Patents

Literature

212results about How to "Save manpower" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

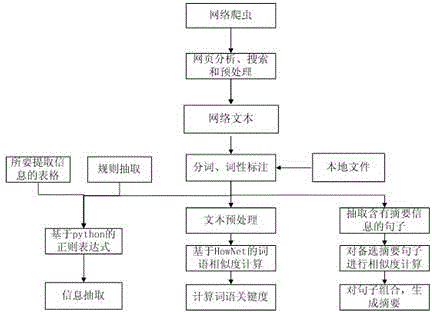

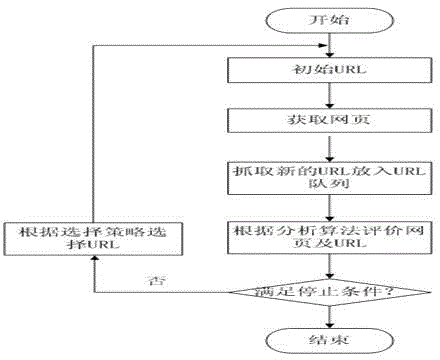

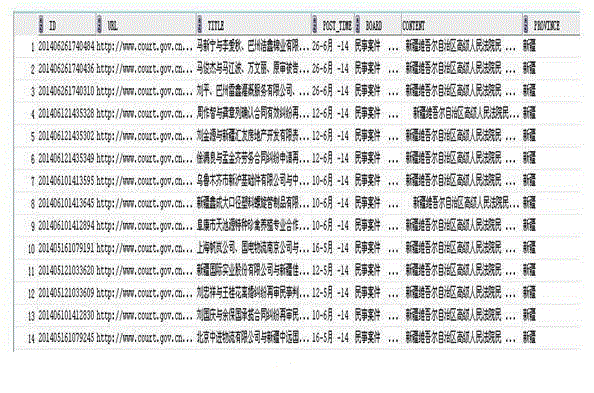

Automatic standardized filing method based on text semantic mining

InactiveCN104572849AFree from readingShorten the timeSpecial data processing applicationsInformatizationSemantics

The invention relates to an automatic standardized filing method based on text semantic mining. The automatic standardized filing method is characterized by comprising the steps: crawling files from a website, and carrying out information extraction, key word extraction and automatic abstract generation on the crawled file and a local file by utilizing text semantics, and finally storing into an informatization system. For the information extraction, a rule set is established by adopting a knowledge engineering method, information points are automatically extracted from the file to form structural data; for the key word extraction, a key word is extracted according to a position and semantics of a word in a text to generate a key word index; for the automatic abstract generation, a content contained by the abstract is firstly set, corresponding information is extracted from the text, the similarity of sentences is calculated, and the texts including the key information in the original file are extracted. By adopting the automatic standardized filing method, business personnel do not need to read a great amount of files, time and labor are saved, and convenience in inquiry and application can be realized.

Owner:MERIT DATA CO LTD

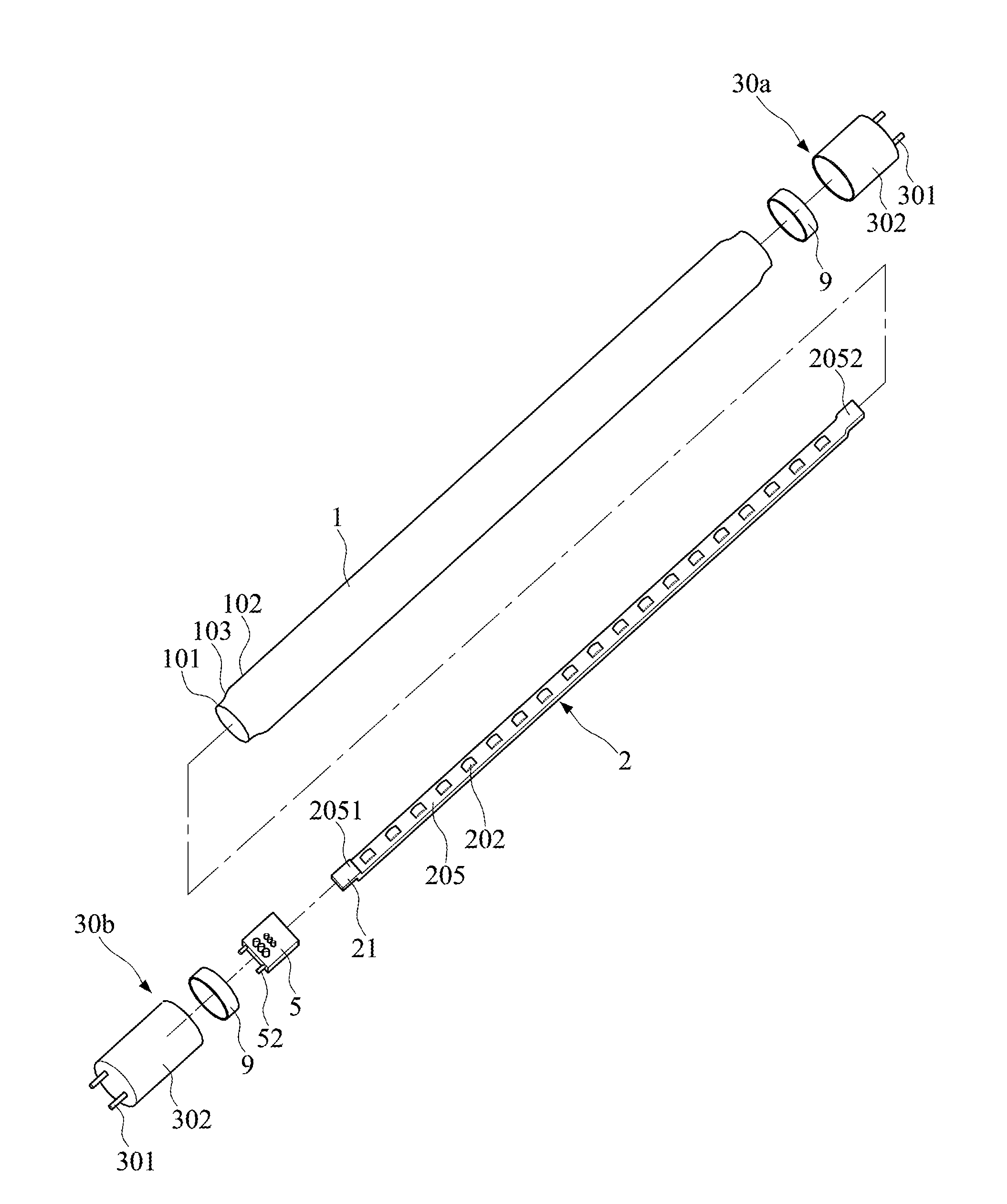

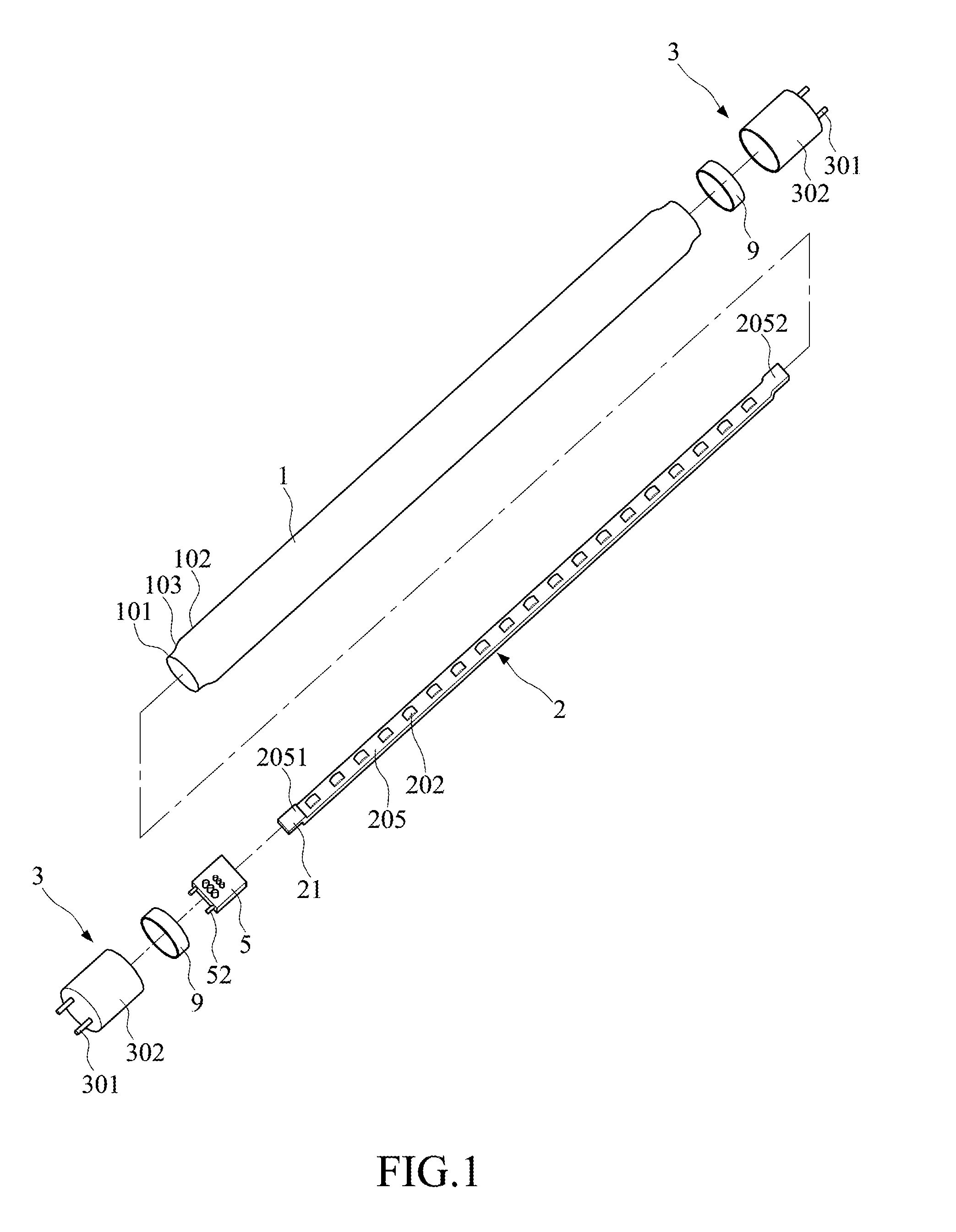

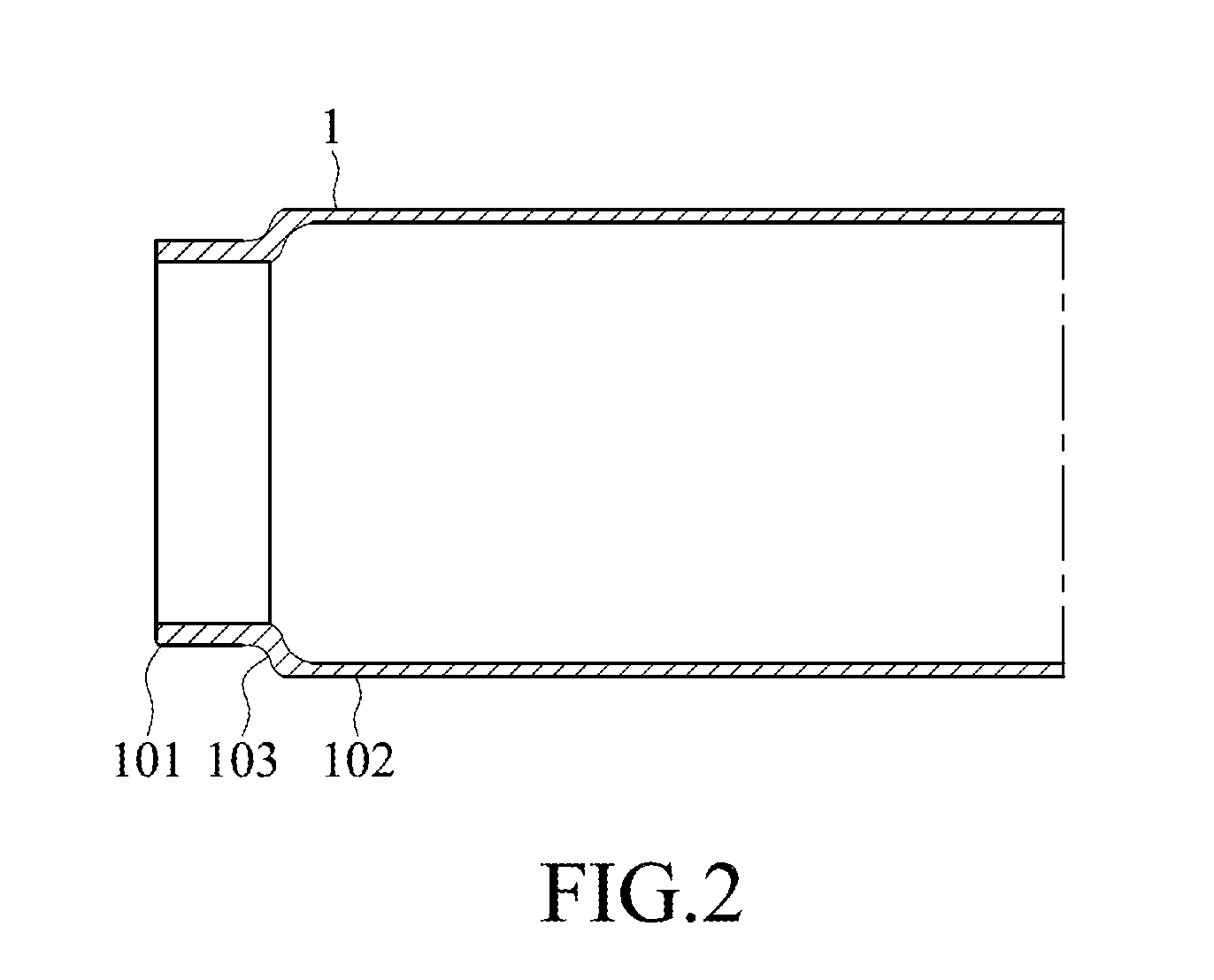

LED tube lamp

ActiveUS20160215936A1Save manpowerIncrease productivityElongate light sourcesElectric circuit arrangementsBody regionEngineering

An LED tube lamp including a glass lamp tube, an LED light strip disposed inside the glass lamp tube, and an end cap attached over an end of glass lamp tube is disclosed. The glass lamp tube includes a main body region, a rear end region, and a two-arc-shaped transition region connecting the main body region and the rear end region. The LED light strip includes a bendable circuit sheet being longer than the glass lamp tube to form a freely extending end portion. In addition, the end cap has at least one opening on surface to dissipating heat resulting from power supply and / or the process of heating of a hot melt adhesive.

Owner:JIAXING SUPER LIGHTING ELECTRIC APPLIANCE

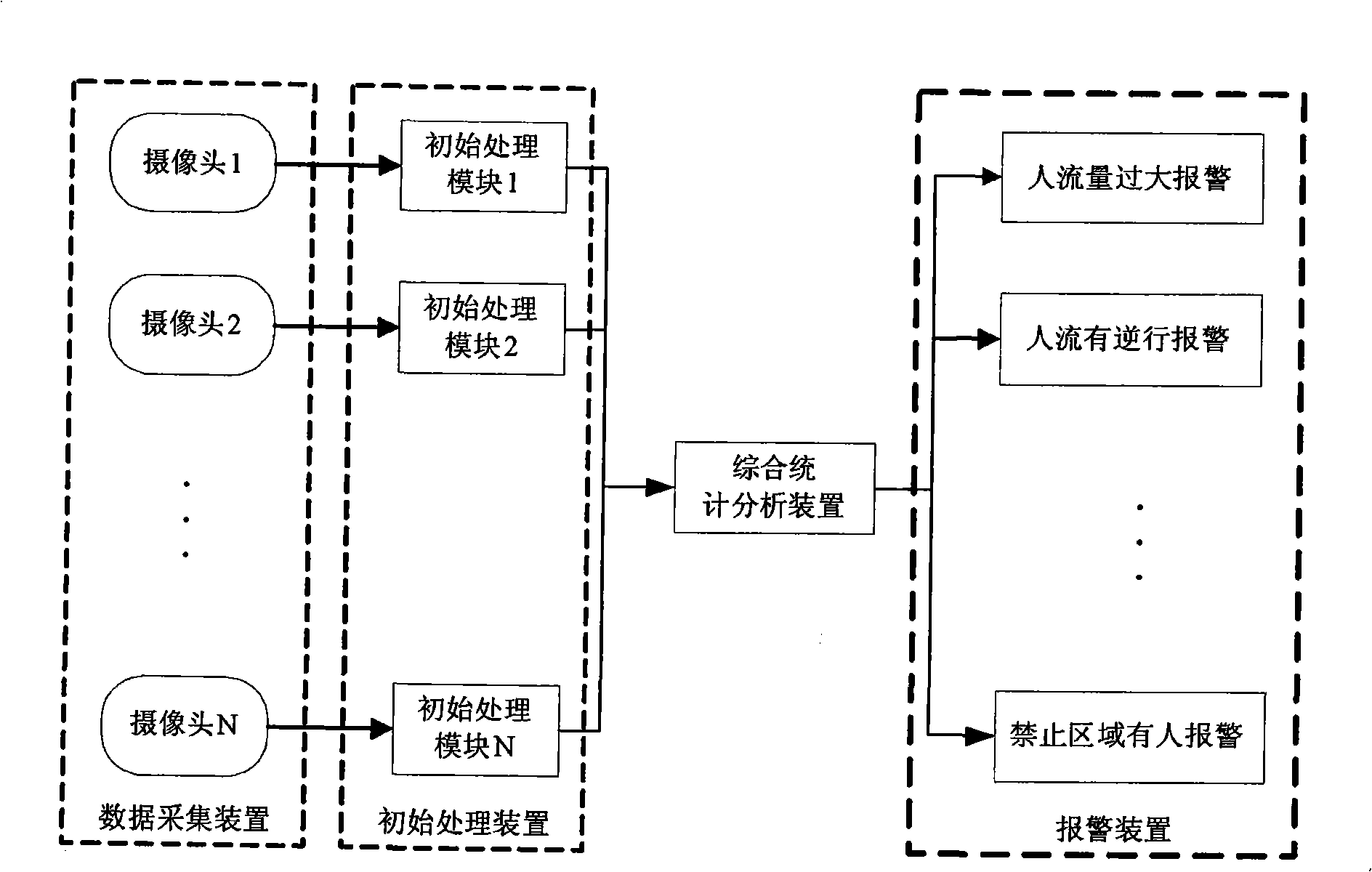

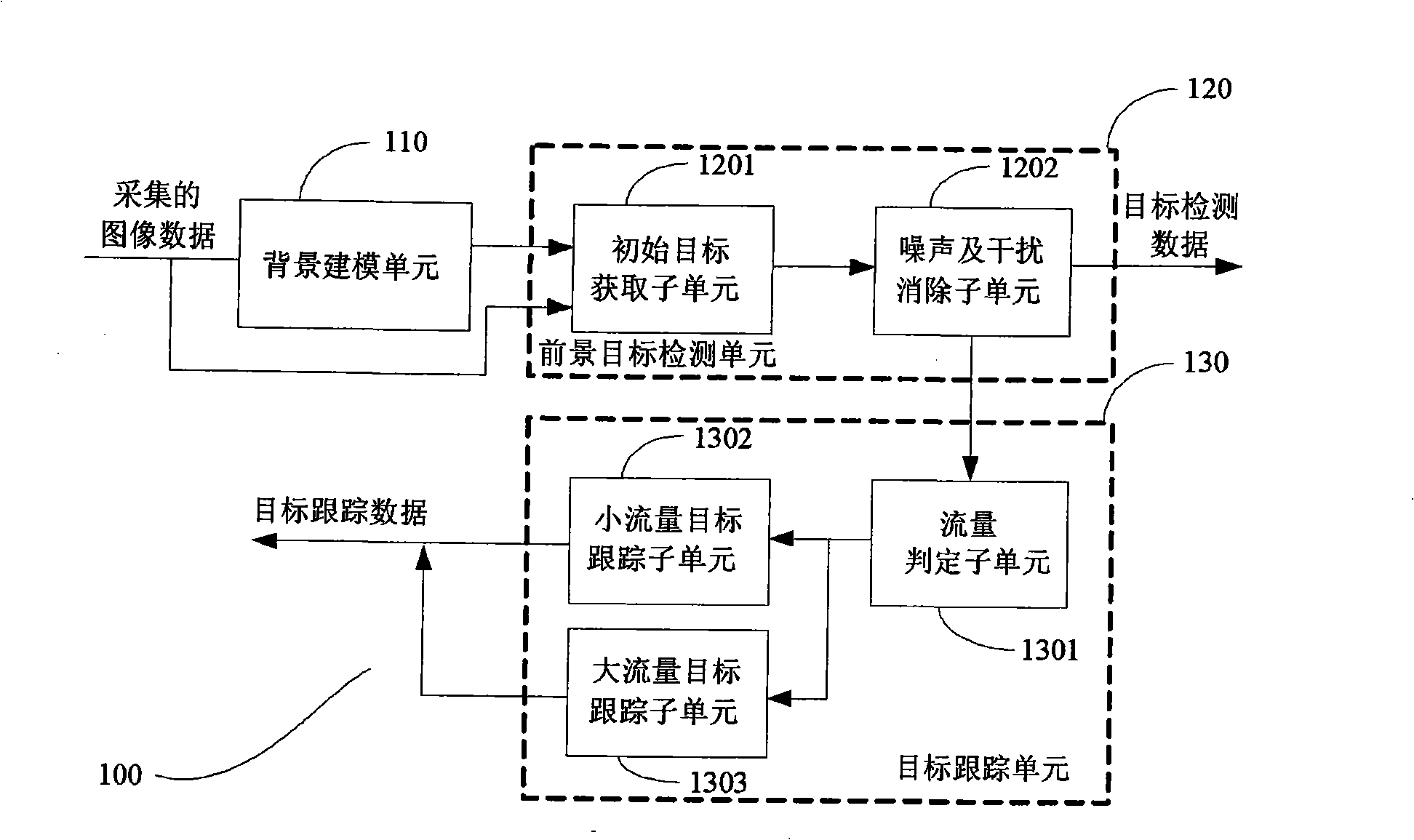

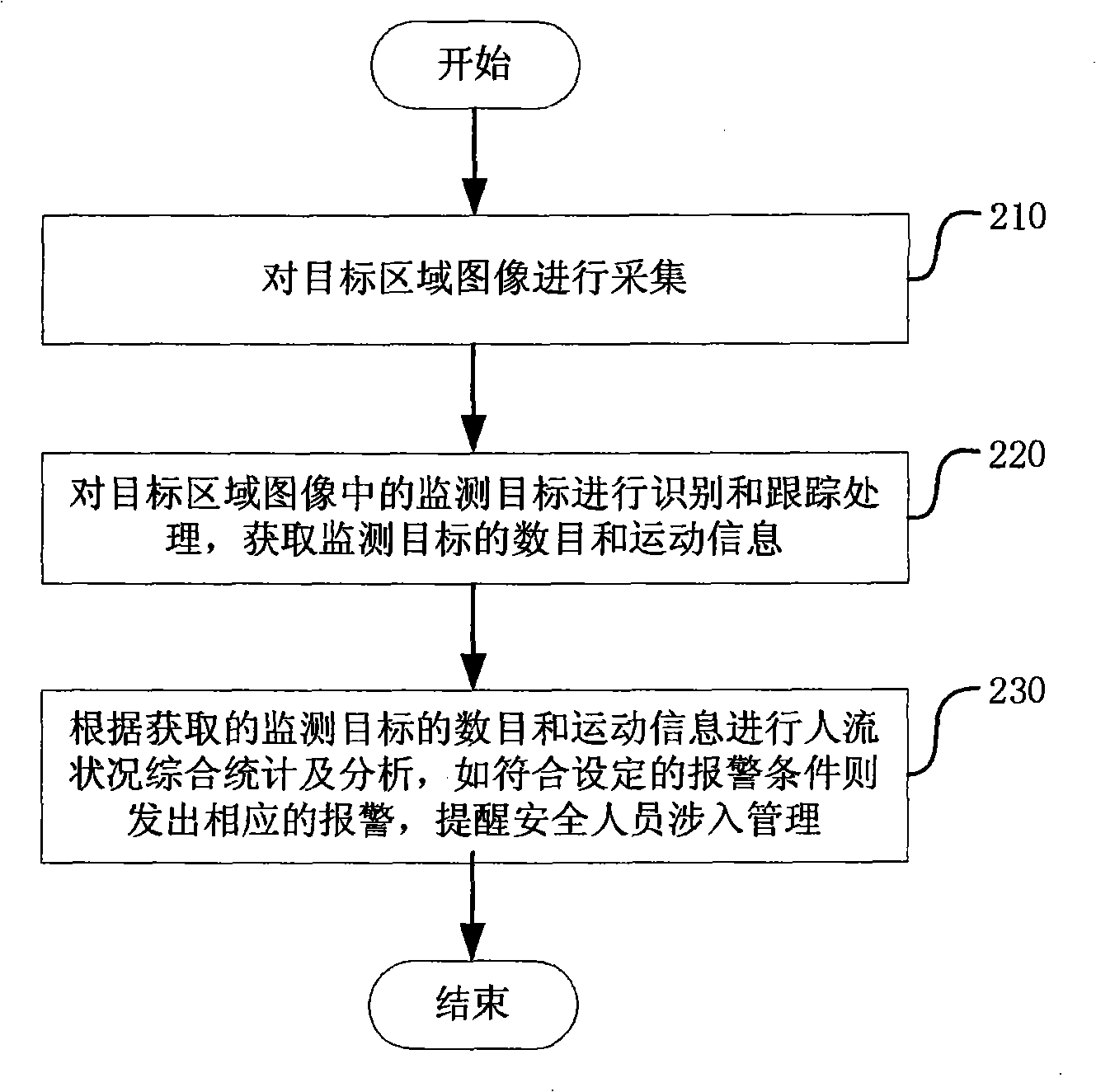

Video monitoring method and system with auxiliary objective monitoring function

InactiveCN101320427AReduce security risksSave manpowerCharacter and pattern recognitionAlarmsTraffic volumeHuman power

A video monitoring method that has auxiliary monitoring function for an object is provided, which comprises the following procedures: a) collecting images in a target area; b) identifying and tracking a monitoring object in the image of target area, so as to acquire the number and / or movement information about the monitoring object; c) carrying out comprehensive statistics and analysis of passenger flow according to the acquired number and / or movement information about the monitoring object. The invention can intelligently assist a safety administrator to manage, so as to effectively reduce the potential safety hazard and save a great amount of management manpower. What is more, with unique background updating mechanism, the invention can ensure more reliable application in places with great passenger flow such as the platform of rail transit, the entrance of department store and entrance of passage. In addition, by tracking the monitoring object according to different passenger flow, the invention not only simplifies the elaborated tracking algorithm, but also ensures better processing effect.

