Patents

Literature

177results about How to "Reduced antioxidant capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Preparation method of edible film with antibacterial and antioxidant functions

InactiveCN103159970AHas antibacterial propertiesAntioxidantFlexible coversWrappersAntioxidantGlycerol

The invention relates to a preparation method of an edible film with antibacterial and antioxidant functions, and belongs to the technical field of edible packaging materials. The preparation method disclosed by the invention comprises the following steps: 1) dissolving and gelatinizing corn starch; 2) dissolving gelatin; 3) dissolving chitosan; 4) adding glycerin and plant essential oil or essential oil components; 5) mixing, homogenizing and refining; 6) degassing; 7) tape-casting; and 8) drying and stripping the film. The preparation method disclosed by the invention has the beneficial effects that the chitosan, the corn starch and the gelatin are taken as base materials of the edible film, the sources of the raw materials are wide, the cost is low, and the prepared edible film has the advantages of strong mechanical properties, high barrier performance and great transparency. Oregano oil, carvacrol and cinnamaldehyde are taken as an antibacterial agent and an antioxidant so as to be added into the edible film, the processing process is simple and easy to operate, the cost is low, the edible film is non-toxic and safe to eat, and the prepared edible film has great antibacterial and antioxidant properties.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Cantonese style sausage prepared via mixed bacterial fermentation and preparation method thereof

The invention discloses a cantonese style sausage prepared via mixed bacterial fermentation. According to a preparation method of the cantonese style sausage, raw material meat, water, table salt, sugar, monosodium glutamate, and sodium nitrite are mixed and are subjected to pickling; inoculation of microorganisms is carried out so as to prepare sausage; and the cantonese style sausage is prepared via fermentation. Based on the weight of the raw material meat, 1 to 3.5% of table salt, 1 to 12.0% of sugar, 0.01 to 0.2% of monosodium glutamate, 0.1 to 2% of liquor, 0.005 to 0.015% of sodium nitrite, and 1 to 3% of water are used. The invention also discloses the preparation method of the cantonese style sausage. The cantonese style sausage possesses unique fragrance, is safe and good for health; the preparation method is simple; fermentation is fast; and cost is low.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

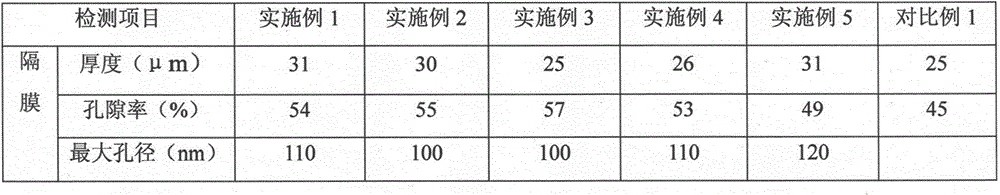

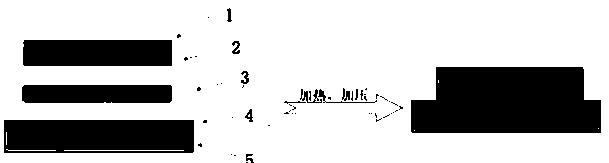

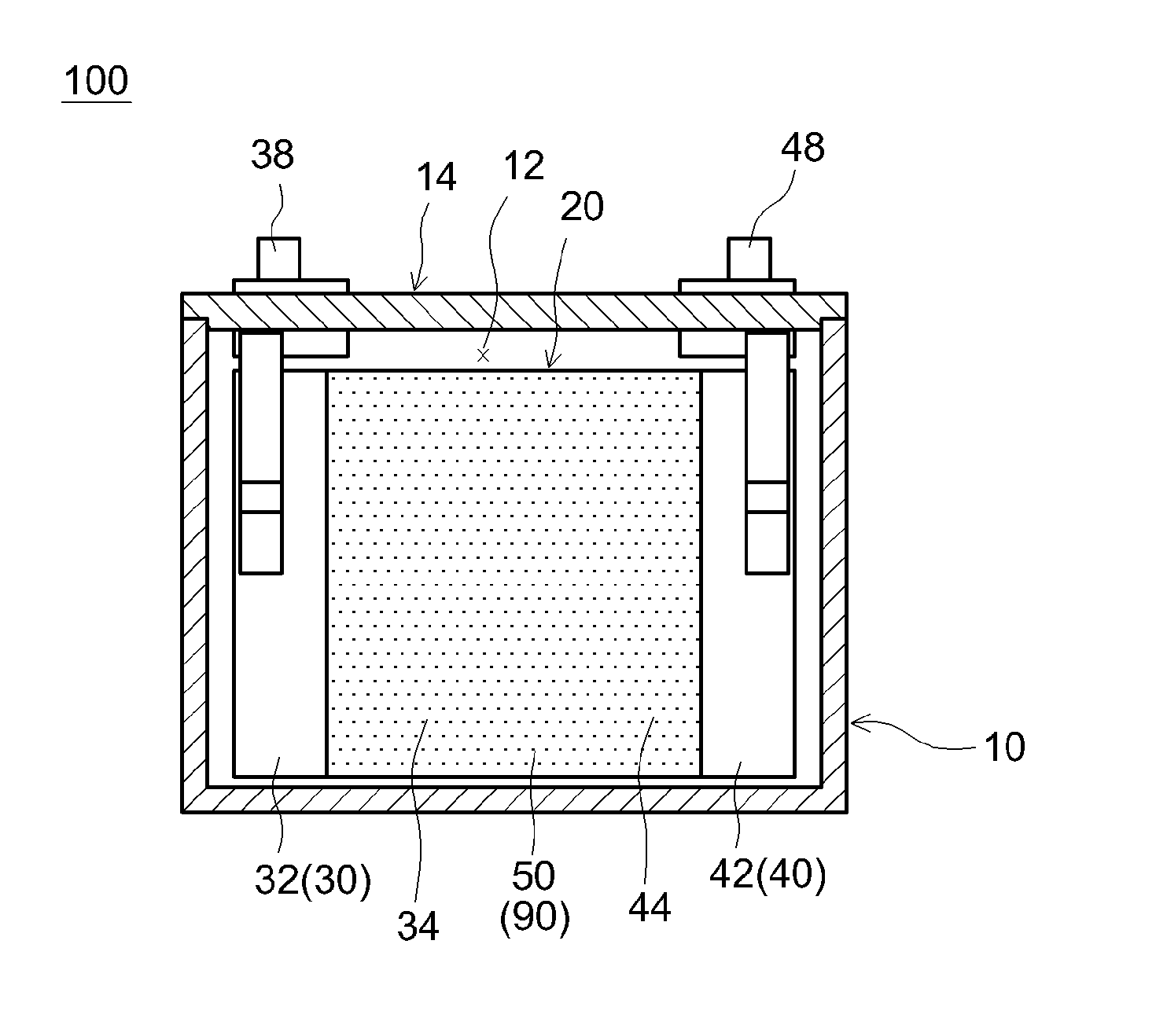

Power lithium ion battery and composite diaphragm thereof

ActiveCN102751462AHigh porosityReduce the chance of short circuitsSynthetic resin layered productsSecondary cellsComposite filmOxidation resistant

The invention discloses a composite diaphragm of a power lithium ion battery. The composite diaphragm comprises a supporting layer and an inorganic coating layer, and is characterized by further comprising a polytetrafluoroethylene layer, wherein the inorganic coating layer is coated on the supporting layer, the polytetrafluoroethylene layer is coated on the inorganic coating layer, and the surface and interior of the inorganic coating layer have porous interconnection structures. According to the composite diaphragm of the power lithium ion battery, organic / inorganic composite films are compounded with a polytetrafluoroethylene microporous film, and due to the existence of the polytetrafluoroethylene microporous film, in the process of manufacturing the composite diaphragm of the power lithium ion battery and in the process of manufacturing a wound electrode group of the battery, the inorganic coating layer has good adhesive property on the composite diaphragm and is difficult to fall off; and the composite diaphragm has the advantages of high tearing strength, perforation resistant strength, high-temperature and low temperature resistance, high corrosion resistance, electrical insulating property and chemical stability, and particularly the high oxidation-reduction resistance of polytetrafluoroethylene has more superiority for prolonging the service life of the lithium ion battery and improving the use safety of the lithium ion battery.

Owner:CHINA HAISUM ENG

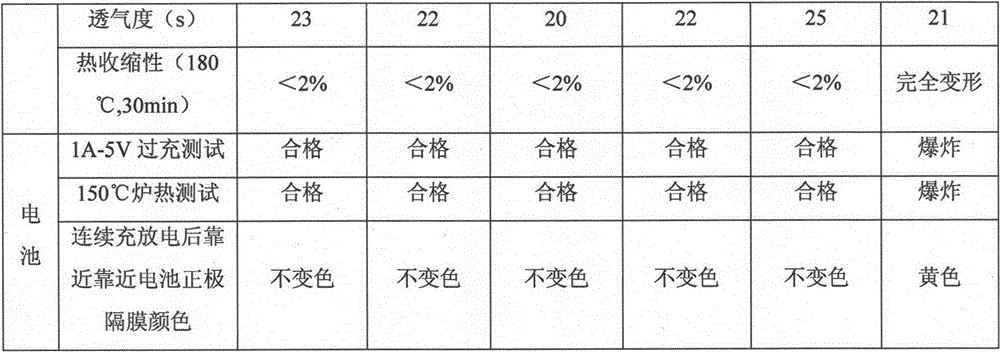

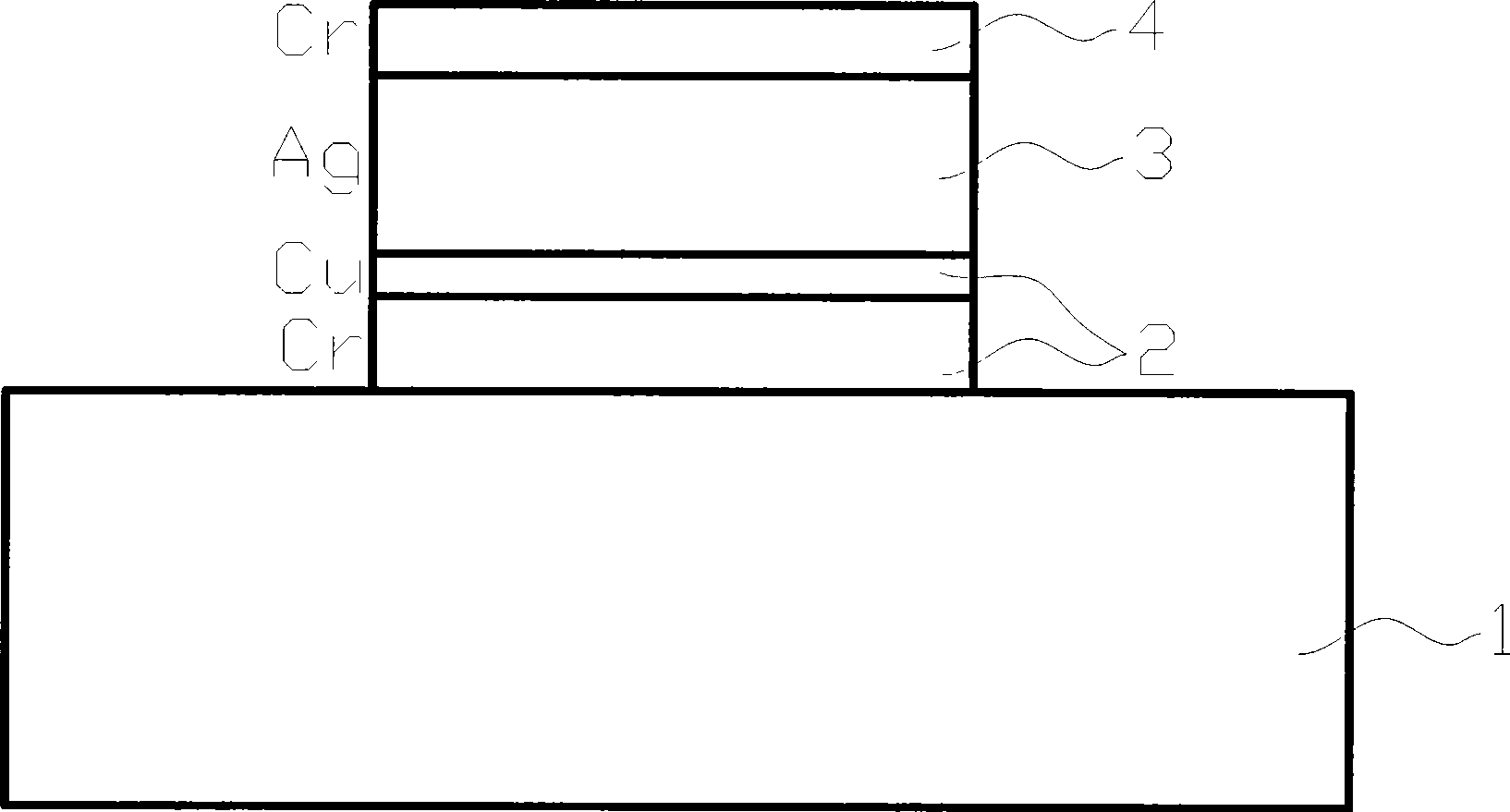

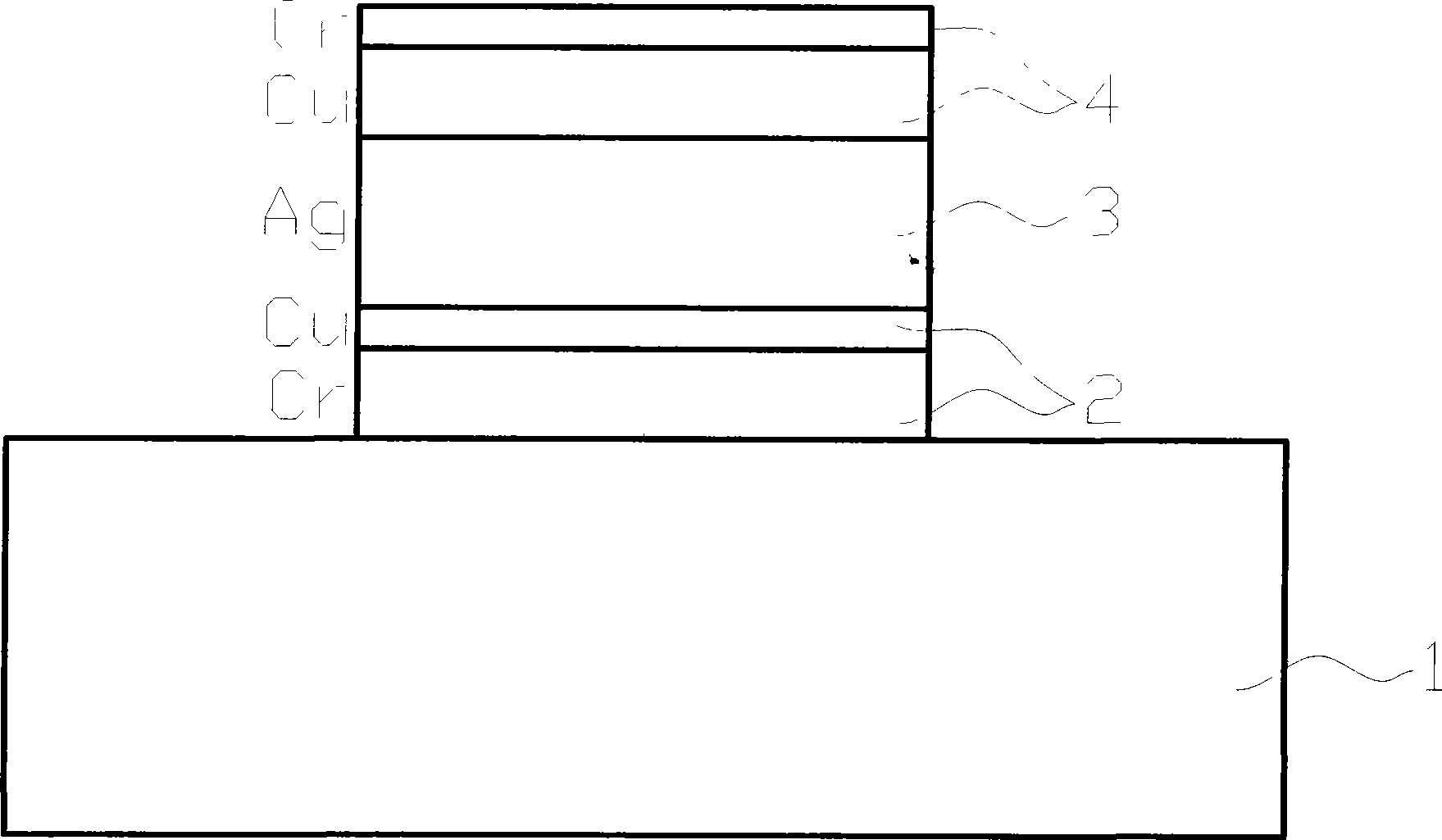

Anti-oxidation composite membrane electrode

ActiveCN101546684AReasonable designSimple structureCathode ray tubes/electron beam tubesDischarge tube/lamp detailsFlat panel displayOxidation resistant

The invention relates to an anti-oxidation composite membrane electrode, which comprises a substrate. The substrate is provided with a transition layer, a conducting layer and a protective layer in turn. The transition layer is made of a metal material (such as chromium, aluminum, titanium, molybdenum, niobium, tantalum, nickel and copper) or a compound material (such as indium oxide, zinc oxide, nickel oxide, vanadium oxide, silicon oxide, aluminum oxide, silicon nitride, aluminum nitride, and silicon oxynitride). The conducting layer is made of silver with high electrical conductivity, a silver-containing alloy or a mixture containing silver metal. The protective layer is made of a metal material (such as the chromium, the aluminum, the titanium, the molybdenum, the niobium, the tantalum, the nickel and the copper) or a compound material (such as zinc sulfide, the zinc oxide, tin dioxide, tungsten oxide, the indium oxide, the nickel oxide, the vanadium oxide, molybdenum oxide, titanium oxide, chromium oxide, niobium oxide and tantalum oxide). The membrane electrode can bear high-temperature thermal treatment and is not oxidized, thereby avoiding electrode oxidation in a sealing process, reducing the resistance of a flat display electrode and improving the display quality of a flat display.

