Patents

Literature

90results about How to "Avoid oxidation burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

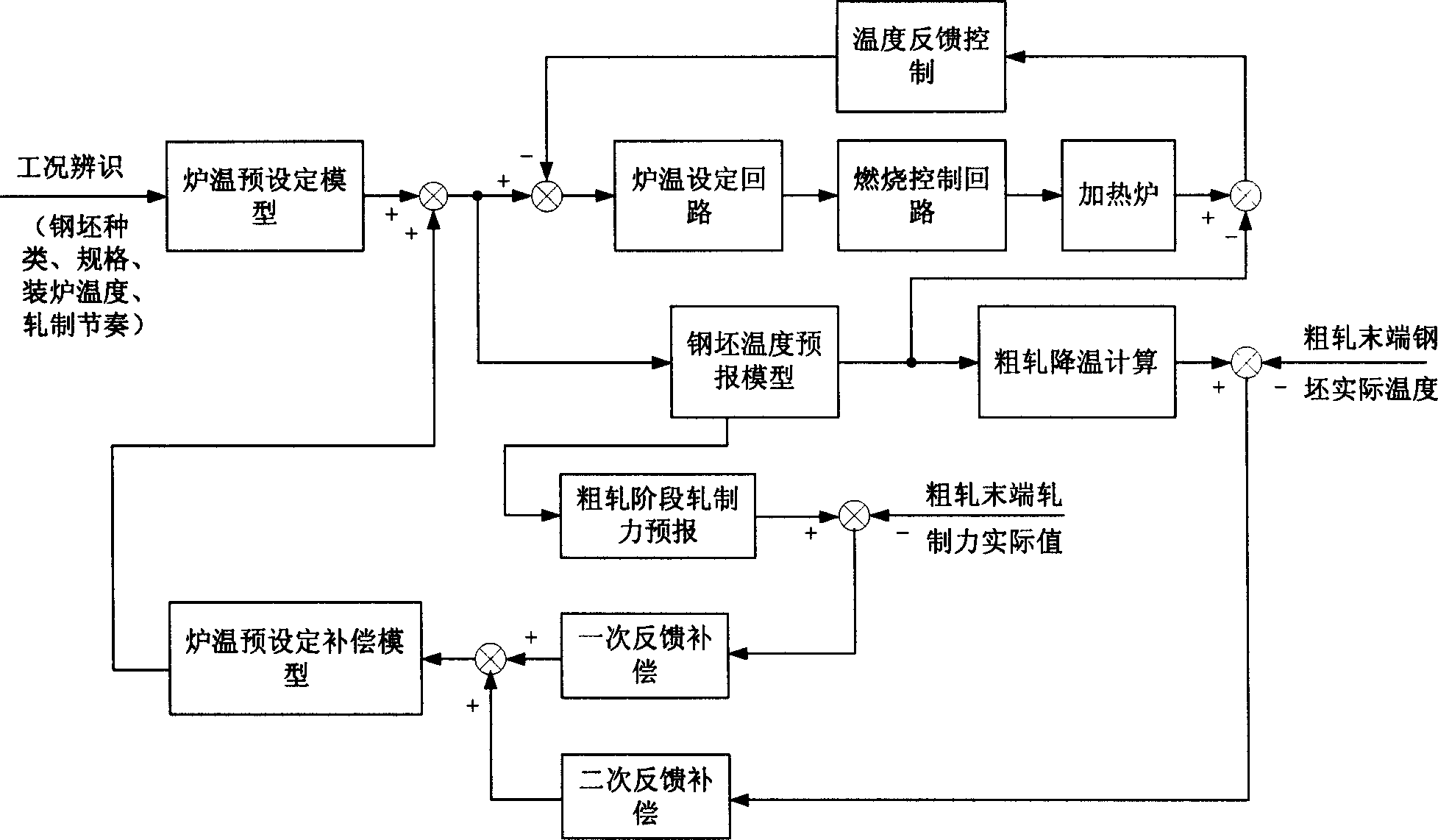

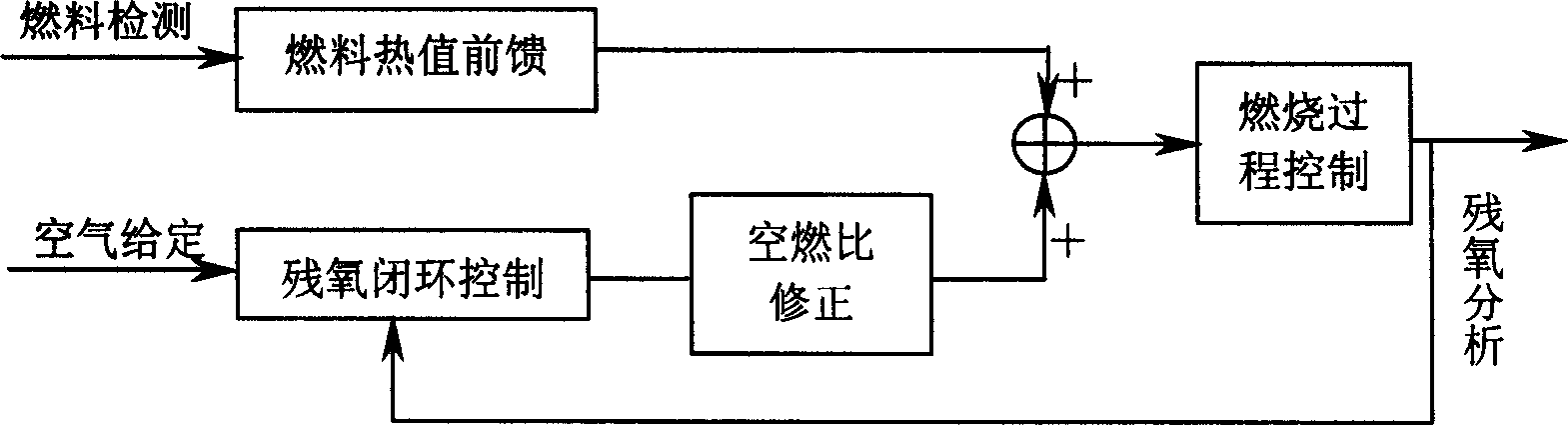

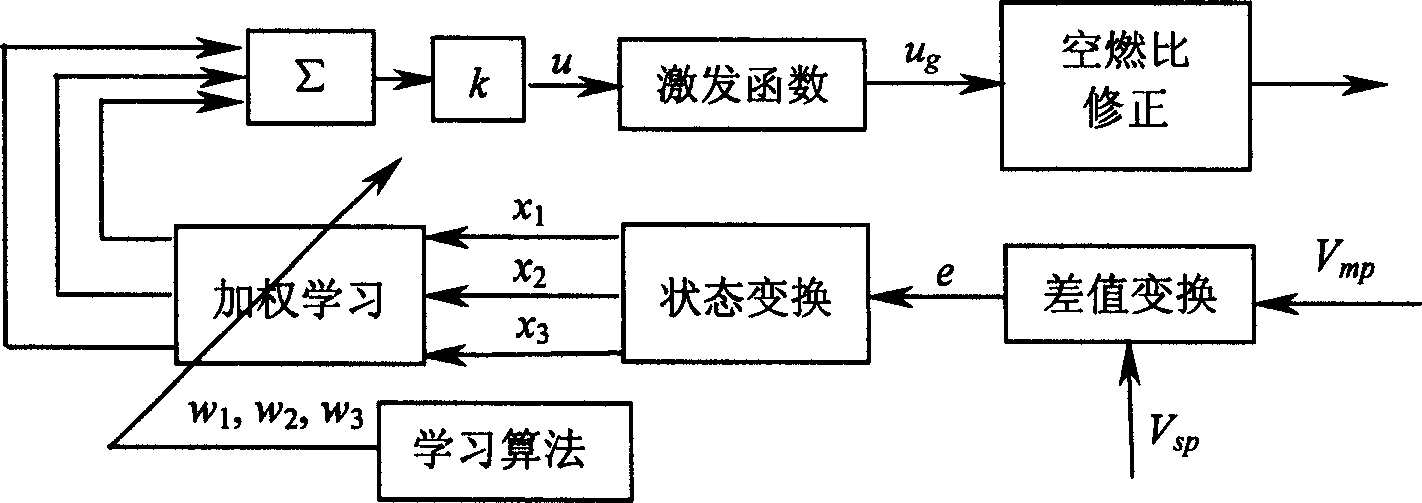

Heating furnace comprehensive optimizing controlling system designing and controlling method for hot rolling process

InactiveCN1644257AReduce the total energy consumption of productionAchieve optimal controlTemperature control deviceAdaptive controlProduction lineControl system design

A design and control method for the optimizing control system of intermediate rolling mill and heating furnace in order to improve the heating quality of billet in the heating furnace and save energy features that the heating furnace and intermediate rolling mill constitute a closed loop system, the information (rolling force, temp, etc) is fed back to heating furnace for dynamically changing the heating temp, and the optimizing control strategy and control algorithm are used in the billet heating process.