Owner:VIMICRO CORP

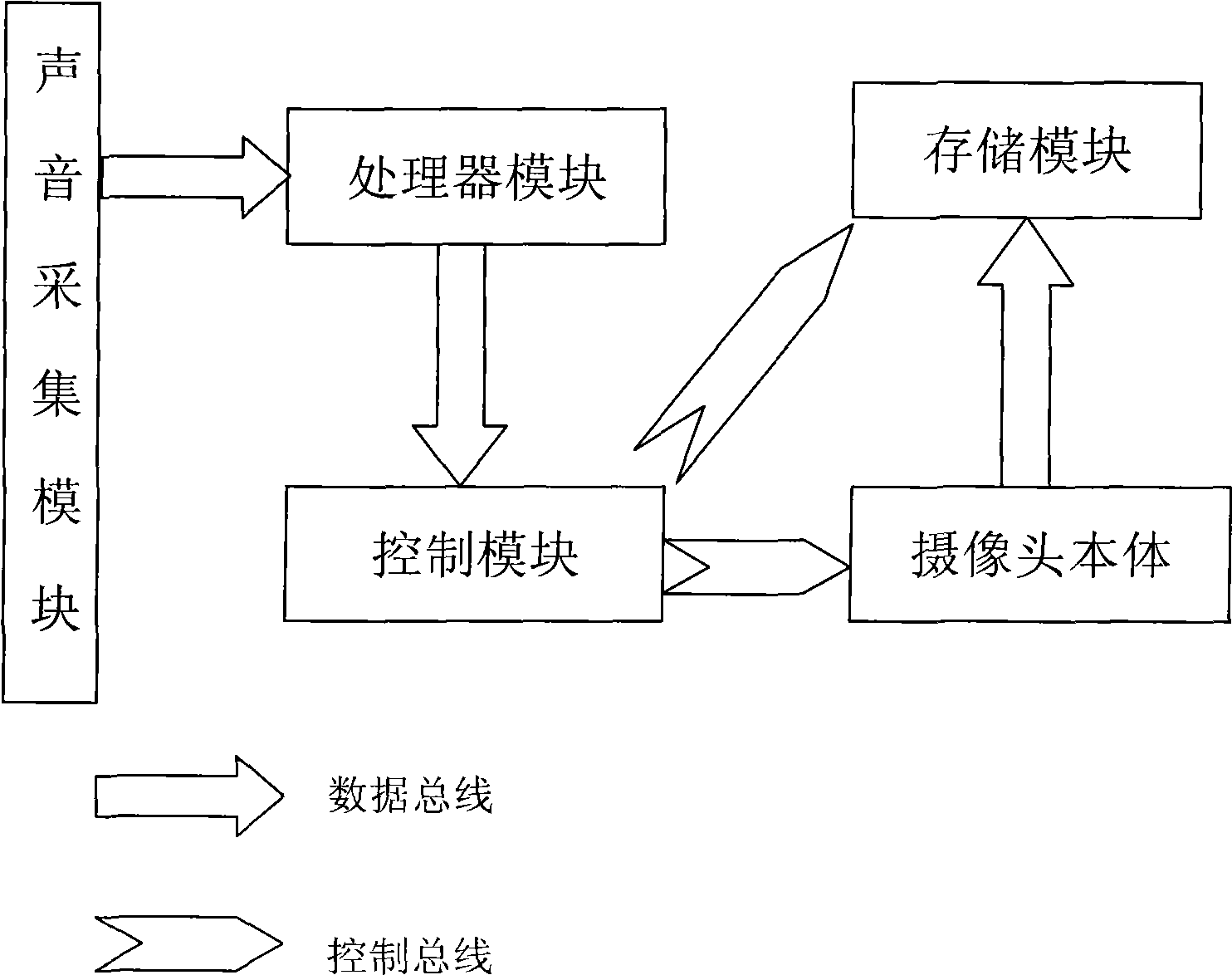

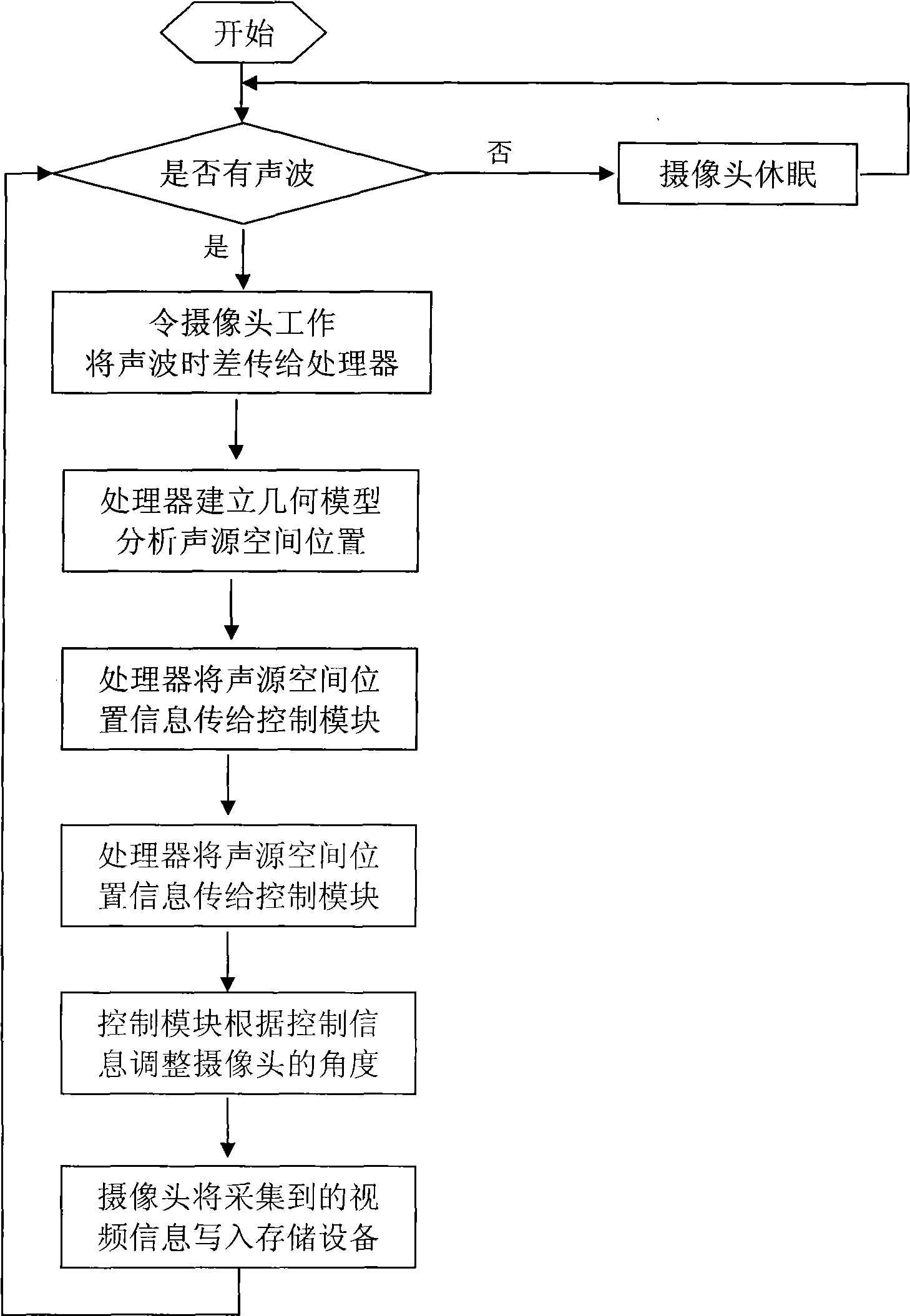

Intelligent monitoring pick-up head device using acoustic location

InactiveCN101511000ASave time at workExtend your lifePosition fixationClosed circuit television systemsWork periodVideo monitoring

The invention relates to an intelligent monitoring camera device which locates by means of acoustic waves, comprising a sound collection module, a processor module, a control module, a camera body and a storage module. The utilization of the device saves expensive storage resources, improves the effectiveness of collected video information and can also reduce the working time of a video monitoring device. At the same time, when target objects appear at monitoring places, a monitoring screen can automatically open, which is convenient and greatly improves the working efficiency.

Owner:SUN YAT SEN UNIV

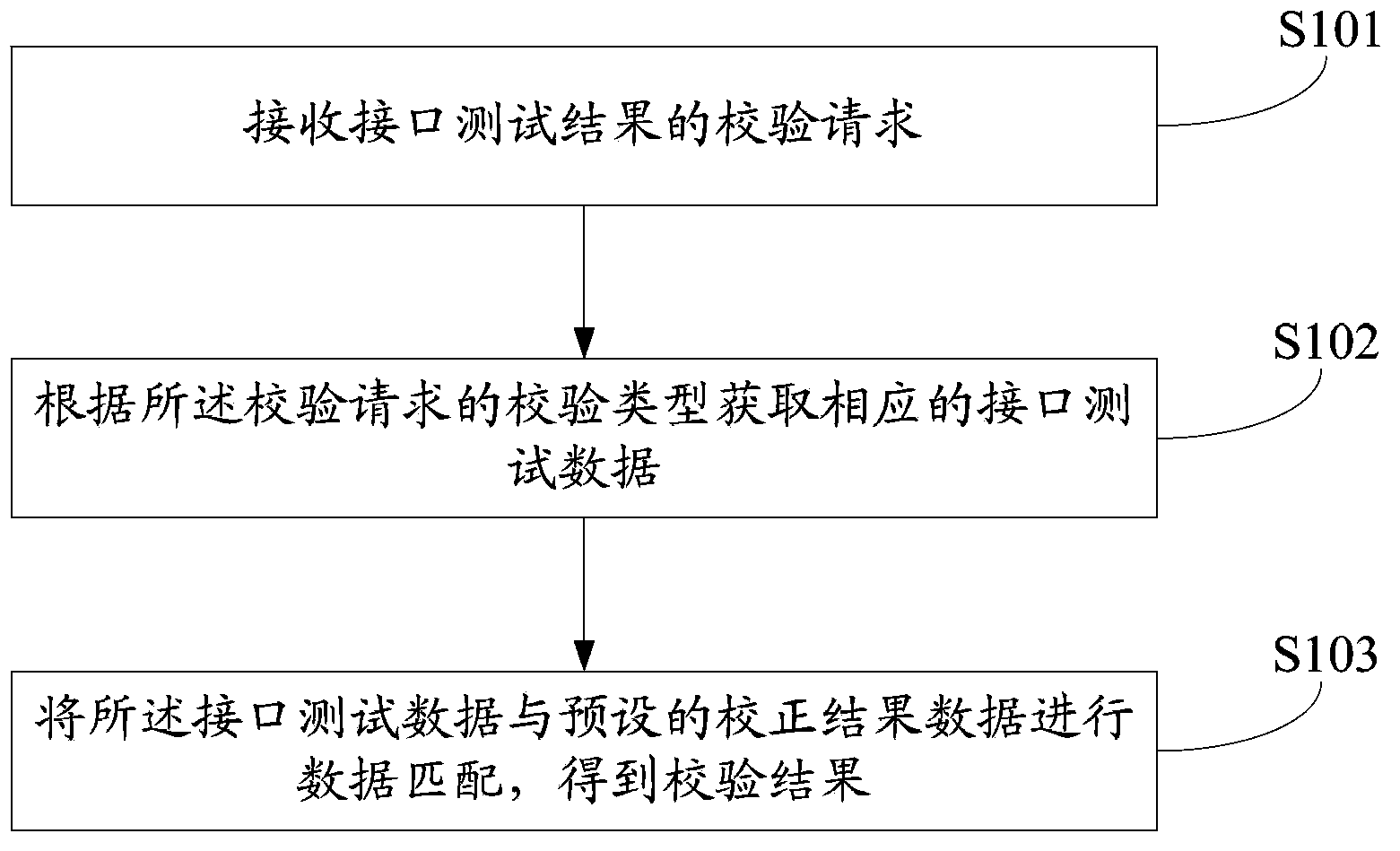

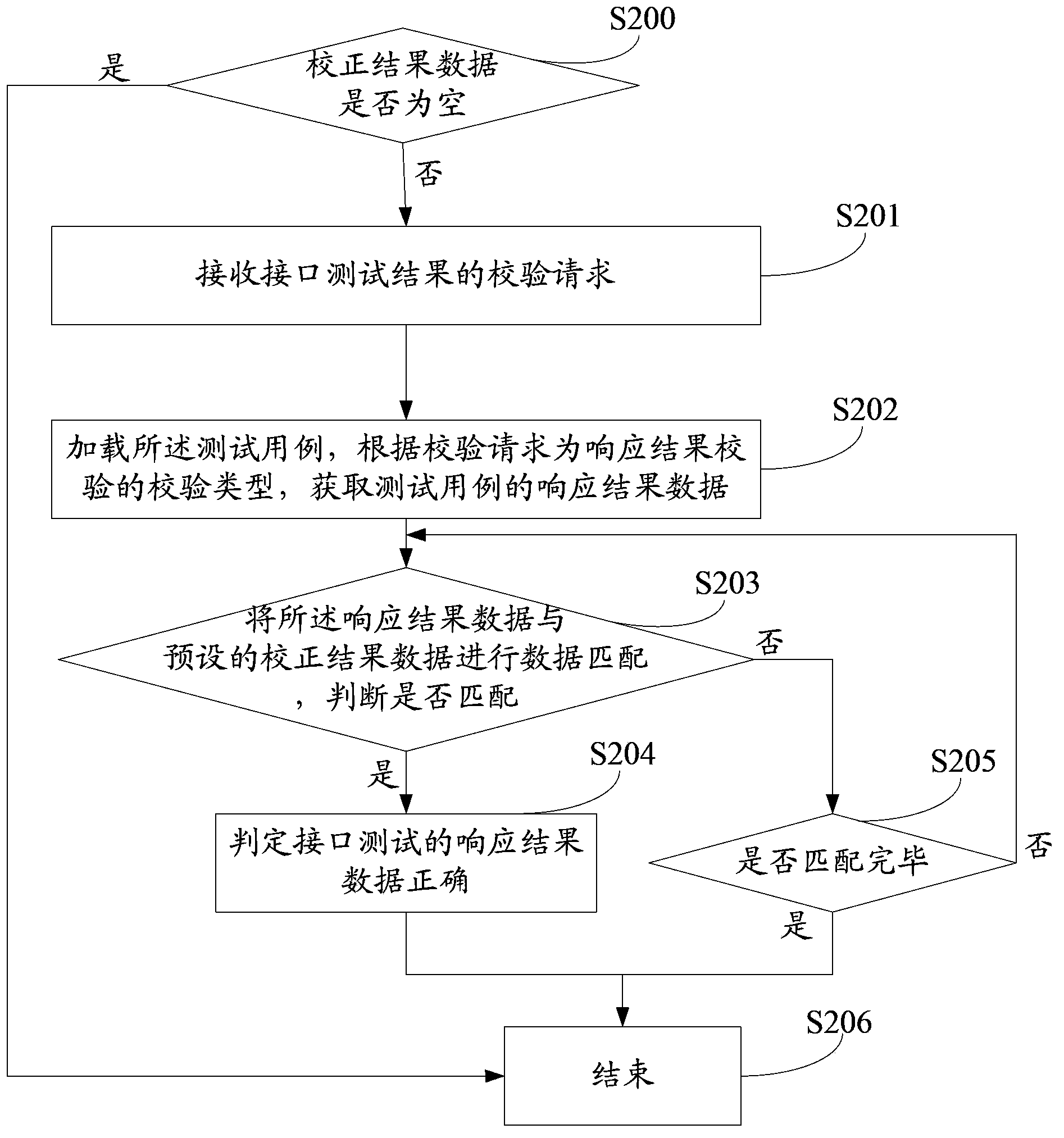

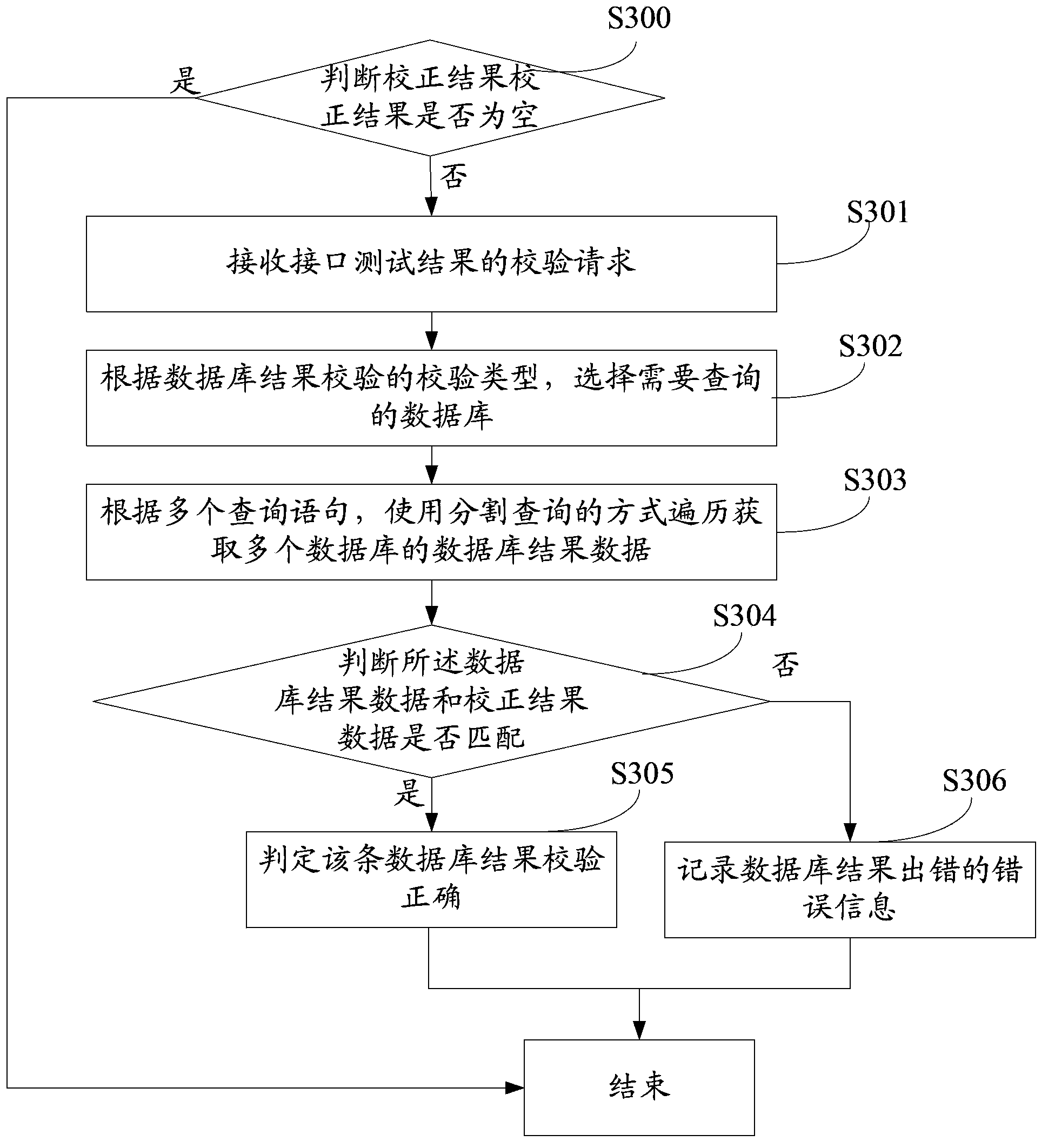

Method and device for verifying interface test results

ActiveCN104111885ASave manpowerReduce false detection rateError detection/correctionData matchingComputer hardware

The invention provides a method and a device for verifying interface test results and is applicable to the field of interface test. The method includes steps of receiving verifying requests of the interface test results, wherein the verifying requests include verifying types of the interface test results; acquiring corresponding interface test data according to the verifying requests; matching the interface test data with preset correction result data to obtain verifying results. The corresponding interface test data can be acquired according to the verifying request types and are automatically compared and matched with the correction result data, and compared with existing manual comparison way, the method has the advantages that a great deal of labor can be saved, mistaken verifying rate is decreased, verifying efficiency is improved and cost is reduced.

