Patents

Literature

169results about How to "Save manpower and" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

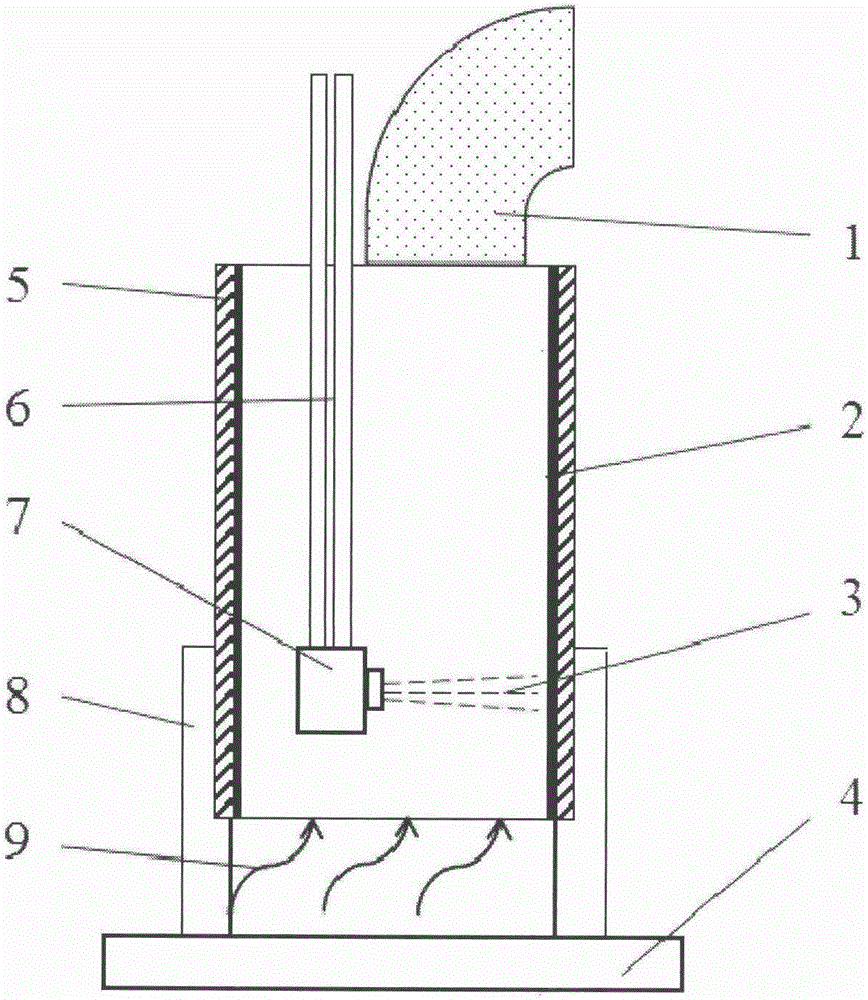

Cleaning, recycling and compression device for plastic beverage bottles

InactiveUS20200094299A1Save manpower andSave material resourcesHollow article cleaningPlastic recyclingElectric machineryProcess engineering

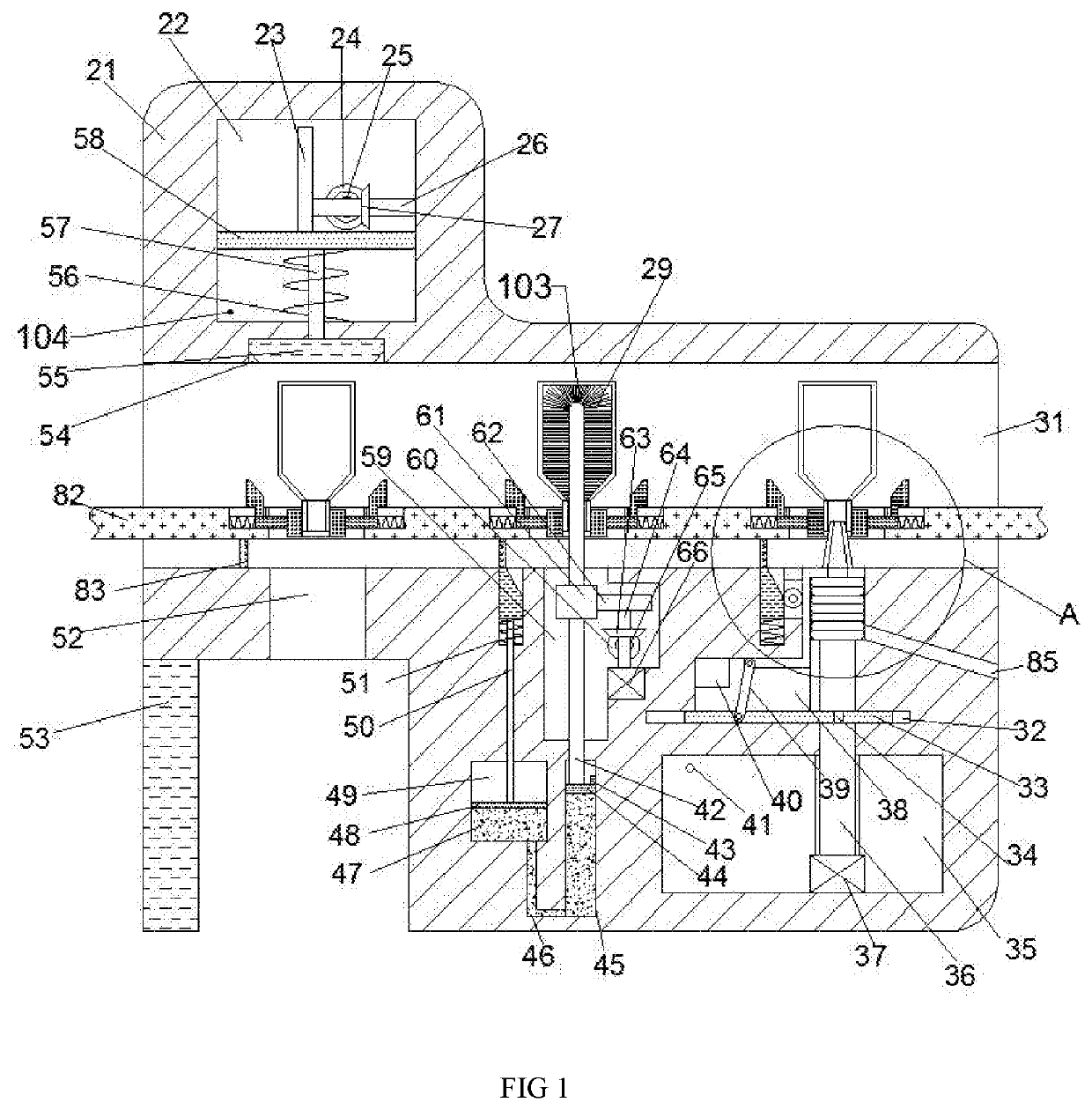

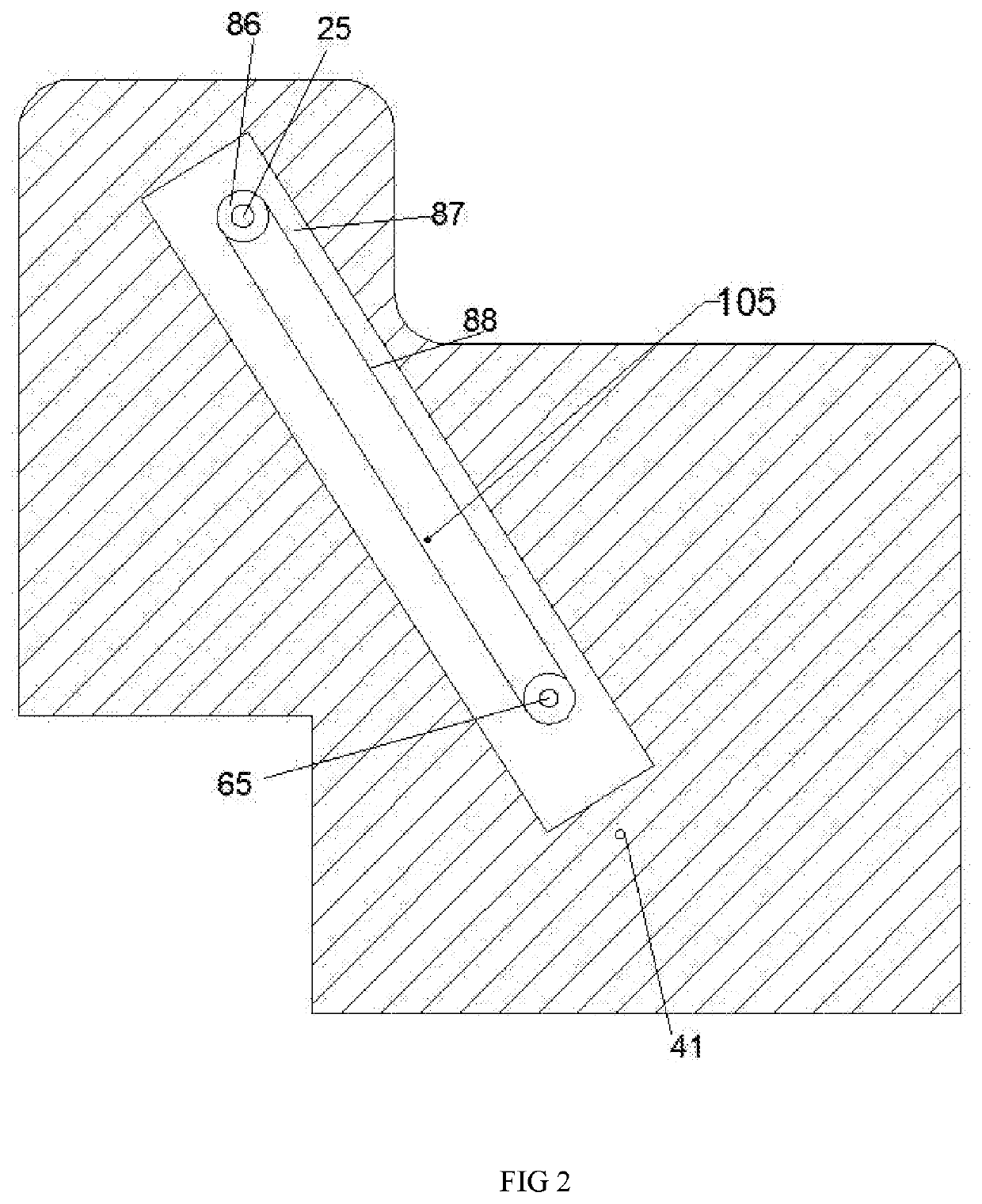

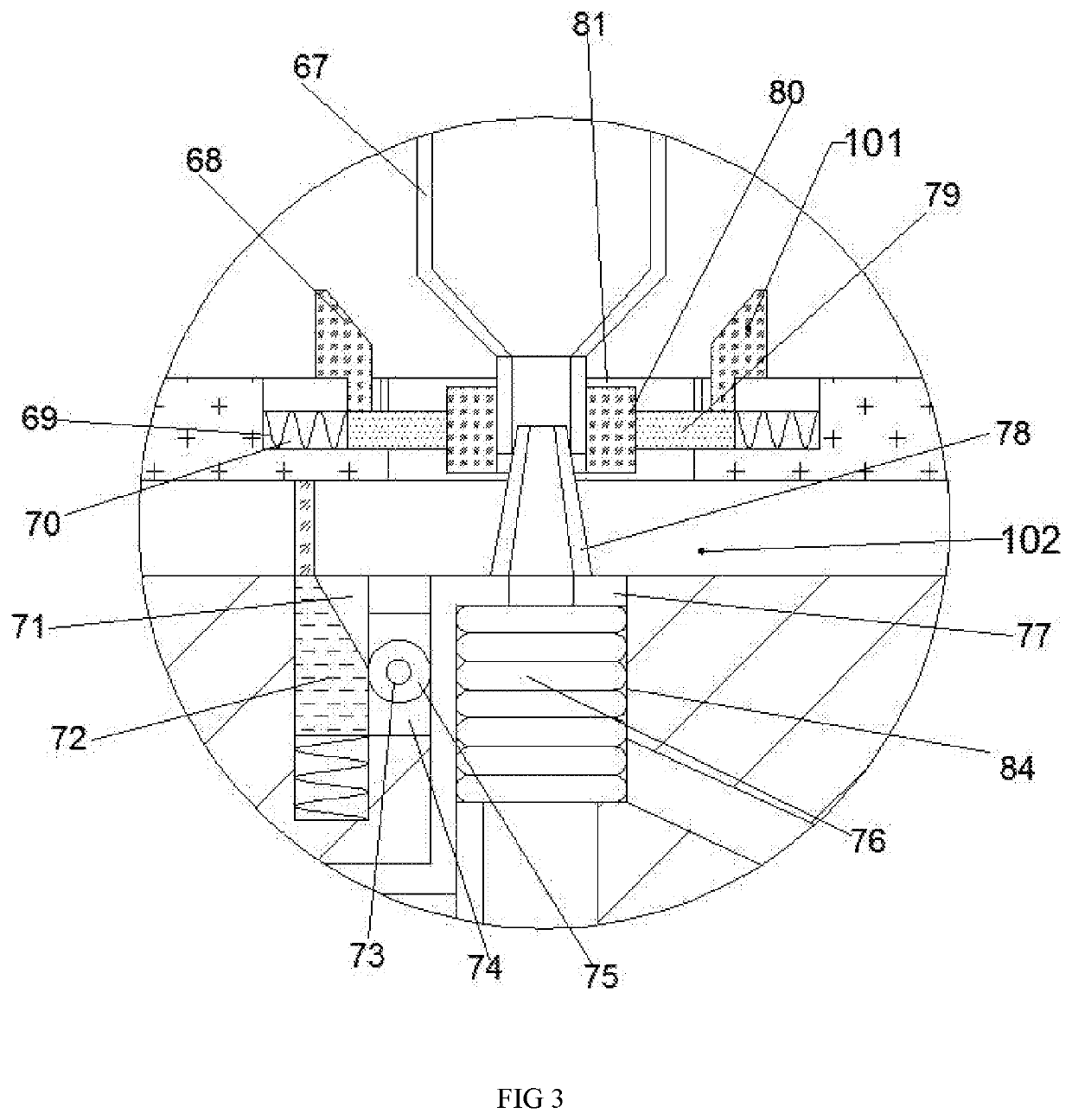

The invention discloses a device for cleaning, recycling, and compressing a plastic beverage bottle, which includes a body. The body is provided with a working cavity. The working cavity is provided with a moving conveyor belt. The conveyor belt is provided with a fixed cavity. The cavity is provided with a fixing device for fixing the water bottle. The motor is first moved away, and the plastic bottles are fixed between the fixing blocks, and then water is injected into the water injection port. The device can wash and clean the plastic bottles after drinking, thus completing the automatic preliminary treatment of plastic bottles. Compared with traditional processing methods, the device does not require manual processing of plastic bottles, saving manpower and material resources. At the same time, the device cleans plastic bottles, which can ensure that during subsequent reprocessing, there can be health protection.

Owner:SHU YONGJUN

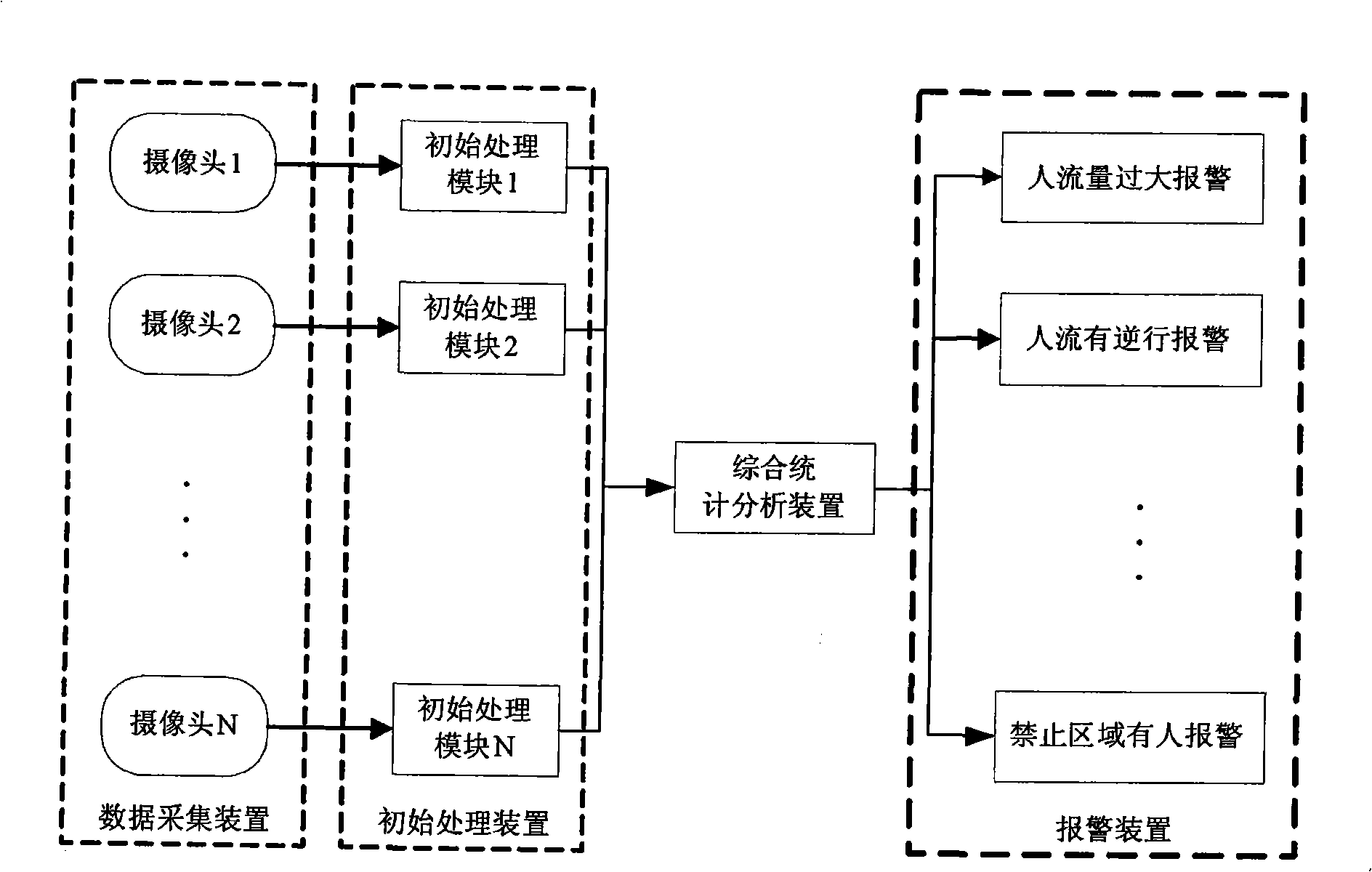

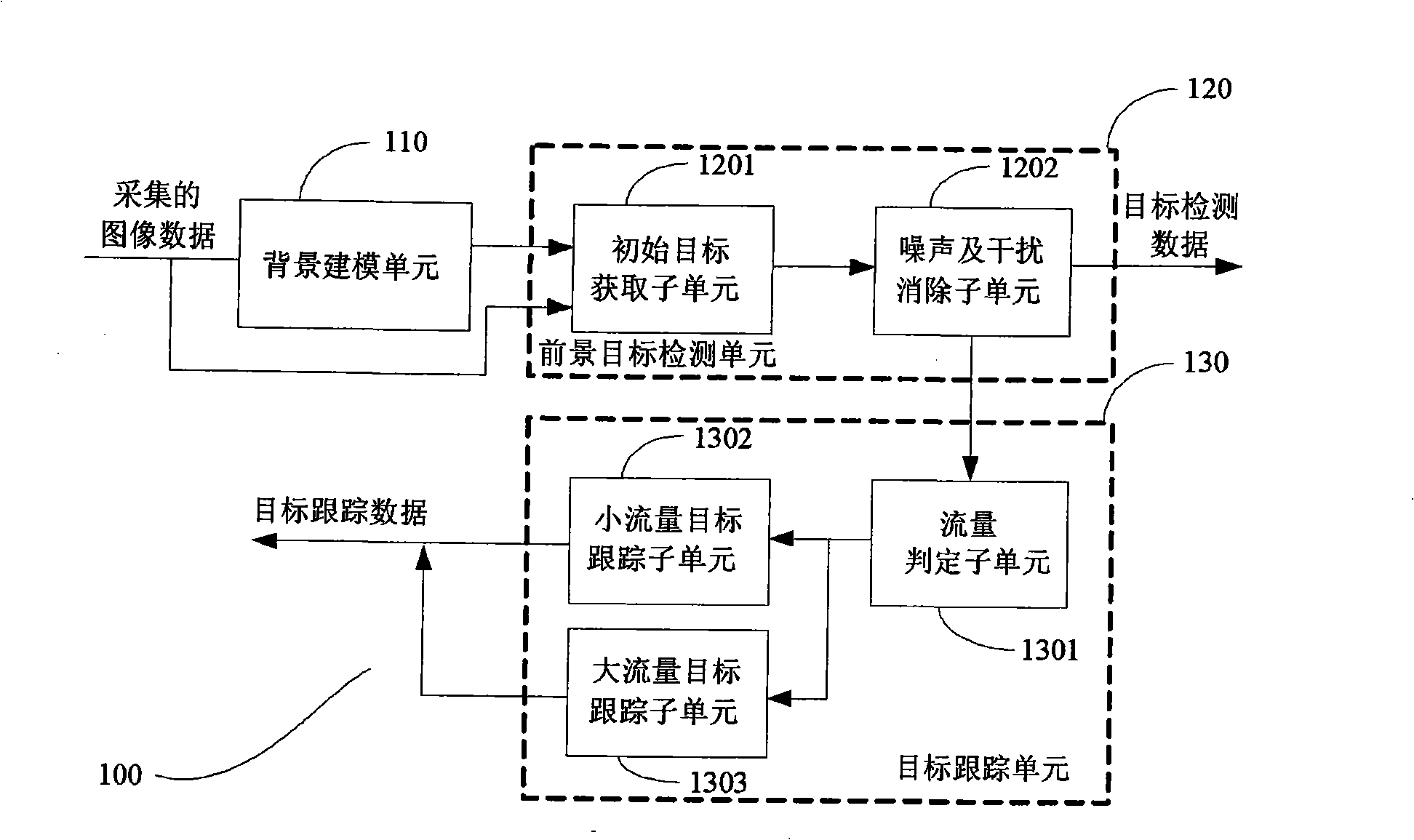

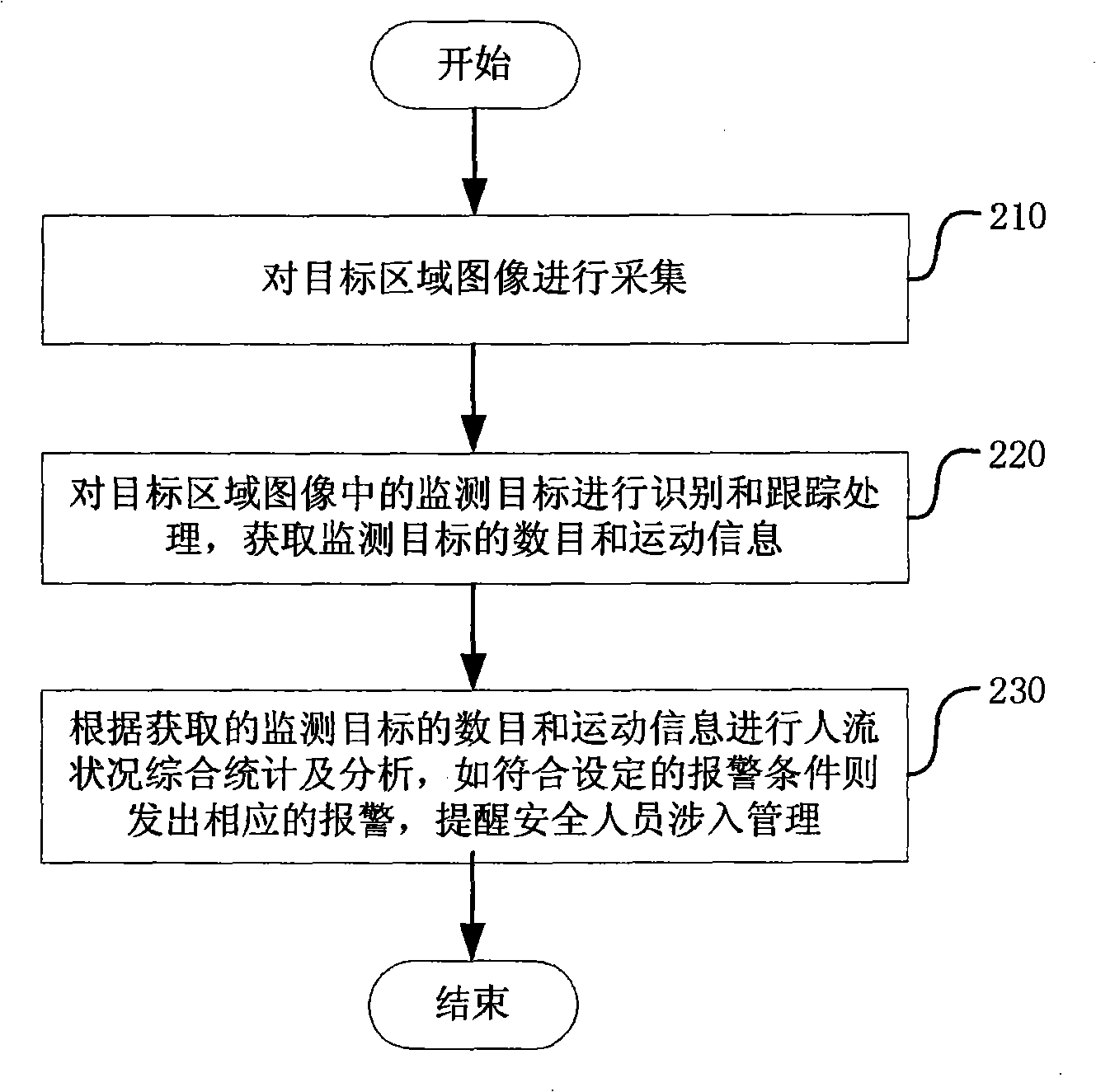

Video monitoring method and system with auxiliary objective monitoring function

InactiveCN101320427AReduce security risksSave manpowerCharacter and pattern recognitionAlarmsTraffic volumeHuman power

A video monitoring method that has auxiliary monitoring function for an object is provided, which comprises the following procedures: a) collecting images in a target area; b) identifying and tracking a monitoring object in the image of target area, so as to acquire the number and / or movement information about the monitoring object; c) carrying out comprehensive statistics and analysis of passenger flow according to the acquired number and / or movement information about the monitoring object. The invention can intelligently assist a safety administrator to manage, so as to effectively reduce the potential safety hazard and save a great amount of management manpower. What is more, with unique background updating mechanism, the invention can ensure more reliable application in places with great passenger flow such as the platform of rail transit, the entrance of department store and entrance of passage. In addition, by tracking the monitoring object according to different passenger flow, the invention not only simplifies the elaborated tracking algorithm, but also ensures better processing effect.

Owner:VIMICRO CORP

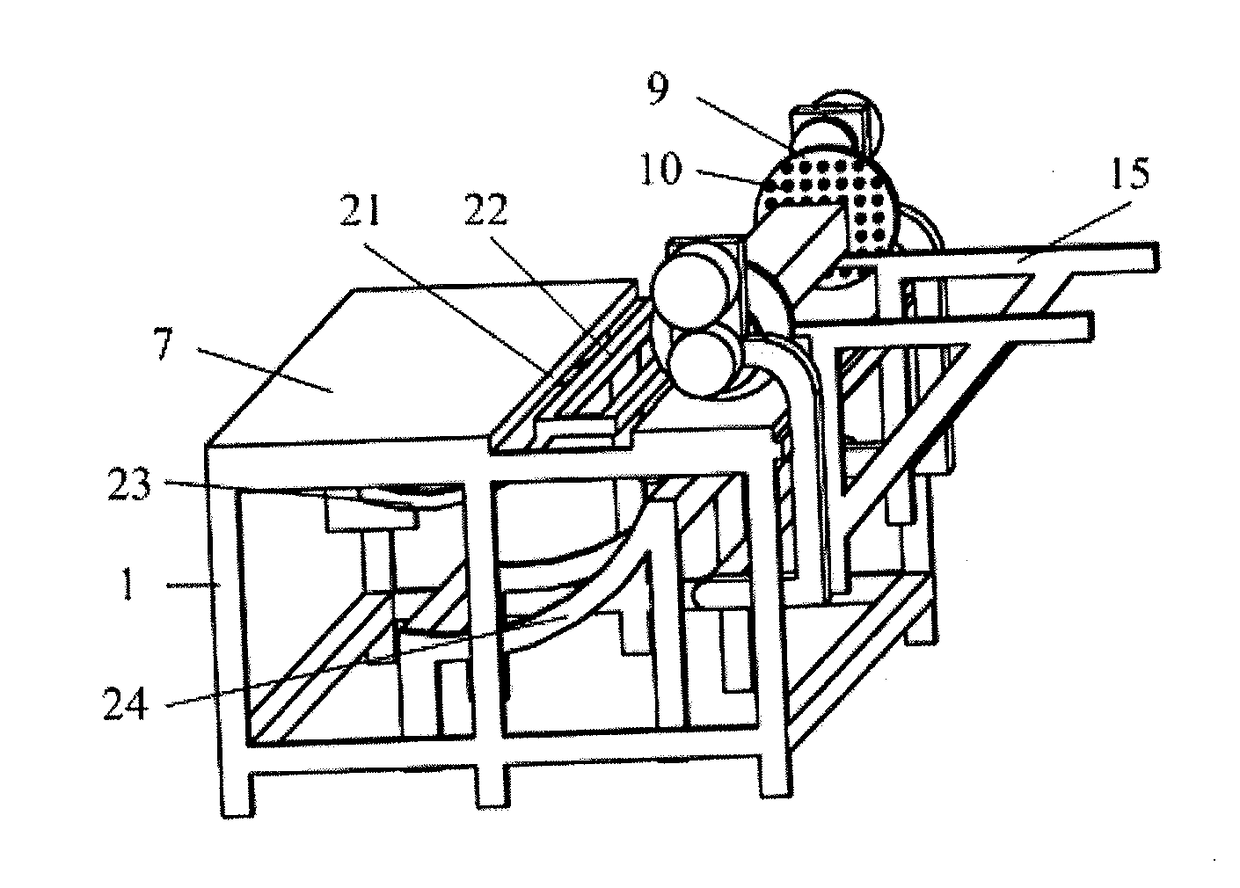

Method for automatic classification separately collection and automatic transportation of the solid waste

InactiveUS20160001297A1Expand the scope of recognitionIncrease valueWaste collection and transferRefuse receptaclesAutomationWaste management

A method for automatic classification separately collection and automatic transportation of the solid waste is designed to replace the manual door to door collection of the waste by the computer, and getting the waste for valuable recycle and reuse comprises of putting the waste into the automatic waste collectors set at the source of the waste producing and connected with pipeline, identifying the waste by the main board (21), classifying the waste by the selector (6), depositing the waste in the containers (1), (2) and (3), fluidizing the wastes by rolling fluidizing assembly (15), under the monitoring of the supervisory control center, separately transporting the wastes into the correspond waste recycle center, and getting the solid waste automation.

