Patents

Literature

32results about How to "Increase the carrying load" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

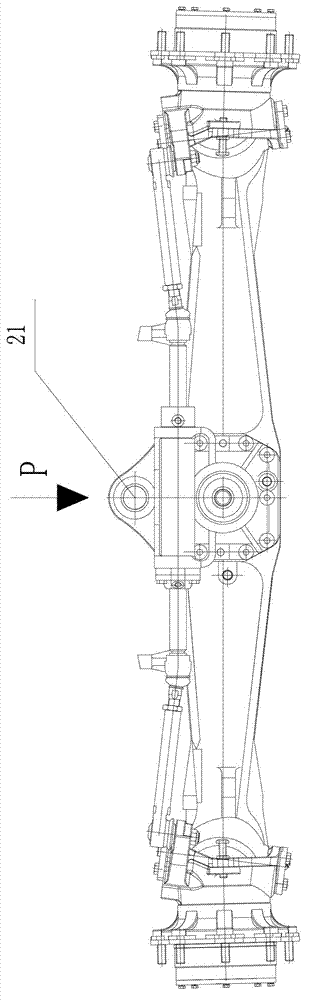

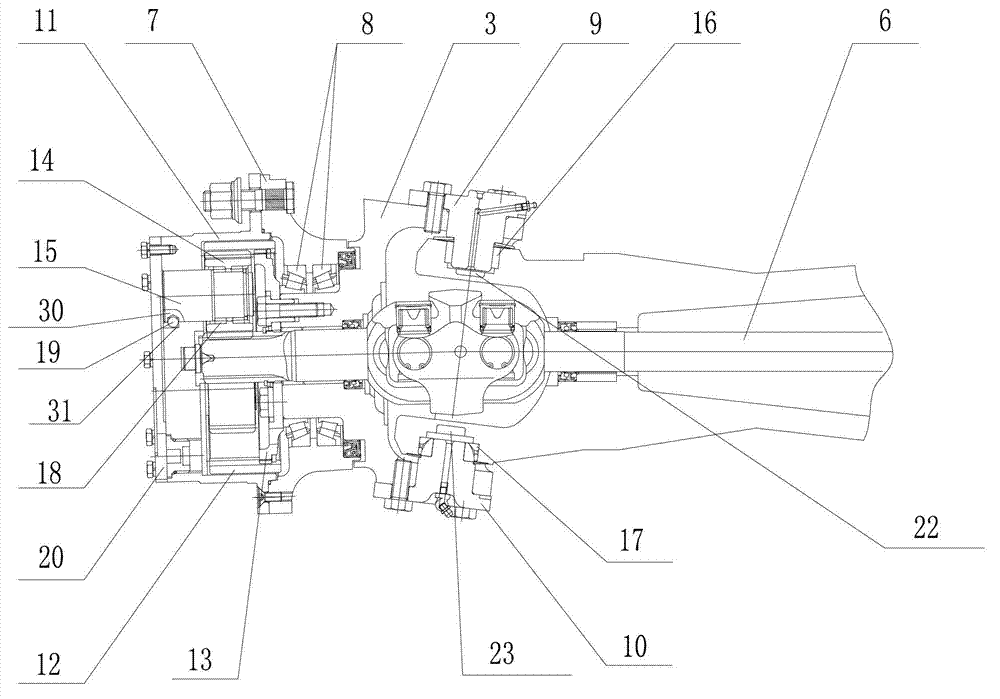

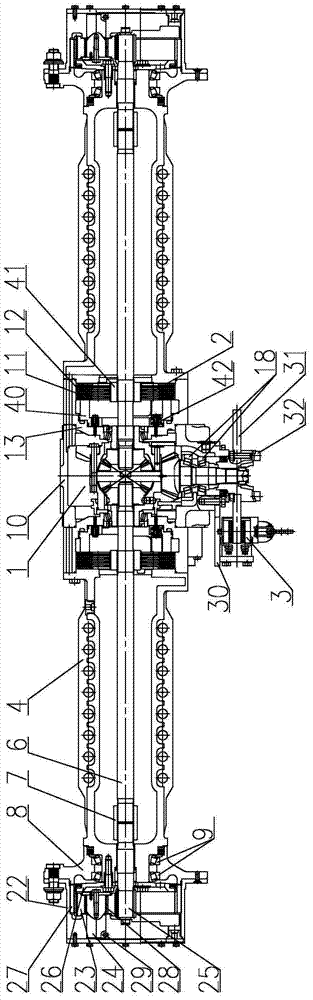

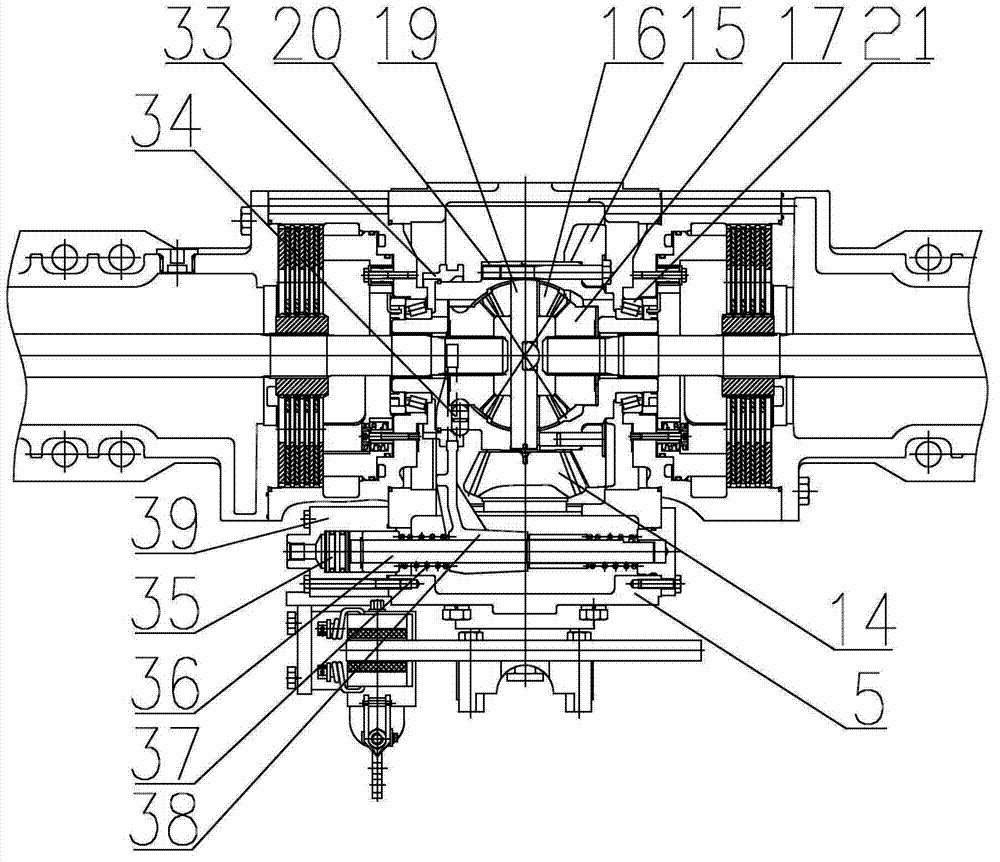

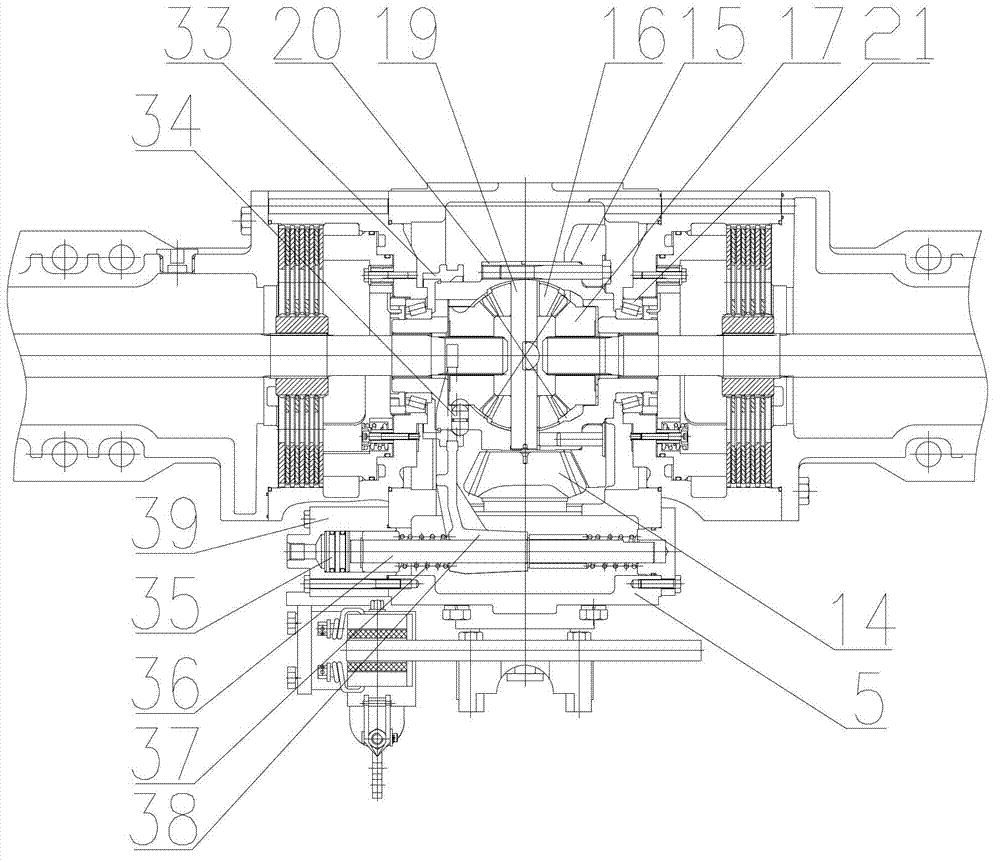

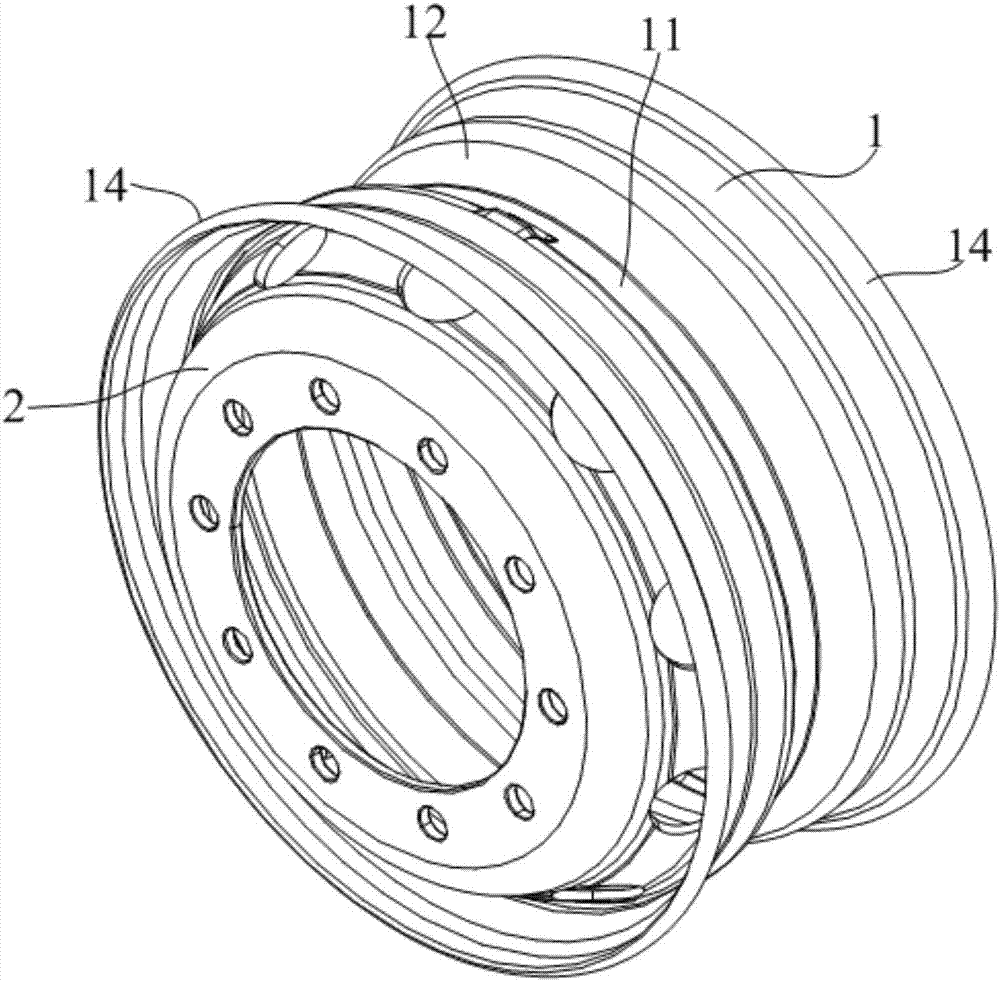

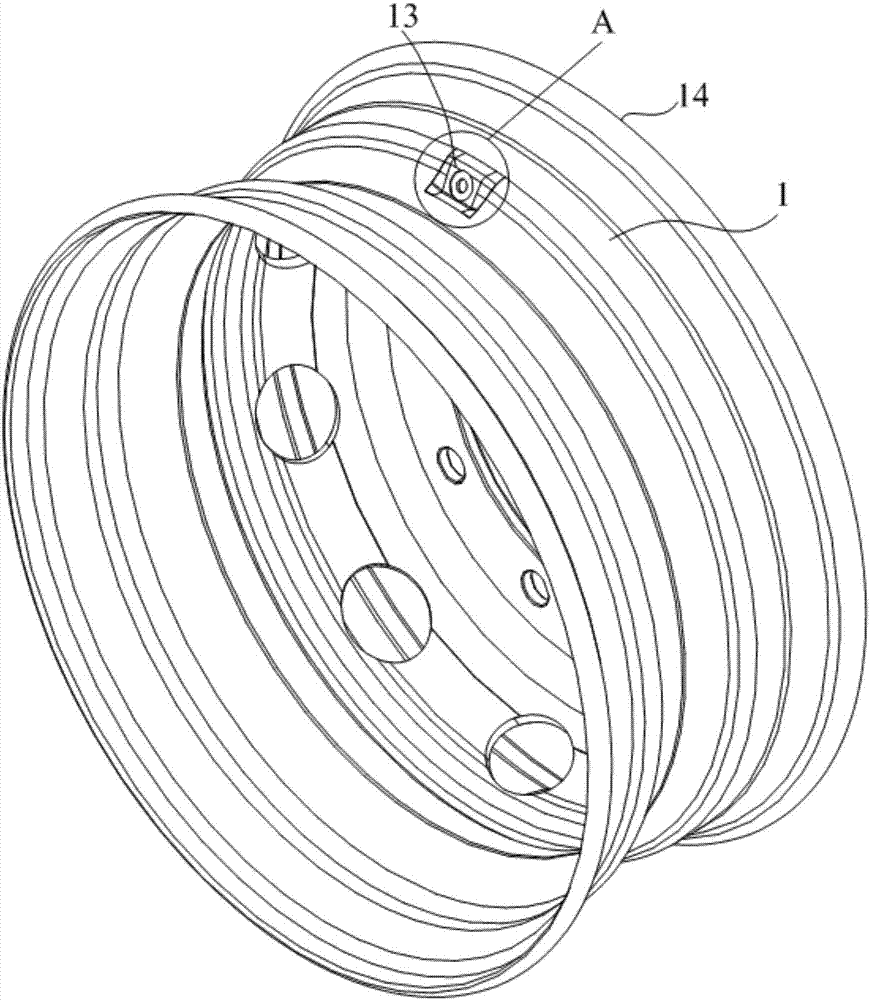

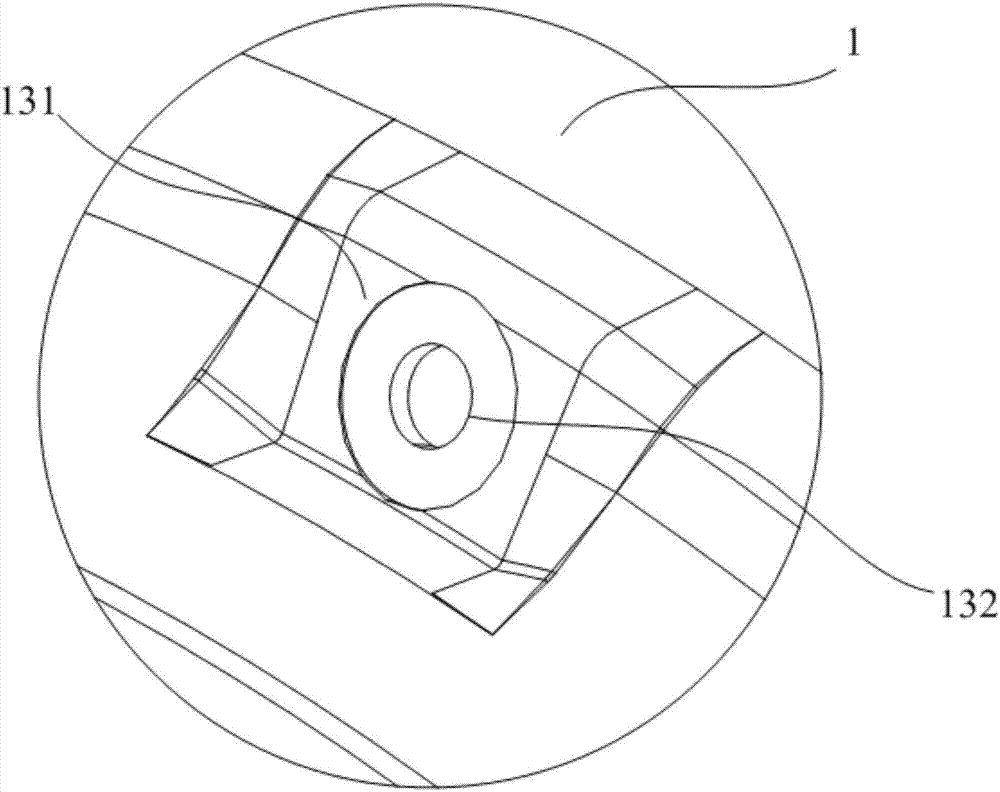

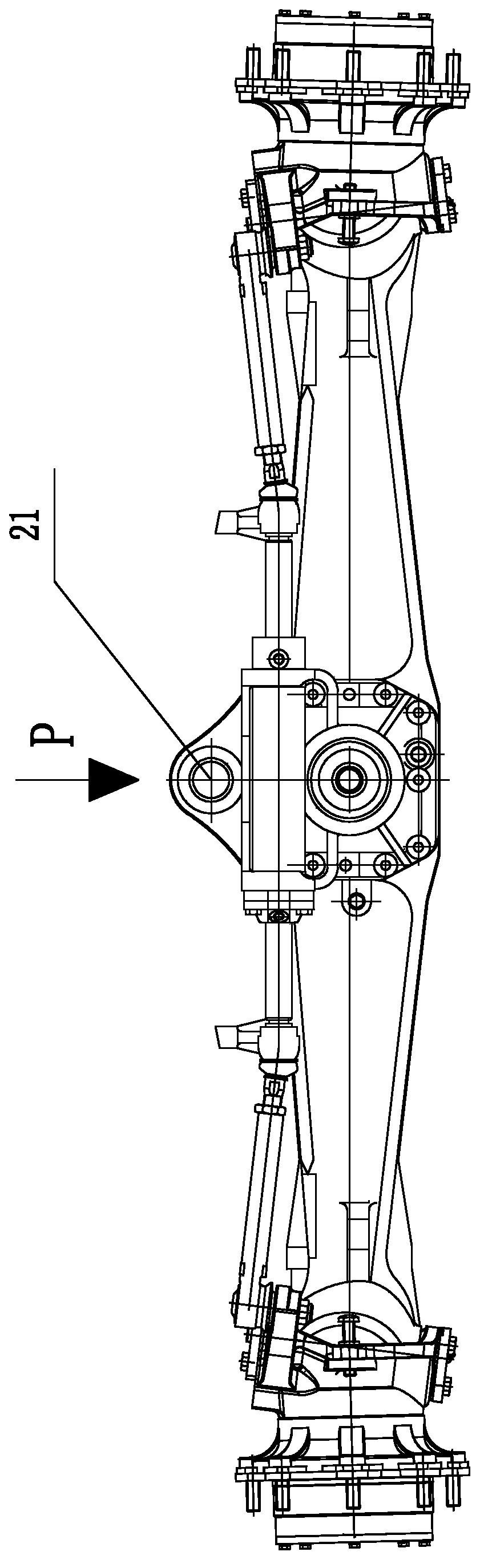

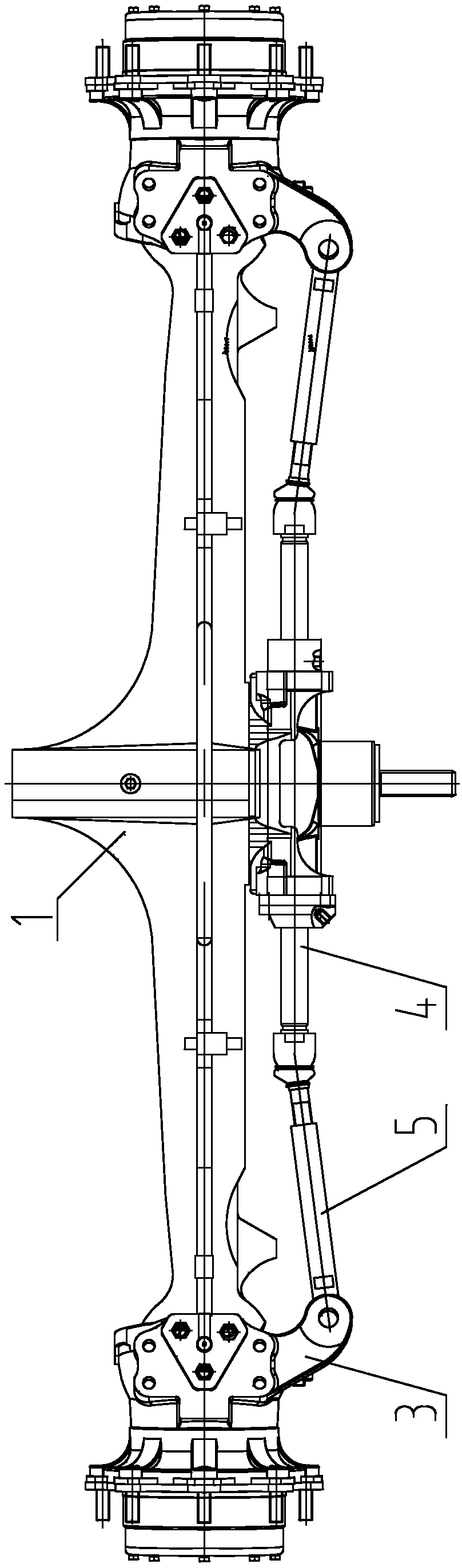

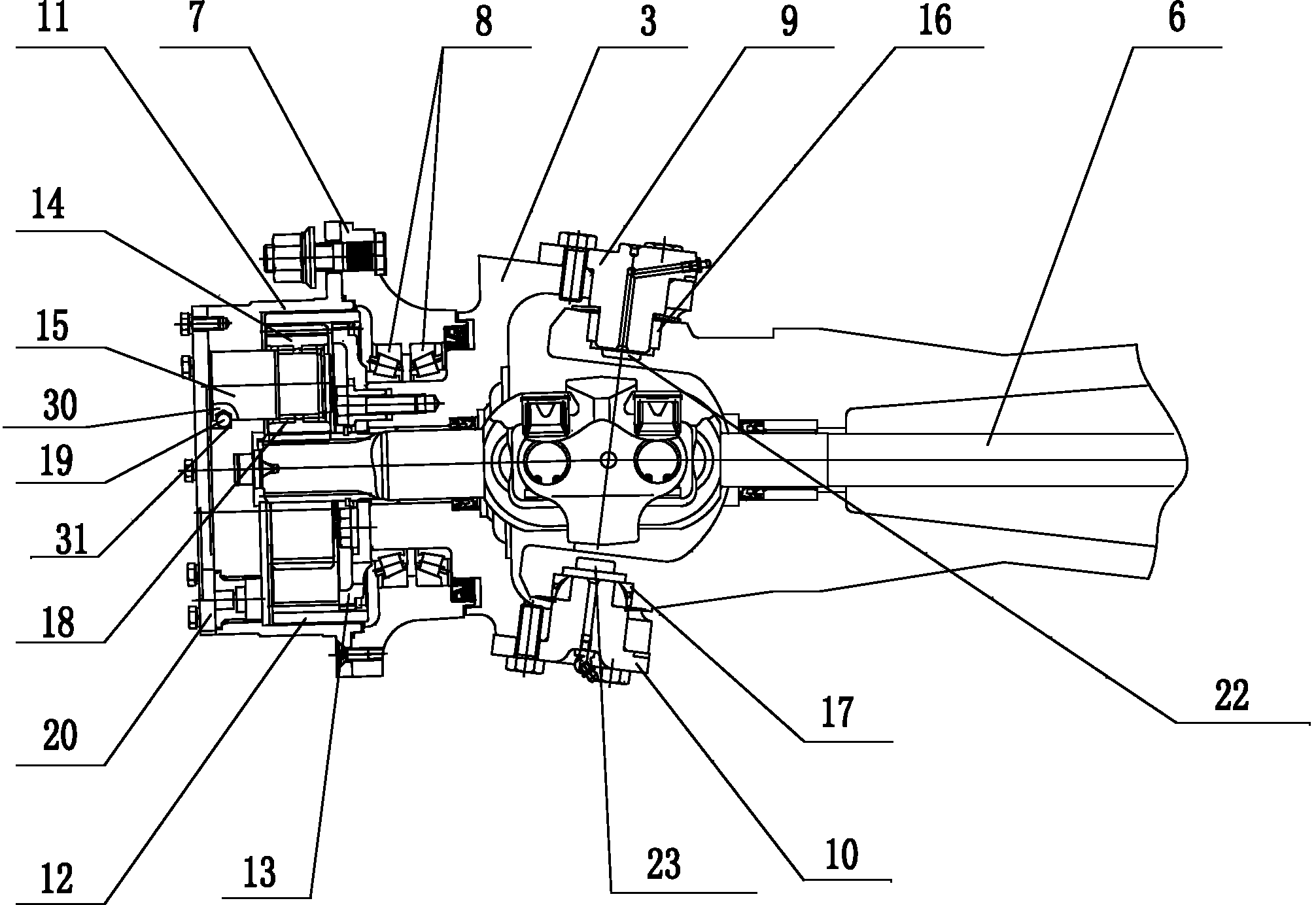

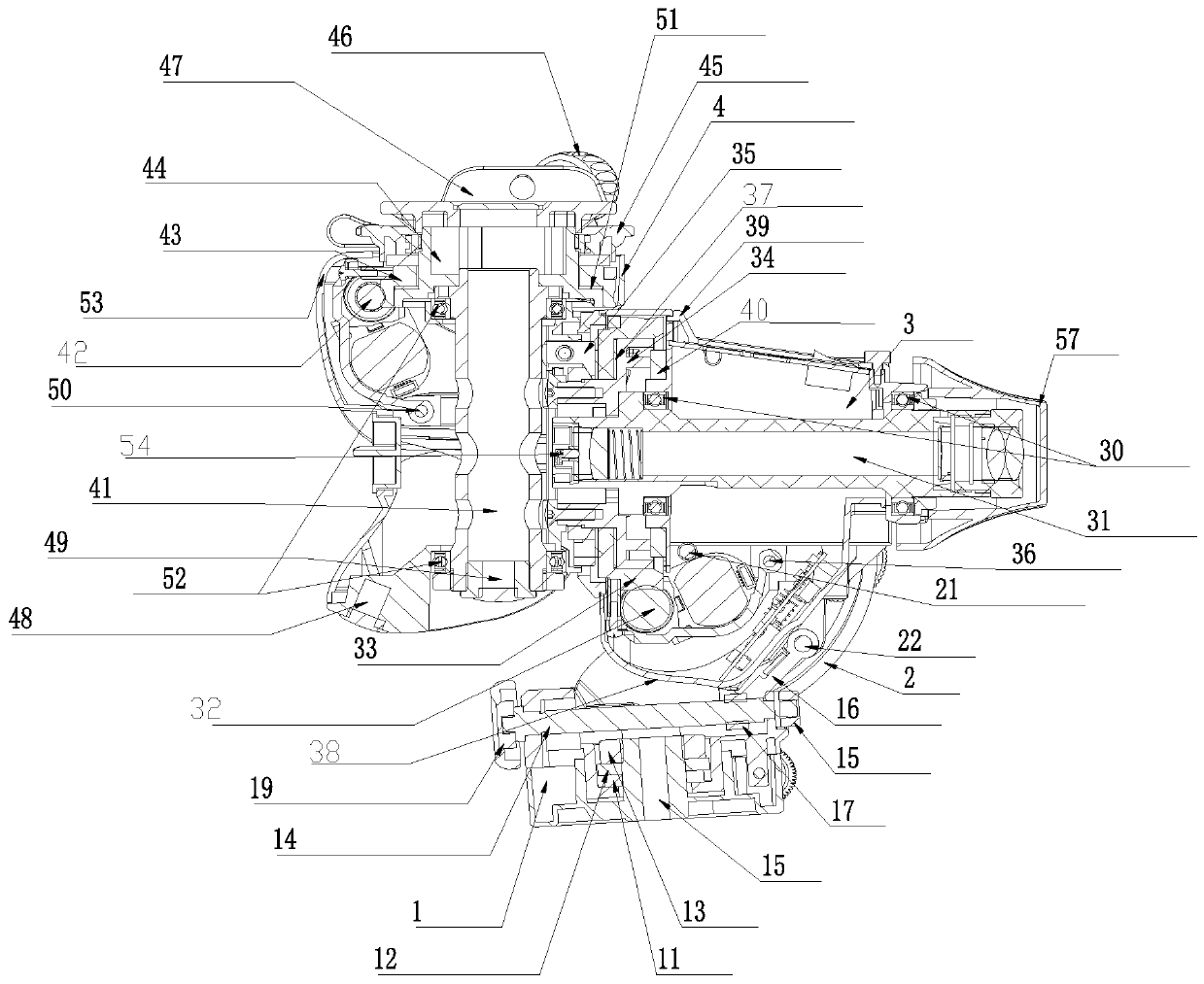

Front steering drive axle assembly

The invention discloses a front steering drive axle assembly which comprises an axle housing (1), hubs (7), a main speed reducer belt differential assembly and wheel rim speed reducers, wherein the axle housing is provided with a balance pin hole (21) connected with a vehicle chassis; the two hubs are connected to the left end and the right end of the axle housing by hub steering structures (3); the middle part of the axle housing is provided with a cavity; the main speed reducer belt differential assembly is arranged inside the cavity; each of the two sides of the main speed reducer belt differential assembly is connected with a driving shaft (6) in a rotating mode; the driving shafts are rotatably connected with the wheel rim speed reducers on the two ends of the axle housing; the axle housing is provided with a wheel steering drive device (4); the wheel steering drive device is respectively connected with the hub steering structures of the two hubs; the section of the axle housing is in a cavity structure in a square shape; the edge of a planet wheel axle (15) is provided with a small hole (30); a wheel rim speed reducer (11) is correspondingly provided with a sinking slot (31); an anti-shifting ball (19) is installed between the hole and the slot; and the outmost side of the wheel rim speed reducer shell is provided with an end cover (20).

Owner:南京创捷和信汽车零部件有限公司

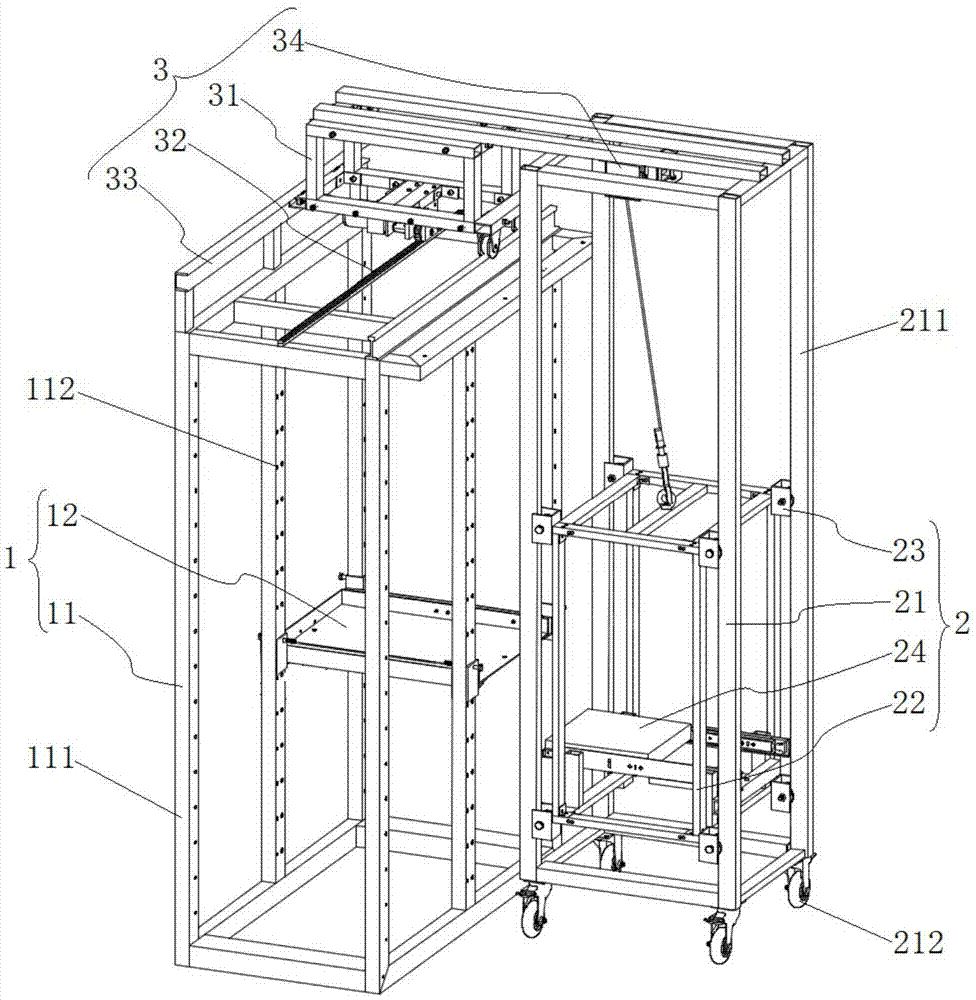

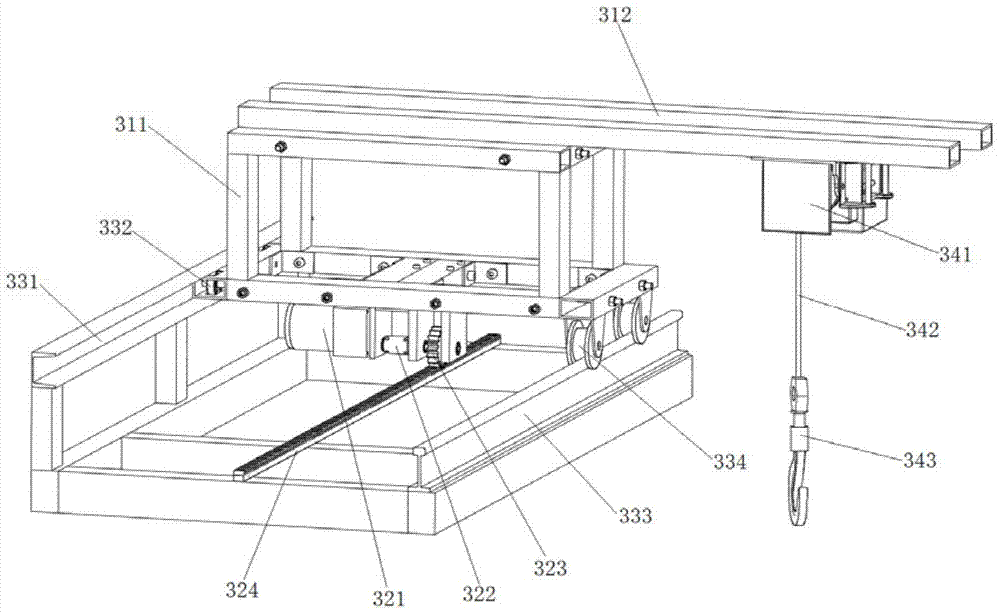

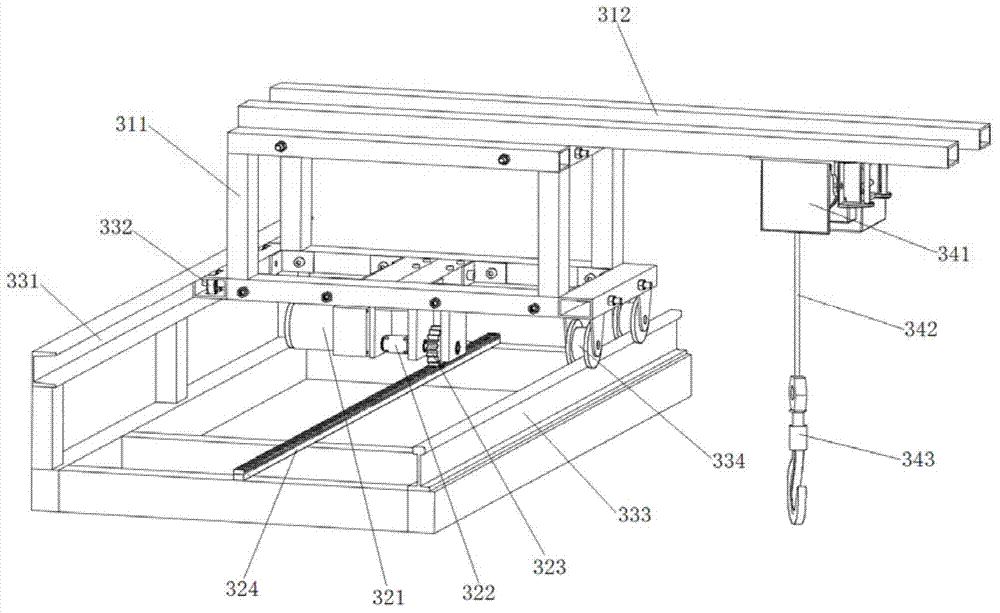

High level rack with intelligent and automatic loading and unloading functions