Owner:TENCENT TECH (SHENZHEN) CO LTD

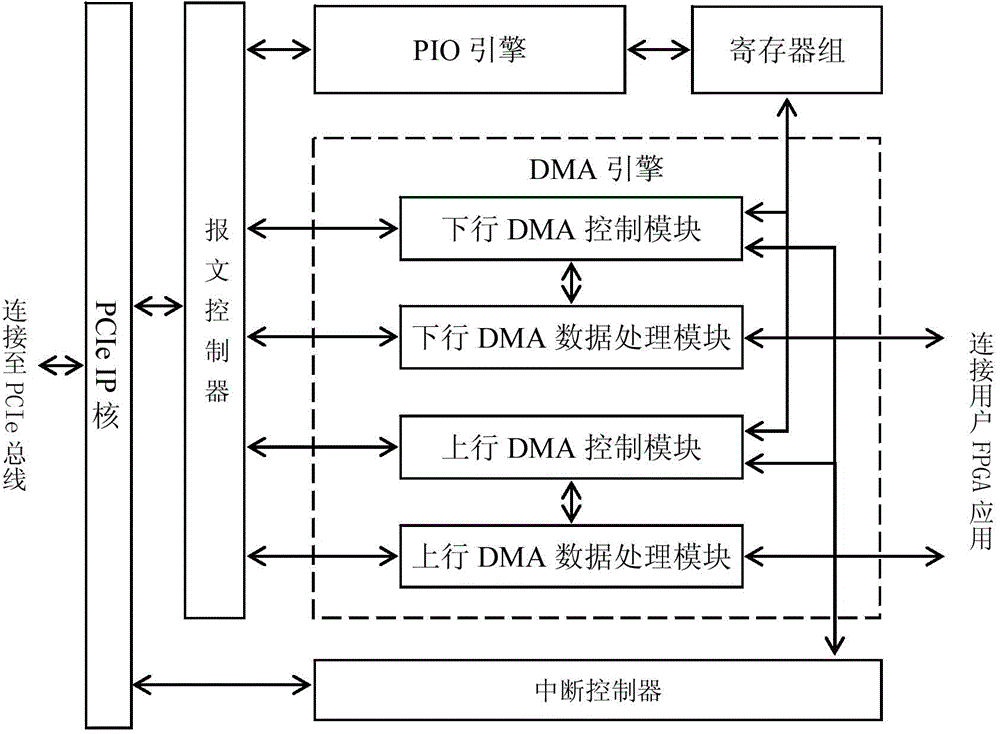

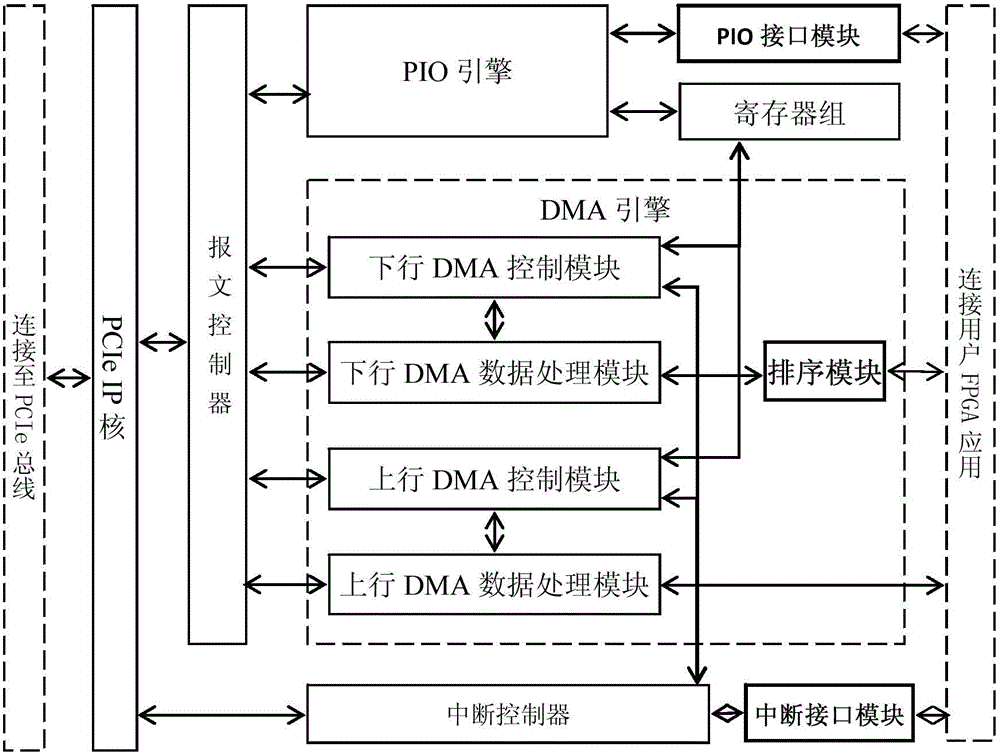

Communication system between FPGA (field programmable gate array) and computer

ActiveCN103559156AImprove integration efficiencySpeed up research and developmentElectric digital data processingControl flowData stream

The invention provides a communication system between an FPGA (field programmable gate array) and a computer. The communication system comprises a DMA (directly memory access) engine, a PIO (programmed input / output) engine, a register block, a message controller, an interrupt controller and a PCIe IP (peripheral component interface-express intellectual property) core. Full-duplex and high-throughput DMA data transmission is realized by a sending module and a receiving module which are stand-alone in FPGA hardware, low-delay data transmission is realized by stand-alone processing of data flow and control flow in the sending module or the receiving module, and the FPGA and the computer are linked together by the DMA data transmission. By utilizing the technical scheme provided by the invention, the efficiency of the integration of an FPGA application and the computer can be increased, the research and development speed, the testing speed and the speed to market of the FPGA application are picked up, and the time and the human input consumed by the integration of the FPGA application and the computer are saved.

Owner:PEKING UNIV

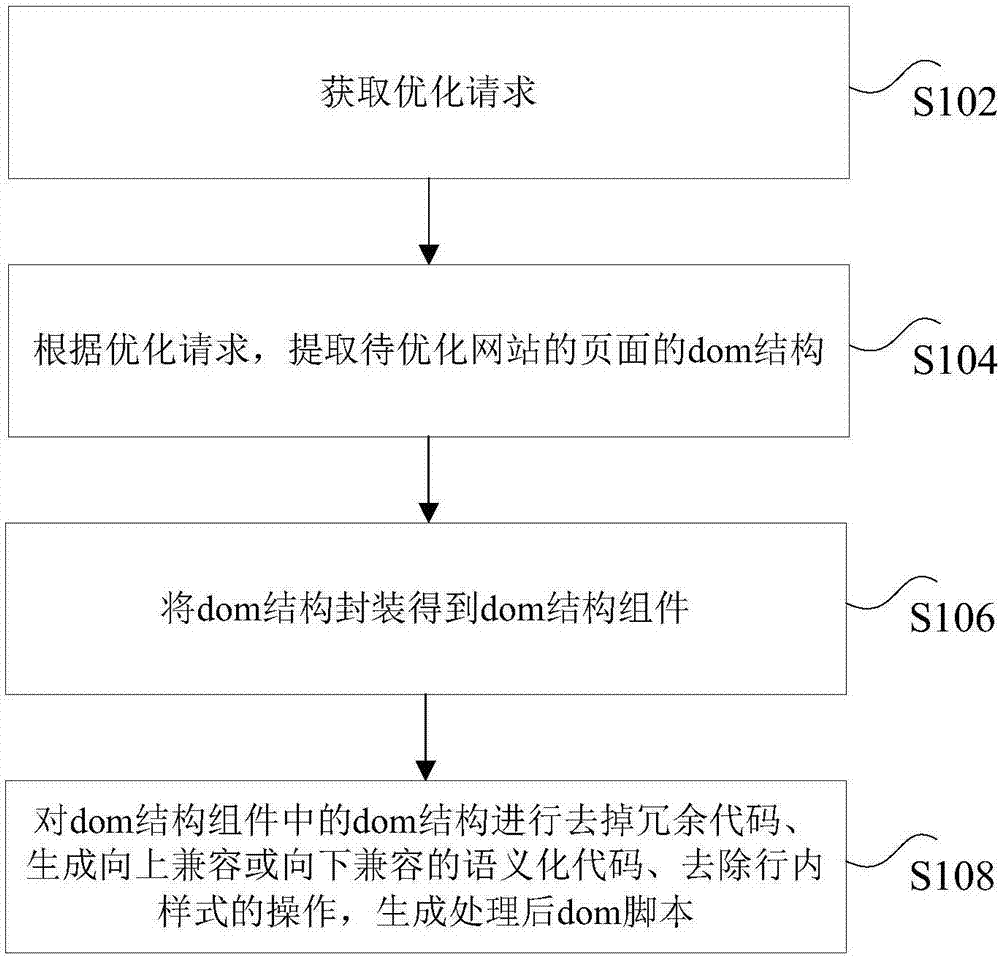

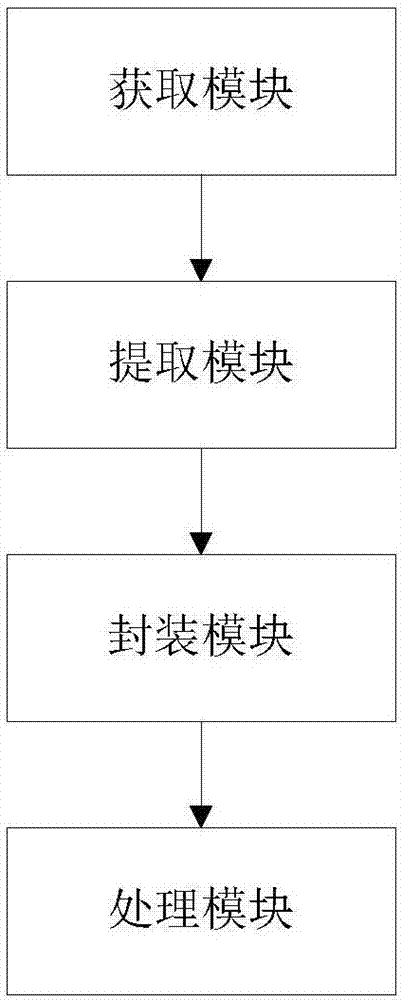

Website performance optimization method and apparatus

InactiveCN106980497AEasy to upgradeEasy to optimizeSpecific program execution arrangementsDOM scriptingRedundant code

The present invention discloses a website performance optimization method and apparatus. The method comprises: obtaining an optimization request; extracting a dom structure of a page of a to-be-optimized website according to the optimization request; encapsulating the dom structure to obtain the dom structure component; and carrying out redundant code removal, upward compatible or backward compatible semantics code generation, and intra-line style removal operations on the dom structure in the dom structure component, and generating a processed dom script. According to the method and apparatus disclosed by the present invention, the technical problems of huge consumption of the time, the manpower and financial resources due to secondary development or re-escalation of some old projects of the website in the prior art are solved.

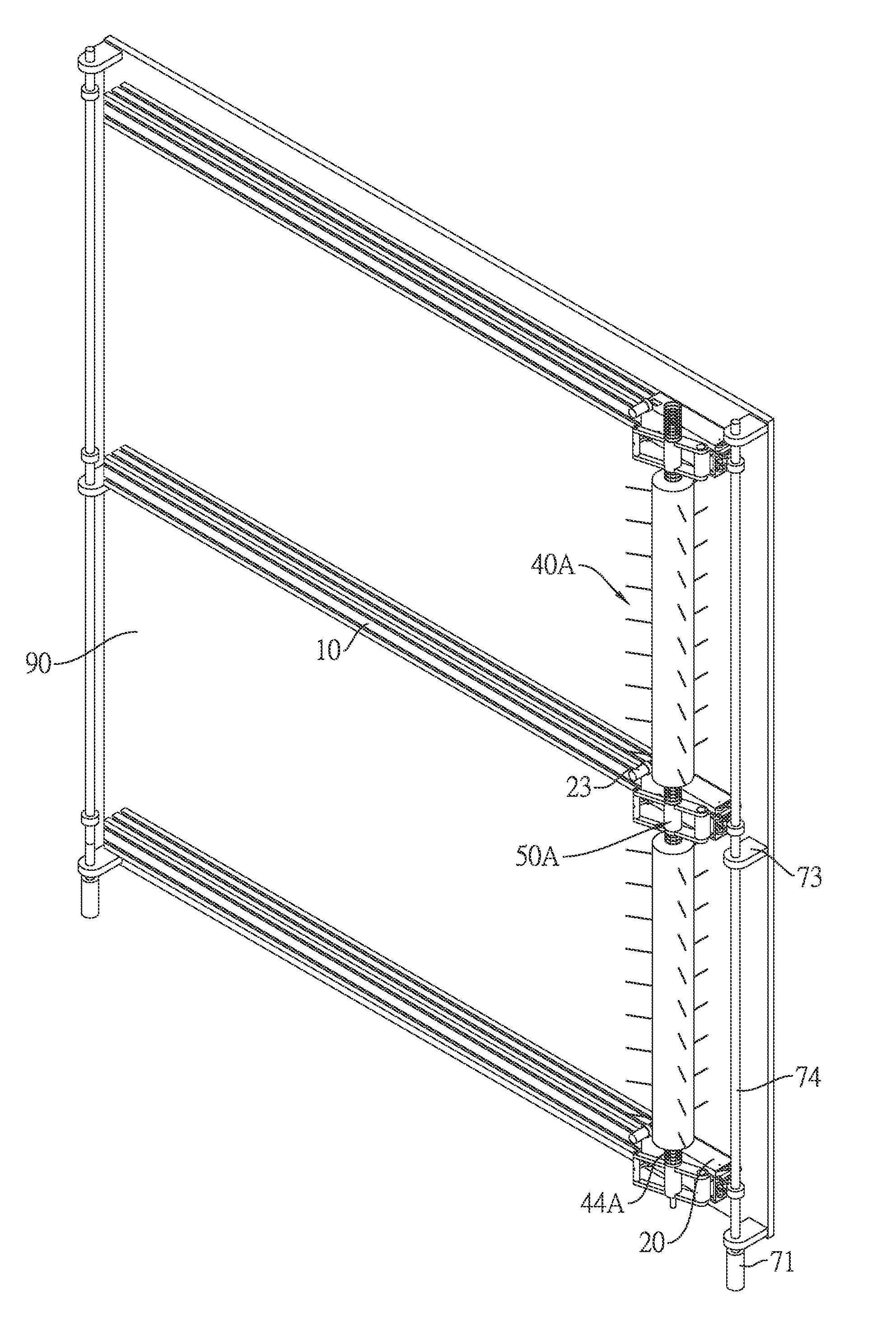

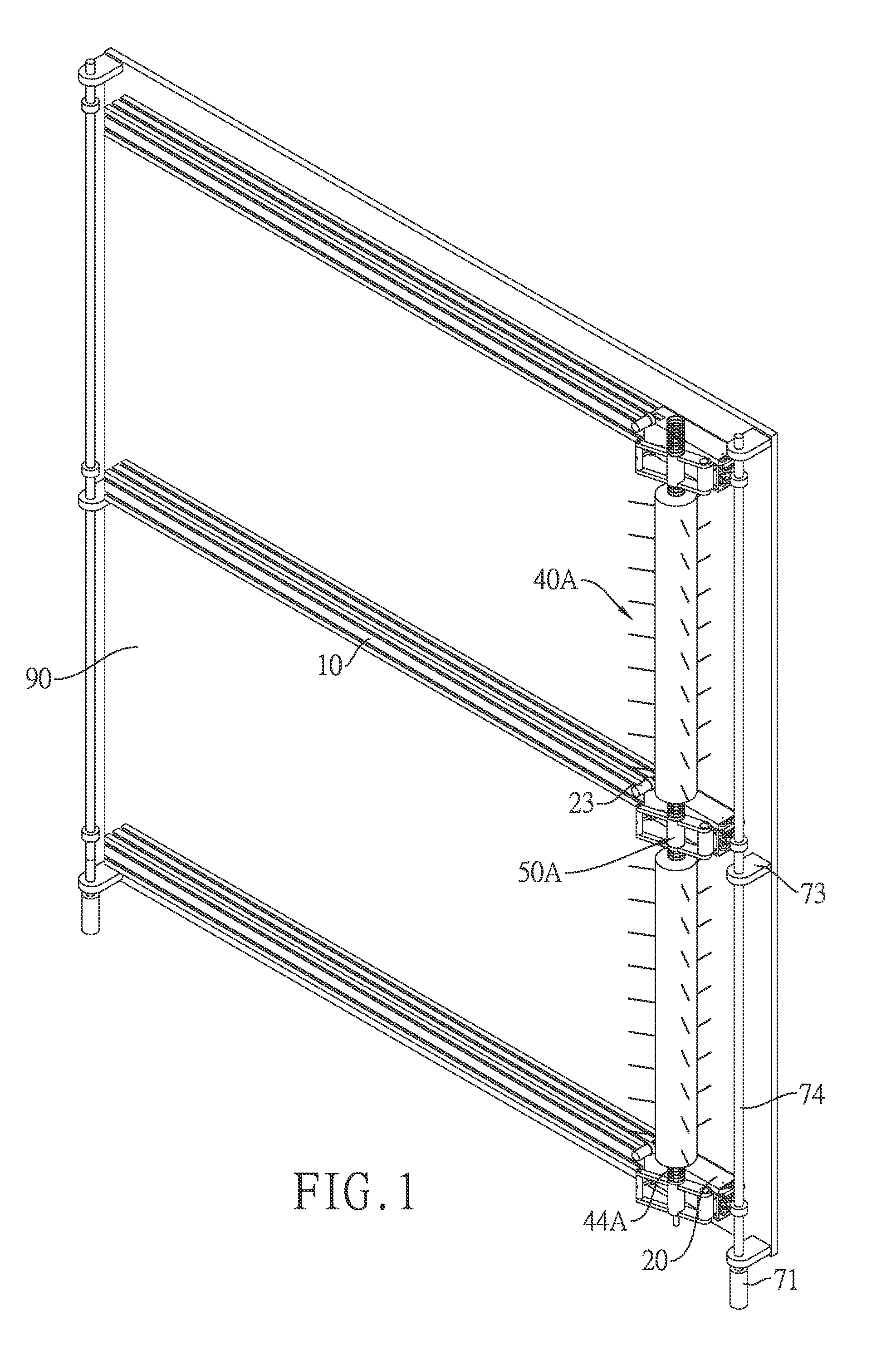

Automatic machine for cleaning wallboards

An automatic machine for cleaning wallboards, such as the wallboards of wall, glass or solar panels. Pluralities of long axial tracks are arranged parallel in an array. Water guide pipes and electric rails are formed on the long axial tracks. The walls of the water guide pipes are provided with a plurality of magnetic valves at intervals. Sliding engine bases are arranged on the long axial tracks. The sliding engine bases are provided with conduction frames corresponding to the electric rails and a long axial magnet body which can open and close cleaning water by magnetic force relative to the magnetic valves. At least two brush supporting bases are provided movably on the corresponding sliding engine bases to close to or leave away from the sliding engine bases by a power extending object. A long axial brush is provided between two nearby brush supporting bases of the sliding engine bases. The setting direction of the long axial brush is vertical to that of the long axial tracks. The long axial brush is driven by a shaking device to brush and wash the wallboards. Protective cover plates are arranged at the outer side of the long axial brush.

Owner:LIAO FU CHANG

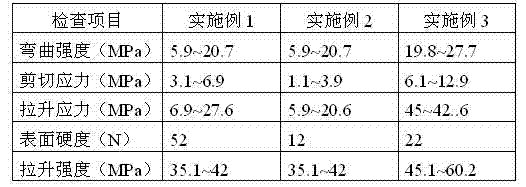

Method for producing paperboards and paper tubes

InactiveCN102248562AImprove adhesionHigh compressive and flexural strengthWood compressionGrain treatmentsFiberAnimal fiber

The invention relates to a method for producing paperboards and paper tubes, comprising the following steps of: (1) carrying out steam blasting and fluid energy milling on plant waste materials to obtain a raw material A; (2) carrying out the steam blasting on waste and old textiles and animal fibers to obtain a raw material B; (3) preparing a sodium silicate solution with the mass concentration of 12-15% to obtain a raw material C; (4) uniformly mixing the raw material A with the mass percent of 84-86%, the raw material B with the mass percent of 6-9%, the raw material C with the mass percent of 6-8% and thermosetting resin with the mass percent of 0-4%, putting the mixture into a paper pressing machine to prepare the paperboards and the paper tubes; and (5) carrying out air drying and curing on the obtained paperboards and paper tubes or curing by adopting a drying machine or a blast blower. The invention has the advantages that: process is simple, raw materials are available; manpower and energy are saved, production efficiency is improved, production cost is reduced; and the obtained paperboards and the paper tubes have good and stable quality, thus the method is applicable topopularization and application and is environment-friendly for papermaking.

Owner:强光初

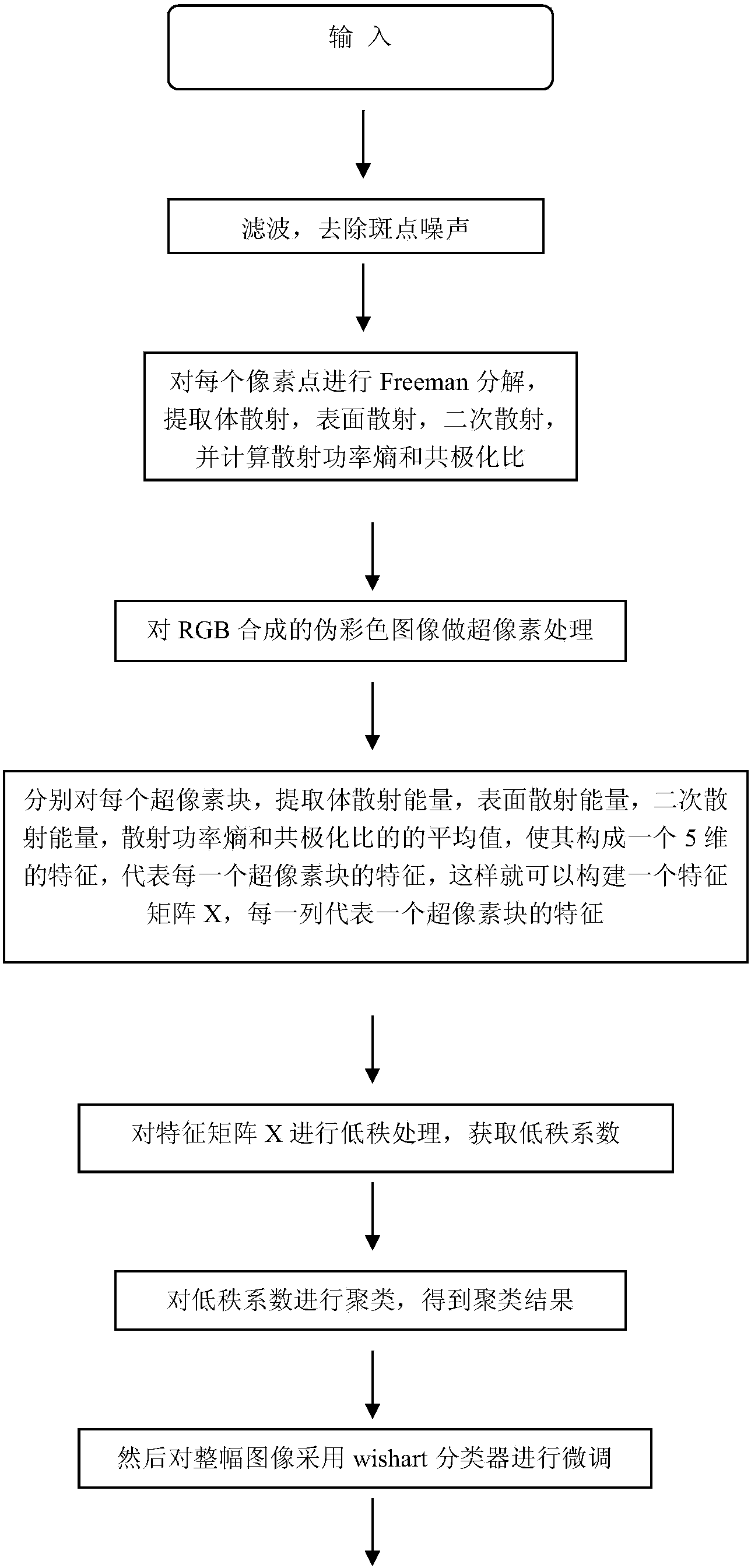

Low-rank-represented polarization SAR image classification method based on superpixel features

InactiveCN103839077AImprove classification accuracyOvercome the problem of boundary classificationCharacter and pattern recognitionDecompositionClassification methods

The invention discloses a low-rank-represented polarization SAR image classification method based on superpixel features. The method mainly improves the marginal classification accuracy of an existing classical algorithm and mainly comprises the steps that (1) Freeman decomposition is conducted on polarization SAR data, surface scattering energy, volume scattering energy and secondary scattering energy are obtained, and a scattering power entropy and a co-polarization ratio are calculated through the surface scattering energy, the volume scattering energy and the secondary scattering energy; (2) superpixel processing is conducted on an RGB composite graph, and a superpixel result graph is obtained; (3) the average value of five features is extracted from each superpixel, a feature matrix of all the superpixels is built, and each row represents the features of each superpixel; (4) low-rank representation is conducted on the feature matrix, and low-rank coefficients are obtained and clustered; (5) wishart adjustment is conducted on the clustered result, and coloring is conducted finally. Compared with other classical methods, the low-rank-represented polarization SAR image classification method based on the superpixel features can better improve classification accuracy and can be used for polarization SAR image classification.

