Horizontal combined numerical control lathe

A CNC lathe, horizontal technology, applied in the field of parts turning, can solve the problems of low labor efficiency, long production cycle, high cost, etc., achieve the effect of reducing labor intensity, simple structure, saving manpower and financial resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

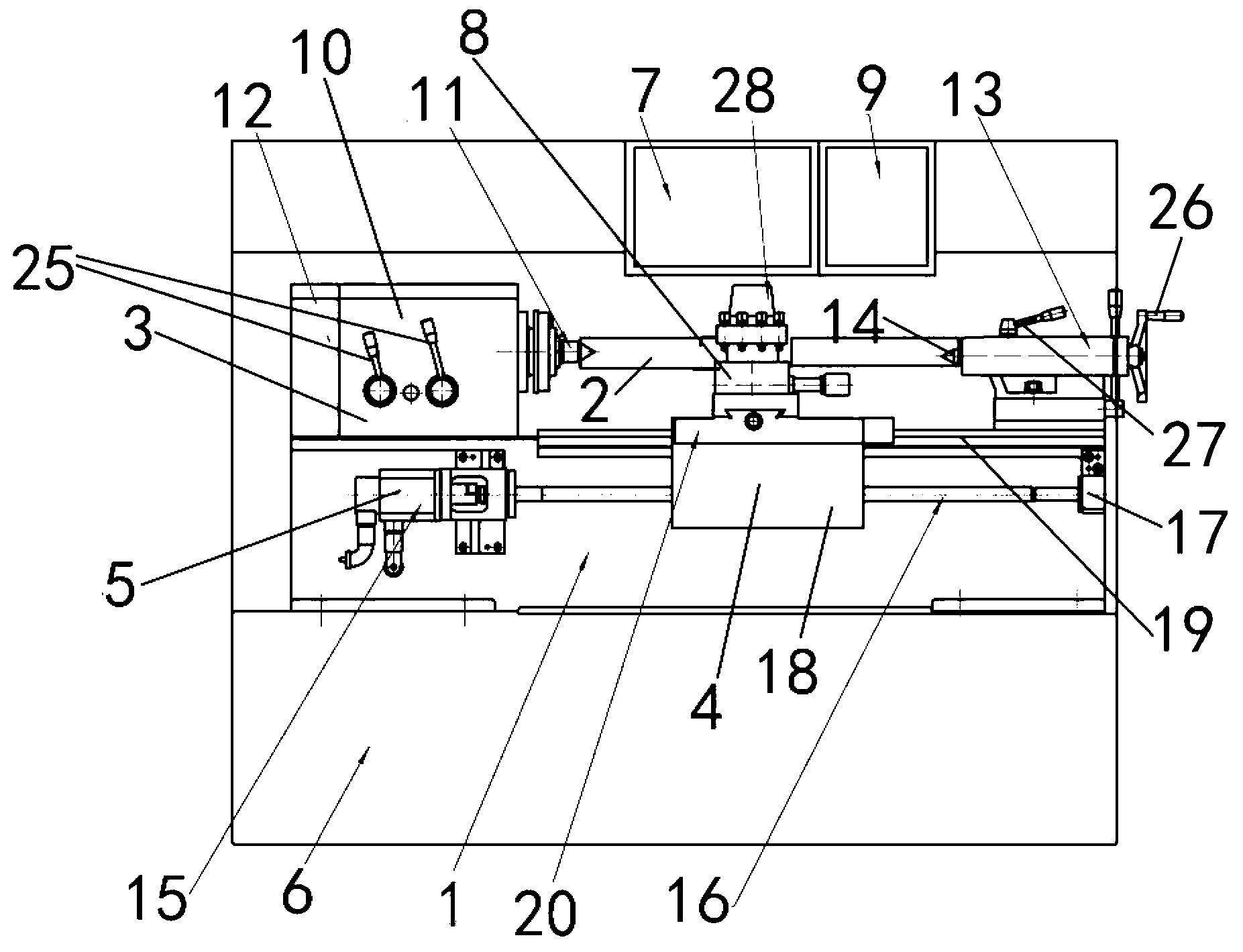

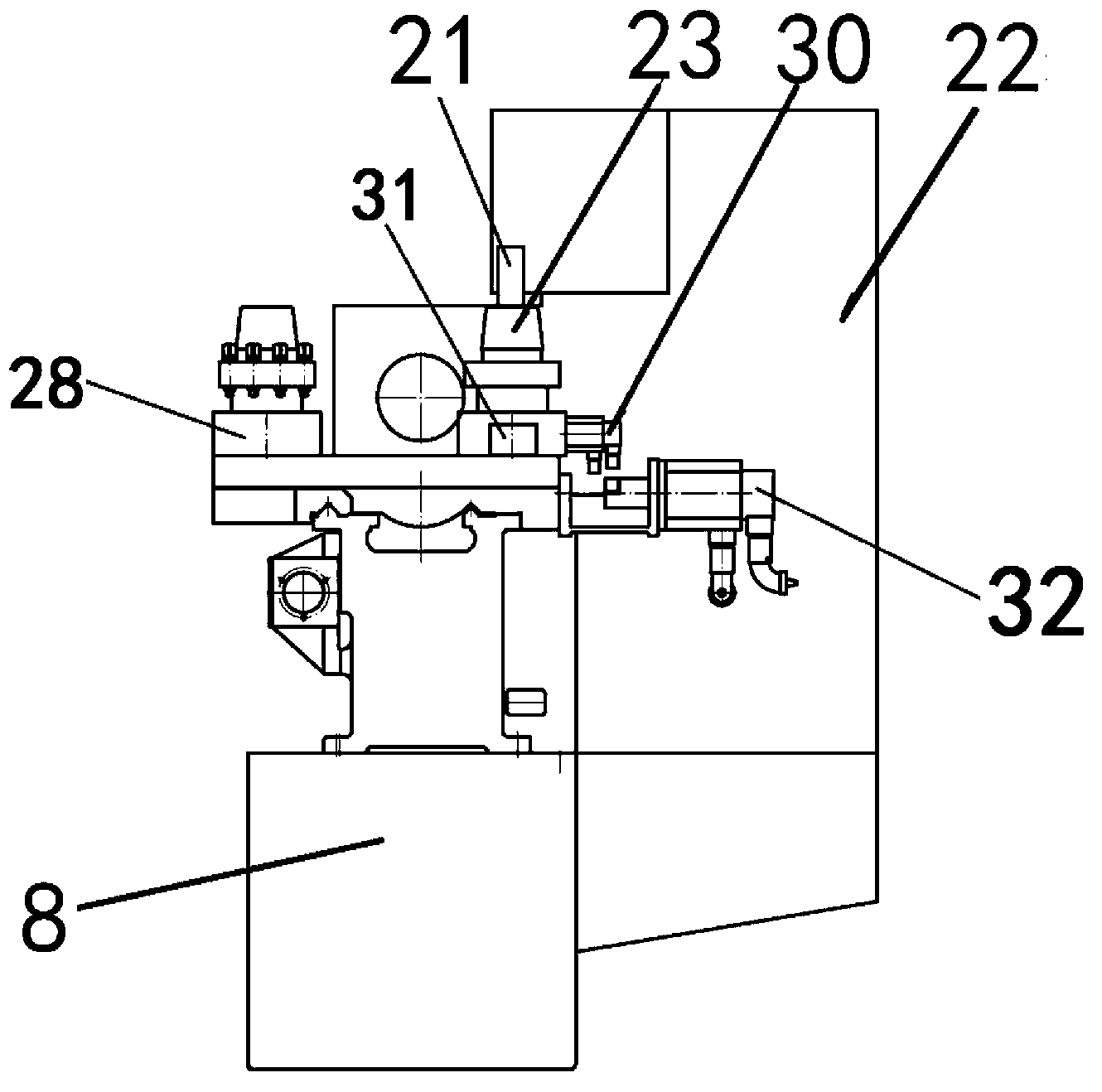

[0024] Below with reference to the accompanying drawings, through the description of the embodiments, the specific embodiments of the present invention, such as the shape, structure, mutual position and connection relationship between the various parts, the role and working principle of the various parts, etc., will be further described. Detailed instructions:

