NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

An ethylene cracking furnace, high temperature resistant technology, used in welding equipment, welding media, manufacturing tools, etc., can solve the problem of poor oxidation resistance and corrosion resistance of furnace tubes, a large amount of waste gas, waste liquid and solid waste, affecting wire feeding And arc stability and other issues, to ensure high temperature mechanical properties, improve high temperature resistance and oxidation resistance, excellent welding process and mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

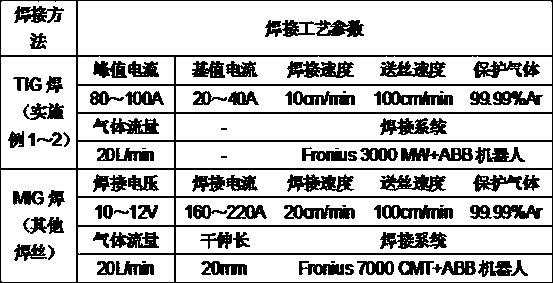

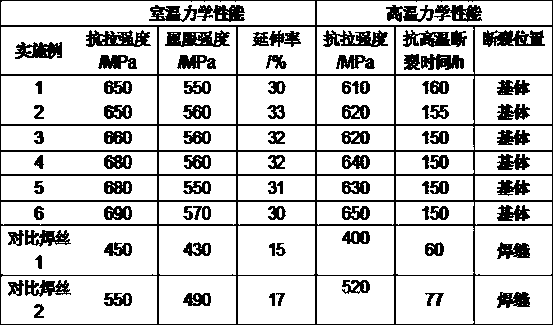

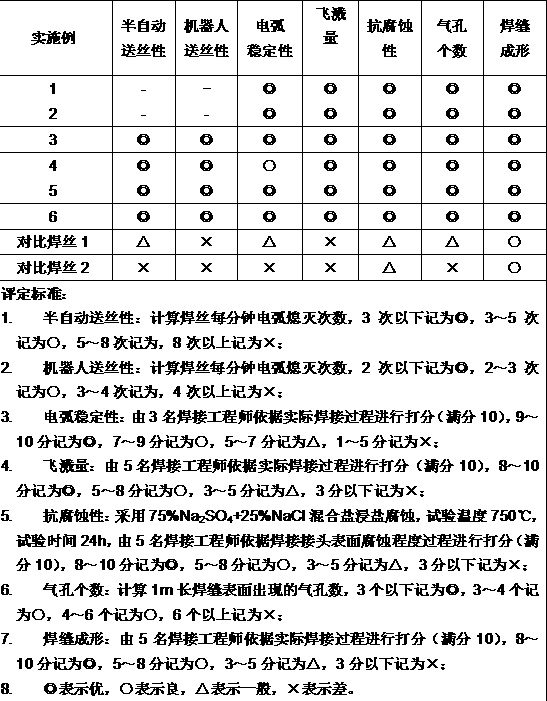

Embodiment 1

[0040]A NiCrNb-Re high-temperature-resistant and corrosion-resistant welding wire for ethylene cracking furnace casting pipes and its preparation method, the components in the welding wire and their weight percentages are: Ni: 45%, Cr: 35%, Nb: 1.00%, Ce: 0.05%, C: 0.35%, Si: 0.50%, Mn: 1.50%, Al: 0.01%, Ti: 0.05%, Zr: 0.05%, and the balance is Fe and unavoidable impurities. The particle size of each powder in the welding wire is between 60 and 100 mesh. Concrete preparation steps are as follows:

[0041] (1) Alloy smelting: The raw materials are put into the vacuum induction furnace for smelting according to the ratio, and the vacuum degree needs to reach 6.5×10 -2 Above Pa, and cast into electrode rod;

[0042] (2) Electroslag remelting: Using electroslag remelting equipment, the surface of the electrode rod described in step (1) is ground and treated as an electrode and inserted into the slag for remelting, and the slag is remelted using CaF 2 -Al 2 o 3 -CaO slag syste...

Embodiment 2

[0049] A NiCrNb-Re high-temperature-resistant and corrosion-resistant welding wire for ethylene cracking furnace casting pipes and its preparation method, the components in the welding wire and their weight percentages are: Ni: 46%, Cr: 36%, Nb: 1.00%, Y: 0.10%, C: 0.30%, Si: 1.00%, Mn: 2.00%, Al: 0.05%, Ti: 0.15%, Zr: 0.05%, and the balance is Fe and unavoidable impurities. The particle size of each powder in the welding wire is between 60 and 100 mesh. Concrete preparation steps are as follows:

[0050] (1) Alloy smelting: The raw materials are put into the vacuum induction furnace for smelting according to the ratio, and the vacuum degree needs to reach 6.5×10 -2 Above Pa, and cast into electrode rod;

[0051] (2) Electroslag remelting: Using electroslag remelting equipment, the surface of the electrode rod described in step (1) is ground and treated as an electrode and inserted into the slag for remelting, and the slag is remelted using CaF 2 -Al 2 o 3 -CaO slag syste...

Embodiment 3

[0058] A NiCrNb-Re high-temperature-resistant and corrosion-resistant welding wire for ethylene cracking furnace casting pipes and its preparation method. The components in the welding wire and their weight percentages are: Ni: 46%, Cr: 38%, Nb: 1.20%, La: 0.10%, C: 0.40%, Si: 0.50%, Mn: 2.00%, Al: 0.02%, Ti: 0.20%, Zr: 0.05%, and the balance is Fe and unavoidable impurities. The particle size of each powder in the welding wire is between 60 and 100 mesh. Concrete preparation steps are as follows:

[0059] (1) Alloy smelting: The raw materials are put into the vacuum induction furnace for smelting according to the ratio, and the vacuum degree needs to reach 6.5×10 -2 Above Pa, and cast into electrode rod;

[0060] (2) Electroslag remelting: Using electroslag remelting equipment, the surface of the electrode rod described in step (1) is ground and treated as an electrode and inserted into the slag for remelting, and the slag is remelted using CaF 2 -Al 2 o 3 -CaO slag syst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com