Owner:XIDIAN UNIV

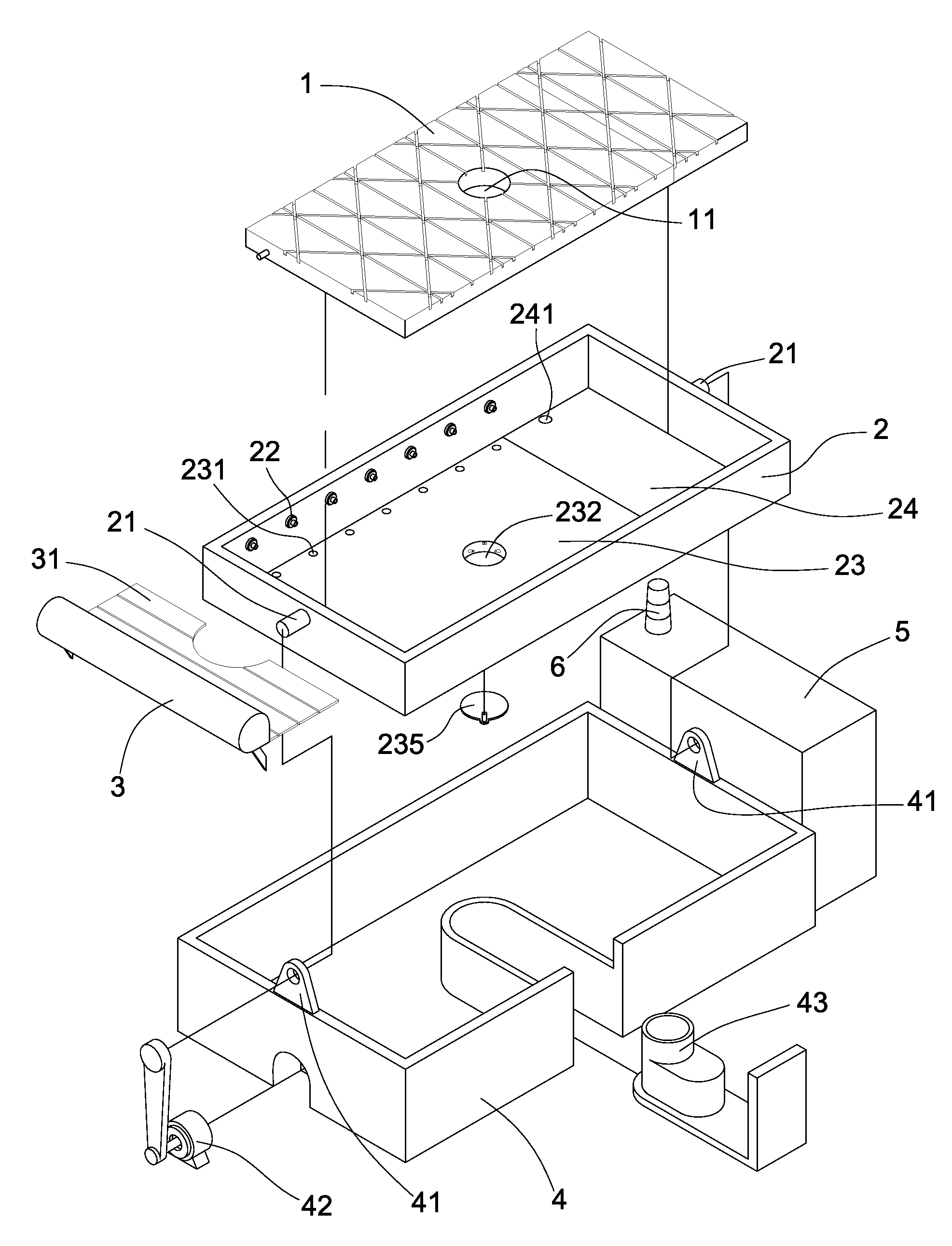

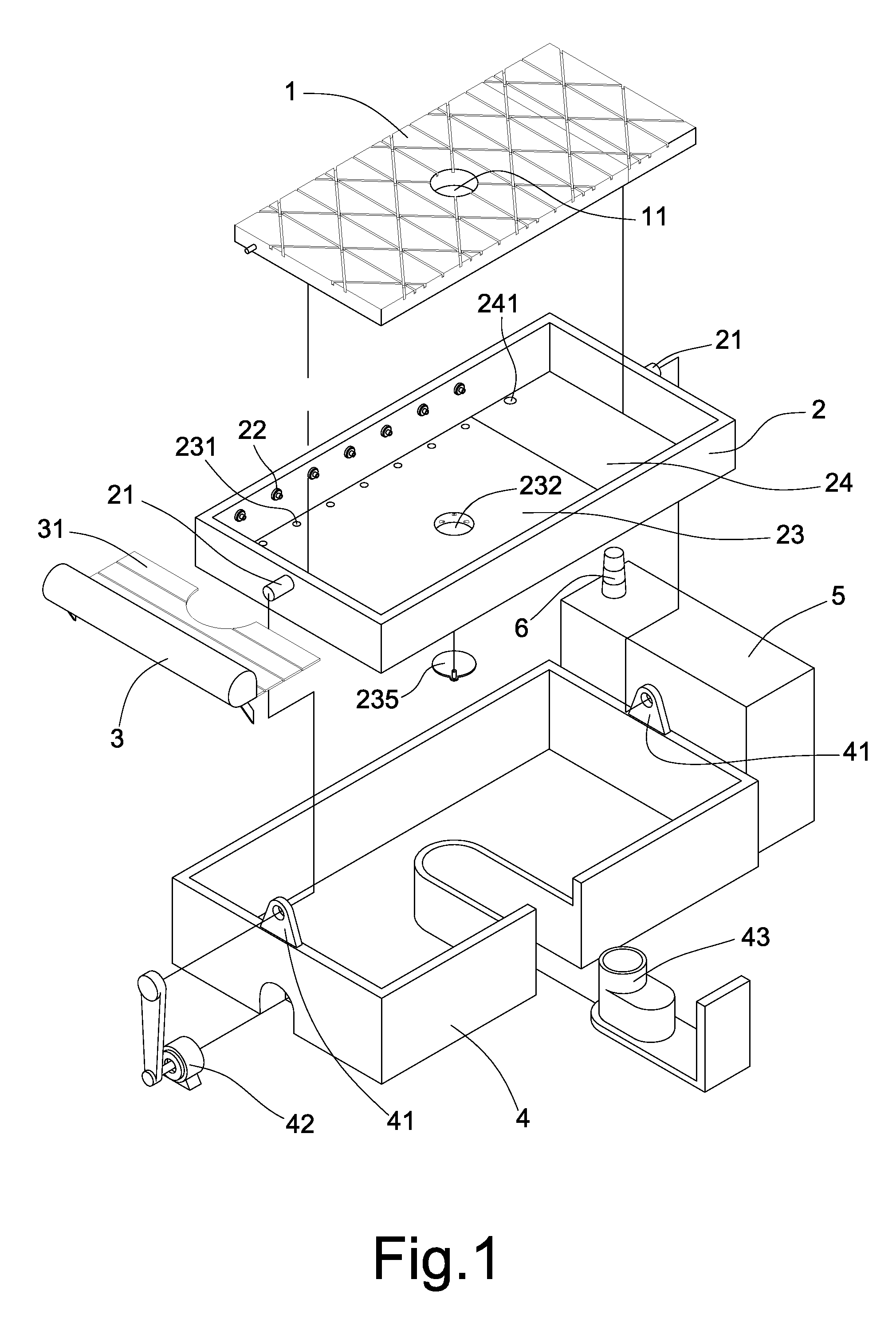

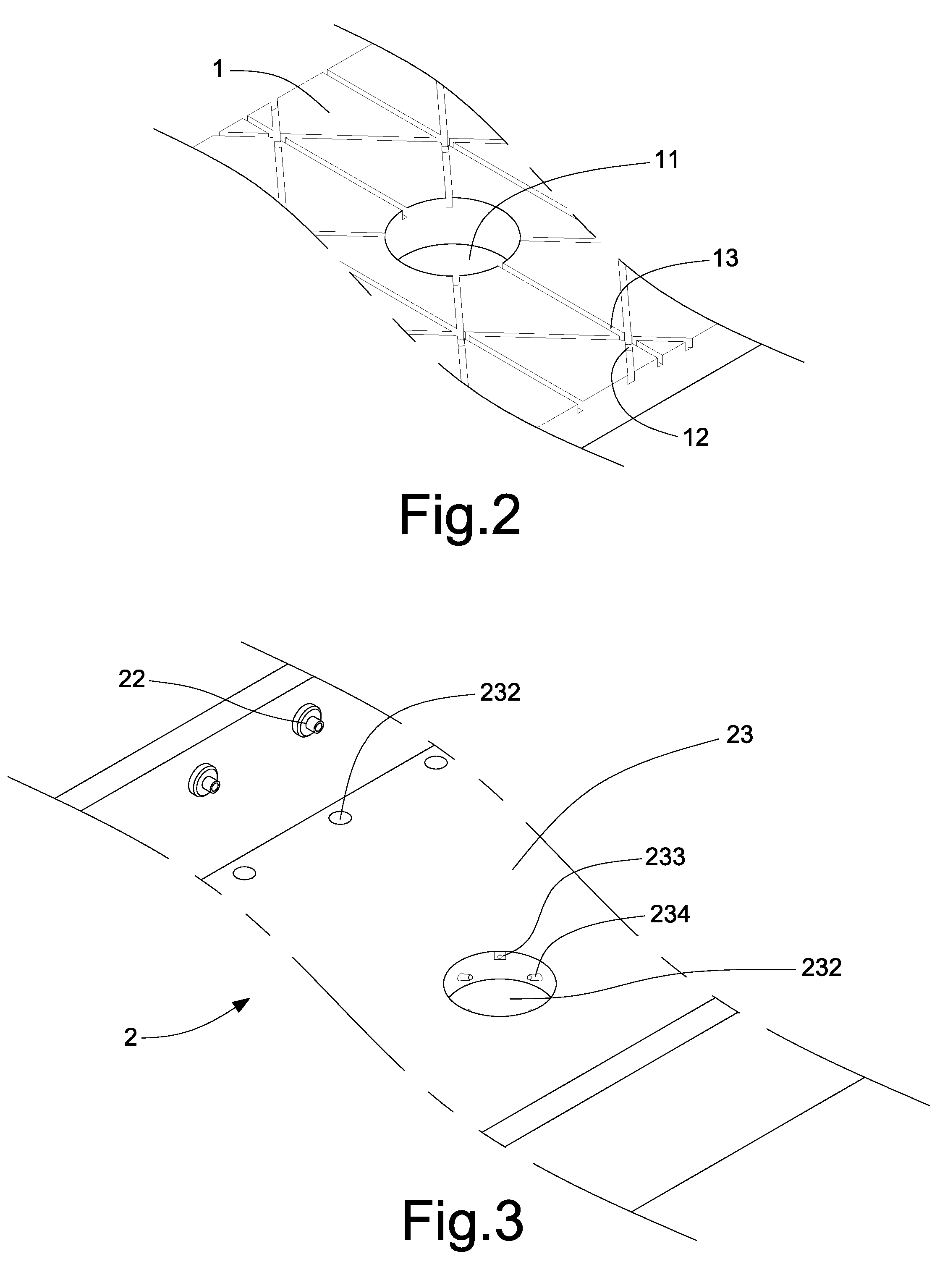

Medical Bed Structure

A medical bed structure includes a bed frame. The bed frame is provided with a plurality of spray nozzles on its edge. The bottom of the bed frame is formed with a discharge hole and a cleaning set on the discharge hole. The spray nozzles are capable of spraying water for cleaning. The discharge hole is adapted to discharge feces. The cleaning set is adapted to clean the anus of the patient after having a bowel movement. The present invention provides a patient who lies in bed for a long period of time to take a bath and to clean the feces automatically.

Owner:CHANG WEN LUNG

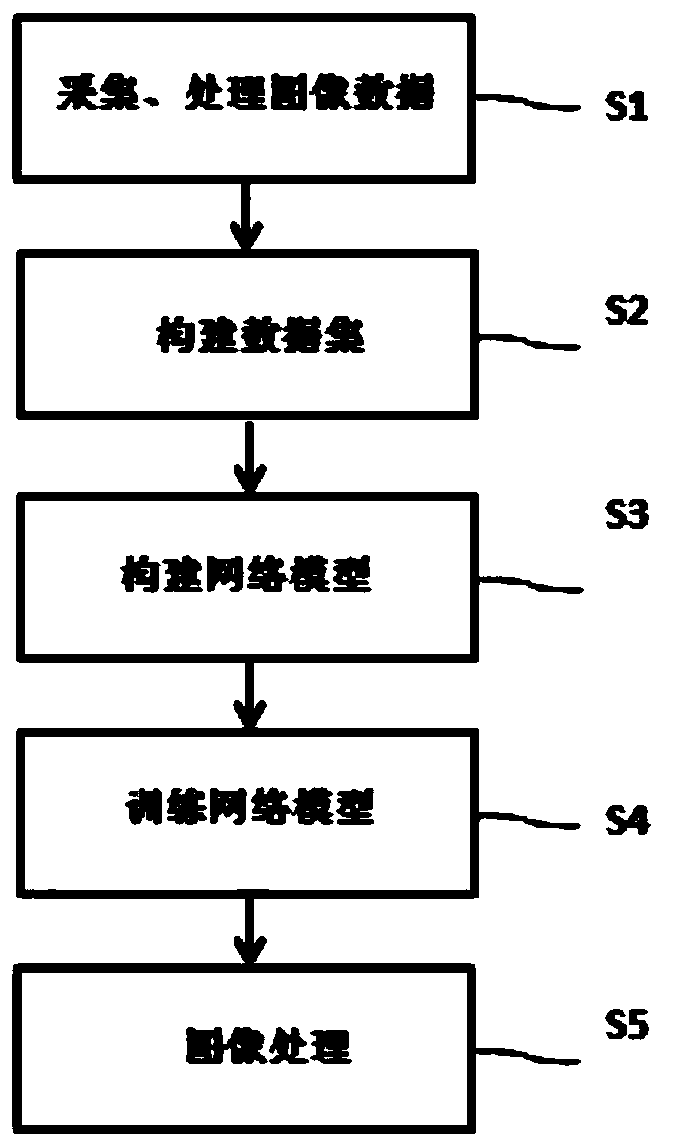

Image processing method and device based on deep learning and electronic device

ActiveCN110533607AQuality improvementLow costImage enhancementImage analysisWavefrontImaging processing

The invention discloses an image processing method and device based on deep learning, and an electronic device. The image processing method comprises the steps of collecting first image data; generating second image data according to the first image data; constructing a data set by using the first image data and the second image data; constructing a forward-reverse convolutional neural network model; training the forward-inverse convolutional neural network model by using the data set; and carrying out image processing by using the trained forward-inverse convolutional neural network model. According to the invention, correction of various errors occurring when a wavefront coded image is decoded by using a traditional method is realized, a clear image with defocus blur removed is finally obtained, super-large depth-of-field imaging is realized, a high-quality image is obtained, the speed is faster, the process is simpler, manpower is saved, and the image processing cost is effectivelyreduced.

Owner:北京威睛光学技术有限公司

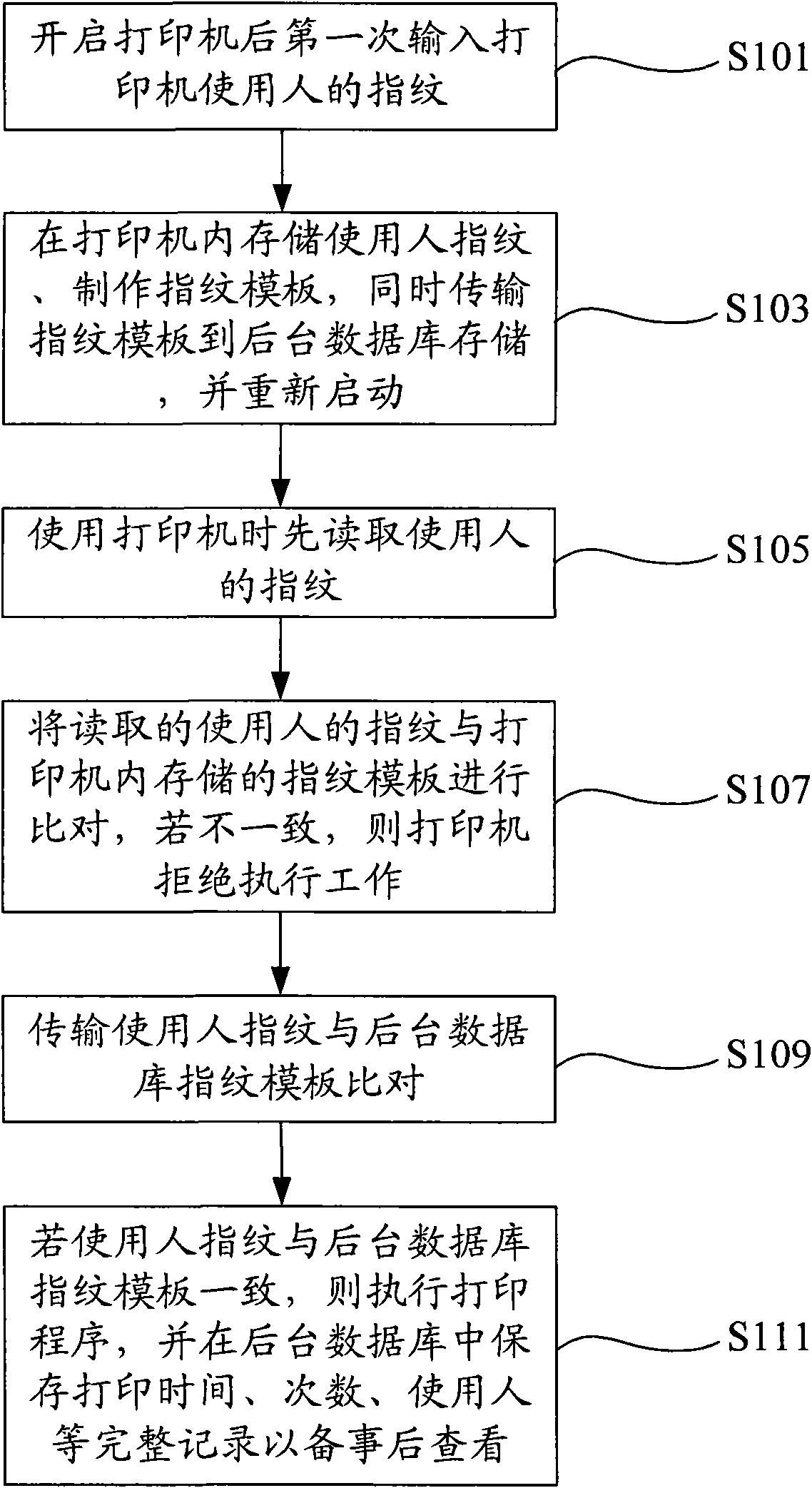

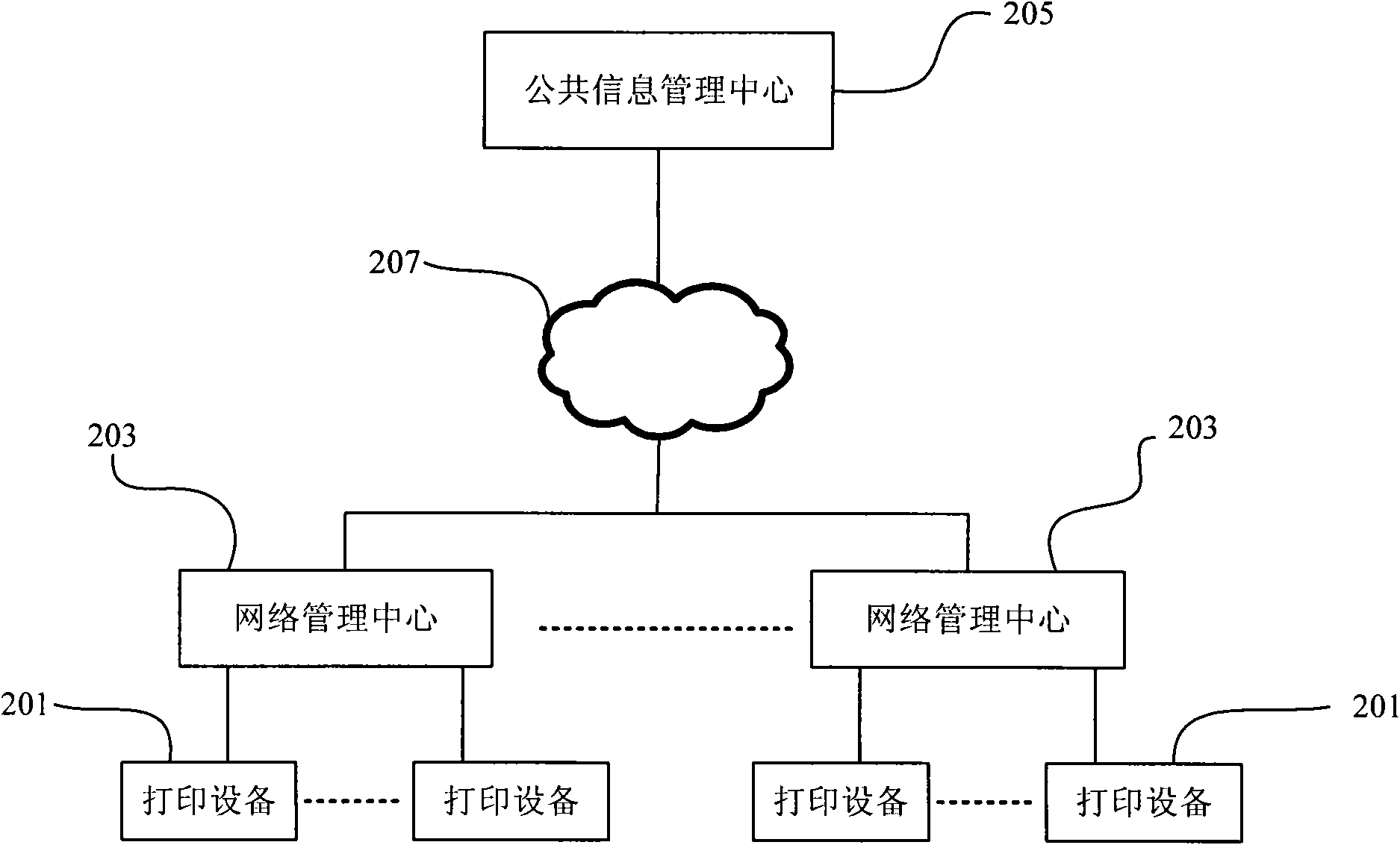

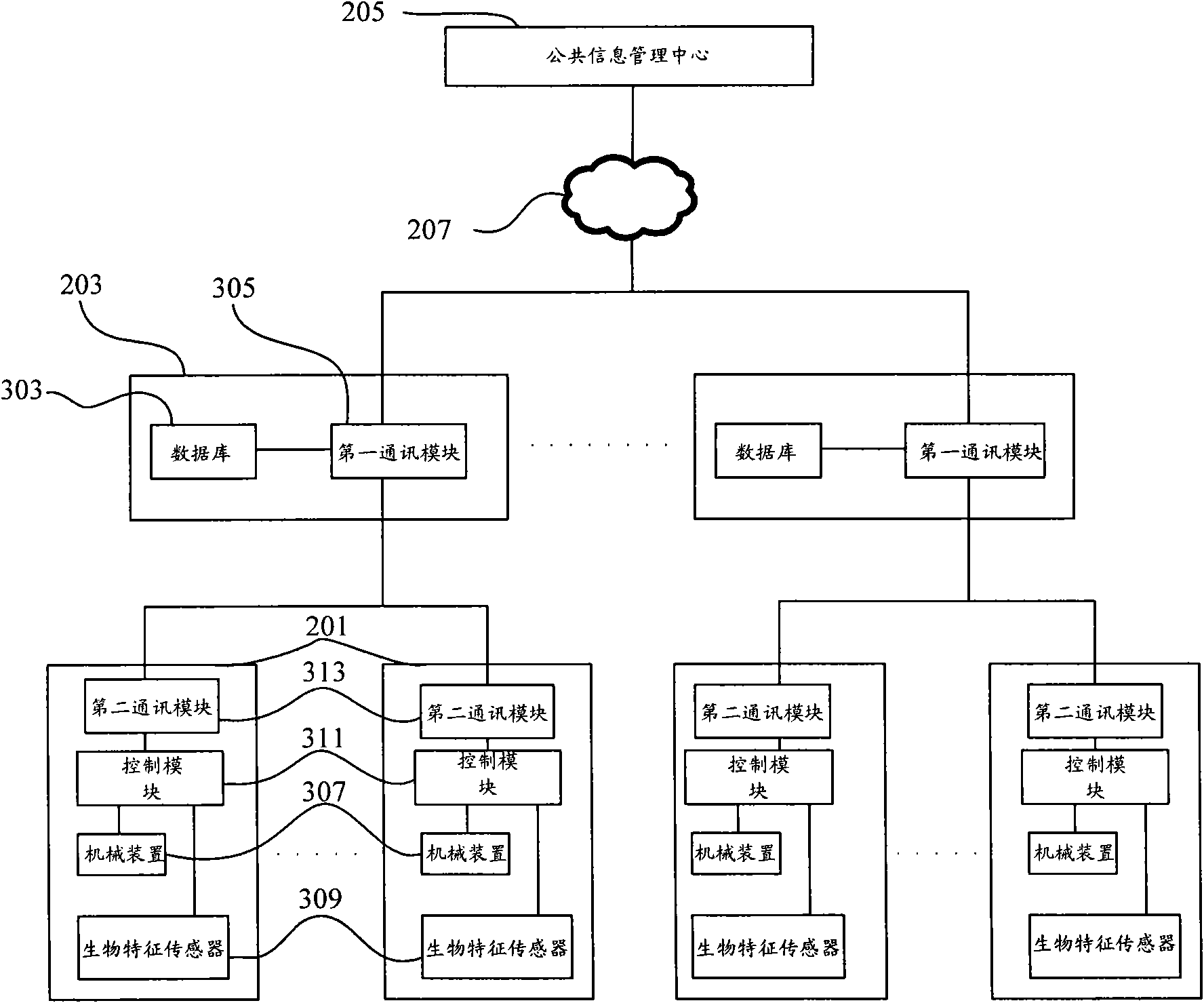

System and method for self-help printing by using biological identification technology and printing device

ActiveCN101576809AImprove work efficiencySave manpowerCharacter and pattern recognitionDigital output to print unitsNetwork managementEngineering

The invention provides a system and a method for self-help printing by using a biological identification technology and a printing device. The system for self-help printing by using the biological identification technology comprises at least one printing device, at least one network management centre and a public information management centre, wherein the printing device is connected to the network management centre; and the public information management centre is connected to the network management centre through a network. Due to the adoption of the invention, users can print files in administrative offices more safely, efficiently and conveniently.