Owner:FUZHOU UNIVERSITY

Extraction process of tea polysaccharide

The invention discloses an extraction process of tea polysaccharide. The process includes: firstly washing fresh tea leaves with clean water, then performing microwave vacuum drying, then crushing the tea leaves, adding water into the obtained tea powder, and adding acid to adjust the pH value of the solution, then adding cellulase and polyphenol oxidase, carrying out hydrolysis under certain temperature, sending the obtained enzymolysis liquid into ultrasonic equipment to conduct ultrasonic treatment, then performing filtering and sending the filtrate into ultrafiltration equipment to conduct ultrafiltration treatment, then putting the ultrafiltrate into a centrifugal machine to conduct centrifugal separation, concentrating the obtained centrifugate, adding ethanol into the concentrated solution, carrying out centrifugal separation, and drying the tea polysaccharide, thus obtaining tea polysaccharide. By adopting the microwave low temperature vacuum drying and ultrasonic wave synergistic treatment technology, the process provided by the invention ensures effective wall breaking, and significantly improves the yield and antioxidant activity of polysaccharide.

Owner:GUANGXI DONGXING DINGKANG PLASTIC IND

Low-fat chicken fermented sausage and preparation method thereof

InactiveCN104323305AOptimization of fermentation process parametersGrowth inhibitionFood preparationSaccharumGallic acid ester

The present invention discloses a low-fat chicken fermented sausage and a preparation method thereof, and belongs to the technical field of deep processing of agricultural products. The low-fat chicken fermented sausage comprises the following components by mass: 100 parts of chicken breast, 12-14 parts of corn oil, 9-12 parts of inulin, 1.2-1.4 parts of soy protein isolate, 0.5-0.7 part of sucrose, 3.5-4 parts of salt, 0.01 part of butyl hydroxyanisole, 0.02 part of sodium nitrite, 0.04 part of sodium nitrate, 0.007 part of gallic acid, 0.03 part of pepper powder, 9.5-10.5 parts of water, 0.001-0.004 part of probiotics and 0.035-0.038 part of leaven. According to the low-fat fermented sausage, chicken is inoculated with lactic acid bacteria so as to prepare a fermented meat product, so that the color of the product is improved, the digestibility and net utilization rate of proteins are increased, the safety of the product are improved, the shelf life of the product is prolonged, and a unique flavor is provided to the product.

Owner:HENAN UNIV OF SCI & TECH

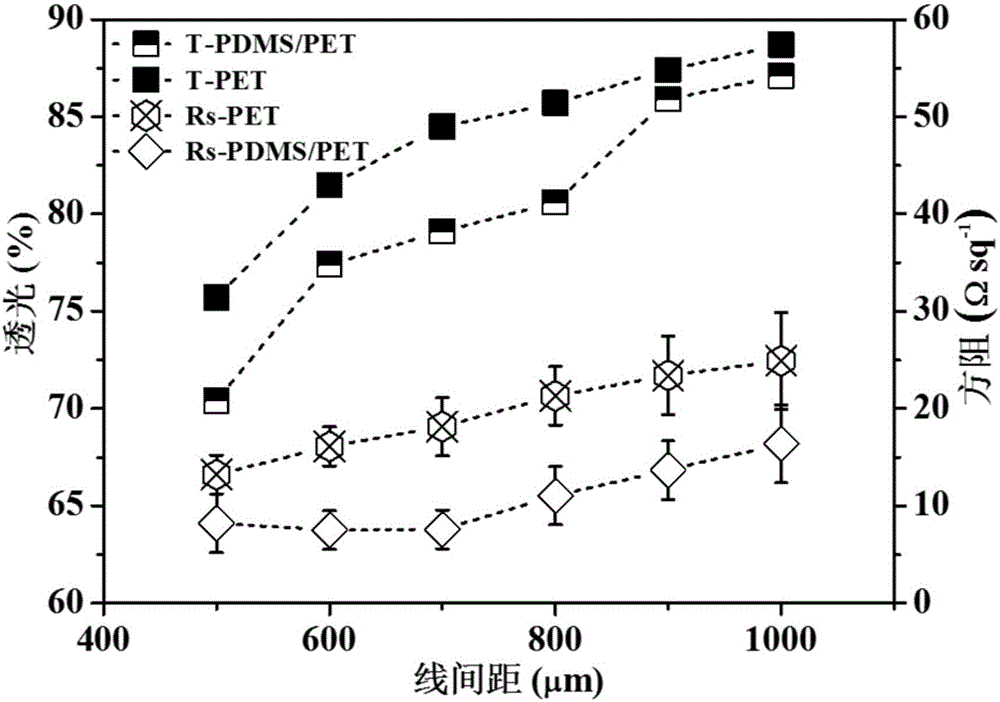

Flexible transparent silver grid composite electrode and production method thereof

ActiveCN105895197AReduce surface roughnessReduced antioxidant capacityConductive layers on insulating-supportsCable/conductor manufacturePolyethylene terephthalate glycolPolyvinyl alcohol

The invention discloses a flexible transparent silver grid composite electrode and a production method thereof. The electrode structure is as follows: A / a silver grid / an elastic substrate. The A can be conductive polymer (PEDOT:PSS), a metal-oxide-semiconductor (ZnO), and a binary complex of the above mentioned materials. The substrate adopts high elasticity plastics, such as polyethylene terephthalate (PET), polyimide (PI), polyvinylalcohol (PVA), polydimethylsiloxane (PDMS), polyurethane acrylate(PUA), and hydrogel, and so on. The production method is characterized in that the metal grid and the A material are sequentially printed on the high elasticity plastic substrate by adopting the ink-jet printing technology. The produced transparent electrode is advantageous in that the comprehensive performance is excellent, the square resistance is low, the flexibility is good (the electrode can be bent, distorted, and even stretched at will), the surface is leveled, the oxidation-resistant capability is strong, and the shape and the size can be adjusted at will.

Owner:NANJING UNIV OF POSTS & TELECOMM

Surface-treated graphene, surface-treated graphene/organic solvent dispersion liquid, surface-treated graphene/electrode active material composite particles and electrode paste

ActiveUS20190051903A1Improved dispersibilityReduced antioxidant capacityMaterial nanotechnologyCell electrodesCarbonyl groupBenzene

The purpose of the present invention is to provide a graphene which has high dispersibility, high electrical conductivity and oxidation resistance namely a graphene which has high electrochemical stability. In order to achieve the above-described purpose, a surface-treated graphene according to the present invention is obtained by having a compound represented by general formula (1) or a neutralized salt thereof adhere to a graphene. In general formula (1), A represents a benzene-based aromatic group with a condensation number of 1-4, which has no phenolic hydroxy group; R1 represents a direct bond, a divalent hydrocarbon group having 1-12 carbon atoms, or a divalent organic group having 1-12 carbon atoms, which has a structure selected from the group consisting of an ether bond, an ester bond, an alcohol structure and a carbonyl structure; each of R2 and R3 independently represents a hydrogen atom, a hydrocarbon group having 1-12 carbon atoms, or an organic group having 1-12 carbon atoms, which has a structure selected from the group consisting of an ether bond, an ester bond, an alcohol structure and a carbonyl structure; and n represents an integer of 1-6.

Owner:TORAY IND INC

Magnesium smelting reduction pot and preparation method thereof

InactiveCN101805833APrevent oxidationImprove high temperature resistanceFoundry mouldsFoundry coresPOWDERED CELLULOSEEmulsion

The invention relates to a magnesium smelting reduction pot and a preparation method thereof, which belong to the technical field of metal smelting. The magnesium smelting reduction pot comprises a pot body and an external application coating layer, and is characterized in that: the pot body comprises the following components in percentage by weight: 0.2 to 0.4 percent of C, 1.0 to 2.0 percent of Mn, 0.6 to 2.0 percent of Si, 24.0 to 26.0 percent of Cr, 6.0 to 8.0 percent of Ni, 0.015 to 0.05 percent of Ti, 0.03 to 0.10 percent of Re, and the balance of iron; and the external application coating layer comprises the following components in percentage by weight: 47.9 to 74.1 percent of zircon powder or graphite with the particle size of 200 to 270 meshes, 1.5 to 3.8 percent of bentonite, 1.5 to 2.9 percent of powdered cellulose (carboxymethylcellulose sodium), 0.7 to 2.4 percent of white latex (polyvinyl acetate emulsion), and 22.2 to 43.0 percent of ethanol. All types of the components of the pot body are put into an intermediate frequency furnace and are melted for pouring, and are brushed with a coating according to the component proportion after being cooled. Starting from each process step of preparing the magnesium smelting reduction pot, the components of materials of the reduction pot, a melting process and a centrifugal casting process are optimized and adjusted, and a high-temperature resistant coating is brushed on the surface of the reduction pot to effectively promote the oxidation resistance of the reduction pot at a high temperature, so the service life of the pot body is prolonged.

Owner:BAOTOU BINGKE SILICON MAGNESIUM MATERIAL ENG TECH RES CENT

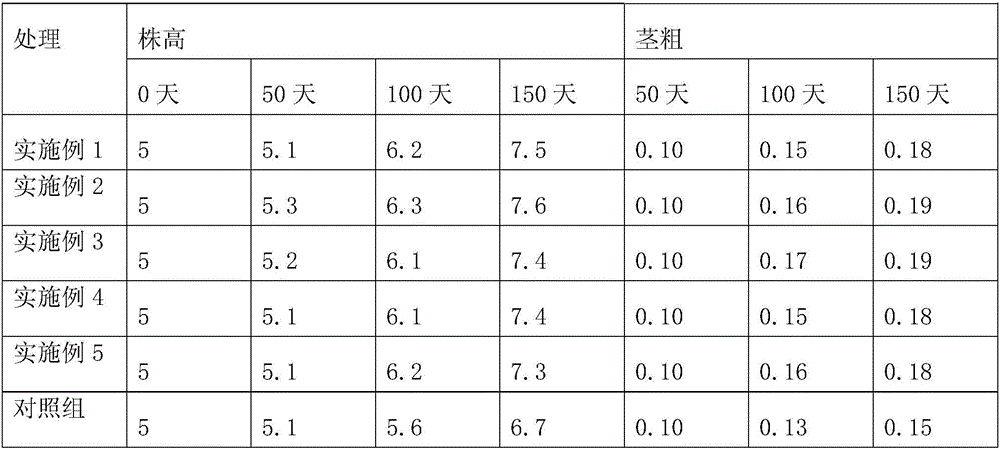

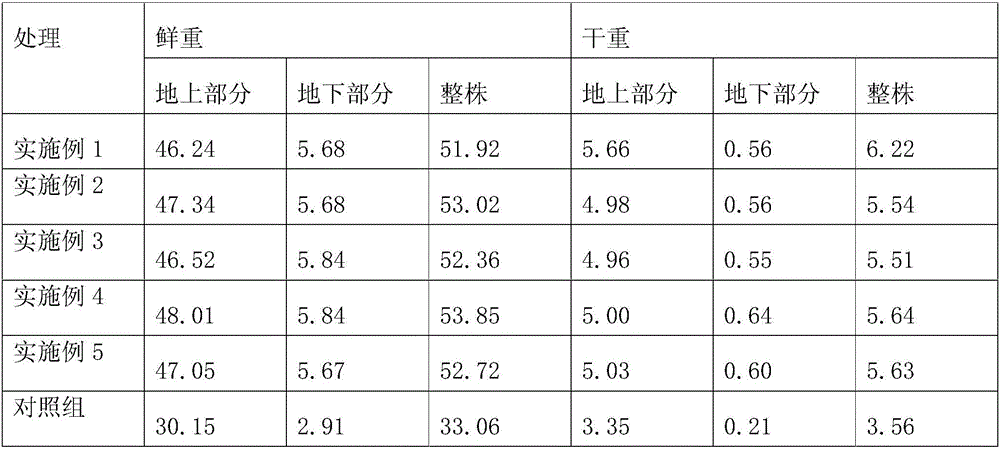

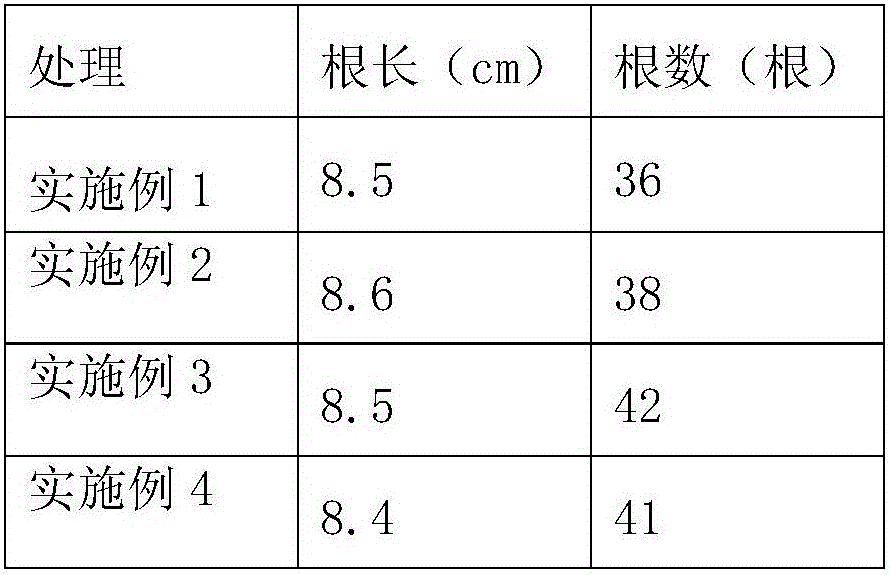

Wild-imitating planting substrate for dendrobium huoshanense and preparation method for wild-imitating planting substrate

InactiveCN105918084AQuality improvementImprove fertilityGrowth substratesCulture mediaBiologyMoisture

The invention discloses a wild-imitating planting substrate for dendrobium huoshanense. The wild-imitating planting substrate comprises a bottom-layer substrate, a middle-layer substrate and an upper-layer substrate which are arranged in a manner of being superposed sequentially from bottom to top, wherein the bottom-layer substrate is prepared from 10-20 parts (by weight) of dried corn stalks or dried sugarcane leaves; the middle-layer substrate is prepared from a mixture of 5-15 parts (by weight) of vermiculite and the like; and the upper-layer substrate is prepared from a mixture of 15-35 parts (by weight) of modified biocarbon, 15-45 parts (by weight) of rotten wood and the like. A preparation method for the planting substrate comprises the steps of preparing the modified biocarbon, preparing the bottom-layer substrate, the middle-layer substrate and the upper-layer substrate and then carrying out superposition. The preparation method for the planting substrate is simple and easy to understand; and the planting substrate prepared by the preparation method has the advantages that the condition that the substrate is rotted, is air-proof and does not hold moisture in long-term use is overcome, the cost is low, the nutrition is complete, the growth of the dendrobium huoshanense is better facilitated, dendrobium huoshanense stems are promoted to grow more sturdy, and dendrobium huoshanense root systems are promoted to be more developed.

Owner:GUANGXI ZHIBAO TECH CO LTD

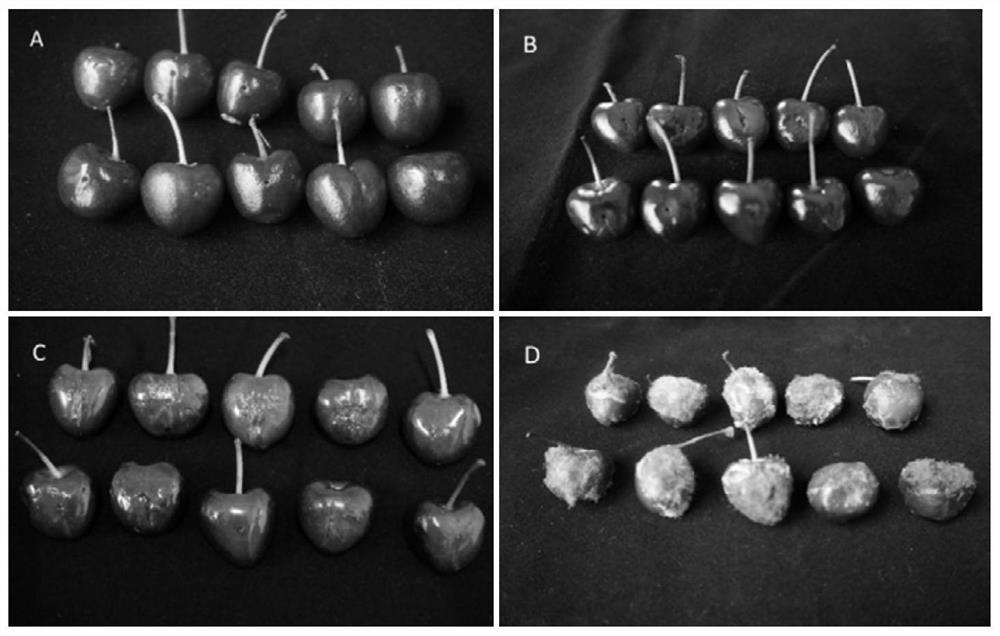

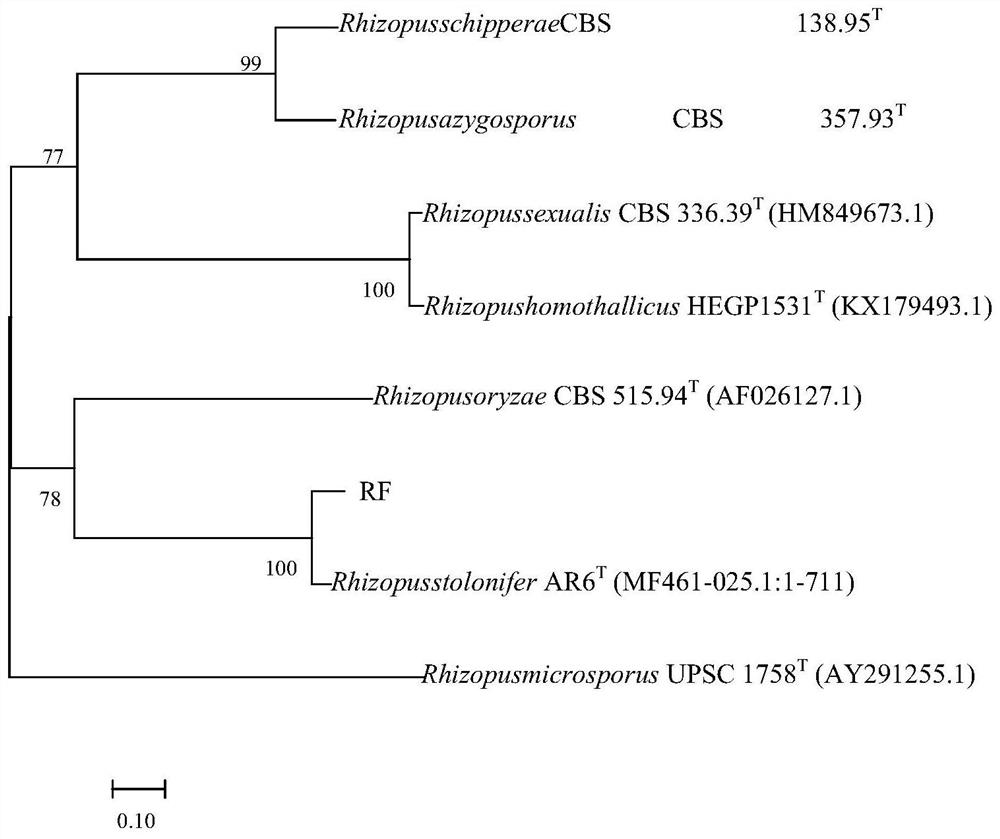

Cherry preservative and fresh-keeping microbial preparation and preparation method and application thereof

ActiveCN111961629AEnhanced inhibitory effectSlow down the corruption processFruit and vegetables preservationBacteriaBiotechnologySporeling

The invention relates to a cherry preservative and fresh-keeping microbial preparation and a preparation method and application thereof. The cherry preservative and fresh-keeping microbial preparationis prepared from bacillus velezensis TA-3-BV which is preserved in China General Microbiological Culture Collection Center on July 17, 2020, and the preservation number is CGMCC NO. 20398. The microbial preparation disclosed by the invention can effectively inhibit mycelial growth and spore germination of pathogenic bacteria rhizopus stolonifer and effectively inhibit morbidity of soft rot of sweet cherries at the same time, after the picked cherries are soaked in bacillus velezensis TA-3-BV bacterial suspension, the fruit spoilage process can be delayed, and fruit spoilage is delayed by 2-3days. Meanwhile, through treatment of the bacillus velezensis TA-3-BV, the disease resistance and oxidation resistance of plants can be induced, the basic immunity of cherry fruits is triggered, and anew method is provided for preservation and fresh keeping of the harvested sweet cherries.