Owner:DALIAN UNIV OF TECH

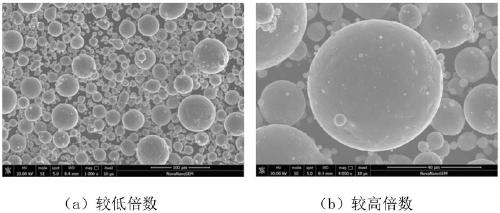

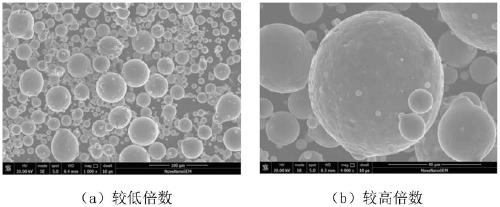

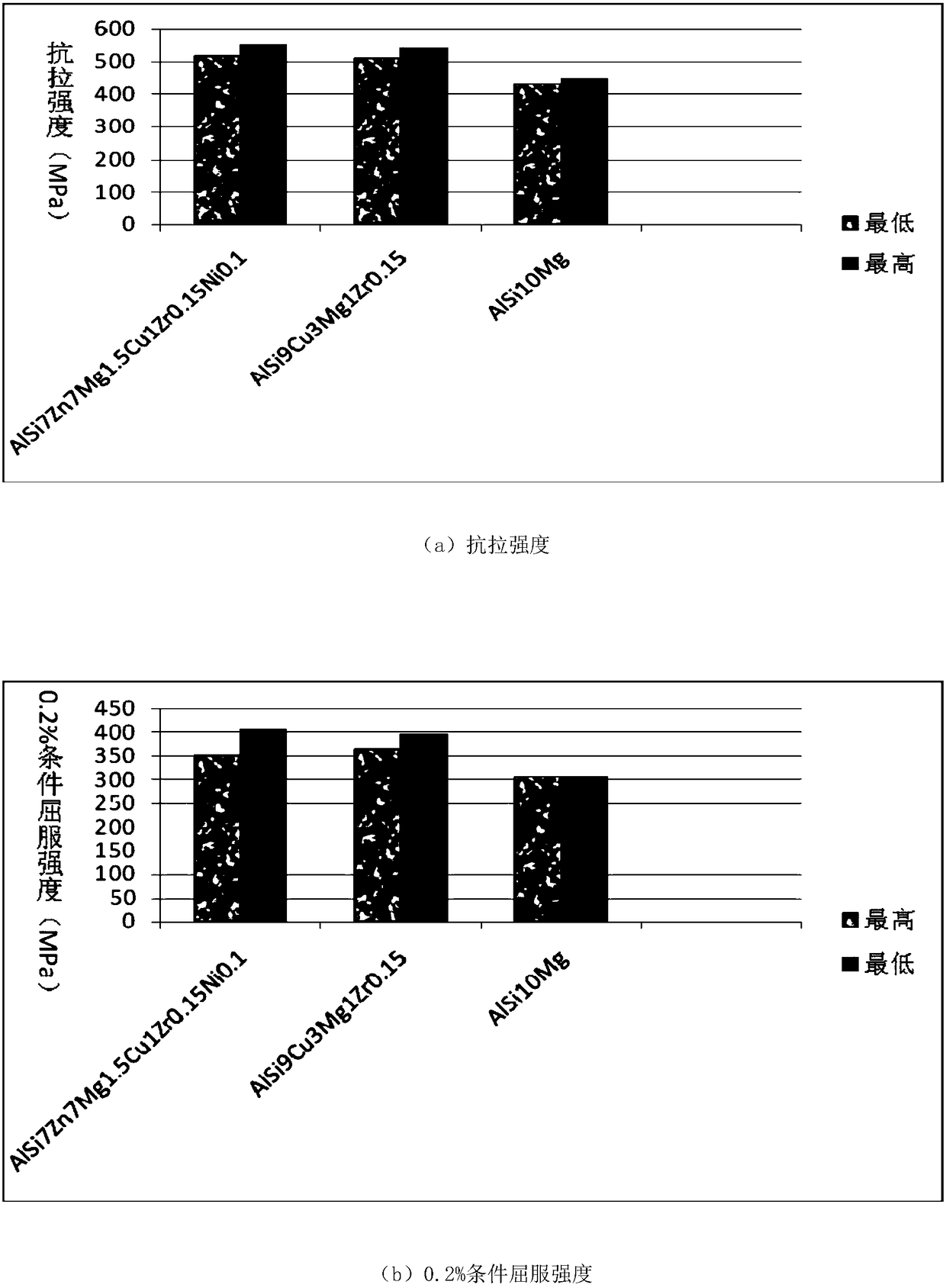

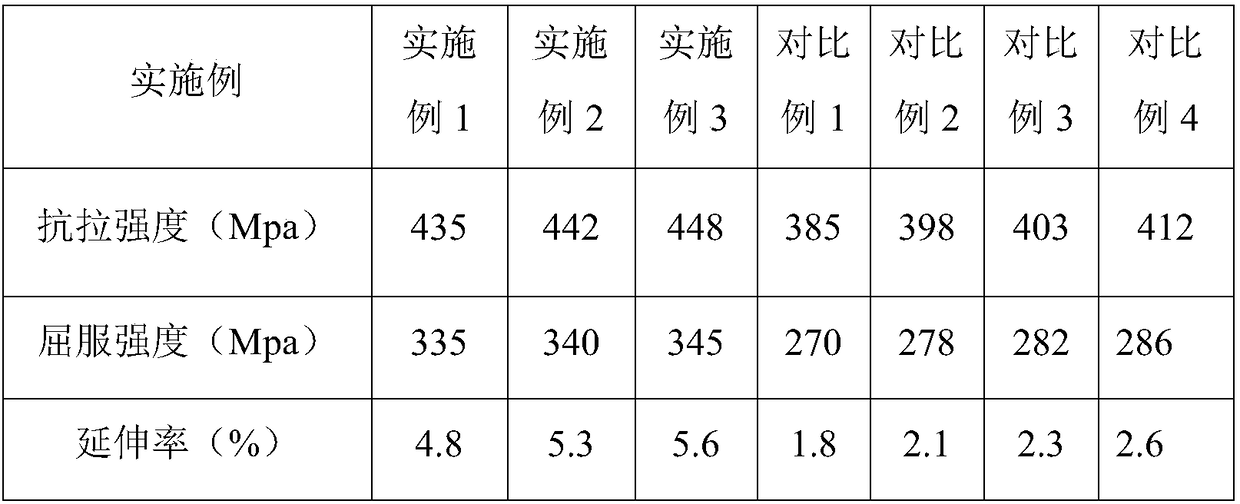

High-strength aluminum alloy for additive manufacturing and preparation method of high-strength aluminum alloy powder

ActiveCN109280820AGuaranteed yieldAvoid oxidation burnAdditive manufacturing apparatusTransportation and packagingTest sampleMedium frequency

