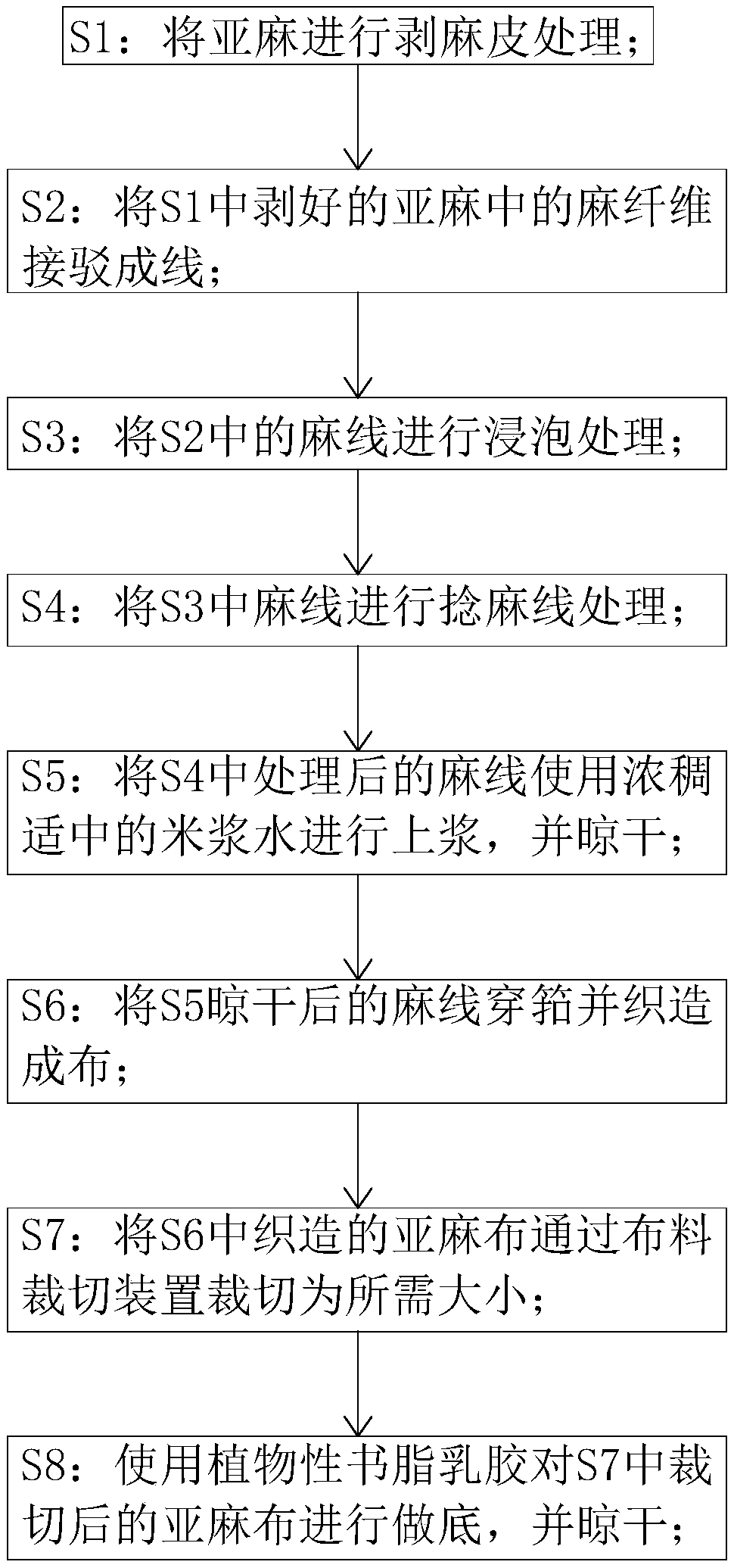

Pure linseed oil canvas production process

ActiveCN108914527AAvoid wrinklesRealize continuous cuttingSevering textilesWoven fabricsLinseed oilCheck valve

