Electronically controlled silicon oil fan control method and controller

A fan control and silicon oil technology, applied in the control of coolant flow, machine/engine, engine components, etc., can solve the problems that the control strategy cannot be automatically corrected and the control accuracy is not high, so as to save manpower and time costs, flexible adjustment, The effect of reducing fuel consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

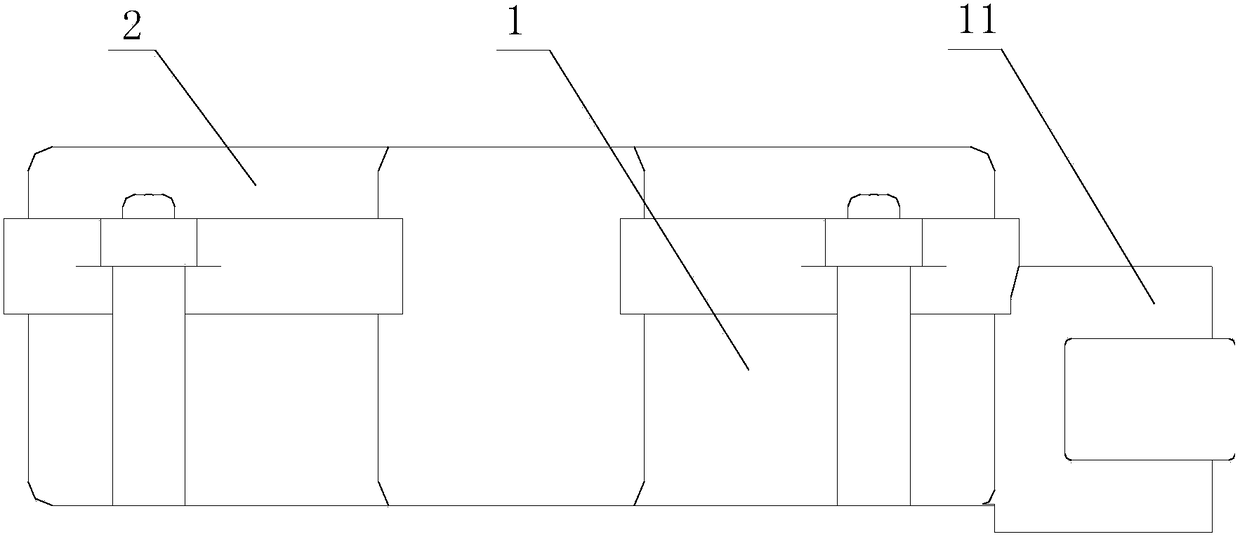

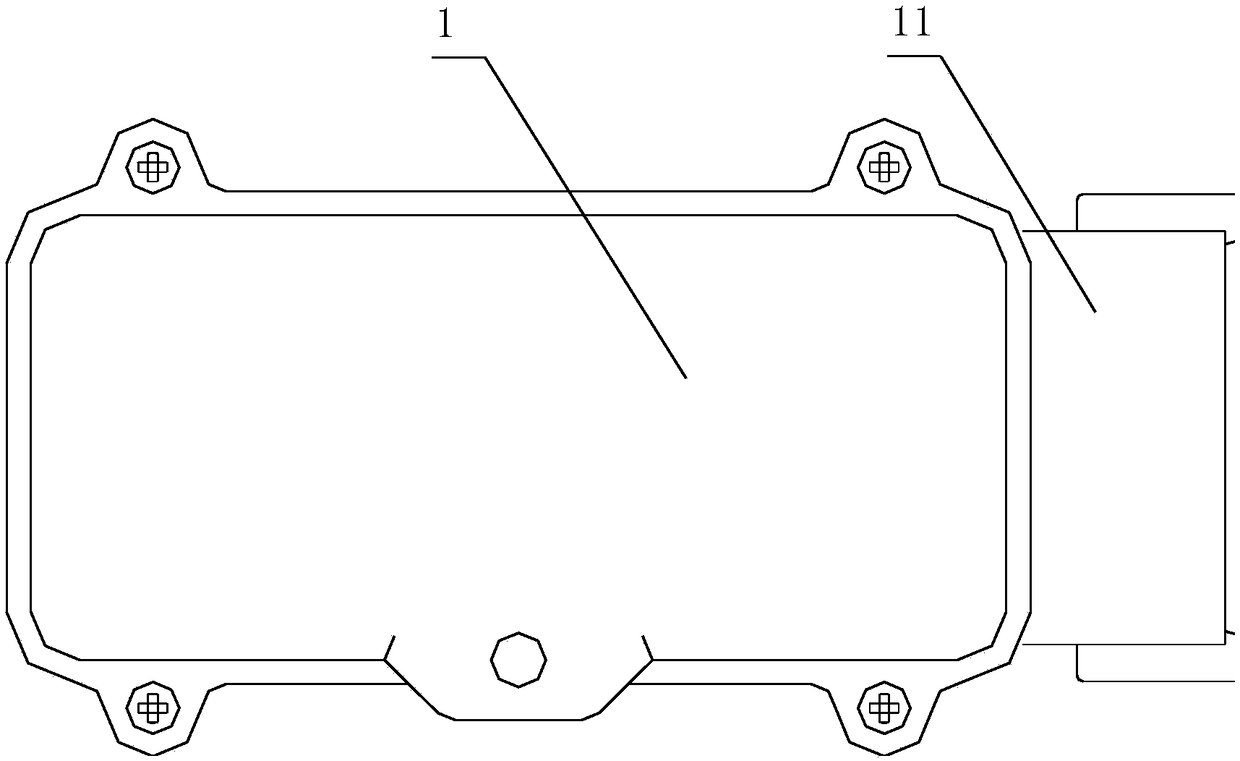

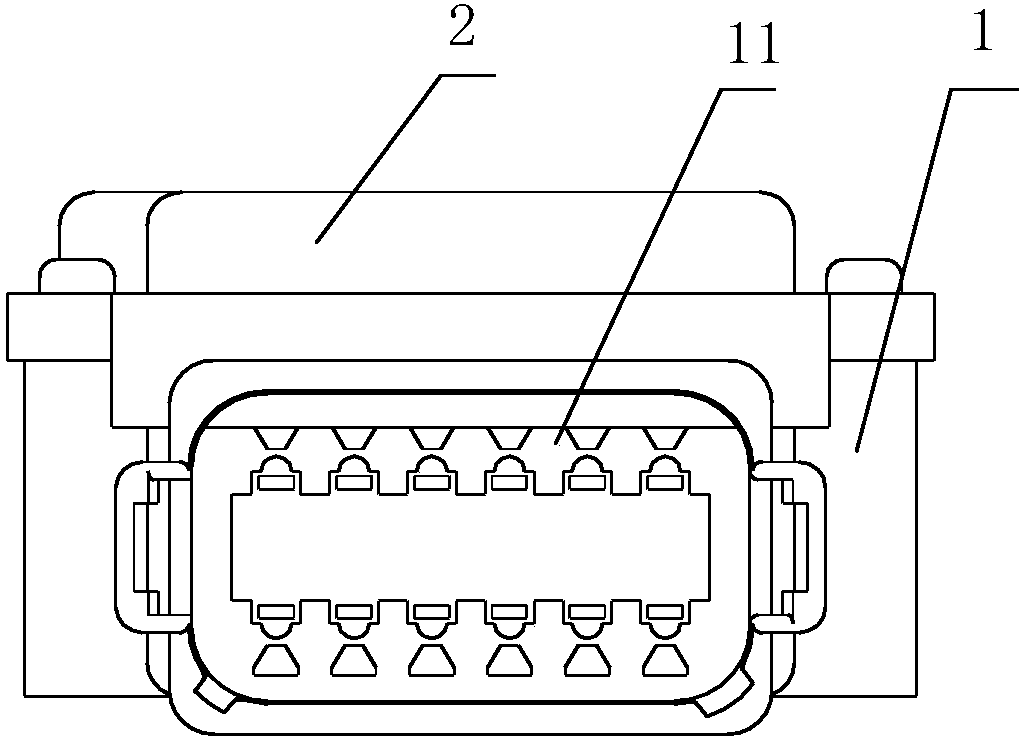

[0040] Such as Figure 1-3 As shown, an electronically controlled silicon oil fan controller of the present invention is placed in the engine compartment to intelligently adjust the speed of the silicon oil fan. The main structure of the controller includes a lower cover 1 and an upper cover 2 covered on the lower cover 1, the lower cover 1 and the upper cover 2 constitute the outer shell of the controller, between the lower cover 1 and the upper cover 2 A circuit board is installed in the inner space of the room, and a small cover plate is provided at the bottom of the socket 11 on one side of the lower cover plate 1 . The four legs of the lower cover 1 and the upper cover 2 are fixedly connected together by screws, and a sealing ring is arranged at the joint surface of the lower cover 1 and the upper cover 2 .

[0041]In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com