Automatic tray filling machine of mooncakes

An automatic and machine-supporting technology, applied in packaging, food packaging, transportation and packaging, etc., can solve the problems of sanitation, labor-intensive, low efficiency, etc., and achieve the effect of improving production efficiency, high degree of automation, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

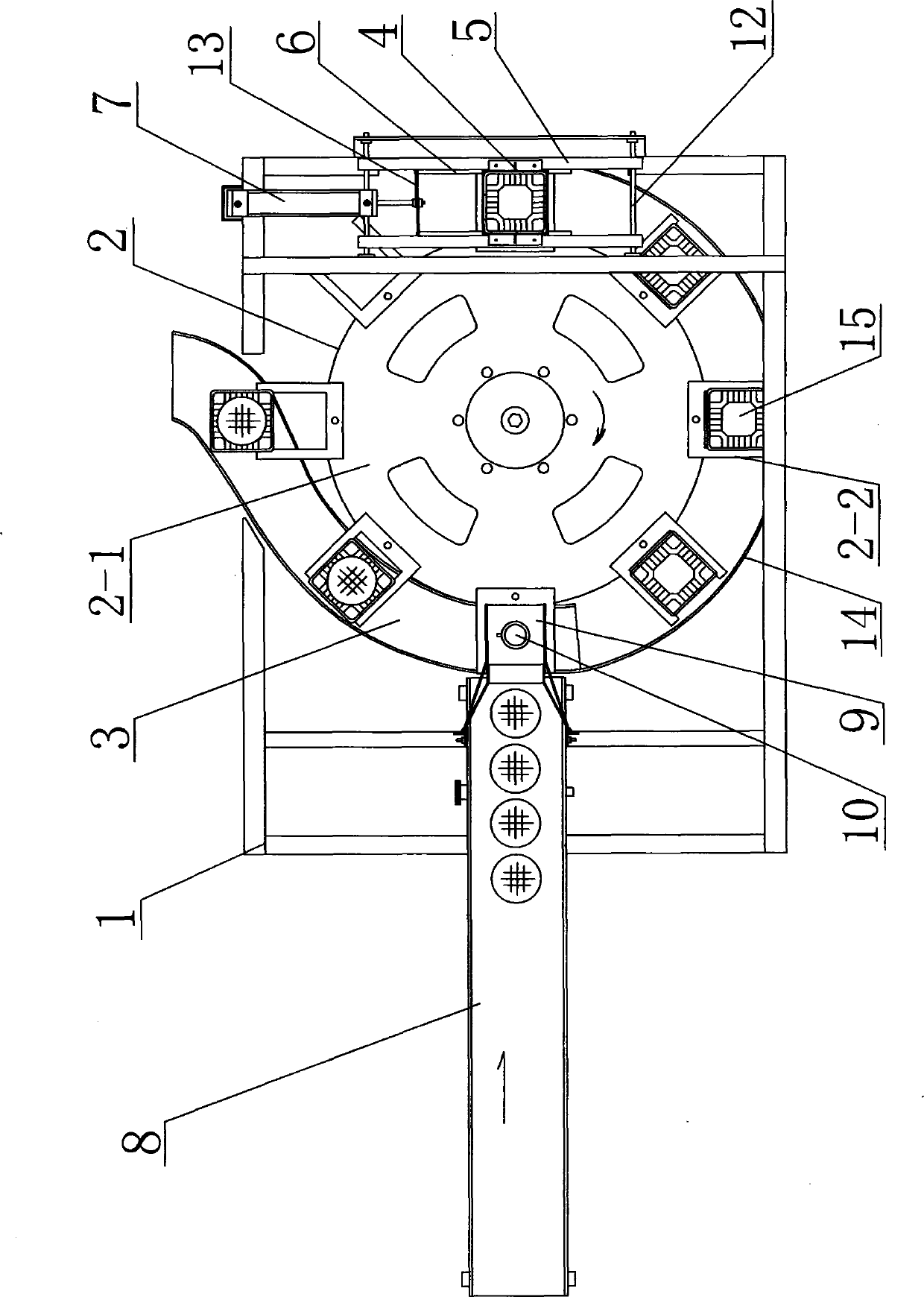

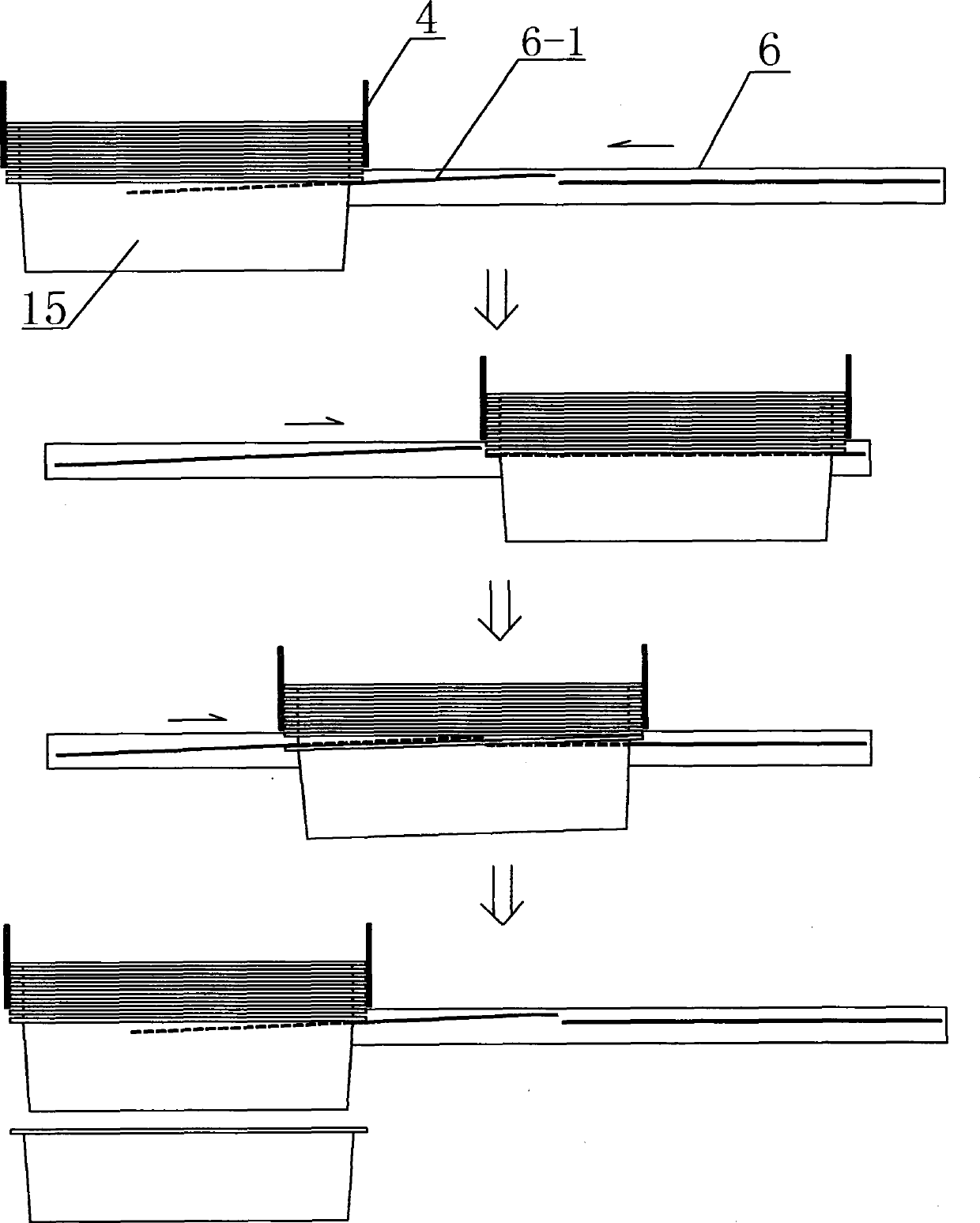

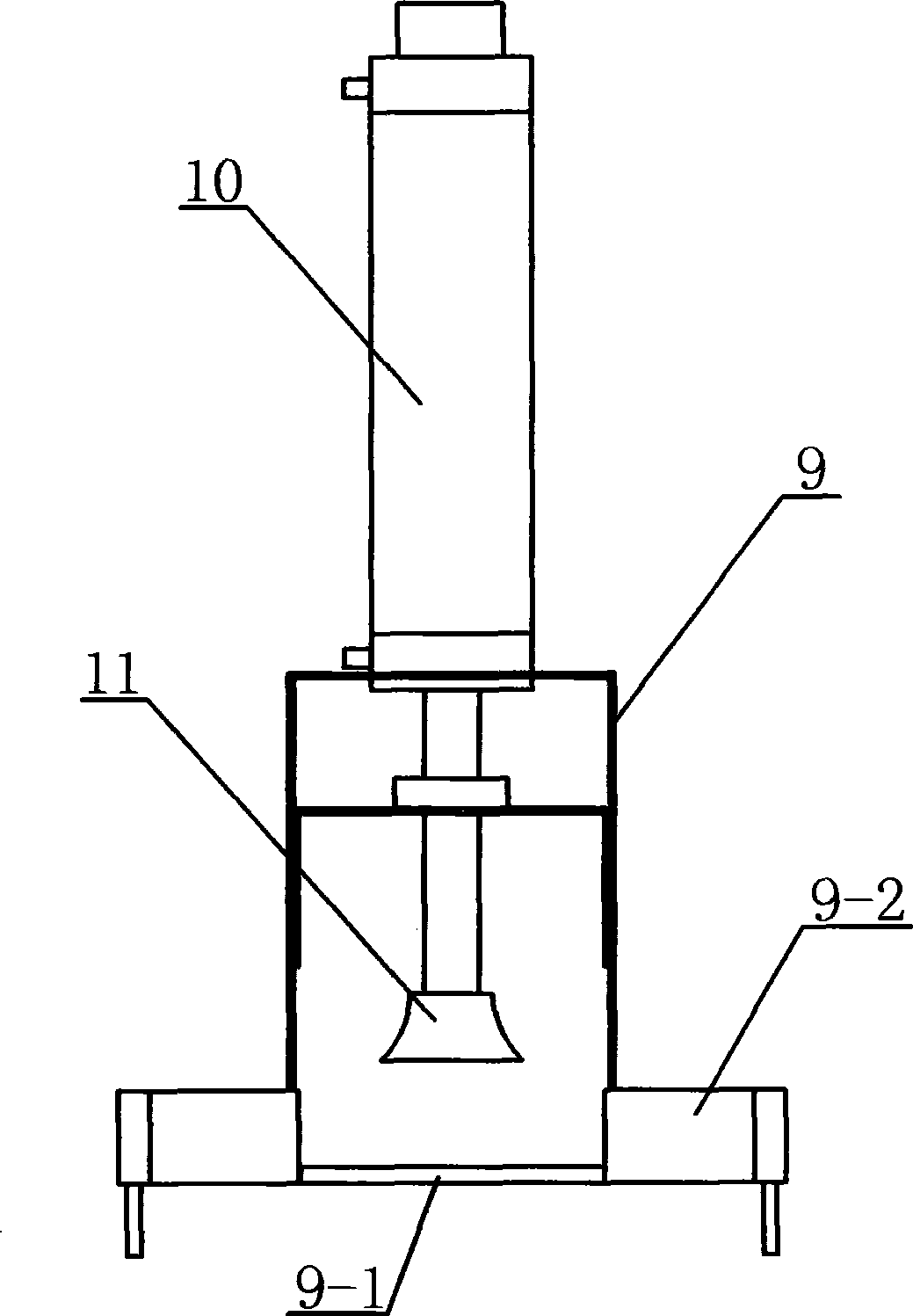

[0017] A moon cake automatic loading machine, such as figure 1 As shown, it includes a frame 1 and a carrier mechanism installed on the frame 1, a drop mechanism, a cake feeding mechanism and a cake drop mechanism; the carrier mechanism includes a carrier turntable 2 driven by a stepping motor deceleration, The edge of the carrier turntable 2 has open carrier brackets 2-2 evenly arranged along the circumference, and an involute type outlet bracket 3 is arranged below the side edge of the carrier turntable 2, and the involute type outlet bracket 3 The lower side of the open carrier 2-2 which is close to the edge of the carrier turntable 2; The working cylinder 7, the scraper rod guide rail 5 and the scraper rod 6 are all a pair, and the holding holder 4 is vertically and fixedly erected in the center above the two parallel scraper rod guide rails 5, and the lower opening of the holding holder 4 and its lower part The positions of the open carrier 2-2 on the edge of the carrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com