ActiveCN105438704AImprove loading and unloading efficiencySimple structureStorage devicesEngineeringMechanical engineering

Owner:美玛特电子科技(常州)有限公司

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724AImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed onthe bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolongedat a maximum level.

Owner:KINGDREAM PLC CO +2

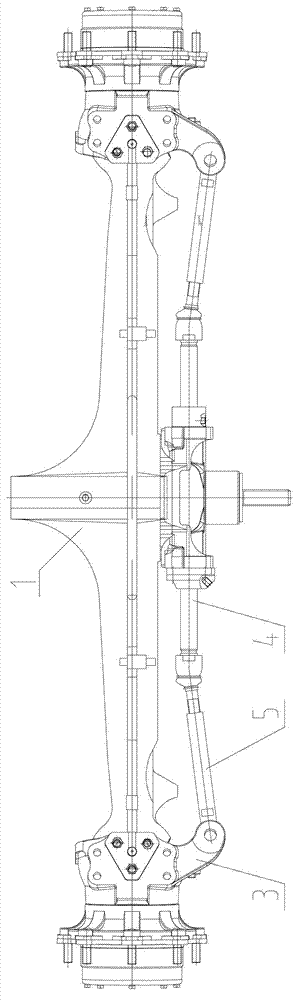

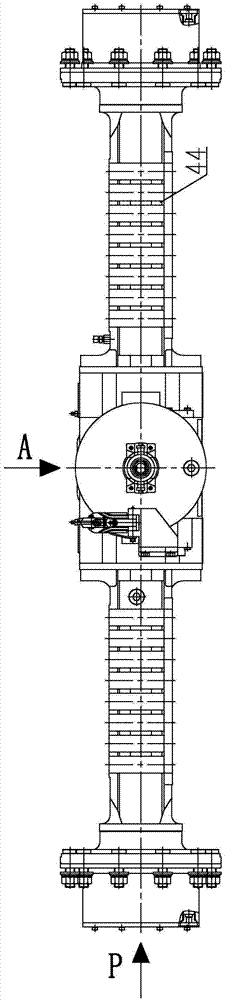

Rear drive axle assembly

ActiveCN102774240ASimple structureEffective decelerationBraking element arrangementsAxle unitsDrive shaftReduction drive

The invention discloses a rear drive axle assembly. The rear drive axle assembly comprises an axle casing which is in a girder structure, two wheel hubs, a main reducing gear and differential mechanism assembly, a braking assembly, a hub reduction gear, a forced differential lock and a parking brake, wherein the forced differential lock comprises a sliding meshing sleeve, a differential mechanism lockpin, a piston, a selector rod, a back-moving spring and a shifting fork, the shifting fork is connected fixedly with a shifting fork shaft, the back-moving spring is arranged between the shifting fork and the shifting fork shaft, a groove which is matched with the shifting fork is arranged on the sliding meshing sleeve, grooves which are matched with the differential mechanism lockpin are arranged on the sliding meshing sleeve and a driving shaft gear of the main reducing gear and differential mechanism assembly correspondingly, the parking brake comprises a brake body and a brake disk, the brake body is arranged on a main reducing gear casing of the main reducing gear and differential mechanism assembly, the brake disk is arranged on a main tooth flange, and a plane and an installation hole, which are connected with the machine base plate, are arranged on the axle casing. The rear drive axle assembly has the advantages of being good in parking and heat radiation performance, large in bearing capacity, simple in structure and convenient to process and produce.

Owner:南京创捷和信汽车零部件有限公司

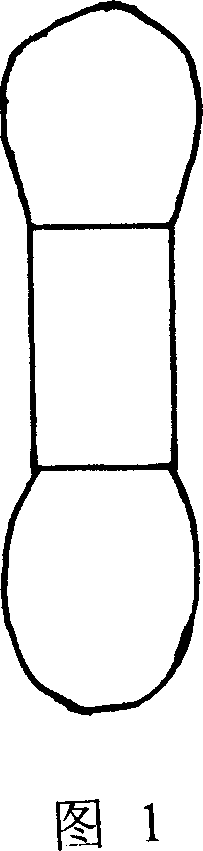

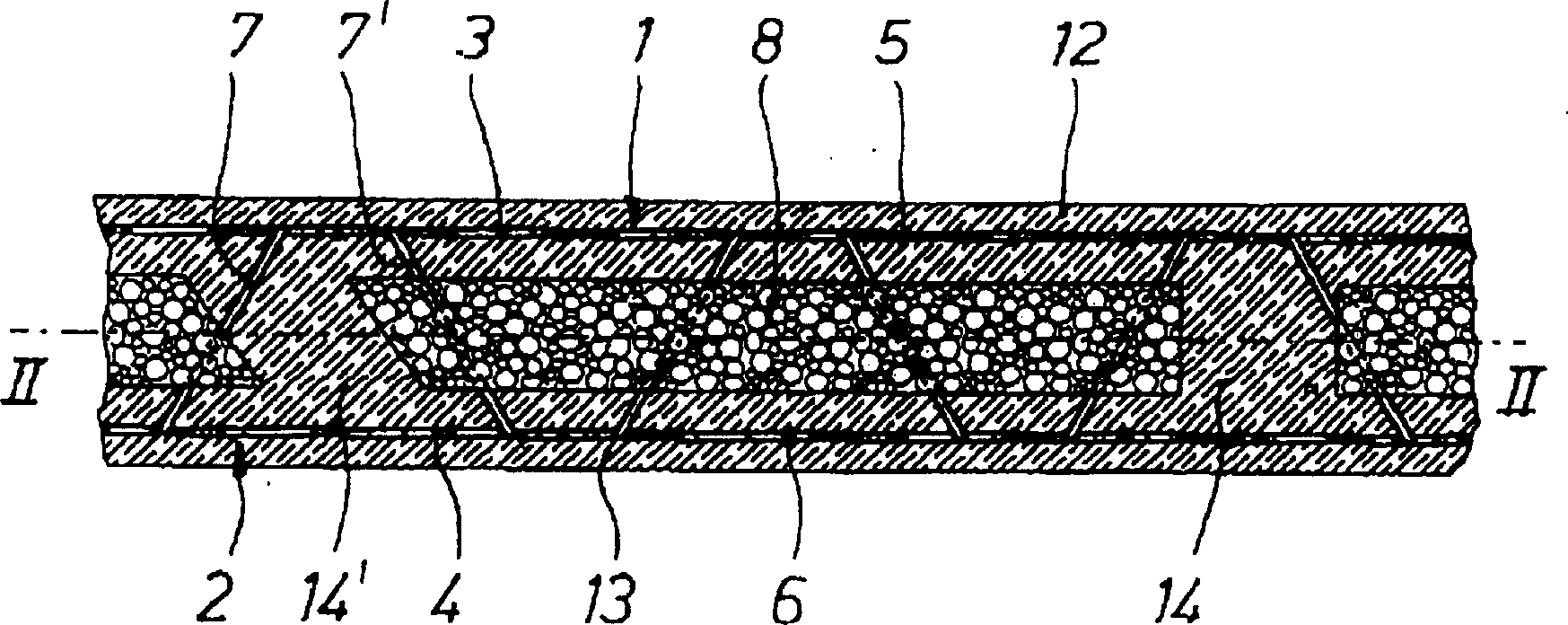

High-speed elevator balancing compensation chain and production method of anchor chain thereof