Owner:QIU ZEGUO

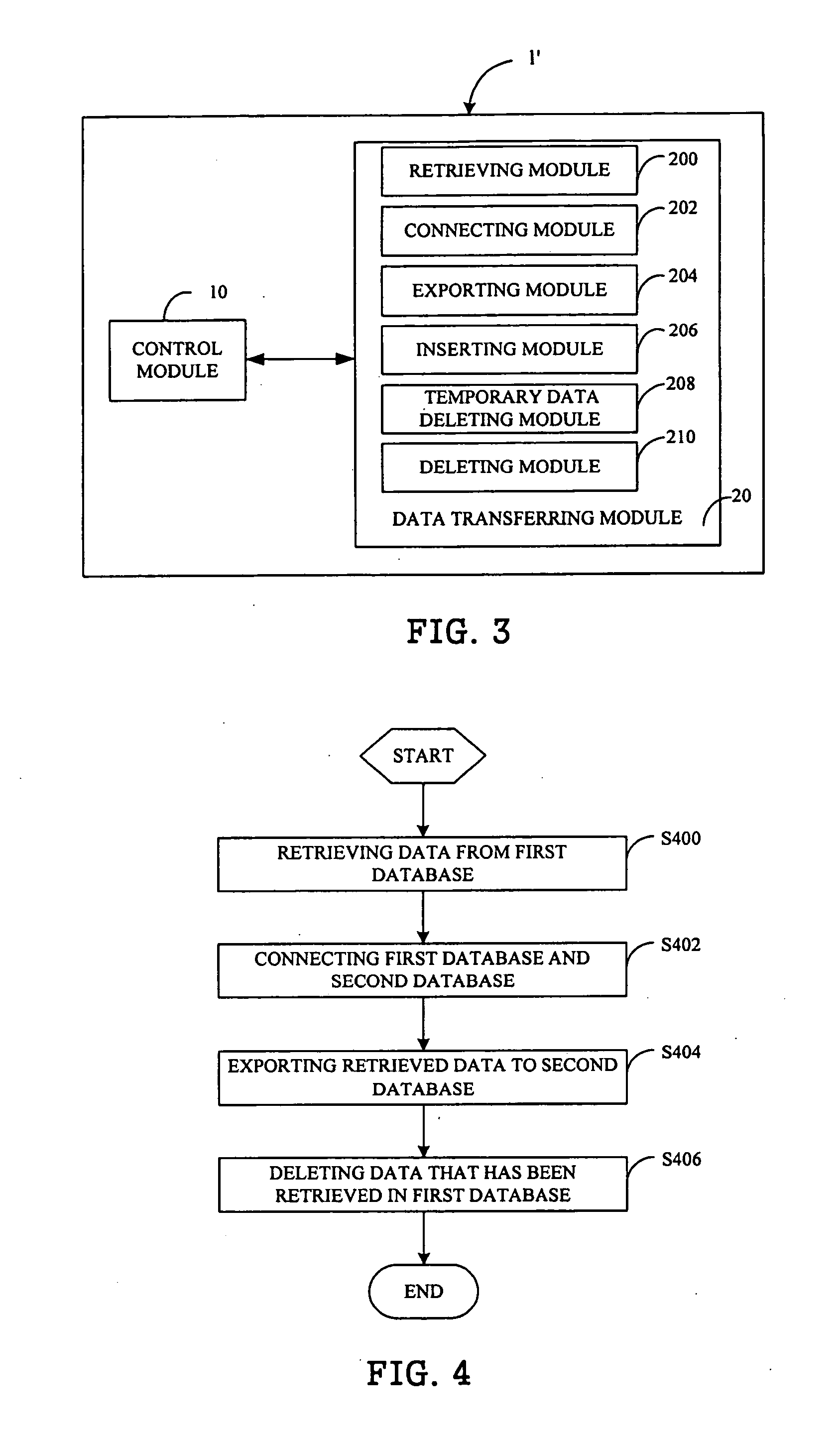

Cultivation techniques of cost-saving and yield-increasing winter-planted potatoes in southern China

InactiveCN102257917AReduce labor costsSave manpower andSeed and root treatmentFertilising methodsLiquid manureAgricultural engineering

The invention belongs to the technical field of culture of potato, and particularly discloses a cost-saving and yield-increasing culture technique for southern winter planting potato. The technique comprises the following steps of: selecting a land, preparing the land and furrowing; applying a base fertilizer; treating potato seeds; seeding; covering with soil; covering with a film; earthing up the film; managing liquid manure, weeds and insect pests; and harvesting, wherein a method of earthing up the film is that: a layer of smashed soil of 5-8 centimeters is covered on the film by using a machine or a hoe, so that the film on a ridge surface is covered fully. In the technique, an integral water manure furrow application method is used innovatively, so that the labor per acre is saved by 7 persons, and the acre yield is up to 9,136 jin. Due to the adoption of the technique, the increase in of the yield of potato is facilitated, the production cost is lowered, and the economic benefit of potato production is increased. On the aspect of technique, the process flow of potato production is completed, the production time of potato is shortened, and a solid technical foundation is laid for the popularizing scale, standardization and commercial production of the potato industry.

Owner:HUIDONG COUNTY JIUHUA FARMING & TRADING

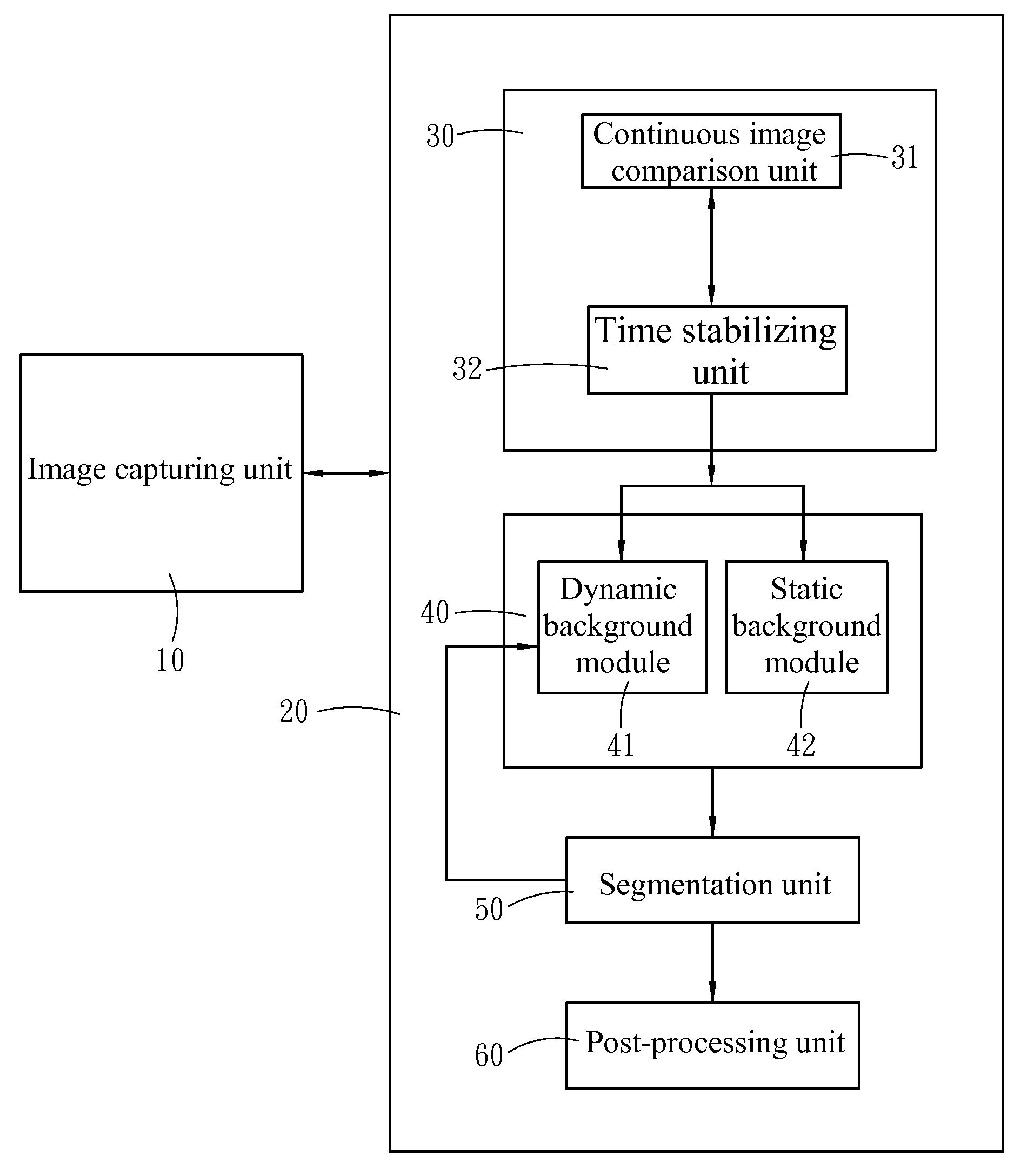

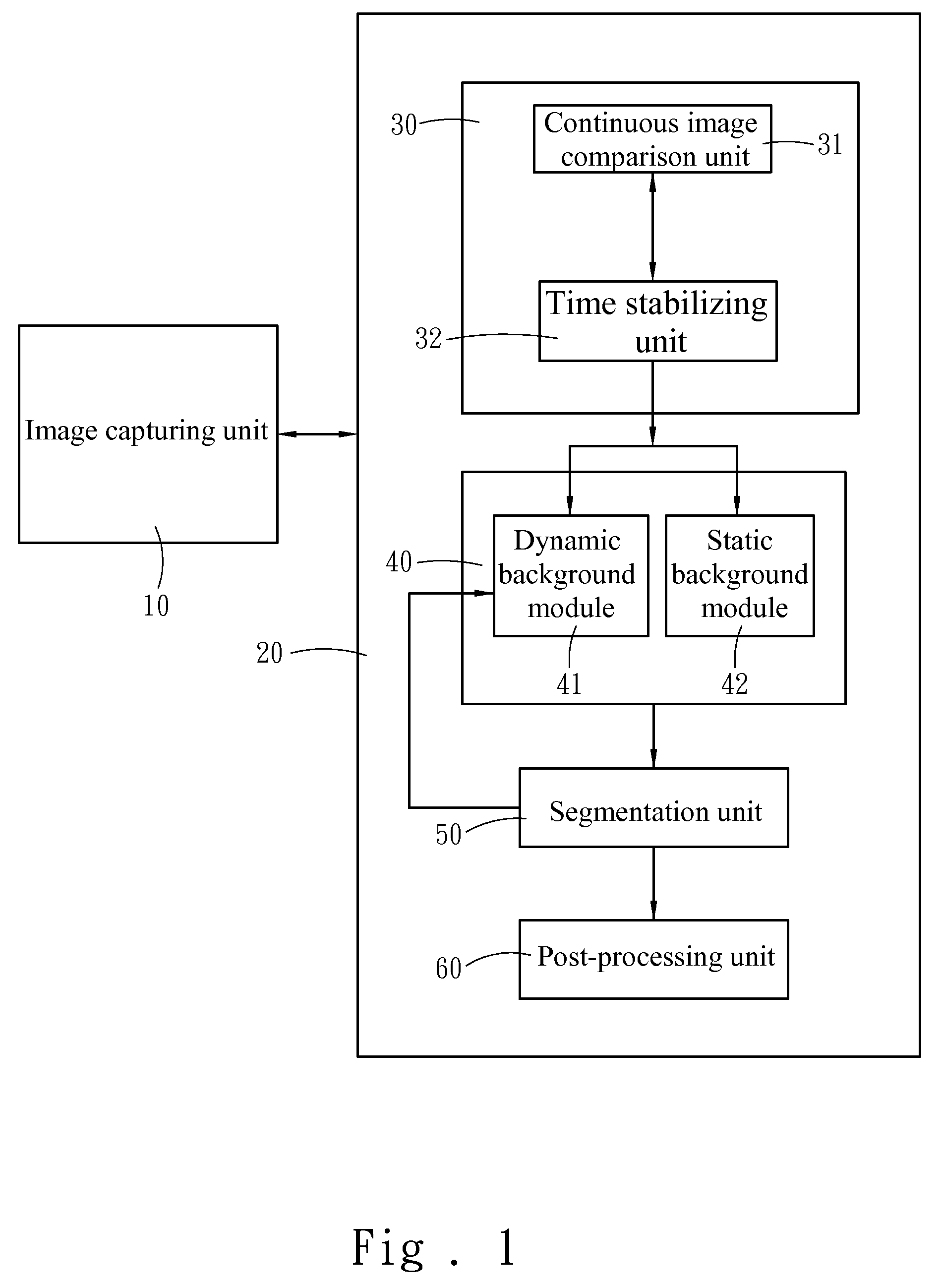

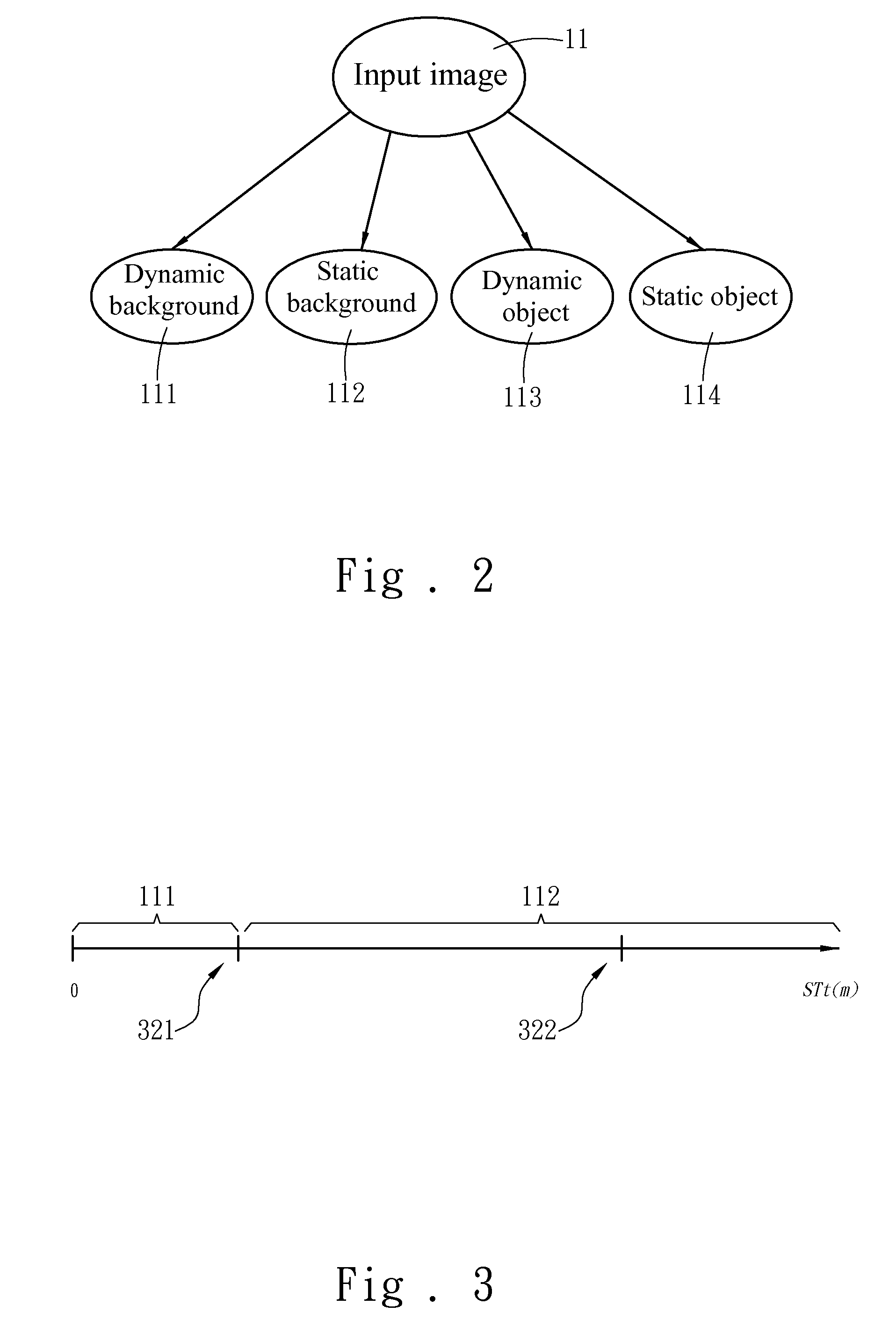

Intelligent monitoring system

InactiveUS20100131442A1Improve monitoring qualitySave manpower andCharacter and pattern recognitionKnowledge representationBackground informationReal-time computing

An intelligent monitoring system aims to perform object surveillance and tracking, and can quickly build accurate and reliable background data in a complex image condition to achieve desired monitoring result. Based on a dynamic background and a temporary static object and user's requirements, monitoring objects in a background module can be added or deleted to match the actual background information. The whole background data can be tracked according to characteristics of a targeted object set by users, and post-processing can be done for the tracked object, such as zooming, identifying, capturing, surveillance of behaviors, and the like. Thus whether a special attention is needed for a dynamic or static object can be notified. And an alert can be issued to relevant people for timely handling.

Owner:NATIONAL YUNLIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

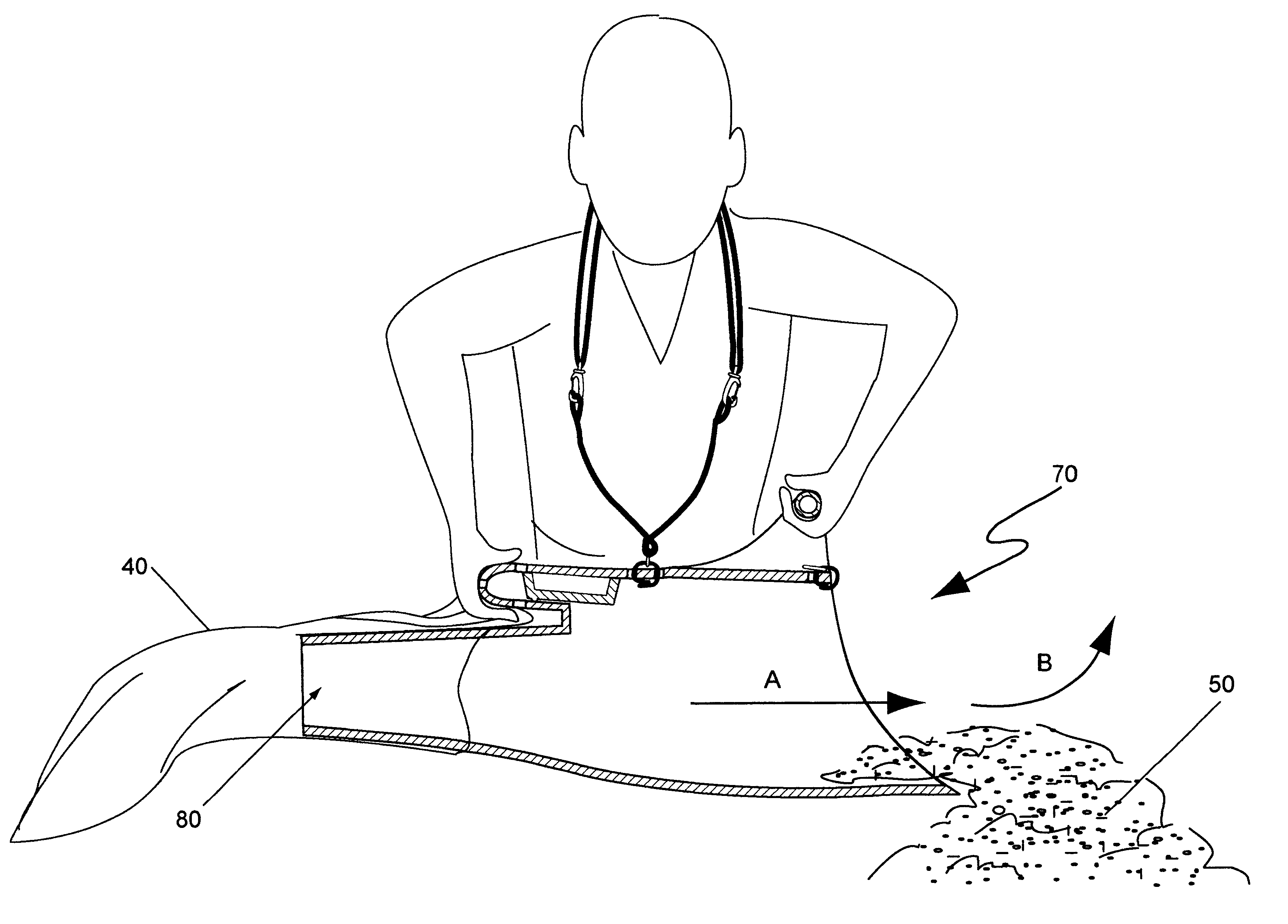

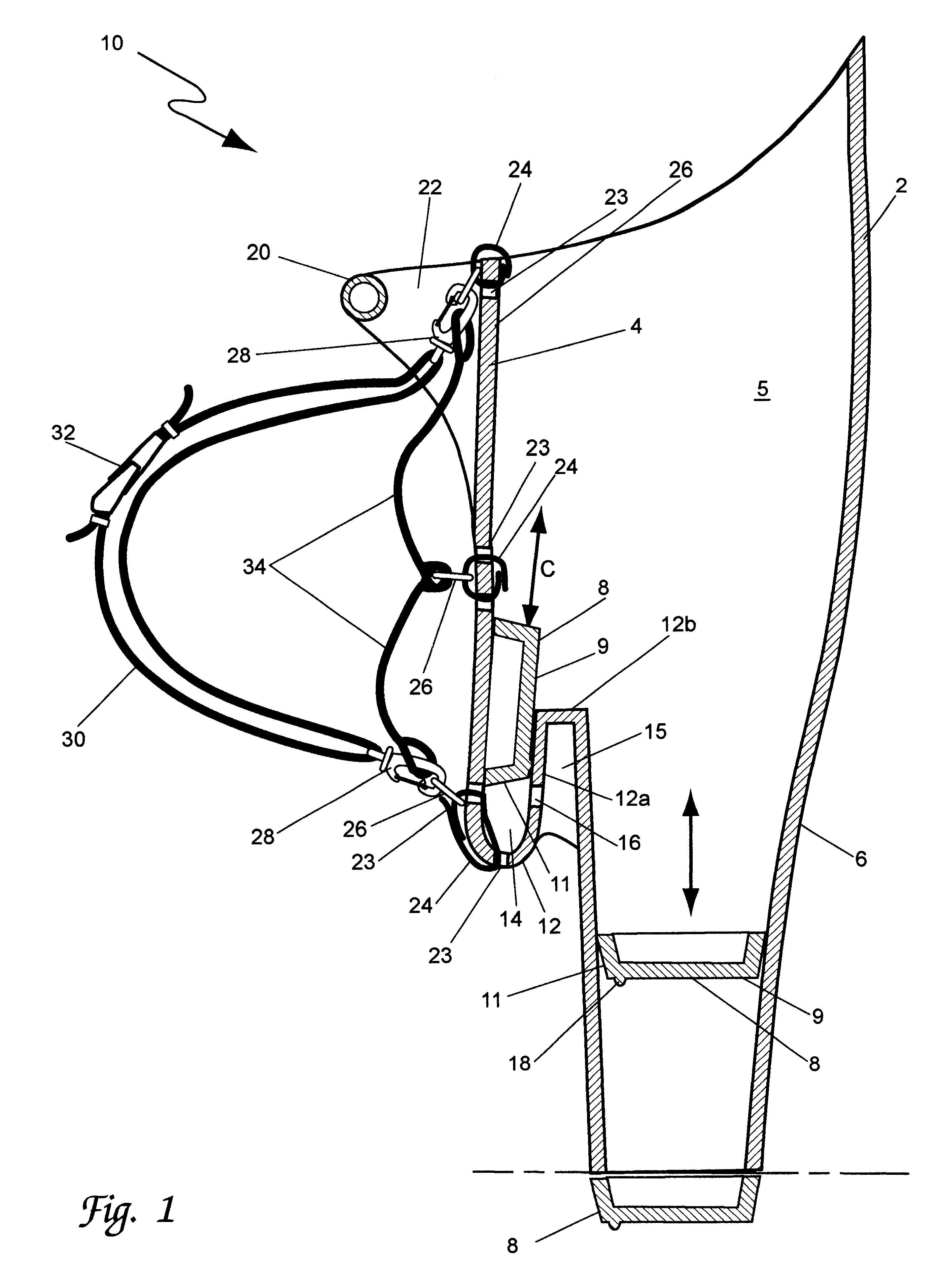

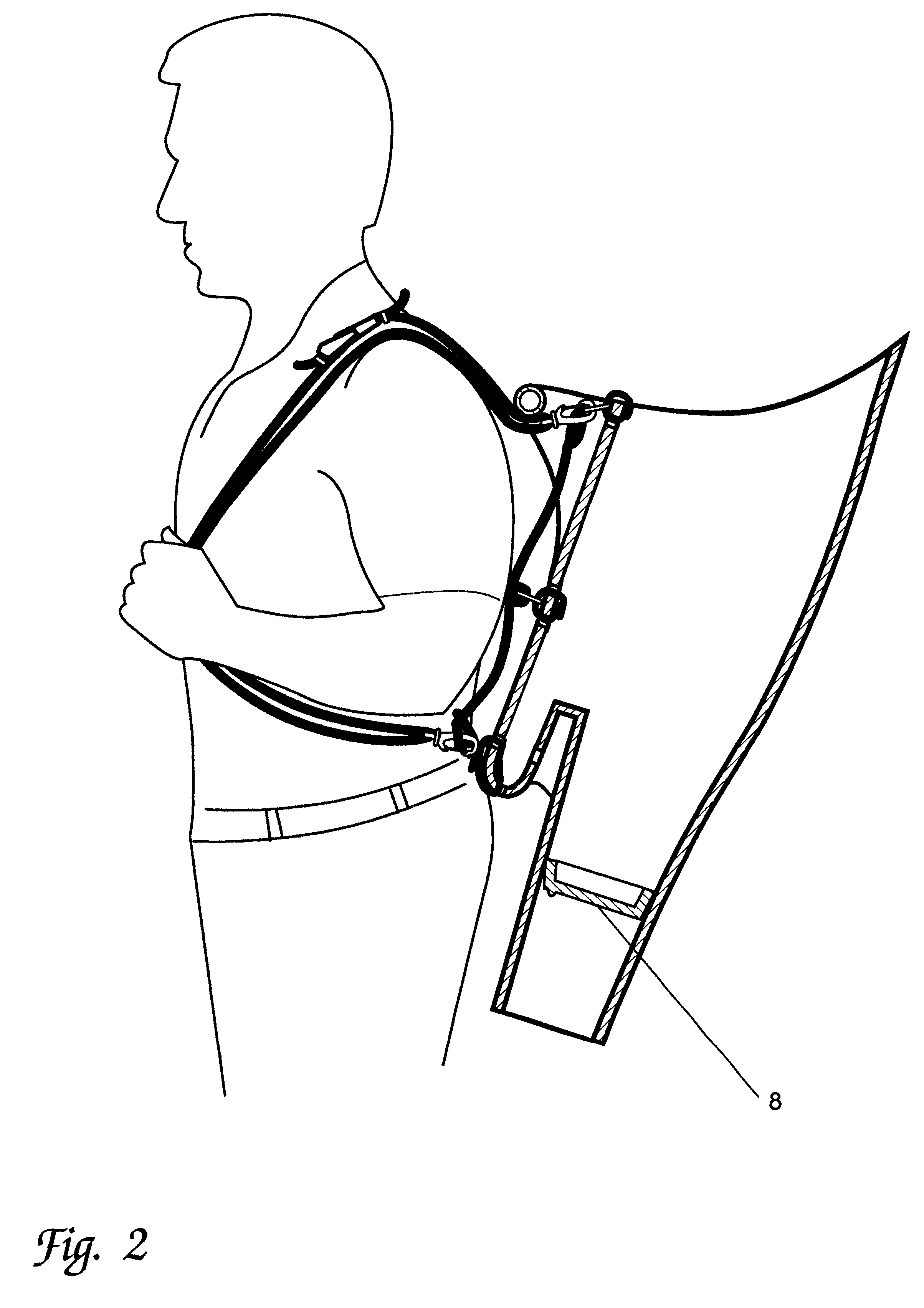

Carrier convertible from a sling carried vessel to a scoop and bag filler

Provided is a carrier convertible from a sling supported vessel to a material handler for filling portable receptacles such as bags from a bulk lot of material. The front end of this unit is a scoop for gathering fluent material. Over top the scoop is a hood that prevents spill out of any material when the unit is raised into an upright position. The hood terminates at a projection that defines a hand grip. The scoop tapers into a flue. This tapering permits multiple units to nest into one another for storage purposes. The flue ends at an opening and the opening is sized so that an industry-specific standard bag fits over the opening. The length of the flue is dimensioned so that upon the bag being placed over the flue a hand can grasp both the carrier and bag easily at the projection. When grasped, the bag is tightened and secured to the carrier by the grasping hand. Other bags of different sizes can be accommodated by either gathering any slack with the gripping hand or making different size units. Above the hood are a pair of stanchions that have a handle traversing the pair. Also, provided is a plug that when placed in the flue inhibits material from passing through that flue and when held in the interior by the projection is stored out of the way during the bagging process.