The invention provides a high-strength aluminum alloy for additive manufacturing and a preparation method of high-strength aluminum alloy powder. The high-strength aluminum alloy powder is prepared byadopting a gas atomization process. The preparation method comprises the following steps of: firstly, melting an Al-Si-Zn-Cu-Mg-X alloy prefabricated ingot by adopting a medium frequency induction furnace, then powdering by adopting a supersonic speed gas atomization process, sieving and preparing powder of different specifications for additive manufacturing. A test sample obtained by adopting the high-strength aluminum alloy powder through additive manufacturing has compact texture without crack defects, the strength of extension exceeding 500MPa and the elongation exceeding 3%; the strengthperformance of the test sample is obviously superior to the strength performance of additive manufacturing test samples of AlSi10Mg, AlSi7Mg and AlSi12; and the performances of the test sample are also superior to the performances of additive manufacturing test samples of conventional 2000 series and 7000 series alloys. The alloy powder can be used for preparing aluminum alloy parts with compacttexture, complicated shapes and high strength in an additive manufacturing method to meet the requirements of use occasions on high specific strength and complicated shapes in the fields of aviation,spaceflight and automobiles.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method has high temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Electroslag remelting process of titanium-containing alloy steel

The invention discloses an electroslag remelting process for titanium alloy steel, which comprises the following steps of: (1) preparing consumable electrodes; (2) preparing electroslag; (3) forming slag through electroslag; (4) remelting electroslag. The step (3) of slag formation comprises the following procedures of: firstly, adding one third of total slag material into a crystallizer to form slag, mixing a right amount of mixture including Al powder and FeTi powder into the rest residue material, and adding the rest residue material with the mixture into the crystallizer to form slag. Theelectroslag remelting process for titanium alloy steel does not need special slag purification process, the investment to slag purification equipment is reduced, the technological flow is shortened, and the production cost is greatly lowered. By adding the mixture of Al powder, FeTi powder and CaF2 powder into a slag pool in the process, oxygen generated by unstable oxides in the molten slag can be prevented from entering the slap pool and a molten pool to oxidize elements in steel, and the massive uncertain oxidation burning of Ti element in steel is avoided. Therefore, the content of Ti element in the titanium alloy steel obtained by the process can accurately reach the standard requirement, and the quality of the titanium alloy steel is ensured.