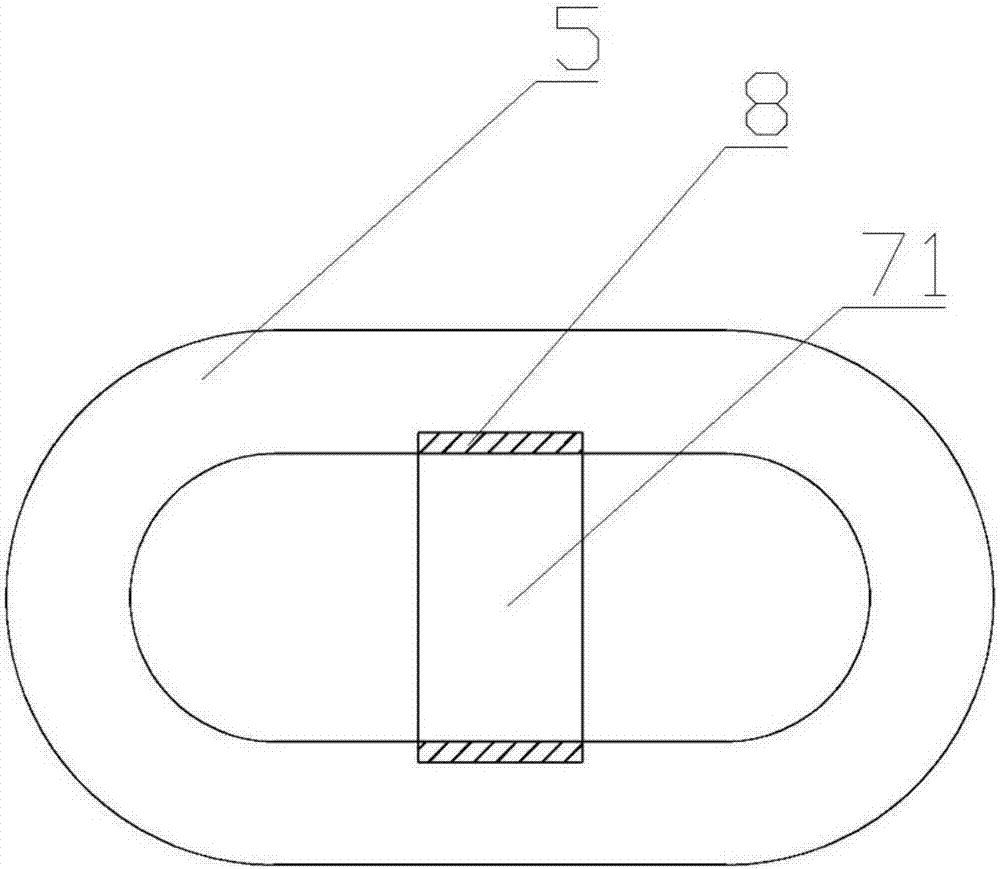

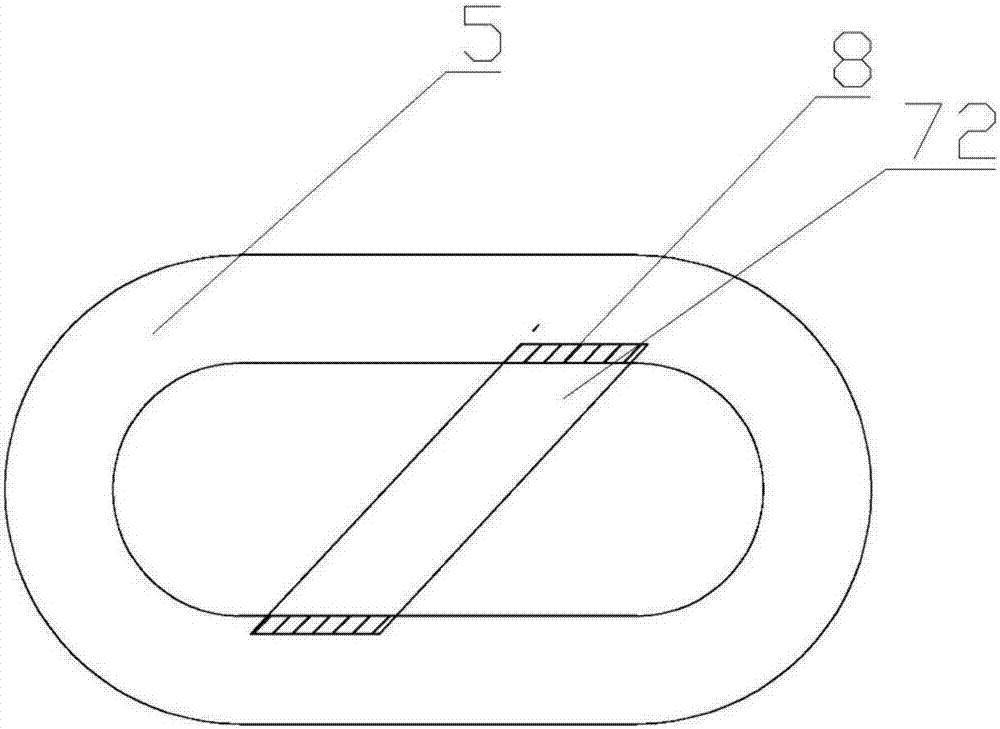

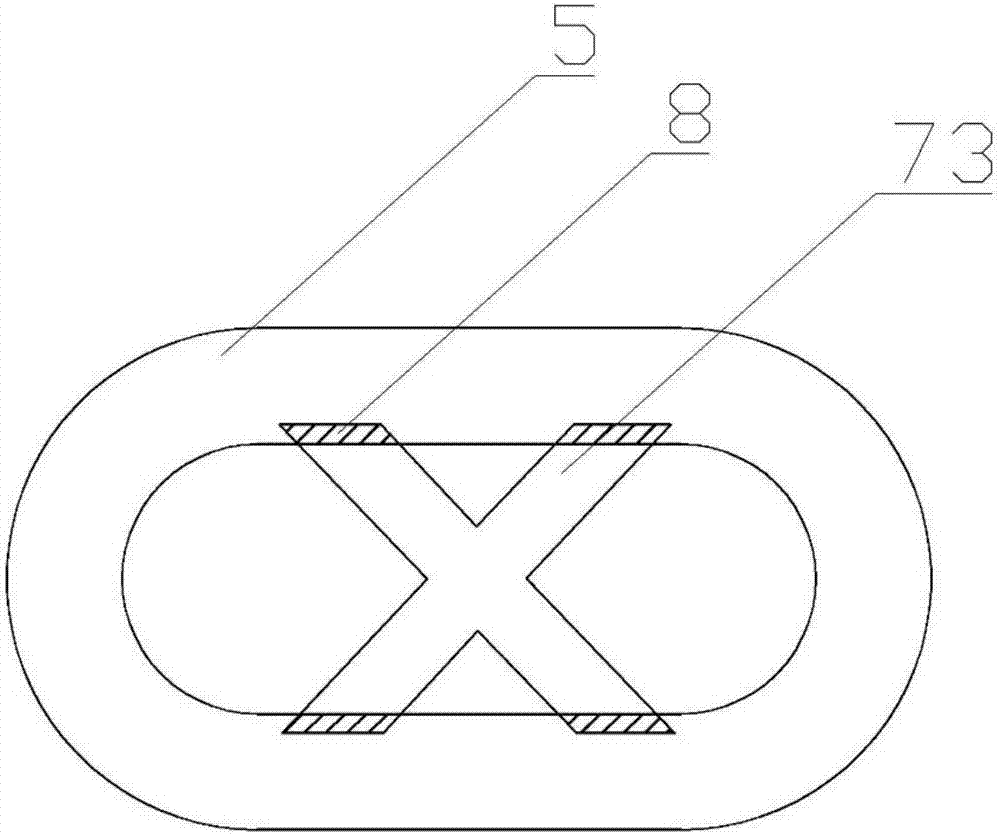

InactiveCN107082341AHigh strengthIncrease the carrying loadElevatorsEngineeringMechanical engineering

The invention provides a high-speed elevator balancing compensation chain and a production method of an anchor chain thereof. The anchor chain comprises unstudded anchor chains and interior-studded anchor chains, the interior-studded anchor chains comprise chain rings I and stay pins, the stay pins are located in the chain rings I and placed in the middles of the interior portions of the chain rings I, the stay pins connect the upper and lower portions of the chain rings I, and the stay pins and the chain rings I are connected through connecting buckles. The unstudded anchor chains comprise chain rings II, the unstudded anchor chains and the interior-studded anchor chains are connected in a mode of 1 : 1-3, and the length of the chain ring II of each unstudded anchor chain is one to two times as much as the length of the chain ring I of each interior-studded anchor chain. According to the high-speed elevator balancing compensation chain and the production method of the anchor chain thereof, through the connecting mode, the chain rings of the anchor chain are not prone to loosing and slipping down in the operating process, noise in the operating process is reduced effectively, and the elevator balancing compensation chain is not prone to being twisted; and meanwhile, the strength and the borne load of the elevator balancing compensation chain are effectively enhanced on the premise that the whole weight is not added, and the elevator balancing compensation chain can be suitable for a high-speed elevator at a speed greater than 3 m / s.

Owner:JIANGSU XINGHUA RUBBER BELT

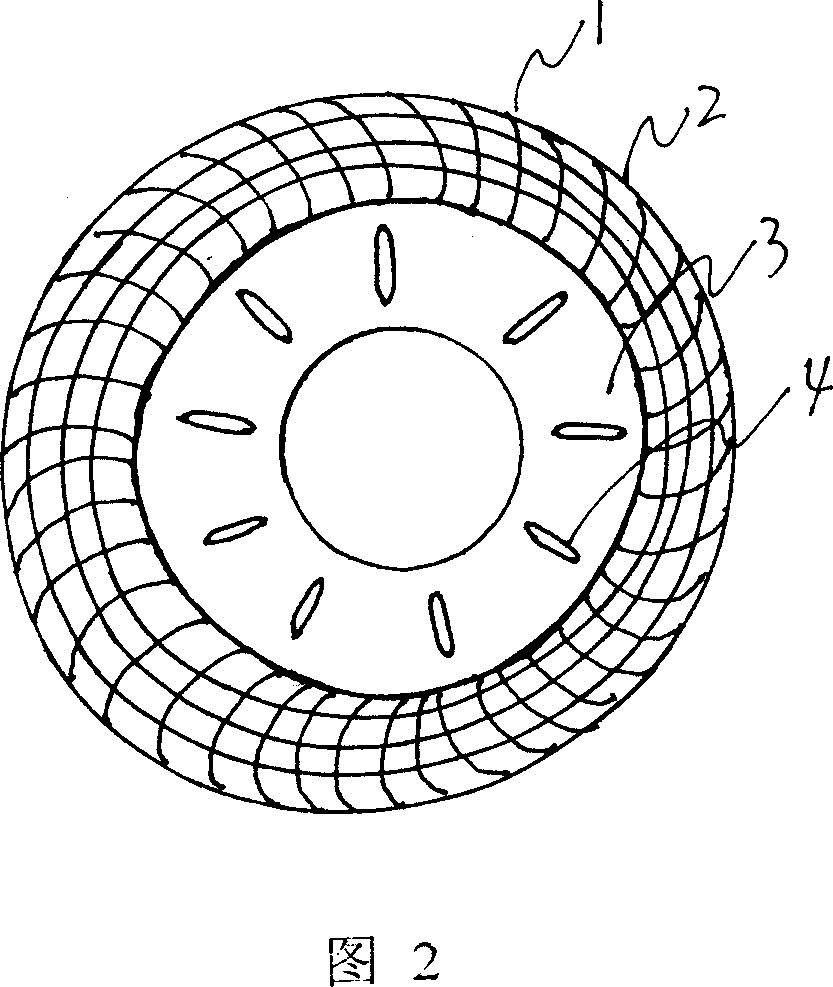

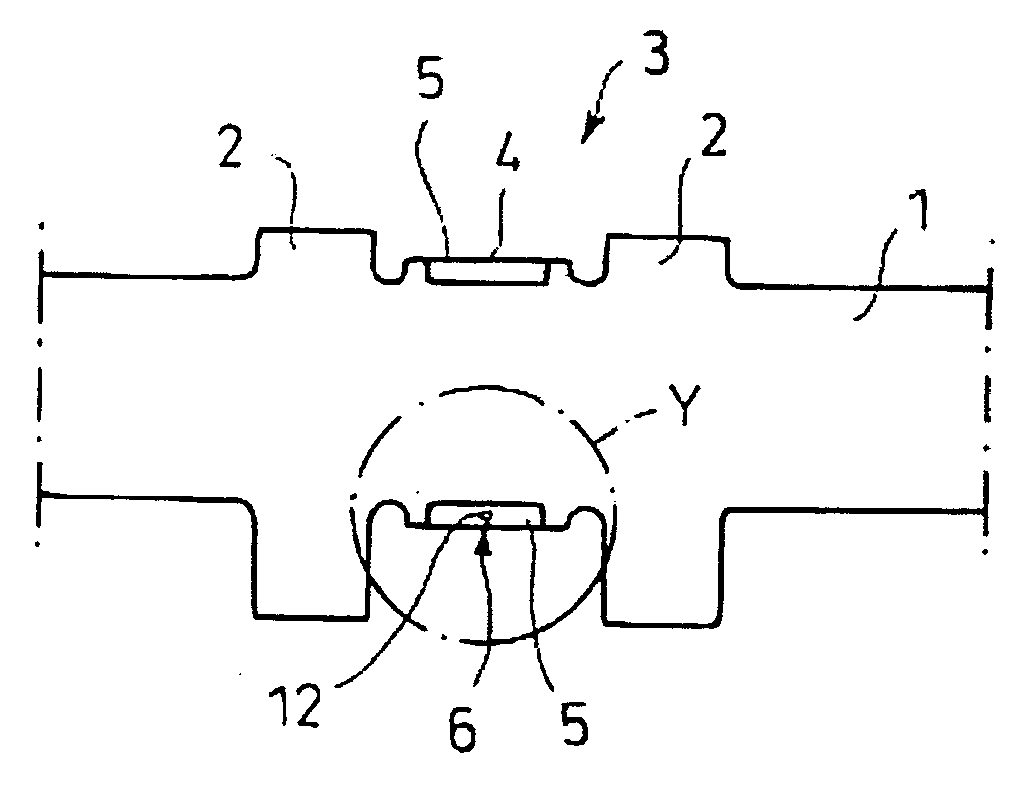

Non-inflation and explosive-proof tyre

InactiveCN101073973AIncrease the carrying loadIncrease elasticityNon-inflatable tyresWoven fabricsElastomerEngineering

Owner:王伟鹏

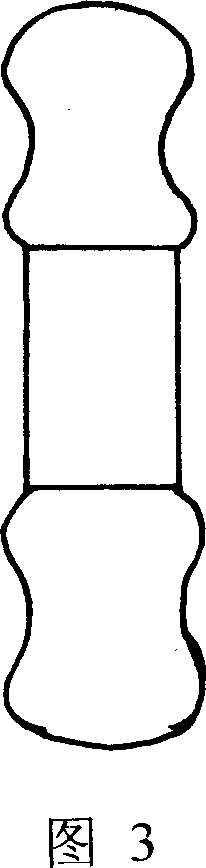

Production technology for elevator balance chain

PendingCN111618532AIncrease the carrying loadAvoid distortionManufacturing engineeringSurface smoothness

The invention relates to a production technology for an elevator balance chain. The production technology comprises the following steps of: S1: pointing; S2: drawing wires: carrying out drawing processing on a steel material by an inverted wire drawing machine, in a wire drawing process, adding wire drawing powders to lubricate the steel material, recycling the wire drawing powders, and supplementing taken-away loss in fixed time so as to prevent from generating waste wire drawing powders; S3: knitting: enabling the steel material to be formed into a spiral shape by a chain automatic knittingmachine, shearing the spiral steel material to enable the spiral steel material to be formed into an annular shape, clamping two ends of the annular steel material, enabling one end to rotate for 45 degrees, twisting a chain link into a three-dimensional annular shape to finish the shaping of one chain link, feeding the spiral material to enable the spiral material to penetrate through the shapedchain link, and circulating to form the chain; S4: carrying out butt welding; S5: correcting; and S6: carrying out shot blasting: utilizing friction between leather and the chain to carry out lubricating and polishing processing on the balance chain. The production technology has the following advantages that the bearing load of the elevator balance chain is improved, the elevator balance chain isprevented from twisting and deforming, and a surface degree of finish and surface smoothness can be improved.

Owner:南通市博创新材料有限公司

Self-repairing multi-soap based composite bearing lubricating grease and preparation method thereof

ActiveCN100412179CReduced antioxidant capacityGuaranteed validityDrill bitsAdditivesStructural ModifierPetroleum

The related composite poly-soap self-repair bearing lubricating grease comprises the basic liquid, composite calcium sulfonate, composite Ca-Li-base thickener, non-oxidizing anti-corrosion additive, metal deactivator, tungsten disulfide extreme pressure additive, wear-well additive, self-repair additive, and structural modifier; has well anti-oxidation ability and bearing capacity, can repair wore part on condition of extreme pressure and high temperature to supply the silver-plating lacking on bearing radial surface effectively, prolongs bearing service time on maximum limit, and has special application in oil drilling exploration.

Owner:SINOPEC OILFIELD EQUIP CORP +1

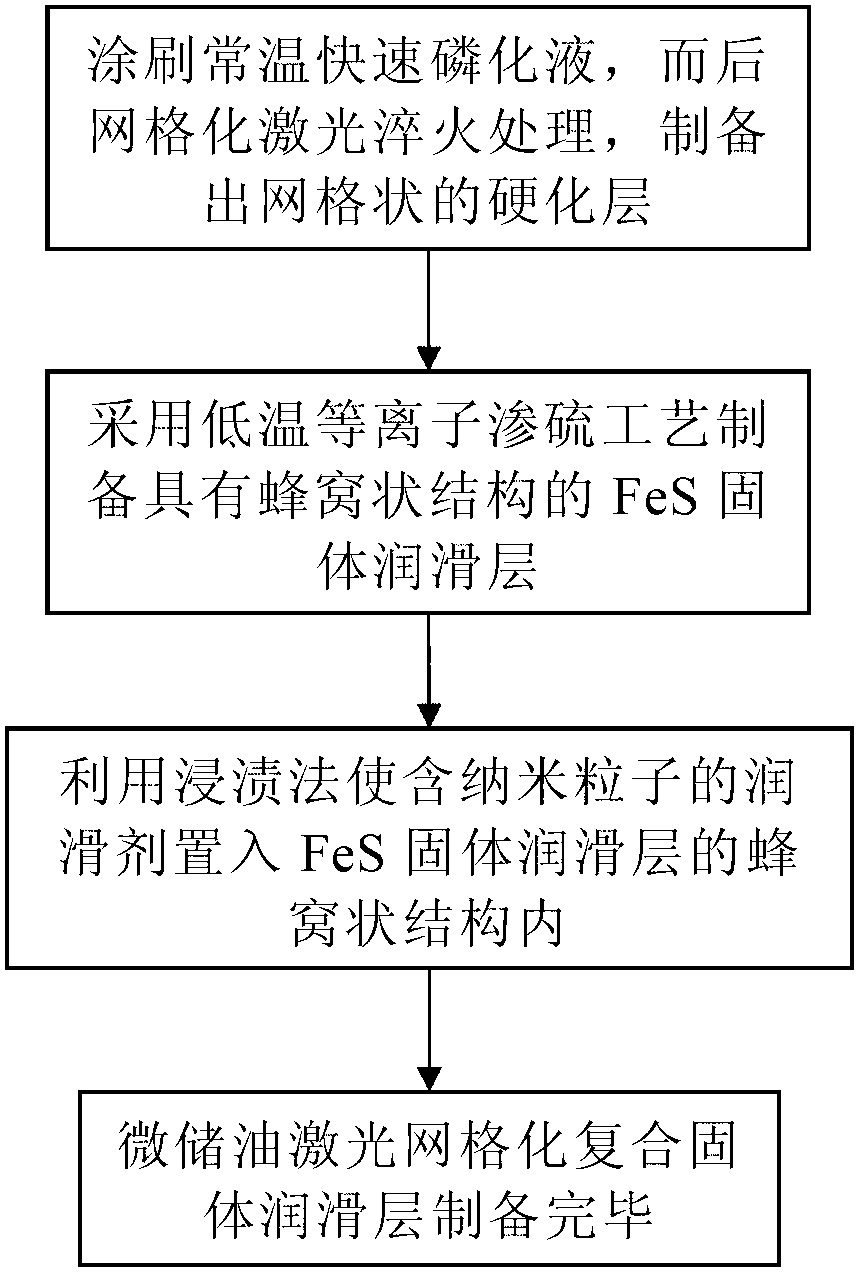

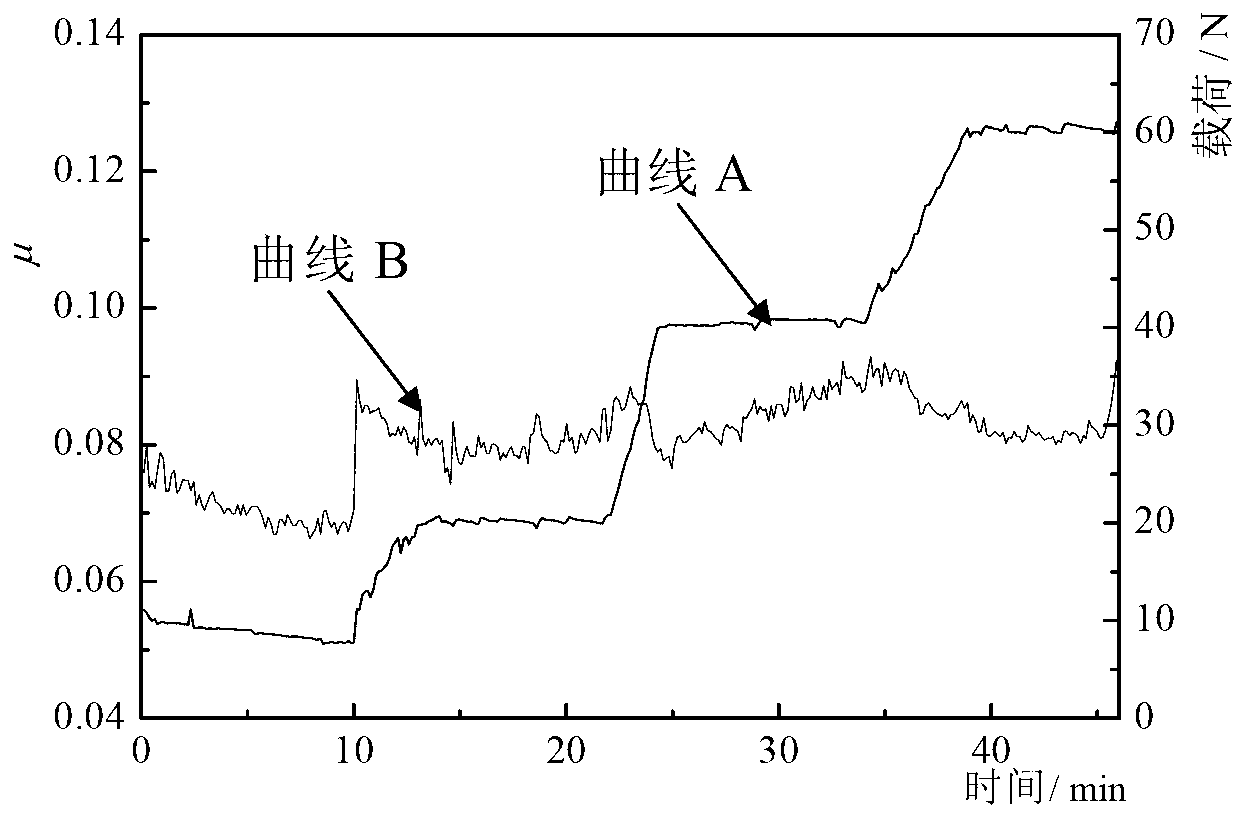

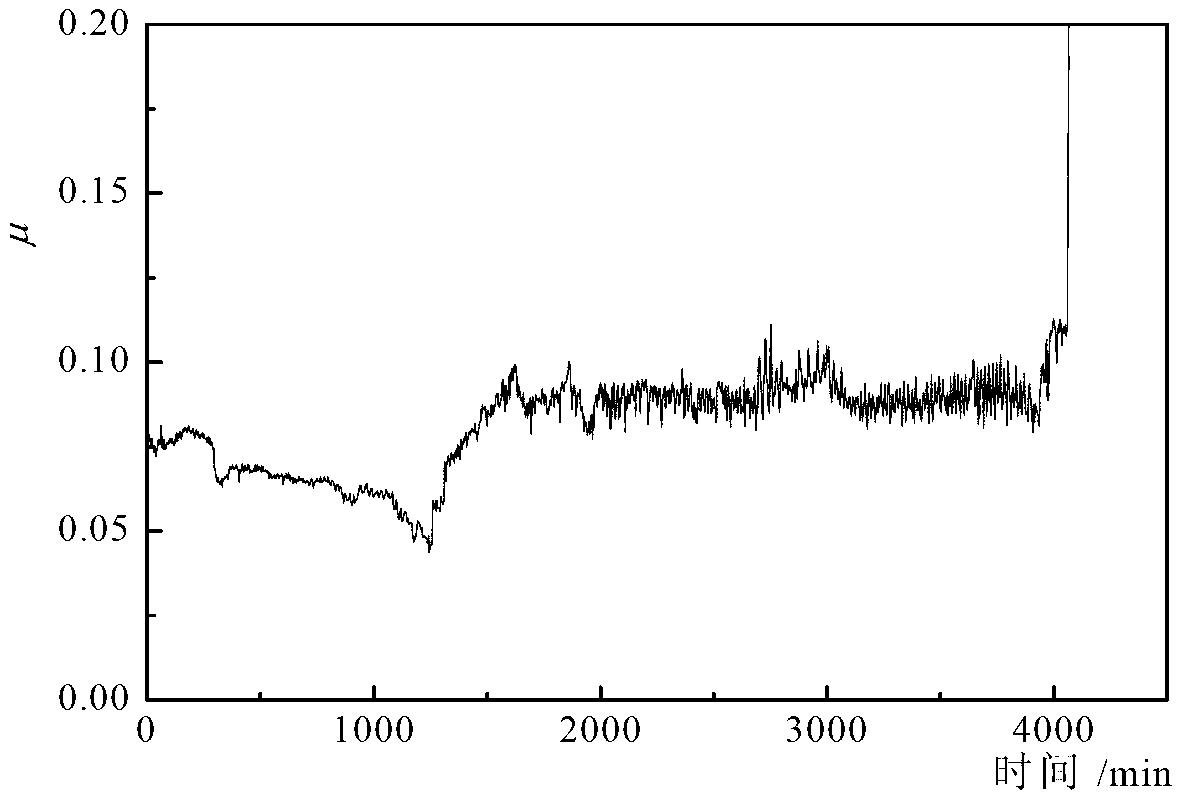

Preparation method for micro-oil storage laser grid composite solid lubricating layer

InactiveCN103276395AReduce coefficient of frictionImprove anti-wear performanceSolid state diffusion coatingSuperimposed coating processOptoelectronicsMechanical equipment

The invention discloses a preparation method for a micro-oil storage laser grid composite solid lubricating layer. The method comprises the following steps. Room-temperature quick phosphating solution is painted on the surface of chromium, molybdenum, and copper alloy cast iron of mechanical equipment parts to be processed. After the room-temperature quick phosphating solution is dried, grid laser-quenching treatment is carried out. A gridded hardened layer is formed on the surface of the chromium, molybdenum, and copper alloy cast iron. A FeS solid lubricating layer with a honeycomb structure is prepared on the hardened layer by the low-temperature plasma sulfurizing technology. Nanoparticle-containing lubricant is loaded in the honeycomb structure of the FeS solid lubricating layer by the impregnation method and therefore the micro-oil storage laser grid composite solid lubricating layer is finished. The micro-oil storage laser grid composite solid lubricating layer is advantaged by low friction coefficient, high abrasion resistance and high load carrying capacity. The micro-oil storage laser grid composite solid lubricating layer can raise the reliability of mechanical equipment parts, extend the service life and reduce the maintenance cost.