Owner:MATTHEW HAIN PINER

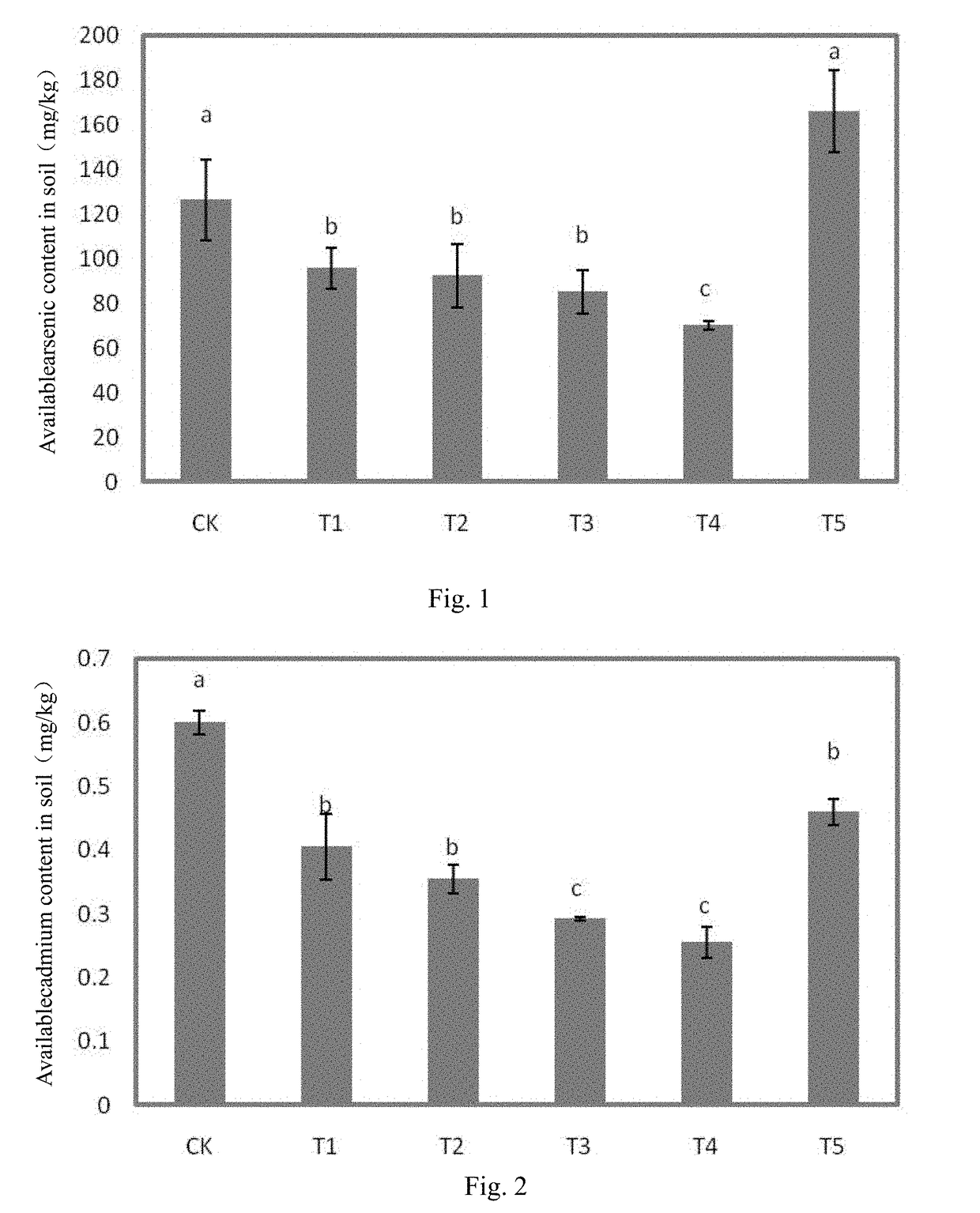

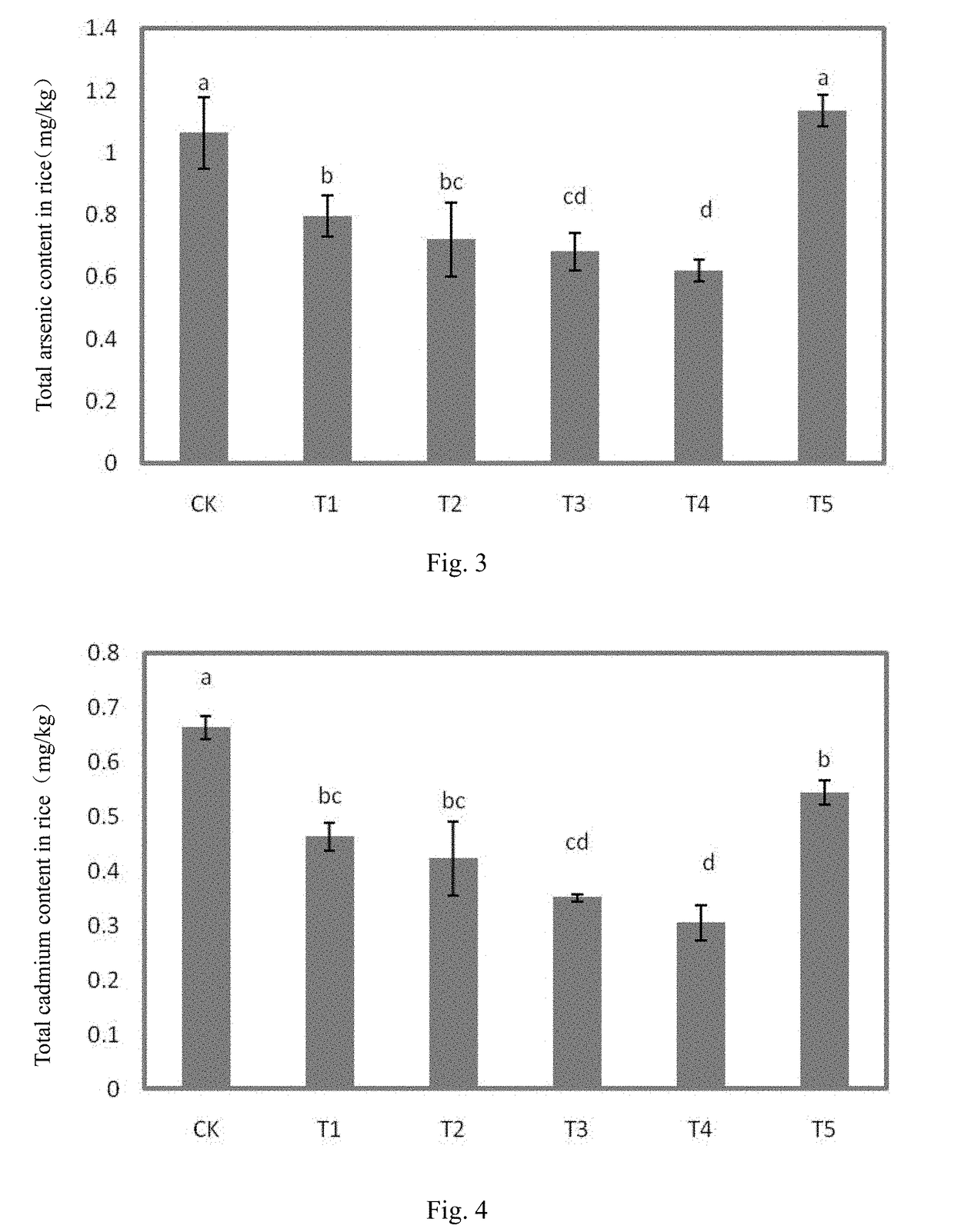

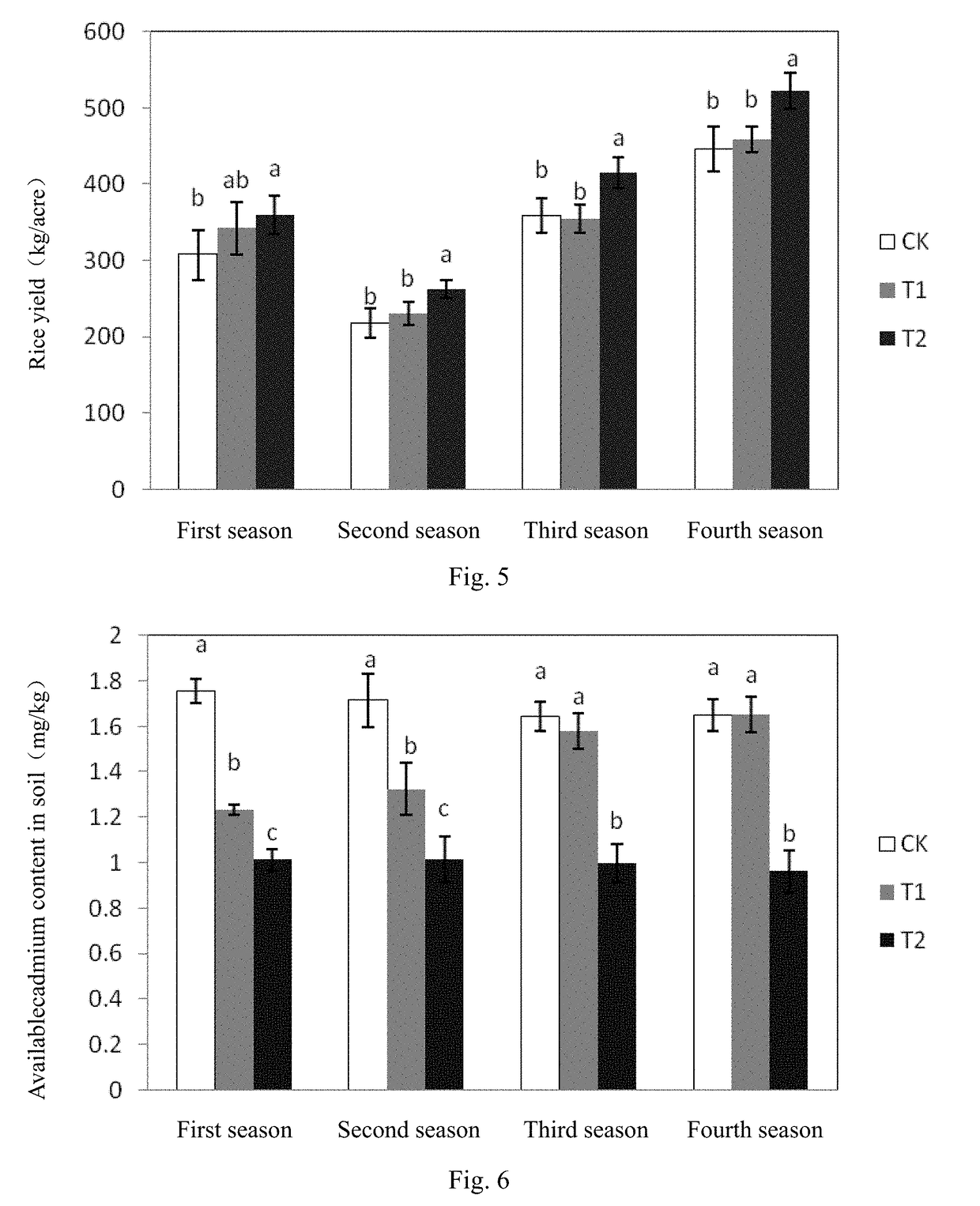

Preparation and use of slow-release iron-based biochar soil heavy metal passivator

ActiveUS20180119008A1Broaden applicationSave materialAgriculture tools and machinesContaminated soil reclamationSoil heavy metalsGrowing season

The invention discloses a method for the preparation and use of a slow-release iron-based biochar soil heavy metal passivator. The slow-release iron-based biochar soil heavy metal passivator of the present invention is prepared by an one-step method, wherein iron-based biochar, kaolin and a biological starch are mixed into a core material in a specific ratio; an acidic silica sol and a chitosan solution are prepared, under the effects of an alkaline catalyst and an emulsifier, as a chitosan and silica-sol composite material as a coating, and the iron-based biochar is coated with the alkaline coating material, with the core material and the coating material being controlled at a certain volume ratio. The passivator has a wide raw material source, a simple and convenient preparation process, easy industrialized production, and can passivate the heavy metal arsenic and cadmium efficiently and inhibit the absorption and accumulation of arsenic and cadmium. The passivator prepared by the present invention can last for 4 growing seasons and has a higher passivation efficiency and a longer action time than common iron-based biochar passivators. The passivator can be widely used in the control of arsenic and cadmium pollution farmland.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

Electronically controlled silicon oil fan control method and controller

PendingCN108518268ASave manpower andShorten the timeCoolant flow controlMachines/enginesControl signalControl engineering

The invention relates to an electronically controlled silicon oil fan, in particular to an electronically controlled silicon oil fan control method and a controller. The controller is arranged in an engine compartment, and a circuit board is arranged between an upper cover plate and a lower cover plate. Electrical elements arranged on the circuit board constitute a control circuit, and the controlcircuit includes a CAN acquisition circuit, an MCU integrated circuit, a power supply circuit and a PWM control circuit. The operating parameters in an ECU of a vehicle are read by the CAN acquisition circuit and sent to the MCU integrated circuit; a fan control signal is formed through the logical judgment of the collected operating parameters by the MCU integrated circuit and sent to the PWM control circuit; the PWM control circuit converts the received fan control signal into a PWM signal to be used for controlling the rotation speed of a fan; and the actual rotation speed value of the fanis dynamically controlled by reading the collected real-time operating parameters of the vehicle.