Owner:CHONGQING IRON & STEEL (GRP) CO LTD

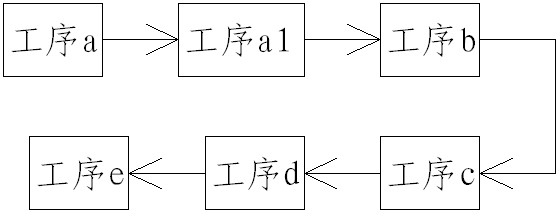

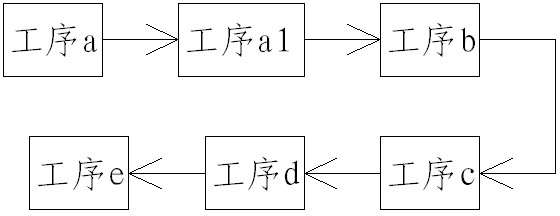

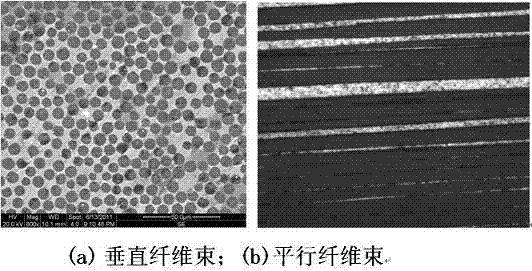

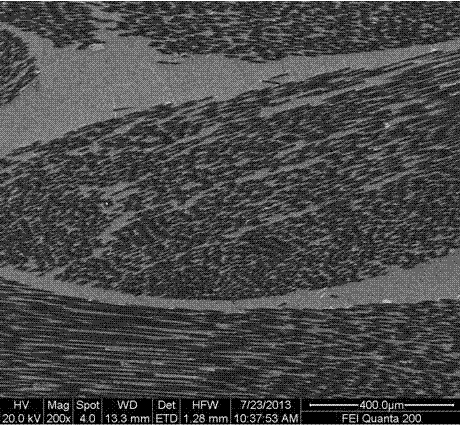

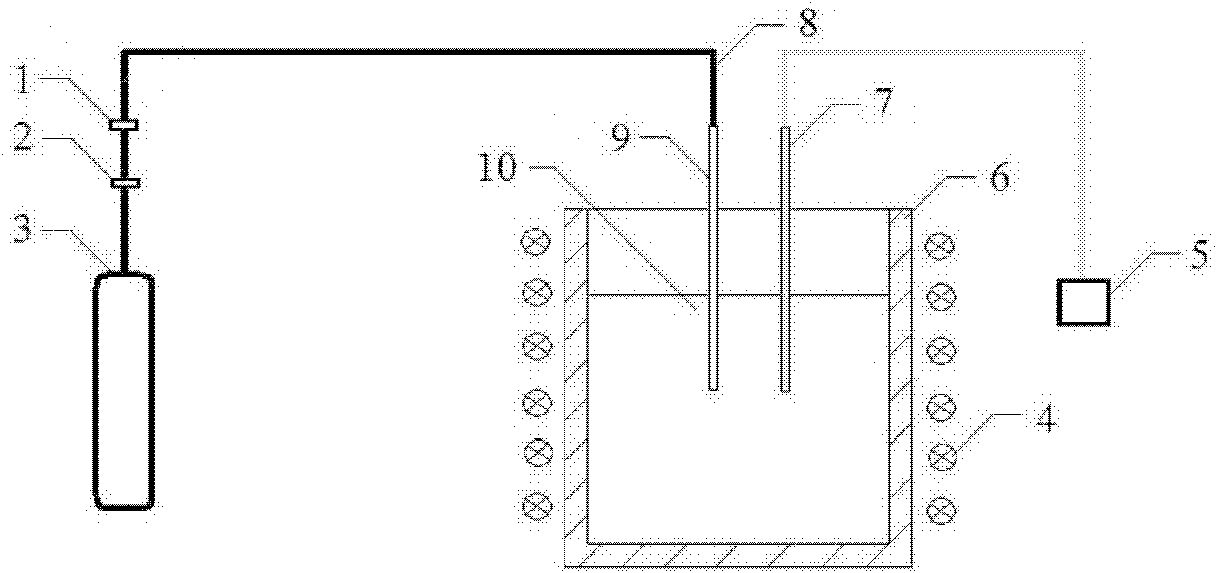

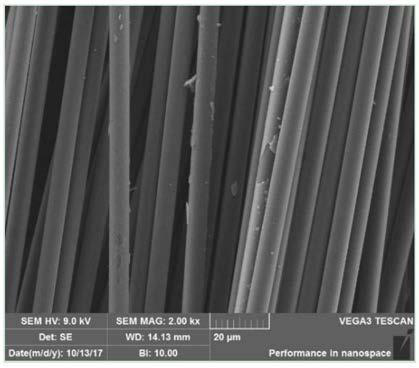

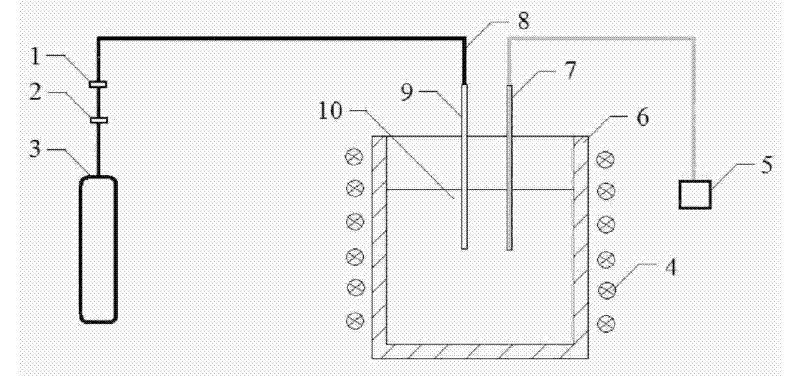

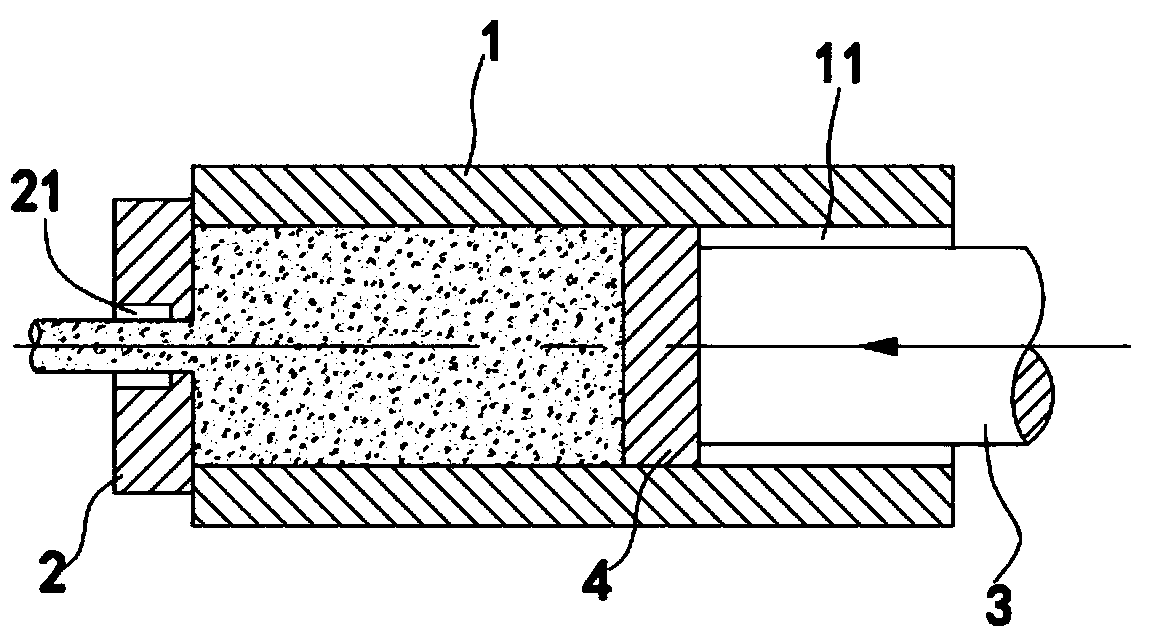

Liquid-state near-net forming method and device for continuous carbon fiber enhanced aluminum-based composite material

InactiveCN103540873ARealize hypoxic temperature control preheatingAchieve cooling rate controlFiberCarbon fibers

The invention discloses a liquid-state near-net forming method and device for a continuous carbon fiber enhanced aluminum-based composite material, namely a vacuum-assisted pressure-adjusting and infiltration casting method and device. The method comprises four procedures of smelting an alloy and pre-heating fibers, carrying out vacuum-assisted pressure-adjusting and infiltration, condensing at a high pressure and cooling rapidly. The device is composed of an alloy smelting device, a vacuum-assisted pressure-adjusting and infiltration device and a casting rapid cooling device. The liquid-state near-net forming method and device have the characteristics that (1) low-oxygen and temperature-controllable pre-heating of nickel-plated carbon fibers is realized; (2) low-pressure infiltration and high-pressure condensation of the aluminum-based composite material are realized; (3) the control of a cooling speed in the condensation of a composite material casting is realized. According to the liquid-state near-net forming method and device for the continuous carbon fiber enhanced aluminum-based composite material, oxidization and burning loss caused by pre-heating the carbon fibers, prefabricated body deformation in the infiltration process and interface reaction problems in the condensation process of the composite material are solved. The liquid-state near-net forming of the continuous carbon fiber enhanced aluminum-based composite material can be realized and the prepared composite material has the advantages of dense tissues, few interface reactions, high mechanical properties and the like.