Owner:ACADEMY OF ARMORED FORCES ENG PLA +1

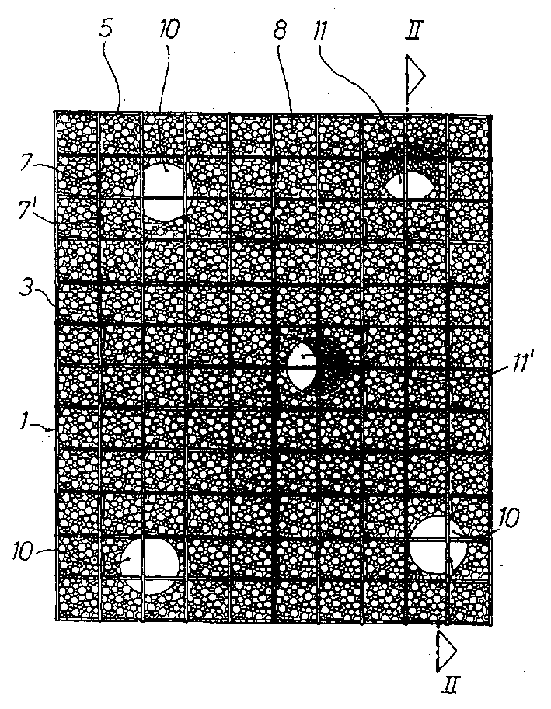

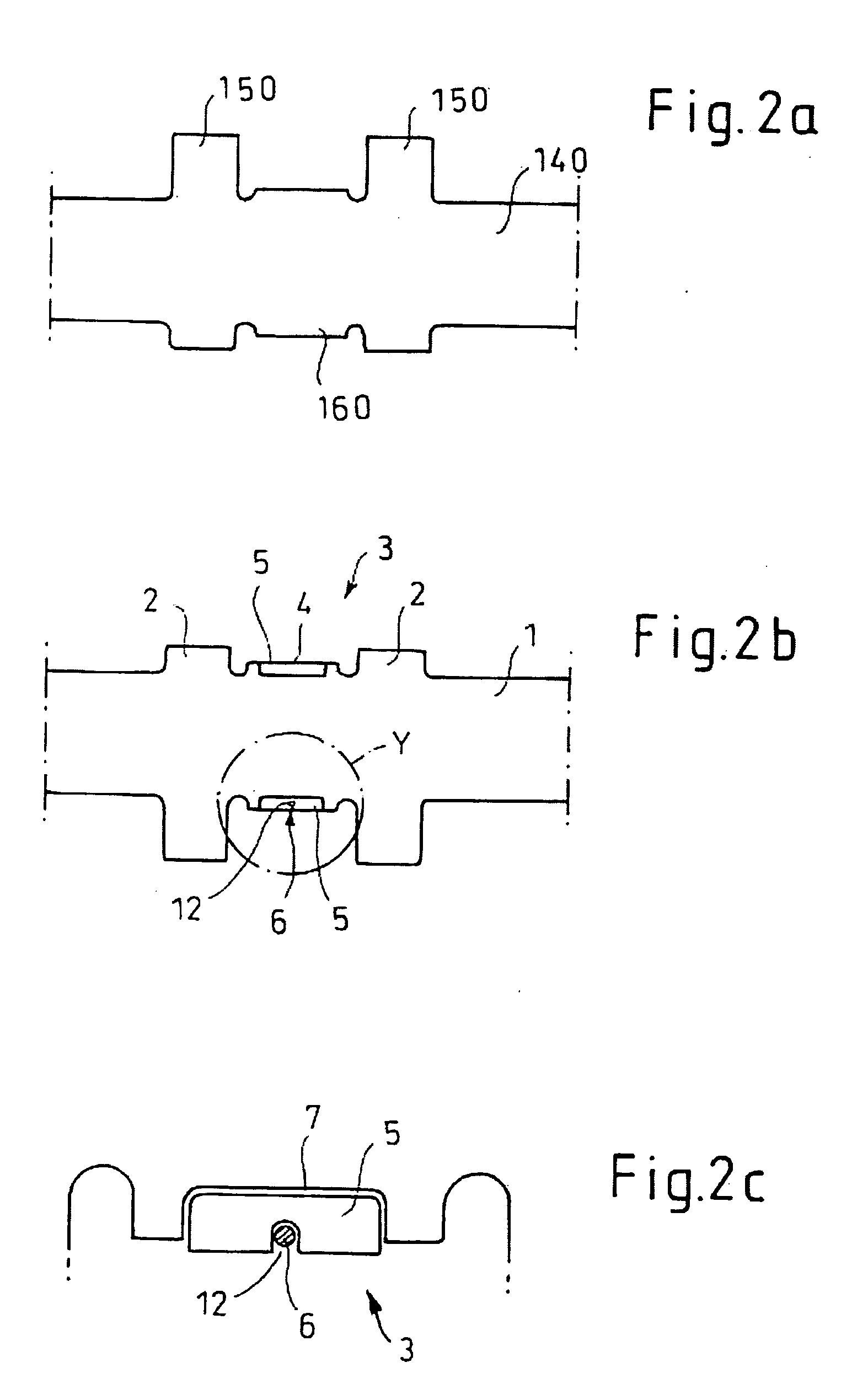

Building element

InactiveCN1131913CImprove insulation effectIncrease the carrying loadConstruction materialArchitectural engineeringRebar

Owner:EVG ENTWICKLUNGS & VERW GMBH

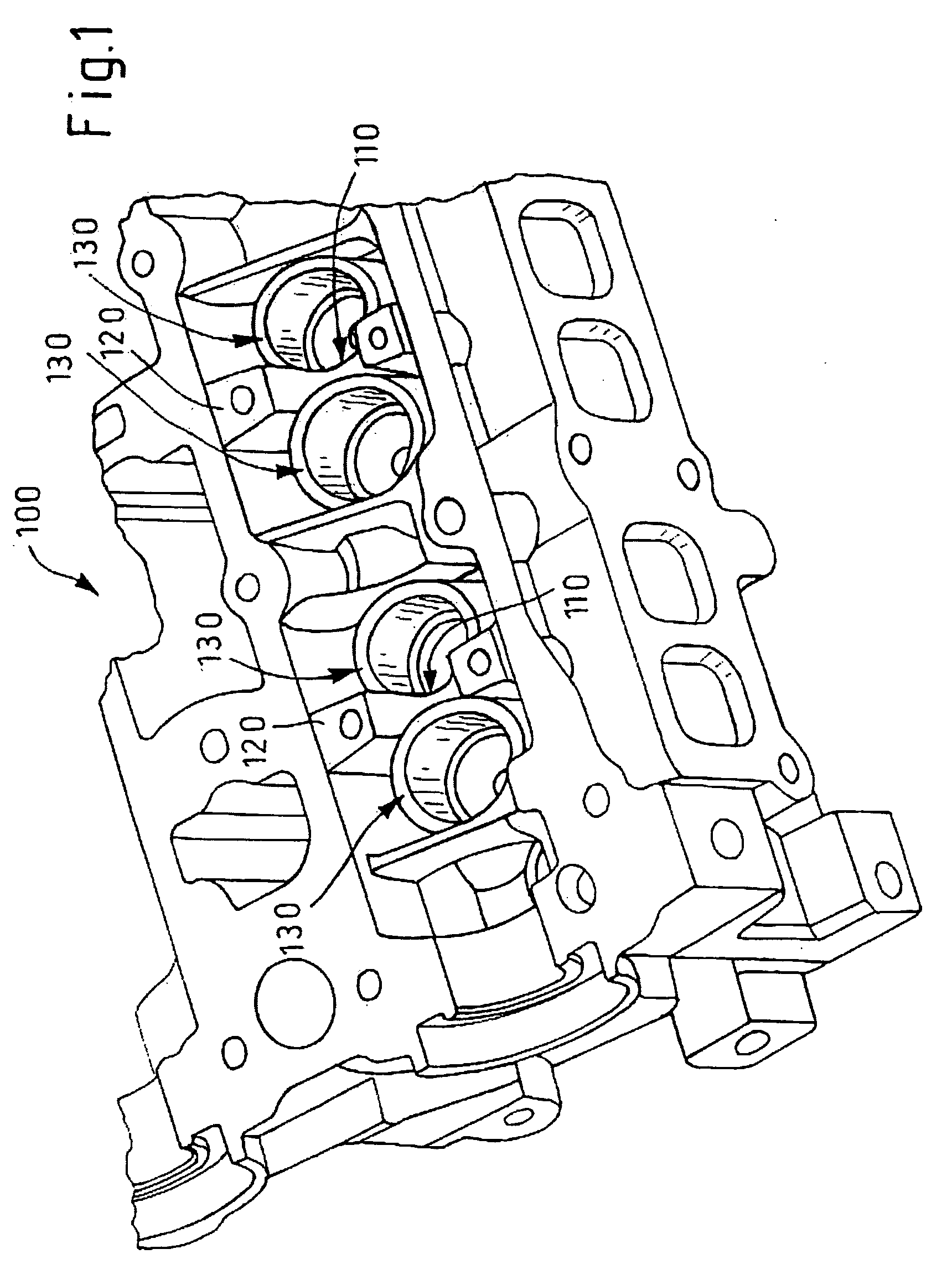

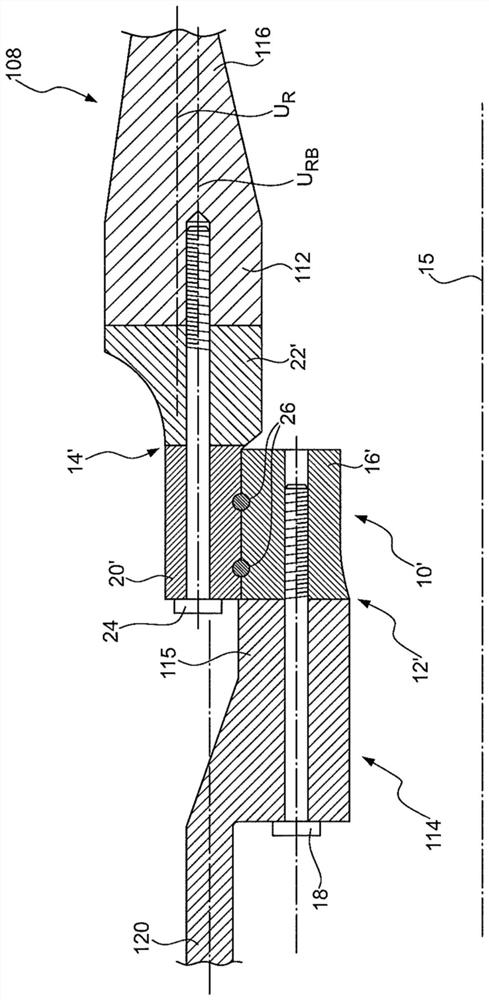

System with camshaft and camshaft receptacle

InactiveUS20060096559A1Increase the carrying loadIncrease frictionLubrication of auxillariesValve drivesStructural engineeringPlain bearing

The invention relates to a system, comprising a camshaft with at least two bearing points, a two-part camshaft receptacle which has, in a lower part, at least two bearing saddles and, in an upper part, at least two bearing covers corresponding to the bearing saddles, the camshaft being mounted with its bearing points in the bearing saddles and bearing covers. Further, bearing half shells are provided, of which in each case two are arranged in pairs between a bearing point and the bearing saddle and bearing cover receiving this bearing point, so that, the bearing half shells are supported on the bearing saddle or bearing cover and in each case two bearing half shells, together with a bearing point form a radial plain bearing.

Owner:FORD GLOBAL TECH LLC

Power transmission equipment capable of preventing accumulated snow

InactiveCN112751303AReduce the chance of separationAvoid transmission work impactSuspension arrangements for electric cablesSnow removalSnowpack

The invention relates to power transmission equipment capable of preventing accumulated snow; the equipment comprises a main body, a supporting box and two wiring devices, and further comprises a snow removing mechanism and two fixing mechanisms, each fixing mechanism comprises two fixing assemblies, and each fixing assembly comprises a fixing box, a fixing plate, an air bag, a pulling plate, a connecting pipe, two connecting rods and two first springs. The snow removing mechanism comprises a heating rod, an inflation assembly, a vibration assembly and two driving assemblies, the power transmission equipment realizes a cable clamping function through the fixing mechanism, and reduces the probability of separation of a cable and a binding post, thereby improving the stability when the cable is connected with the binding post, and avoiding the influence on the power transmission work. And through the snow removing mechanism, the snow removal function is realized, so that accumulated snow cannot cover the binding post, the connection between the cable and the binding post cannot be influenced, the power transmission work cannot be influenced, and the reliability of the equipment is improved.

Owner:南京威日通电子科技有限公司

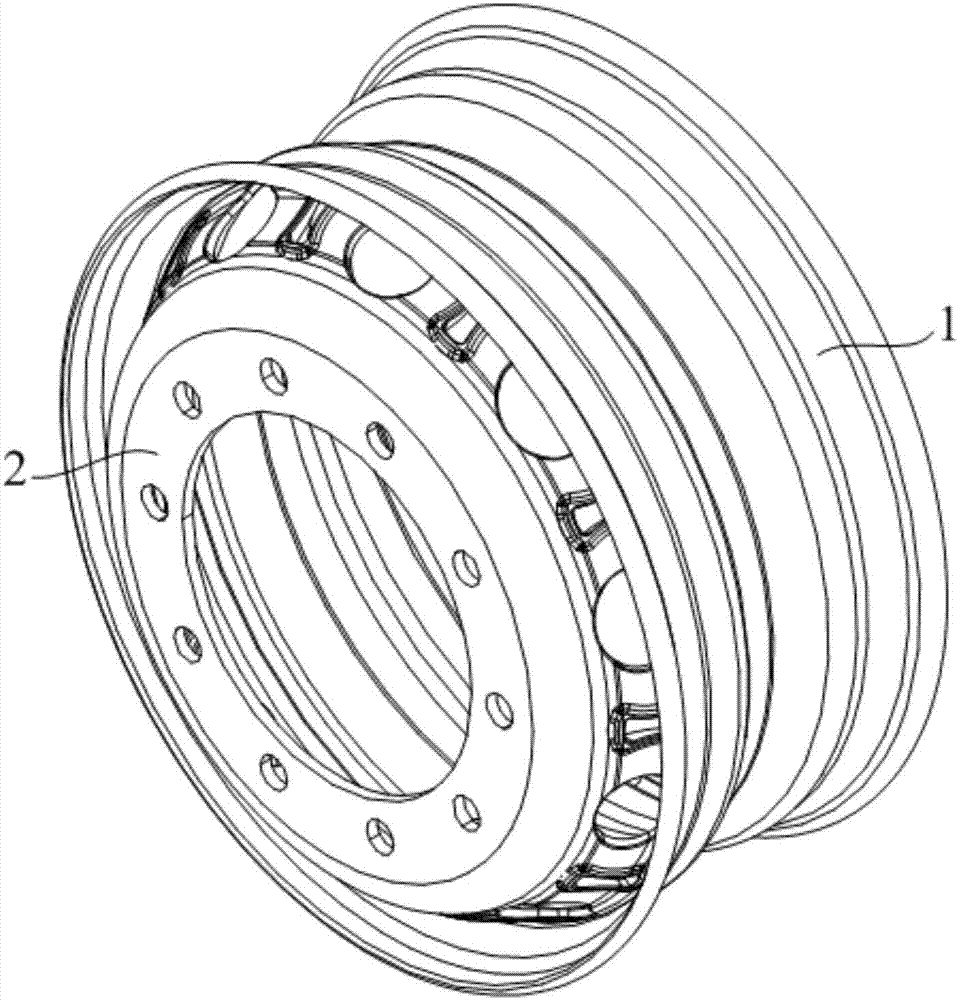

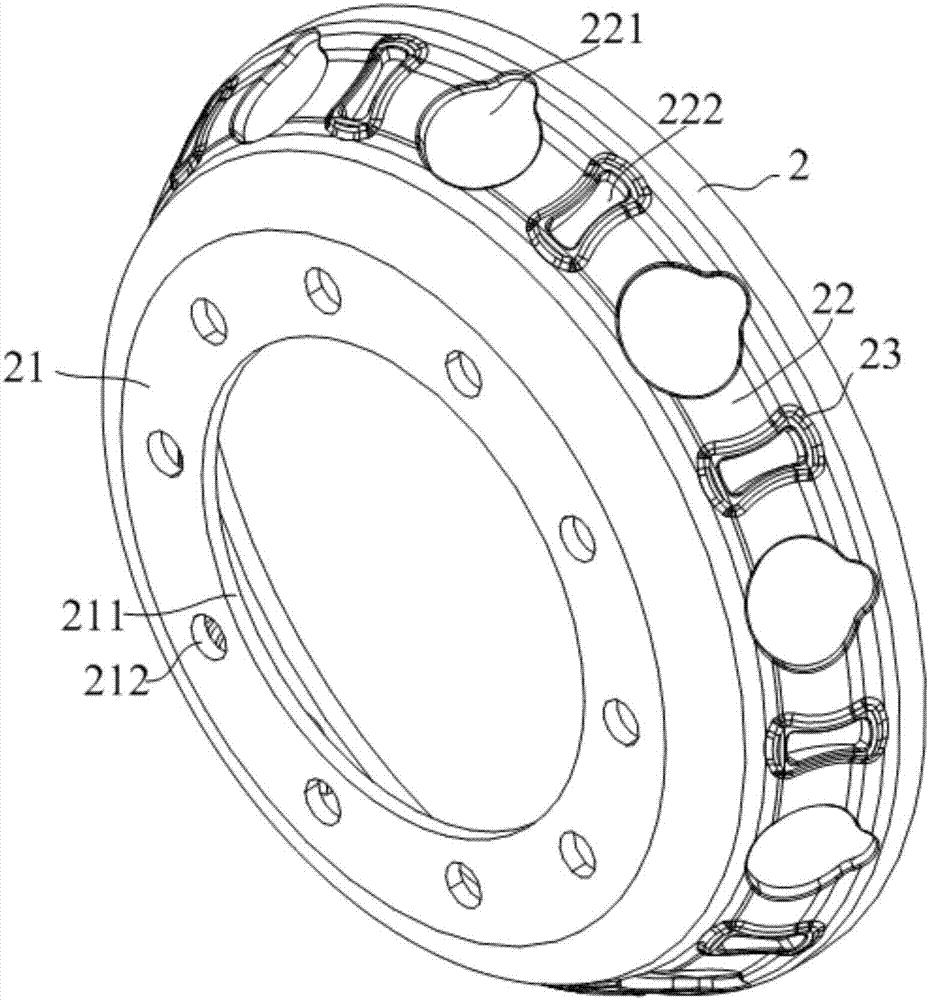

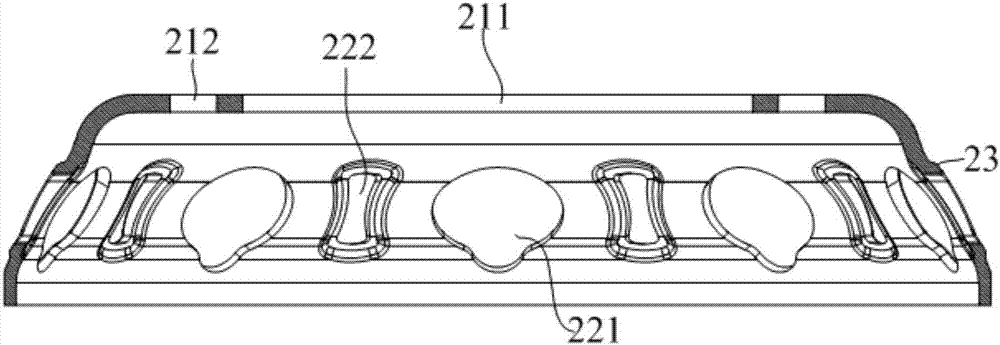

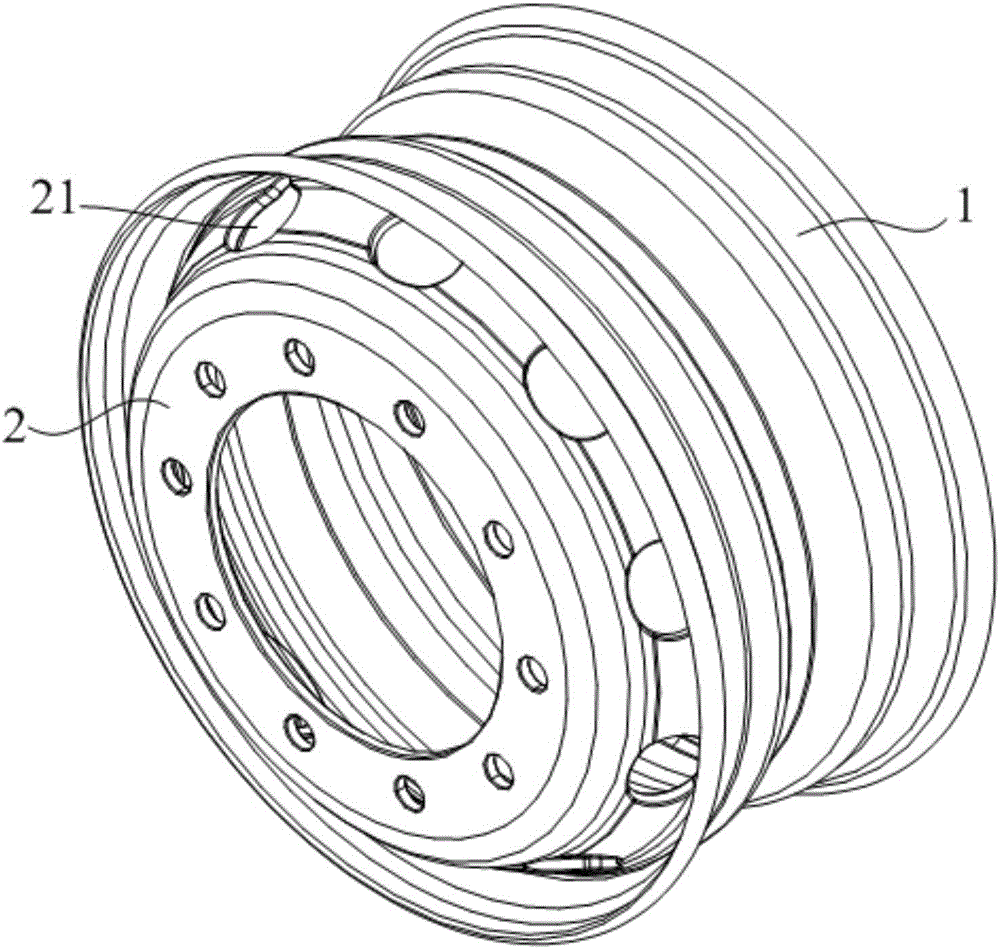

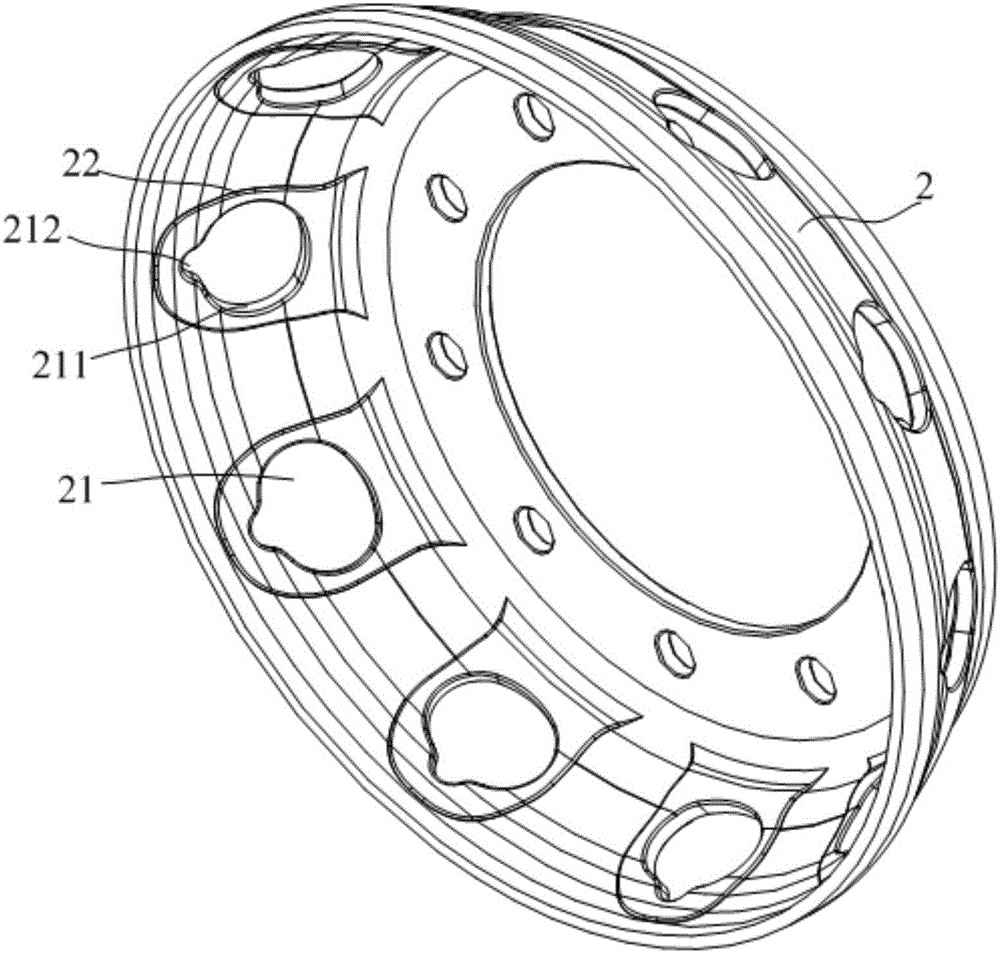

Lightweight wheel with flanging irregular hole spoke

The invention belongs to the field of light weight and particularly relates to a lightweight wheel with a flanging irregular hole spoke. The lightweight wheel comprises a wheel body and the spoke; the spoke comprises a mounting part and a slope part; a center hole is formed in the center position of the mounting part; mounting holes formed in the mounting part are uniformly formed in the outer side of the center hole; peach-shaped air holes are uniformly formed in the slope part; and flanging irregular holes are formed between every two peach-shaped air holes. Through the design that the irregular holes are formed between the air holes in the spoke, and the irregular holes turn edges toward the periphery of the arc surface of the spoke, the air hole strength of the spoke is increased, the weight of the spoke is reduced, the service life of the spoke is greatly prolonged, the overall stiffness of the wheel is strengthened, the bearing load of the wheel is greatly improved, and a new way is opened up for wheel light weight.