Owner:SHANDONG INST OF POMOLOGY

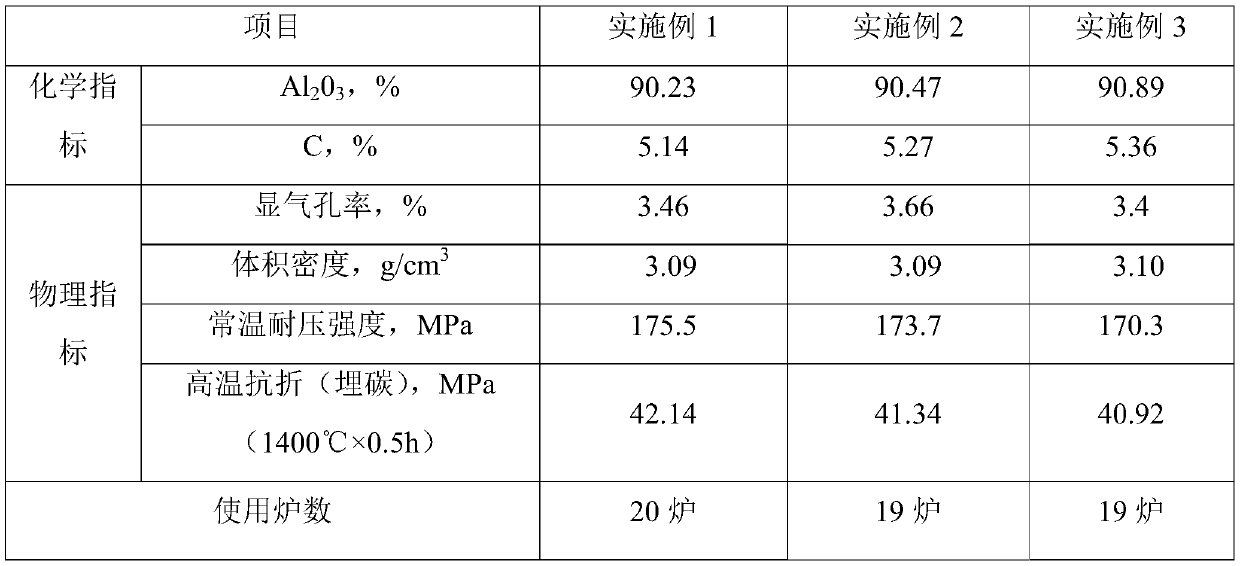

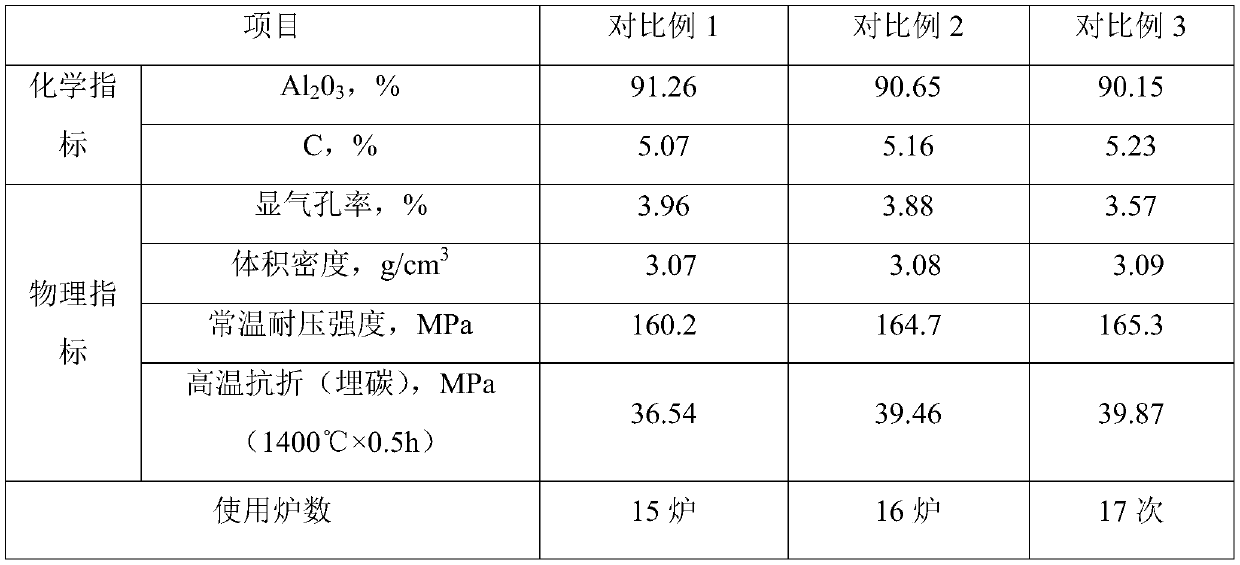

Al4SiC4 ternary non-oxide converter slag-stopping sliding plate and preparation method thereof

The invention discloses an Al4SiC4 ternary non-oxide converter slag-stopping sliding plate and a preparation method thereof, and belongs to the technical field of sliding plates. The sliding plate includes the following components: 25-33 wt% of plate-shaped corundum particles having a particle size of 2.3-1 mm, 16-24 wt% of plate-shaped corundum particles having a particle size of 1-0.5 mm, 20-26wt% of plate-shaped corundum particles having a particle size of 0.5-0.045 mm, 10-15 wt% of plate-shaped corundum fine powder having a particle size of 0-0.045 mm, 5-8 wt% of active alpha-Al2O3 micropowder, 2-6 wt% of Al4SiC4 fine powder, 2-3 wt% of carbon black, 4-8 wt% of active metal aluminum powder, and 4 wt% of a composite antioxidant; and a compound liquid resin binder accounting for 4-5% ofthe total weight is added. The thermal shock stability, high-temperature thermal strength and high-temperature oxidation resistance of the converter sliding plate are improved, and the service life of the sliding plate is prolonged.

Owner:MAANSHAN LIER KAIYUAN NEW MATERIAL

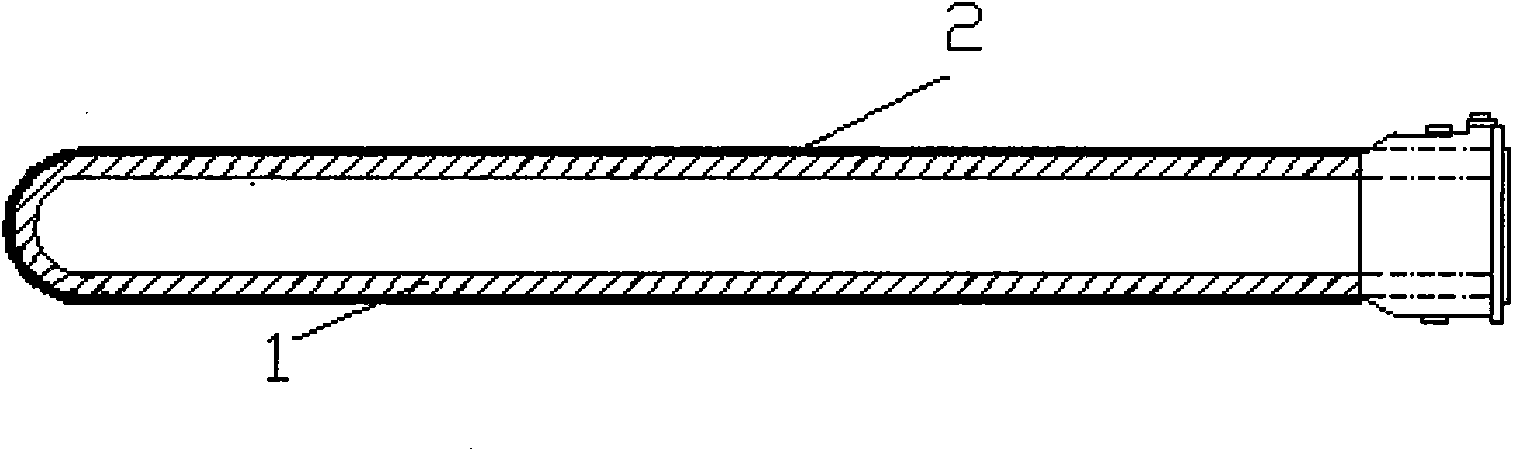

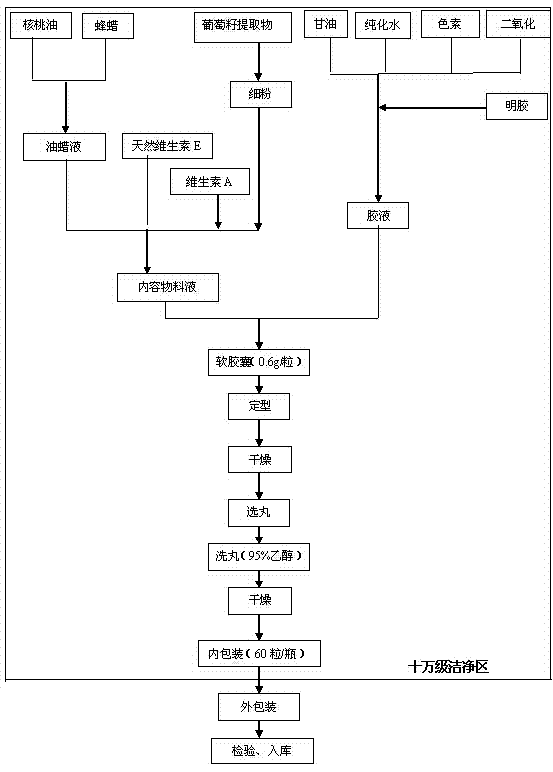

Soft capsule with anti-oxidation function and preparation method of soft capsule

InactiveCN104705652AReduced antioxidant capacityReduce the level of peroxidationFood shapingFood preparationBiotechnologyGlycerol

The invention discloses a soft capsule with an anti-oxidation function and a preparation method of the soft capsule. The soft capsule is prepared from walnut oil, a grape seed extract, vitamin E, vitamin A, beewax, gelatin, glycerol, purified water, titanium dioxide and a pigment. Every 1000 soft capsules contain 400-600g of walnut oil, 40-60g of the grape seed extract, 20-30g of vitamin E, 0-1g of vitamin A, 10-30g of beewax, 80-110g of gelatin, 30-50g of glycerol, 80-120g of purified water, 0.5-10g of titanium dioxide and 5-15mg of pigment. The soft capsule which is developed by taking walnut oil as a raw material and has the anti-oxidation function can eliminate redundant oxidation free radicals in human bodies, and has a certain prevention function on diseases and relevant aging diseases caused by free radicals, and thus the market prospect is wide.

Owner:HARBIN INST OF TECH

Method for producing bound trotters through artificial inoculation and fermentation

InactiveCN104997042AUnique flavorQuality improvementFood ingredient functionsFood preparationNutritive valuesReady to eat

The invention discloses a method for producing bound trotters through artificial inoculation and fermentation, and belongs to the technical field of food processing. The method comprises the following steps: preparing trotter skin; pretreating raw materials; pickling the pretreated raw materials at a low temperature; rolling and kneading the pickled raw materials; inoculating and fermenting the kneaded raw materials; encrusting the fermented raw materials, and bundling up the encrusted raw materials; marinating the bundled raw materials; cooling the marinated raw materials, and vacuum packing the cooled raw materials; and sterilizing the packed raw materials at high pressure, cooling the sterilized raw materials, packing the cooled raw materials in boxes, and warehousing the boxes. According to the method disclosed by the invention, a conventional processing method is combined with a microorganism fermentation technique, mixed bacteria species of bulgaricus milk bacillus, saccharomyces cerevisia or bulgaricus milk bacillus and staphylococcus carnosus are used for fermentation in a bacteria species mixing manner, so that a novel and convenient ready-to-eat health food is provided for society. The bound trotters processed by the method disclosed by the invention are unique in special flavor, deep red in color, loose in meat quality, high in nutrient value, easy to preserve, stable in quality, and high in edible safety, and effectively reduce the content of nitrite.

