Full-intelligent-control 360-degree bionic rubbing and kneading technique

A technology of intelligent control and technology, applied in dough mixing/kneading method, structural components of mixing/kneading machinery, dough mixer, etc., can solve problems such as difficult cleaning, affecting health, easy to damage gluten, etc., to save time and human labor, to ensure the health of food, and to ensure the effect of sanitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

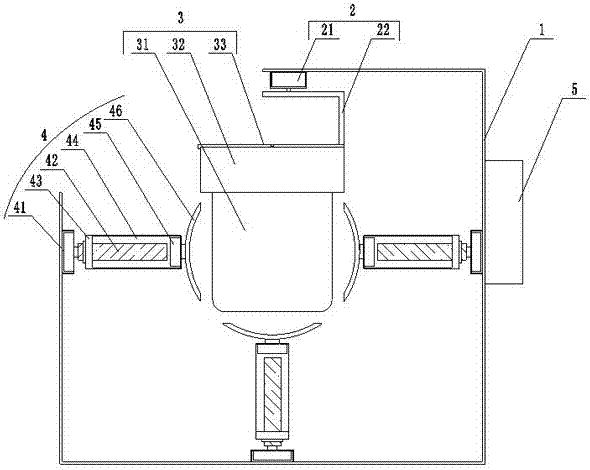

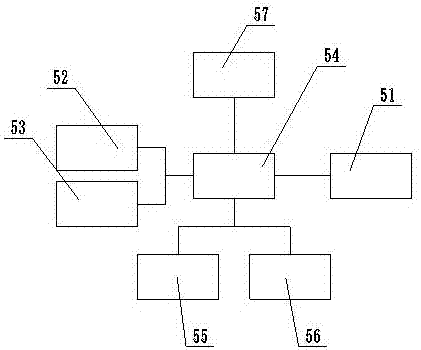

[0024] Such as figure 1 and figure 2 As shown, a fully intelligent control 360° bionic kneading kneading technology of the present invention includes a frame 1, a driving mechanism 2, a kneading cavity assembly 3, a bionic kneading mechanism 4 and a control system 5. The frame 1 It is a semi-closed structure, the driving mechanism 2 is arranged on the upper end of the frame 1, and the power output end of the driving mechanism 2 is facing downwards, and it is connected with the mixing chamber assembly 3 for driving the mixing chamber The assembly 3 rotates, and a plurality of the bionic kneading mechanisms 4 are distributed around the kneading cavity assembly 3, and the bionic kneading mechanisms 4 are fixedly arranged on the frame 1, and the power output ends of the bionic kneading mechanisms 4 The bionic kneading action can be realized by being in contact with the kneading cavity assembly 3, the control system 5 is set on the frame 1, and the control system 5 controls the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com