Owner:胡爱君

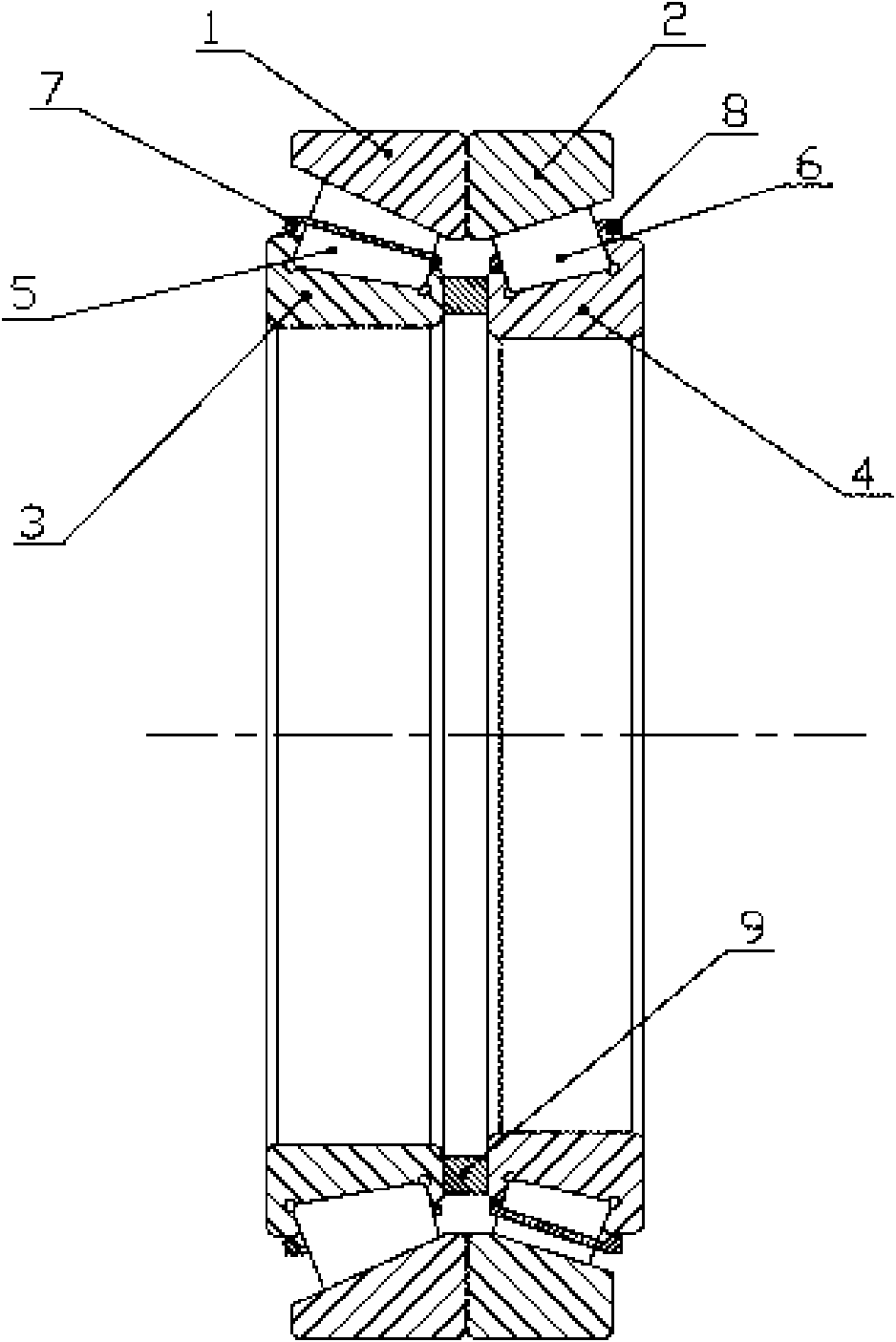

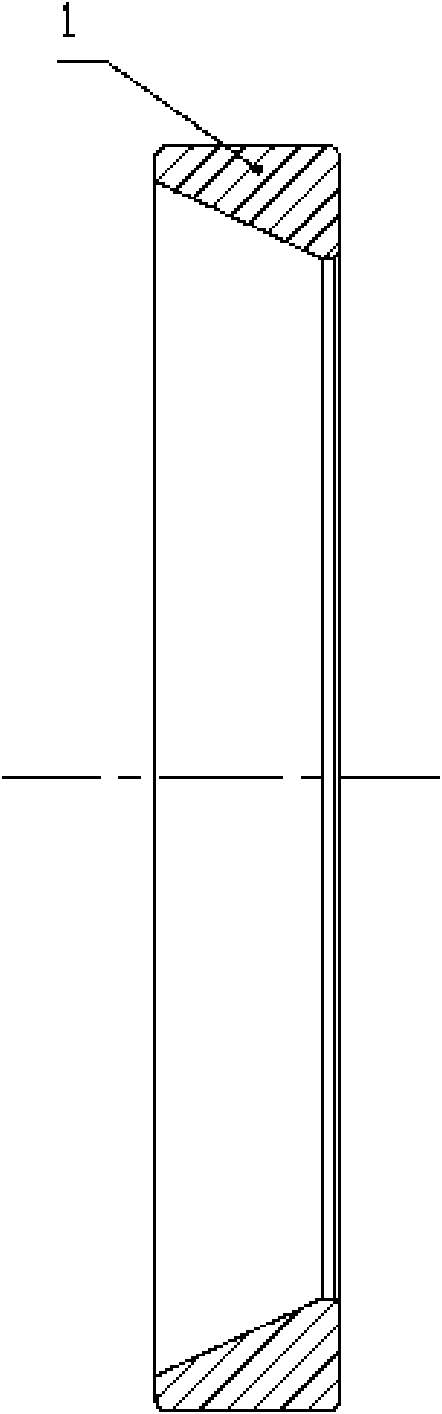

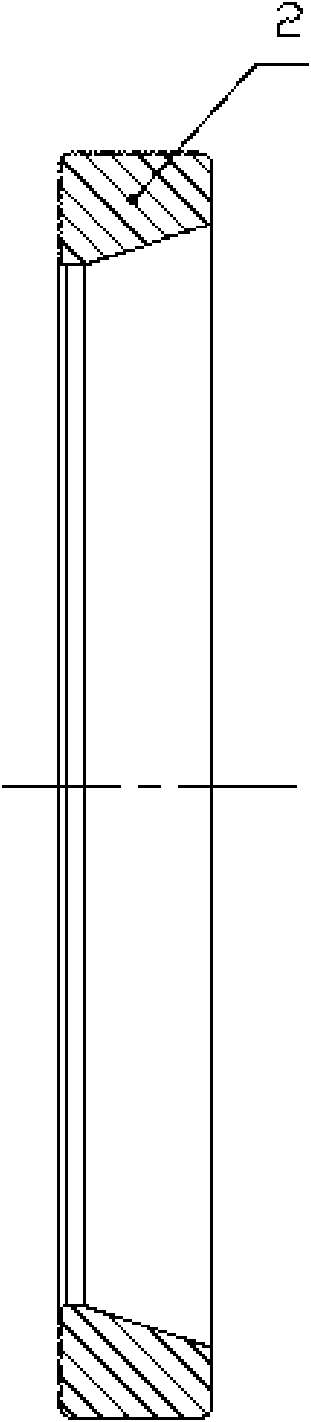

Reducing tapered roller bearing for single-row matching

The invention discloses a reducing tapered roller bearing for single-row matching, which comprises two rows of outer rings (1, 2) arranged oppositely, inner rings (3, 4) and tapered rollers (5, 6) between the inner and outer rings. An inner separation ring (9) is arranged between two rows of the inner rings. The tapered rollers (5, 6) are limited on a retainer between the inner and outer rings respectively, wherein a taper angle of the outer ring (1) on one side is larger than that of the outer ring (2) on the other side, the width of the outer ring (1) is larger than that of the outer ring (2), an inside diameter of the inner ring (3) on one side is longer than that of the inner ring (4) on the other side, and the width of the inner ring (3) is greater than the width of the inner ring (4). The double-row reducing tapered roller bearing of the invention has the advantages of reasonable design, simple structure, reliable property, high rotary speed, high bearing load and long service life.

Owner:瓦房店第一轧机轴承制造有限公司

Rear drive axle assembly

ActiveCN102774240BSimple structureEffective decelerationBraking element arrangementsAxle unitsDrive shaftReduction drive

The invention discloses a rear drive axle assembly. The rear drive axle assembly comprises an axle casing which is in a girder structure, two wheel hubs, a main reducing gear and differential mechanism assembly, a braking assembly, a hub reduction gear, a forced differential lock and a parking brake, wherein the forced differential lock comprises a sliding meshing sleeve, a differential mechanism lockpin, a piston, a selector rod, a back-moving spring and a shifting fork, the shifting fork is connected fixedly with a shifting fork shaft, the back-moving spring is arranged between the shifting fork and the shifting fork shaft, a groove which is matched with the shifting fork is arranged on the sliding meshing sleeve, grooves which are matched with the differential mechanism lockpin are arranged on the sliding meshing sleeve and a driving shaft gear of the main reducing gear and differential mechanism assembly correspondingly, the parking brake comprises a brake body and a brake disk, the brake body is arranged on a main reducing gear casing of the main reducing gear and differential mechanism assembly, the brake disk is arranged on a main tooth flange, and a plane and an installation hole, which are connected with the machine base plate, are arranged on the axle casing. The rear drive axle assembly has the advantages of being good in parking and heat radiation performance, large in bearing capacity, simple in structure and convenient to process and produce.

