Ethylene vinyl acetate (EVA) cutting equipment

A kind of equipment and cutting technology, applied in the direction of metal processing, etc., can solve the problems of material size instability, accident-prone, EVA pollution, etc., to achieve the effect of easy operation, prevention of industrial accidents, and reduction of waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

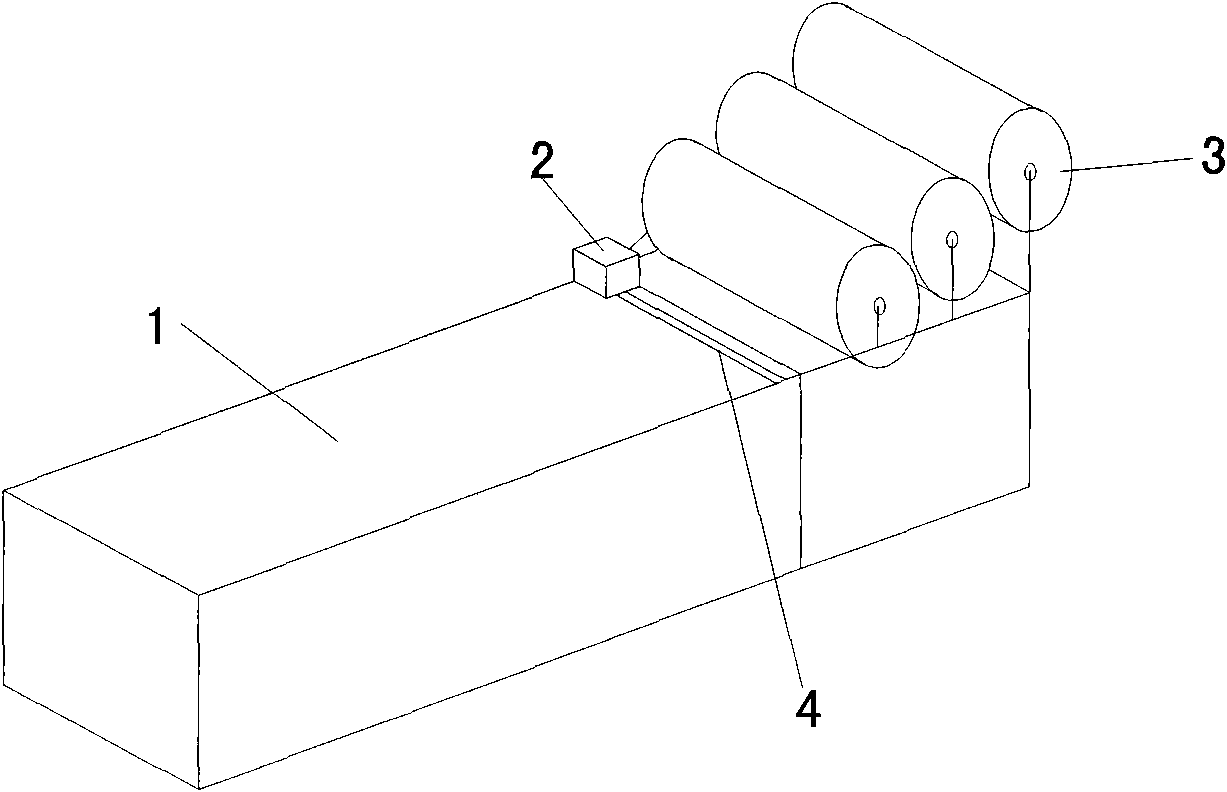

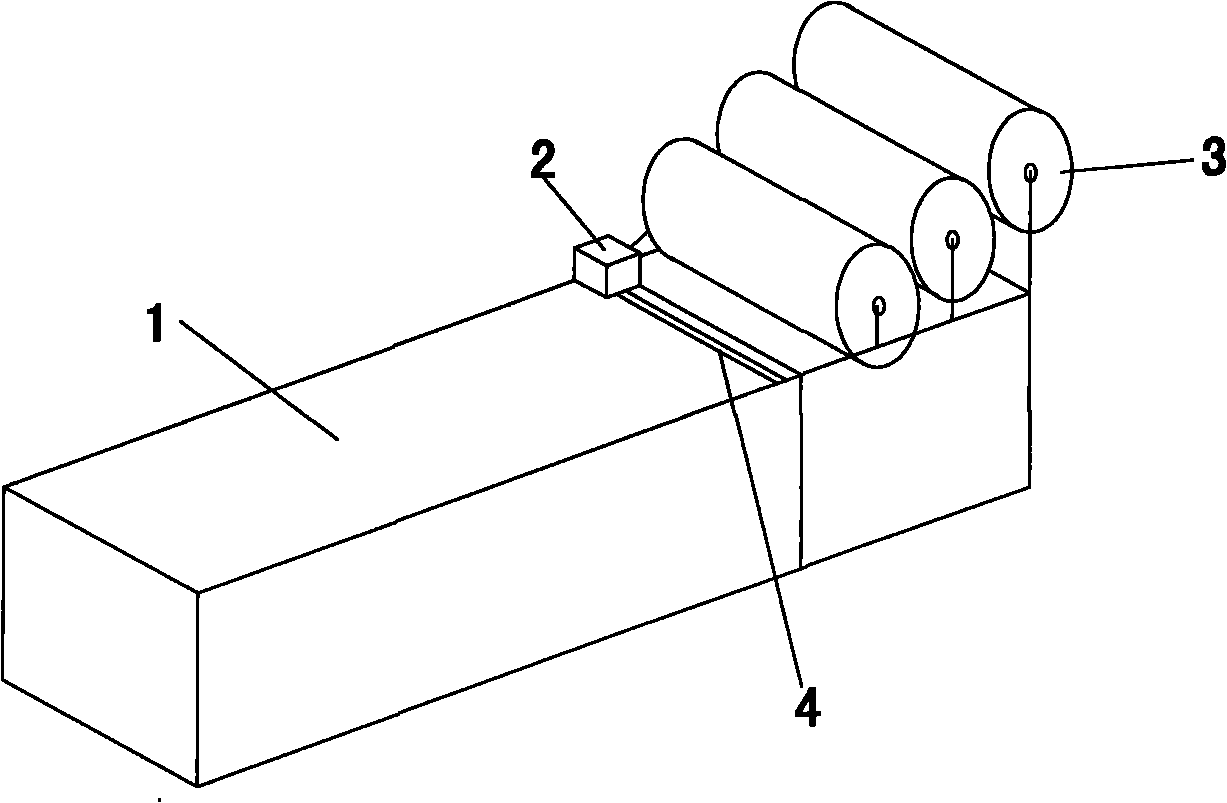

[0010] figure 1 It is a preferred embodiment of the present invention, and the present invention is not limited to this embodiment.

[0011] see figure 1 , the EVA cutting equipment of the present invention includes a workbench 1, a cutting machine 2 and a rack 3 installed on the workbench 1. An aluminum alloy track 4 is erected on the workbench 1 .

[0012] The cutting machine 2 in the present invention is a mobile linear cutting machine, which adopts a circular cutting knife and is provided with an automatic sharpening mechanism, and the radius of the blade can meet the requirements for cutting multi-layer EVA. The cutting machine is installed on the aluminum alloy track 4 and can move along the aluminum alloy track, and one end of the aluminum alloy track 4 is rotatably connected with the workbench 1 through a rotating mechanism.

[0013] The material rack 2 in the present invention includes three supports of different heights, which can simultaneously place three rolls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com