Pork tenderness detection sampler

A sampler and tenderness technology, applied in sampling devices and other directions, can solve problems such as failure to meet detection requirements, no blade, damage to the blade, concave deformation, etc., to save time and effort, improve sample cutting speed, and quickly and accurately sample. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

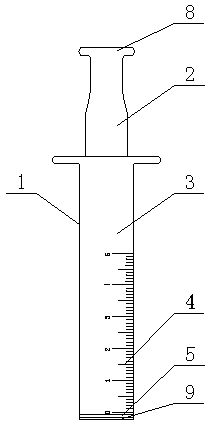

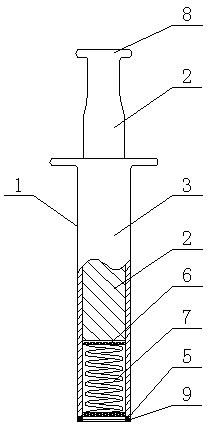

[0020] Attached below figure 1 To attach image 3 The present invention is described further:

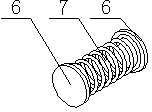

[0021] A pork tenderness detection sampler, comprising a sampler body 1, the sampler body 1 includes a shearing knife cylinder 3 and a push rod 2, the shearing knife cylinder 3 is a hollow cylinder, and the upper and lower ends All openings, the lower part of the outer surface of the shearing knife cylinder 3 is provided with a scale 4, the bottom surface of the shearing knife cylinder 3 is fixedly provided with a shearing knife 5, and the shearing knife 5 is an annular knife, and the annular knife The inner diameter of the inner diameter of the shearing knife barrel 3 is the same and can be tightly and stably wedged together; the outer diameter of the push rod 2 is the same as the inner diameter of the shearing knife barrel 3, and the push rod 2 can The cutter cylinder 3 moves back and forth, and the bottom surface of the push rod 2 is fixedly provided with a spring assembly in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com