Owner:南京创捷和信汽车零部件有限公司

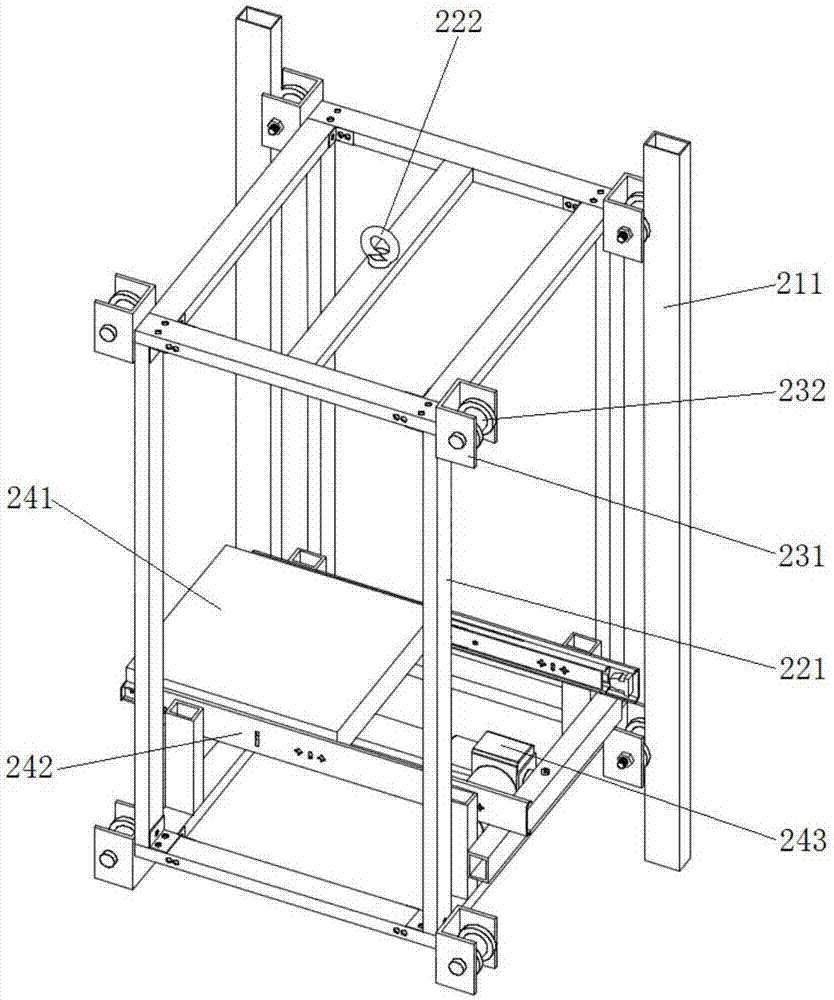

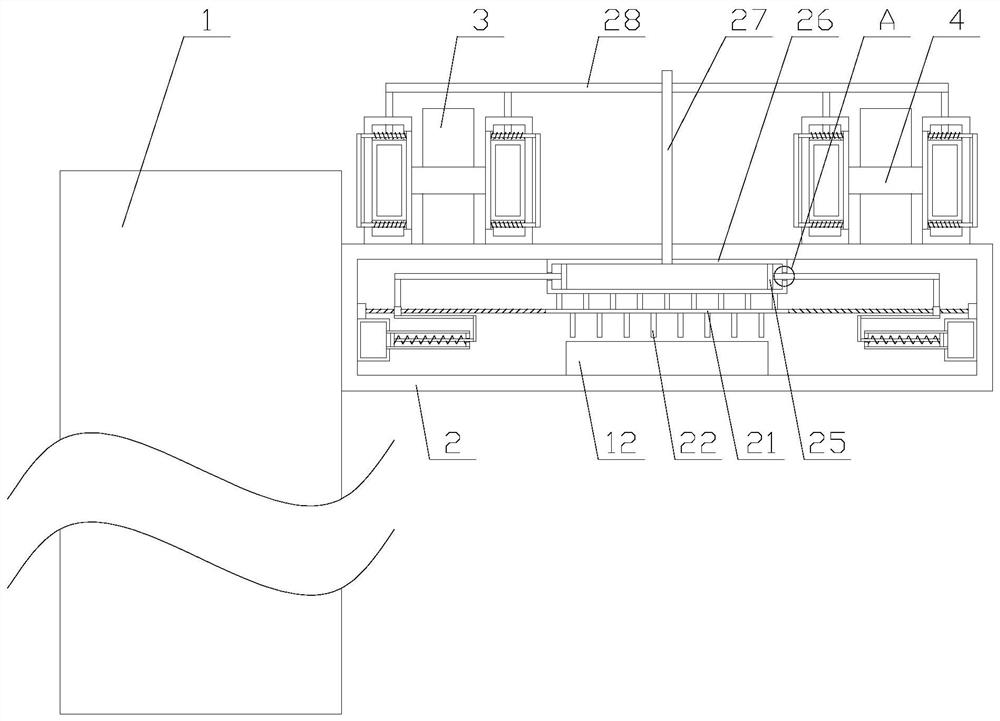

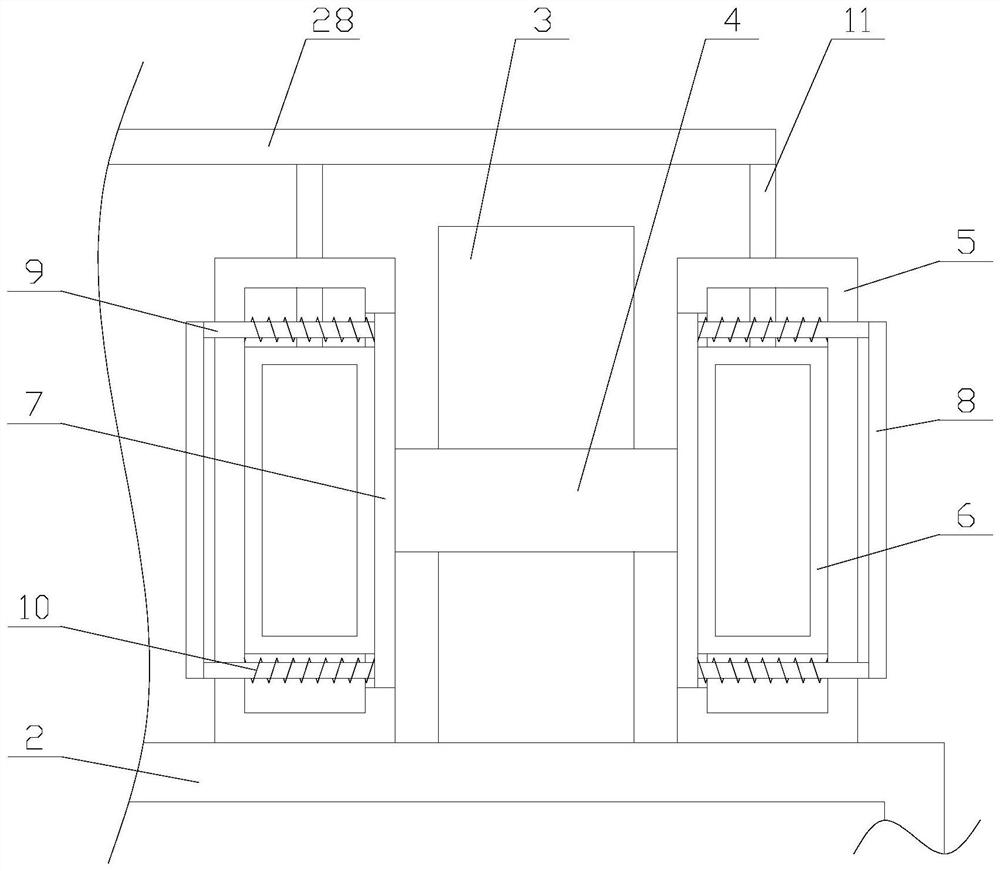

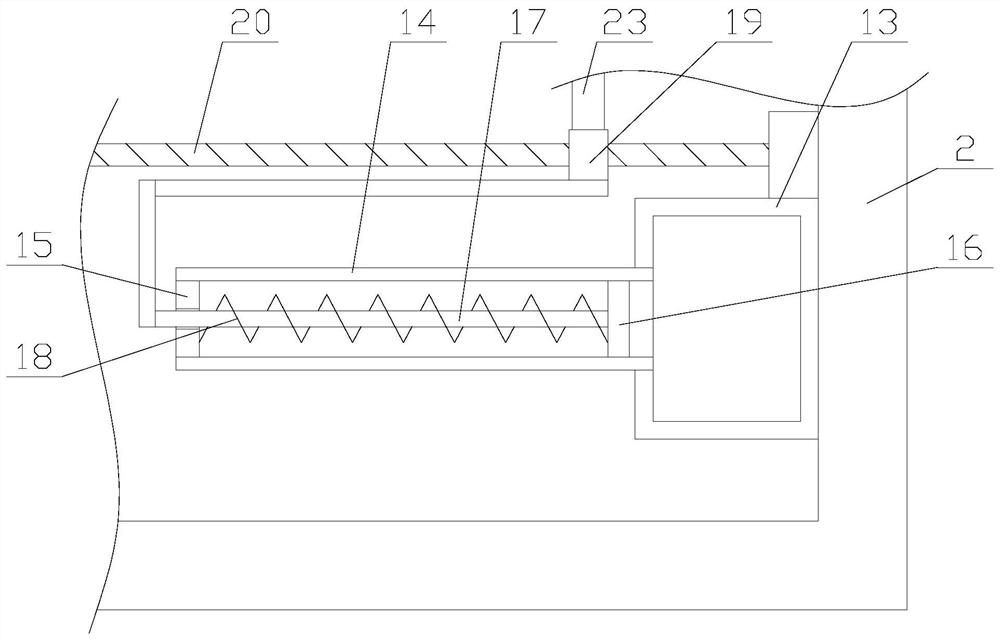

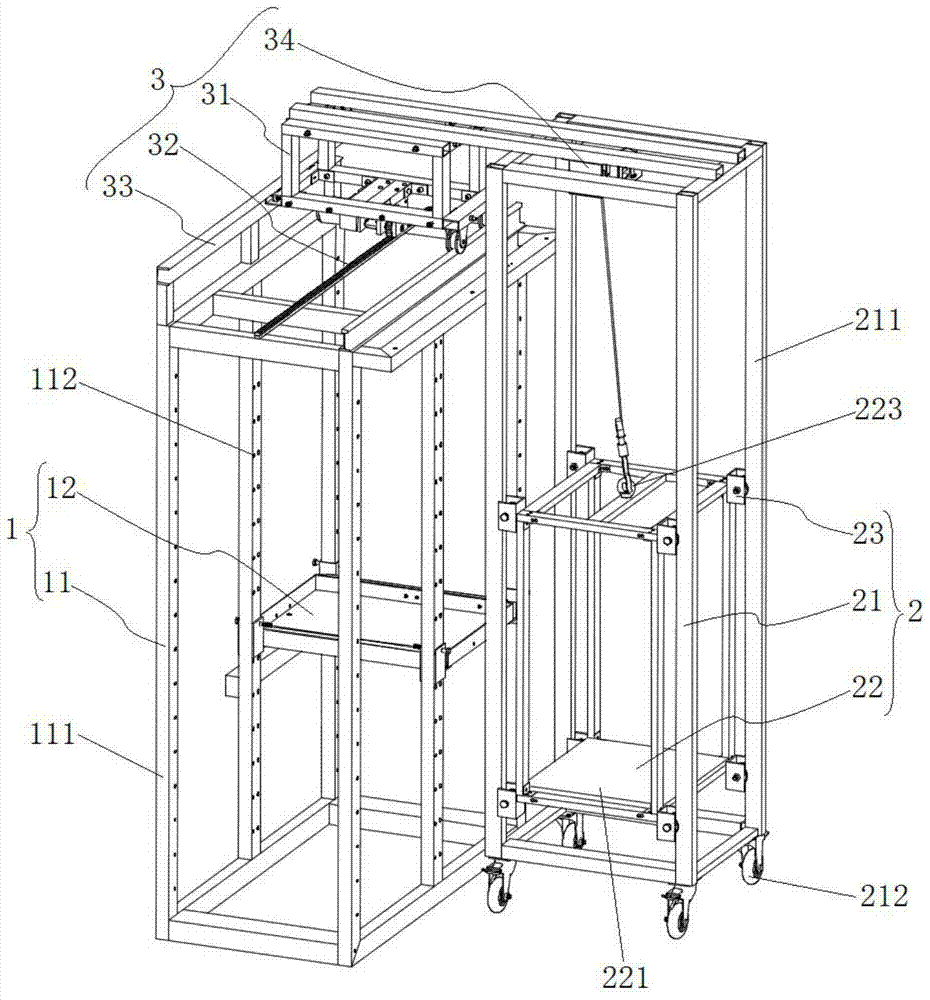

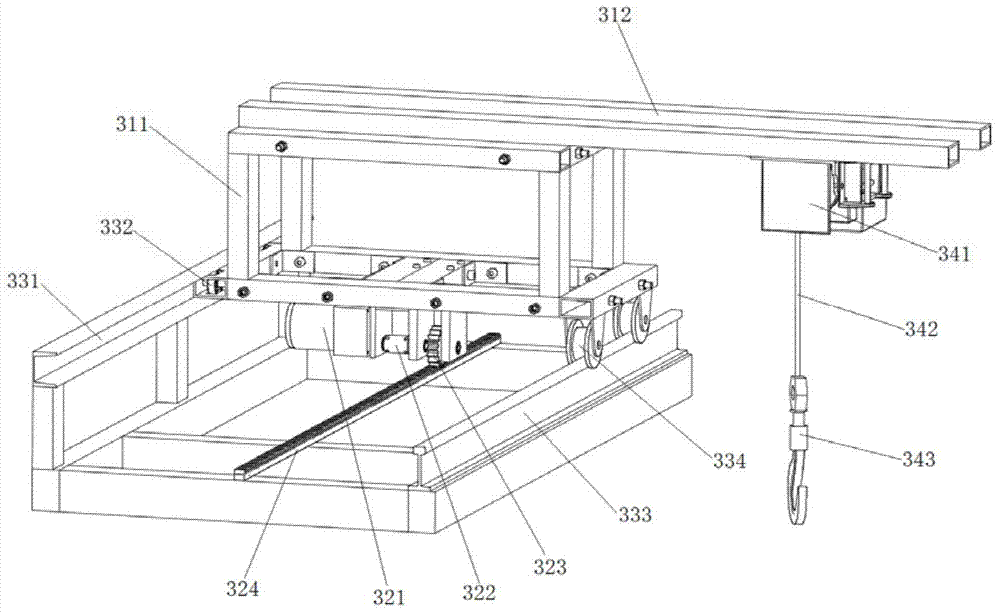

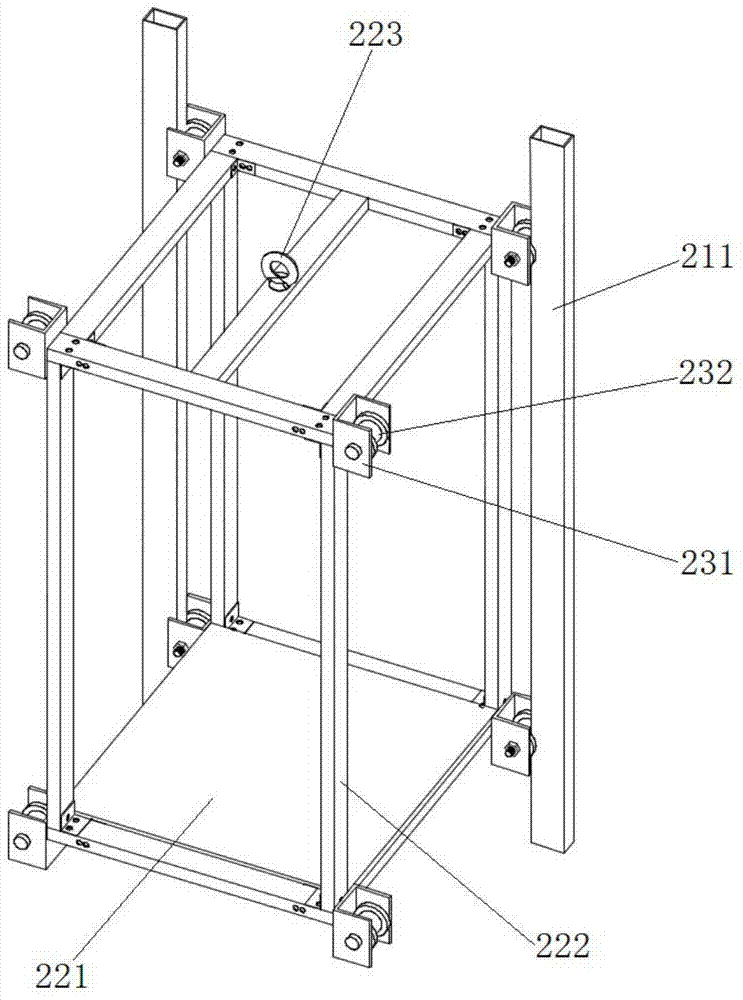

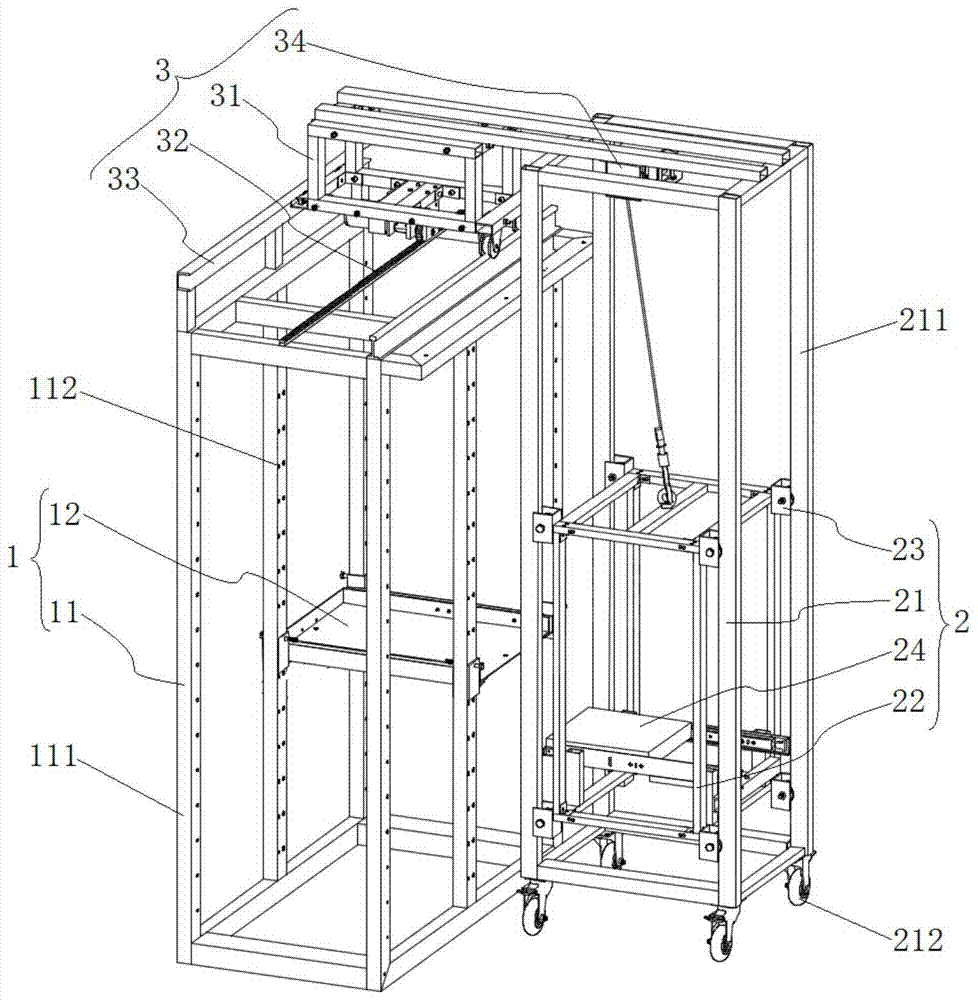

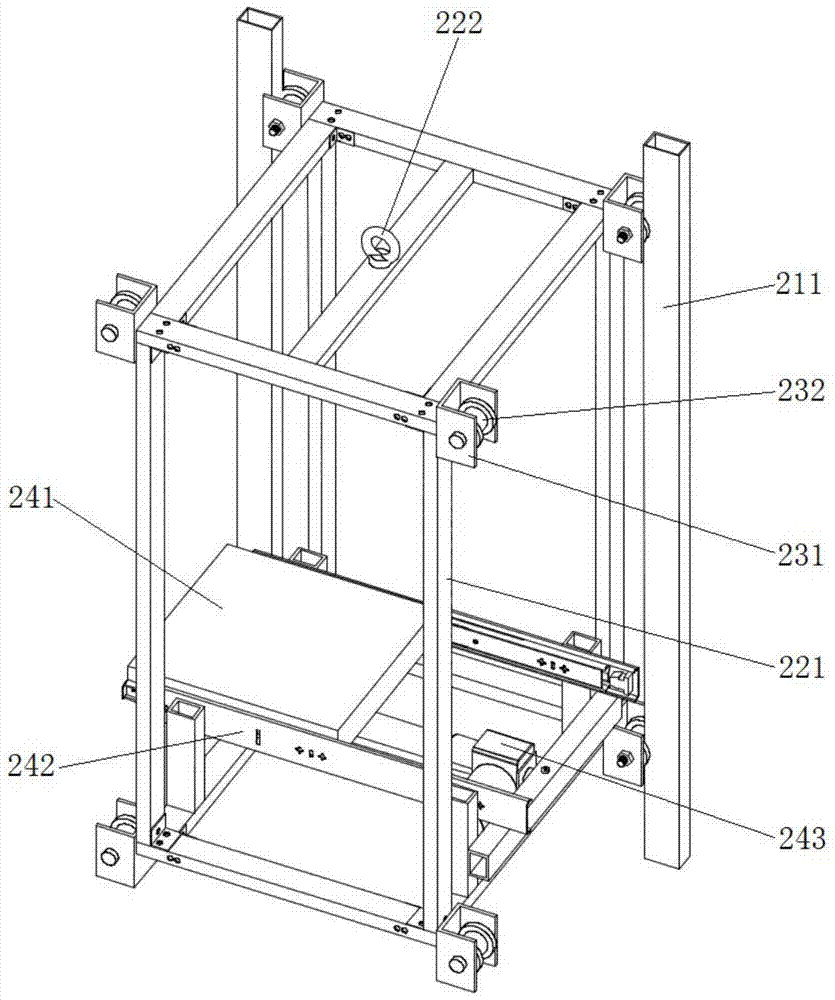

A lift-type manned loading and unloading high-rise shelf

ActiveCN105292897BSolve loading and unloading difficultiesImprove loading and unloading efficiencyStorage devicesElectric carsHigh lift

The invention discloses a lifting type manned loading and unloading high-rise shelf, which belongs to the field of storage equipment. The invention includes a storage shelf, a movable cage and an electric control trolley, the electric control trolley is installed on the top of the storage shelf and connected with the movable cage, and is used to drive the movable cage to move laterally along the storage shelf; The movable cage includes an outer frame and an inner frame. The inner frame is installed in the outer frame through a lifting and sliding mechanism. The bottom of the inner frame is provided with a working platform for workers to stand and store goods; the electric control trolley includes a car body , a driving mechanism, a guiding mechanism and a lifting mechanism, the driving mechanism drives the car body to slide laterally on the top of the storage shelf, and the lifting mechanism is connected with the inner frame. The invention solves the problem of difficult loading and unloading of high-rise goods by setting a movable electronically controlled trolley on the top of the storage shelf, and drives the workers and goods to lift together through the lifting mechanism, reduces the labor intensity of the workers, and improves the safety of the workers performance and high-level cargo handling efficiency.

Owner:常州东吉路国际贸易有限公司

Lightweight wheel with novel 15 degrees DC arc-shaped rim gutter bottom

InactiveCN107042732AHigh strengthStress reliefRimsWheel manufactureEngineeringUltimate tensile strength

The invention belongs to the technical field of lightweight wheels, and particularly relates to a lightweight wheel with a novel 15 degrees DC arc-shaped rim gutter bottom. The wheel comprises a rim and a spoke welded to the rim, an R-shaped side concave circular arc-shaped groove is arranged in the middle of the side face of the rim, an inflating valve holder is arranged on one side, close to the spoke, of the side concave circular arc-shaped groove, a convex peak is arranged on one side, away from the spoke, of the side concave circular arc-shaped groove, the inflating valve holder comprises a holding inclined plate arranged in the side concave circular arc-shaped groove, an inflating valve hole is formed in the holding inclined plate, and an inflating valve is arranged in the inflating valve hole. By arranging the side concave circular arc-shaped groove, the convex peak and the inflating valve holder on the rim, the overall strength of the lightweight wheel can be effectively improved, the bearing load of the wheel is greatly improved, and a new way is opened for the lightweight wheel.

