Automatic spreading and cutting machine for rubber inner tube base plate

A rubber inner tube and cutting machine technology, which is applied in metal processing, winding strips, thin material processing, etc., can solve the problems of high labor intensity, irregular edges, inconvenience, etc., and achieve accurate length, spreading and cutting Fast, smooth-edged results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

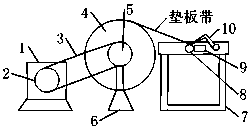

[0010] As shown in the figure, a pulley 2 is installed on the power machine 1, and the pulley is connected to the roller pulley 5 provided on the backing roller 4 through the belt 3. The backing roller is installed on the roller support 6, and the backing roller The cylinder other side is equipped with backing plate spreading roll 8 by cutting frame 7, travel switch 9 is housed on the cutting frame adjacent to backing plate spreading roll outside, and cutter 10 is housed on the cutting frame outside travel switch.

[0011] Described cutter is contained on the cutting shaft, and cutting shaft is contained on the upper beam of cutting frame, and cutting shaft can rotate and cut.

[0012] The backing plate is a backing plate body with a bottom layer.

[0013] Working process of the present invention:

[0014] Roll the backing plate on the backing plate roller, start the drive motor to run, and rotate the backing plate roller through the belt, and the front end of the backing pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com