Owner:XUZHOU UNIV OF TECH

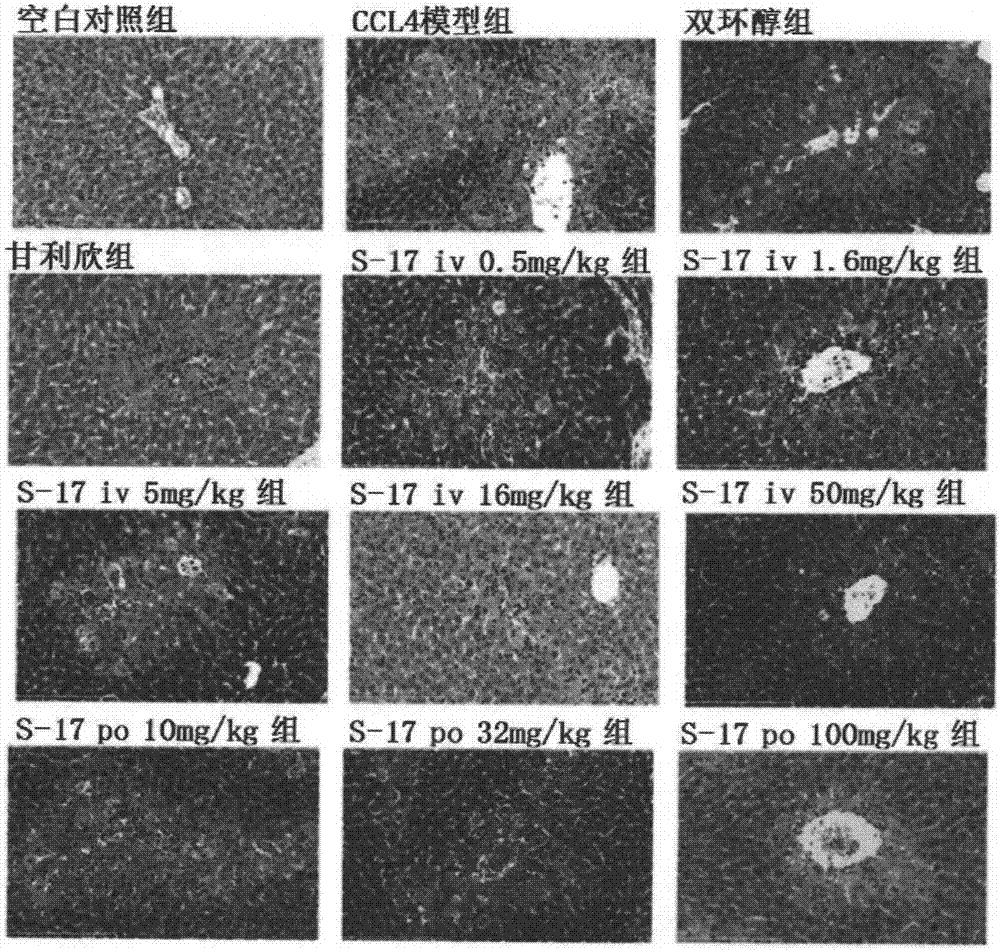

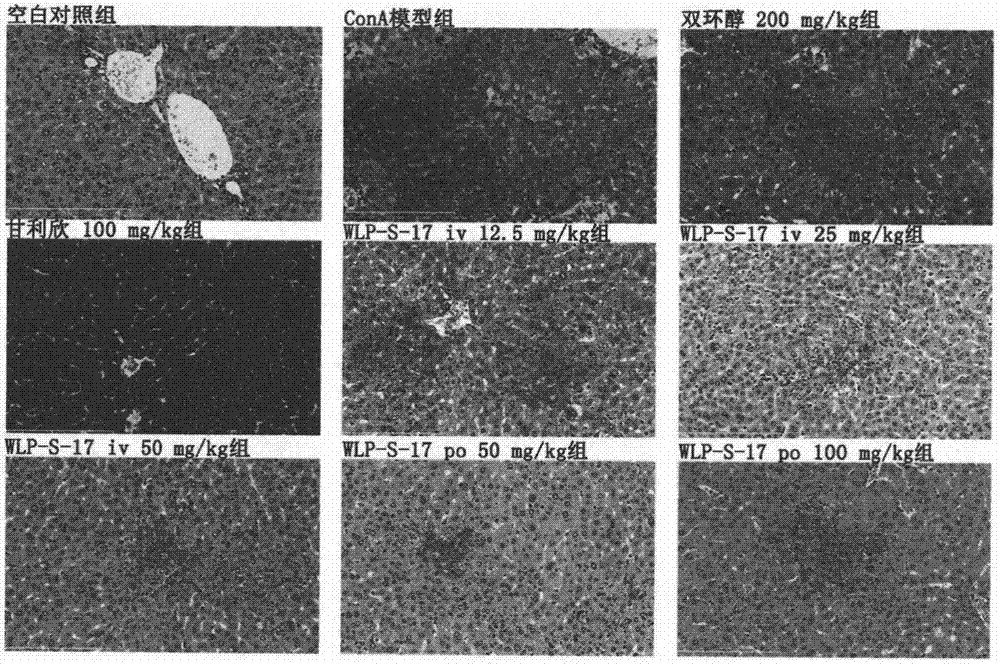

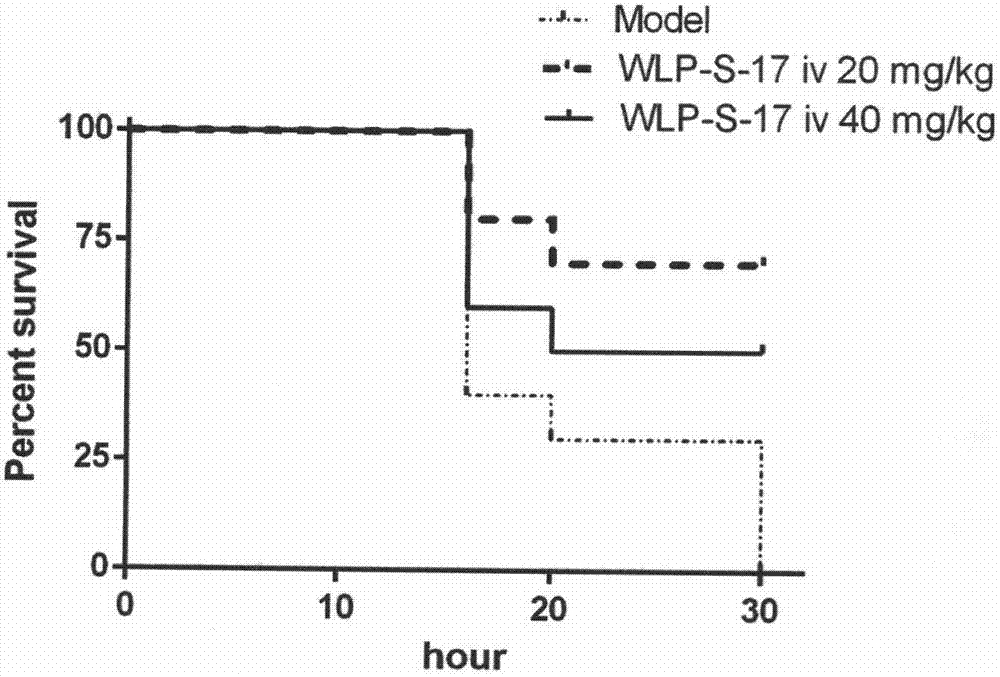

Bicyclol-based derivative, preparation and applications thereof

ActiveCN107488162AGood effectReduce necrosisOrganic active ingredientsOrganic chemistryHepatic DiseasesMedicine

The present invention belongs to the field of medicinal chemistry, and particularly relates to a bicyclol-based derivative and a pharmaceutically acceptable salt thereof, a preparation method of the bicyclol-based derivative, and applications of the bicyclol-based derivative in preparation of drugs for prevention and / or treatment of liver diseases and the like. The formula I is defined in the specification.

Owner:INST OF MATERIA MEDICA AN INST OF THE CHINESE ACAD OF MEDICAL SCI

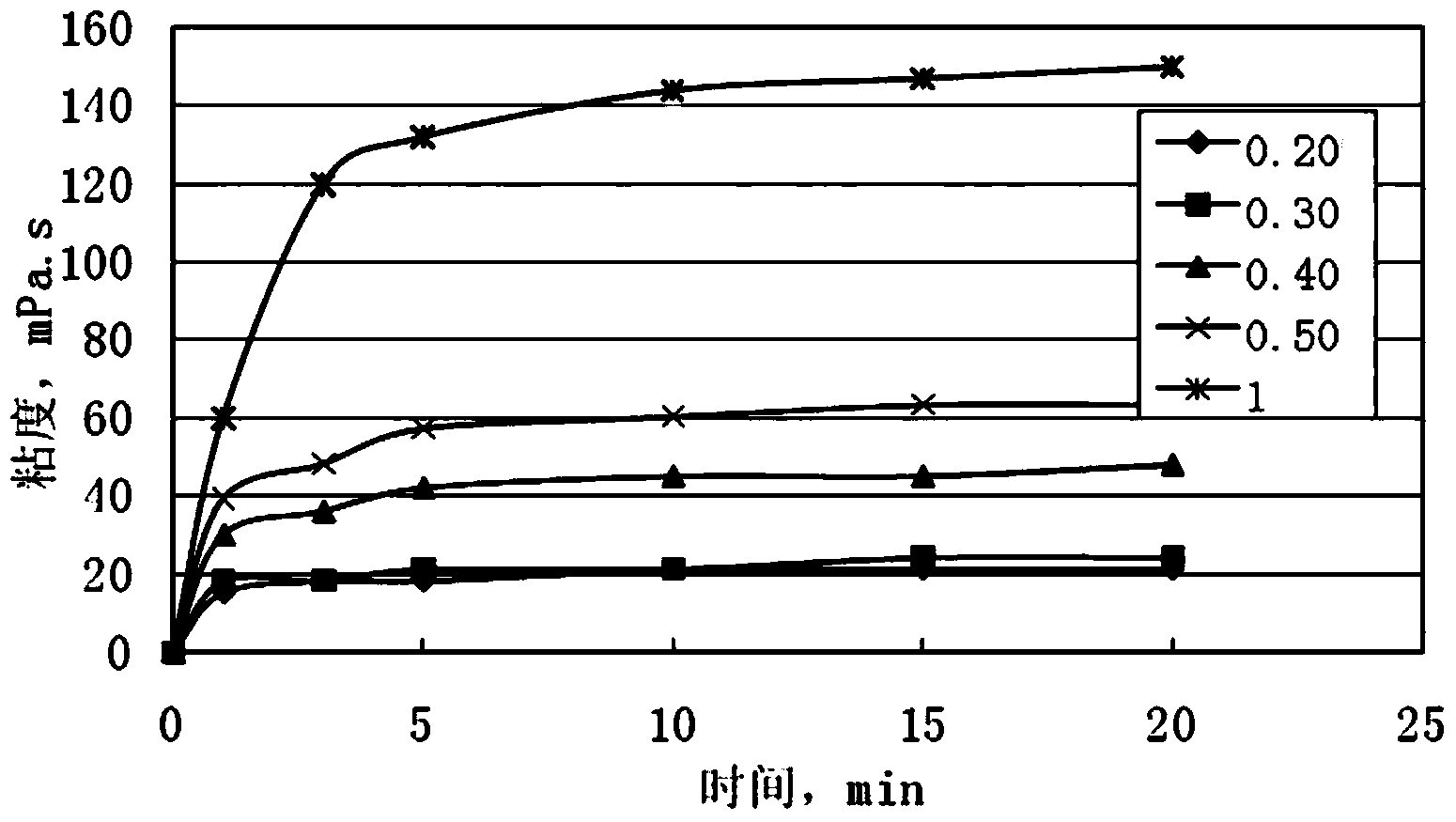

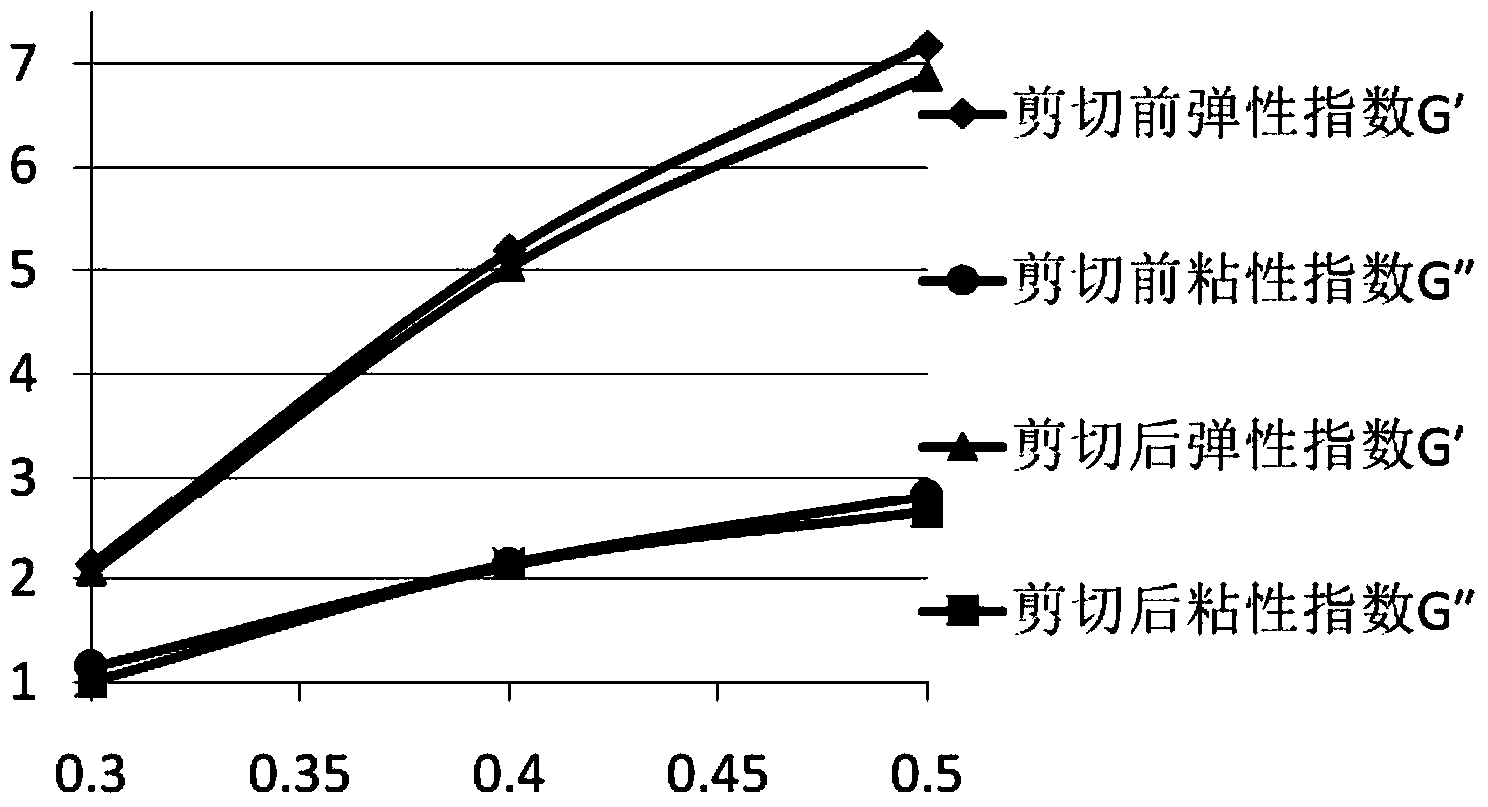

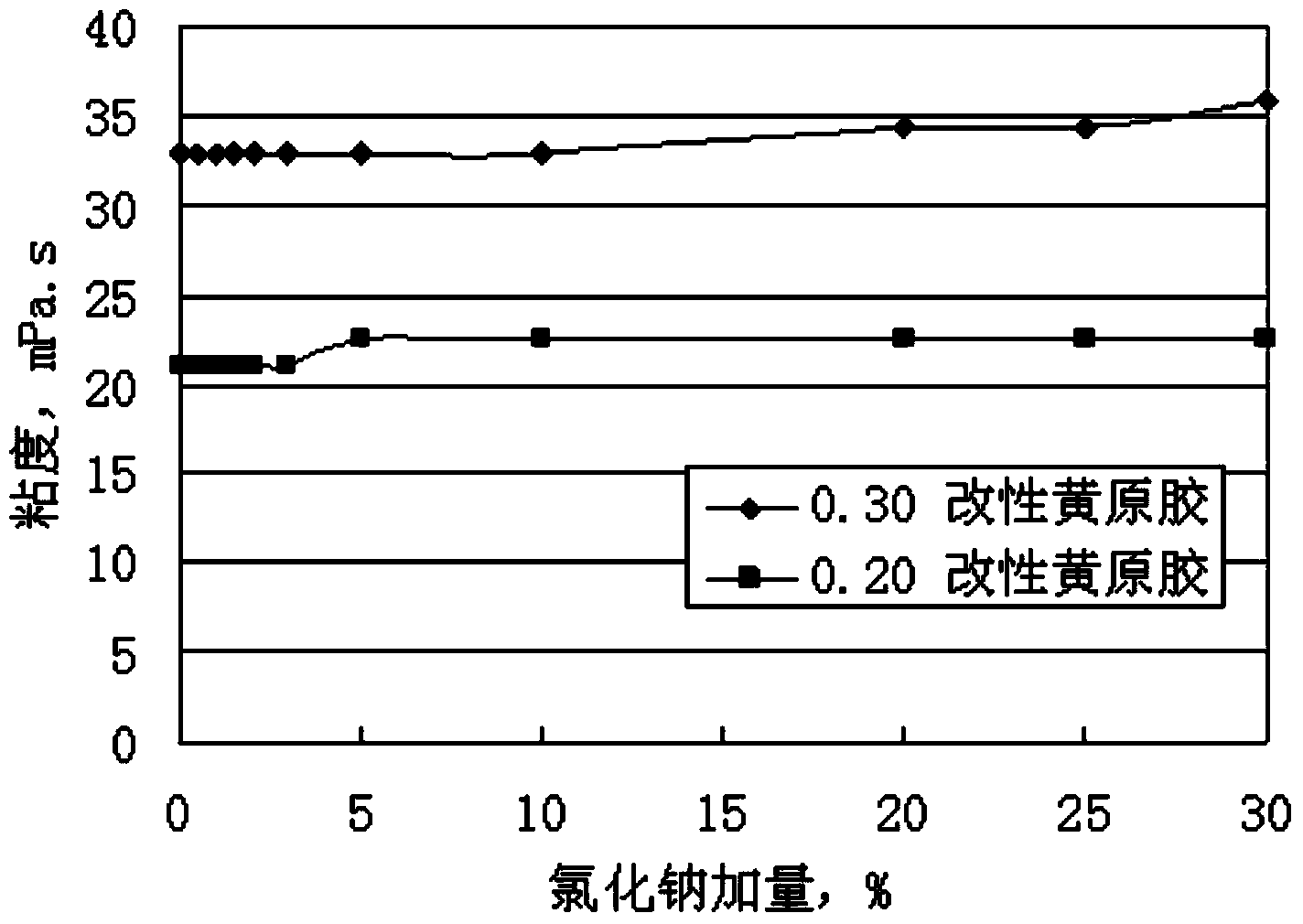

Low-viscosity and high-elasticity non-crosslinking fracturing fluid and preparation method thereof

ActiveCN103881686ALow costReduced antioxidant capacityDrilling compositionSalt resistancePolymer science

The invention relates to a low-viscosity and high-elasticity non-crosslinking fracturing fluid which comprises the following components: 0.15-2.0 parts by weight of thickening agent, 0.02-2.0 parts by weight of gel breaker and 100 parts by weight of water, wherein the thickening agent is one or more than one of a xanthan gum esterification derivative, a xanthan gum hydroxypropylation derivative and a xanthan gum carboxymethylation derivative. The invention further provides a preparation method of the low-viscosity and high-elasticity non-crosslinking fracturing fluid. The low-viscosity and high-elasticity non-crosslinking fracturing fluid has the advantages of high viscosity, high dissolving speed, temperature resistance, shearing resistance, and salt resistance, and can be easily broken; and the low-viscosity and high-elasticity non-crosslinking fracturing fluid is a novel fracturing liquid which is low in price, easy to obtain, and easy to operate, and can be used in all phases of fracturing construction. The instant dissolving characteristic of the low-viscosity and high-elasticity non-crosslinking fracturing fluid is especially suitable for online liquid preparation, and the fracturing factorized operation is favorably realized.