Owner:胡爱君

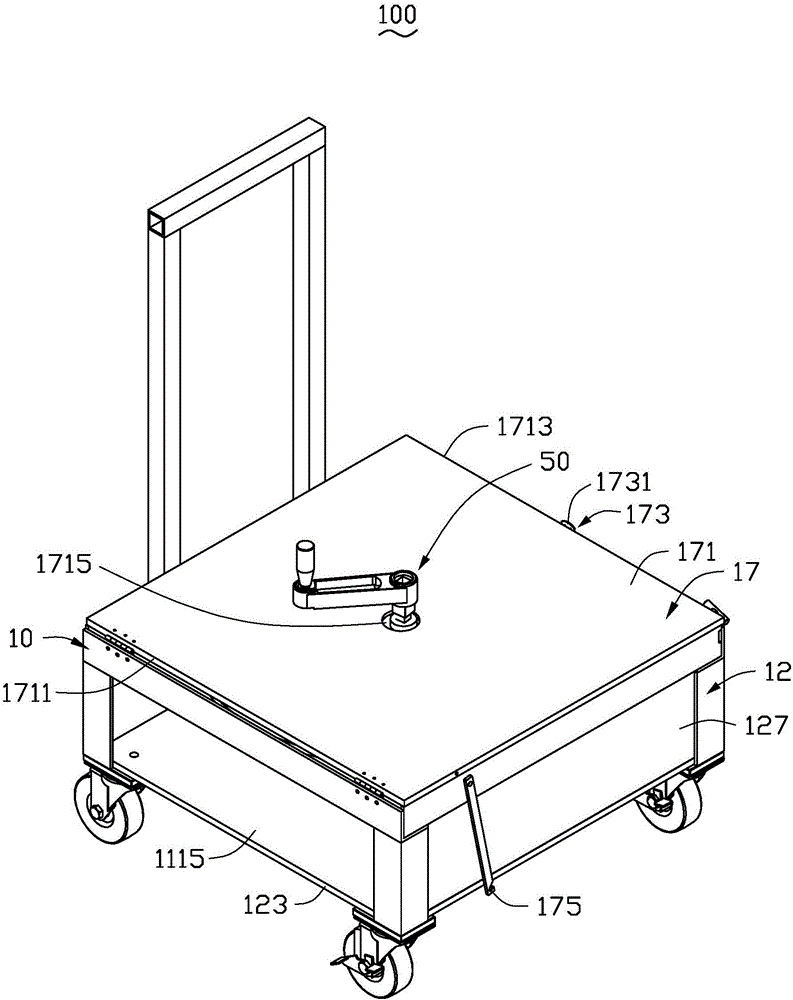

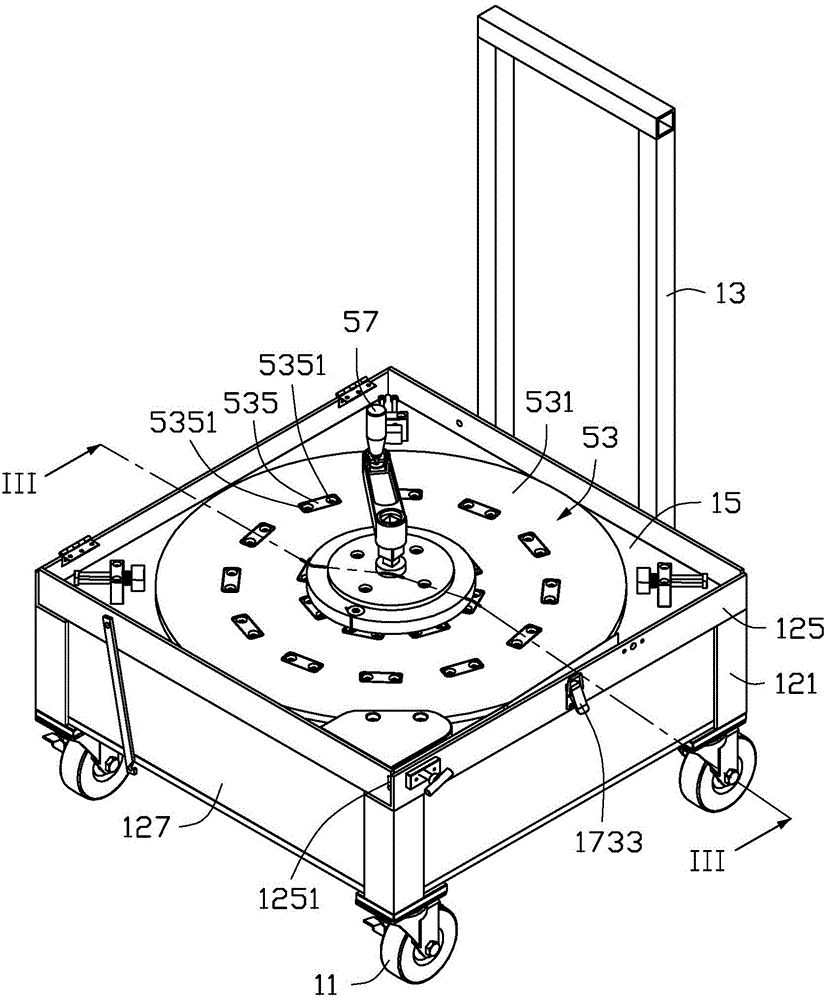

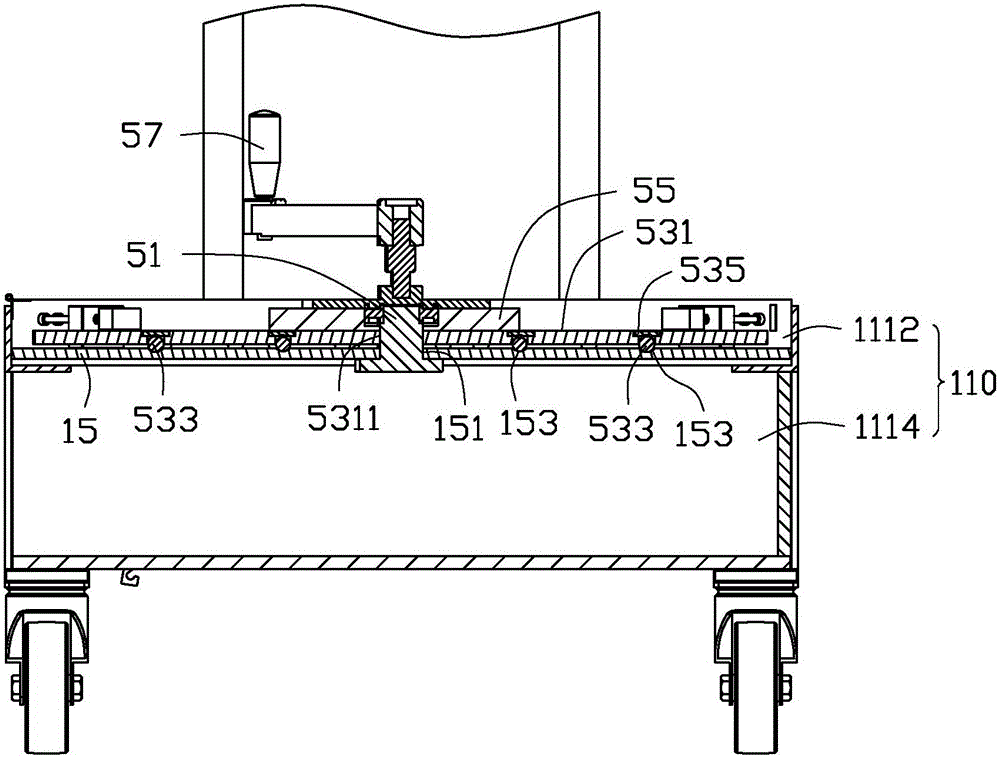

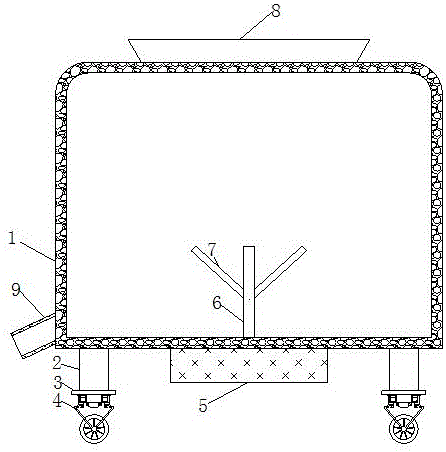

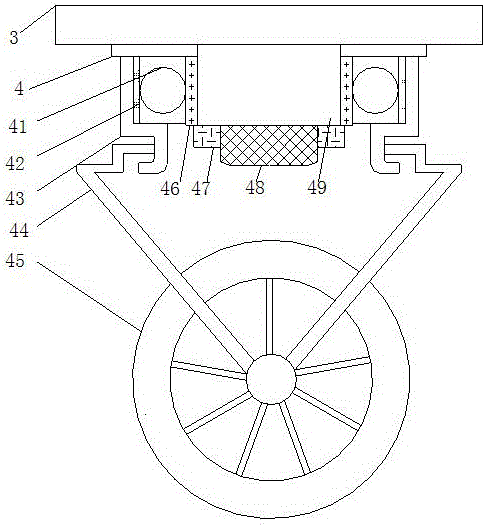

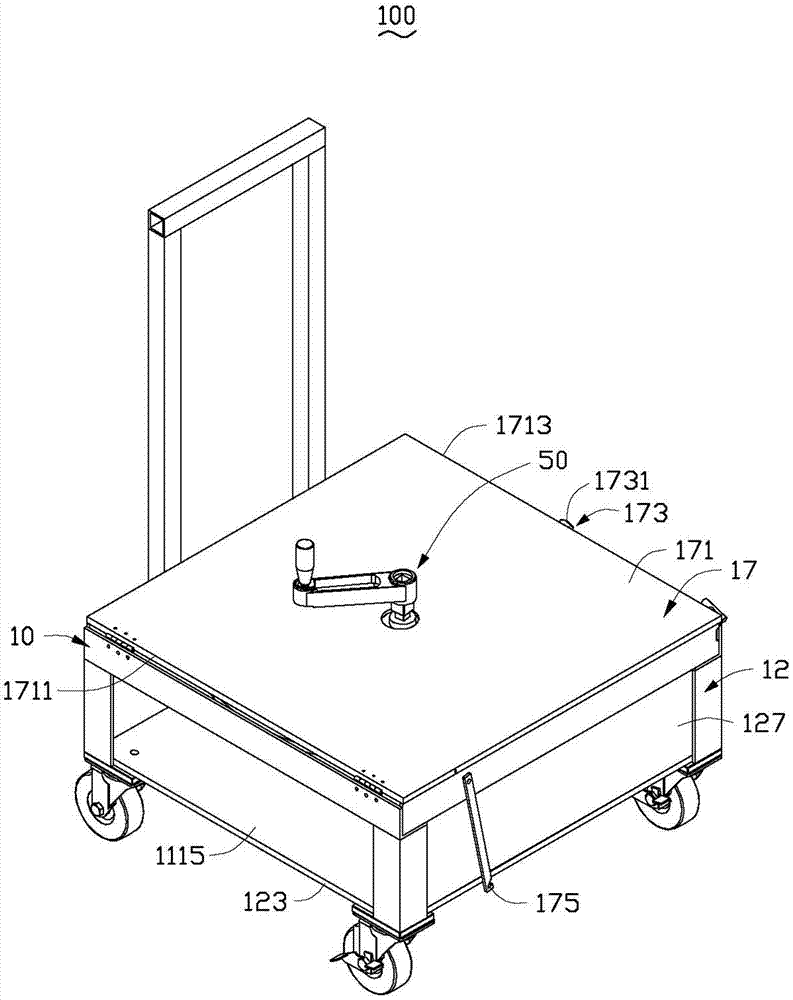

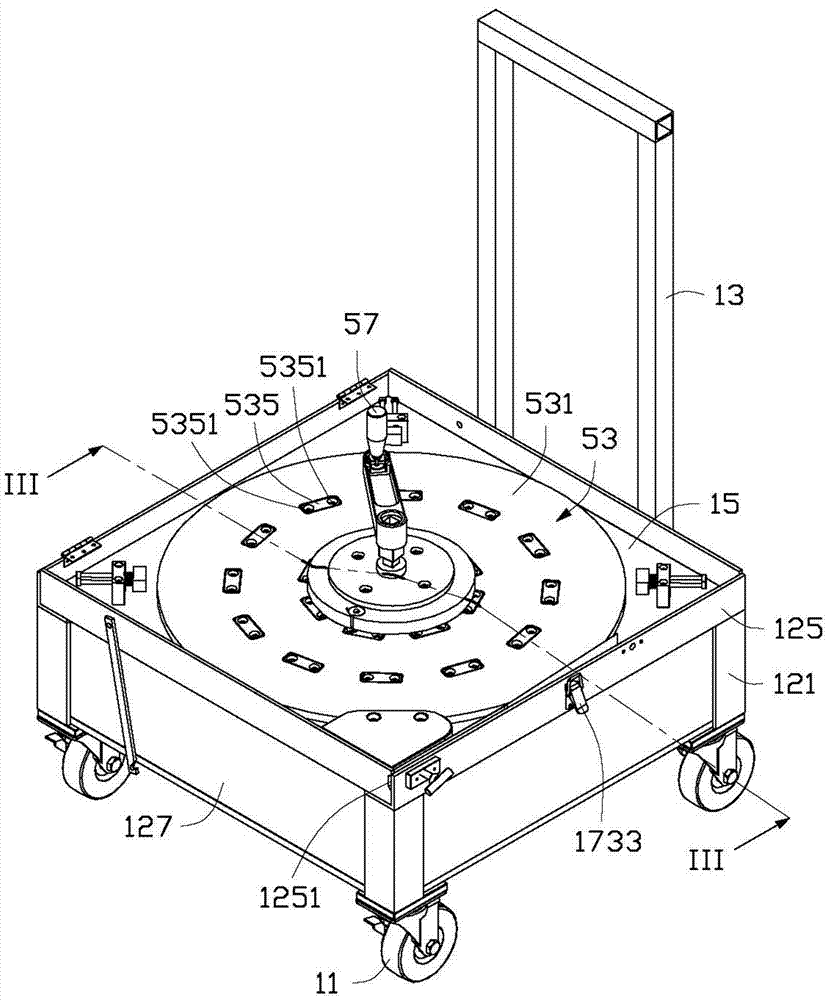

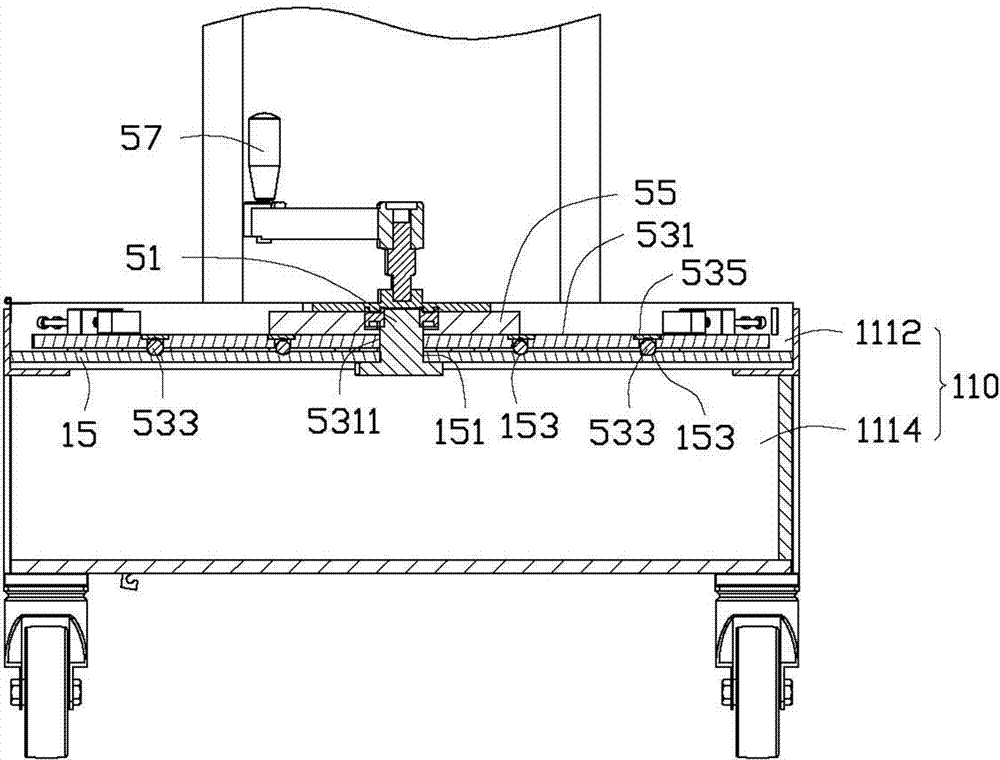

cart

InactiveCN104742945BEffective rotationIncrease the carrying loadWrapping material feeding apparatusHand carts with multiple axesVehicle frameEngineering

A cart is used for handling and drawing sheet strip packaging materials coiled into rings. The cart comprises a frame. The frame comprises wheels, a bracket being supported on the wheels, and a support plate arranged on the bracket. The cart also comprises a coiling mechanism installed on the support plate. The coiling mechanism comprises a bearing part and a rotation shaft, wherein the bearing part comprises a bearing plate and a plurality of roll balls; the bearing plate is installed on the support plate through the rotation shaft movably; the plurality of roll balls are arranged between the bearing plate and the support plate and used for bearing the bearing plate in a rolling manner; the bearing plate are borne on the plurality of roll balls and can rotate relative to the rotation shaft. According to the invention, the packaging materials do not need to be unloaded from the cart again for handling in the packaging process, and the use is convenient.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Light weight wheel with convex peach-shaped air holes

PendingCN106626961AExtended service lifeImprove rigidityDisc wheelsEngineeringUltimate tensile strength

The invention belongs to the field of wheels, and relates to a light weight wheel, in particular to a light weight wheel with convex peach-shaped air holes. The wheel comprises a rim and spokes arranged on the rim in a welded mode, the middle portion of the rim is provided with a center hole, the outer side of the center hole is evenly provided with fixing holes, the oblique plane of the spokes are evenly provided with the peach-shaped air holes, and the inner sides of the peach-shaped air holes are provided with air hole convex reinforced layers arranged at the inner sides of the oblique plane of the spokes and fitted with the peach-shaped air holes. According to the light weight wheel with the convex peach-shaped air holes, the peach-shaped air holes are formed in the spokes, an air hole convex reinforced layer design is arranged at the inner side surfaces of the air holes, and the spoke air holes with a peach-shaped design not only improve the intensity of the spokes, but also greatly prolong the service life of the spokes, enhance the overall stiffness of the wheel, drastically increase the bearing load of the wheel, and open a new way for wheel light weight.

Owner:胡爱君

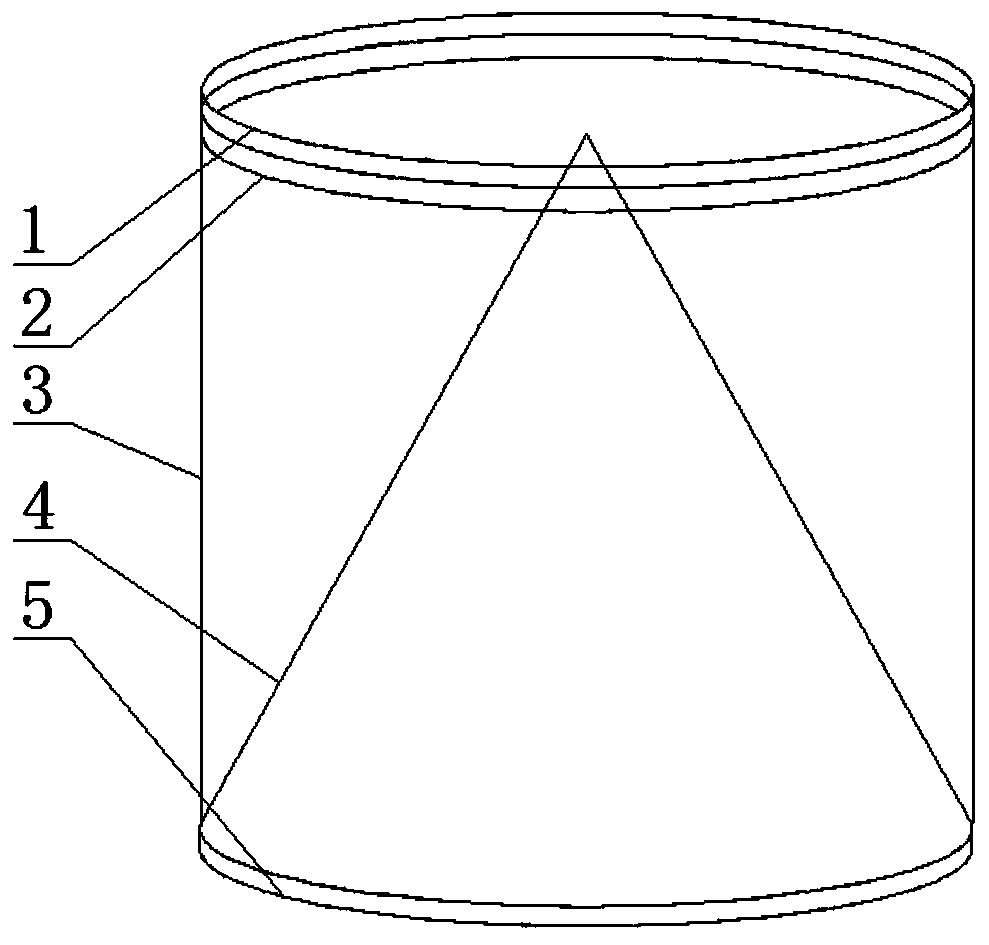

Ring steel structure support platform

ActiveCN108086660BEasy height adjustmentMaintain pressure resistanceBuilding scaffoldsWorkbenchIndustrial engineering

The invention discloses a circular steel-structured support platform. A base comprises an upper ring and a lower ring arranged in parallel. The upper ring and the lower ring are connected through a plurality of supports arranged at equal intervals; a conical post is extended from the center of the upper ring to the periphery of the lower ring; a worktable is rotationally mounted on the upper ringof the base through a slide rail; the worktable includes an upper support panel and a lower support panel from top to bottom; retaining plates are mounted on the periphery of the lower surface of theupper support panel and are hinged between the upper and lower support panels; a support post is mounted in the middle of the lower surface of the upper support panel; the bottom of the support post is extended into the lower support panel and is fixedly connected with the lower support panel. The base satisfies horizontal supporting force of the worktable; the vertical supports and the conical post can improve vertical bearing force, so that bearing capacity can be improved; the connection performance is stable, and the service life is longer. The worktable provides improved working efficiency and improved service effect, and the circular steel-structured support platform is widely applicable.

Owner:QINGJIAN GRP CO LTD

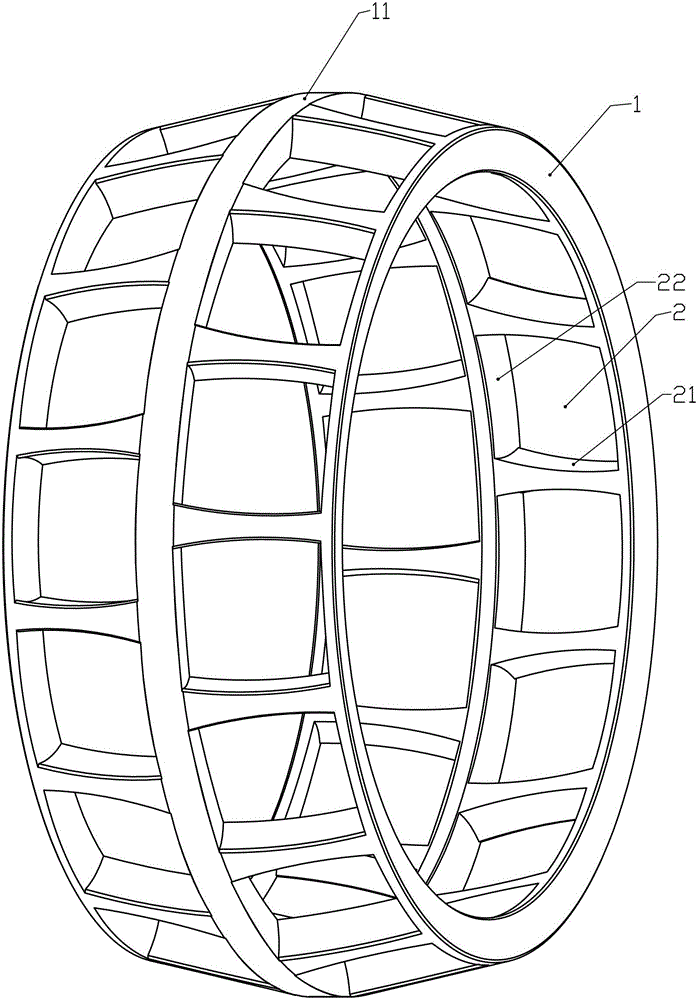

A brass solid spherical roller bearing cage and its forming method

ActiveCN103115070BIncrease the carrying loadHigh strengthRoller bearingsBearing componentsLow noiseEngineering

The invention relates to a self-aligning roller bearing retainer for a brass entity. The self-aligning roller bearing retainer comprises a retainer body which is integrally formed by machining. The self-aligning roller bearing retainer is characterized in that the retainer body is internally provided with two rows of roller mounting holes which are evenly distributed in a staggered way; the retainer body comprises an intermediate ring and an internal shell nosing cone which extends towards two sides symmetrically from the intermediate ring; the plurality of roller mounting holes are evenly machined in the circumferential direction of the internal shell nosing cone; the axes and the normals of the roller mounting holes intersect at one point; and rollers are arranged in the roller mounting holes and can be used for guiding the retainer independently. The self-aligning roller bearing retainer for the brass entity has the advantages of high bearing load, low noise and vibration, high stability, self-lubrication and self-guiding by the rollers.