The invention belongs to the technical field of canvas preparation and specifically relates to a pure linseed oil canvas production process. The process comprises a frame body; the frame body is designed in H-type; a first sealed barrel is provided with a magnet plate, and the magnet plate isolates the first sealed barrel into upper and lower parts; the upper portion of the first sealed barrel isconnected to the outside air through a conduit, and the conduit is provided with a check valve so that the outside air can only enter the first closed barrel; a second spring is fixedly connected to the inner surface of the magnet plate and the inner wall of a transmission cabin; a magnet block fixedly connected to the inner diameter of the first spring is disposed below the first sealed barrel; the first spring rotates to move the magnet block in a circular motion; when the magnet block rotates to the position closest to the magnet plate, the magnet block repels the magnet plate, and the magnet plate is moved upward to squeeze the second spring, and at the same time, an extrusion gas is generated; when the magnet block is turned to a position farthest away from the magnet plate, the magnet block is attracted to the magnet plate, and the second spring is used to move the magnet plate downward.

Owner:乳山吾星纤维有限公司

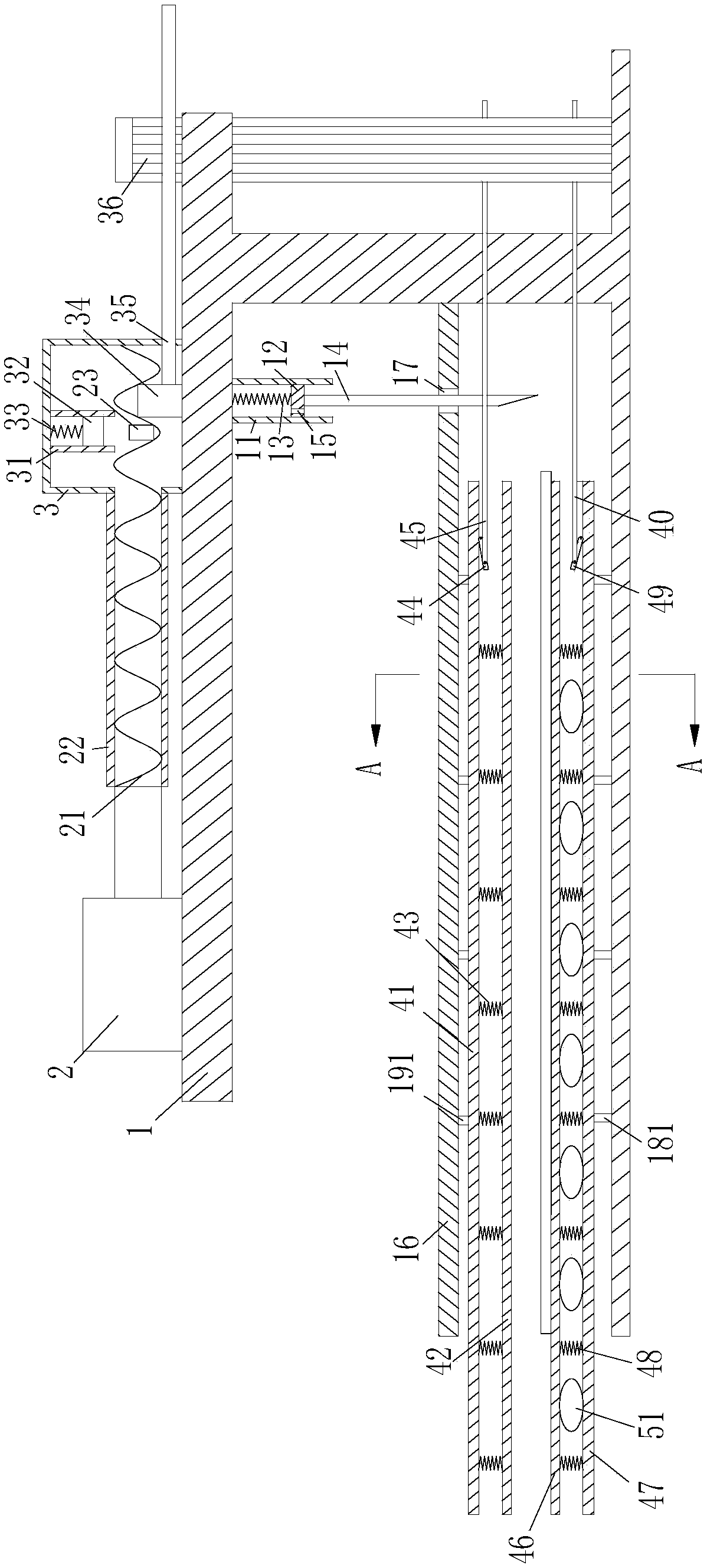

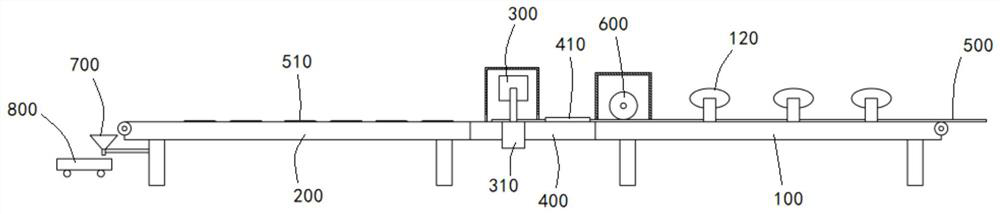

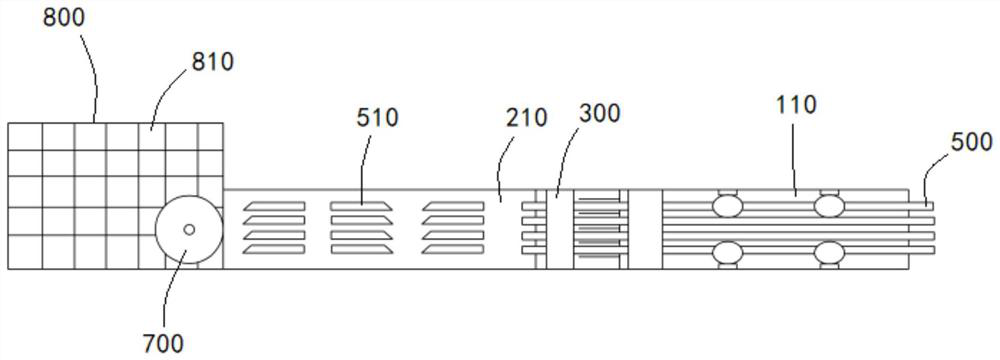

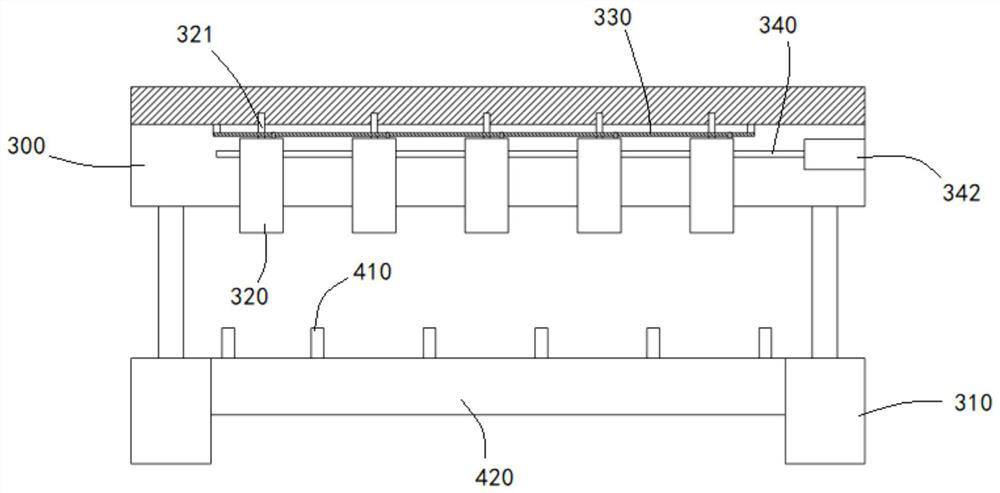

Cutting processing system for edible straw

ActiveCN111993478AFast cuttingMobile mechanizationMetal working apparatusAgricultural engineeringStructural engineering

