Mud-water separation type sludge anaerobic digestion treatment system and method

An anaerobic digestion and mud-water separation technology, which is applied in anaerobic digestion treatment, water/sludge/sewage treatment, centrifugal separation water/sewage treatment, etc., can solve the problem of long residence time and redundant volume of sludge anaerobic digestion tank , Sludge is easy to deposit on the bottom of the tank, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

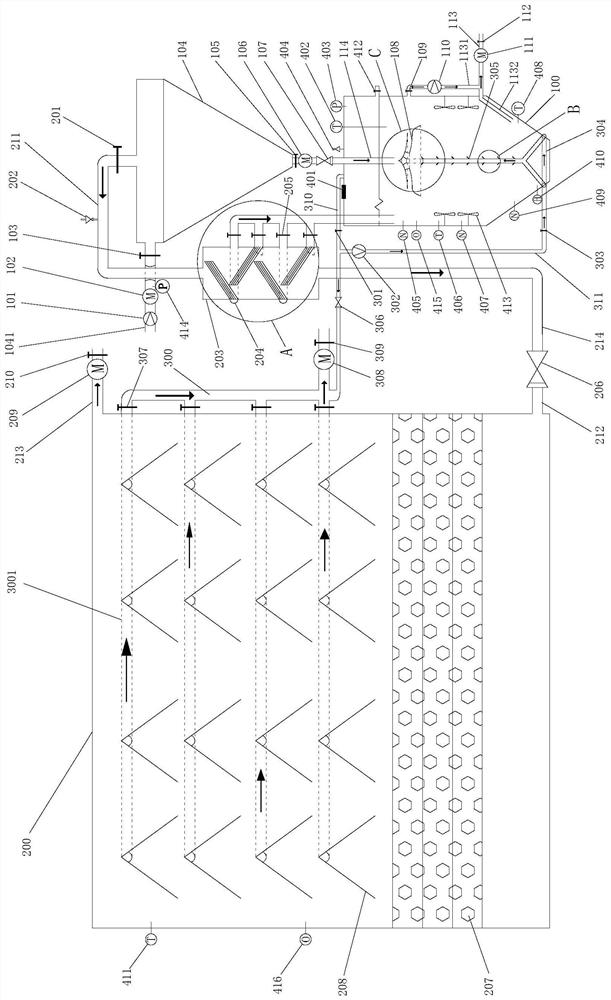

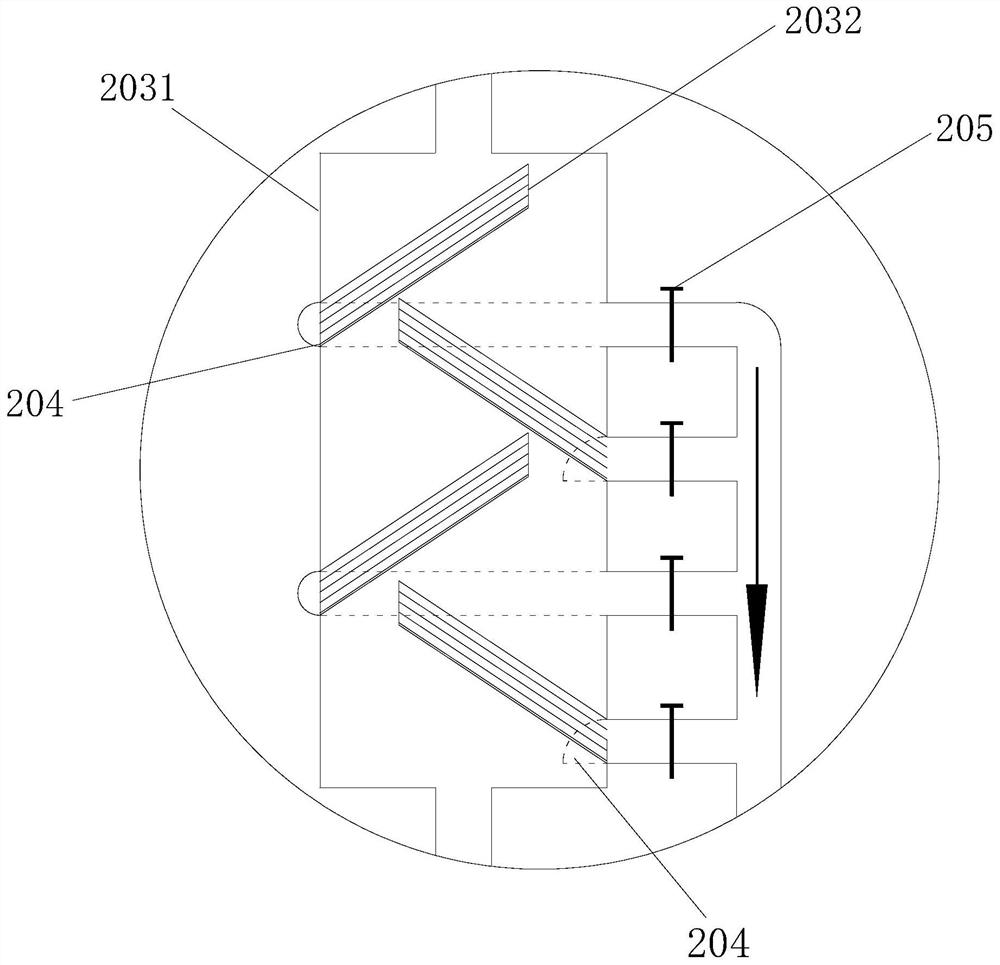

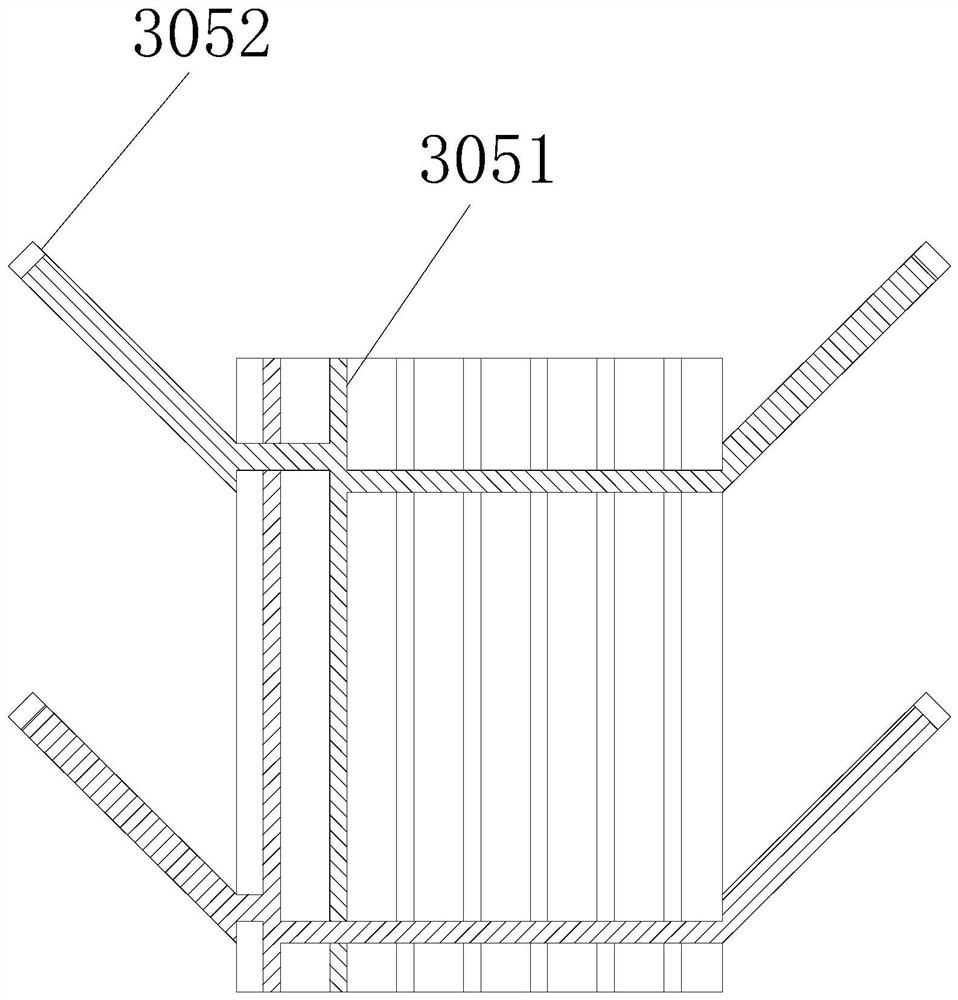

[0041] Such as Figure 1 to Figure 5 As shown, the mud-water separation sludge anaerobic digestion treatment system of the present invention includes: a sludge anaerobic digestion unit, a drainage assembly and a cyclone 104 for realizing sludge-water separation. The sludge anaerobic digestion unit includes a sludge anaerobic digestion tank 100. The sludge anaerobic digestion tank 100 is provided with a sludge inlet pipe 114, a sludge circulation stirring component and a detection element. The top of the cyclone 104 is connected to the drainage component. The bottom end of the cyclone 104 is connected with the mud inlet pipe 114 . A feed pipe 1041 is provided on the side of the cyclone 104 , and an electric pump 101 , a first flow detection element 102 , a second pressure detection element 414 and a first opening valve 103 are arranged in sequence on the feed pipe 1041 . The electric pump 101 can specifically be a rotor pump. Through the high-pressure action of the electric pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com