Owner:SHANDONG KAIMEIRUI BEARING TECH CO LTD

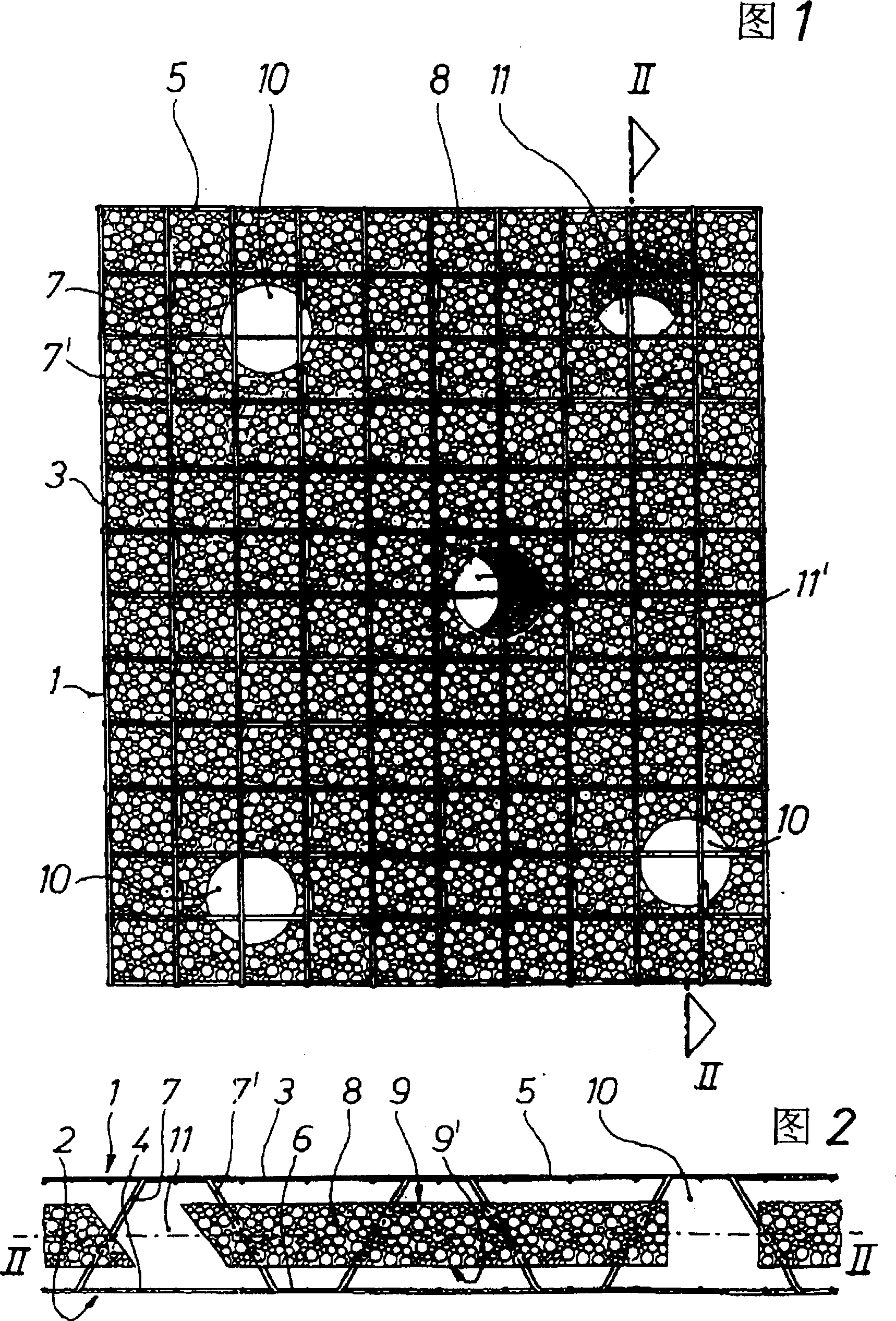

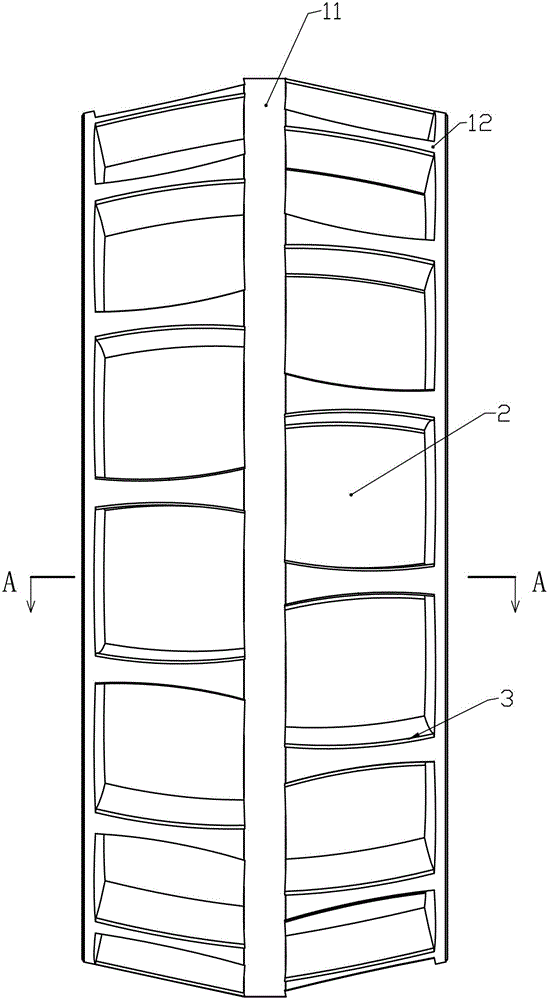

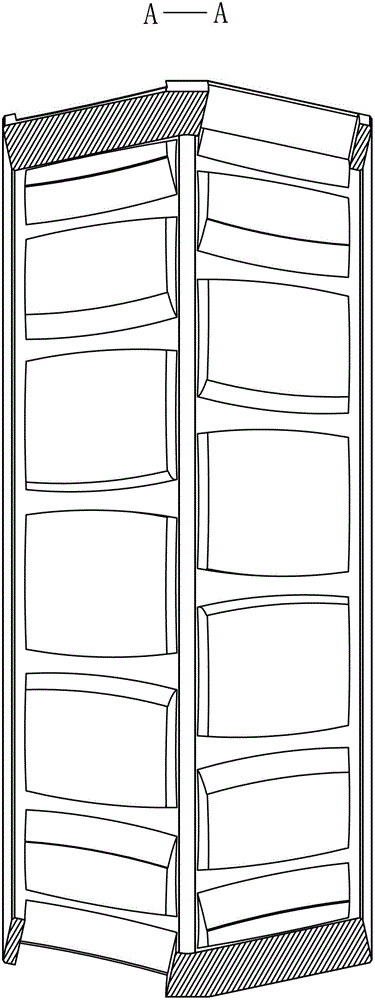

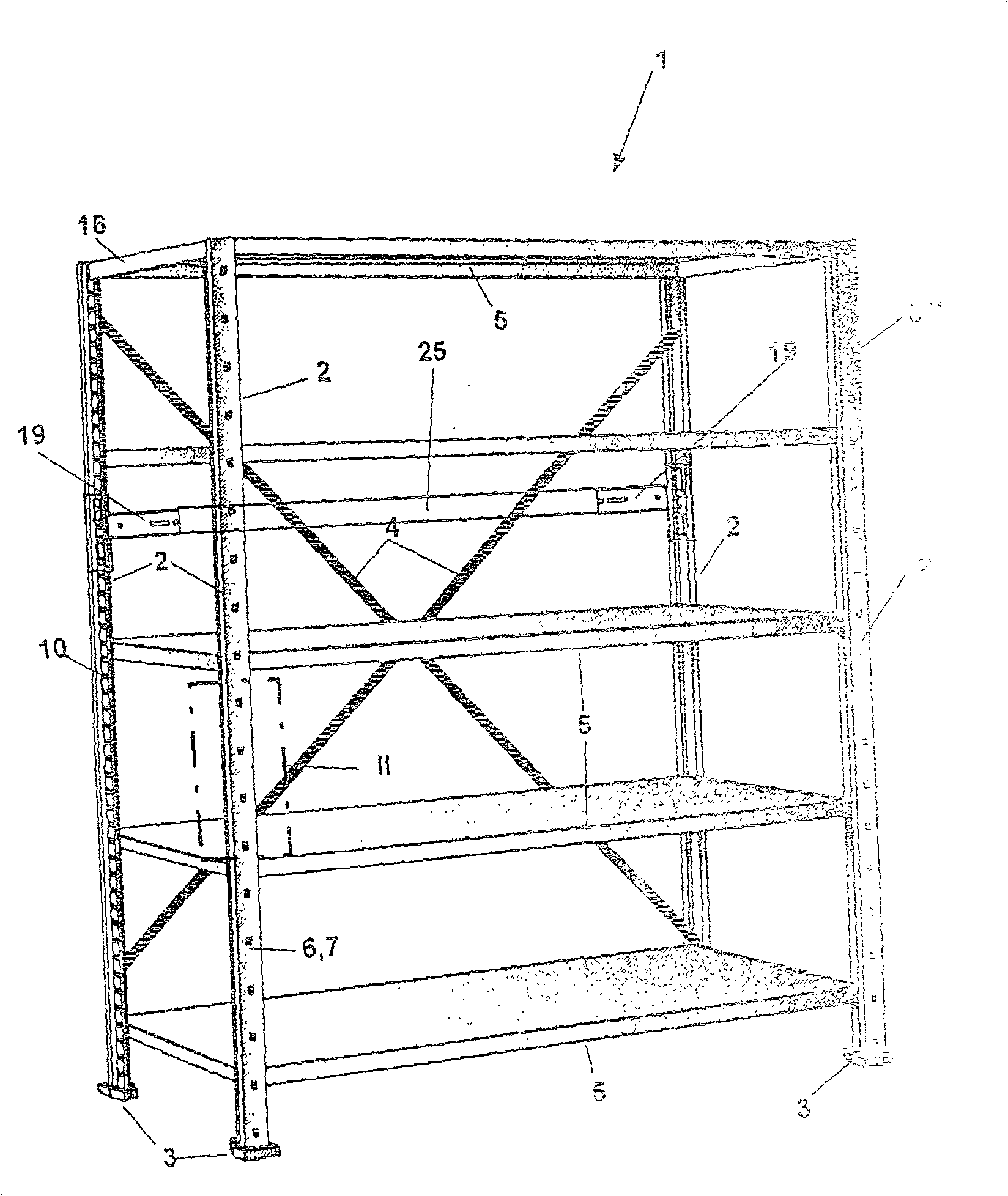

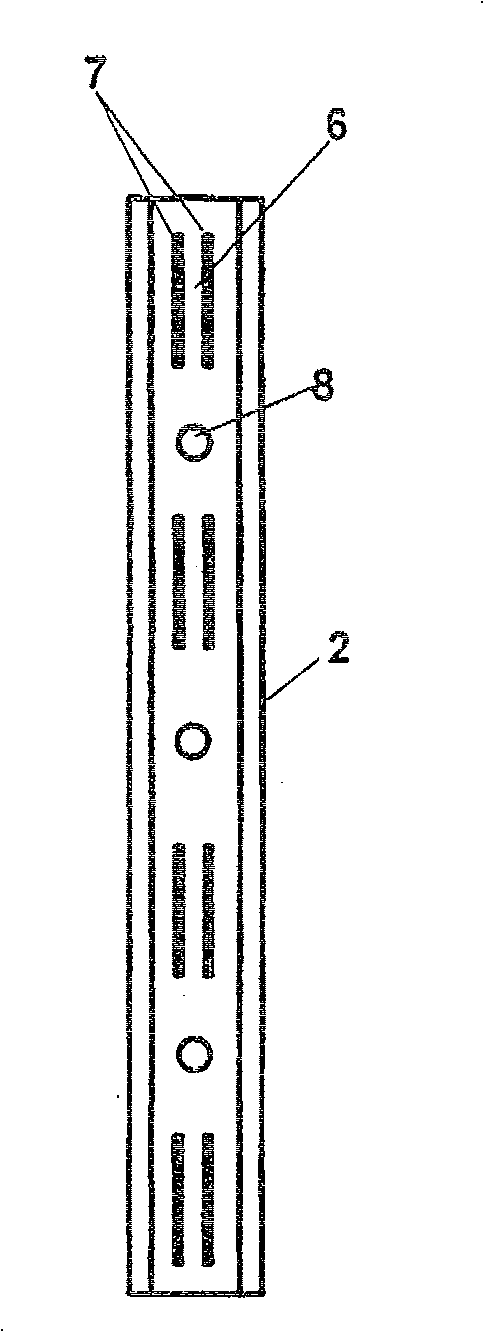

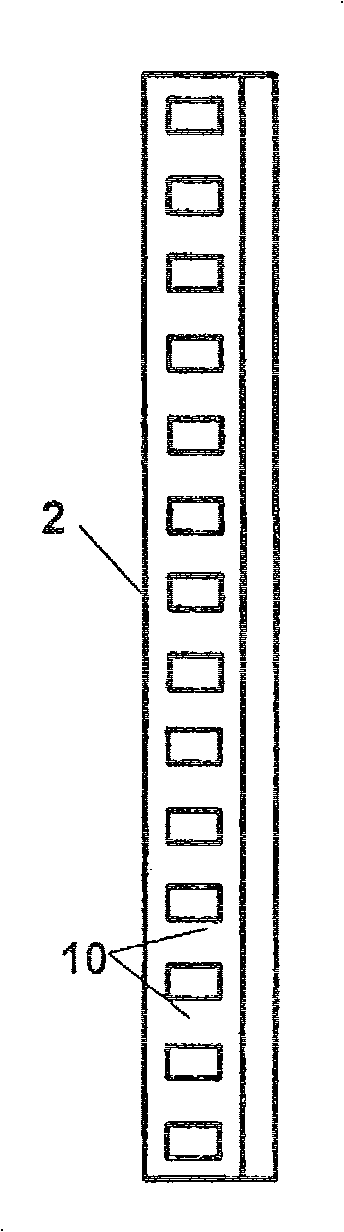

Shelf system for storing and archiving objects

InactiveCN100515270CIncrease the carrying loadWide range of usesDismountable cabinetsFeetCarrying capacityComputer terminal

The stand system for storing objects comprises at least one stand (1) with vertical vertical columns (2) on which bag-shaped crossbeams (15) are fixed, and the crossbeams can at least be used to fix the loading plate (5 ). The vertical columns (2) have recesses (10) for carrying the hook pairs (18) of the crossbeams (15) and grid-shaped gaps (6) for carrying additional platform components. This shelf system has a high degree of stability and load-bearing capacity, and can store various objects of different sizes, shapes and weights. For this purpose, the bench system has insertion knots (19) and / or stabilizing profiles (28) with hooks (22) which can be inserted into the gaps (6) of the longitudinal columns (2) The angle plate (38) of the column (2) is used to connect the foundation (2, 37), a pair of spacer angle irons (34) are used to connect several benches (1) and / or connect a foundation (37), swing rail The suspension (30) of (31) can be packed in the crossbeam (15).

Owner:伊瑞佳股份公司

An intelligent automatic loading and unloading high-rise shelf

ActiveCN105438704BImprove loading and unloading efficiencySimple structureStorage devicesEngineeringHigh rise

Owner:美玛特电子科技(常州)有限公司

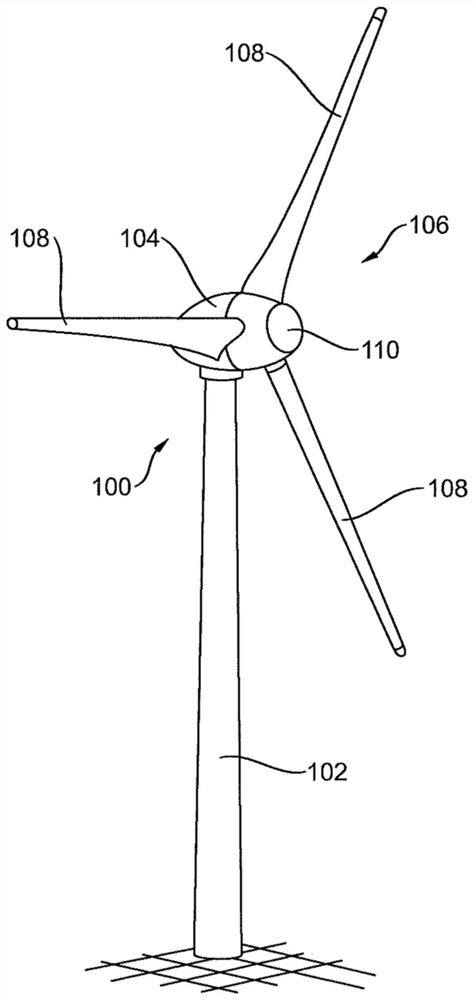

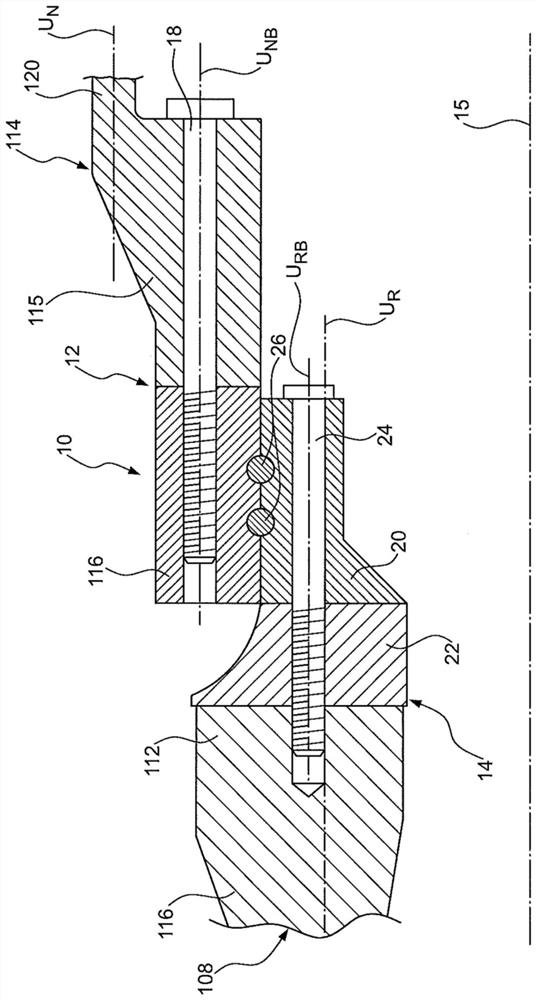

Wind turbine, wind turbine rotor blade and blade bearing for a wind turbine

PendingCN113137329AReduce usageFull tensionEngine fuctionsMachines/enginesClassical mechanicsEngineering

The disclosure concerns a wind turbine, comprising: a hub with a hollow cylindrical region with a mean circumference UN; at least one rotor blade mounted rotatably on the hub, with a blade laminate which extends in the longitudinal direction of the rotor blade and at least in portions forms a hollow cylinder with a mean circumference UR; and at least one blade bearing for mounting the rotor blade on the hub, with a first bearing ring which is arranged on the hub side and connected by means of a first flange connection to a rotor hub flange formed on a rotor-blade side end portion of the hub, wherein the first flange connection has at least one hub longitudinal bolt which is arranged on a circumference UNB coaxially to the blade bearing; and a second bearing ring which is arranged on the rotor blade side and connected by means of a second flange connection to a rotor blade flange formed on a hub-side end portion of the rotor blade, wherein the second flange connection has at least one rotor blade longitudinal bolt which is arranged on a circumference URB coaxially to the blade bearing. The disclosure achieves the fundamental object in that a first radial offset V1 is formed between the circumference UN and the circumference UNB, and / or a second radial offset V2 is formed between the circumference URB and the circumference UR. In a further aspect, the disclosure achieves the fundamental object with a wind turbine rotor blade and a rotor blade bearing.

Owner:WOBBEN PROPERTIES GMBH

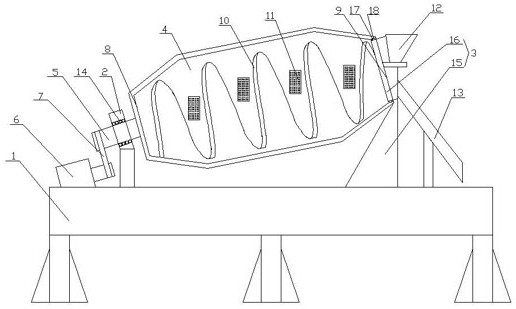

Movable industrial stirrer

InactiveCN106000176AExtended service lifeIncrease the carrying loadTransportation and packagingRotary stirring mixersAgricultural engineering

Owner:李明科

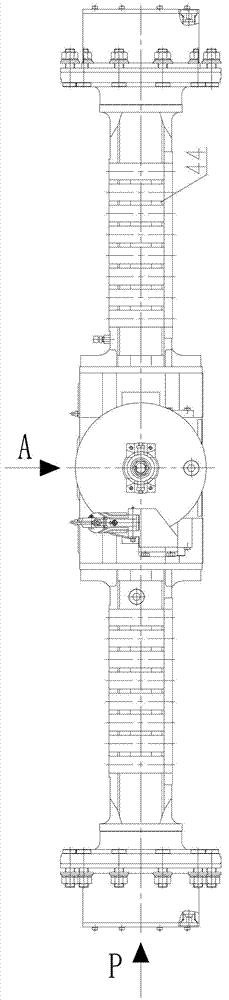

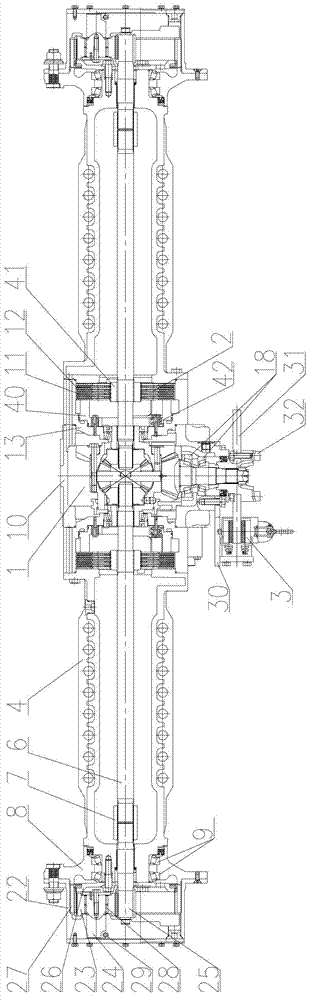

Front steering drive axle assembly

The invention discloses a front steering drive axle assembly which comprises an axle housing (1), hubs (7), a main speed reducer belt differential assembly and wheel rim speed reducers, wherein the axle housing is provided with a balance pin hole (21) connected with a vehicle chassis; the two hubs are connected to the left end and the right end of the axle housing by hub steering structures (3); the middle part of the axle housing is provided with a cavity; the main speed reducer belt differential assembly is arranged inside the cavity; each of the two sides of the main speed reducer belt differential assembly is connected with a driving shaft (6) in a rotating mode; the driving shafts are rotatably connected with the wheel rim speed reducers on the two ends of the axle housing; the axle housing is provided with a wheel steering drive device (4); the wheel steering drive device is respectively connected with the hub steering structures of the two hubs; the section of the axle housing is in a cavity structure in a square shape; the edge of a planet wheel axle (15) is provided with a small hole (30); a wheel rim speed reducer (11) is correspondingly provided with a sinking slot (31); an anti-shifting ball (19) is installed between the hole and the slot; and the outmost side of the wheel rim speed reducer shell is provided with an end cover (20).

Owner:南京创捷和信汽车零部件有限公司

Light automatic star finding starfield equatorial telescope bracket

PendingCN110440104AReduce weightImprove stabilityLighting elementsStands/trestlesDrift angleEngineering

The invention discloses a light automatic star finding starfield equatorial telescope bracket. The light automatic star finding starfield equatorial telescope bracket is characterized by comprising abase mechanism, a rotary seat mechanism, a hour angle box mechanism and a drift angle box mechanism; and the base mechanism is connected with the drift angle box mechanism. The light automatic star finding starfield equatorial telescope bracket has the advantages that thin wall feature design is adopted, the weight of the bracket is reduced, and the load bearing capacity is improved; and comparedwith like products, the light automatic star finding starfield equatorial telescope bracket is smaller in product size, lower in weight, better in stability and higher in precision. A polar axis illuminating device is arranged inside, scale marks on a dividing plate with a polar axis arranged inside can be clearly seen at night, and a user can carry out polar axis calibration more conveniently. The light automatic star finding starfield equatorial telescope bracket is simple in adjusting mode, comfortable in adjusting hand feeling and better in stability.

Owner:NANTONG SCHMIDT OPTO ELECTRICAL TECH CO LTD

Environment-friendly composite multisoap base self-repairing bearing grease and preparation method thereof

ActiveCN102604724BImprove performanceOvercoming the lack of extreme pressure wear resistanceLubricant compositionMaximum levelWear resistant

The invention relates to environment-friendly composite multisoap base self-repairing bearing grease and a preparation method of the bearing grease. The bearing grease is prepared from composite base liquid, a composite calcium soap thickening agent, an oxidation and corrosion resistant additive, a tungsten disulfide extreme pressure additive, a metal deactivator, a polarization graphite wear resistant additive, a self-repairing additive and a structure improving agent. According to the bearing grease provided by the invention, an additive containing non-heavy metal elements is used to replace the originally used additive containing heavy metal elements. Because base liquid, a thickening agent and an additive are all optimized, the bearing grease provided by the invention is more excellent in combination property and highlighted in abrasion resistance, maintains an excellent level in extreme pressure property, can fully meet the requirements of the bit bearing extreme pressure, the high temperature, a deep well with high temperature, the high-impact load and the abrasion resistance, meanwhile, can effectively supplement the defect that silver coating is not sufficiently brushed on the bearing axial diameter plane, and acts a function of repairing an abrasion resistant layer on a metal seal and a rubber seal of a bit bearing, so that the service life of the bearing is prolonged at a maximum level.

Owner:KINGDREAM PLC CO +2

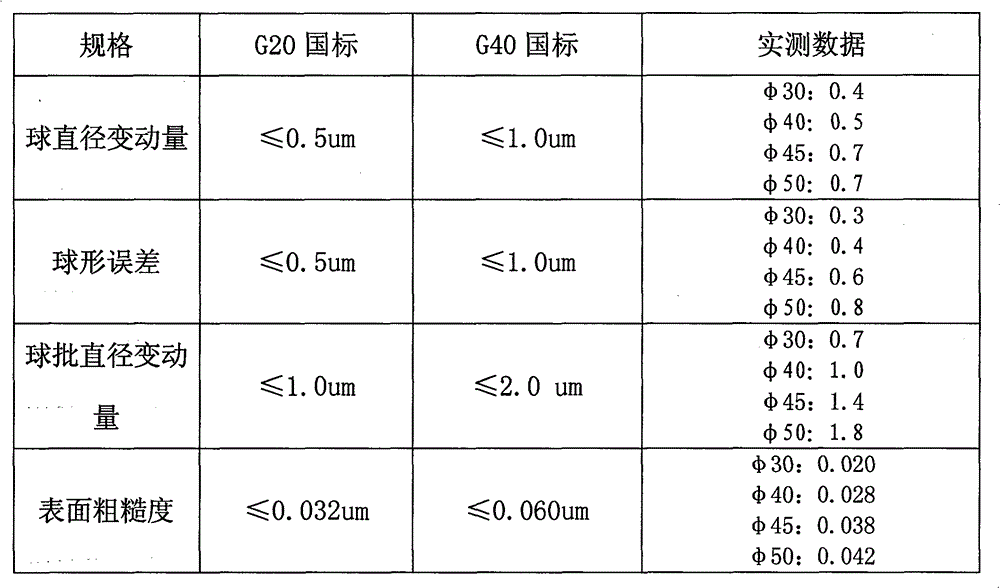

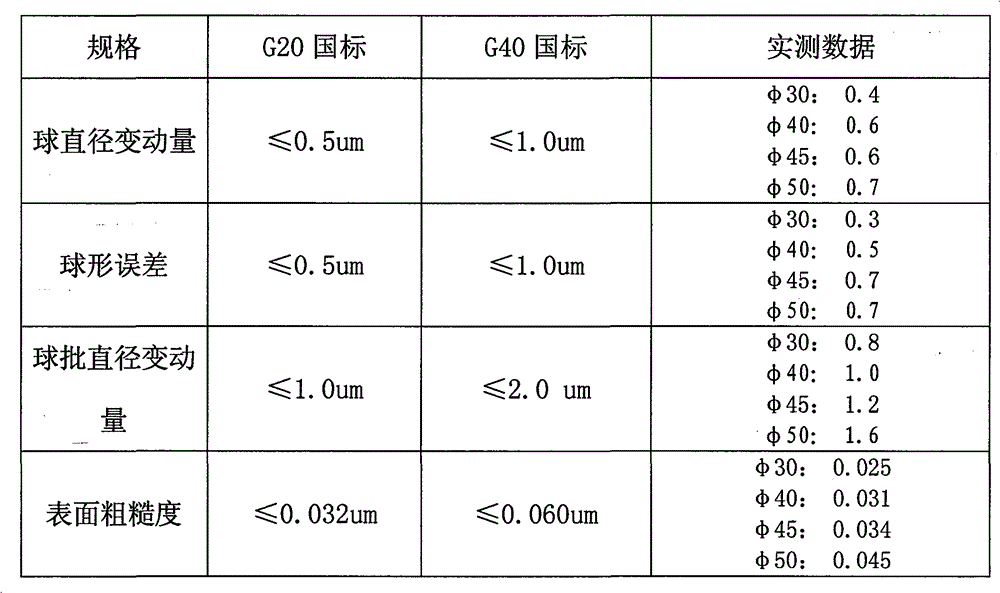

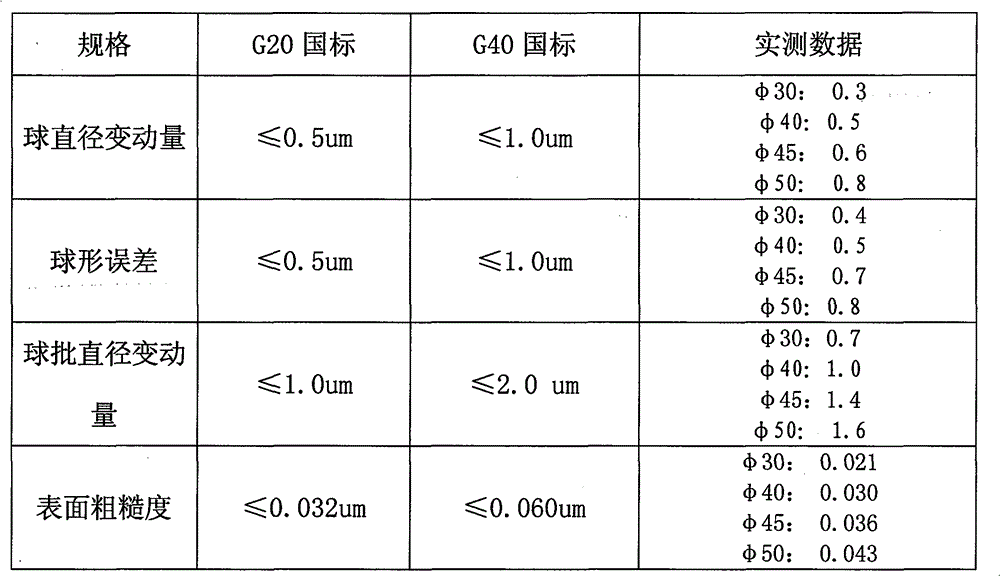

Method for manufacturing steel ball for fan bearing

InactiveCN101749323BImprove enduranceIncrease the carrying loadBearing componentsEngine componentsMetallurgySteel ball

The invention relates to a method for manufacturing a steel ball for a fan bearing, which comprises the steps of grinding, wherein the grinding step comprises a hot heading machining process and a continuous annealing process. The hot heading machining process and the advanced continuous annealing process can tighten tissues in the steel ball, and are favorable for enhancing the bearing capacity of the steel ball against impact and improving the bearing load of the steel ball; and the method solves the problems that the steel ball for the fan bearing prepared by the existing method for manufacturing the steel ball for the fan bearing has low capacity against the impact, small bearing load and short service life.

Owner:上海钢球厂有限公司

Cart

InactiveCN104742945AEffective rotationIncrease the carrying loadWrapping material feeding apparatusHand carts with multiple axesEngineeringCart

A cart is used for handling and drawing sheet strip packaging materials coiled into rings. The cart comprises a frame. The frame comprises wheels, a bracket being supported on the wheels, and a support plate arranged on the bracket. The cart also comprises a coiling mechanism installed on the support plate. The coiling mechanism comprises a bearing part and a rotation shaft, wherein the bearing part comprises a bearing plate and a plurality of roll balls; the bearing plate is installed on the support plate through the rotation shaft movably; the plurality of roll balls are arranged between the bearing plate and the support plate and used for bearing the bearing plate in a rolling manner; the bearing plate are borne on the plurality of roll balls and can rotate relative to the rotation shaft. According to the invention, the packaging materials do not need to be unloaded from the cart again for handling in the packaging process, and the use is convenient.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com