Owner:PETROCHINA CO LTD

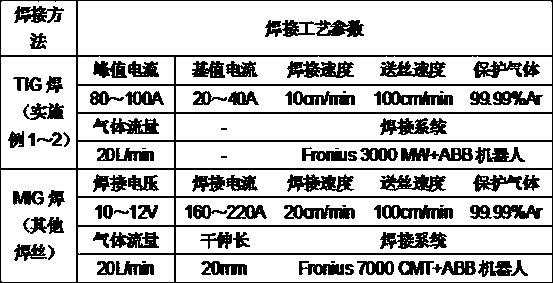

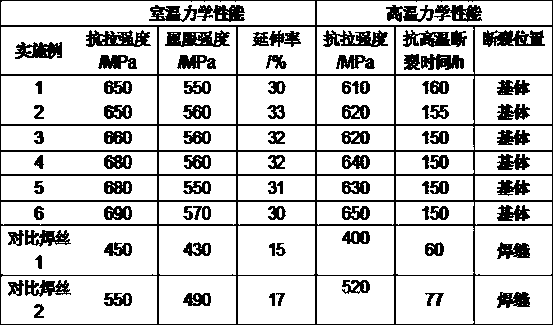

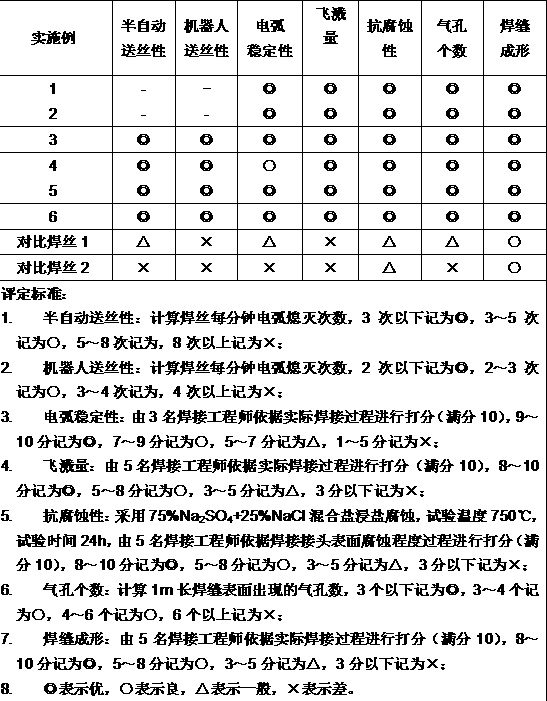

NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

InactiveCN109894770AAvoid oxidation burnAvoid welding requirements for high temperature and corrosion resistanceWelding/cutting media/materialsSoldering mediaAcid washingAlloy

The invention discloses a NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and a preparation method thereof, and belongs to the field of welding materials. The welding wire comprises the following components in percentage by weight: 45-50% of Ni, 35-40% of Cr, 1.00-1.50% of Nb, 0.01-0.10% of Re, 0.30-0.55% of C, 0.50-2.00% of Si,1.00-2.00% of Mn, 0.01-0.10% of Al, 0.05-0.20% of Ti, 0.01-0.10% of Zr, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of alloy smelting-electroslag remelting-blooming by hot forging-hot-rolled annealing-mechanical stripping-diameter reduction by drawing-straightening and cutting or precise layer winding. The preparation method is environmentally friendly, free of acid washing pollution, stable in welding arc, free of splashing, beautiful in welding line molding, excellent in welding process and mechanical performance and dense in welding line structure, and can totally meet high-temperature-resistance and corrosion-resistance welding requirements of the ethylene cracking furnace cast pipes.

Owner:DANYANG XINHANG SPECIAL ALLOY

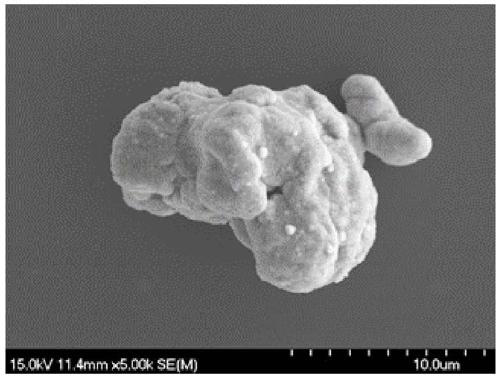

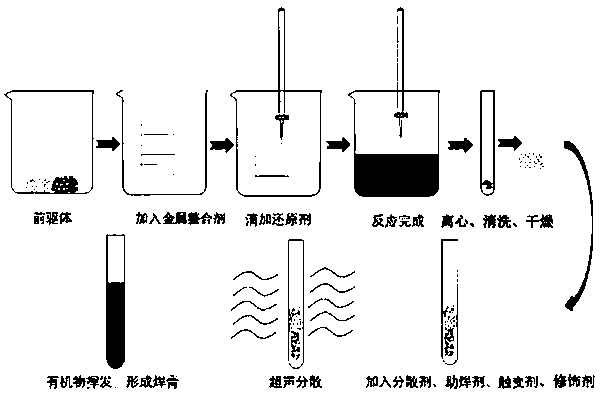

Silver-coated copper powder, preparation method thereof and electronic paste

ActiveCN111304640AIncrease coverageImprove conductivityTransportation and packagingConductive materialMetallurgyHigh conductivity

The invention belongs to the technical field of electronic paste, and particularly relates to a preparation method of silver-coated copper powder. The preparation method comprises the following steps:copper powder is obtained, and mixed with a first silver ammonia solution and a first reducing agent, ammonia water is added, mixing and separation are performed, and an intermediate product is obtained, wherein the molar ratio of the copper powder, the first silver ammonia solution to the first reducing agent is 1.26: (0.06-0.30): (0.05-0.25); the intermediate product is mixed with a second silver ammonia solution and a second reducing agent for a reaction, separation is performed, and the silver-coated copper powder is obtained; the molar ratio of the copper powder, the second silver ammonia solution to the second reducing agent is 1.26: (0.06-0.20): (0.02-0.15). The preparation method of the silver-coated copper powder is simple to operate and suitable for industrial large-scale production and application; and the prepared silver-coated copper powder has high conductivity and low resistivity of 1.1*10<-5> omega.cm.

Owner:深圳市哈深智材科技有限公司

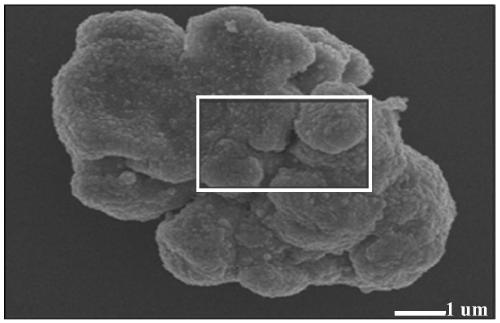

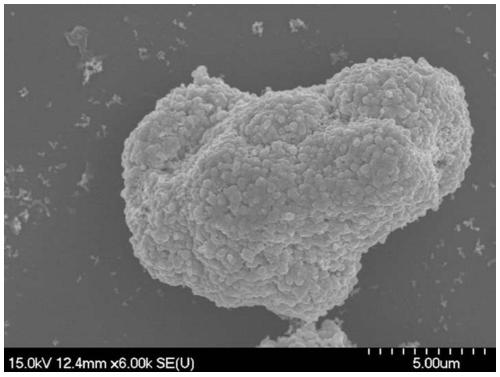

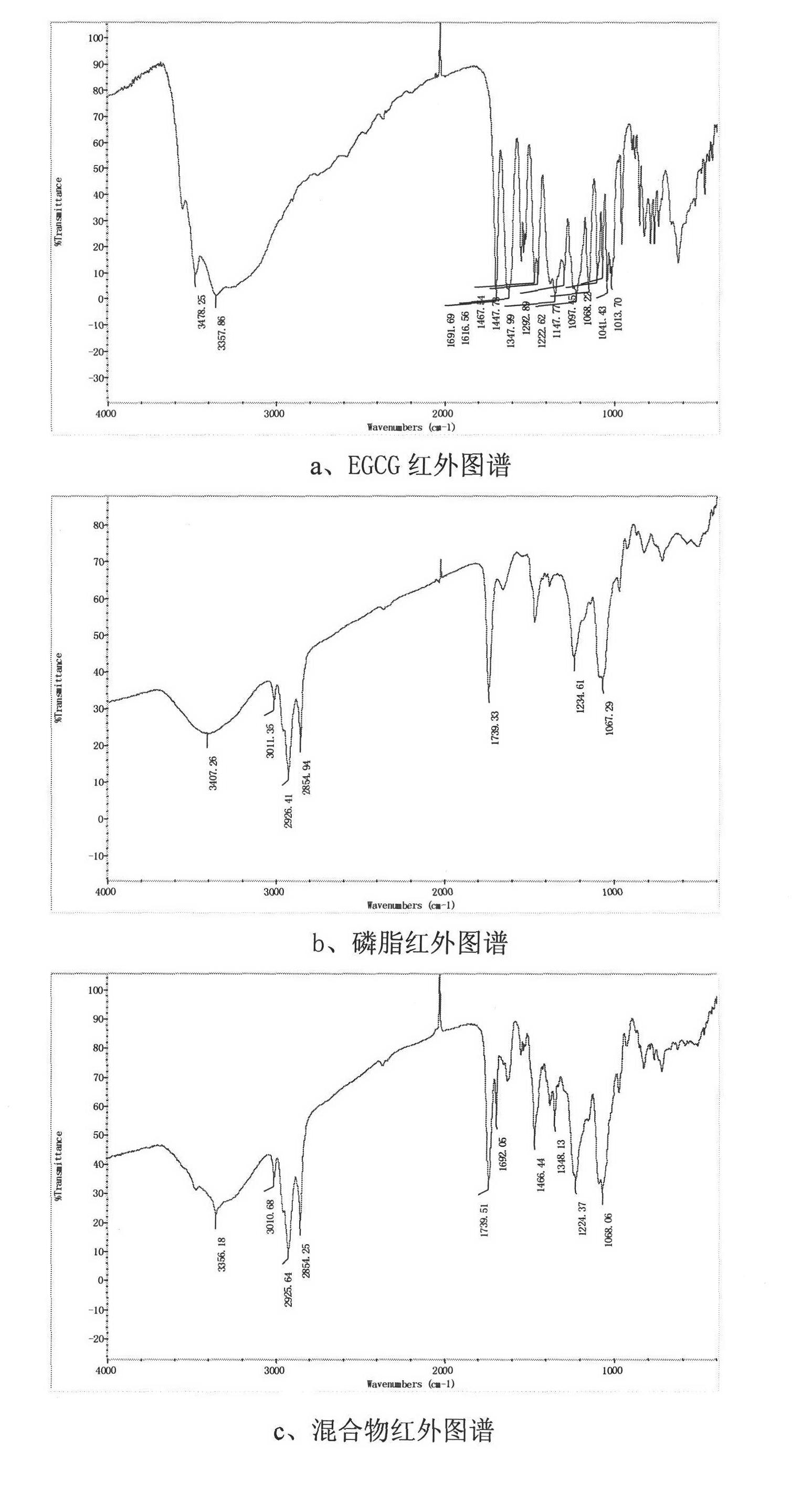

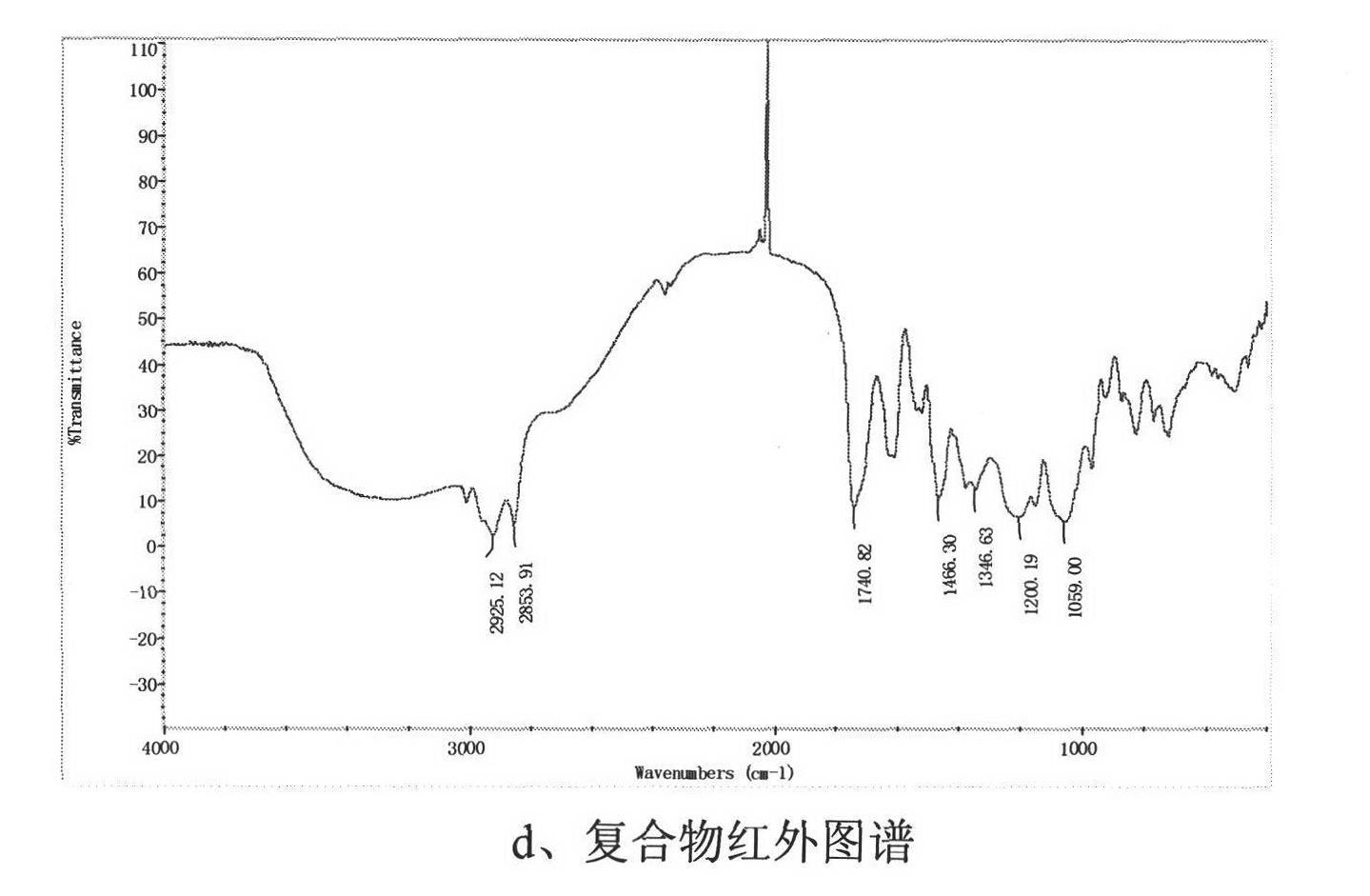

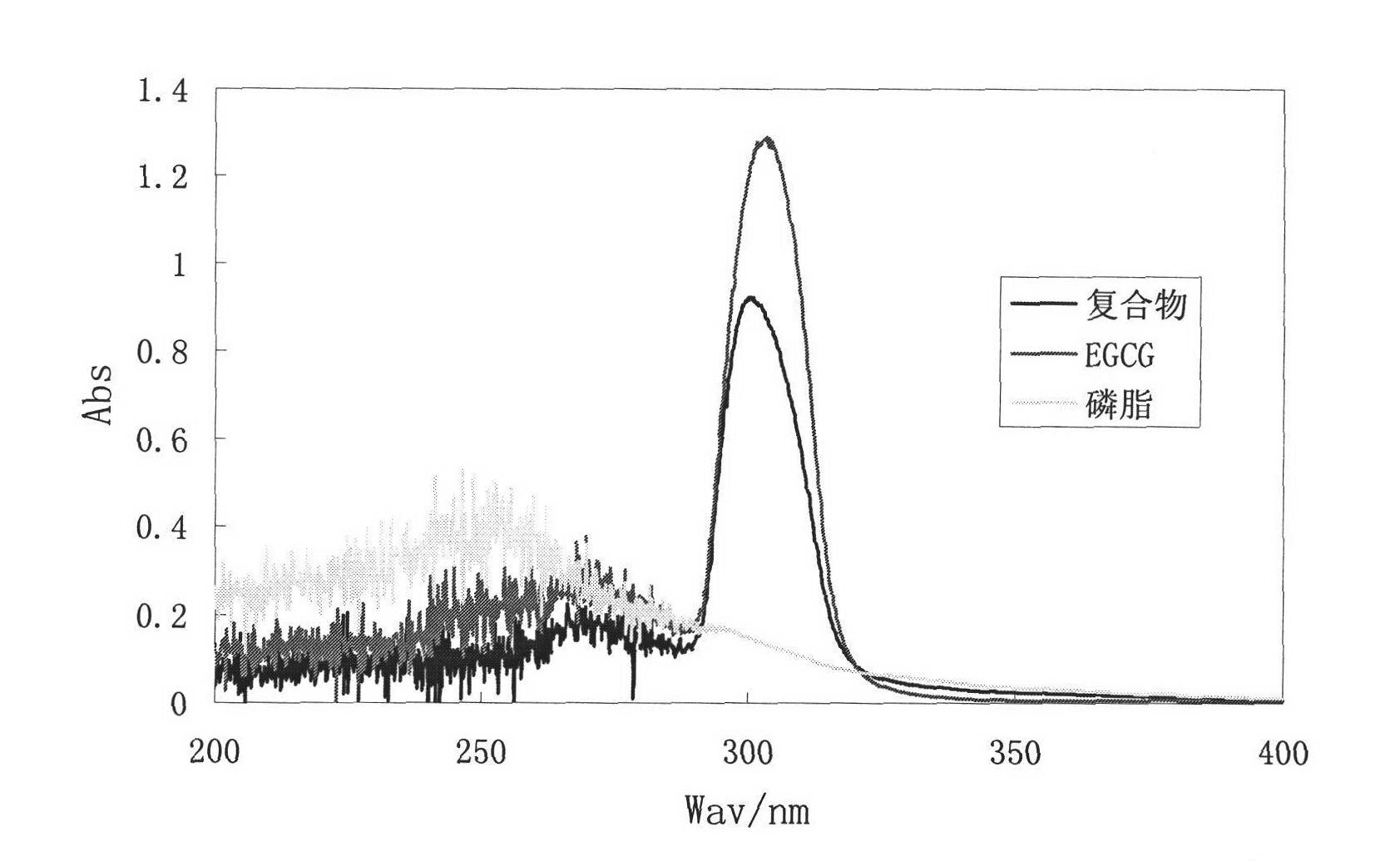

Preparation method for EGCC phosphatide compound

InactiveCN102580112ALow content of active ingredientsReduced antioxidant capacityOrganic active ingredientsAntipyreticOrganic chemistryPhospholipid

The invention discloses a preparation method for an EGCC phosphatide compound. The EGCC phosphatide compound is prepared by compounding EGCC and phosphatide, wherein, the mol ratio of EGCC to phosphatide is 1: 1-3. The EGCC phosphatide compound prepared by using the method can effectively change physical and chemical properties of EGCC, maintain or enhance antioxidation performance of EGCC in different environments and improve bioavailability of EGCC, thereby enlarging application fields of EGCC.