Owner:ZHEJIANG MIAXIS TECH CO LTD

Garbage can

InactiveCN104261026ASave manpowerSave manpower and material resourcesRefuse receptaclesPublic placeSoftware engineering

The invention provides a garbage bin. According to the technical field, the garbage bin provided with a balancing device comprises a garbage bin body, an throwing port, the balancing device and a fixing rod. The garbage bin is characterized in that the balancing device is mounted below the throwing port; the balancing device comprises a baffle, a supporting rod, a bearing and a round ball; the baffle and the round ball are connected through the supporting rod; and the balancing rod is mounted on the fixing rod through the bearing. According to eh garbage bin, the balancing device provided with the baffle (a cover of the garbage bin body) and the round ball by the leverage, gravity effect of garbages is utilized to allow the garbages to fall into the garbage bin automatically, labor force and material are saved, and the garbage bin is adaptable for houses, offices and public spaces.

Owner:钟橙

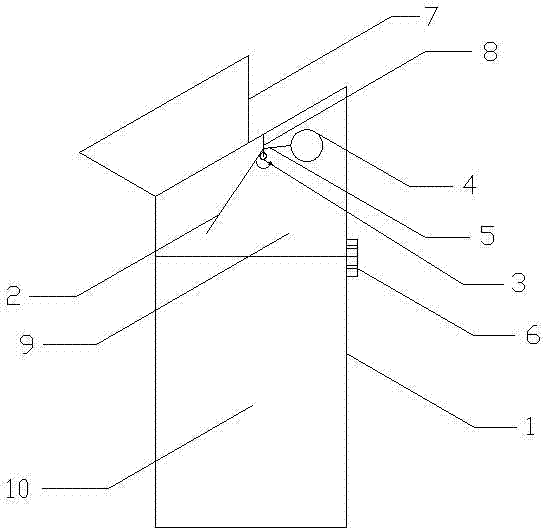

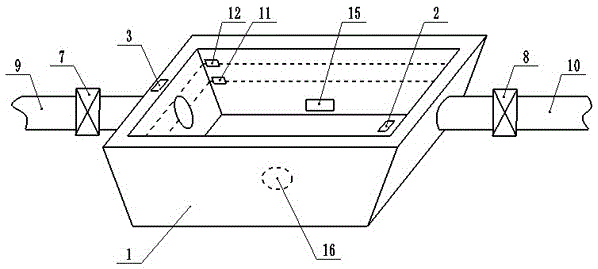

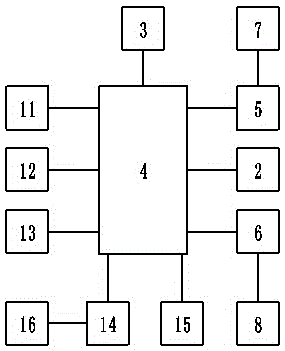

Water supply system for animal husbandry

ActiveCN104170765BImprove farming efficiencySimple structureAnimal watering devicesComputer moduleEngineering

The invention relates to a water supply system for livestock farming, and solves the technical problem that the water supply system for the livestock farming can automatically supply constant temperature water without manual operation; the adopted technical scheme lies in that the water supply system for the livestock farming comprises a water tank, a water temperature sensor, an infrared sensor, a control circuit board, a first relay module, a second relay module, a first electromagnetic valve and a second electromagnetic valve, wherein the water temperature sensor is arranged at the bottom of the water tank; the infrared sensor is arranged on the edge at the top of the water tank; the first electromagnetic valve is arranged on a cold water pipeline communicated with the water tank; the second electromagnetic valve is arranged on a hot water pipeline communicated with the water tank; the control circuit board is connected with the water temperature sensor, the infrared sensor, the first relay module and the second relay module respectively; the first relay module and the second relay module are connected with the first electromagnetic valve and the second electromagnetic valve respectively. The water supply system is applicable to the field of livestock farming.

Owner:ZHEJIANG HUATENG ANIMAL HUSBANDRY LIMITED

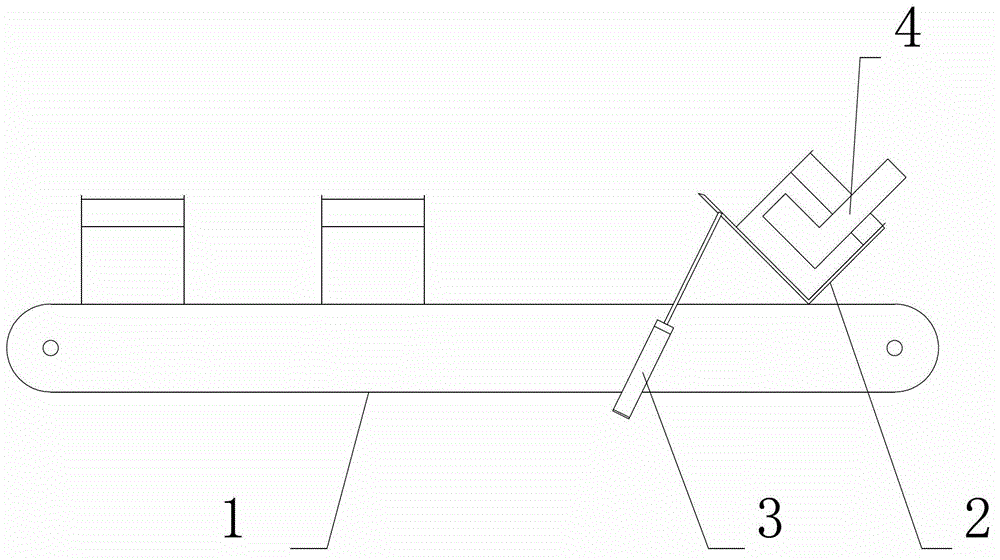

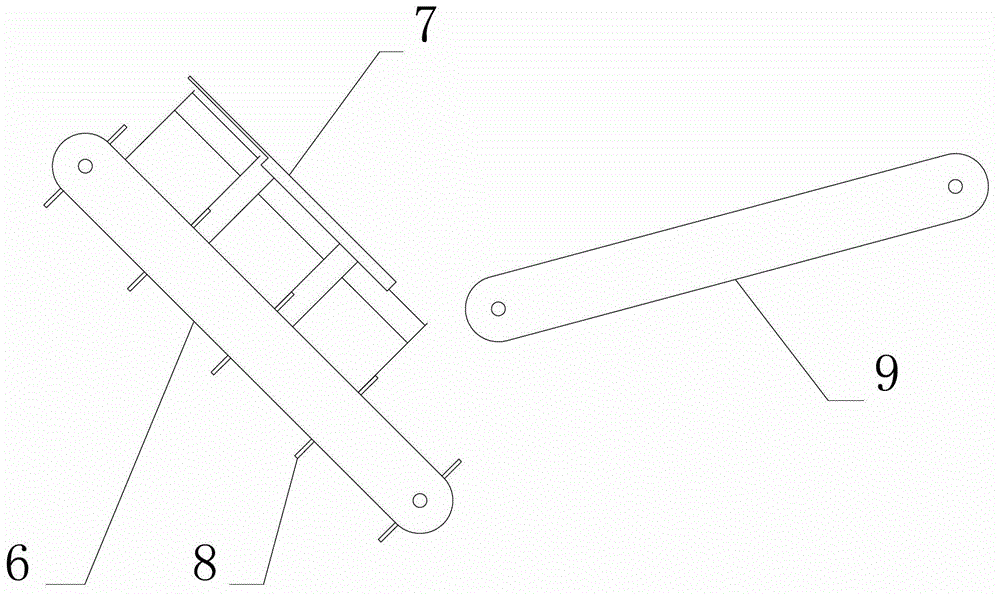

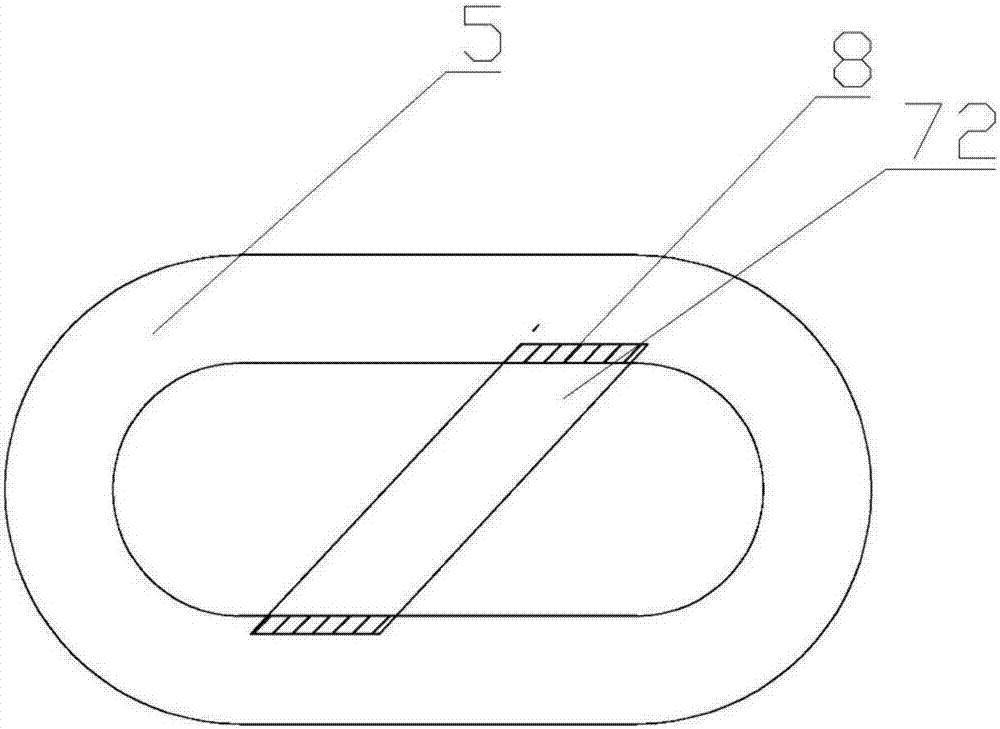

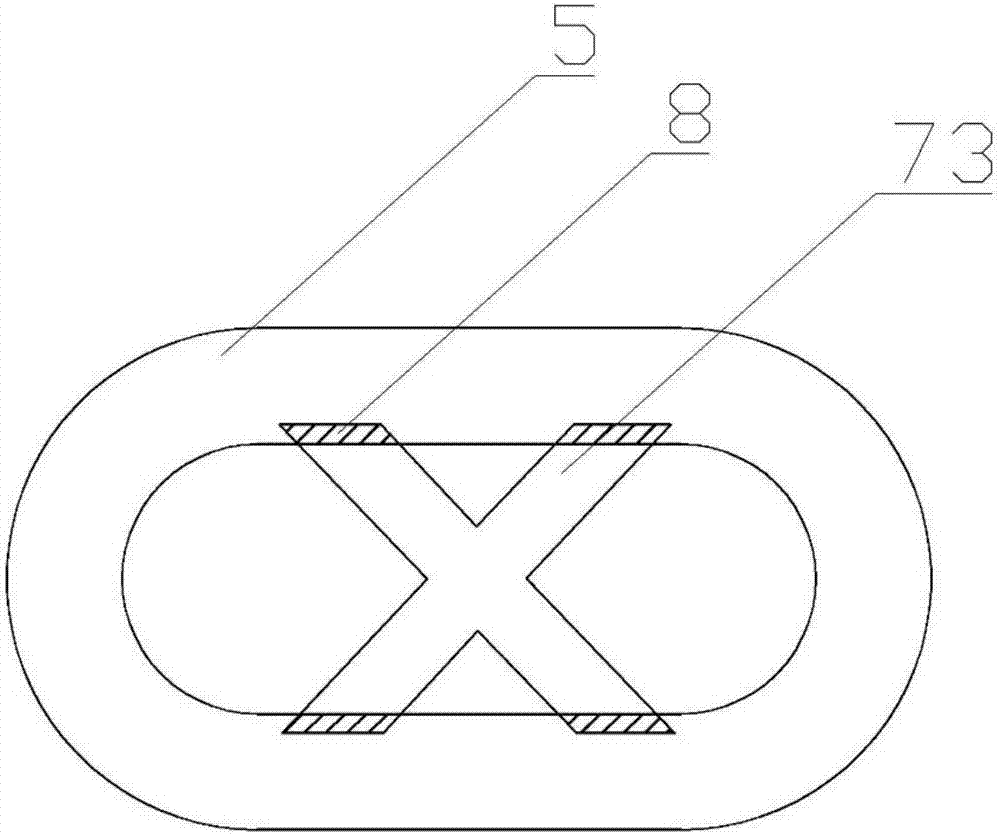

Boxing machine and boxing method

ActiveCN103332314AStrong connectionIncrease production capacityIndividual articlesCartoning machineEngineering

The invention discloses a boxing machine and a boxing method. The boxing machine at least comprises a box inlet mechanism, an overturning mechanism, a box lifting mechanism, a bag inlet mechanism, a box outlet mechanism and a frame, wherein during working, a packing box coming from the box inlet mechanism is firstly placed on the box lifting mechanism, and is kept in an oblique state; the bag inlet mechanism is used for feeding sterile soft bags which are in vertical states relative to the bottom of the packing box into the packing box at a fixed feeding position; after the sterile soft bags enter the packing box and are stable in state, the packing box moves downwards for a certain distance along an oblique direction along with the box lifting mechanism, stops, and continues to be fed with sterile soft bags which are in vertical states relative to the bottom of the packing box; the boxing process is repeated till the packing box is filled fully; and after boxing, the packing box is output through the box outlet mechanism. Due to the adoption of the boxing machine and the boxing method, the aim of providing boxing operation for sterile soft bags is fulfilled by using automatic equipment, labor force cost is reduced, and the production efficiency is increased.

Owner:HANGZHOU ZHONGYA MACHINERY CO LTD

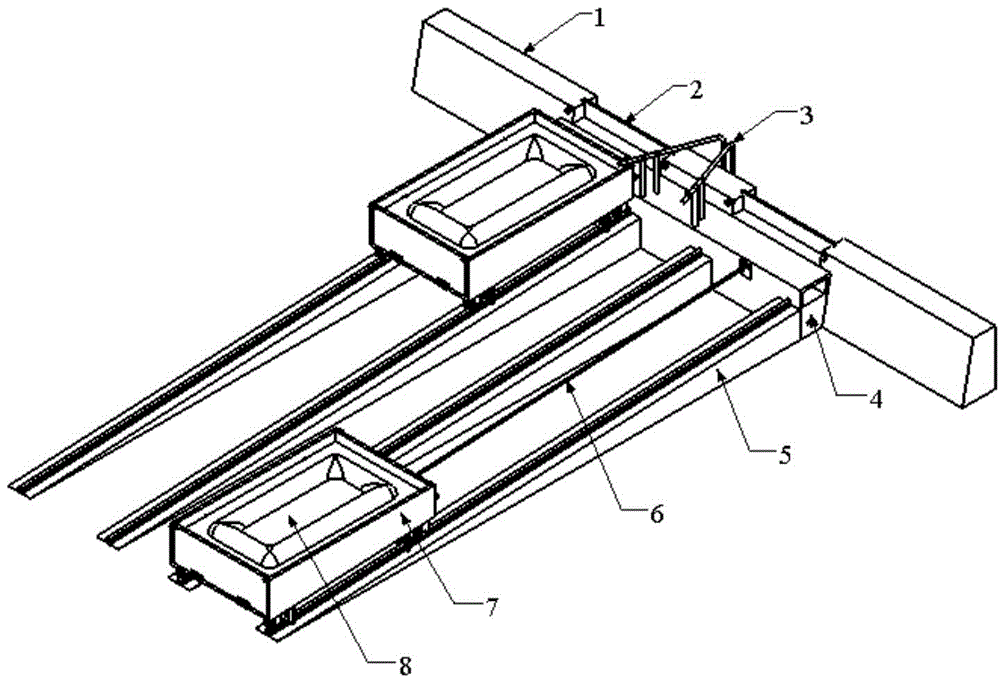

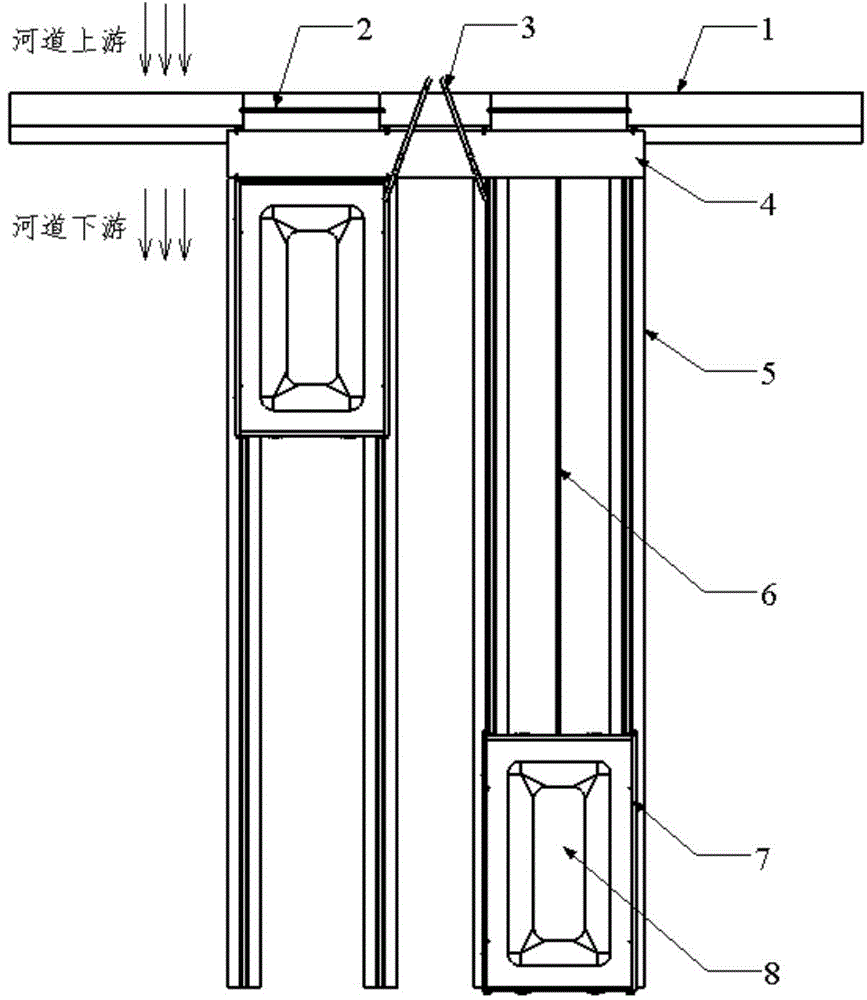

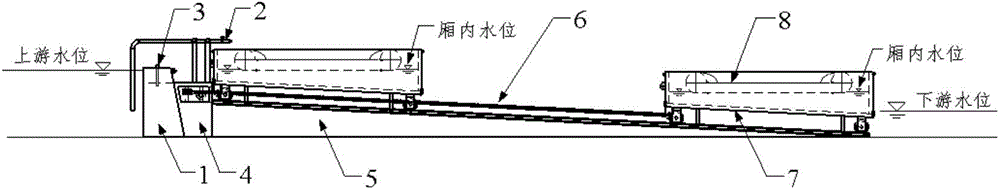

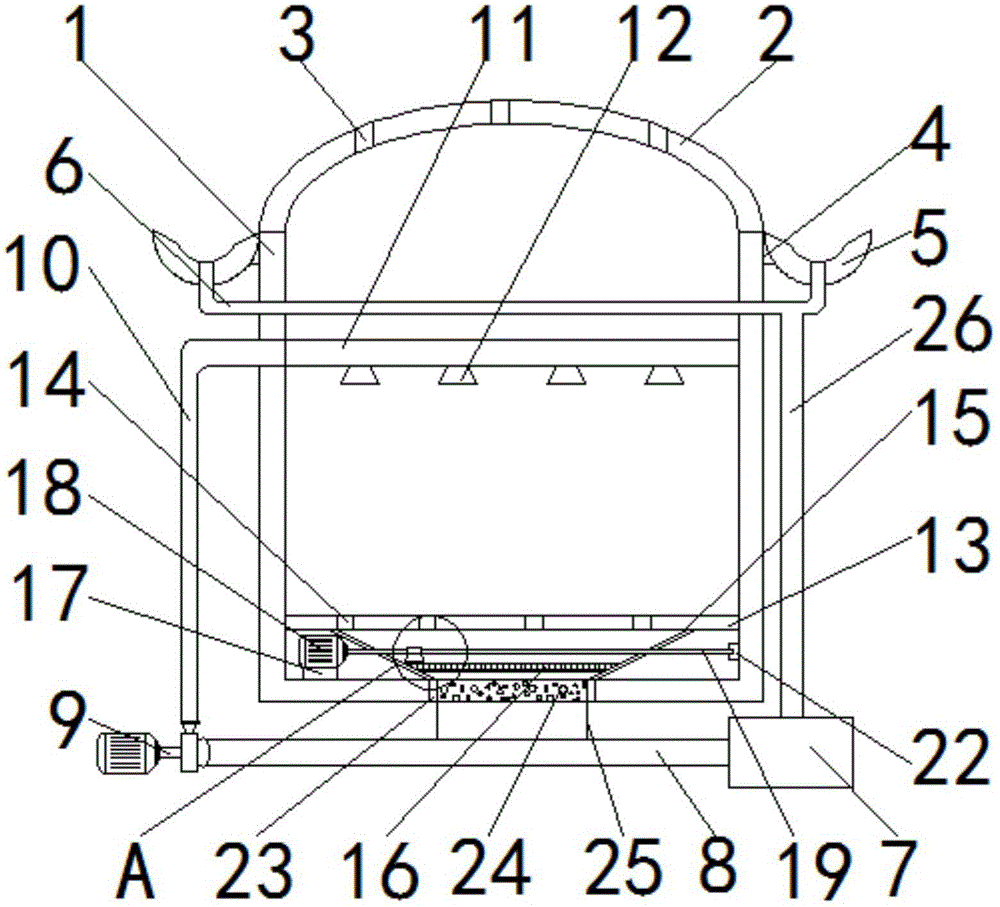

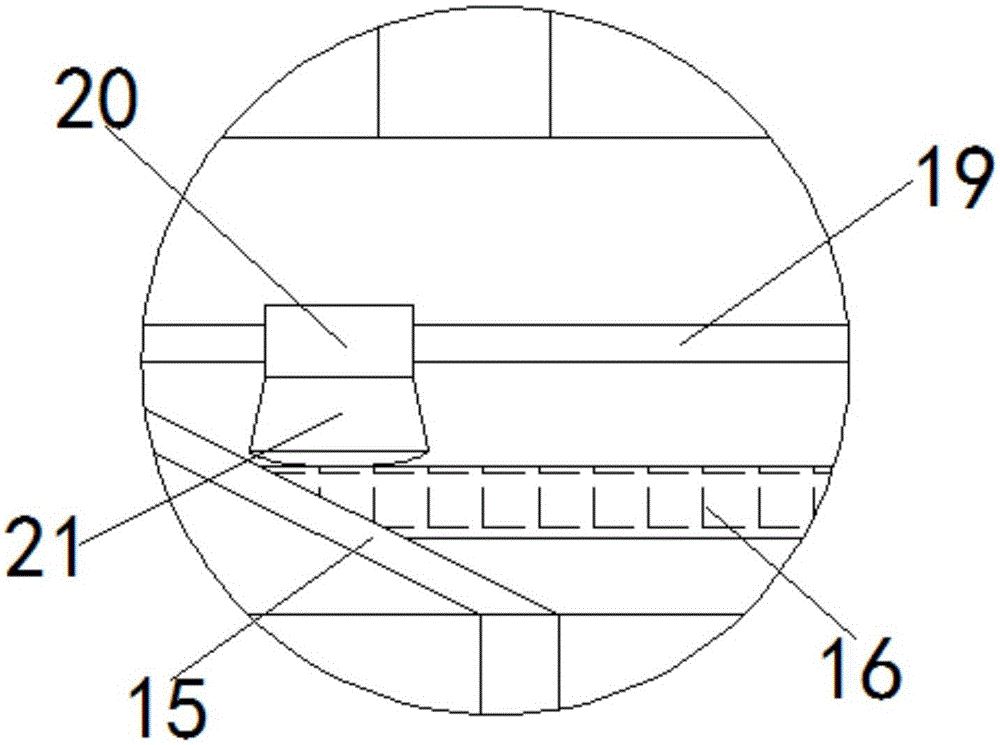

Two-way inclined ship lift

ActiveCN104404938AEasy and Safe CrossingMeet the needs of crossing the damInclined ship-liftingReinforced concreteMarine engineering