Owner:DONGFENG BEHR THERMAL SYST

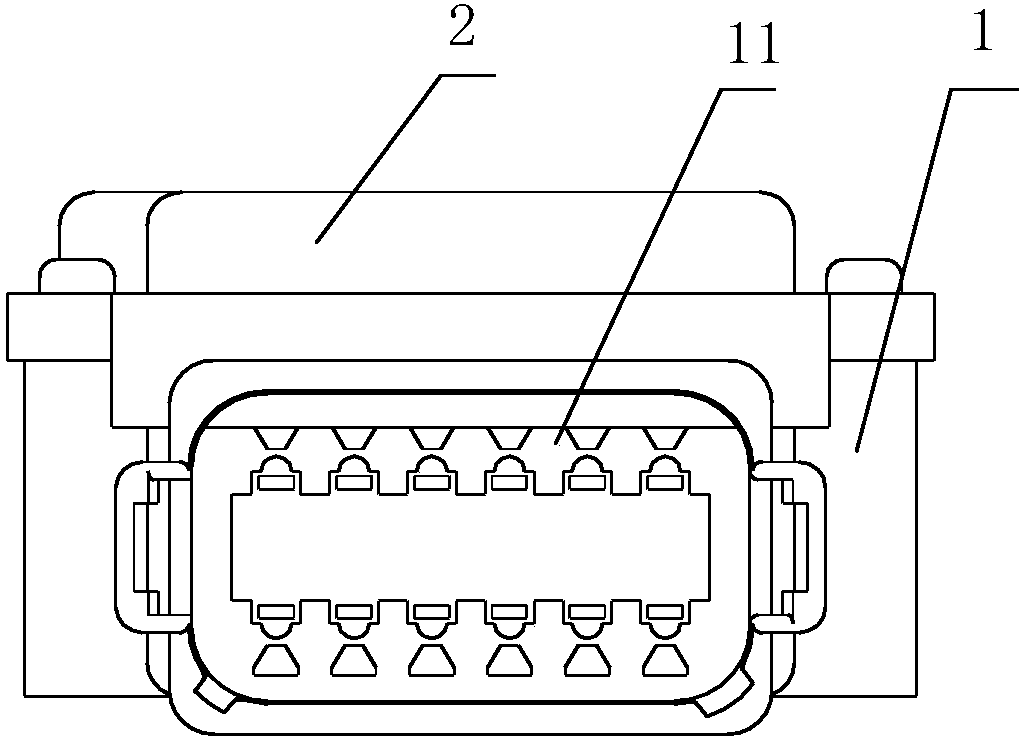

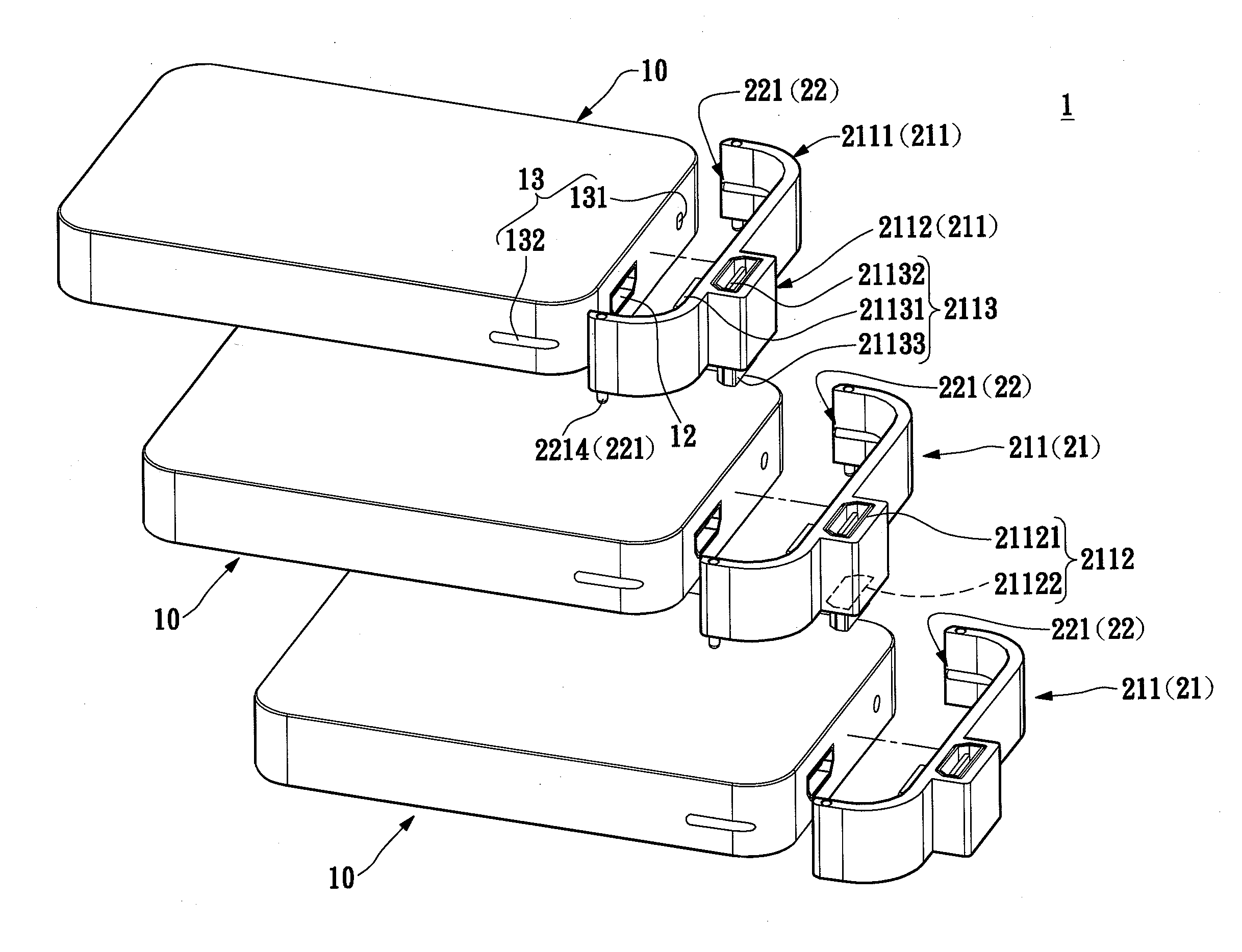

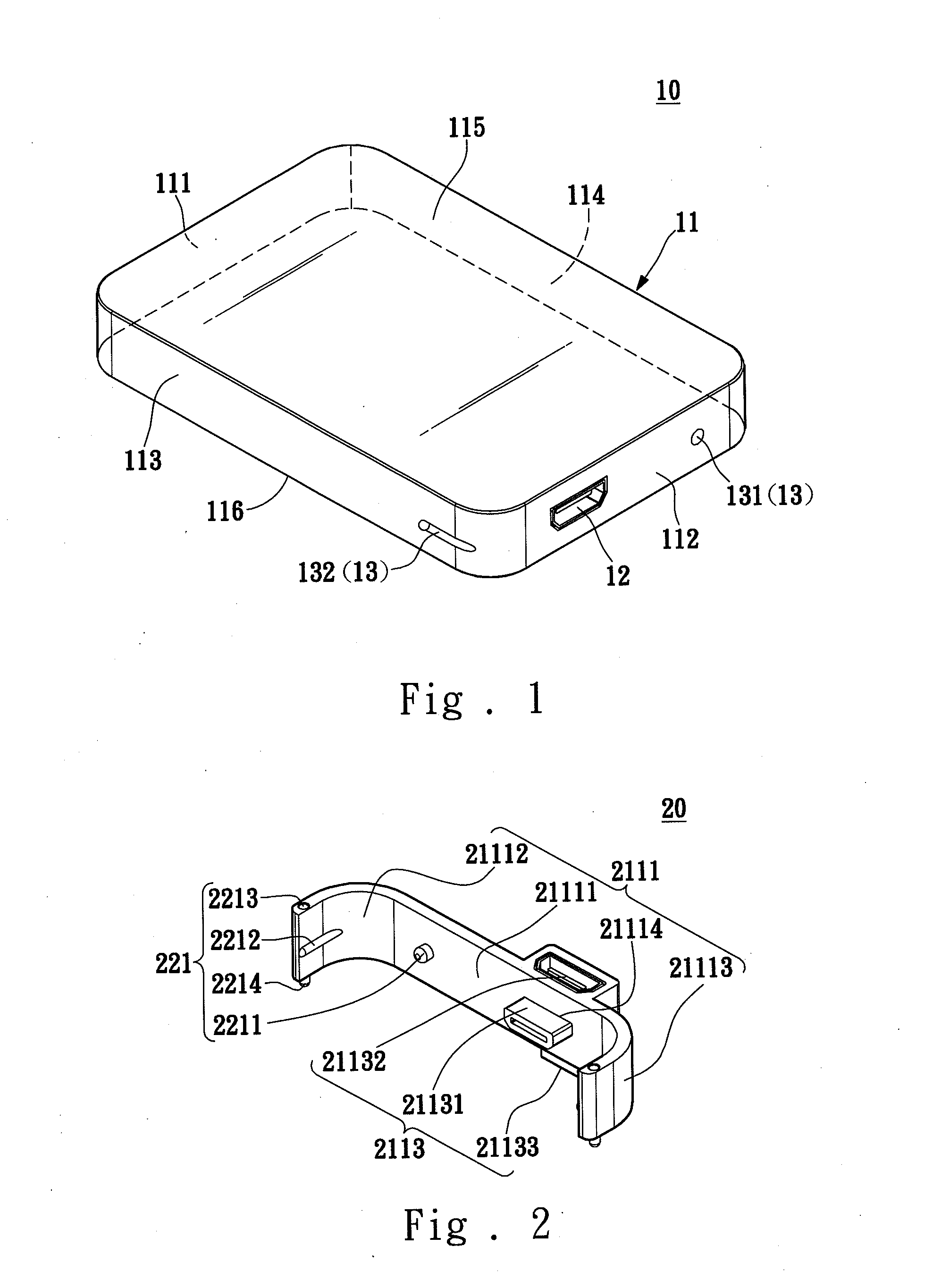

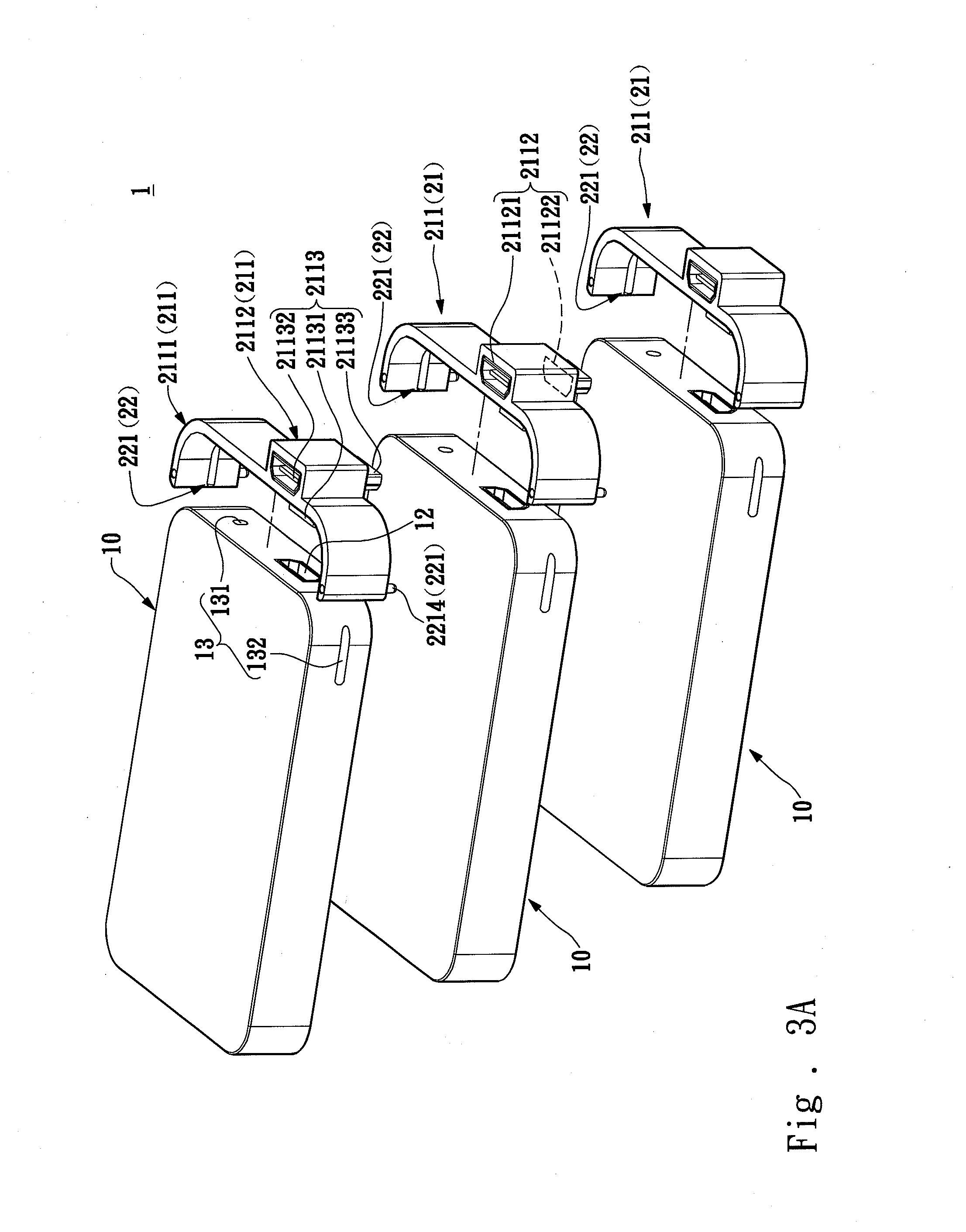

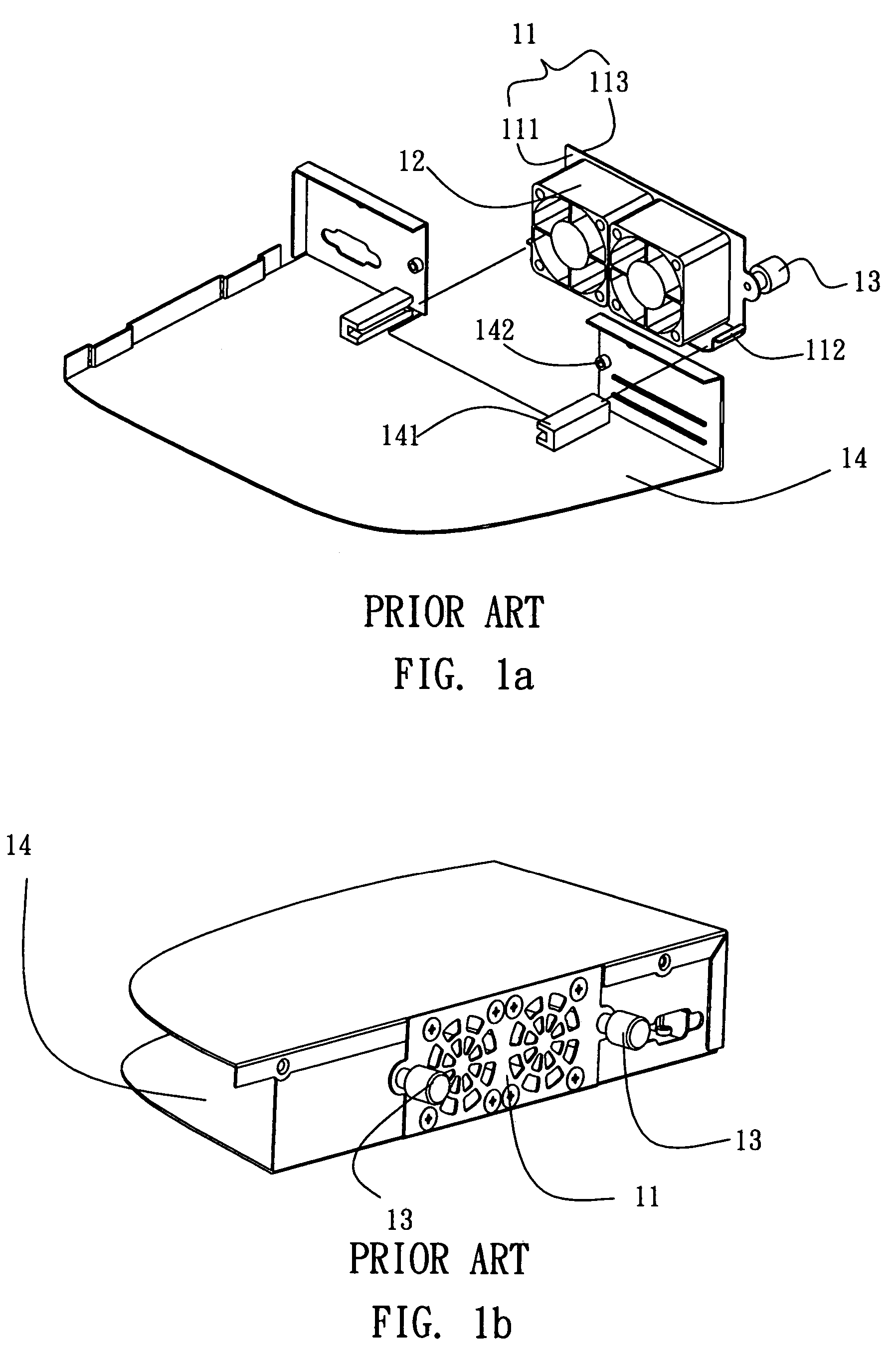

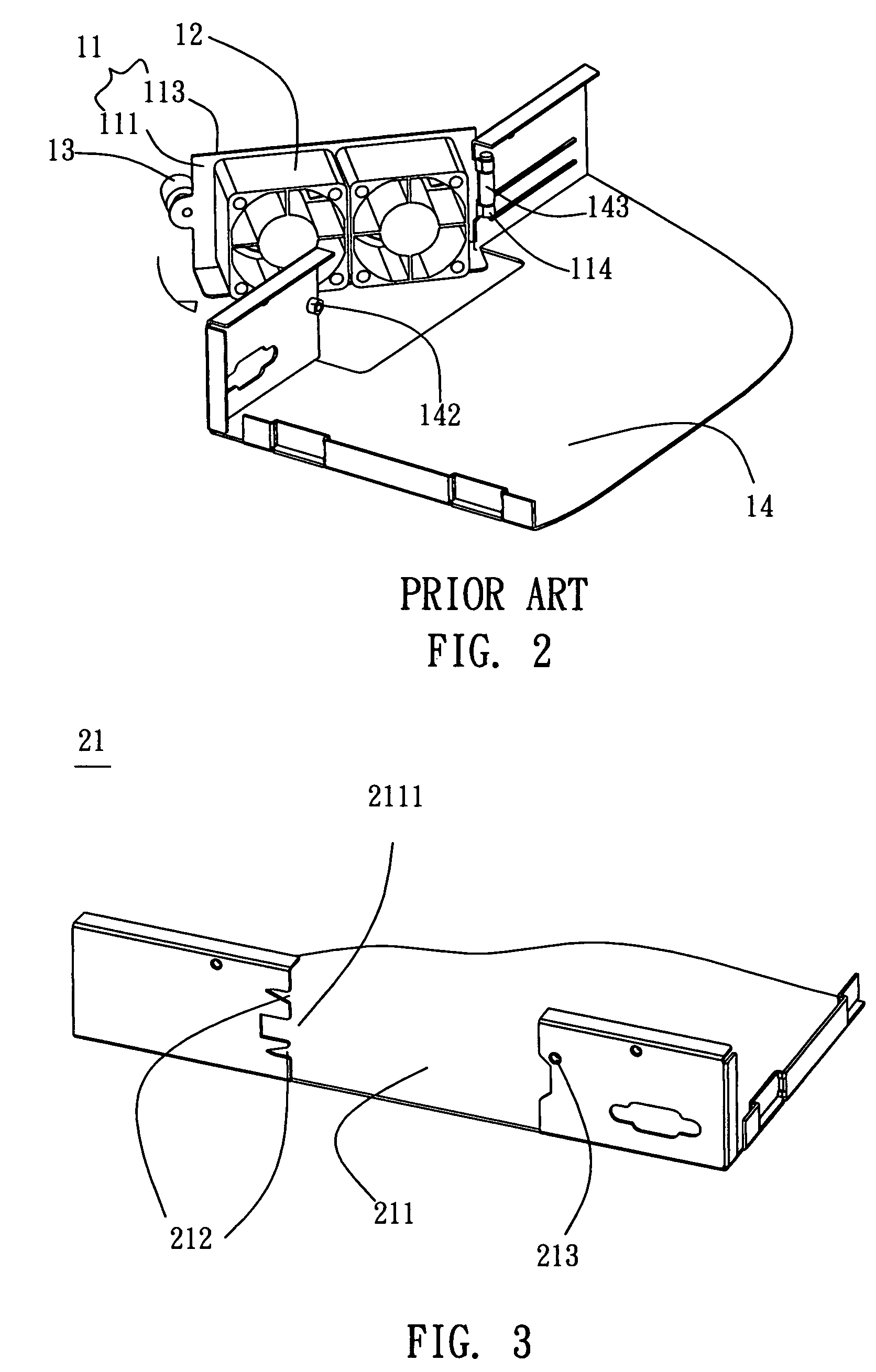

Electronic device assembly structure

ActiveUS20130280940A1Save assembly timeSave manpower andEngagement/disengagement of coupling partsDigital data processing detailsUSBAssembly structure

An electronic device assembly structure comprises two electronic devices and at least one connection module. Each electronic device includes a body and at least one USB located on the body. The connection module connects to the two electronic devices and includes an electric connection unit and a fastening unit. The electric connection unit is electrically inserted into the USBs of the two electronic devices. The fastening unit fastens the bodies of the two electronic devices together in an integrated manner.

Owner:GEMTEK TECH CO LTD

Electronic coin bank

An electronic coin bank comprises a coin bank, a coin-throwing device and a circuit structure, which changed the single function of saving money of a conventional coin bank into an electronic coin bank, wherein a coin-throwing device is provided for setting the values of the coins and throwing the coins, a circuit structure is provided for setting the stored values, the preparedly stored values, the saving progress, the rewarding music, time and alarm clock, and a transmission connector is connected to a computer. Since the diversifying of the functions and by using the finance-managing software installed in the computer, the children will form a good habit of saving.

Owner:I KIDDO

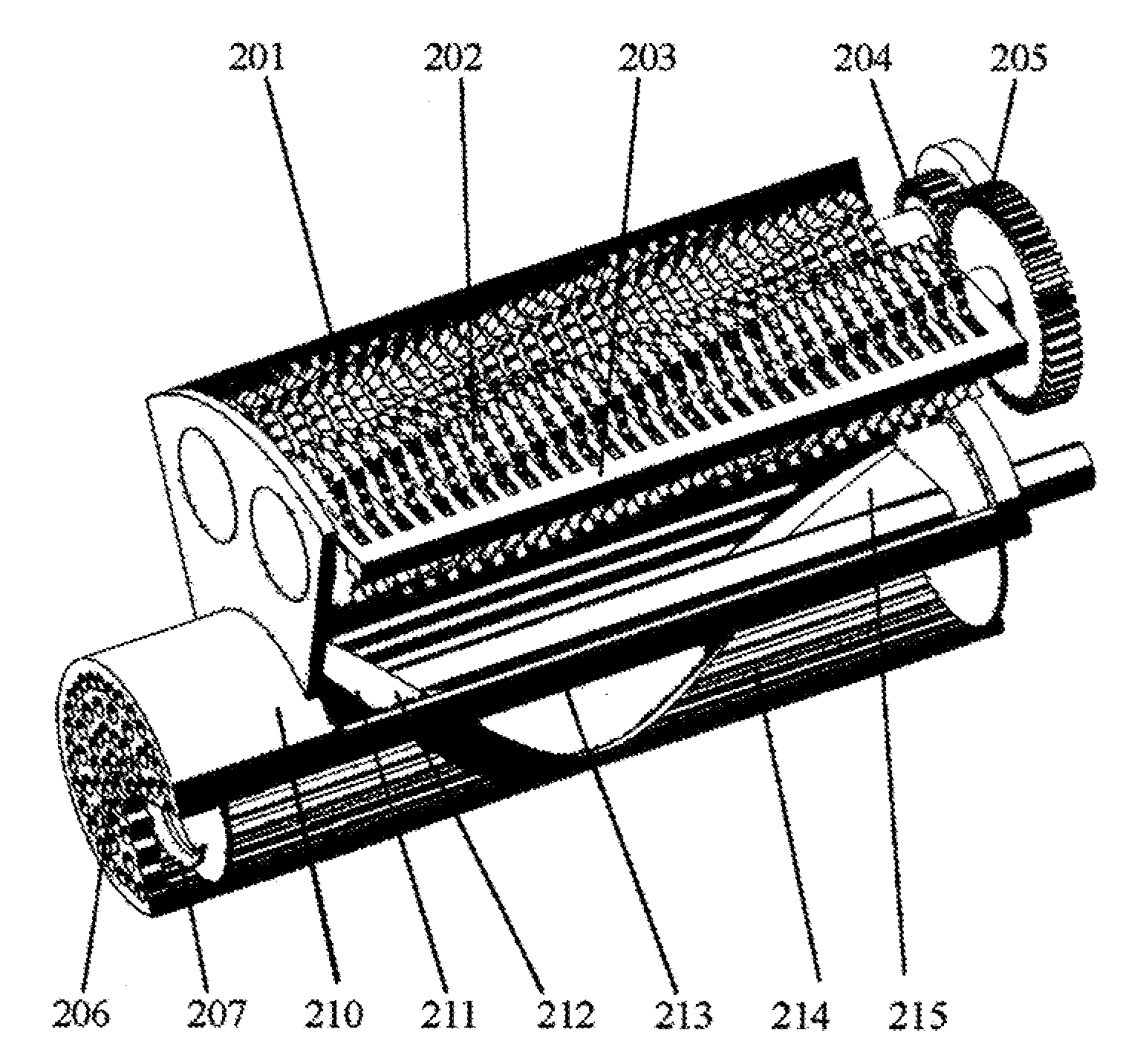

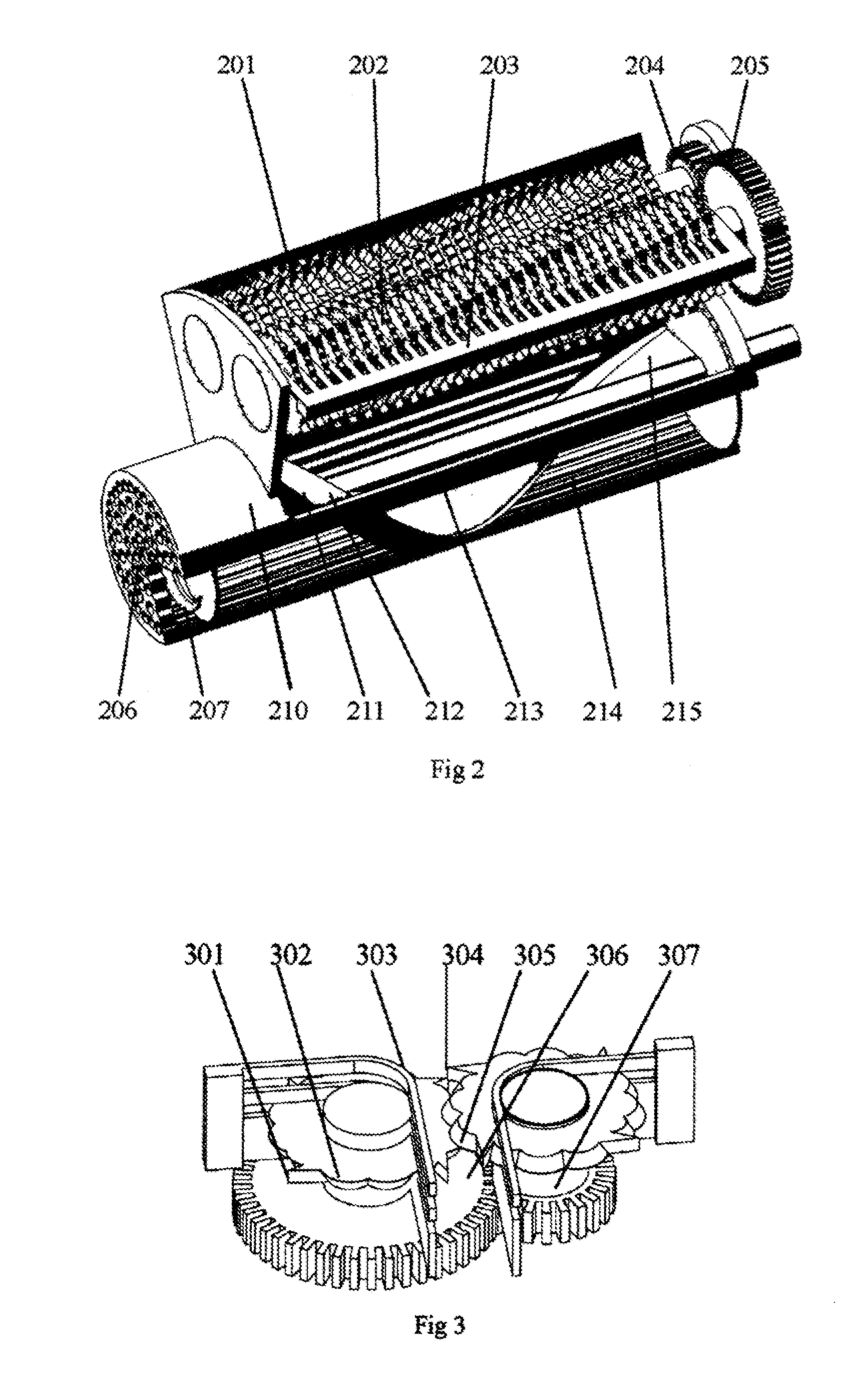

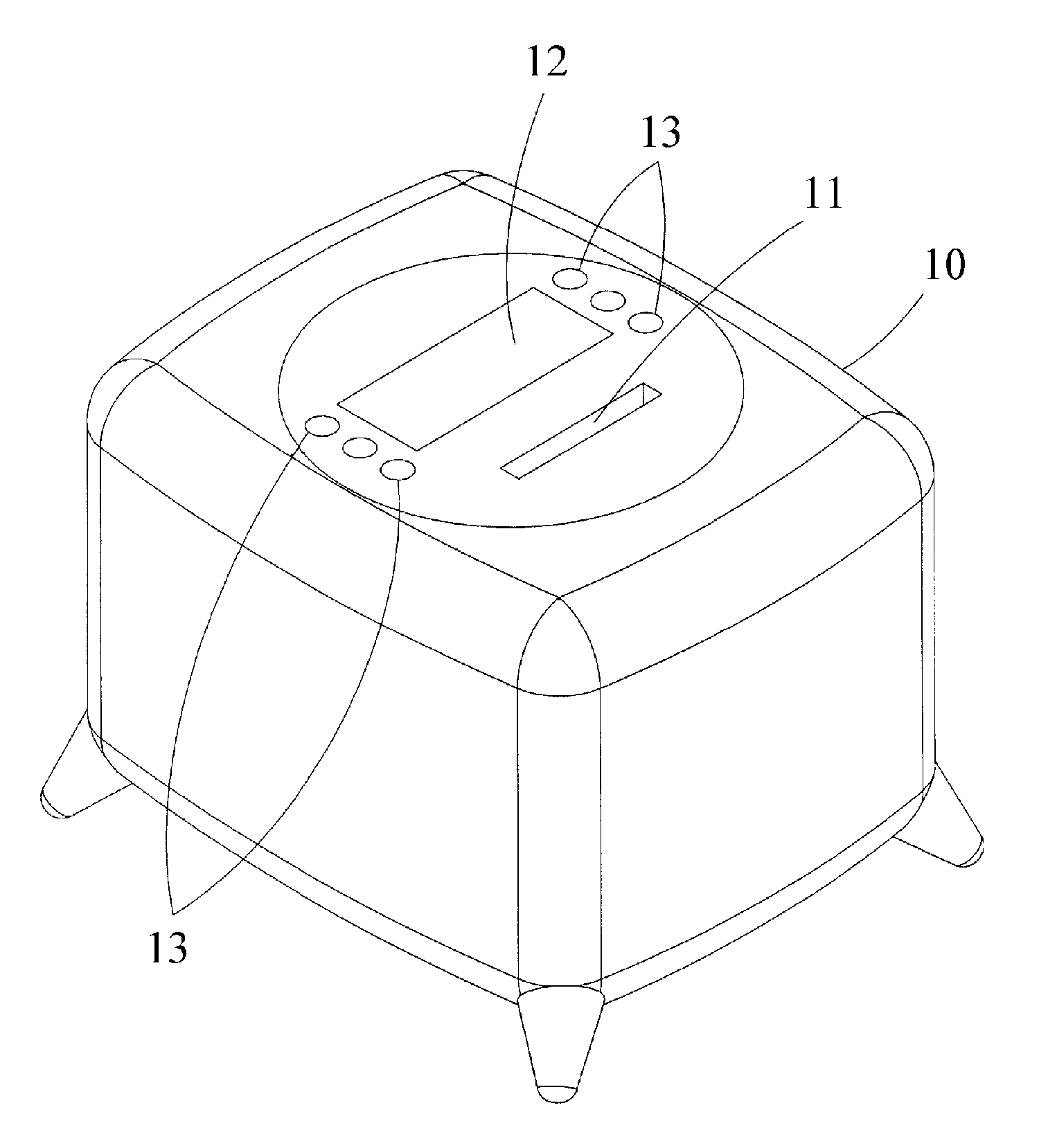

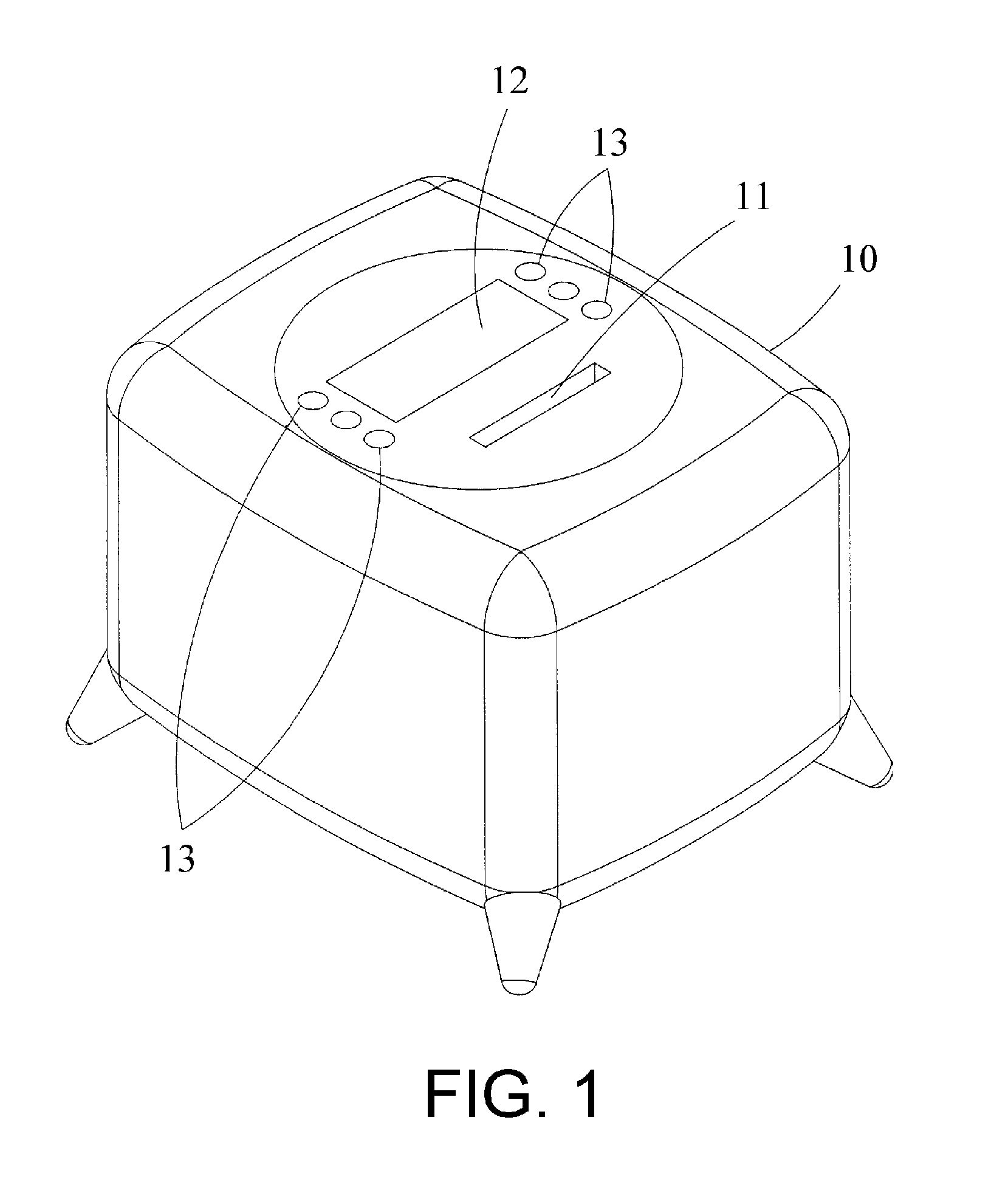

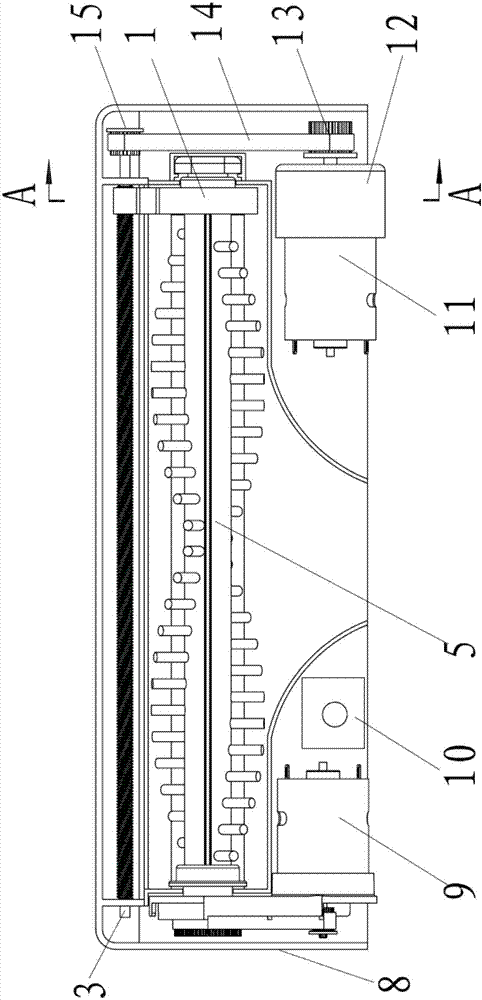

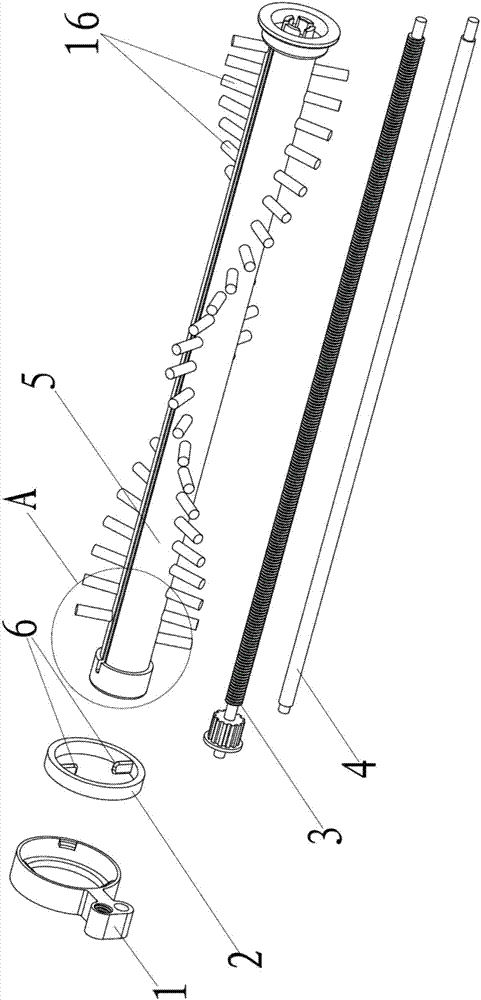

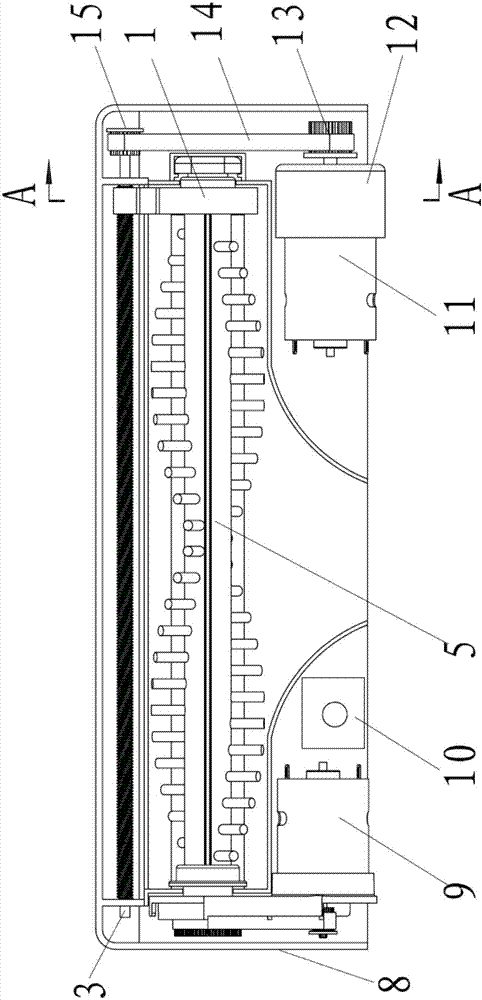

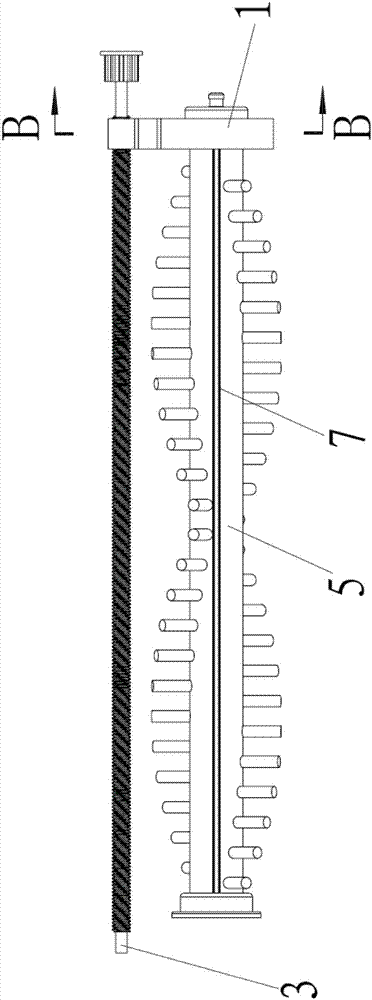

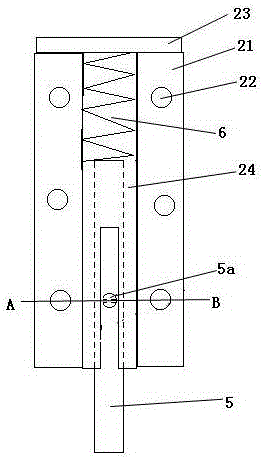

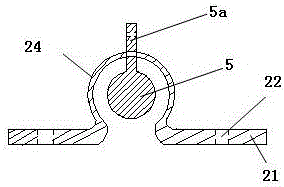

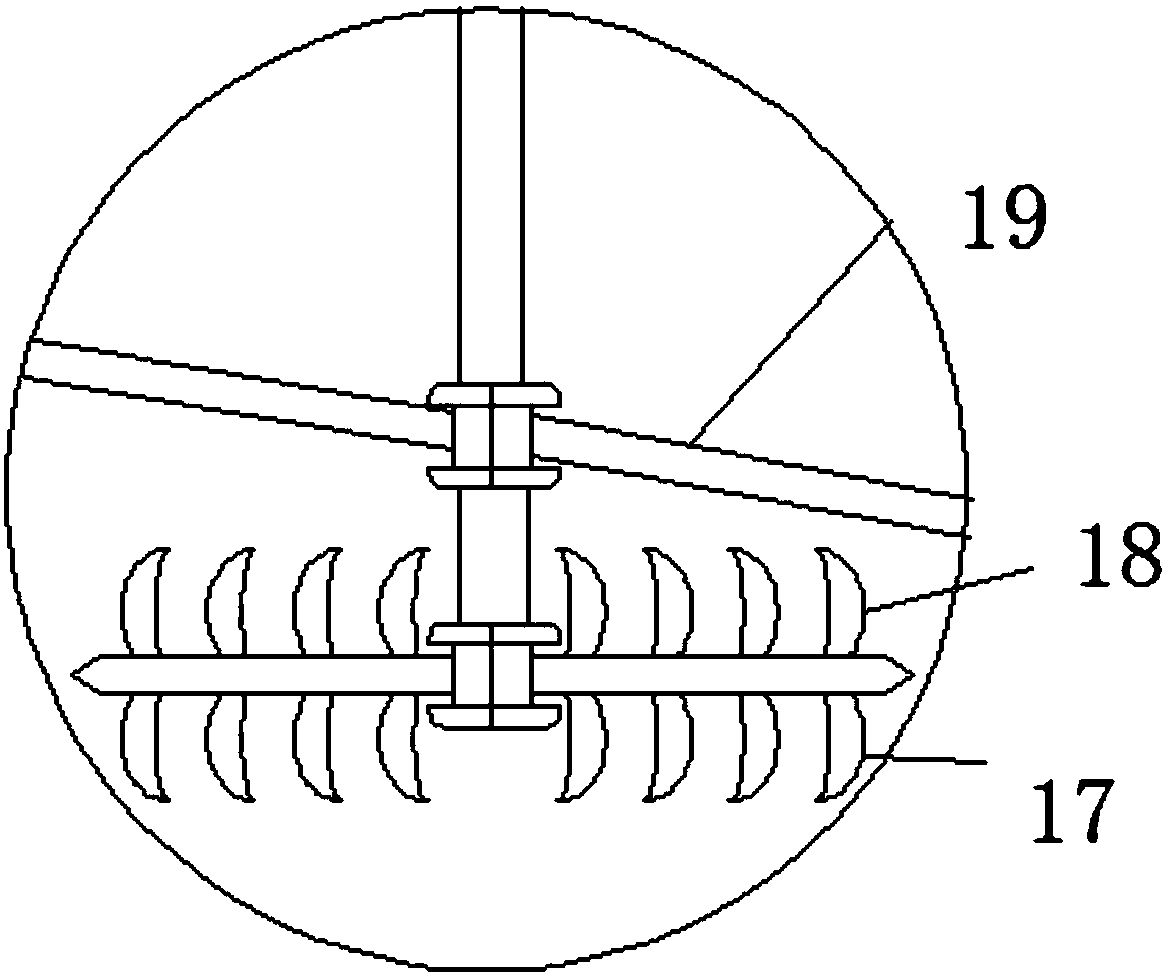

Cutter for cutting rolling brush entanglement on cleaning appliance and cleaning appliance thereof