Owner:NANJING AGRICULTURAL UNIVERSITY

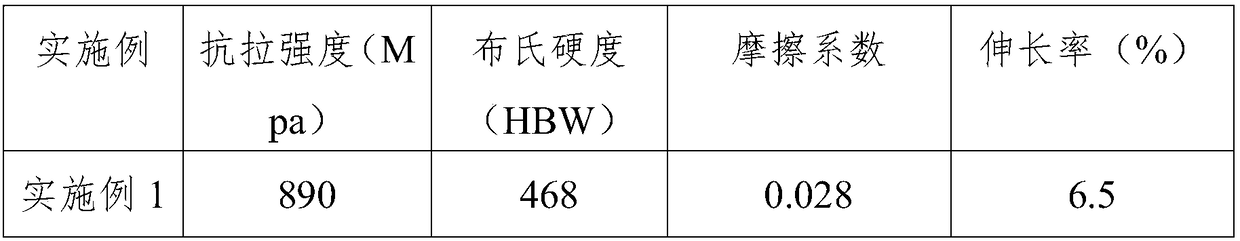

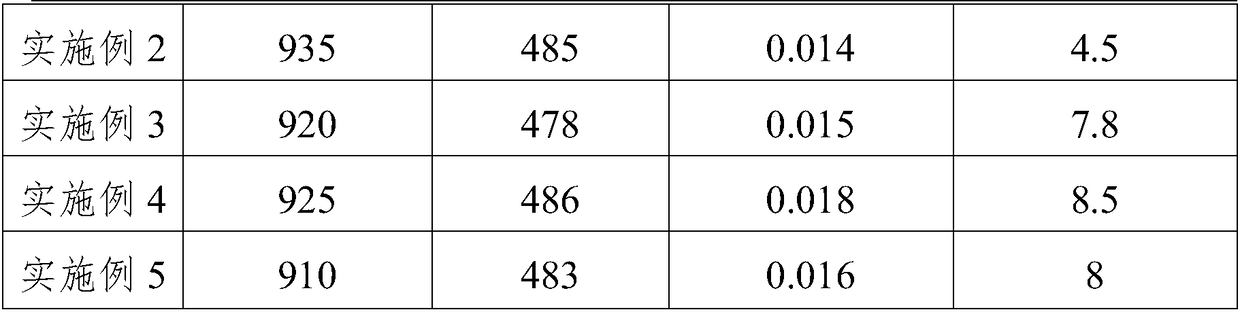

Nodular cast iron for automobile braking disc and preparation method thereof

InactiveCN108441752AReduce hardenabilityImprove hardenabilityProcess efficiency improvementHigh intensityDuctile iron

The invention relates to the technical field of nodular cast iron, and particularly relates to nodular cast iron for an automobile braking disc and a preparation method thereof. The nodular cast ironis prepared from the following elements according to mass percent: 3.2 to 3.6% of C, 2.8 to 3.2% of Si, 0.4 to 0.8% of Cr, 0.2 to 0.6% of Mn, 0.2 to 0.8% of Al, 0.2 to 0.8% of Ni, 0.2 to 0.8% of Mg, 0.2 to 0.6% of Cu, 0.2 to 0.4% of Mo, 0.08 to 0.10% of Ta, 0.04 to 0.06% of Y, 0.02 to 0.03% of Sb, less than or equal to 0.02% of S, less than or equal to 0.04% of P and the balance of Fe and inevitable impurities. The invention provides the nodular cast iron for the automobile braking disc and the preparation method thereof. The elements and the content are reasonably optimized, so that the prepared nodular cast iron has the advantages of high strength, high toughness and wear resistance and high high-temperature resistance, and the service life of the automobile braking disc is prolonged during use.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

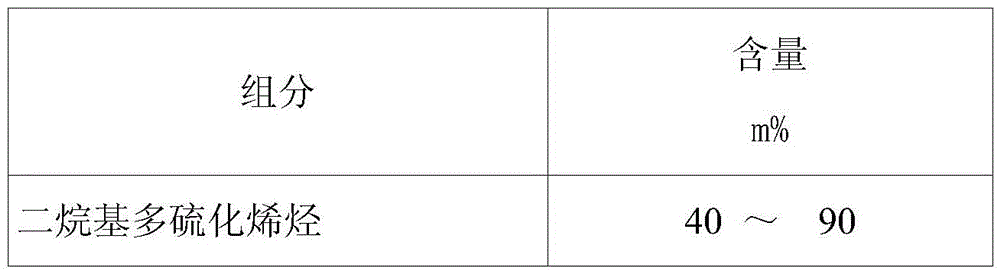

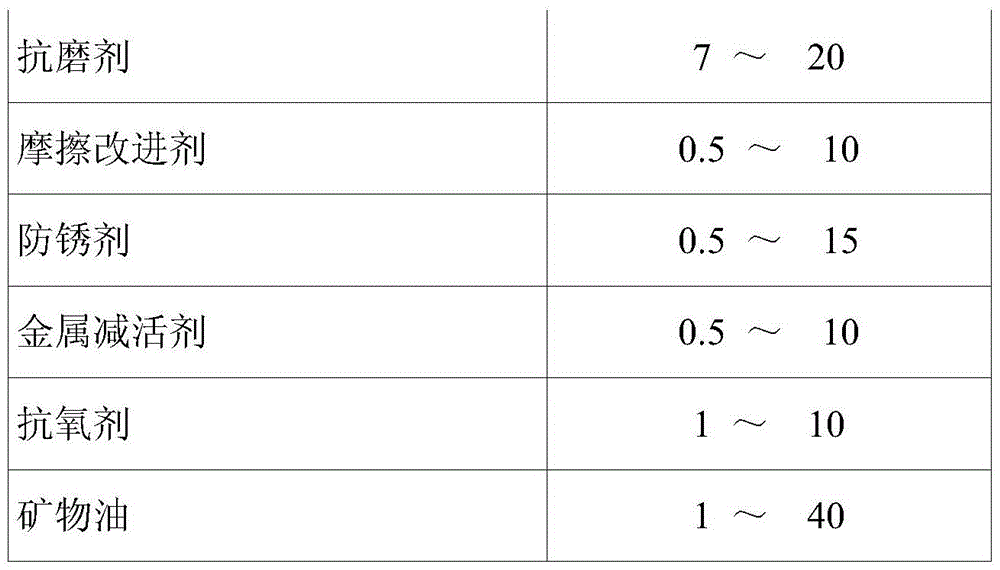

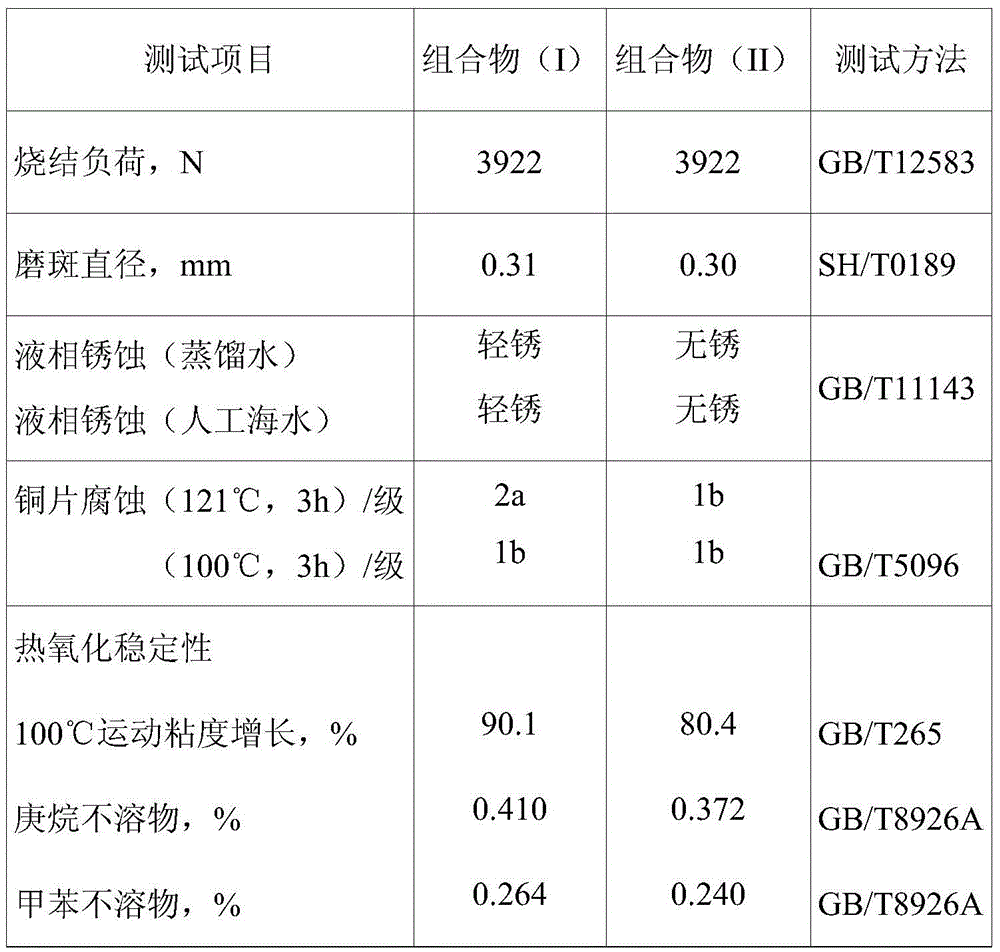

Weak-smell low-corrosion gear lubricant additive composition and preparation method thereof

A weak-smell low-corrosion gear lubricant additive composition and a preparation method thereof comprise the following materials: an extreme pressure agent, an anti-wear agent, a friction modifier, an antirust agent, a metal deactivator, an antioxidant, and mineral base oil. During preparation, in a blending kettle, the materials are mixed well to transparency to form a gear lubricant additive. The invention has the advantages that this composition has weak smell, is free of stimulus and fluorine, has low environmental damage, and has good extreme pressure and anti-wear performances, emulsion resistance, anti-rust and anti-corrosion performance, oxidation resistance, and anti-foam performance.

Owner:JINZHOU DPF TH CHEM CO LTD

Method for preparing low-temperature interconnected high-temperature in-service joint by using single-phase nano silver-copper alloy solder paste

ActiveCN109545696AReduced antioxidant capacityLow resistance to electromigrationPrecision positioning equipmentDecorative surface effectsInterfacial reactionOxidation resistant

The invention, which relates to the technical field of micro-connection, provides a method for preparing a low-temperature interconnected high-temperature in-service joint by using a single-phase nanosilver-copper alloy solder paste. The method comprises the following steps: step one, placing a nano inter-metallic compound solder paste on a substrate, completing an alignment process of a to-be-soldered component, and applying a pressure; and step two, placing the system in a reflow furnace, and implementing a preheating phase, a heat preservation phase, a re-flowing phase, and a cooling phaseto complete volatilization of organic matters, uniform sintering among single-phase nano-alloy particles, and wetting and interfacial reaction of a bonding pad. According to the invention, with the single-phase nano silver-copper alloy particles, the powerful driving force is provided for the sintering process based on the excellent surface activity property of the nano particles; the low-temperature connection that is compatible with the traditional reflow soldering process and has the melting point far lower than the melting point of the block is realized; and an excellent joint with the high anti-oxidation, anti-electromigration and anti-electrochemical migration capabilities is formed. The high-temperature service of the low-temperature connection is realized while the compatibility with traditional process is high and the production efficiency is high.