Owner:NANCHANG HANGKONG UNIVERSITY

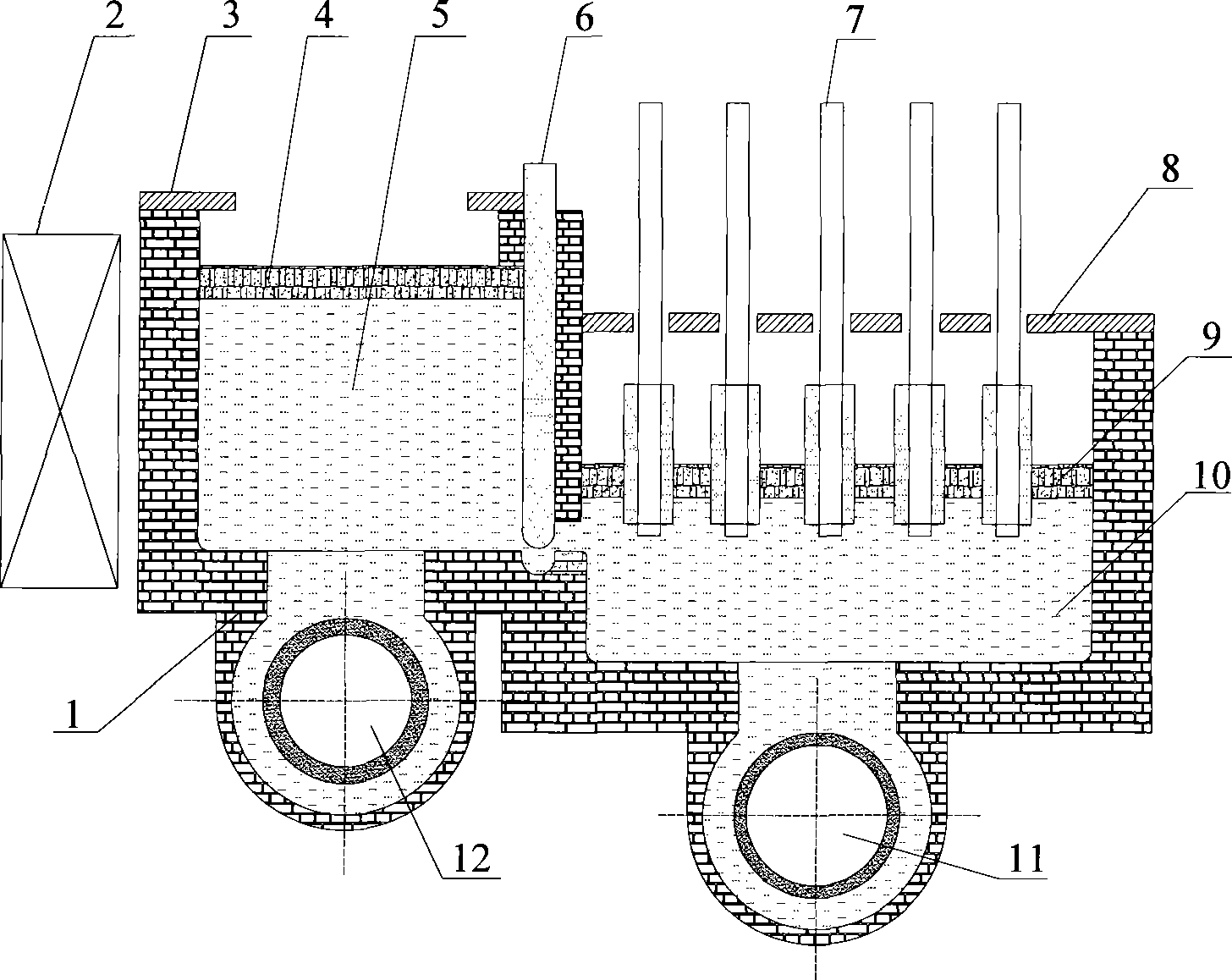

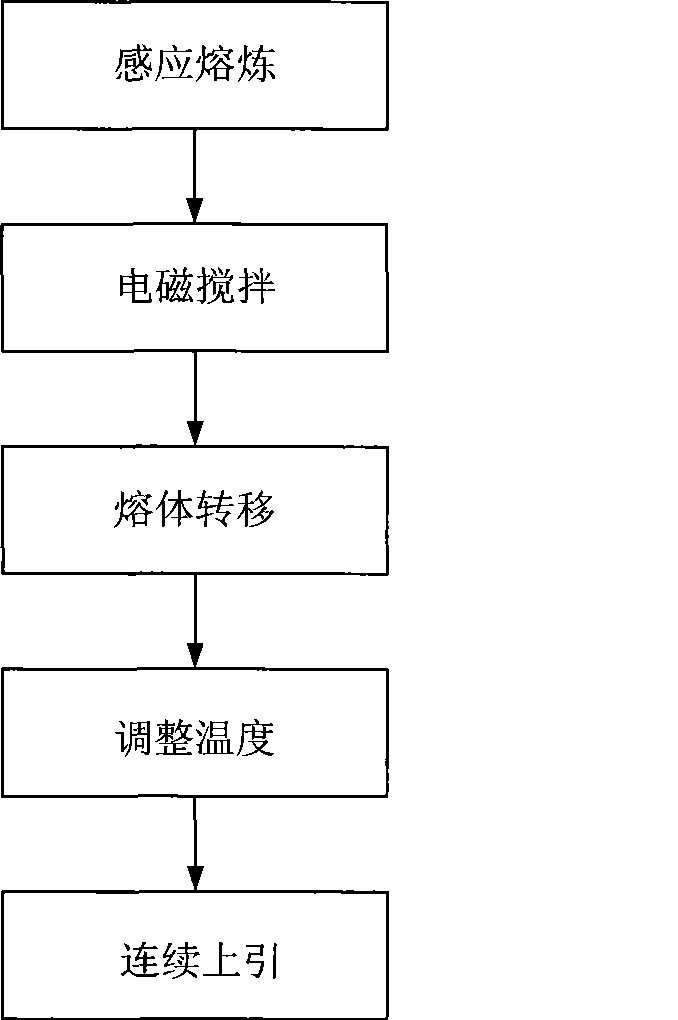

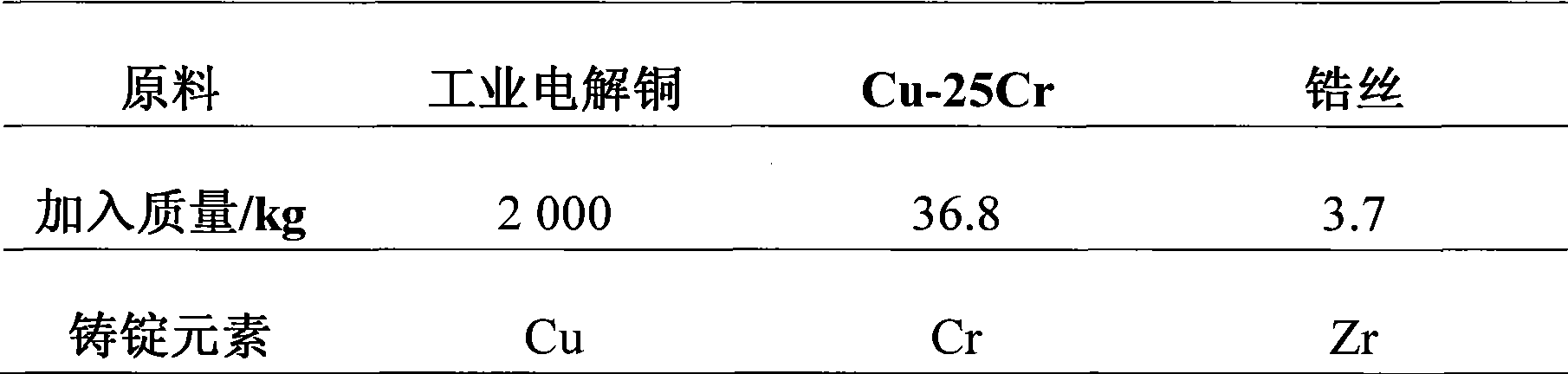

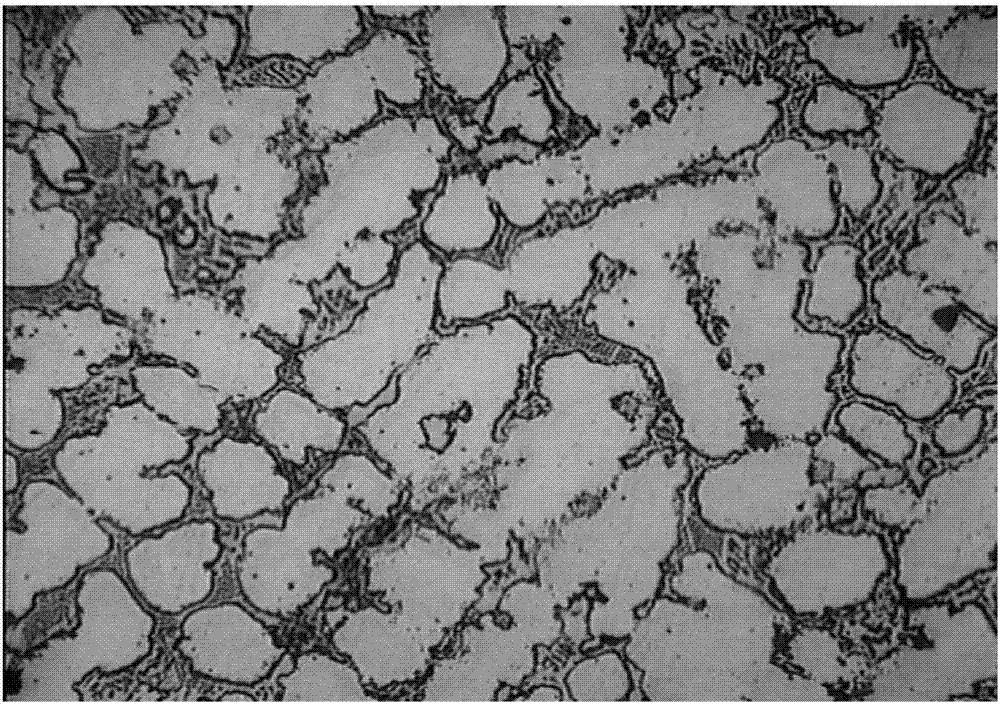

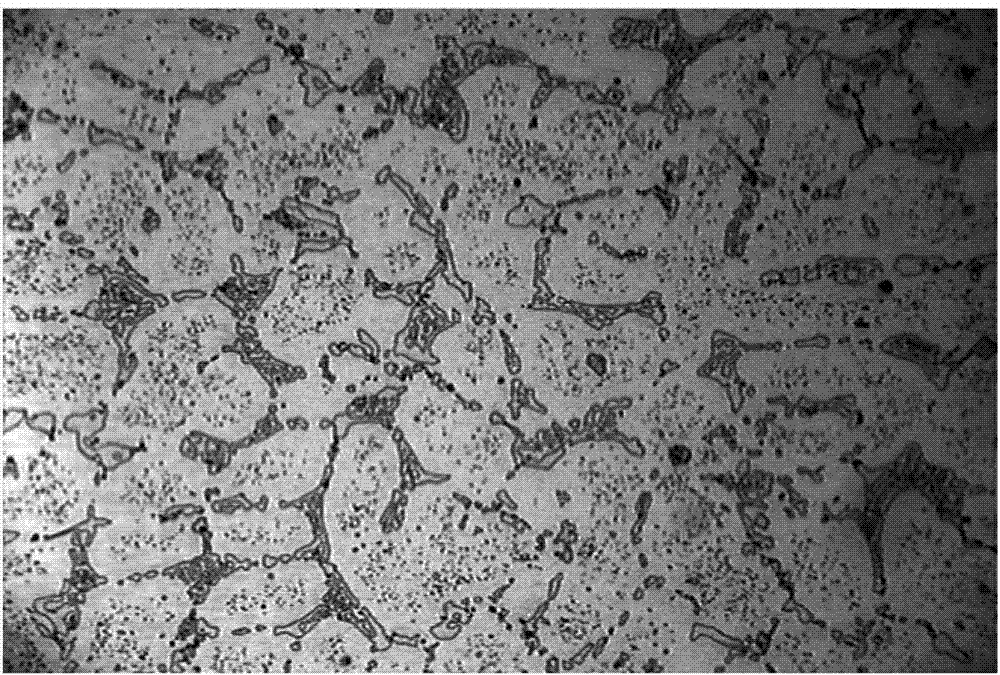

Technique for preparing chromium zirconium copper alloy wire pole

The invention relates to a preparation technology for an alloy mast, wherein the alloy is made from chromium, zirconium and copper. The technology comprises the following steps: adding industrial electrolytic copper into an inductive melting furnace for heating and melting, and covering the surface with graphite powder and charcoal at the same time; starting an electromagnetic stirrer for electromagnetic stirring and aided deoxidation treatment; adding a copper-chromium master alloy and zirconium wires for heating and melting after the industrial electrolytic copper is completely melted, and enabling the melt composition to be uniform by utilizing the electromagnetic stirring; then moving up the baffle between the inductive melting furnace and an inductive holding furnace so that the melt in the inductive melting furnace can be transferred into the inductive holding furnace under the action of the gravity, and covering the melt surface with the