ActiveCN106923758AEasy to cleanImprove cleaning efficiencyMachine detailsSuction nozzlesAxial displacementAnnular cutter

The invention discloses a cutter for cutting a rolling brush entanglement on a cleaning appliance. The cutter comprises a blade and a cutter rest, wherein the blade is used for cutting the entanglement on the peripheral wall of a rolling brush, connected with an annular cutter head and arranged on the inner ring of the annular cutter head; and the annular cutter head is nested into the cutter rest and has the degree of freedom of rotating along the own axis in the cutter rest, and a limiting structure for limiting axial movement of the annular cutter head is arranged between the cutter frame and the annular cutter head. At least one groove extending axially is formed in the peripheral wall of the rolling brush, the blade extends radially and is inserted into the groove. A fixing and guiding mechanism is provided with a sliding rod arranged in parallel beside the rolling brush and guided axially and a lead screw for outputting axial displacement, and the cutter rest is provided with holes matched with the sliding rod and the lead screw. The invention further provides a cleaning appliance. The cutter automatically cuts the entanglement without exposing the rolling brush, thereby improving the cutting environment and improving the cleaning effect and efficiency.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

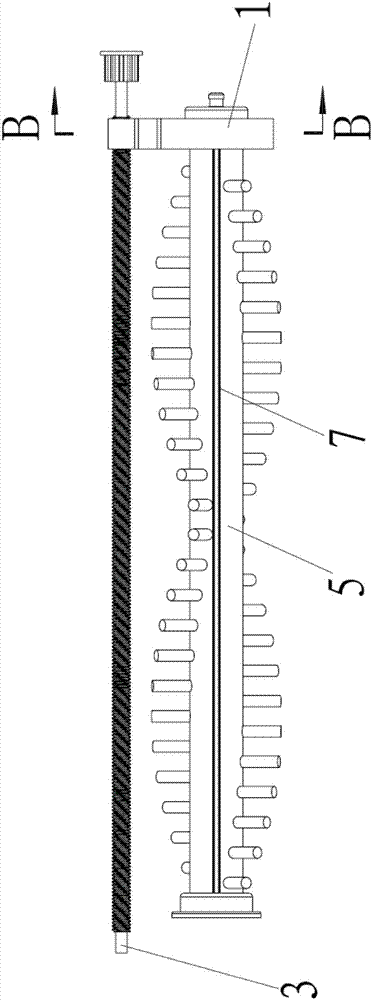

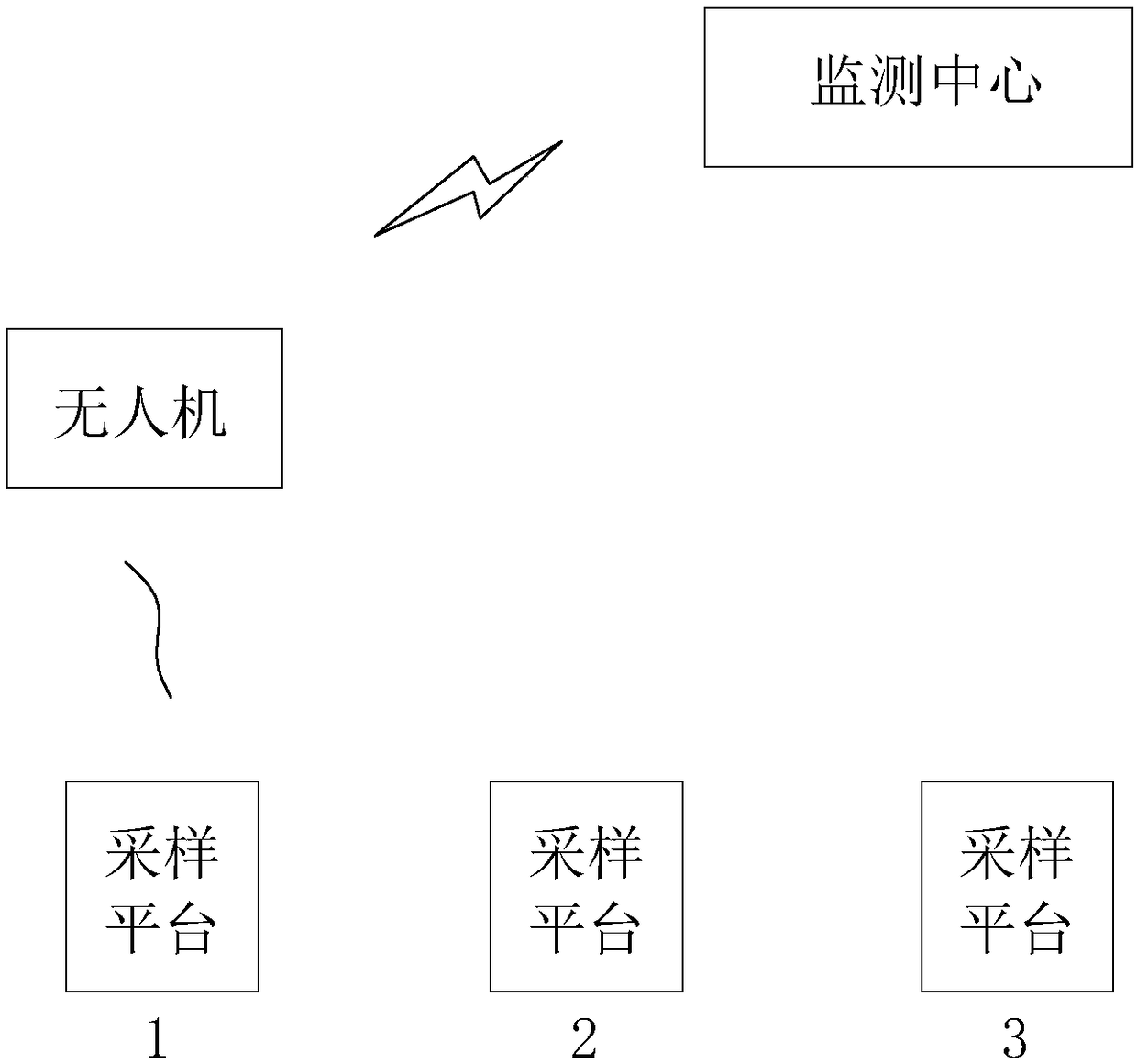

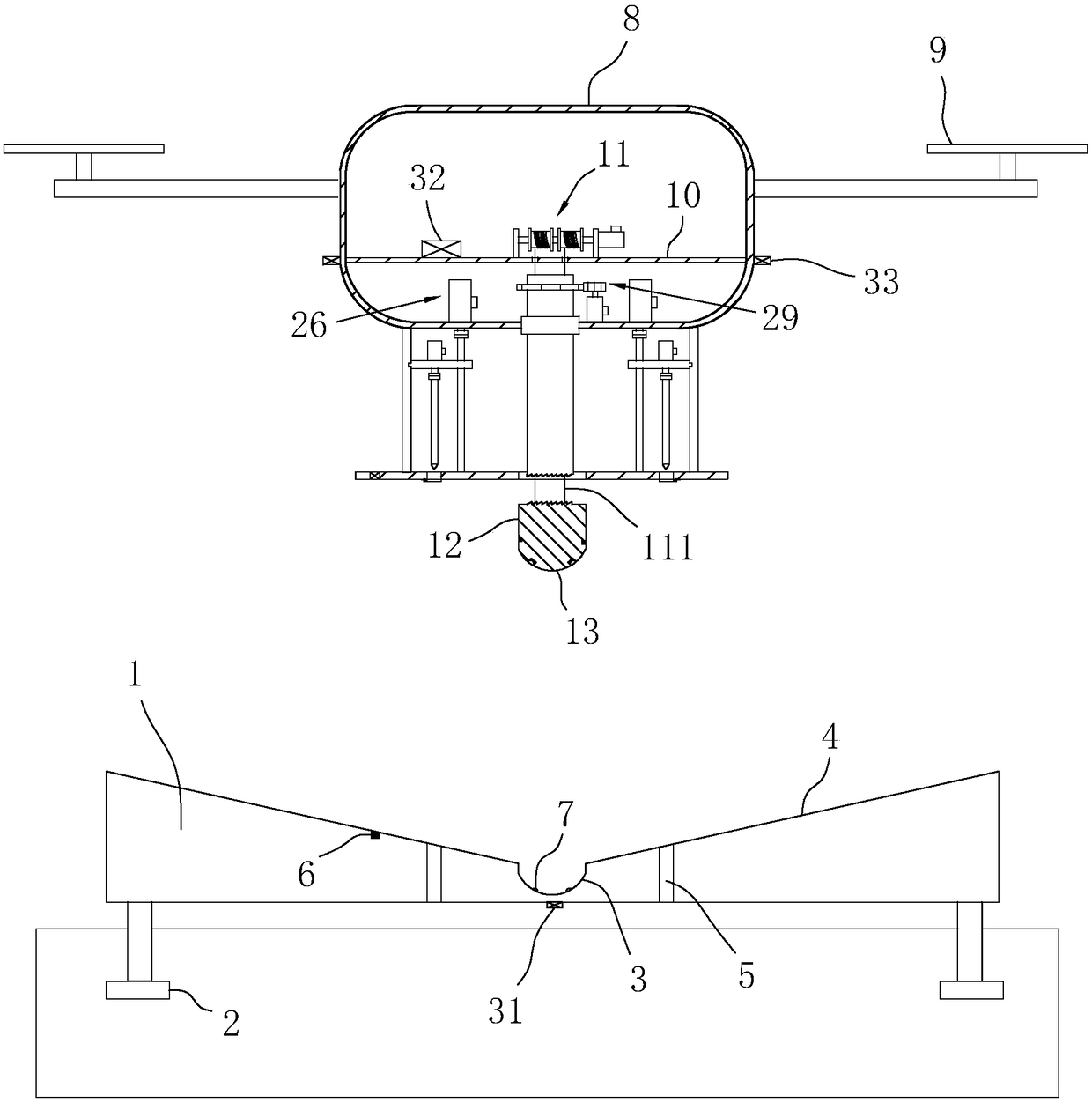

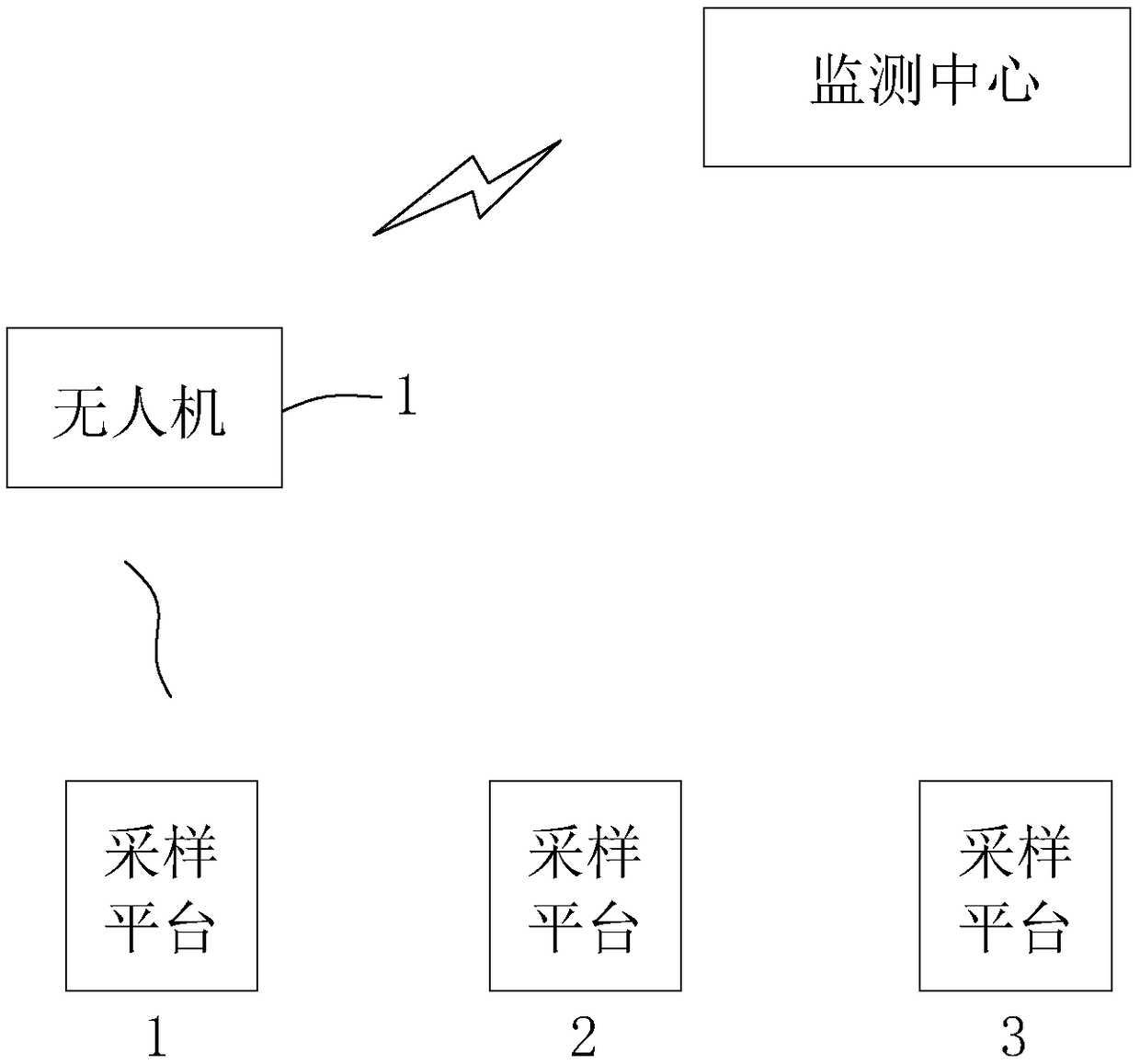

Construction based soil sampling monitoring system and method

InactiveCN108168930AAvoid collectingSave manpower andWithdrawing sample devicesEarth material testingLocation detectionCommunication unit

The invention discloses a construction based soil sampling monitoring system and method. The monitoring system comprises an unmanned plane, a monitoring center, and a sampling platform arranged on a plurality of soil sampling sites. The monitoring center is used to send a driving command to the unmanned plane, and the driving command comprises position information of the soil sampling sites. The unmanned plane comprises a plane body, an unmanned plane controller arranged in the plane body, and a power supply module for supplying electric energy. The unmanned plane controller is connected to anunmanned plane positioning unit and an unmanned plane communication unit. The unmanned plane communication unit responds to the driving command and controls the unmanned plane to start. The unmannedplane controller controls an annular electric magnet and an electric winder to start so as to butt-joint a first connection part and a second connection part, based on a triggering signal sent by a triggering device. A driving part drives a sleeve to rotate so that a position detection device is opposite to a position detection body. An elevating component controls a sampling device to move downwards to go through a sampling opening and a sampling channel to carry out sampling.

Owner:温州市九成建设工程有限公司

Extraction method for shaddock peel essential oil

InactiveCN102618387APromote stratificationImprove qualityEssential-oils/perfumesEconomic benefitsOil water

The invention discloses an extraction method for shaddock peel essential oil. The method comprises the following steps of: firstly selecting fresh shaddocks, peeling off outer shaddock peel oil gland layers and discarding flesh; soaking the shaddock peel oil gland layers in 0.8-1.0 percent NaCl aqueous solution for 2-3 hours, wherein the mass-volume ratio of shaddock peel to the NaCl aqueous solution is 1:4-5; squeezing the soaked shaddock peel by using a spiral squeezer to obtain oil-water mixed liquor containing some pigments, phlegm and shaddock peel residue; standing under reduced pressure and layering, discarding a water layer and the shaddock peel residue to obtain mixed liquor containing some pigments, phlegm and a small amount of water; and distilling the mixed liquor under reduced pressure, cooling distillate to obtain oil-water mixed liquor, naturally layering the oil-water mixed liquor and discarding the water layer to obtain the shaddock peel essential oil. The extraction method has the advantages of good quality of obtained essential oil, low cost, simple process, high operability, high production efficiency and good economic benefit.

Owner:广东帝浓酒业有限公司

Method for testing direct current resistance of large transformer without disconnecting lead

InactiveCN101769961ASave manpower andShorten the timeResistance/reactance/impedenceElectrical testingElectrical resistance and conductanceTransformer

The invention discloses a method for testing direct current resistance of a large transformer without disconnecting a lead. In the method, a direct current resistance tester is used for testing the current resistance of the transformer, during testing, a transformer testing loop comprises a segment of lead, the current resistance tester directly carries out measurement on a node of a pile head of the lead, and after measurement is finished, the obtained resistance minus the resistance of the lead is the required direct current resistance of the transformer. The testing loop comprises a segment of lead, but the direct current resistance required to be measured is obtained by computation, thus realizing measuring the current resistance of the transformer without disconnecting the lead, saving lots of labor power and saving the time.

Owner:上海市南供电设计有限公司 +1

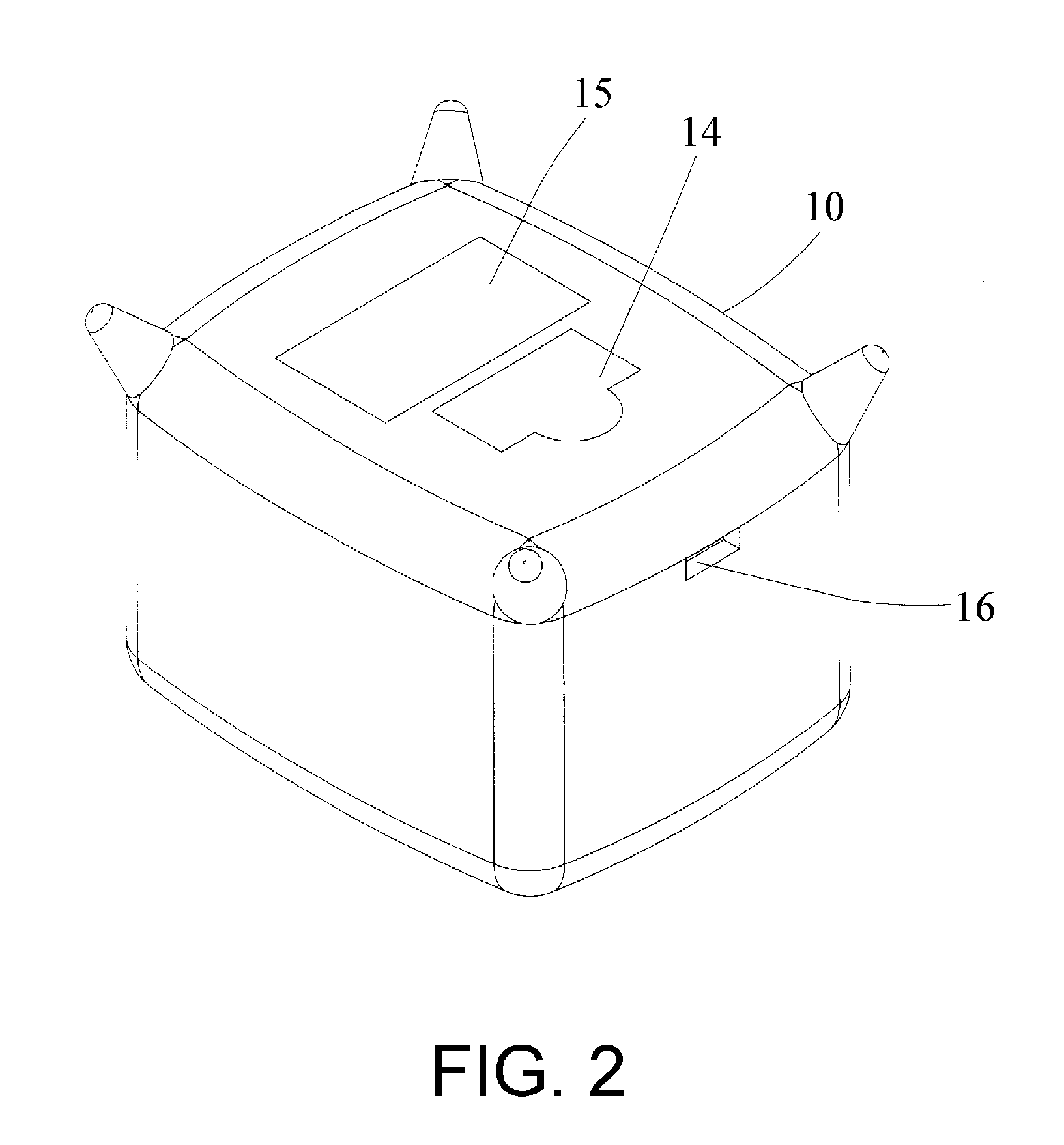

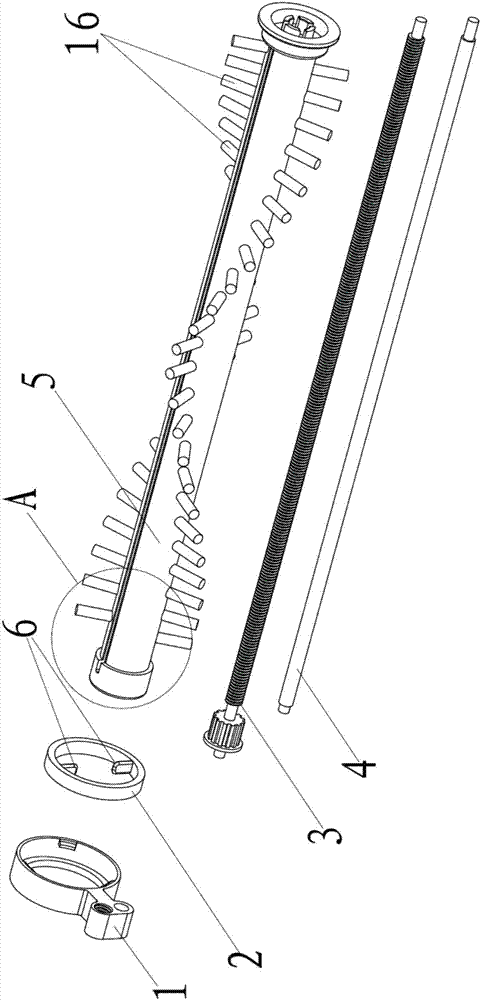

Rolling brush entanglement cutting device for cleaning appliance and cleaning appliance thereof

ActiveCN106923747AEasy to cleanImprove cleaning efficiencyMachine detailsSuction nozzlesAxial displacementAnnular cutter

The invention discloses a rolling brush entanglement cutting device for a cleaning appliance. The device comprises a blade and a fixing and guiding mechanism, wherein the blade is used for cutting the entanglement on the peripheral wall of a rolling brush; and the fixing and guiding mechanism is independently arranged outside the rolling brush and used for fixing the blade and guiding moving and cutting of the blade along the axis of the rolling brush. At least one groove extending axially is formed in the peripheral wall of the rolling brush, and the blade is inserted into the groove. The blade is connected with an annular cutter head, arranged on the inner ring of the annular cutter head, arranged in a manner of extending in the radial direction of the annular cutter head, and provided with cutting edges along two axial ends of the annular cutter head. The fixing and guiding mechanism is provided with a sliding rod arranged in parallel beside the rolling brush and guided axially and a lead screw for outputting axial displacement, and the cutter rest is provided with holes matched with the sliding rod and the lead screw. The invention further provides a cleaning appliance. The device automatically cuts the entanglement without exposing the rolling brush, thereby improving the cutting environment and improving the cleaning effect and efficiency.

