Low-temperature ham/bacon automatic slicing and packaging process

A technology of slice packaging and low temperature ham, applied in the field of slice packaging process, low temperature ham/bacon automatic slice packaging process, can solve the problems of limited labor efficiency, microbial contamination, unstable quality, etc., to reduce labor, reduce pollution, The effect of improving quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the technical solutions of the present invention clearer and clearer to those skilled in the art, the present invention will be further described in detail below in conjunction with the examples and accompanying drawings, but the embodiments of the present invention are not limited thereto.

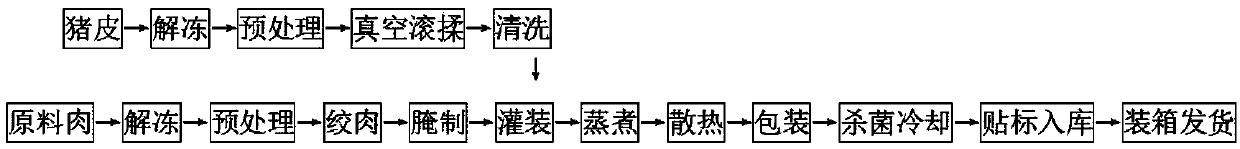

[0033] Such as figure 1 As shown, the low-temperature ham / bacon automatic slicing and packaging process provided in this embodiment includes thawing raw meat, homogeneous injection, rolling, kneading and static pickling, filling and film pressing, cooking and demoulding, smoking, cooling and quick freezing, slicing and Package.

[0034] Further, include the following steps:

[0035] Step 1: Thaw Raw Meat

[0036] Frozen raw meat is used, and impurities are removed after thawing to a central temperature of -2°C to 0°C;

[0037] Step 2: Homogeneous Injection

[0038] After preparing the injection feed liquid with a homogenizer, inject the raw meat with the prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com