The invention discloses a cutting processing system for an edible straw. The cutting processing system comprises a conveying device, a cutting-off device and a combing device; the conveying device comprises a front conveying assembly and a rear conveying assembly which are arranged on the same conveying line; the cutting-off device is arranged between the front conveying assembly and the rear conveying assembly; the cutting-off device comprises a lining plate flush with a front conveying belt and a rear conveying belt; and a knife rest is arranged over the lining plate, a plurality of cuttingknives are parallelly arranged on the knife rest, and a turning mechanism driving the cutting knives to rotate is further arranged on the knife rest. The arranged front conveying belt can ensure thata long pipe can be continuously conveyed forwards, the rear conveying belt can timely send away a finished straw product formed through cutting-off, it is ensured that cutting of the long pipe can becontinuously conducted, during cutting, the turning mechanism can adjust the angle of the cutting knives, thus different angles can be cut through the same cutting knife, the straw can be cut to forma flat end and a tip, and the cutting speed of the straw is increased.

Owner:山东蔚来新材料有限公司

Flexible bar material ring cutting machine

The invention discloses a flexible bar material ring cutting machine. The flexible bar material ring cutting machine comprises a welding frame, a pressing roller assembly, a bearing supporting seat and a ring cutting frame. A base plate is installed on the welding frame, and the pressing roller assembly is arranged above the base plate. The pressing roller assembly is internally provided with a lifting pad plate which is fixed to the upper surface of the base plate through a supporting column, rollers are arranged on two sides of the lifting pad plate, and the rollers on the two sides are connected by a synchronous belt in a drive mode. A driving roller assembly is connected to the end, away from the synchronous belt, of the roller on one side, the driving roller assembly is provided withan adjusting plate, and a pneumatic chuck mounting plate is arranged on the side of the driving roller assembly. A first pad palate and a second pad plate are arranged the side of the pressing rollerassembly, and the first pad plate and the second pad plate are fixedly installed on the upper surface of the base plate. According to the flexible bar material ring cutting machine, the object is a soft pipe, rotation is carried out by adopting a cutter head, a pipe does not move, and the production cost is reduced.