Owner:SUZHOU CHUNJU ELECTRIC CO LTD

Internal Electron Donor Compound for Preparing Alpha-olefin Polymerization Catalyst Component

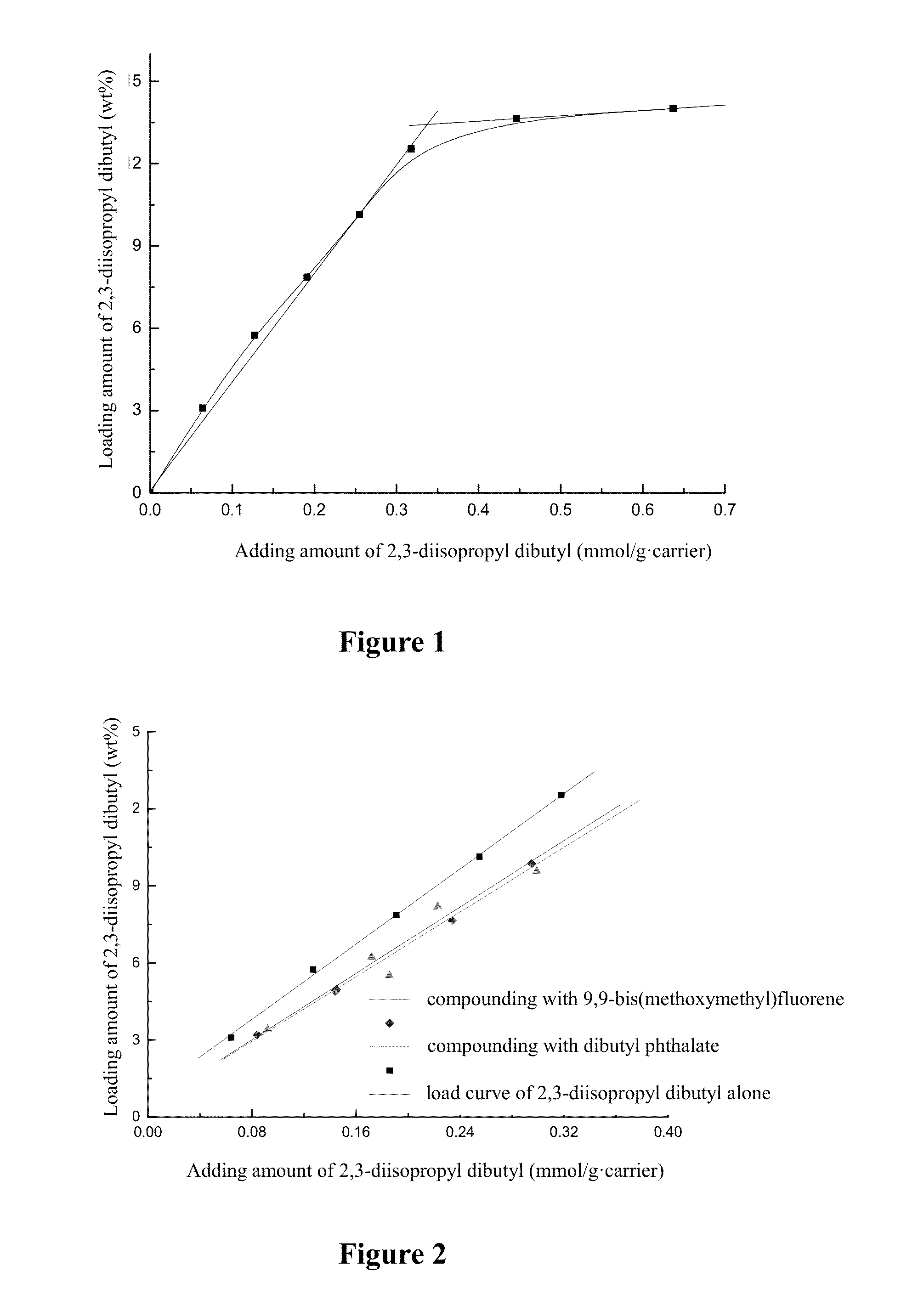

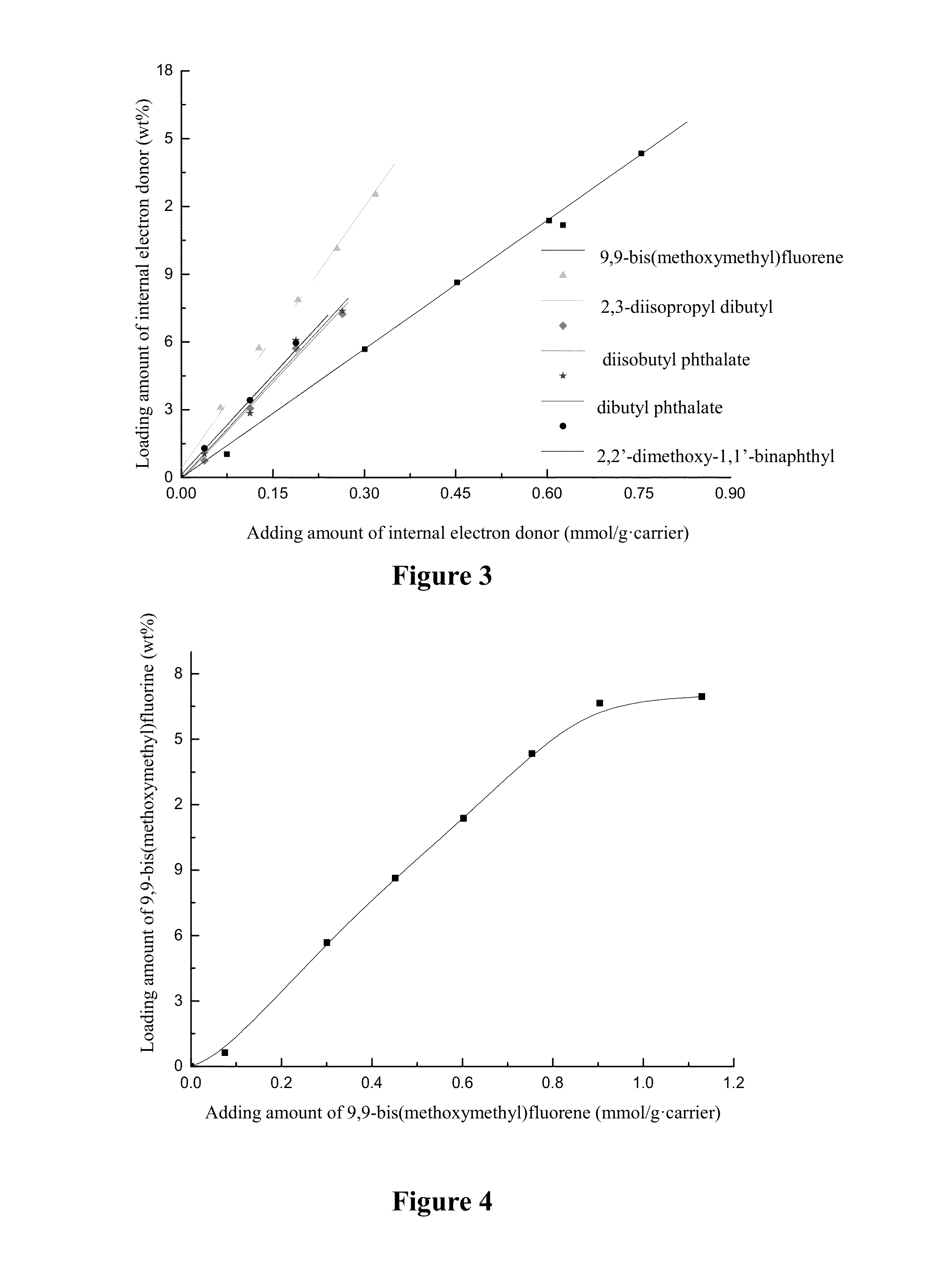

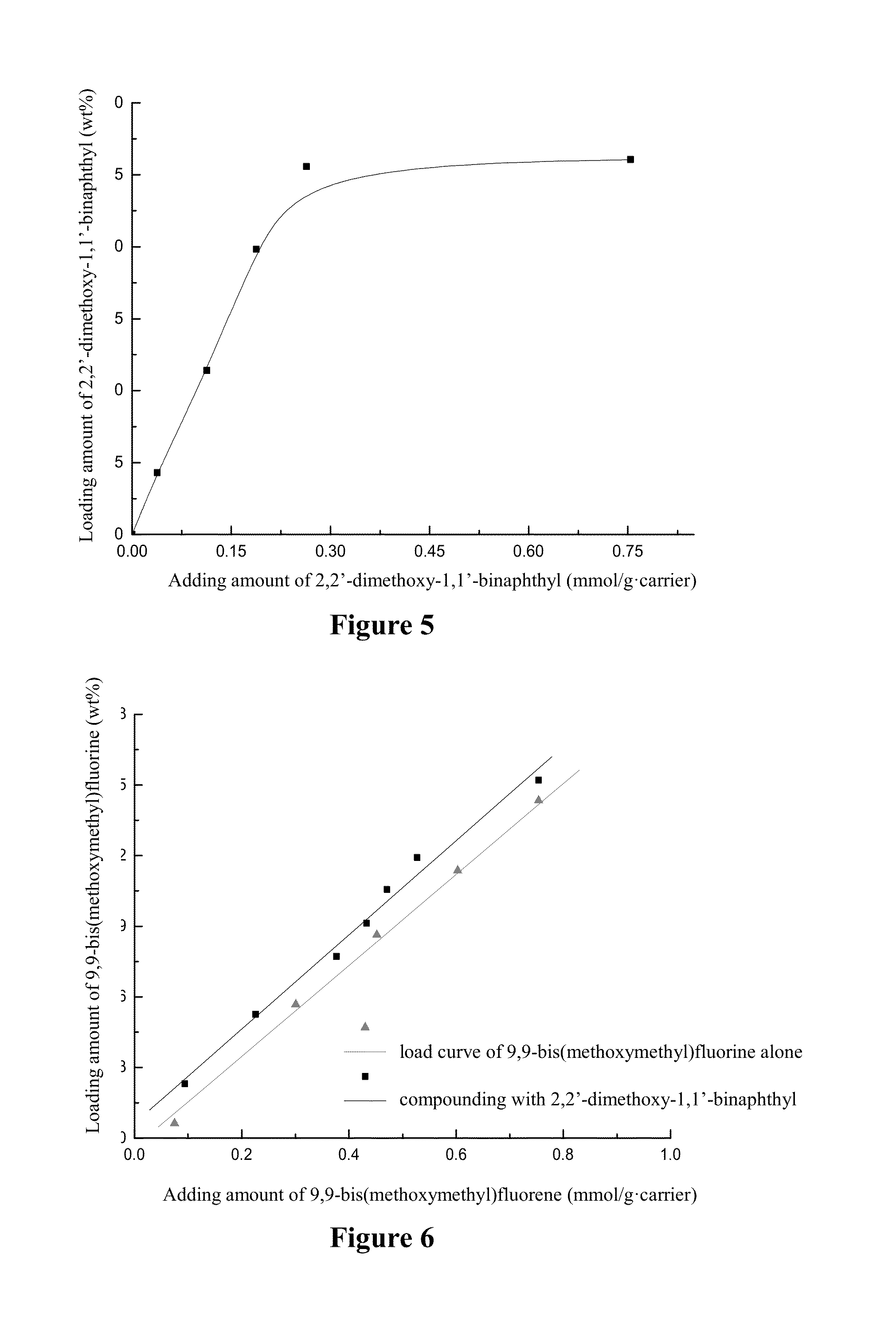

ActiveUS20160229935A1Improve scienceReduce blindnessOrganic chemistryOrganic compound preparationAlcoholElectron donor

An internal electron donor compound for preparing α-olefin polymerization catalyst component, including two kinds of electron donors; the proportion of the two kinds of electron donors in the compounding preparation of the catalyst is determined via designed experiments so as to obtain a catalyst component having good comprehensive performance or a particular performance. The electron donor compound of the present invention can be used in the preparation of α-olefin polymerization and co-polymerization catalyst component, particular the preparation of propylene polymerization catalyst component, and is applicable to prepare the propylene polymerization catalyst component by reacting magnesium chloride-ethanols complex compound carrier with titanium tetrachloride and electron donors, or to directly prepare the propylene polymerization catalyst component by reacting magnesium chloride, alcohols, titanium tetrachloride, and internal electron donor. In addition, also provided is a theoretical basis for selecting a proper electron donor combination from a plurality of electron donors.

Owner:YINGKOU XIANGYANG CATALYST +1

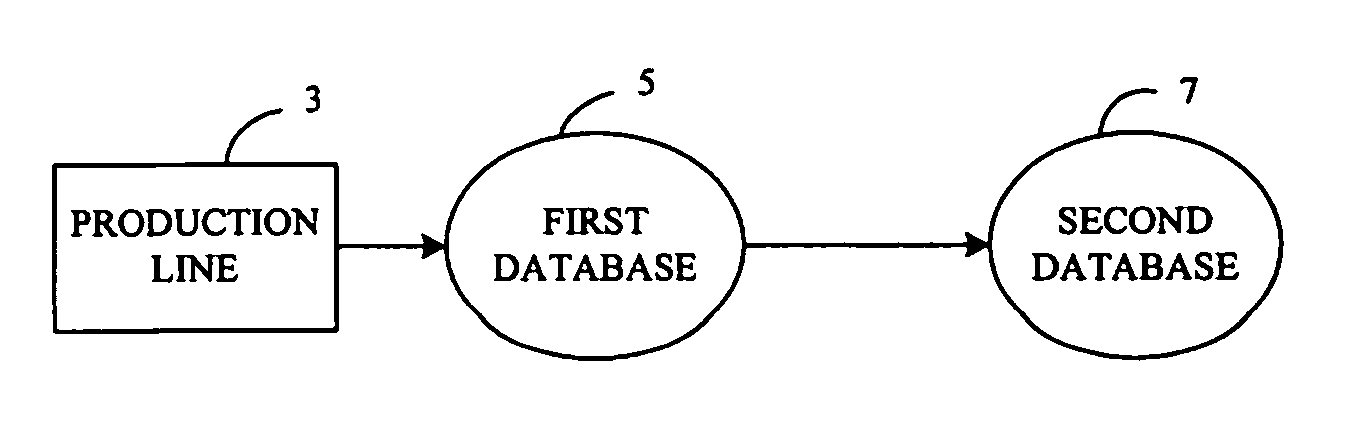

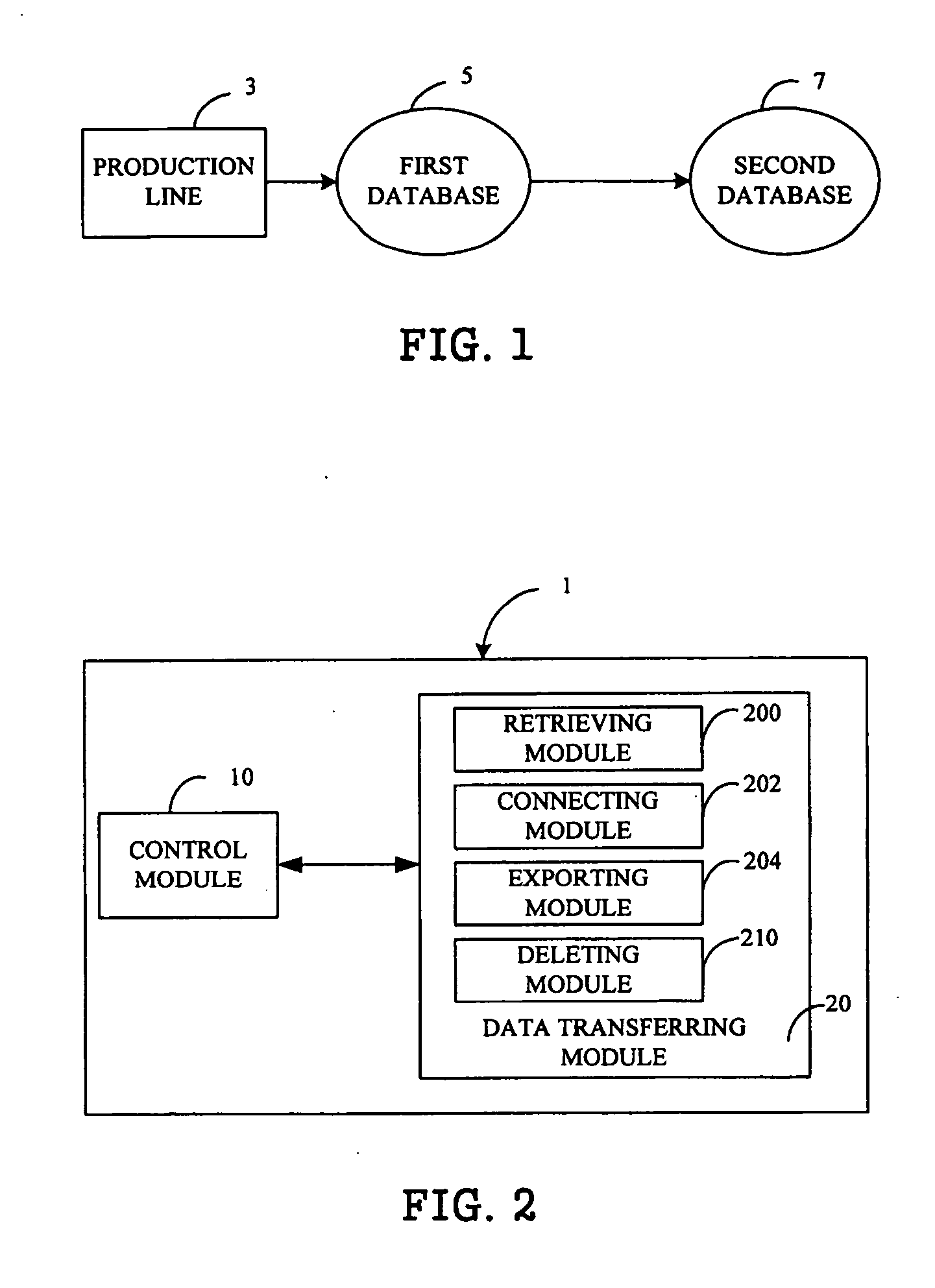

System and method for automatically transferring data from one database to another

InactiveUS20060253499A1Save manpower andShorten the timeStructured data retrievalSpecial data processing applicationsData shippingData transmission

A system (1) for transferring data from one database to another database includes a control module (10) and a data transferring module (20). The data transferring module is controlled by the control module, and in one embodiment includes a retrieving module (200), a connecting module (202), an exporting module (204), and a deleting module (210). The data transferring module automatically retrieves data from a first database (5), exports retrieved data to a second database (7), and automatically deletes data that has been retrieved in the first database. A corresponding method for automatically transferring data from one database to another database is also provided.

Owner:HON HAI PRECISION IND CO LTD

Planting method for Daningcodonopsispilosula

The invention belongs to the technical field of cultivation of traditional Chinese herbal medicines, and particularly relates to a planting method for Daningcodonopsispilosula. The planting method comprises the following steps: (1)ploughing; (2) sowing; (2) transplanting; (3) performing field management. According to the planting method for the Daningcodonopsispilosula provided by the invention, seeds are sown after being uniformly mixed with manure, so that thesoil is not required to be improved by using river sand and the like; the dependence of the codonopsispilosulaon pesticides is reduced by the planting method disclosed by the invention, and the codonopsispilosula is particularly suitable for being planted in southwest regions; in addition, weeding of the field managementof theplanting method is started after autumn, so that the growth of thecodonopsispilosula cannot be influenced; the weeding frequency is reduced; the human labor is reduced; the labor management cost is reduced.

Owner:广西花瓣雨特色中药材种植有限公司

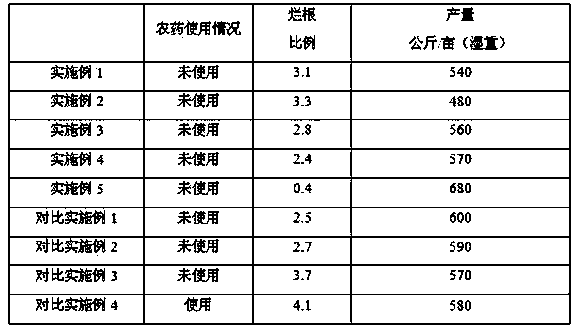

Electrical apparatus

ActiveUS7413402B2Easy to disassembleSave manpower andPump componentsEngine componentsEngineeringMechanical engineering

Owner:ASUSTEK COMPUTER INC

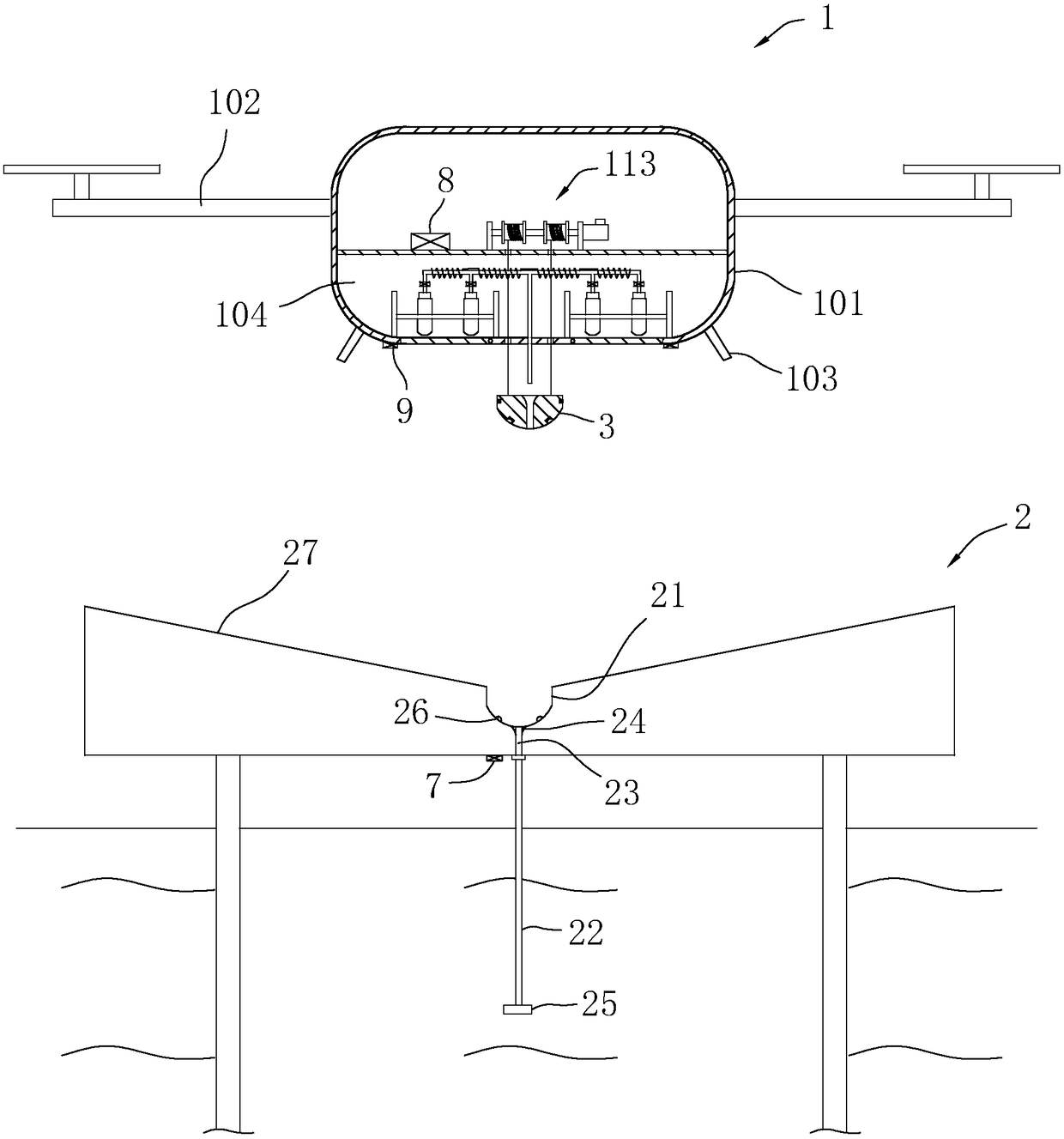

Comprehensive hydro-project quality monitoring system and method

InactiveCN108072543ASave on the use of human laborImprove efficiencyAircraft componentsWithdrawing sample devicesQuality monitoringEngineering

The invention discloses a comprehensive hydro-project quality monitoring system and a comprehensive hydro-project quality monitoring method. According to the technical scheme, the system comprises anunmanned aerial vehicle, a monitoring center and sampling platforms, wherein the sampling platforms are positioned on a plurality of water body sampling points; an air tube and a plurality of samplingbottles in vacuum sealing are arranged inside a machine body; one end of the air tube extends outside the bottom of the machine body; the other end of the air tube is communicated with each samplingbottle; an electromagnetic valve is mounted between each sampling bottle and the air tube; an electronic wire coiler is arranged inside the machine body; the electromagnetic valve and the electronic wire coiler are connected with an unmanned aerial vehicle controller; a traction block matched with an accommodation groove is arranged at the bottom of the machine body; a semispherical surface matched with an inner concave surface is arranged at the bottom of the traction block; the traction block is connected with the electronic wire coiler; a channel is formed in the traction block; the air tube penetrates through the channel and is connected with a siphon tube; a triggering device for detecting whether the traction block is fed into the accommodation groove or not, and an annular electromagnet for sucking an annular iron ring are arranged on the outer wall of the traction block.