A two-way inclined ship lift comprises a retaining dam and track sections having certain gradients relative to upstream and downstream water levels of the retaining dam, wherein the track sections and a dam body are connected through a connecting section adopting a reinforced concrete structure, ship chambers are arranged at the track sections, positioning holes are formed in the ship chambers, ships can be connected with chamber bodies through ropes, an upstream side chamber door and a downstream side chamber door which can be opened outwards are arranged at upstream and downstream ends of each ship chamber respectively, limiting pulleys are mounted at bottoms of the ship chambers, limiting pull rings are arranged on upstream sides of the ship chambers, the ship chambers can be connected with the dam body through safety ropes, a cavity is formed in the connecting section, a guide pulley block is mounted in the cavity and matched with the ship chambers through a wire rope penetrating through a reserved hole of the connecting section, and ascending and descending of the ship chambers are realized. The two-way inclined ship lift has the effects that the inclined ship lift is based on a small low-flow river channel, the dam passing requirement of small ships such as small boats, bamboo rafts, drift ships and the like can be met, the project investment is effectively reduced, manpower and electric power are saved, and the dam passing efficiency of the ships is improved.

Owner:THE FRONTIER TECH RES INST OF TIANJIN UNIV

Vegetable planting greenhouse recycling residual water

InactiveCN107432217ASimple structureEasy to useGeneral water supply conservationIndustrial water supply conservationWater storageGreenhouse

The invention relates to the technical field of greenhouses, and discloses a vegetable planting greenhouse recycling residual water. The greenhouse comprises a greenhouse body, the top of the greenhouse body is fixedly connected with a covering membrane, the top of the covering membrane is provided with through holes, the left side and the right side of the greenhouse body are separately connected with a fixing block, one end of each fixing block far away from the greenhouse body is fixedly connected with a bearing body, the tops of the two bearing bodies are fixedly connected with each other through a collecting pipe, the bearing bodies communicate with the collecting pipe, the collecting pipe runs through the greenhouse body and extends to the exterior of the greenhouse body, a position, located at the right side of the greenhouse body, at the bottom of the collecting pipe is fixedly connected with a first connection pipe which communicates with the collecting pipe, and one end of the first connection pipe far away from the collecting pipe is fixedly connected with a water storage box. The vegetable planting greenhouse recycling the residual water is simple in structure and convenient for usage, and can collect and recycle rainwater and residual water of irrigation in a maximized manner, thus water resources and manpower labor are greatly saved, and the vegetable planting greenhouse is more convenient for usage.

Owner:百色闻远网络科技有限公司

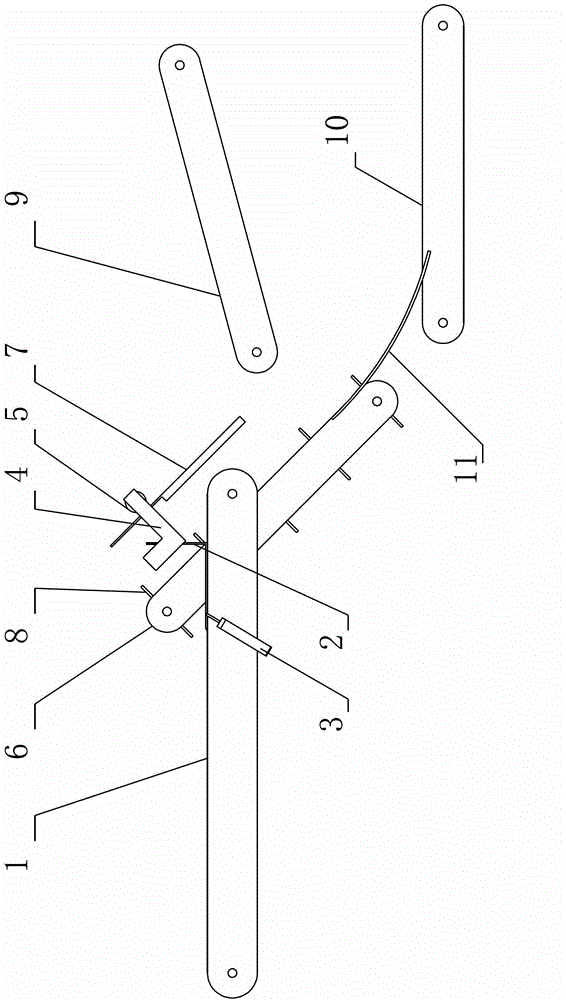

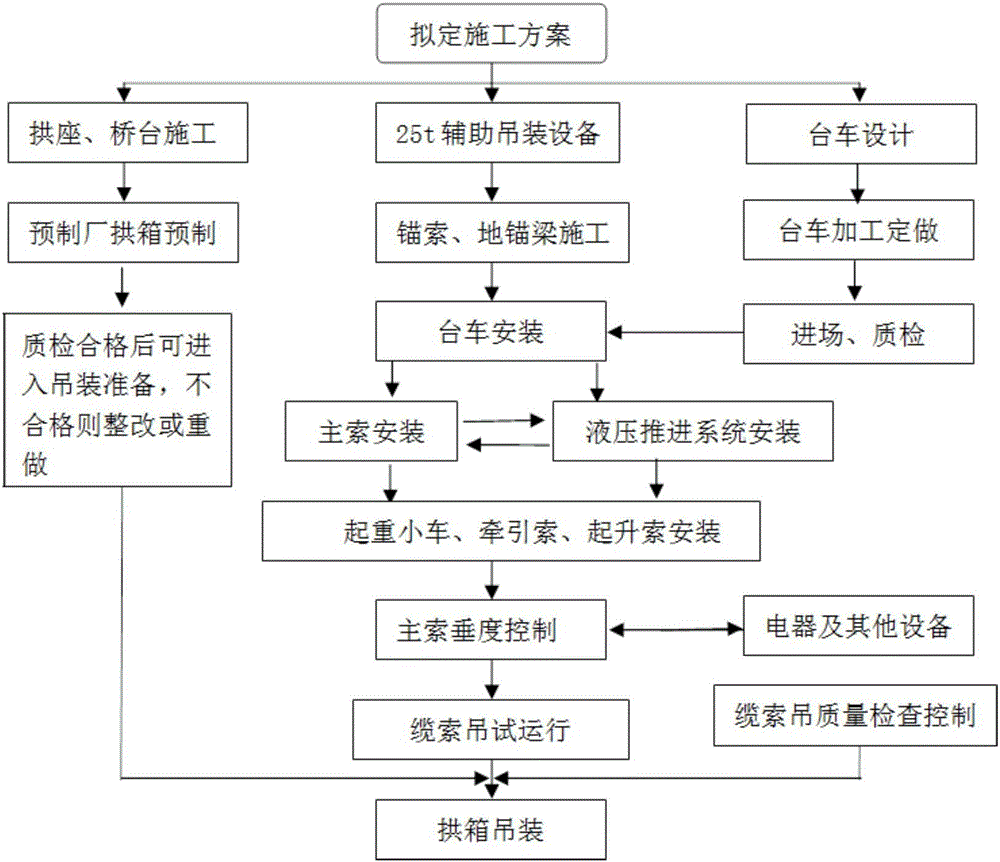

Hoisting method for top push climbing and moving type cable hoisting arch bridge

InactiveCN106284083AQuick lifting and transportationAccurate in placeBridge erection/assemblyArch-type bridgeTerrainEngineering

The invention discloses a hoisting method for a top push climbing and moving type cable hoisting system arch bridge, and aims to provide a hoisting method for the top push climbing and moving type cable hoisting system arch bridge which is high in construction speed. The hoisting method comprises the following steps of (1) drawing up a construction scheme; (2) mounting auxiliary hoisting equipment; (3) constructing an anchor cable and a ground anchorage beam; (4) mounting a handcar; (5) mounting a main cable; (6) mounting a hydraulic propelling system; (7) mounting a jacking-up trolley, a traction cable and a lifting cable; (8) controlling the sagging of the main cable; (9) commissioning a cable hoisting system; (10) hoisting arch boxes; (11) hoisting vertical columns; and (12) hoisting and casting a T beam and a bridge surface system. The hoisting method disclosed by the invention is suitable for erection of prefabricated arch bridge at a river of which two river banks are high, or a canyon of which two banks are steep, namely a deep V-shaped bridge site, and can be used for assembling other prefabricated bridges.

Owner:云南云岭桥隧科技有限公司 +1

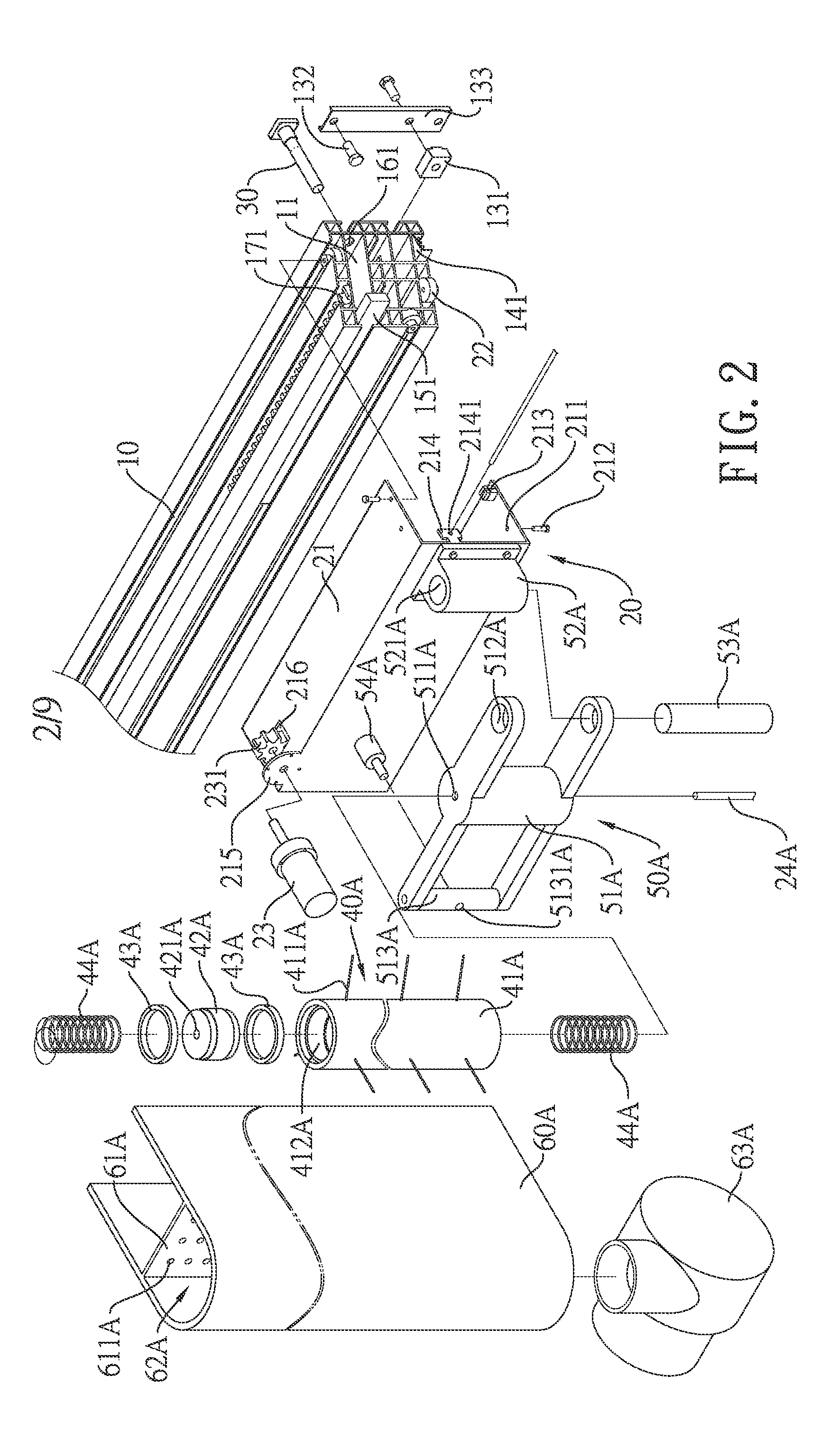

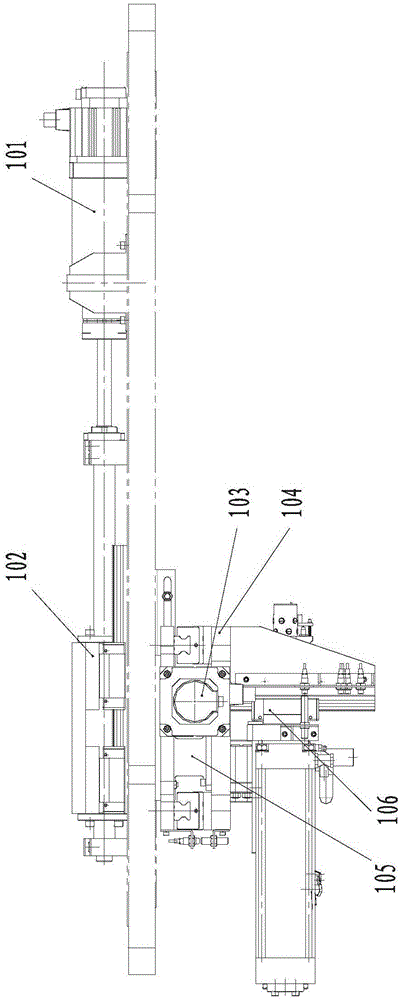

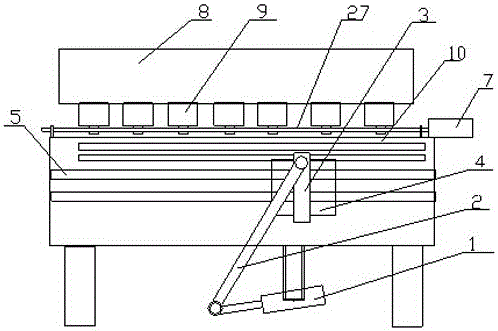

Integrated three-axis linked compound automatic pressing machine for adapter tubes

ActiveCN105583604ASolve mechanical effectsSolve take timeMetal working apparatusEngineeringPositioning system

The invention belongs to the technical field of automobile engine manufacturing, and particularly relates to an integrated three-axis linked compound automatic pressing machine for adapter tubes. The integrated three-axis linked compound automatic pressing machine comprises a machine body, and a horizontal positioning system and a vertical positioning system arranged on the machine body. The horizontal positioning system comprises an integrated three-axis positioning structure and a reverse thrust executing structure arranged on two sides of the machine body respectively. A pressing executing structure, corresponding to the reverse thrust executing structure, is arranged on the integrated three-axis positioning structure. The vertical positioning system comprises an upper limiting structure and a line body lifting structure, which are arranged at the top and bottom of the machine body respectively and correspond to each other. A workpiece to be pressed is placed on the line body lifting structure, and is lifted up by the line body lifting structure to be in contact with the upper limiting structure. The workpiece to be pressed is horizontally positioned by the integrated three-axis lined positioning structure and the reverse thrust executing structure. The integrated three-axis linked compound automatic pressing machine, provided by the invention, is a complete machine of which an integrated X, Y and Z space coordinates positioning device and a pressing mechanism work synchronously, is applicable to two straight adapter tubes and two special-shaped adapter tubes, and can complete compound pressing quickly and effectively.