Owner:南京力旷机电科技有限公司

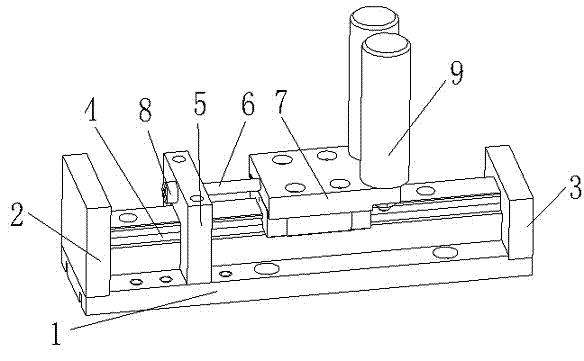

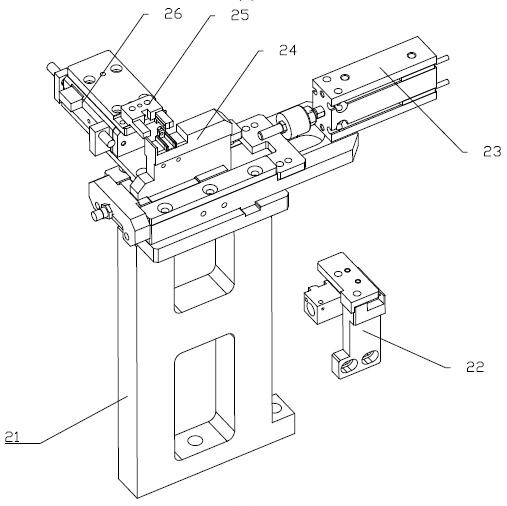

Automatic loading and unloading device

The invention relates to an automatic loading and unloading device, in particular to an automatic loading and unloading device used on a precision machining tool in a matched manner. The automatic loading and unloading device comprises a bottom plate, a bracket, a feed plate, a small shaft, two deep groove ball bearings, a large space ring, a V-shaped locating block, a movable pressing block, a tension spring, a back plate, an inductive switch, a feed bracket, a feed guide sleeve, a small space ring, a loose joint, a cylinder, a rotating shaft and a flat gasket, wherein the bracket is fixed on the bottom plate through two hexagon bolts; the two deep groove ball bearings are mounted in the feed plate, the small shaft penetrates through an inner hole of the feed plate and the large space ring to fix the feed plate on the side surface of the bracket; the V-shaped locating block is fixed at the front end of the feed plate through one cross recessed screw; the movable press block is fixed on the feed plate by an inner hexagon screw, the rear end of the movable press block is connected with one end of the tension spring through one cross recessed screw, and the other end of the tension spring is fixed on the feed plate through one cross recessed screw; the back plate is fixed on the bracket through inner hexagon flat-end set screws II; and the inductive switch is fixed at the upper part of the bracket.

Owner:江苏瑞普机床有限公司

Pneumatic plate-shearing machine

InactiveCN106216755AExtended service lifeAvoid double cuttingShearing machinesEngineeringPneumatic motor

The invention belongs to the technical field of plate-shearing machines, and particularly relates to a pneumatic plate-shearing machine. A pneumatic motor is connected to a pneumatic control box through a pneumatic guide pipe, and a pneumatic system assembly is contained in the pneumatic control box. By means of the pneumatic plate-shearing machine, the problems that in the prior art, due to the fact that a traditional electric plate-shearing machine completes the plate shearing action at a time, impact vibration is large in the junction process, and equipment failures are liable to be caused by overloads are solved. The pneumatic plate-shearing machine has the beneficial technical effects that practicability is high, the plate-shearing efficiency is high, power consumption is reduced, the labor intensity is relieved, and flexibility of plate-shearing machining is improved.