Owner:浙江化工工程地质勘察院有限公司

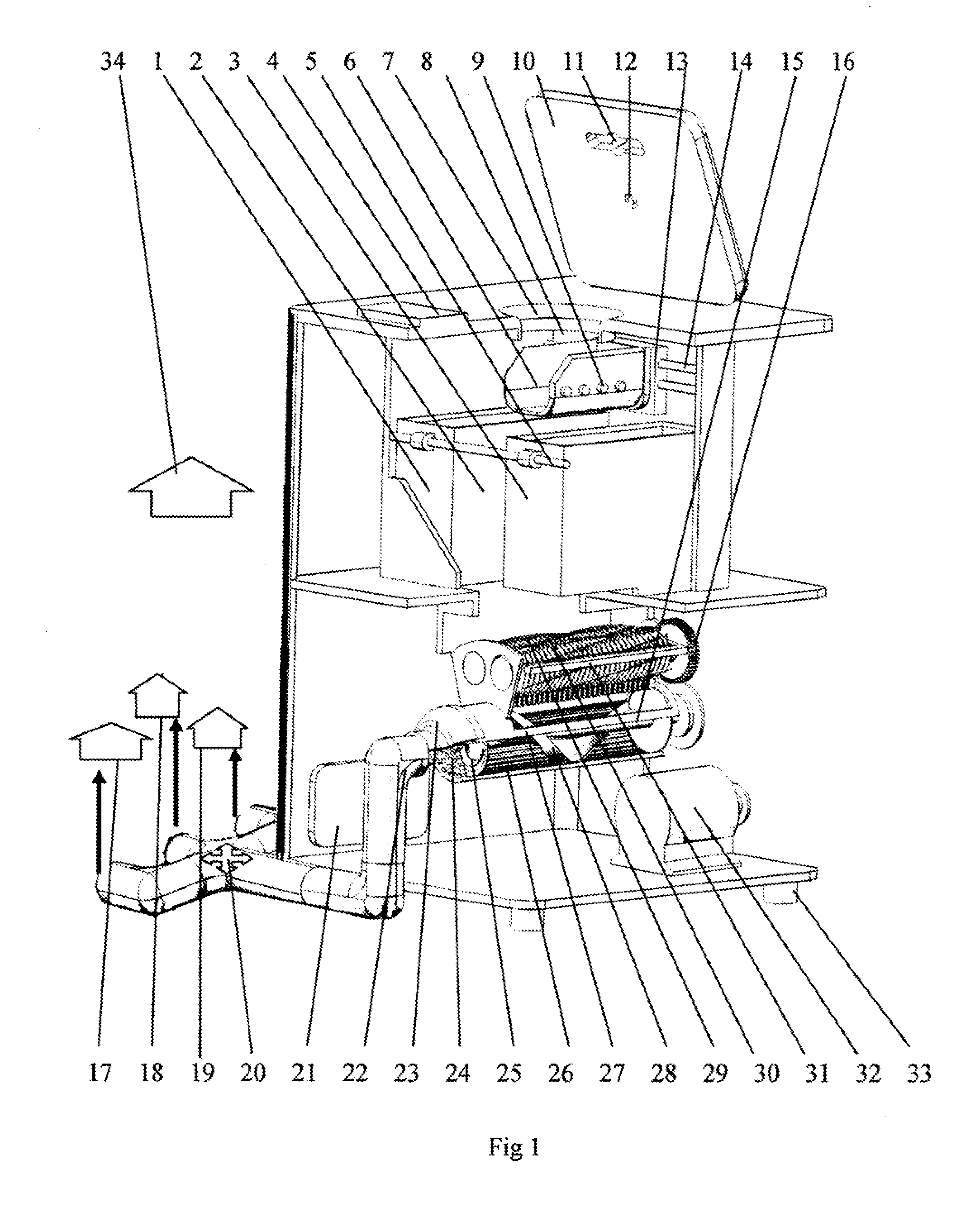

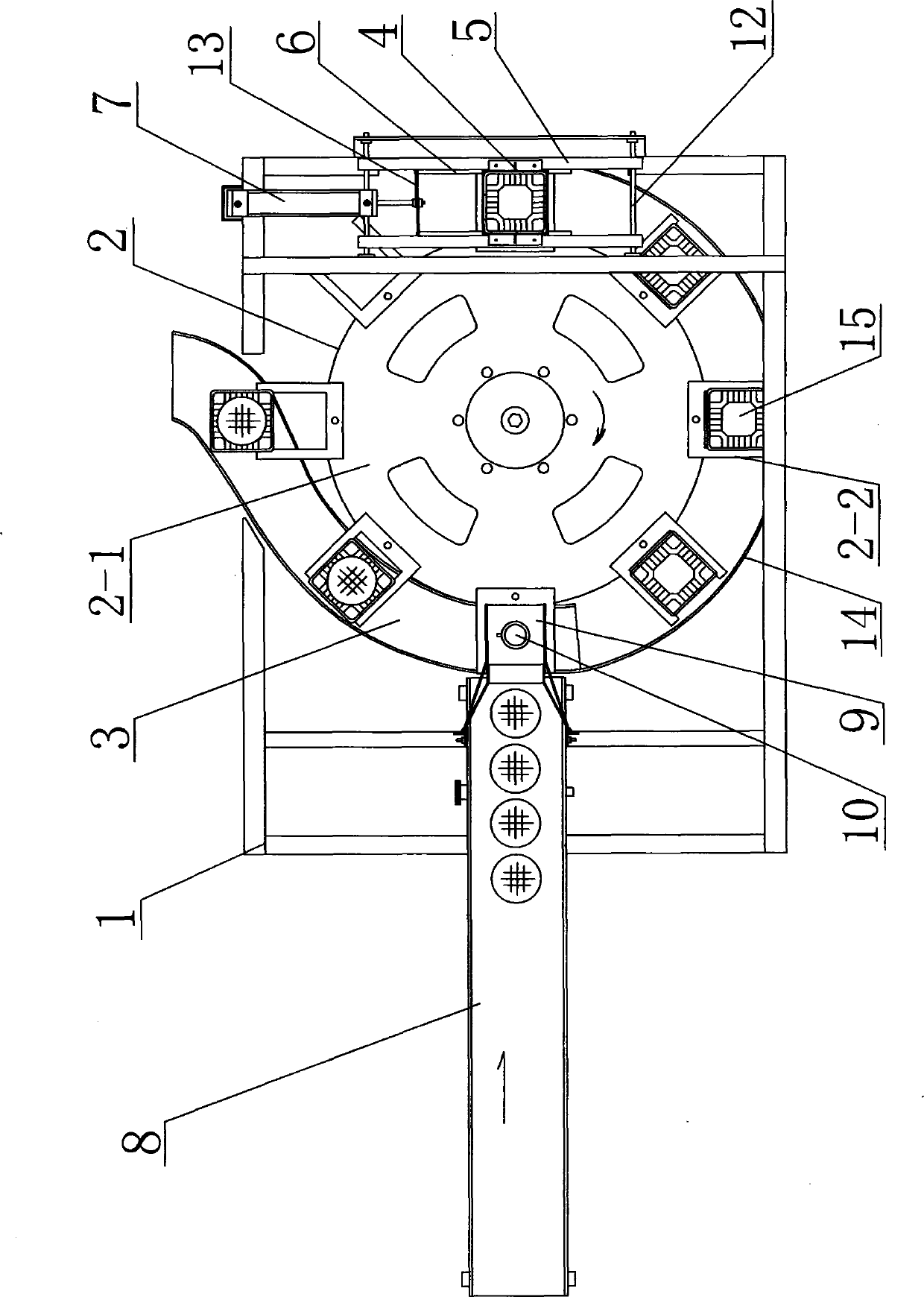

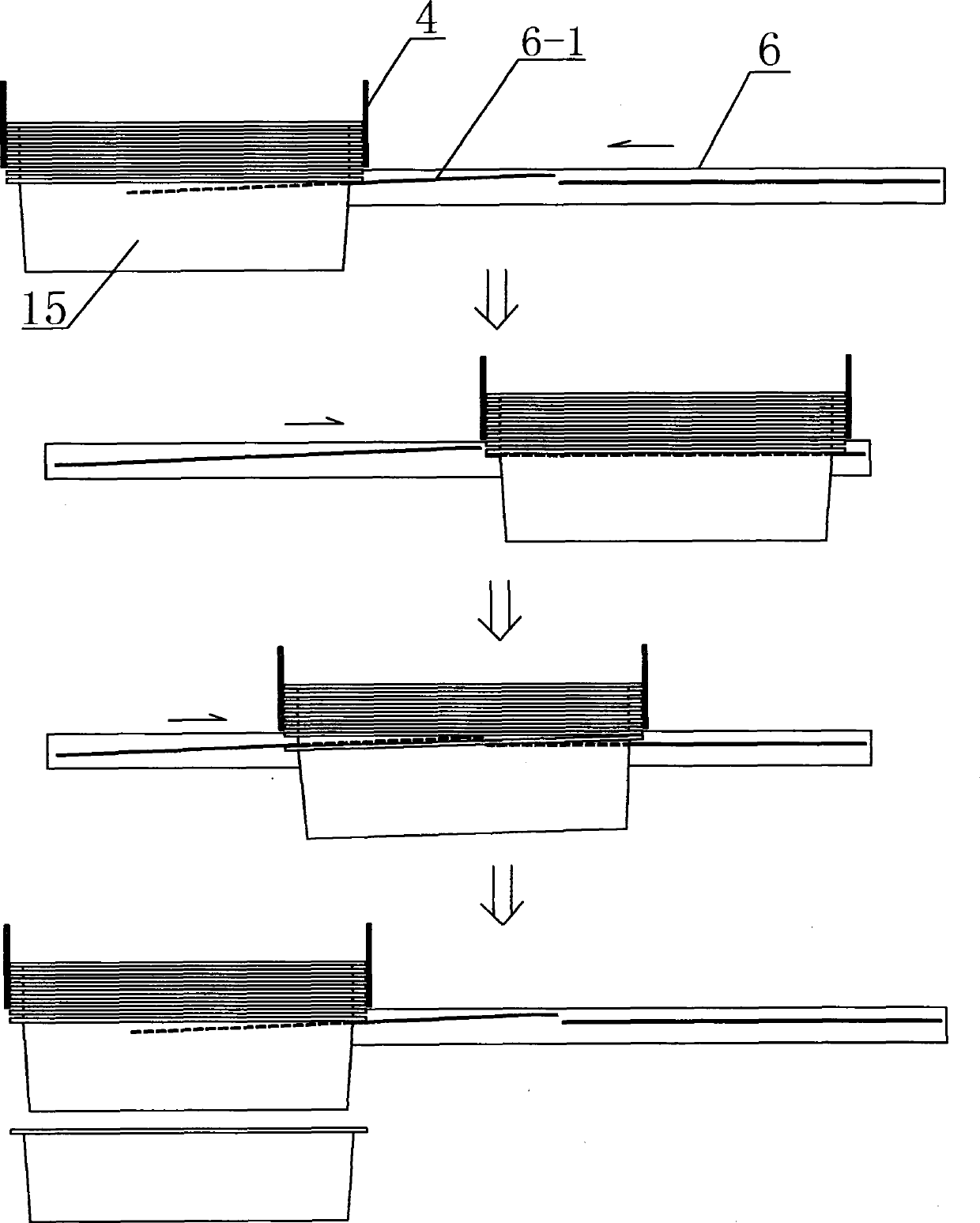

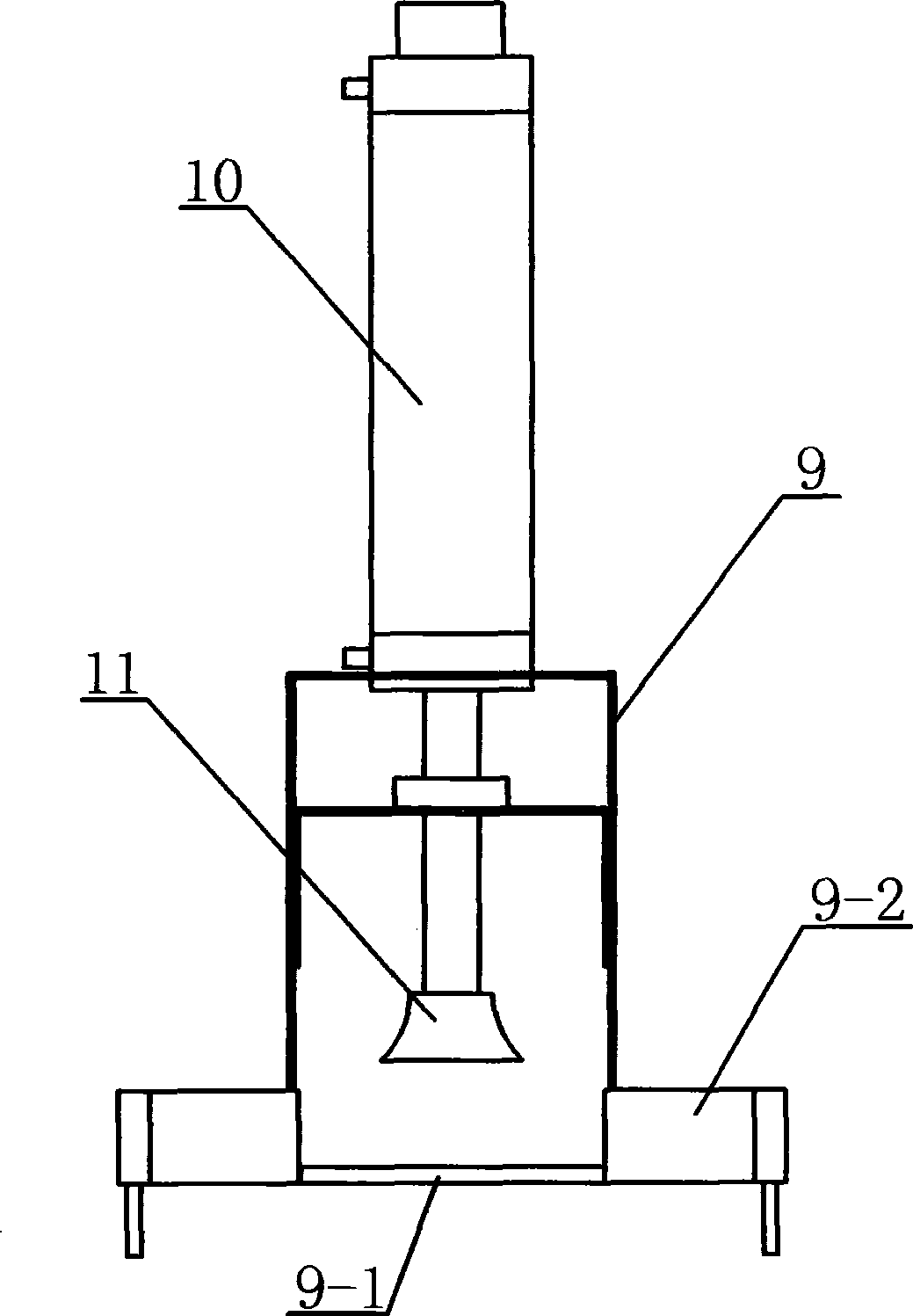

Automatic tray filling machine of mooncakes

InactiveCN103274073AEasy to operateHigh degree of automationPackaging bakeryOperation modeMechanical engineering

The invention relates to an automatic tray filling machine of mooncakes. The automatic tray filling machine of the mooncakes comprises a rack, a tray carrying mechanism, a tray falling mechanism, a mooncake conveying mechanism, a mooncake falling mechanism, a first photoelectric sensor and a second photoelectric sensor, wherein the tray carrying mechanism, the tray falling mechanism, the mooncake conveying mechanism and the mooncake falling mechanism are arranged on the rack. The tray carrying mechanism comprises a tray carrying rotary plate driven by a stepping motor in a speed reduction mode, open type tray carrying frames are evenly arranged on the edge of the tray carrying rotary plate along the circumference of the tray carrying rotary plate, an evolvent type tray outlet groove is formed below the edge of one side of the tray carrying rotary plate, the tray falling mechanism is arranged above one side of the tray carrying rotary plate, the mooncake conveying mechanism is arranged on the other side of the tray carrying rotary plate and comprises a conveying table driven by the stepping motor, the mooncake falling mechanism is provided with a mooncake falling barrel erected at the tail end of the conveying table, the mooncake falling barrel is arranged above the open type tray carrying frames, and the falling opening of the bottom portion of the mooncake falling barrel corresponds to the positions of the open type tray carrying fames. The application of the automatic tray filling machine of the mooncakes can replace a manual operation mode adopted in current mooncake tray filling processing, manpower and manual work are greatly reduced, and producing efficiency is greatly improved.

Owner:保定翔龙食品机械制造有限公司

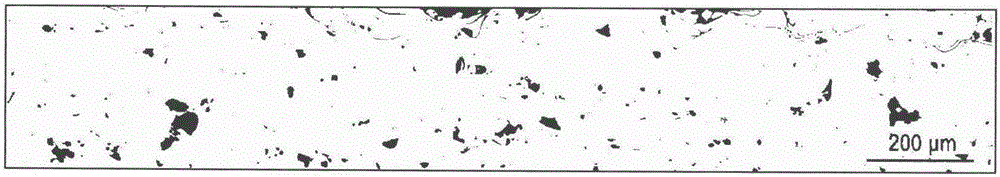

Plasma transfer arc spraying method for strengthening inner wall of cylinder sleeve of heavy truck

The invention relates to a plasma transfer arc spraying method for strengthening the inner wall of a cylinder sleeve of a heavy truck. The plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck comprises the steps that the inner wall of the cylinder sleeve is cleaned, and brown fused alumina is used for sand blasting for roughening treatment; an iron-based cored wire is sprayed to the inner wall of the cylinder sleeve of the truck through plasma transfer arc spraying, so that an abrasion-resistant and corrosion-resistant coating is obtained, wherein the iron-based cored wire is provided with stainless steel skin, and a core is formed by using FeCrBSi or FeCrBSi as a metal base material and adding other materials as compound phases; and the obtained coating is honed through a diamond honing stick. By adoption of the plasma transfer arc spraying method for strengthening the inner wall of the cylinder sleeve of the heavy truck, the defects that frictional power consumption is high, abrasion and corrosion occur easily, the fuel efficiency is low, and tail gas combustion is incomplete are overcome; and the friction coefficient between a piston ring and the inner wall of the cylinder sleeve is decreased, fuel is saved, and the service cycle of an engine is remarkably prolonged.

Owner:YANGZHOU UNIV

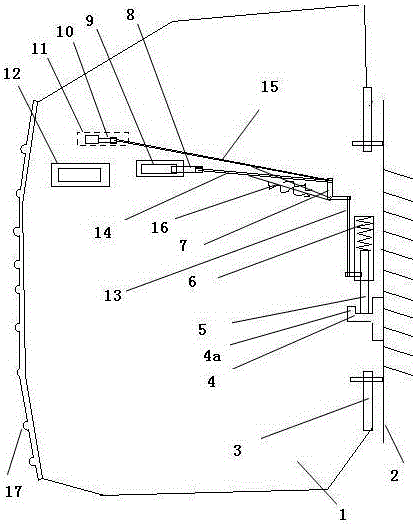

Novel vehicle door opening safety device

ActiveCN105952288AIncrease restoring powerAvoid collisionAcoustic signal devicesPassenger lock actuationCar doorMotion direction

The invention belongs to the field of vehicle parts and discloses a novel vehicle door opening safety device. The novel vehicle door opening safety device comprises a lock pin arranged on a vehicle door on one side of a vehicle door rotating shaft and a lock buckle arranged on a door frame, wherein the lock buckle corresponds to the lock pin, and a gap is reserved between the lock pin and the lock buckle; a new handle is arranged in the vehicle door; the lock pin is connected to a handle outside the vehicle door and the interior newly-arranged handle through a plurality of turning parts capable of changing the motion direction and connection rods. When intending to open the door from inside a vehicle and get off the vehicle, people need to shift the original handle of the vehicle door and shift the newly-arranged handle, and then the vehicle door can be completely opened. Through the safety device, the vehicle is prevented from being colliding with vehicles behind the vehicle when the vehicle door is opened, human injury and economic loss can be reduced, the phenomenon that accidents consume a great deal of manpower or time can be avoided, and creation of the harmonious society and safety traffic can be promoted.

Owner:安徽博格韦尔电气股份有限公司

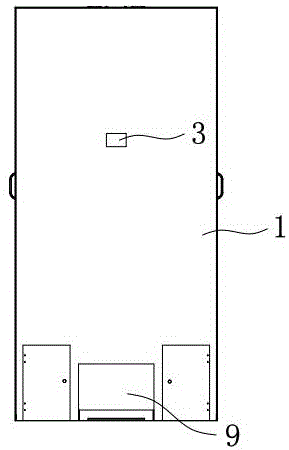

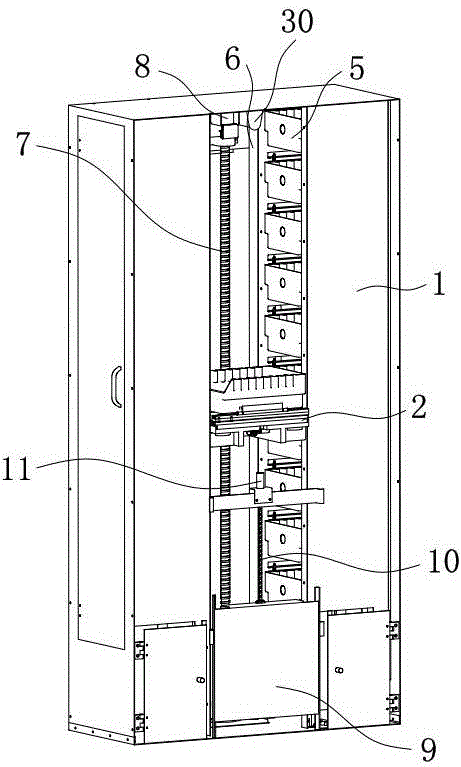

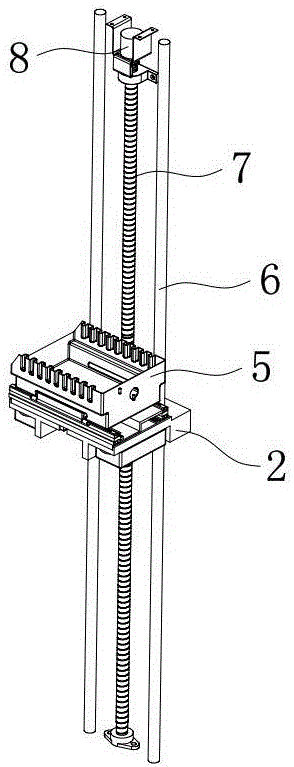

Intelligent locker

The invention discloses an intelligent locker and relates to a storage device with a device for selecting a to-be-fetched article or an automatic control device. The intelligent locker comprises a locker body, a moving platform, a touch screen and a controller, wherein the touch screen is mounted on the outer wall of the locker body, and the internal space is divided into adjacent storage area and working area; multiple drawers are longitudinally and fixedly spaced in the storage area; parallel guide rod and screw rod are longitudinally arranged in the working area; the guide rod passes through the moving platform, and the upper and lower ends are fixed with the locker body; one end of the screw rod is in transmission connection with a screw rod motor, and the other end passes through the moving platform and drives the moving platform to move up and down along the guide rod; and the controller is mounted in the moving platform and is in circuit connection with the moving platform, the touch screen and the screw rod motor respectively. The intelligent locker disclosed by the invention is suitable for storing articles and files at home and in a company; and with a mechanical structure, the time and manpower consumed by frequently opening and closing a locker door by a user are avoided, and the management burden can be relieved while the privacy and secret are protected.

Owner:广西佳品优家具有限公司

All-model aluminum product automatic packing machine

ActiveUS20170113822A1Improve packaging efficiencyImprove packaging qualityWrapping material feeding apparatusWrapper twisting/gatheringEngineeringMechanical engineering

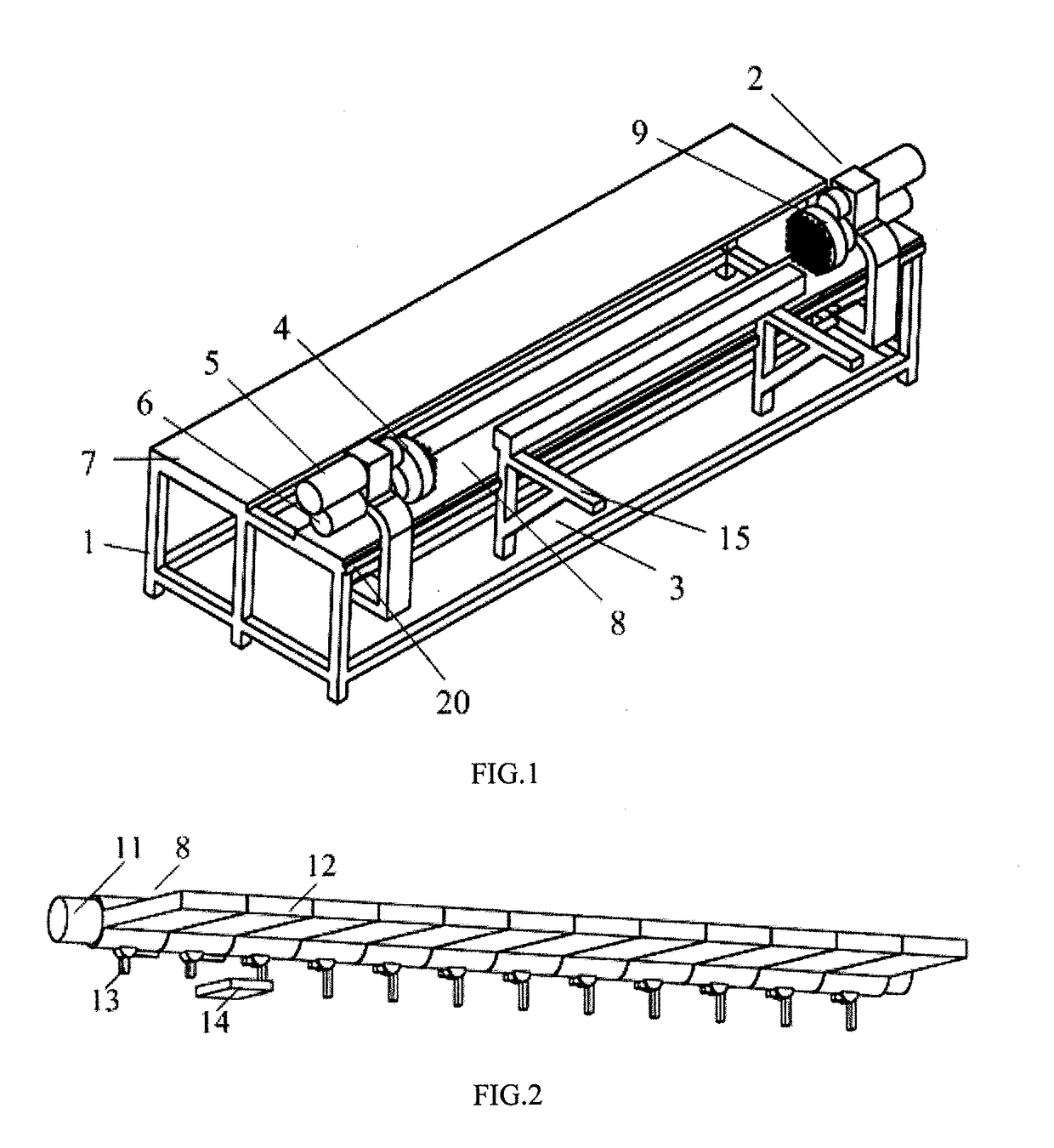

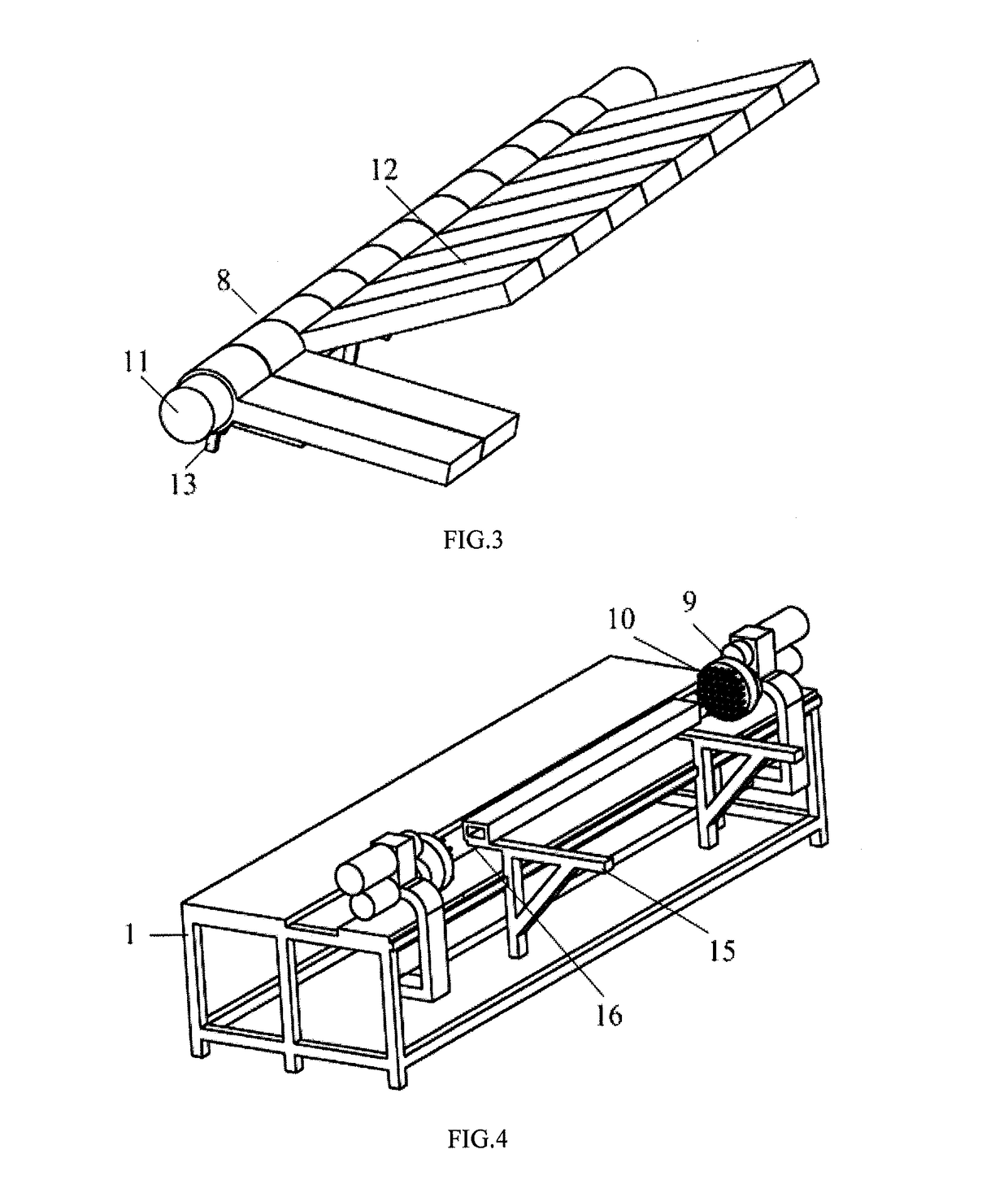

An all-model aluminum product automatic packing machine, comprises: a rack (1), a packing mechanism (2) disposed on the rack (1), and a feeding mechanism (3) for delivering an aluminum product to the packing mechanism (2). The packing mechanism (2) comprises universal clamps (4) symmetrically disposed at two ends of the rack (1); the universal clamps (4) fix one end of the aluminum product, and rotates under the driving of a rotating motor (5), and stretches and retracts under the driving of the pneumatic push rod (6). The rack (1) is provided with a packing platform (7) thereon; and one side of the packing platform (7) corresponding to the universal clamp (4) is provided with a pressing piece (8) capable of turning upward. The packing machine realizes linear automatic packing of all-model aluminum products, improves packing quality and packing efficiency, and saves labor and energy.

Owner:GUANGDONG JMA ALUMINUM PROFILE FACTORY GRP

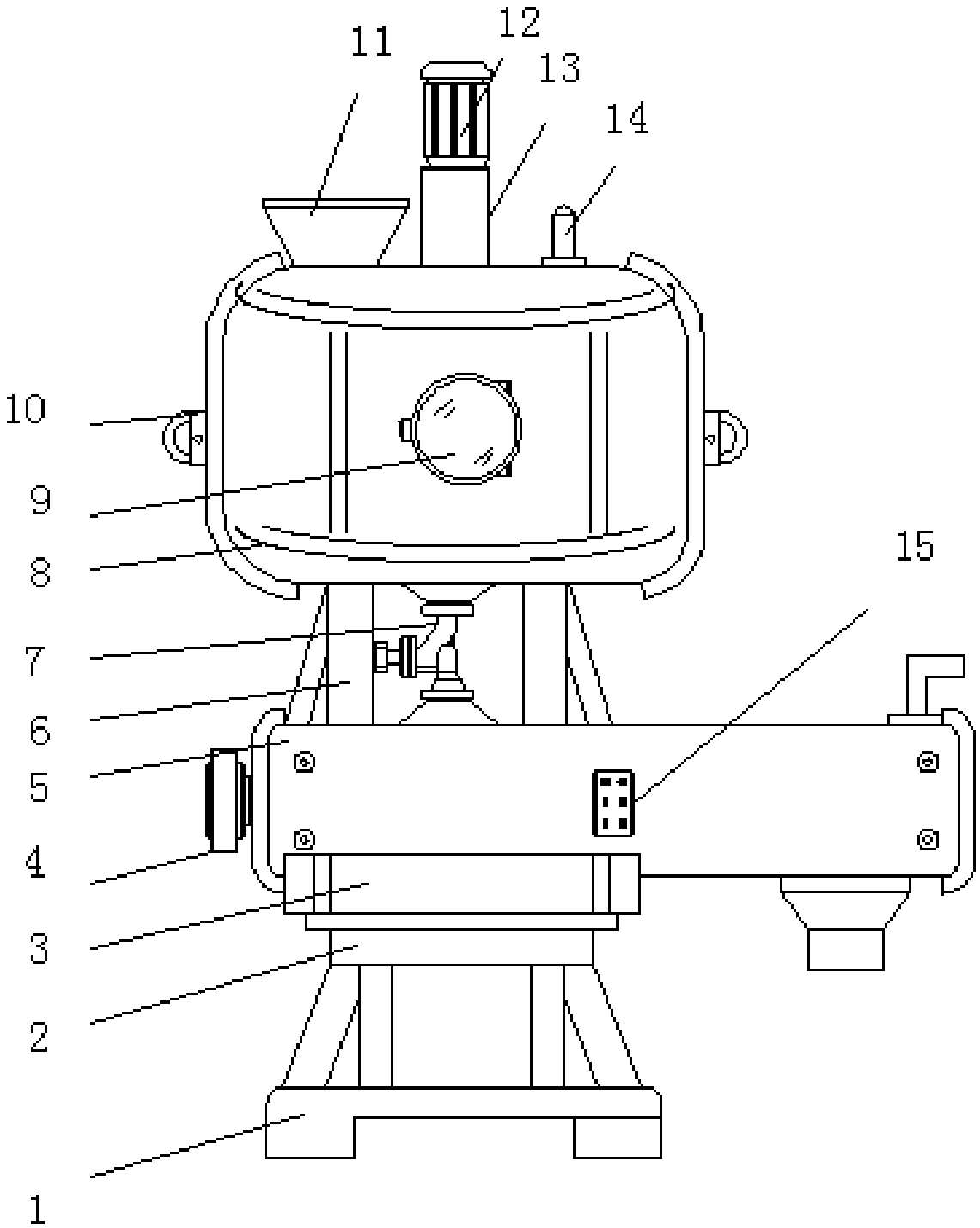

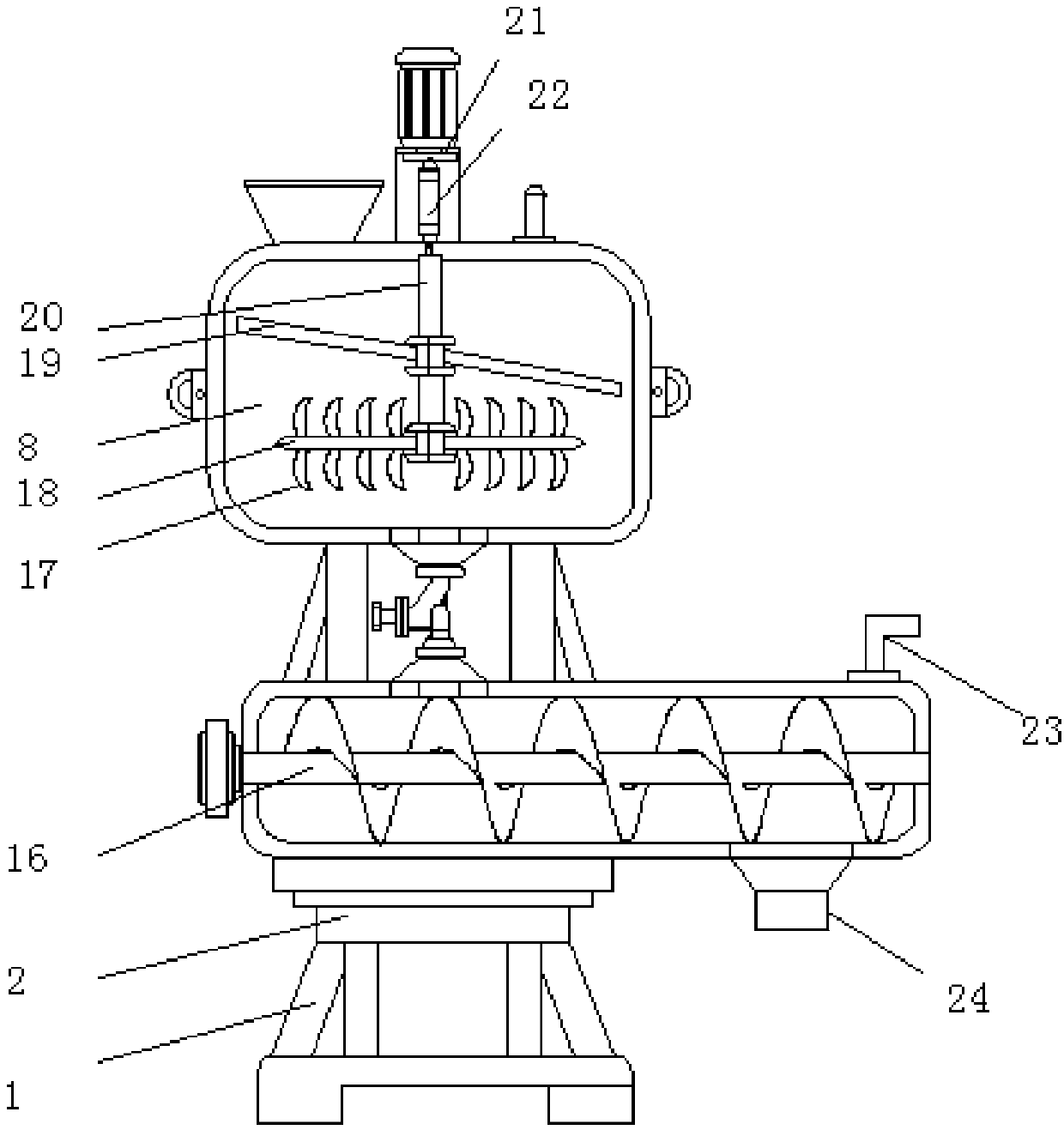

Food automatic processing equipment

InactiveCN107744007AEasy to operateReduce riskMeat mixing apparatusMeat processing devicesSolenoid valveSilo

The invention discloses food automatic processing equipment, which comprises an installing seat, a material supply cabin, a stirring cabin and a rotating shaft, wherein a turntable is arranged above the installing seat; an installing groove is formed in the upper side of the turntable; the material supply cabin is arranged above the installing groove; a first motor is arranged in the middle position of one end of the material supply cabin; a spiral shaft is arranged inside the material supply cabin; the output end of the first motor is connected with the spiral shaft; a discharging valve is arranged at one end, far away from the first motor, at the bottom of the material supply cabin; two groups of installing posts are arranged at one end, near the first motor, of the material supply cabin; the stirring cabin is arranged above the installing posts; an electromagnetic valve is arranged in the middle position of the bottom of the stirring cabin. Through the design of the turntable, the material supply direction of the device can be controlled, so that the operation is more convenient; the potential risk is reduced; the food automatic processing equipment can be arranged on other devices, so that the labor force is reduced.