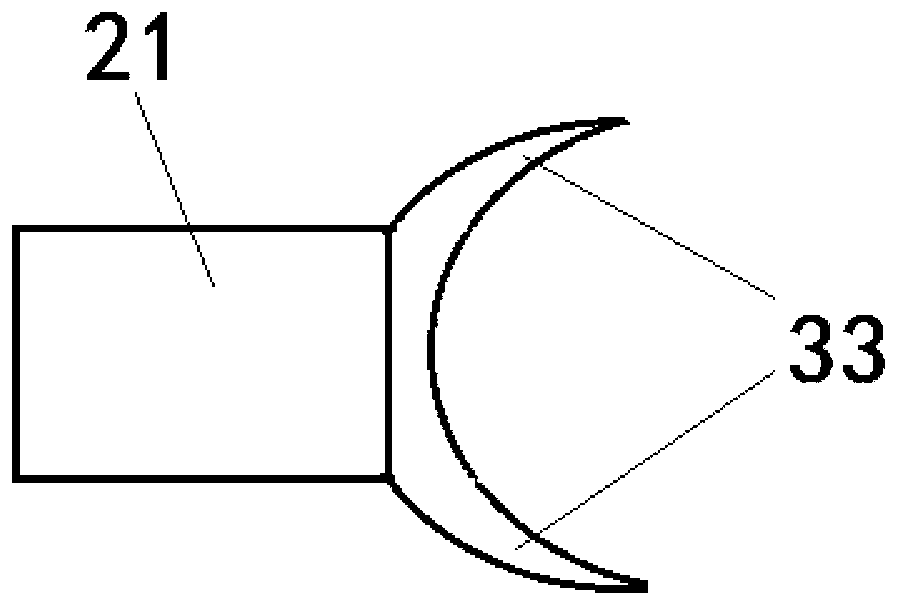

[0025] as attached figure 1 — attached image 3 As shown, the present invention is a kind of horizontal compound numerical control lathe, described numerical control lathe comprises machine tool bed 1, and described machine tool bed 1 is provided with the positioning part 3 that can clamp workpiece 2, machining tool 4, drive Part 5, the drive part 5 is set to a structure capable of driving the movement of the processing tool 4, the drive part 5 and the positioning part 3 are respectively connected with the numerical control part 7, and the machine tool bed 1 or the processing tool 4 is also provided with a movable ult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com