Owner:天津耐斯特宝机电设备有限公司

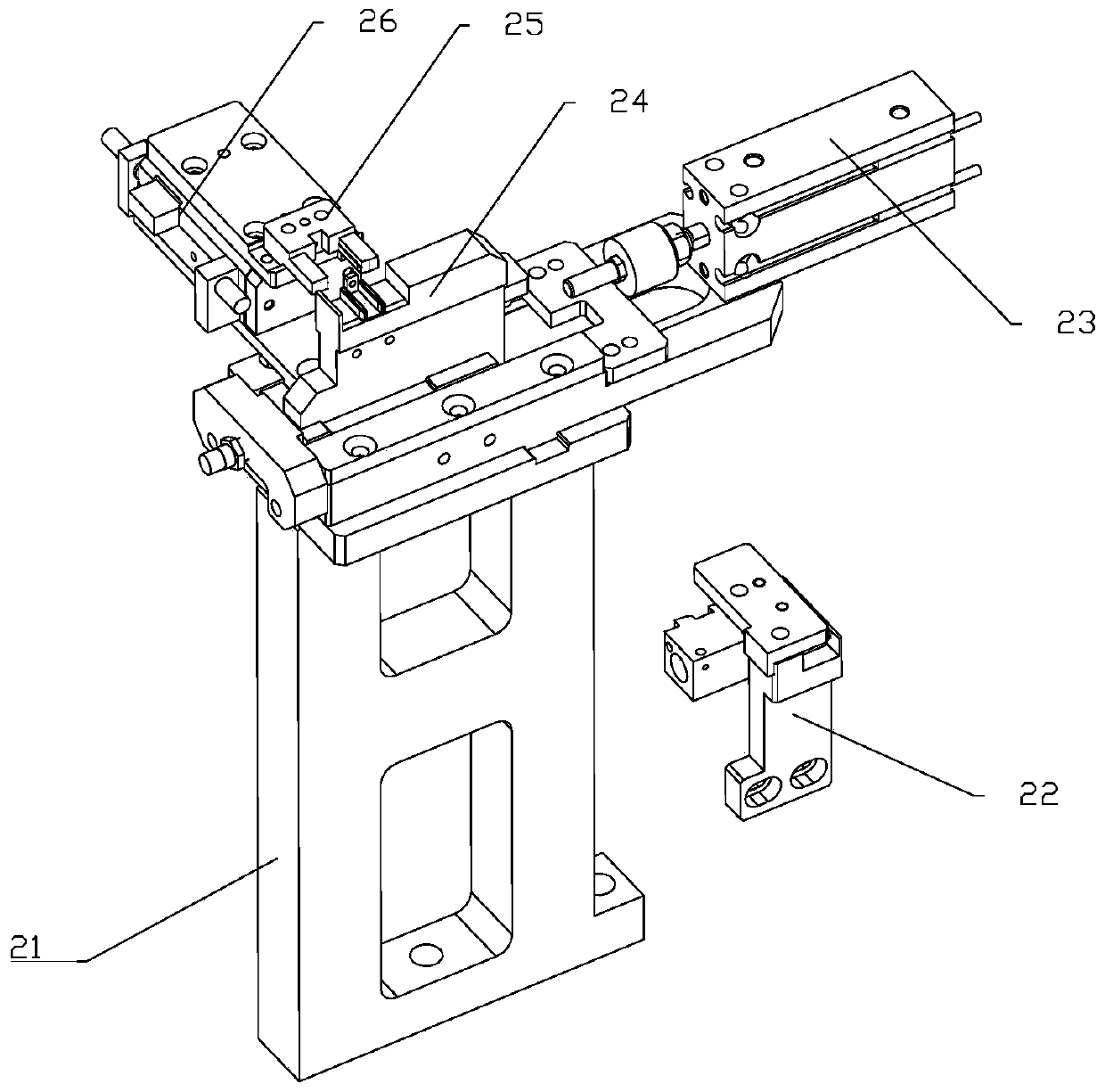

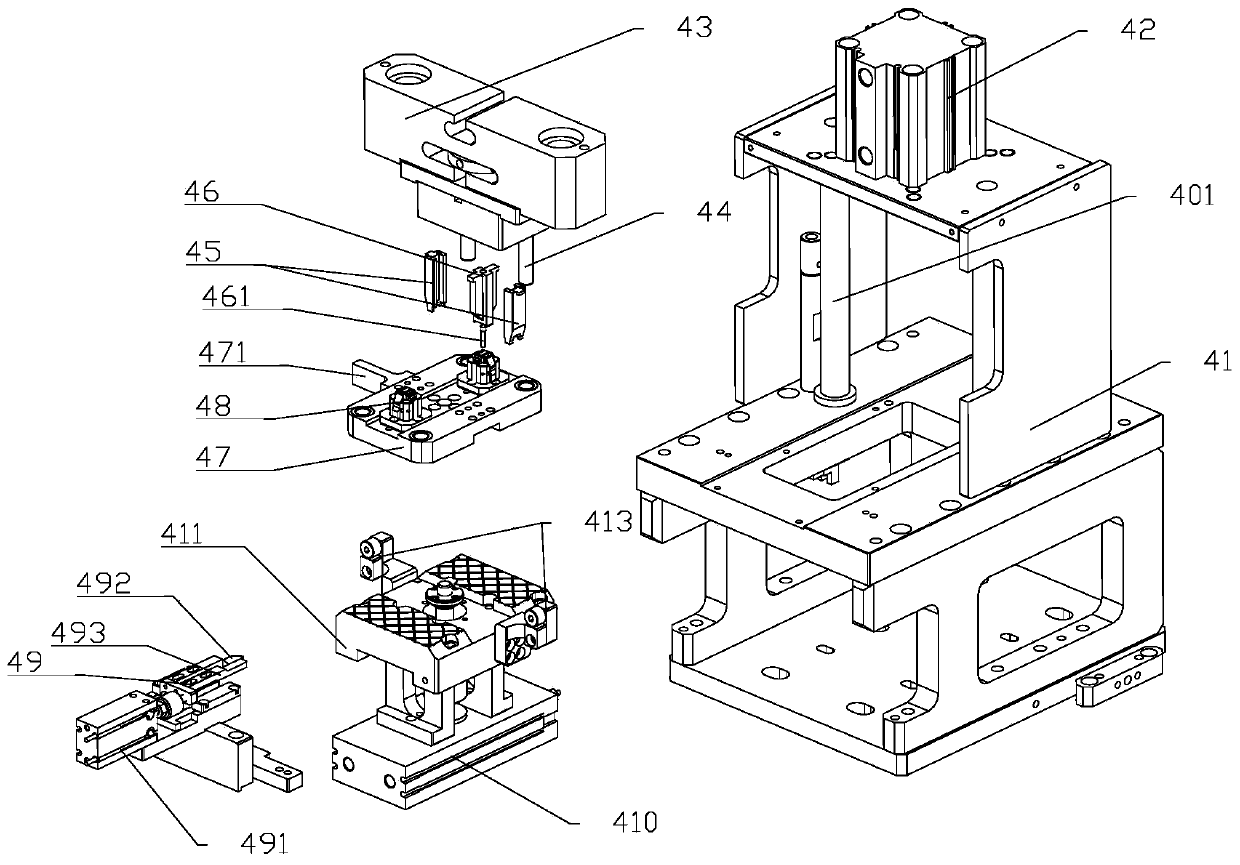

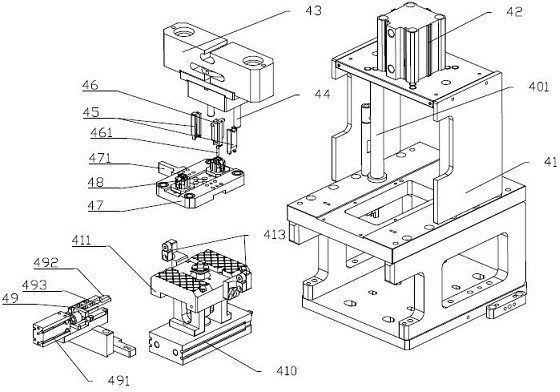

A pin pressing device of an electronic chip loading machine

ActiveCN111151684BHigh precisionImprove compaction efficiencyStacking articlesDe-stacking articlesStructural engineeringElectronic chip

The invention relates to the technical field of electronic chip production. A pin pressing device of an electronic chip loading machine, including a mounting seat, a pressing cylinder, a lifting block, a positioning column, a limit block, a pressing block, a transfer plate, a positioning component, a switch component, a rotating cylinder and a fixing base seat; the mounting seat is fixedly arranged on the frame, the lifting block moves and fits in the mounting seat, the compacting cylinder is arranged on the top of the mounting seat, and the telescopic end of the compacting cylinder is connected with the lifting block; the positioning column is set At the bottom of the lifting block, the pressing block is fixedly arranged on the bottom of the lifting block; a pressing column is arranged in the pressing block, and the pressing column is connected with the pressing block through a spring; The assembly is installed on the transfer board, and the center of the transfer board is installed on the transfer shaft of the rotary cylinder; the switch assembly is arranged on the mounting seat, and the switch assembly is located at the side of the positioning assembly. The pin positioning of the invention is fast and efficient, and the double-station is processed step by step to limit and compress the workpiece.

Owner:江苏顺海科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com