Owner:李毅宏

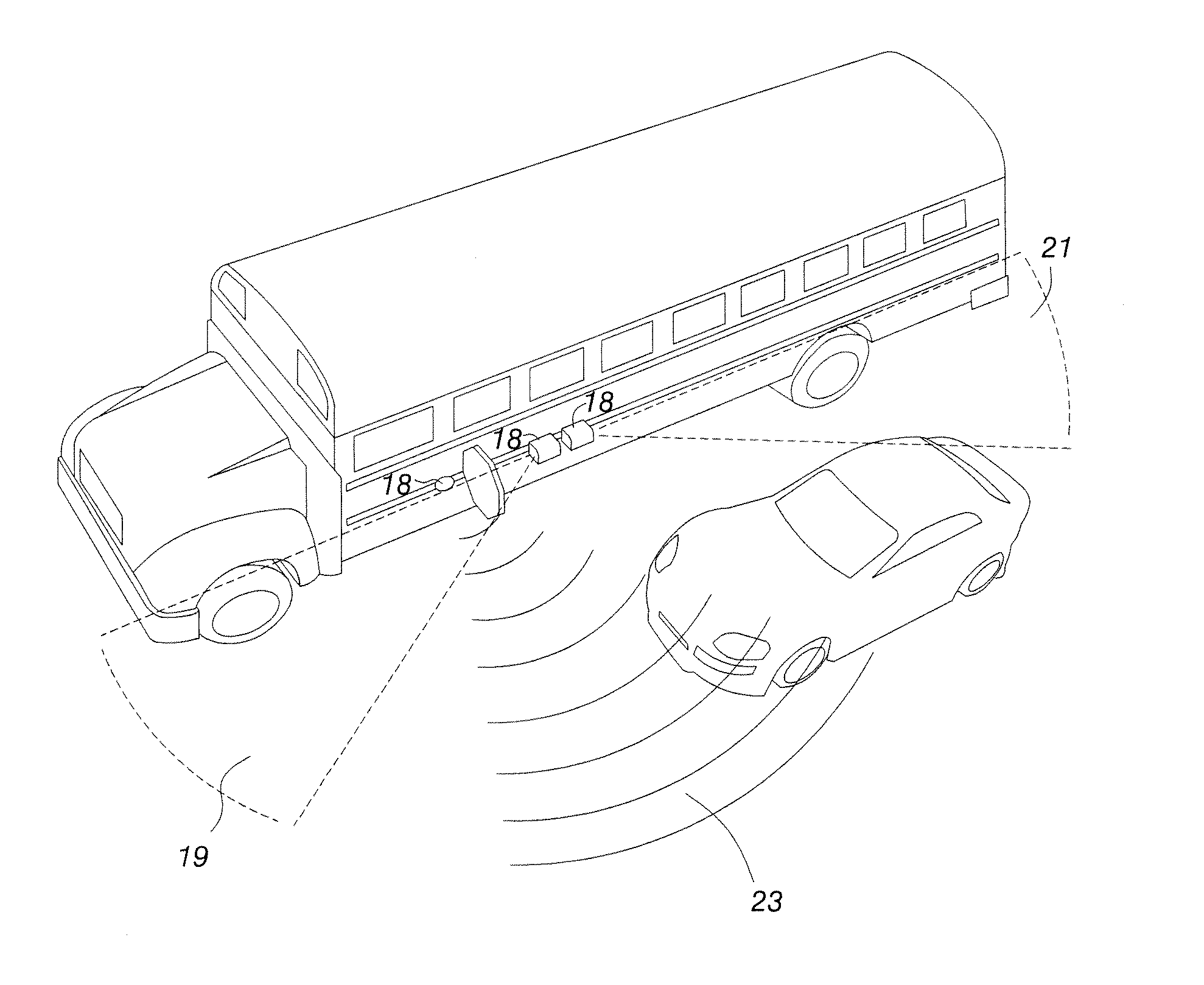

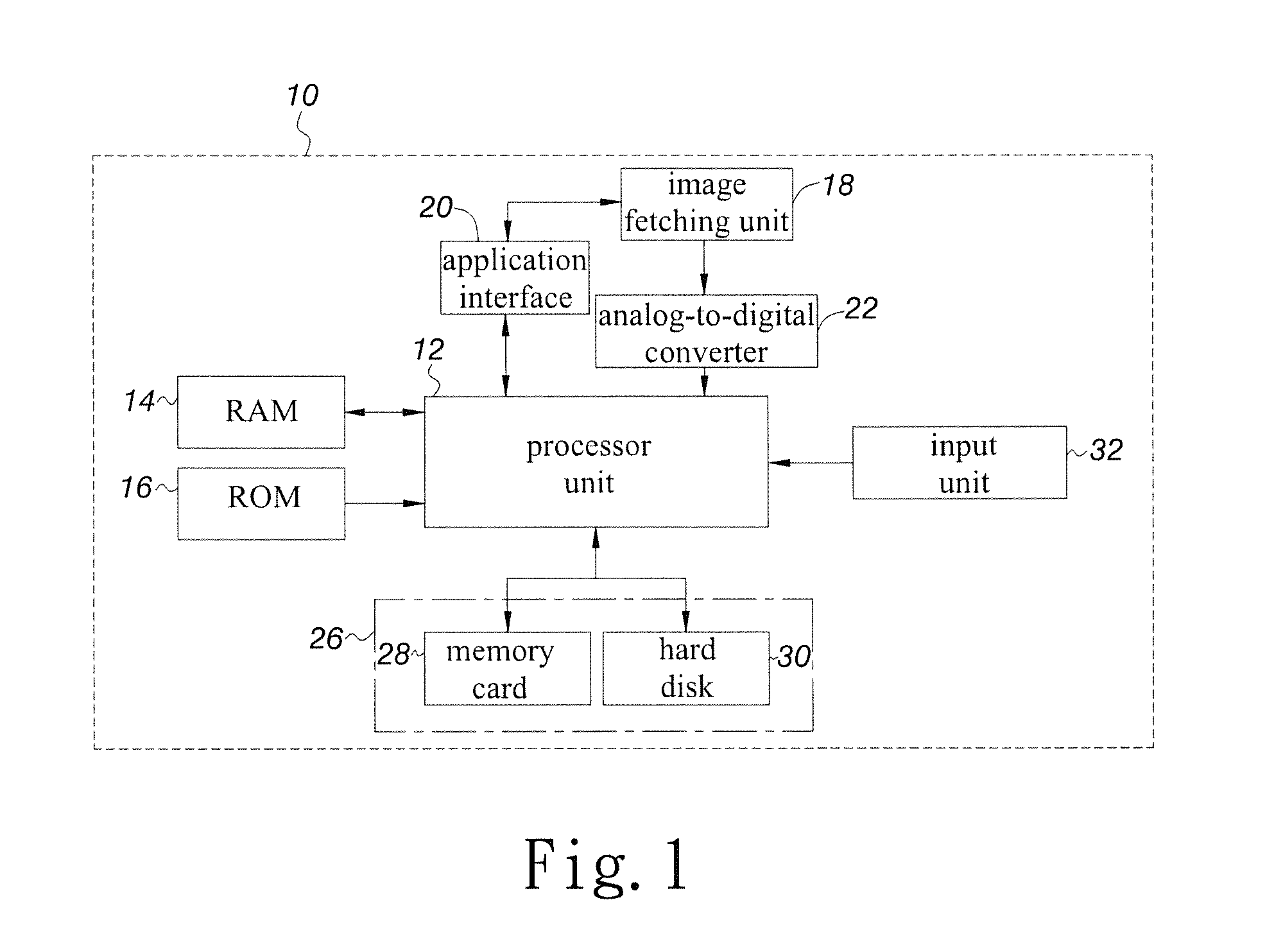

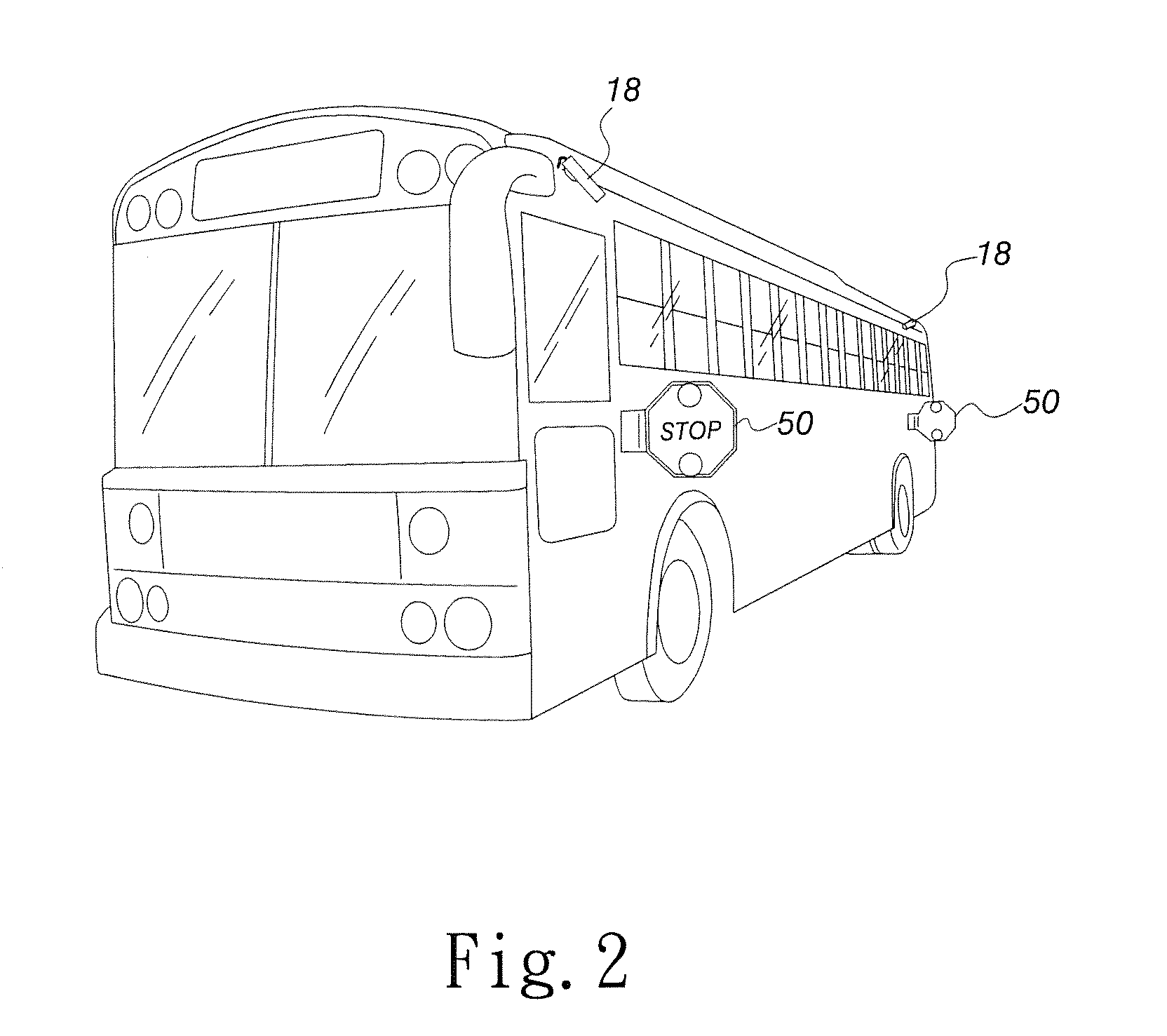

Automatic record detection device and method for stop arm violation event

ActiveUS20130279742A1Shorten the timeSave manpower andCharacter and pattern recognitionDigital dataAnalog-to-digital converter

An automatic record detection device and method for stop arm violation event, comprising: a plurality of image fetching units, to fetch external video signals; at least an analog-to-digital converter, to process said external video signal into digital data; a processor unit, to detect dynamic images of said digital data based on a set sensitivity value, when said set sensitivity value of said dynamic image of a violating vehicle fulfills an image block number, it determines said dynamic image to trigger a violation event, then generates said digital data based on said external video signal. As such, a user can search said dynamic images of said digital data by examining said triggered violation event, to find out license plate number of a violating vehicle, and sends it to an agency concerned for prosecution, thus saving enormous time and manpower in viewing and searching through said digital data.

Owner:IVC +2

Tomato cultivating method

InactiveCN106258341AIncrease productionMeeting nutritional needsPlant cultivationCultivating equipmentsWarm waterBud

The invention relates to a tomato cultivating method. The tomato cultivating method comprises the following steps of 1, performing sowing and seedling culture: performing seedling culture, performing transplanting, and soaking seeds in warm water; 2, performing soil preparation, and applying base fertilizers: generally making ridges at intervals of 4 chi; 3, performing field planting: transplanting seedlings; 4, performing field management, wherein during the period after the field planting and before seedling recovering, watering is not performed generally; 5, pruning branches and auxiliary buds, wherein pinching does not need to be performed on self-topping varieties, pinching needs to be performed on indeterminate growth type varieties, branches on a single trunk are pruned, namely only a main vine is reserved, and 4-5 flowers of each plant are reserved for pinching; and 6, preventing fruit dropping, too high temperature or too low temperature easily causes fruit dropping, so that flowers can be dipped with 2,4-D. The technical means of the tomato cultivating method disclosed by the invention has the beneficial effects that the tomato cultivating method is performed according to growth habits of tomatoes, environment required for the growth of the tomatoes is provided, the cultivated tomatoes are high in yield which can achieve 4000 kilograms / mu generally, besides, the licopersicin content is high, and requirements of people for nutrients of the tomatoes are met. The tomato cultivating method is reasonable in steps, and a great quantity of human resources and labor are saved.

Owner:贵州省仁怀市欢悦红粱种植有限公司

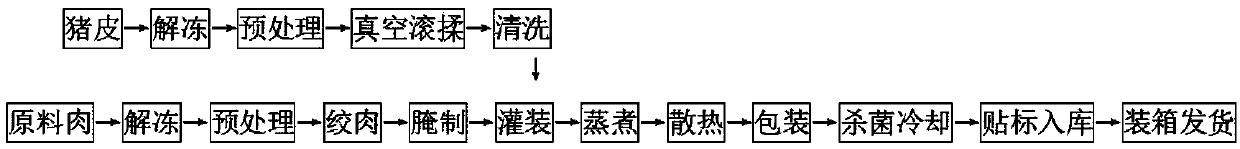

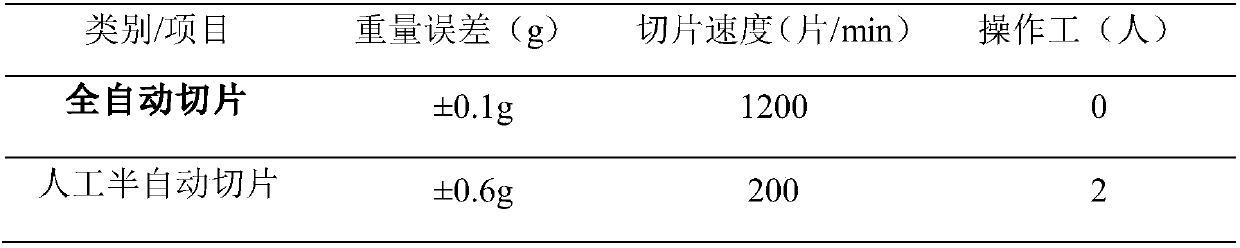

Low-temperature ham/bacon automatic slicing and packaging process

InactiveCN107751826ADetect and adjust quality deviationsReduce quality differencesFood shapingPackaging bakerySlice thicknessProcess engineering

The invention discloses a low-temperature ham / bacon automatic slicing and packaging process, and belongs to the technical field of processing of meat products. The process comprises the steps of unfreezing raw meat, homogeneously injecting, rolling, rubbing, pickling statically, filling, pressing a film, cooking, demoulding, smudging, cooling, quickly freezing, slicing and packaging. A full-automatic slicing and packaging machine is used to scan the cross section and measure the weight, the size and the density, the weight, the volume and the density are calculated through a computer, then thedata are transmitted to a slicer, the weight of each slice is accurately located, the thickness of the slice is uniform, the mass is equal, an unqualified product is automatically removed, the uniform qualified slice is conveyed to a packaging station through a conveyor belt, a packaging robot automatically puts the slice into packaging equipment accurately to fully automatically package the slice, the date of manufacture is automatically printed, automatic labeling and automatic counting and packaging are conducted, so that the process has the advantages that the product difference is reduced, the product quality is improved, the microorganism pollution is reduced, the production efficiency is improved and the like.

Owner:JIANGSU YUNRUN MEAT WARE CO LTD

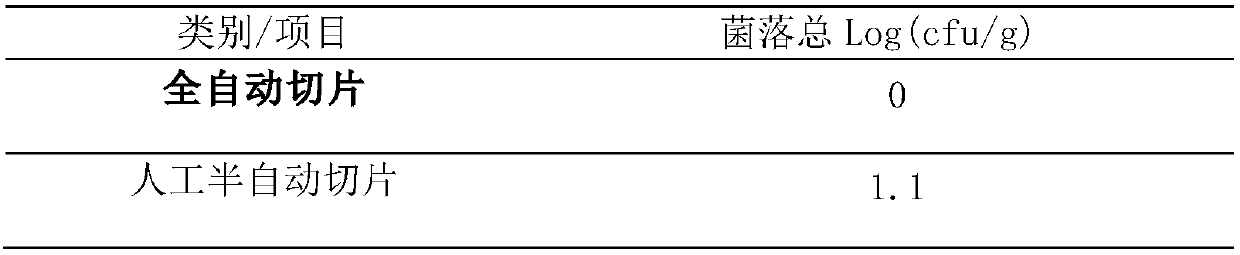

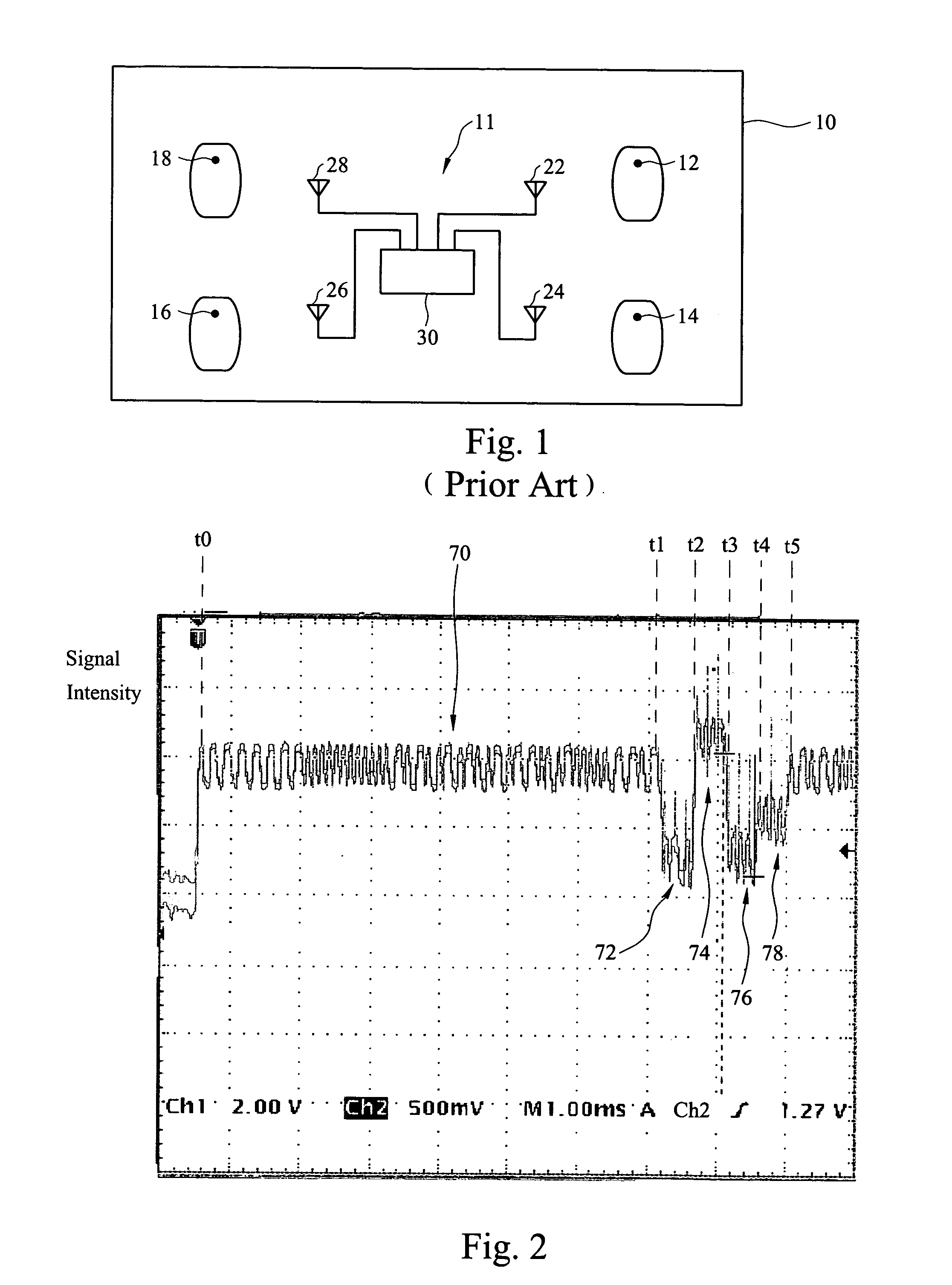

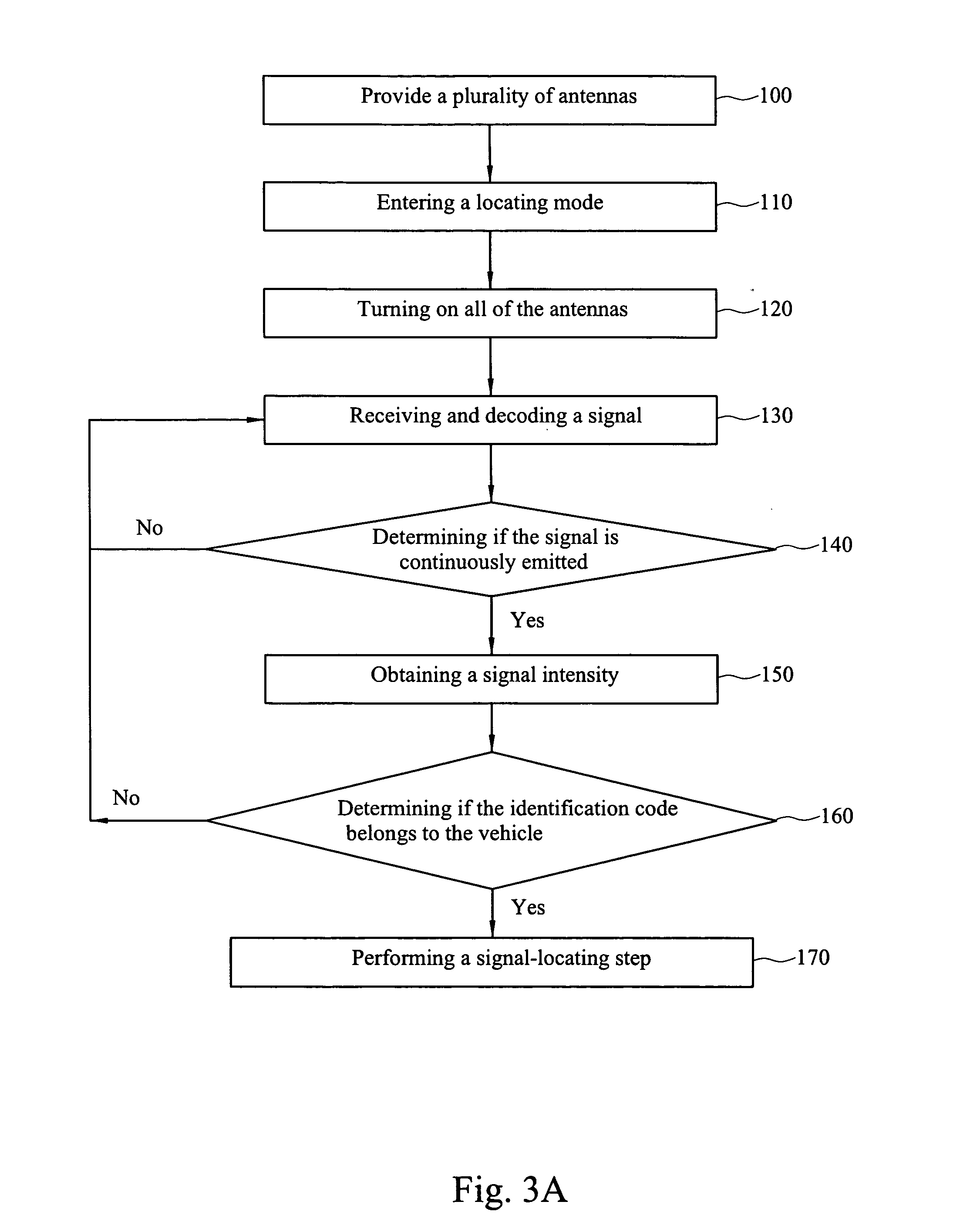

Method for locating tire condition sensing apparatuses

InactiveUS20060055523A1Save manpower andSave material resourcesTyre measurementsAlarmsAutomotive engineeringVIT signals

A method is disclosed for locating a plurality of tire condition sensing apparatuses mounted on a vehicle. At first, all of the antennas in the vehicle are maintained at an activation status for receiving and decoding a signal transmitted from one of tire condition sensing apparatuses of the tired, and a signal intensity is obtained. When a tire condition sensing apparatus is assured to continuously emit the signal, the antennas are alternatively turned on an off so as to obtain a plurality of signal intensity changes, and the tire condition sensing apparatus is located on the tire to which the antenna producing the maximum value of the signal intensity changes is corresponding.

Owner:LITE ON AUTOMOTIVE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com