Owner:中国科学院沈阳计算技术研究所有限公司

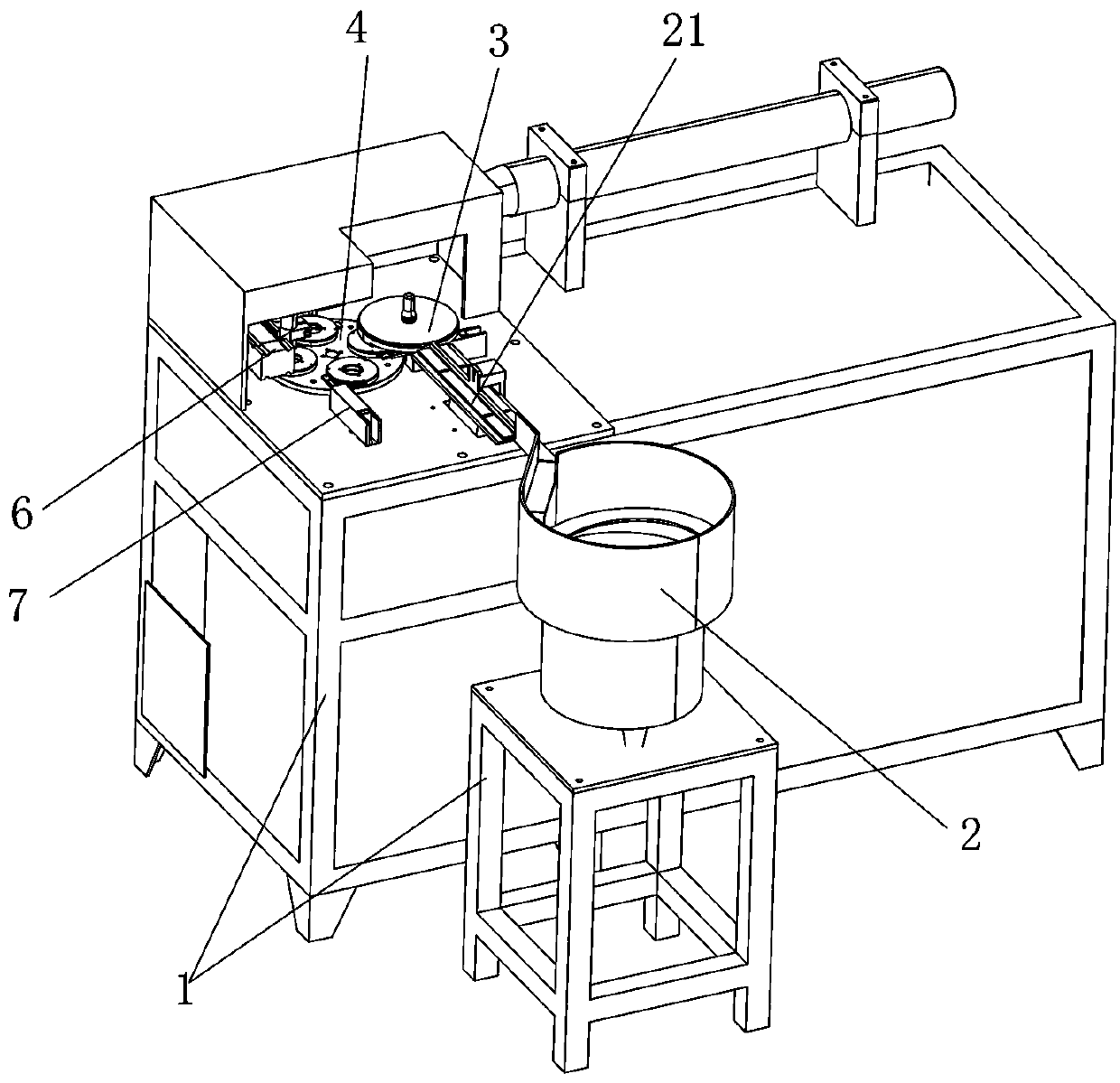

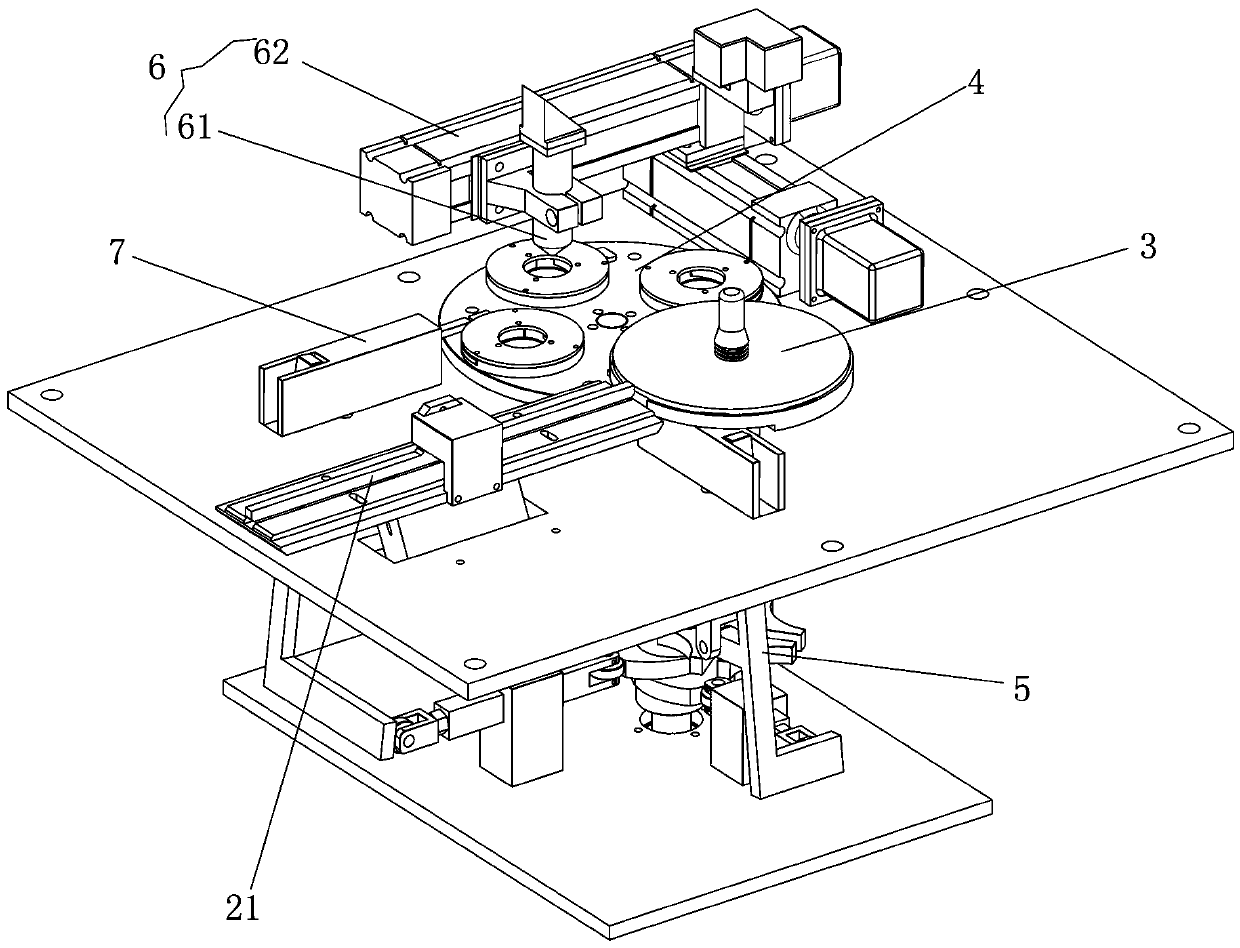

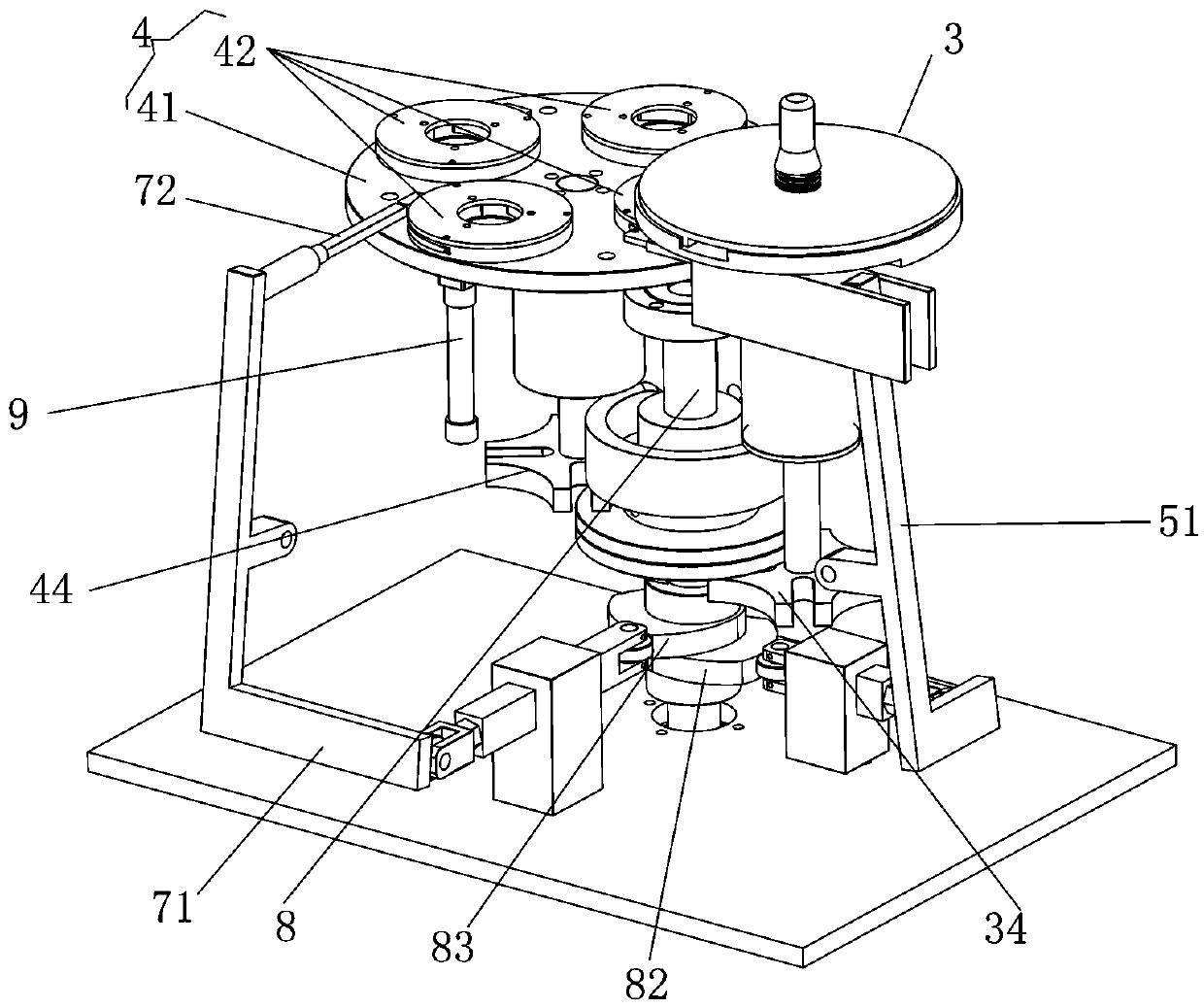

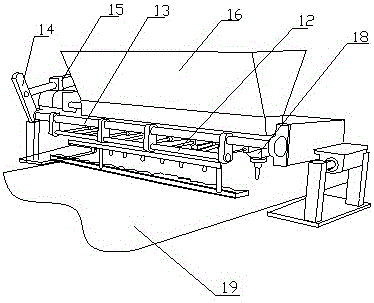

Round resin button laser cutting machine

ActiveCN108031989AReduce labor intensityIncrease productivityLaser beam welding apparatusLaser cuttingEngineering

The invention discloses a round resin button laser cutting machine, and relates to the technical field of round resin button machining equipment. The round resin button laser cutting machine solves the problem that when pattern cutting is carried out on the round resin button surface, the manual placing efficiency is low. The round resin button laser cutting machine comprises a rack provided witha vibrating disc discharging mechanism, a feeding mechanism, a rotating table mechanism, a feeding and clamp opening mechanism, a laser cutting mechanism and a stripping and clamp opening mechanism; the feeding mechanism comprises a fixing chassis, a rotary feeding disc is arranged on the fixing chassis, feeding grooves each capable of containing one button at a time are annularly arranged at theedge of the bottom face of the feeding disc in an arrayed manner, the side edge of the fixing chassis is provided with a feeding opening allowing the buttons flowing out from a button runner to entera material groove in the rotary feeding disc, and the bottom face of the fixing chassis is provided with a discharging opening corresponding the feeding groove of the rotary feeding disc. The buttonsare rotated and moved to the position below the laser cutting mechanism through the rotating table mechanism, cutting is automatically completed through the laser cutting mechanism, after cutting is completed, a button clamp is opened, the buttons fall to a discharging pipe to be discharged out, and full-automatic machining is achieved.

Owner:SHENZHEN LIANDA BUTTON

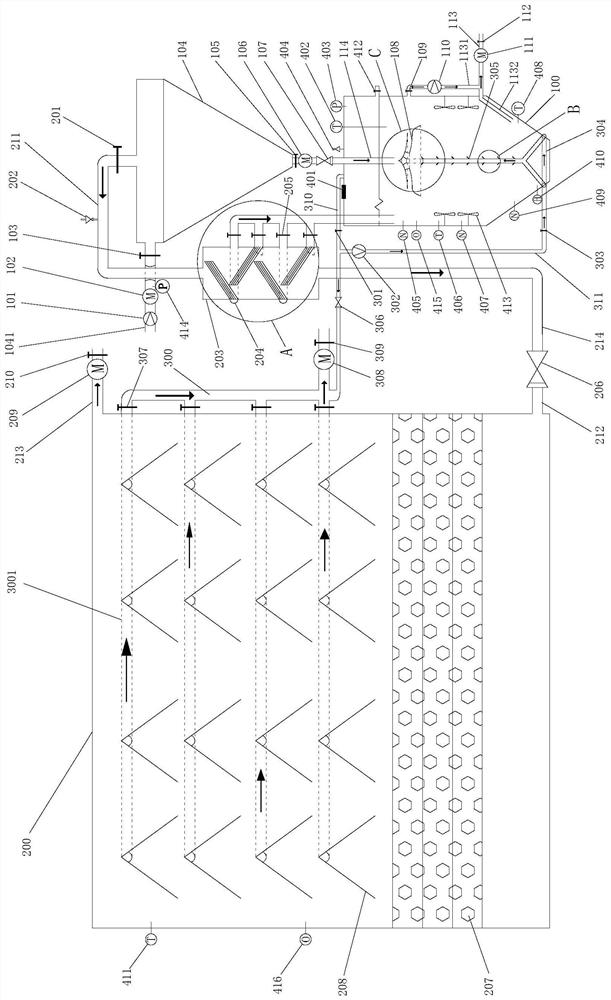

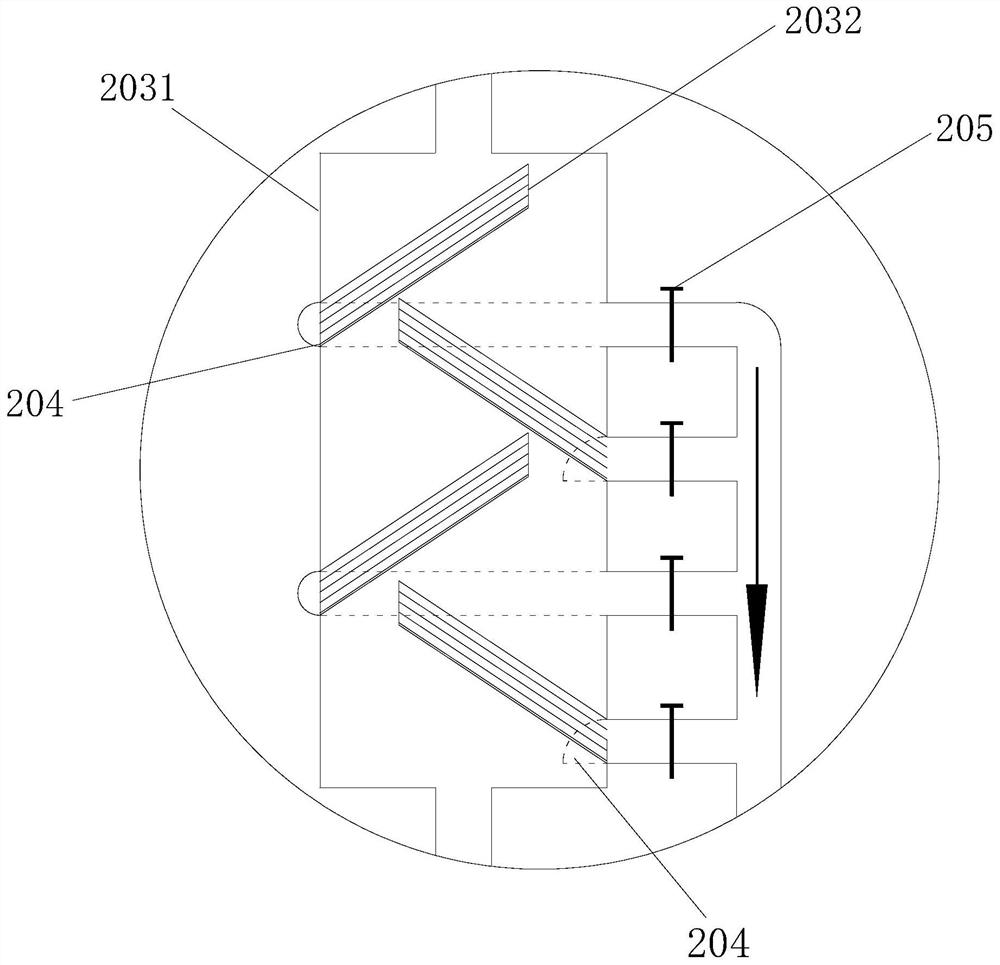

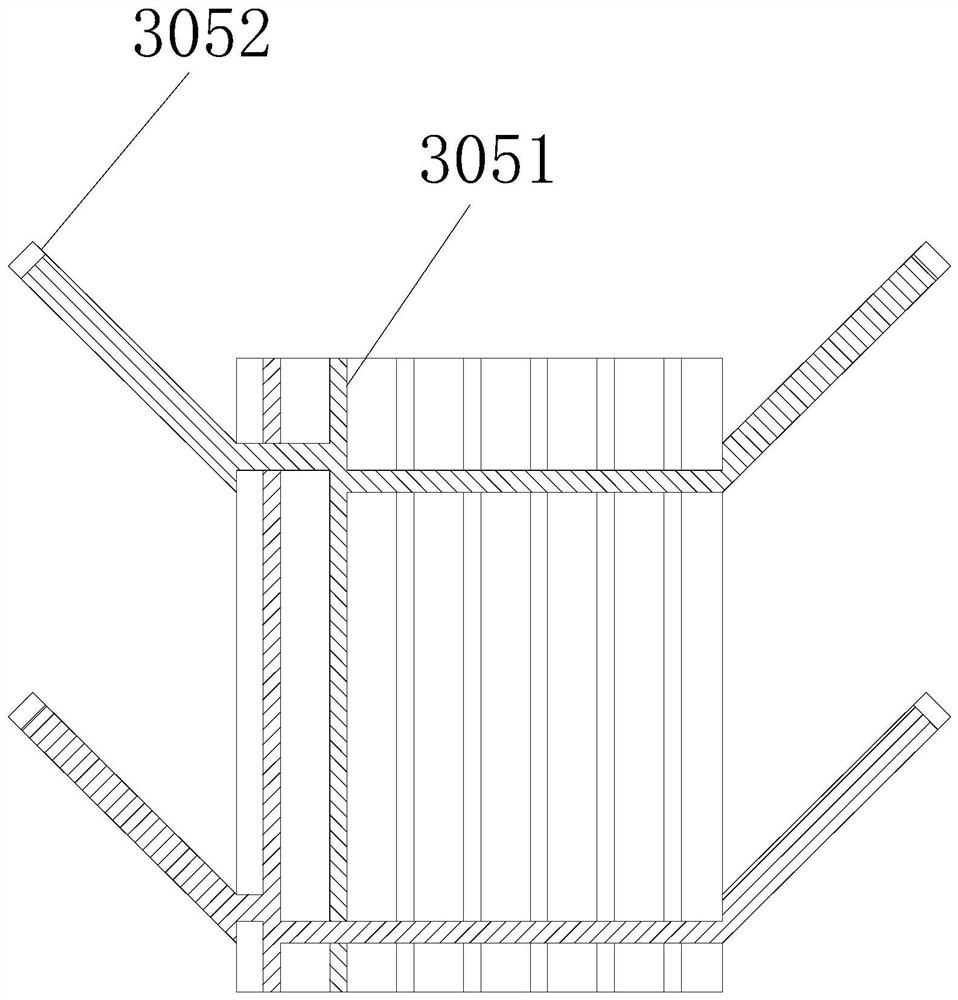

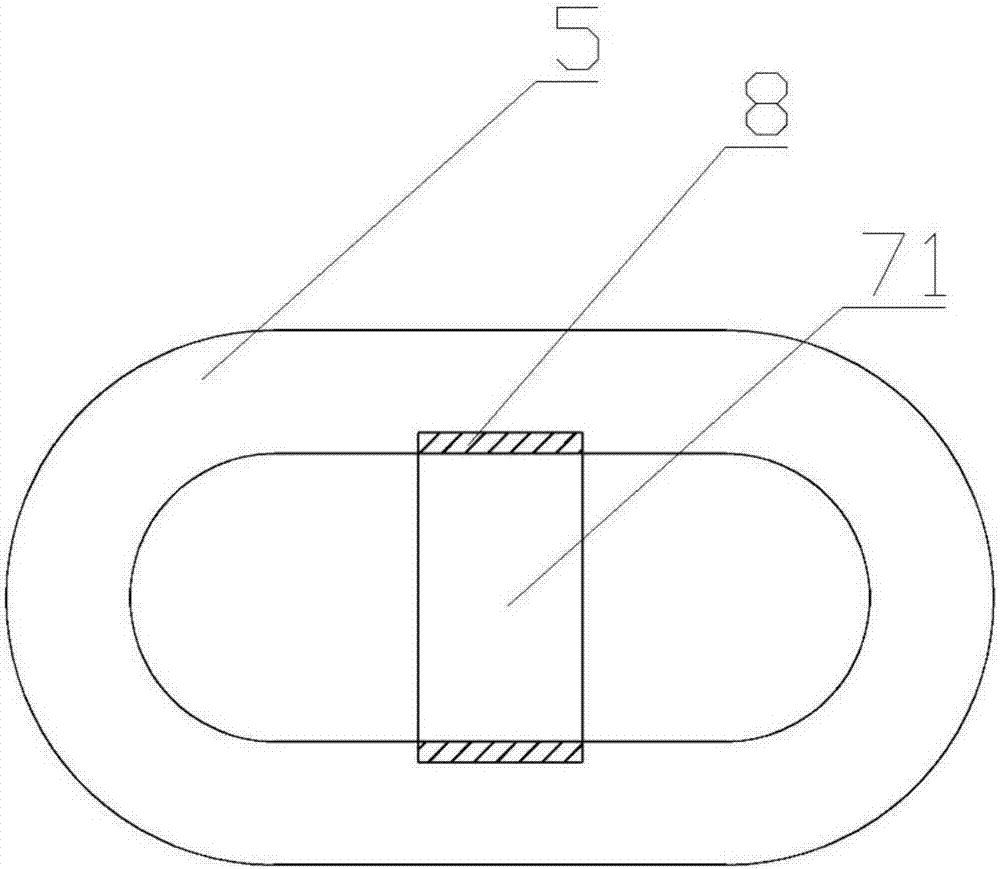

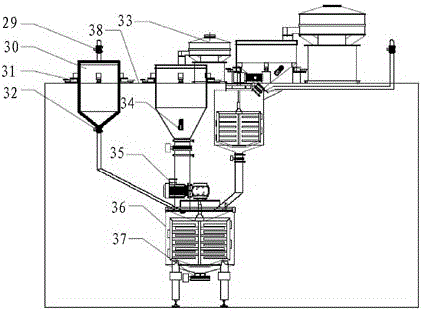

Mud-water separation type sludge anaerobic digestion treatment system and method

ActiveCN112794596AImprove the mixing effectFully anaerobic digestion reactionWater/sewage treatment by centrifugal separationWaste based fuelDigestion TreatmentProcess engineering

The invention discloses a mud-water separation type sludge anaerobic digestion treatment system, which comprises a sludge anaerobic digestion tank, a drainage assembly and a cyclone for mud-water separation. The sludge anaerobic digestion tank is provided with a sludge inlet pipeline, a sludge circulation stirring assembly and a detection element. The cyclone is respectively connected with the drainage assembly and the sludge inlet pipeline. A mechanical stirring assembly and a biogas circulating stirring assembly are arranged in the sludge anaerobic digestion tank, the mechanical stirring assembly is arranged at the side part of a tank body, and the biogas circulating stirring assembly not only collects biogas in the tank, but also stirs sludge by using the biogas. The sludge circulating stirring assembly is used for realizing circulating stirring of sludge in the tank and discharging the sludge out of the tank. The detection element is used for detecting the liquid level, the temperature, the pressure, the viscosity and the potential of the sludge. The treatment system has the advantages of flexibility in disassembly and assembly, small occupied area, high space utilization rate and the like. The invention further discloses a sludge-water separation type sludge anaerobic digestion treatment method. The anaerobic digestion efficiency and dehydration performance of the sludge are improved, and the sludge volume is reduced.

Owner:HUNAN JUNXIN ENVIRONMENTAL PROTECTION CO LTD

High-speed elevator balancing compensation chain and production method of anchor chain thereof

InactiveCN107082341AHigh strengthIncrease the carrying loadElevatorsEngineeringMechanical engineering

The invention provides a high-speed elevator balancing compensation chain and a production method of an anchor chain thereof. The anchor chain comprises unstudded anchor chains and interior-studded anchor chains, the interior-studded anchor chains comprise chain rings I and stay pins, the stay pins are located in the chain rings I and placed in the middles of the interior portions of the chain rings I, the stay pins connect the upper and lower portions of the chain rings I, and the stay pins and the chain rings I are connected through connecting buckles. The unstudded anchor chains comprise chain rings II, the unstudded anchor chains and the interior-studded anchor chains are connected in a mode of 1 : 1-3, and the length of the chain ring II of each unstudded anchor chain is one to two times as much as the length of the chain ring I of each interior-studded anchor chain. According to the high-speed elevator balancing compensation chain and the production method of the anchor chain thereof, through the connecting mode, the chain rings of the anchor chain are not prone to loosing and slipping down in the operating process, noise in the operating process is reduced effectively, and the elevator balancing compensation chain is not prone to being twisted; and meanwhile, the strength and the borne load of the elevator balancing compensation chain are effectively enhanced on the premise that the whole weight is not added, and the elevator balancing compensation chain can be suitable for a high-speed elevator at a speed greater than 3 m / s.

Owner:JIANGSU XINGHUA RUBBER BELT

Automatic sponge wrapping device

ActiveCN105292553AHigh degree of automationImprove consistencyWrappingEngineeringMechanical engineering

The invention discloses an automatic sponge wrapping device and relates to the field of production of wires. The automatic sponge wrapping device comprises a device shell, a guiding mechanism, a dragging mechanism and a shaping mechanism. The guiding mechanism comprises a guiding plate, first pressing rollers and a second pressing roller. A first gap allowing sponge bars with release paper to pass through is formed among the first pressing rollers, the second pressing roller and the guiding plate. An extending plate extending to the inner end of a sponge discharging outlet is arranged at the bottom end of the guiding plate, an ejecting and pressing portion used for ejecting and pressing the sponge bars with the release paper is arranged at the end, away from the guiding plate, of the extending plate, and the second pressing roller is located at the end, away from the ejecting and pressing portion, of the upper portion of the extending plate. The dragging mechanism is arranged at the end, away from the ejecting and pressing portion, of the lower portion of the extending plate. The shaping mechanism comprises a flexible shaping plate and two extrusion rollers, and the extrusion rollers are pivoted to the device shell and used for extruding the end, away from the device shell, of the flexible shaping plate into an inverse U shape. The wires are wrapped by the sponge bars by the automatic sponge wrapping device replacing manpower, and production efficiency is improved.