Owner:HARBIN INST OF TECH

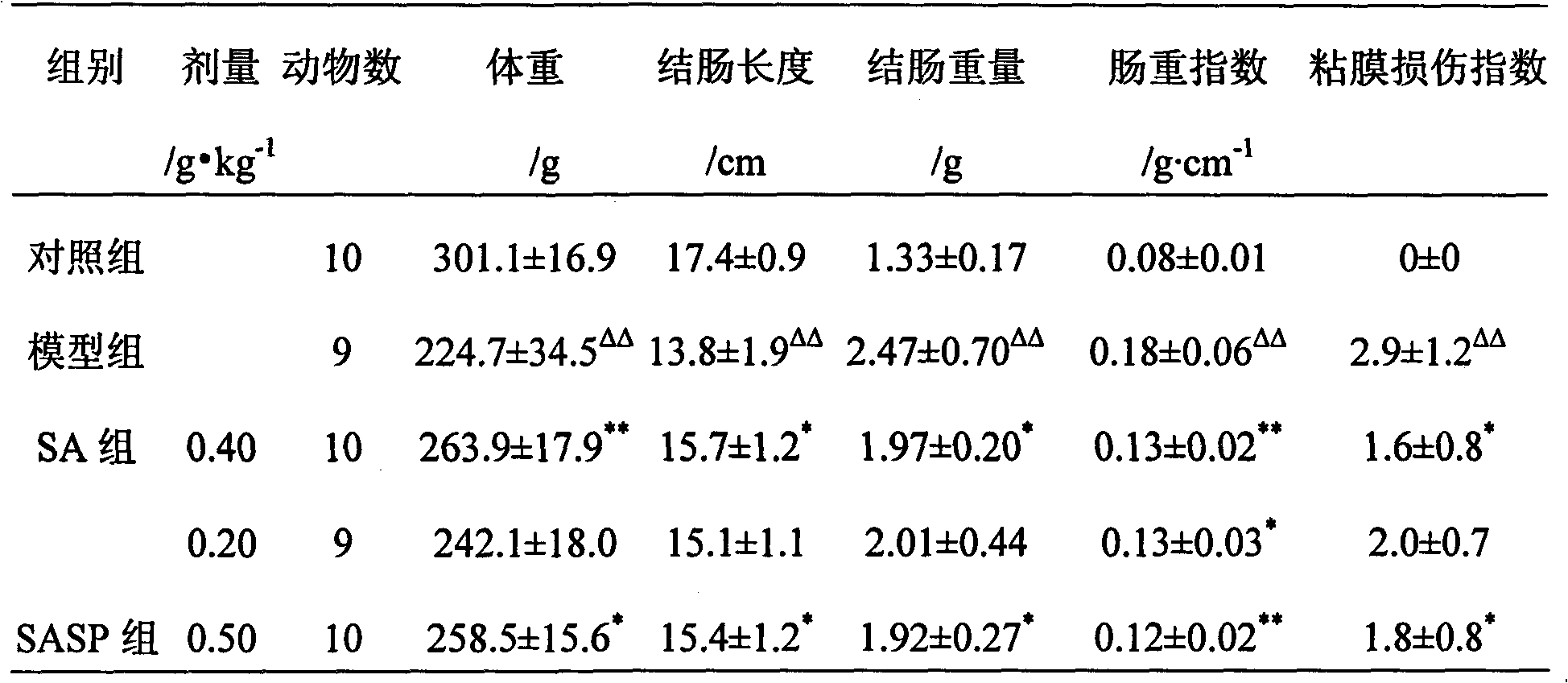

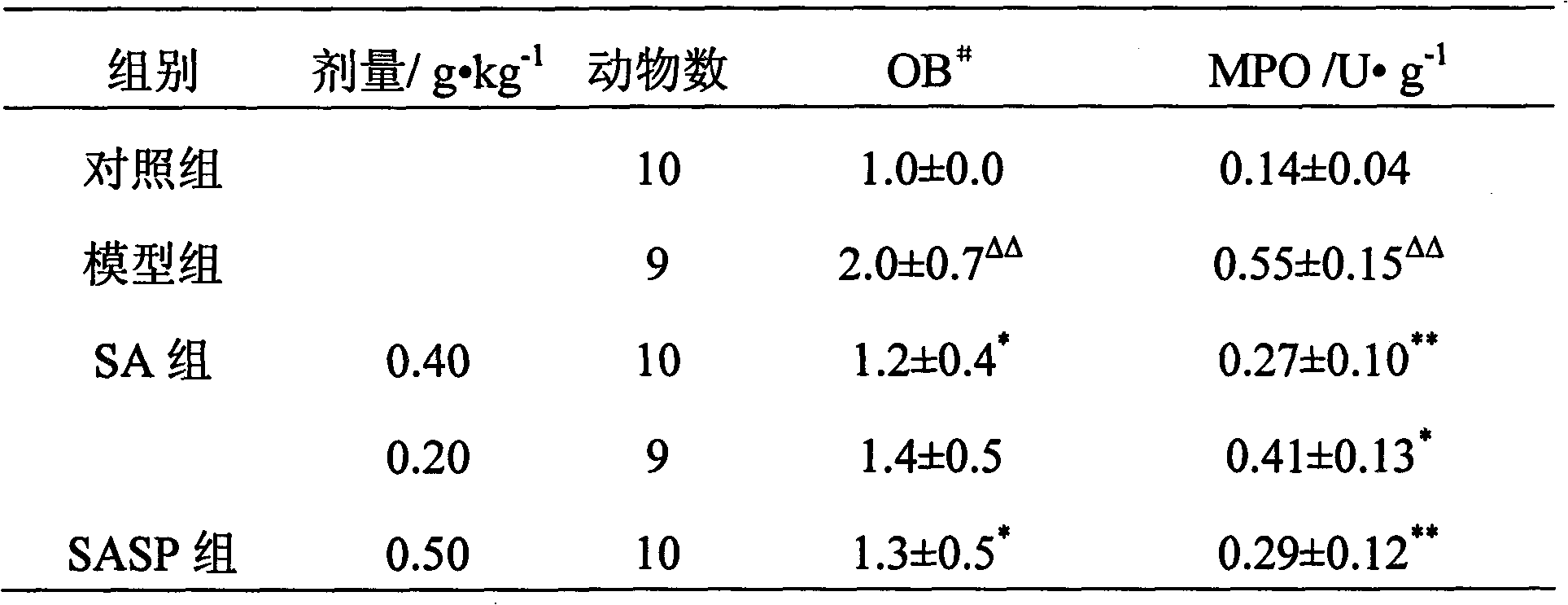

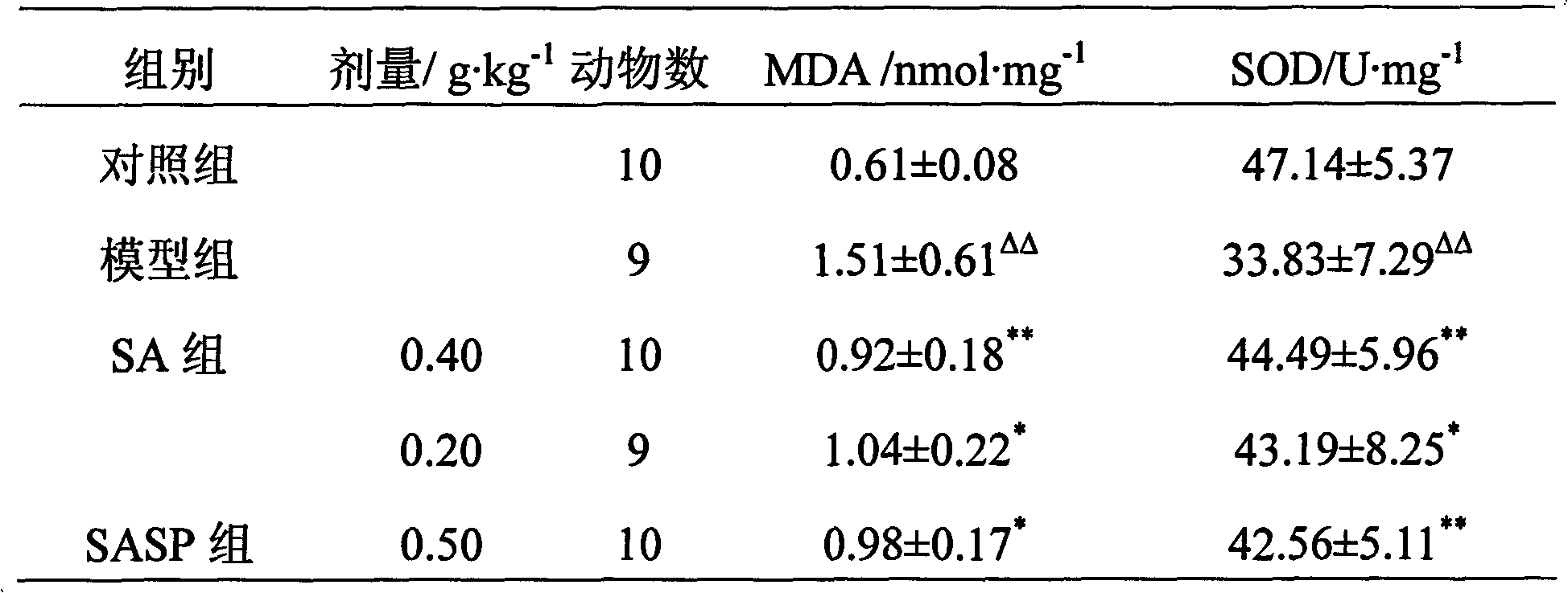

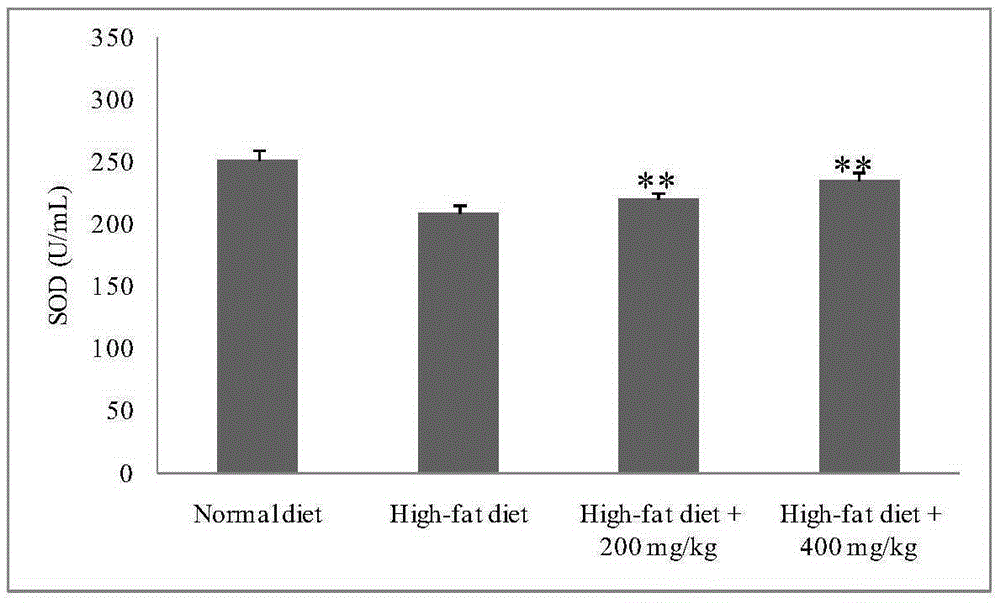

Use of shikimic acid in preparing medicament for treating ulcerative colitis

InactiveCN101352427AExactly what it does to treat ulcerative colitisReduce damage indexOrganic active ingredientsDigestive systemMedicineUlcerative colitis

The invention discloses a shikimic acid used for the new usage of preparing the medicine for treating ulcerative colitis. By utilizing rat ethanoic acid colitis model, the function of shikimic acid for treating ulcerative colitis is inspected, and the shikimic acid is found to have the function of effectively improving the symptoms such as rat diarrhoea, bloody stool, weight lose and colon histomorphology change; the shikimic acid has scavenging action on neutrophilic granulocyte of colonic structure, can obviously reduce the content of MDA and NO in the rat colonic structure of colonitis and the activity of T-NOS and iNOS, and enhance the level of SOD. Therefore, the shikimic acid can be used for preparing the medicine for treating ulcerative colitis.

Owner:XI AN JIAOTONG UNIV

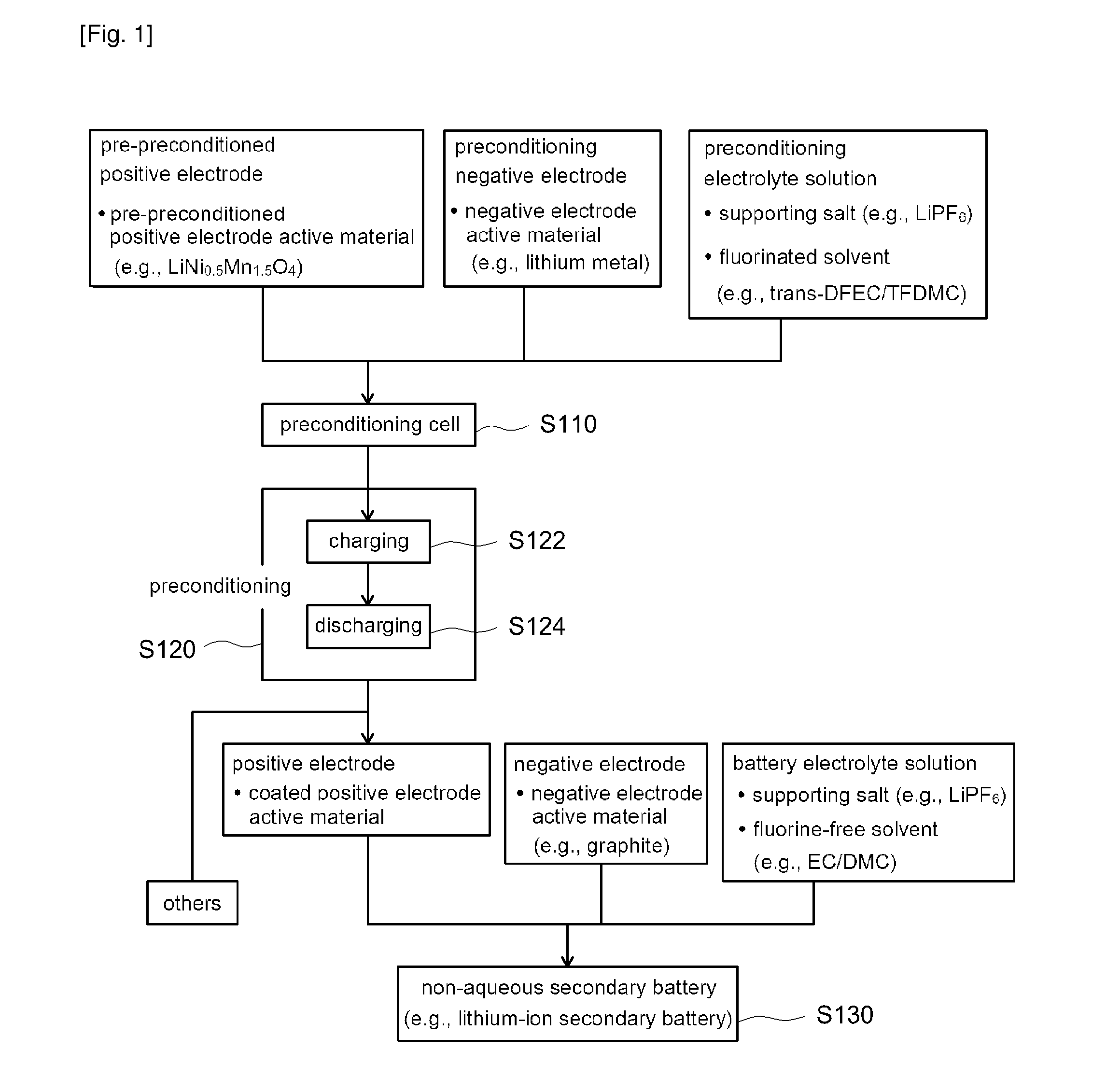

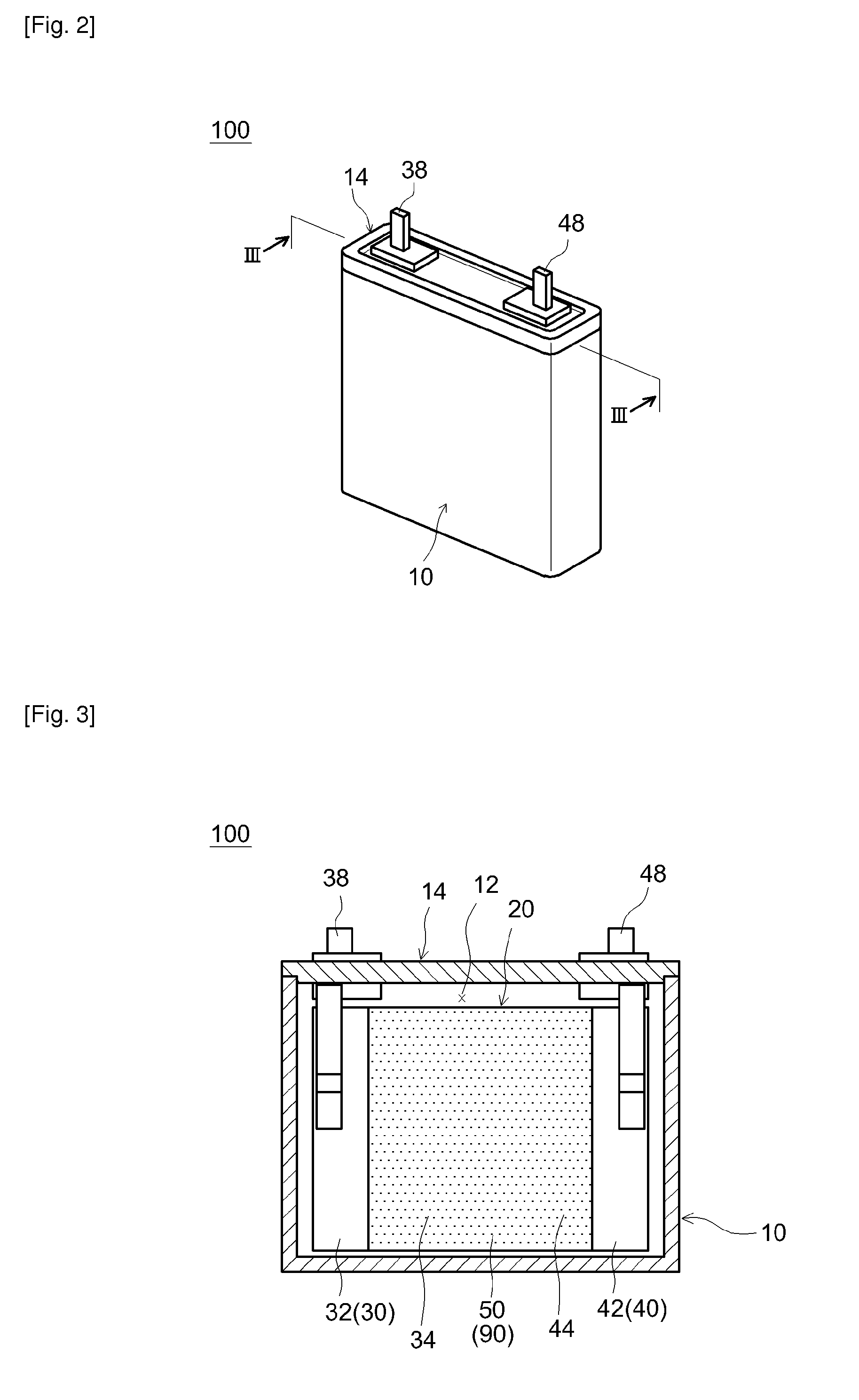

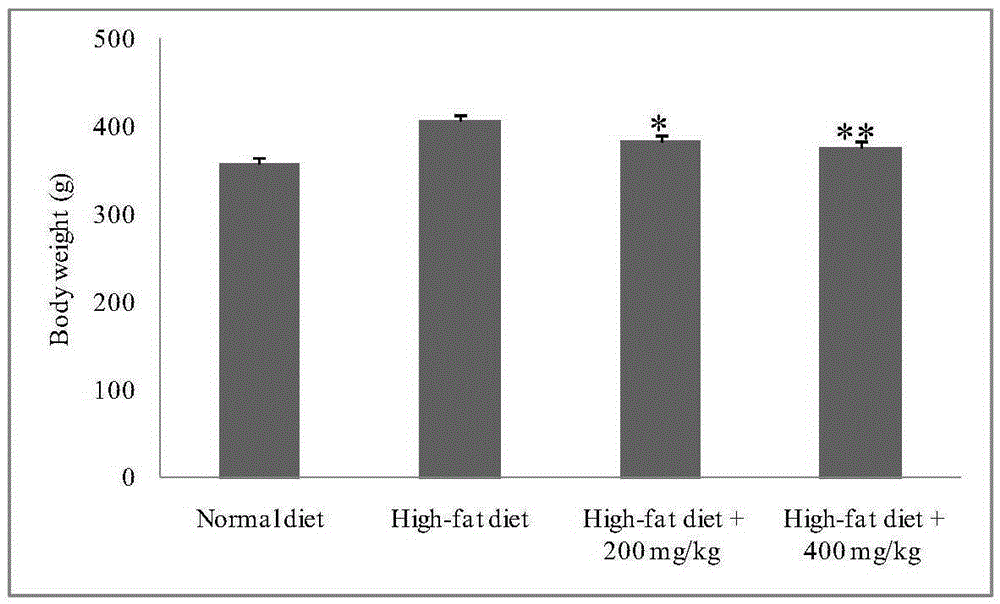

Method For Producing A Non-Aqueous Secondary Battery

ActiveUS20150140361A1Improve cycle performanceIncrease energy densityBatteries circuit arrangementsFinal product manufactureFluorine containingNon aqueous electrolytes

A non-aqueous secondary battery production method is provided. The method comprises constructing a preconditioning cell that comprises a positive electrode comprising a positive electrode active material, a preconditioning electrolyte solution comprising a supporting salt and a fluorine-containing non-ionic compound, and a preconditioning negative electrode (step S110); of carrying out a preconditioning process by charging the preconditioning cell and allowing the fluorine-containing non-ionic compound to be decomposed at the positive electrode to form coatings on surfaces of the positive electrode active material (step S120); and of constructing a non-aqueous secondary battery, using the coated positive electrode active material, a non-aqueous electrolyte solution different from the preconditioning electrolyte solution, and a negative electrode comprising a negative electrode active material (step S130).

Owner:TOYOTA JIDOSHA KK

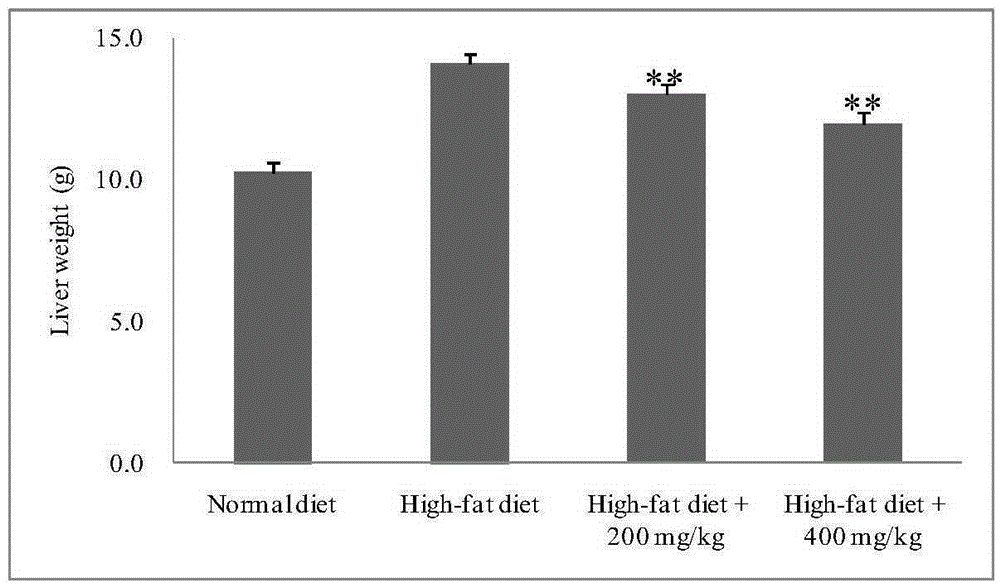

Bambusa textilis leaf extract, preparation method and applications thereof

InactiveCN105381297AGood cholesterolReduce cholesterolMetabolism disorderAntinoxious agentsAnimals experimentsAnhydrous ethanol

The invention relates to a bambusa textilis leaf extract, a preparation method and applications thereof. The preparation method comprises the following steps: grinding bambusa textilis leaves, adding anhydrous ethanol, carrying out ultrasonic extraction at a temperature of 50 to 70 DEG C, filtering, collecting the filtrate, condensing filtrate, and finally drying filtrate in vacuum to obtain the extract. The extract of bambusa textilis leaf is obtained by extracting bambusa textilis leaves in anhydrous ethanol under ultrasonic waves at a specific temperature, collecting liquid extract, condensing and drying; and the animal experiment results have show that the extract can reduce cholesterol, prevent oxidation in human body, and reduce blood fat.