Owner:FOSHAN GUANGDONG TECH UNIV CNC EQUIP TECH DEV +1

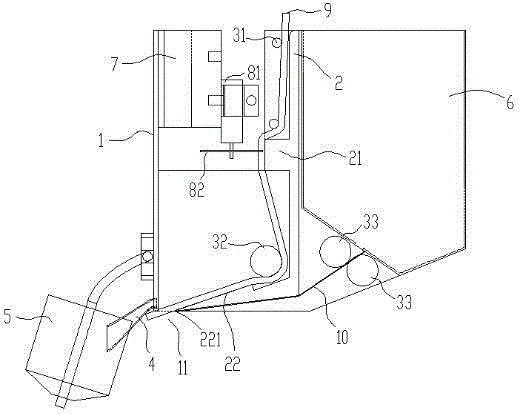

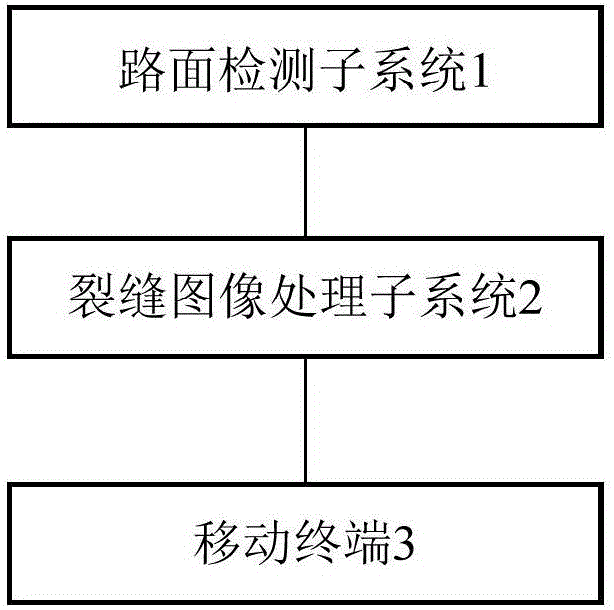

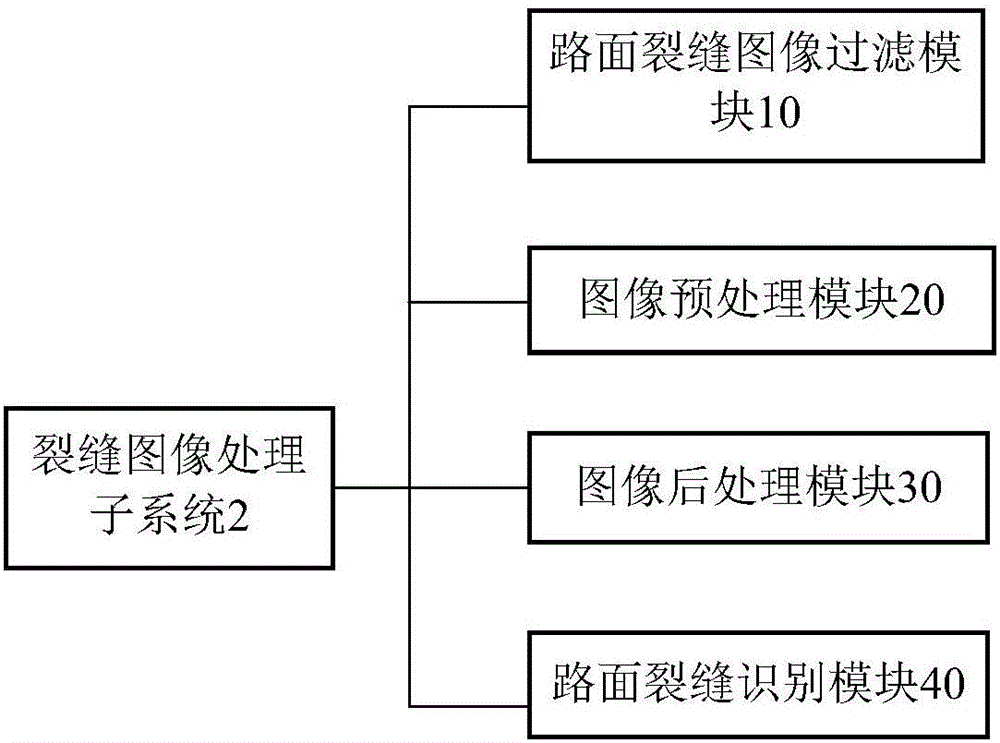

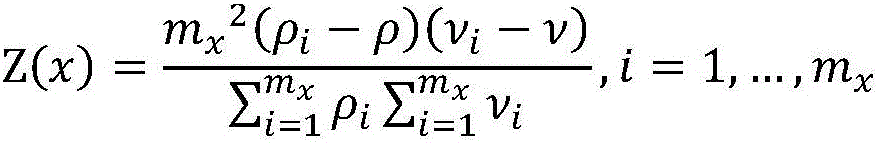

Road crack detecting system

ActiveCN106702870AGet it in timeConducive to follow-up detectionRoads maintainenceImaging processingMaterial resources

The invention provides a road crack detecting system. The road crack detecting system comprises a road surface detecting sub system, a crack image processing sub system and a mobile terminal, which are connected with each other; the road surface detecting sub system is used for shooting a road surface to be detected so as to obtain a road surface crack image; the crack image processing sub system is used for processing the road surface crack image, outputting a road surface crack detecting result and transmitting the road surface crack detecting result to the mobile terminal; and the road surface detecting sub system comprises a plurality of cameras used for shooting the road surfaces to be detected; and during shooting, each camera is provided with different shooting angles for shooting. According to the road crack detecting system, lots of human and material resources can be omitted and information of road surface cracks can be obtained through the mobile terminal in time.

Owner:黑龙江省隆兴公路勘测设计有限公司

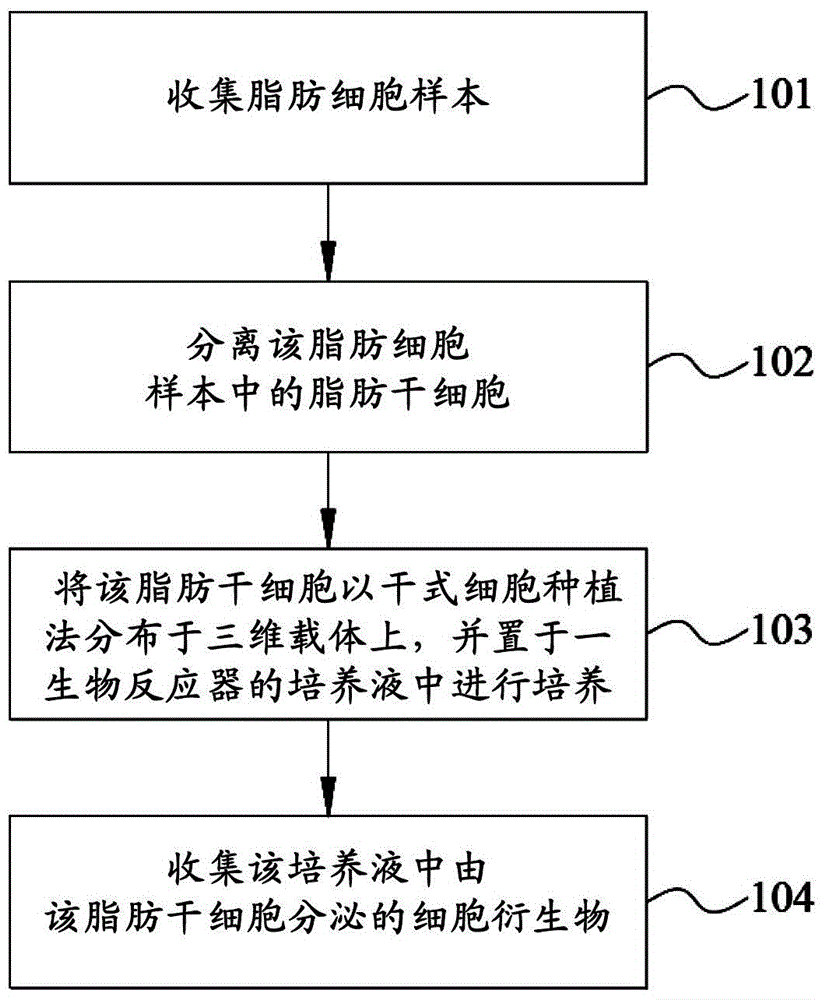

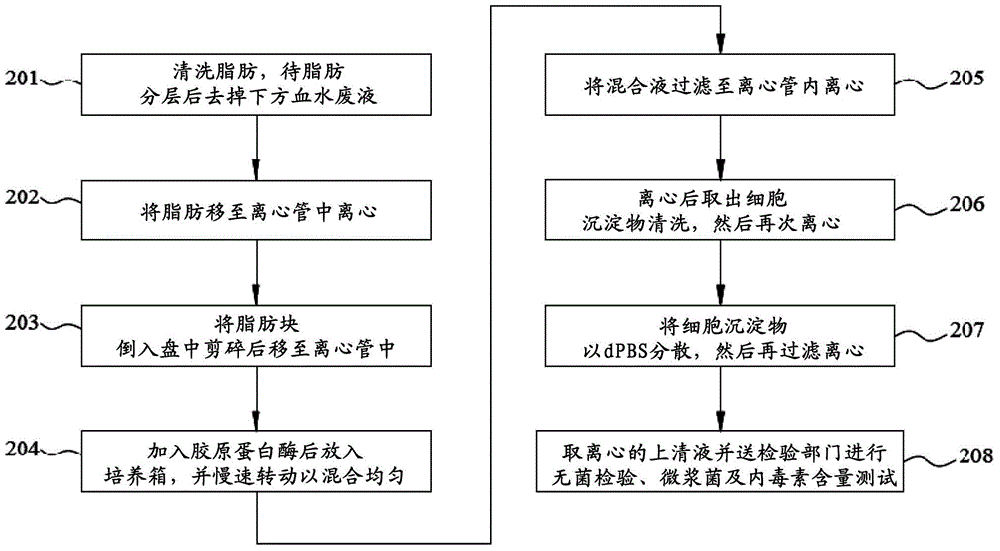

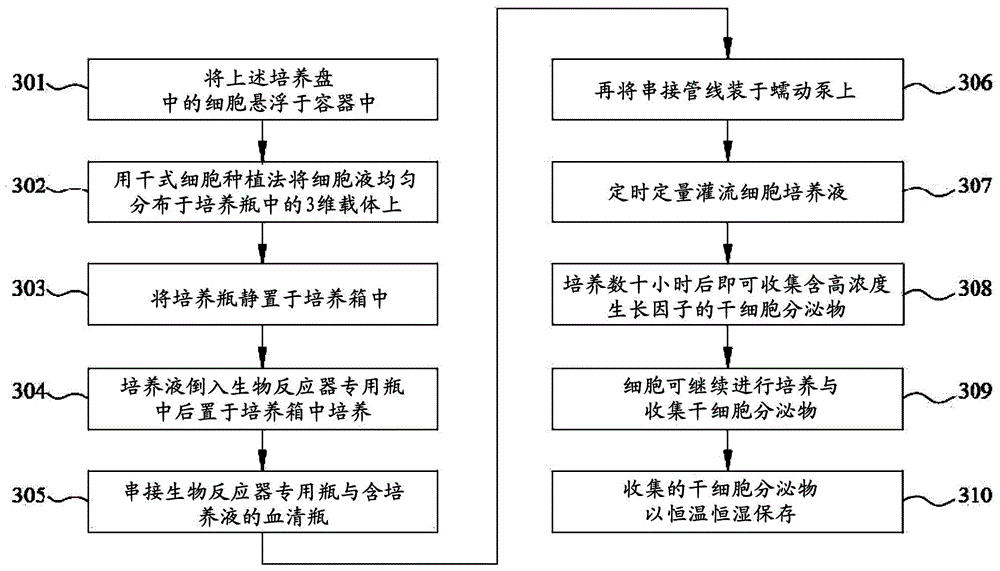

Cultivation and mass-production method of adipose-derived stem cells and stem cell secretion of adipose-derived stem cells

InactiveCN104419659ARapid cultivationImprove the bottleneck of poor coverageSkeletal/connective tissue cellsFermentationDiseaseInterleukin 6

The invention discloses a cultivation and mass-production method of adipose-derived stem cells and stem cell secretion of the adipose-derived stem cells. The method comprises the following steps: (A) collecting an adipose cell sample; (B) separating adipose-derived stem cells from the adipose cell sample; (C) planting the adipose-derived stem cells into a three-dimensional carrier, and cultivating in a bioreactor; and (D) collecting stem cell secretion which is secreted by the adipose-derived stem cells, wherein the stem cell secretion at least comprises one of a vascular endothelial growth factor, a hepatocyte growth factor, an interleukin-6 and type 1 collagen, or combination thereof, and therefore, heavy and complicated steps, and economic cost such as manpower and equipment can be removed, adipose-derived stem cells can be quickly and massively cultivated, the stem cell secretion of the adipose-derived stem cells can be produced, and the cultivation and mass-production method can be applied to the fields of disease treatment, cytothesis and regenerative medicine in the future.

Owner:ISIS BIOMED CO LTD +1

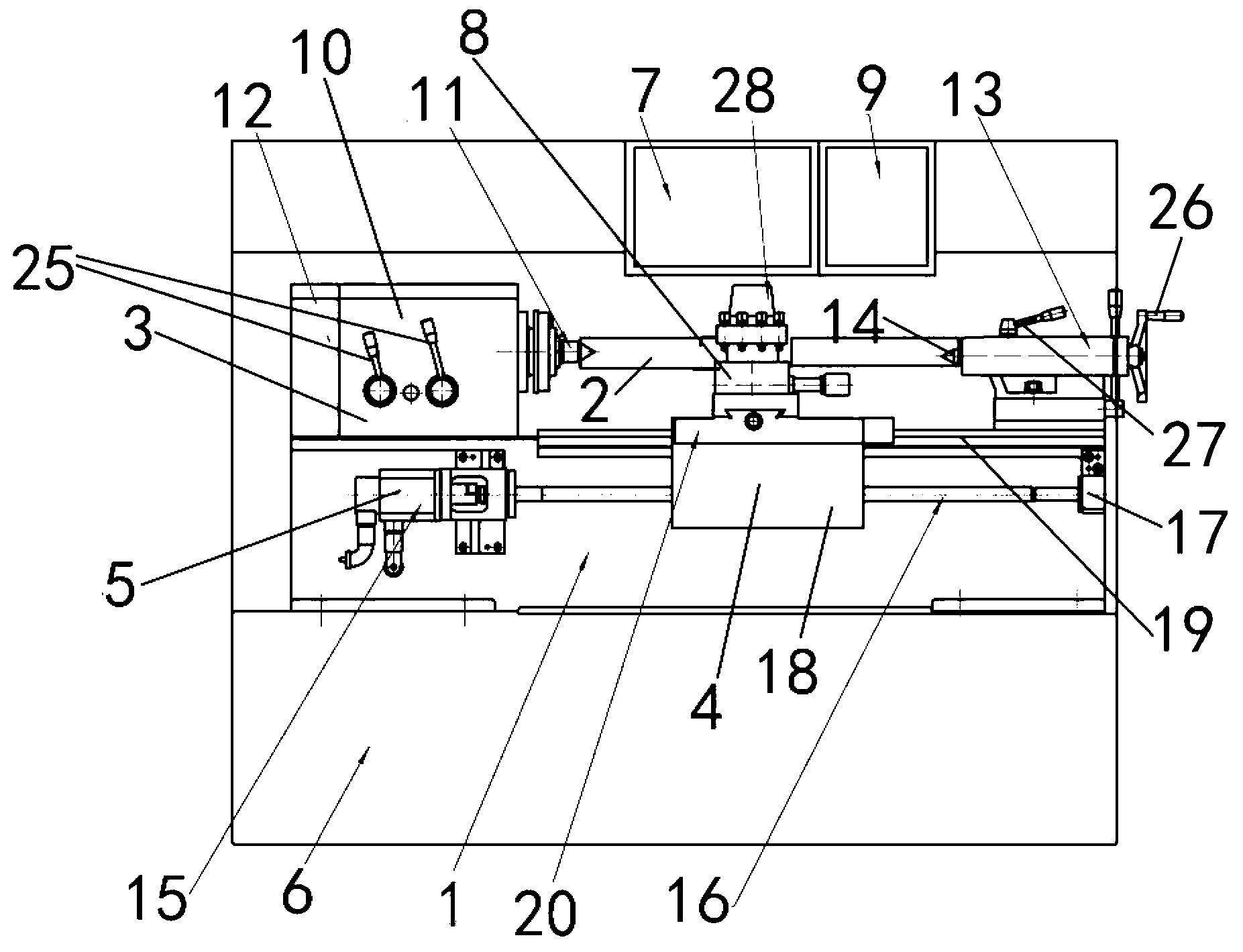

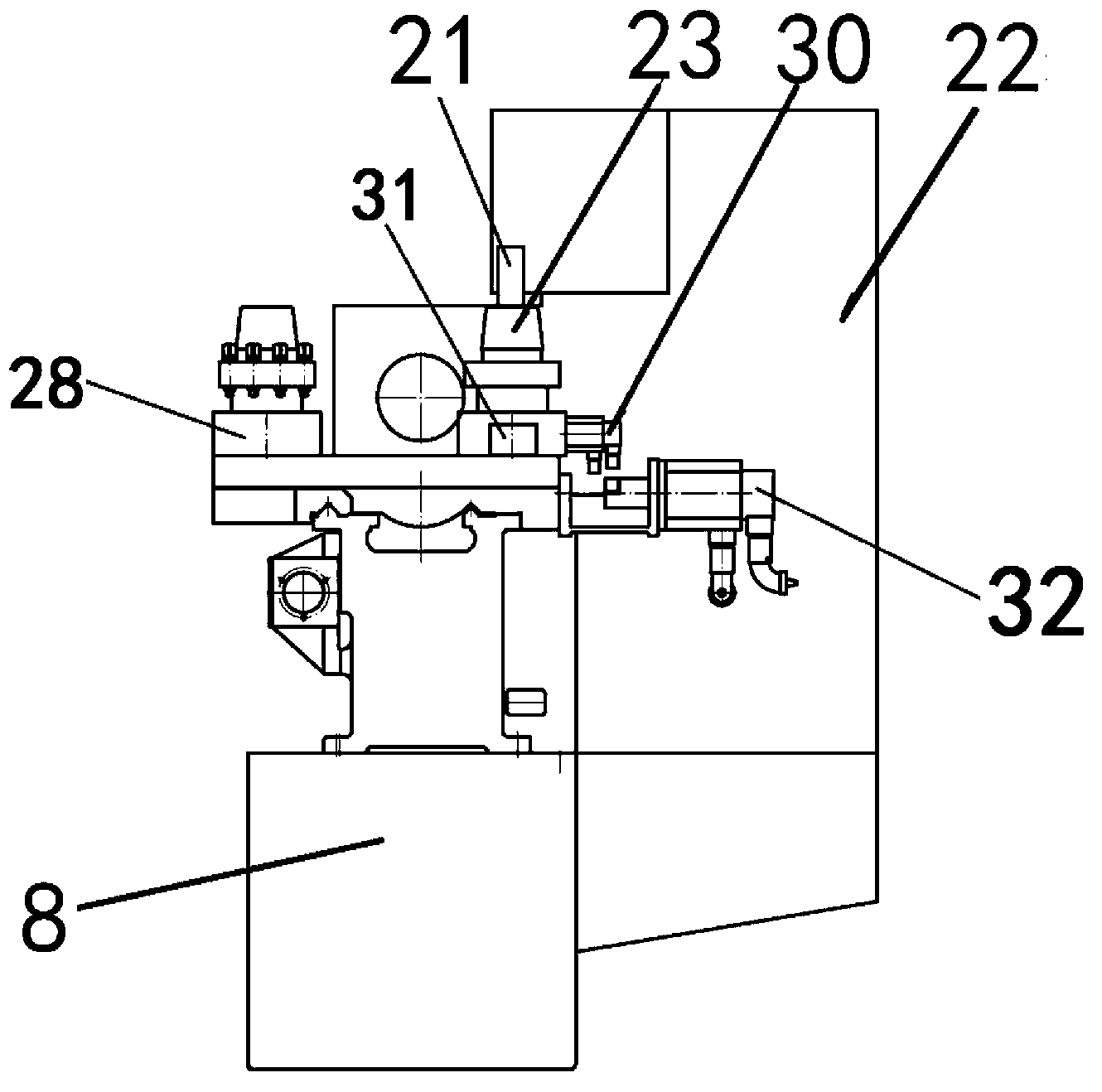

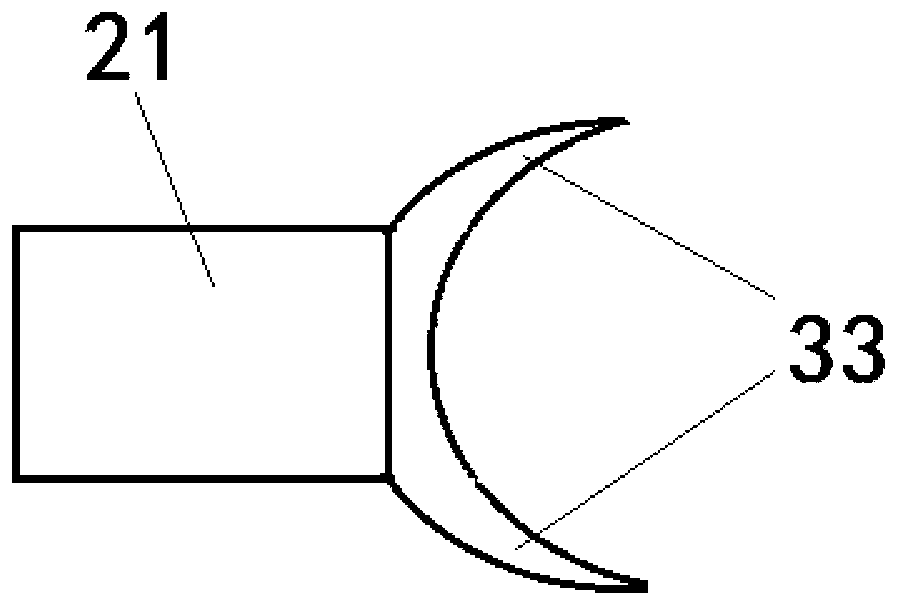

Horizontal combined numerical control lathe

ActiveCN103317153ASimple structureReduce labor intensityAutomatic/semiautomatic turning machinesMeasurement/indication equipmentsNumerical controlRejection rate

The invention provides a horizontal combined numerical control lathe applied to the part turning field. A positioning part (3) capable of clamping a machining element (2), a machining cutter (4) and a drive part (5) are arranged on a lathe body (1) of the numerical control lathe. The drive part (5) can drive the machining cutter (4) to move, the drive part (5) and the positioning part (3) are connected with a numerical control part (7) respectively, a movable ultrasonic flaw detection part (8) is arranged on the lathe body (1) or the machining cutter (4) and connected with a monitoring part (9) receiving and feeding back flaw detection signals. According to the lathe, the structure is simple, synchronous operations or separated operations of machining element lathing machining and ultrasonic flaw detection can be completed, seamless joint of machining and ultrasonic flaw detection of the numerical control lathe is achieved, and the machining element is not required to be moved for ultrasonic flaw detection after lath machining, accordingly, the machining element rejection rate and the labor intensity are reduced.

Owner:宋养信

Automatic production line device of pancakes

InactiveCN106332928AConsistent qualityConsistent quality and tasteBaking plantsProduction lineUniform - quality

An automatic production line device of pancakes is provided; 1. by means of the device, automatic precision weighing, automatic grease spreading, blanking and molding, baking to maturity, precise filling, overturning and pancakes closing and transferring are orderly performed; each step is automatically processed, production is fully and automatically controlled, the automation level is high, the production efficiency is greatly increased, large-scale production requirements of food factories are met, traditional manual practices are replaced, and the production process has significant progress; 2. the produced pancakes have uniform quality and taste which are easily acceptable to customers and is conducive to marketing; 3. the production process barely needs technical staff, human resources are greatly saved, and human factors on the quality and taste of pancakes are greatly reduced, which is conducive to quantitative production; 4. the production line has delicate design, unique technology and simple production technology; the produced pancakes have uniform quality which is conducive to increasing the competitiveness of pancake production.

Owner:HUITOUKE FOOD FUJIAN

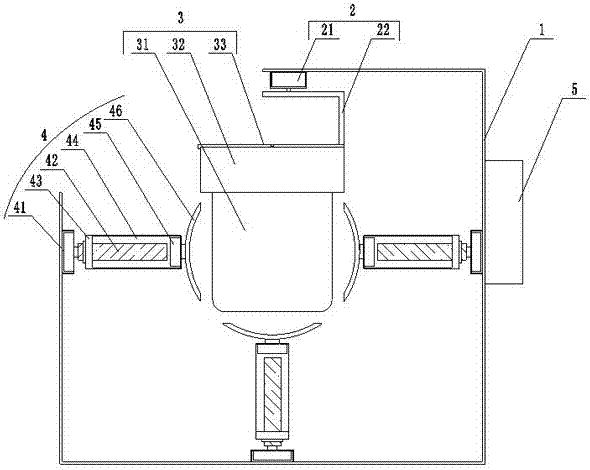

Full-intelligent-control 360-degree bionic rubbing and kneading technique

ActiveCN107509757AKeep healthyPremium tasteMixing/kneading structural elementsDough mixing/kneading methodsEngineeringIntelligent control

The invention discloses a full-intelligent-control 360-degree bionic rubbing and kneading technique, namely an intelligent machine integrated with mechanical automation, process standardization and control digitization. The intelligent machine is utilized for kneading dough, so that the labor and the time are saved, the cost is lowered, and the food health is effectively guaranteed; a traditional dough kneading process is reduced by virtue of bionic mechanical arms, so that the high-quality taste of traditional noodles is guaranteed; the noodles with three tastes of softness, chewiness and glutinousness are successfully produced by virtue of an intelligent control system; and a driving mechanism is connected with a kneading cavity assembly for driving the kneading cavity assembly to rotate, multiple bionic rubbing and kneading mechanisms are distributed around the kneading cavity assembly and are fixedly arranged on a stander, power output ends of the bionic rubbing and kneading mechanisms are in contact with the kneading cavity assembly so as to realize bionic rubbing and kneading actions, a control system is arranged at the stander and can be used for controlling the driving mechanism and the kneading cavity assembly to cooperatively work so as to realize 360-degree bionic rubbing and kneading.

Owner:STATE GRID CORP OF CHINA +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com