Owner:GUANGZHOU INST OF ADVANCED TECH CHINESE ACAD OF SCI

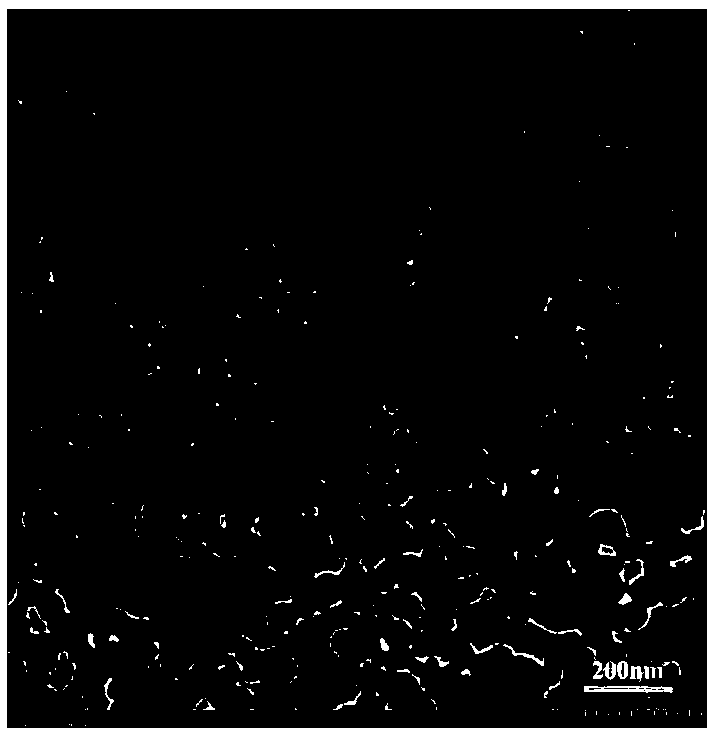

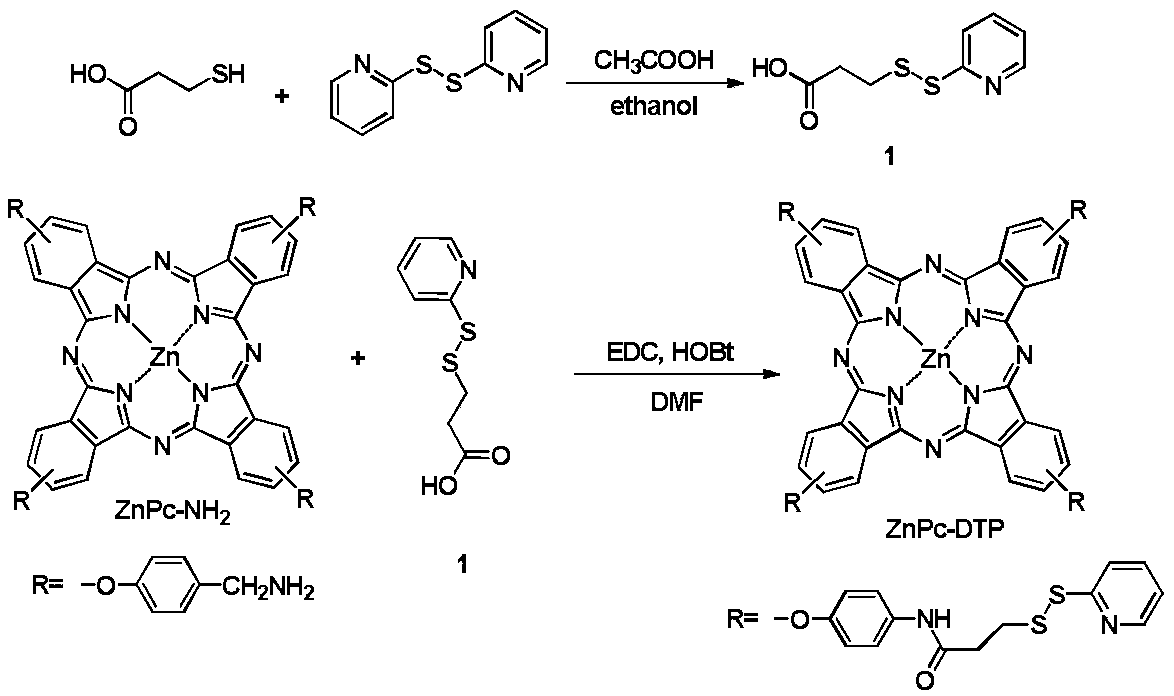

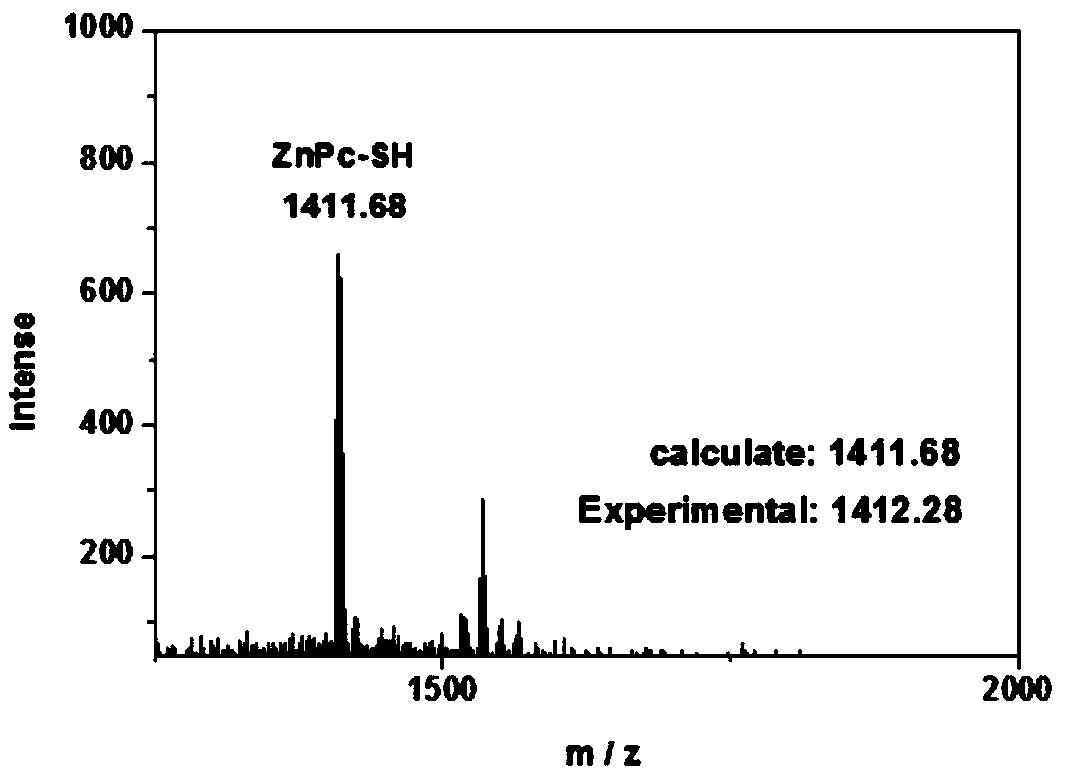

Dithiopyridine modified zinc phthalocyanine as well as preparation method and application thereof

ActiveCN108658995AReduce oxidative damageGood treatment effectOrganic chemistryEnergy modified materialsPhotodynamic therapyPhotosensitizer

The invention discloses dithiopyridine modified zinc phthalocyanine as well as a preparation method and the application thereof. The dithiopyridine modified zinc phthalocyanine has a structural formula as shown in the specification. The novel zinc phthalocyanine disclosed by the invention is simple and convenient in preparation method, wide in raw material source and high in bioavailability; the prepared novel zinc phthalocyanine can be used as a photosensitizer in a photodynamic medicine; the zinc phthalocyanine disclosed by the invention has a natural tumor tissue targeting capability and iscapable of damaging highly expressed anti-oxidation glutathione in tumor cells after being taken by the tumor cells, furthermore light-sensitive antineoplastic activity of photodynamic therapy can beremarkably improved, and the novel zinc phthalocyanine is applicable to light-sensitive anti-tumor treatment with the photodynamic therapy.

Owner:NANJING NORMAL UNIVERSITY

Body-shaping solid beverage

ActiveCN103416823AImprove performanceInhibit blood sugar riseFood preparationThermal energyBody shape

The invention provides body-shaping solid beverage. The body-shaping solid beverage comprises, by weight, 30-50 parts of water-soluble dietary fibers, 20-40 parts of grain formula powder, 5-15 parts of prickly pear juice powder, 3-8 parts of instant tea powder, 1-5 parts of brown algae extracts and 0.05-0.08 part of sweeteners. The body-shaping solid beverage has the advantages that the body-shaping solid beverage is natural and non-transgenic, is made of vegetarian sources, does not contain common allergens, a body-shaping mechanism is unique, normal diet of a drinker is unaffected, and absorption and utilization of parts of calorie nutrition components are blocked, so that the weight of the drinker can be successfully controlled while the drinker can enjoy tasteful food, an excellent mental state and the excellent work efficiency of the drinker can be kept, the body-shaping solid beverage is a novel product with weight control and health promotion effects, and the like.

Owner:浙江诺特健康科技股份有限公司

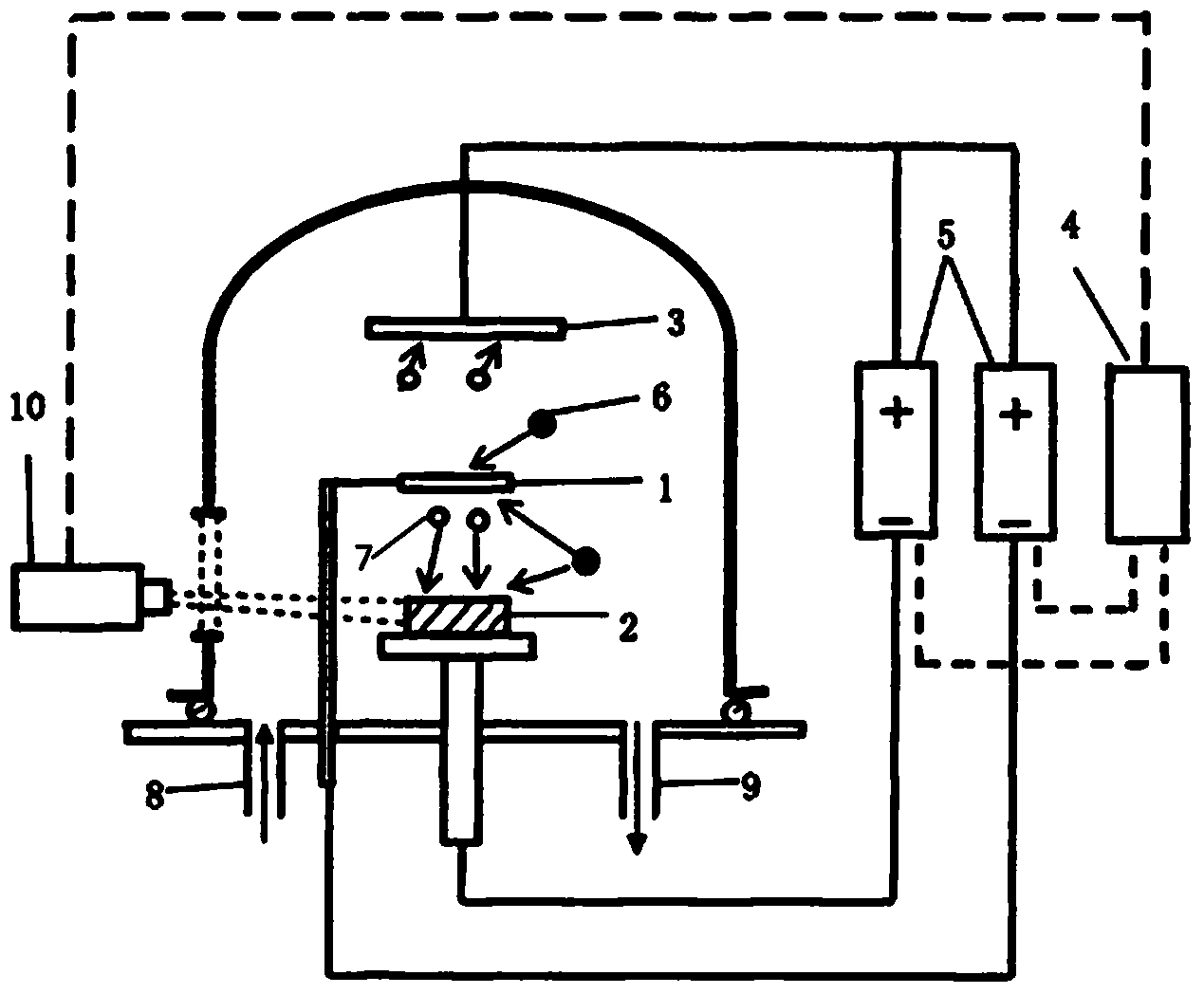

Method for diffusion coating of LaTaAlY alloy layer on surface of gamma-TiAl alloy

ActiveCN104388900AStrong thermal shock resistanceImprove the strengthening effectVacuum evaporation coatingSputtering coatingEvaporationOxidation resistant

The invention discloses a method for diffusion coating of a LaTaAlY alloy layer on the surface of gamma-TiAl alloy. The method comprises the following steps: heating a gamma-TiAl alloy workpiece and an LaTaAlY target material by utilizing glow discharge of two hollow cathodes; putting the LaTaAlY target material on a source electrode rack, heating to melt the LaTaAlY target material under bombardment of plasmas generated by glow discharge, so as to form evaporation and sputtering, depositing on the surface of the workpiece and diffusing inwards; and forming an LaTaAlY deposition layer which is 3-10 mu m and an LaTaAlY diffusion layer which is 5-10 mu m on the surface of the workpiece by regulating and controlling the working pressure, the source electrode voltage, the workpiece voltage and the source electrode-workpiece distance. By adopting the method, a diffusion coating treatment is carried out on the surface of the gamma-TiAl alloy workpiece, an excellent oxidation resistance can be given to the gamma-TiAl alloy workpiece under a high-temperature long-term service condition, and moreover the gamma-TiAl alloy workpiece has reliable bonding strength and excellent thermal shock resistance due to the existence of the diffusion layer with gradient compositions.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

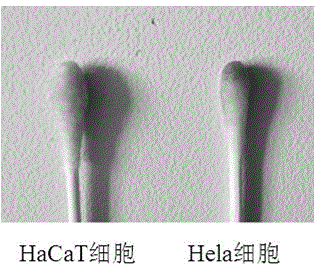

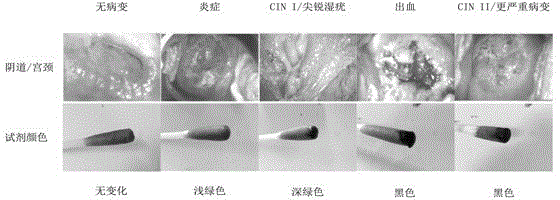

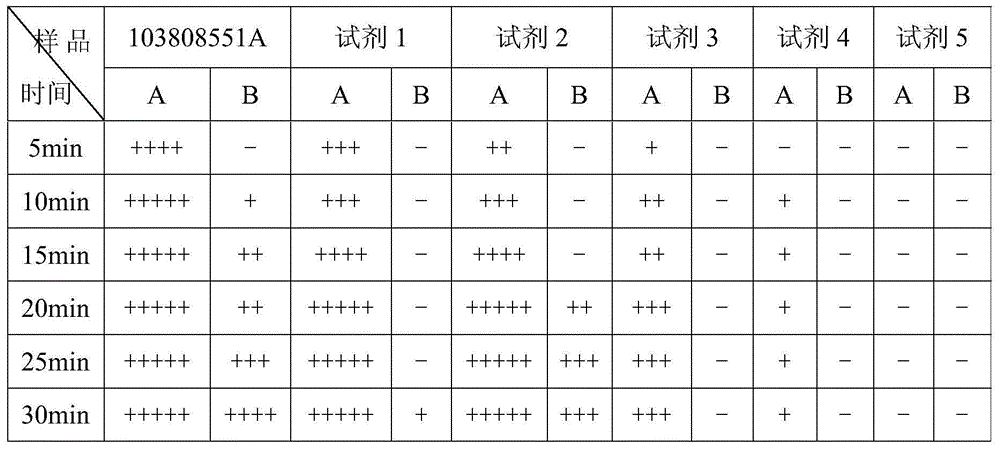

Diagnostic reagent for cervical cancer cell detection and preparation method thereof

ActiveCN104483472ALow priceEasy to get materialsMaterial analysis by observing effect on chemical indicatorBiological testingDissolutionDetection rate

The invention discloses a diagnostic reagent for cervical cancer cell detection and a preparation method thereof. The diagnostic reagent comprises components in parts by mass as follows: 10 parts of glucose, 0.5 parts of folic acid, 0.4 parts of methylene blue, 0.8 parts of lycopene, 0.5 parts of a 3mol / L sodium hydroxide aqueous solution, 90 parts of dimethyl sulfoxide, 4 parts of acetic acid, 0.01 parts of dithiothreitol and 0.05 parts of sodium methyl parahydroxybenzoate. The preparation method comprises steps as follows: the glucose, the lycopene and acetic acid are dissolved in dimethyl sulfoxiderespectively; the folic acid is added to the sodium hydroxide aqueous solution for dissolution and then added to the dimethyl sulfoxide with theglucose and the lycopene dissolved, then methylene blue is added, stirred and dissolved, the dimethyl sulfoxide with theacetic acid dissolved is added, and the dithiothreitol and the sodium methyl parahydroxybenzoate are added after even mixing. The diagnostic reagent is convenient to use and high in sensitivity and stability, cotton swabs are dipped in the diagnostic reagent during usage, and the diagnostic detection rate is up to 90%.

Owner:SHENZHEN HUAZHONG BIOLOGICAL PHARMA MACHINERY

Low-alloy medium-silicon vermicular graphite cast iron glass mold material and preparation method thereof

The invention discloses a low-alloy medium-silicon vermicular graphite cast iron glass mold material and a preparation method thereof. The low-alloy medium-silicon vermicular graphite cast iron glassmold material comprises, by mass, 87.5-92.12% of iron, 2.8-2.89% of silicon, 3.4-3.6% of carbon, 0.4-0.5% of manganese, 0.2-0.29% of chromium, 0.1-0.15% of vanadium, 0.08-0.1% of titanium, 0.4-0.5% ofnucleating agent and 0.5-0.6% of vermiculizer. Through the optimized formula, the oxidation resistance and wear resistance of a mold are greatly improved. Meanwhile, through the mutual cooperative effect of the added materials, the toughness, oxidation resistance and wear resistance of the glass mold are greatly improved. Thus, the service life of the mold is prolonged.

Owner:CHENGDU XINZHI IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com