graphite powder and the charcoal; adjusting the melt temperature to 1200 DEG C to 1250 DEG C; and then starting an up-pulling system and continuously up-pulling CuCrZr alloy masts, and continuously adding new furnace burdens into the melting furnace during the up-pulling process. Under a non-vacuum condition, the technology can prepare the alloy (containing chromium, zirconium and copper) mast which is easily oxidized and difficult in adding element zirconium by utilizing the electromagnetic stirring function and through the tight coverage of a covering agent, and the technology is very simple.

Owner:苏州有色金属研究院有限公司

High-temperature alloy, alloy hood manufactured from same and manufacturing technology of alloy hood

ActiveCN103173692AHigh hardnessImprove high temperature oxidation resistanceChemical/physical processesManufacturing technologyHardness

The invention provides a high-temperature alloy which comprises the components such as C, Cr, Ni, Mo, Mn, Si, Nb, RE, N, Ti, B, Zr and the like, wherein the optimal content of each component is selected after reasonable analysis and repeated tests so that the components of the alloy realize the best interaction effect; and the tests prove that the high-temperature alloy provided by the invention is obviously superior to 25-20 steel and 316 steel in terms of average hardness, high-temperature oxidation resistance, high-temperature corrosion resistance and high-temperature washout resistance, and has good high-temperature comprehensive performance.

Owner:浙江科得力新材料有限公司

Method for producing aluminum alloy ingot

The invention discloses a method for producing an aluminum alloy ingot. A smelting furnace is preheated before being used, reaction time can be shortened, and the phenomenon that materials do not fully react can be avoided; a powdery dreg remover is scattered into the surface of melt, Al2O3 included slag brought from an electrolytic cell can be preliminarily removed, and furnace wall hanging slag can be reduced; coating painting treatment is carried out through a launder, and it is ensured that a launder lining is completely dry before the launder is used; a gas refining system in a heat preservation furnace is started, H2 and oxide inclusions in the aluminum melt can be fully removed, and meanwhile impurities Na can be removed well; and the launder, a sprue, the lining, a coating and seams are inspected while pretreatment so as to guarantee that molten aluminum can be injected into the heat preservation furnace fast and stably.

Owner:惠州卫生职业技术学院

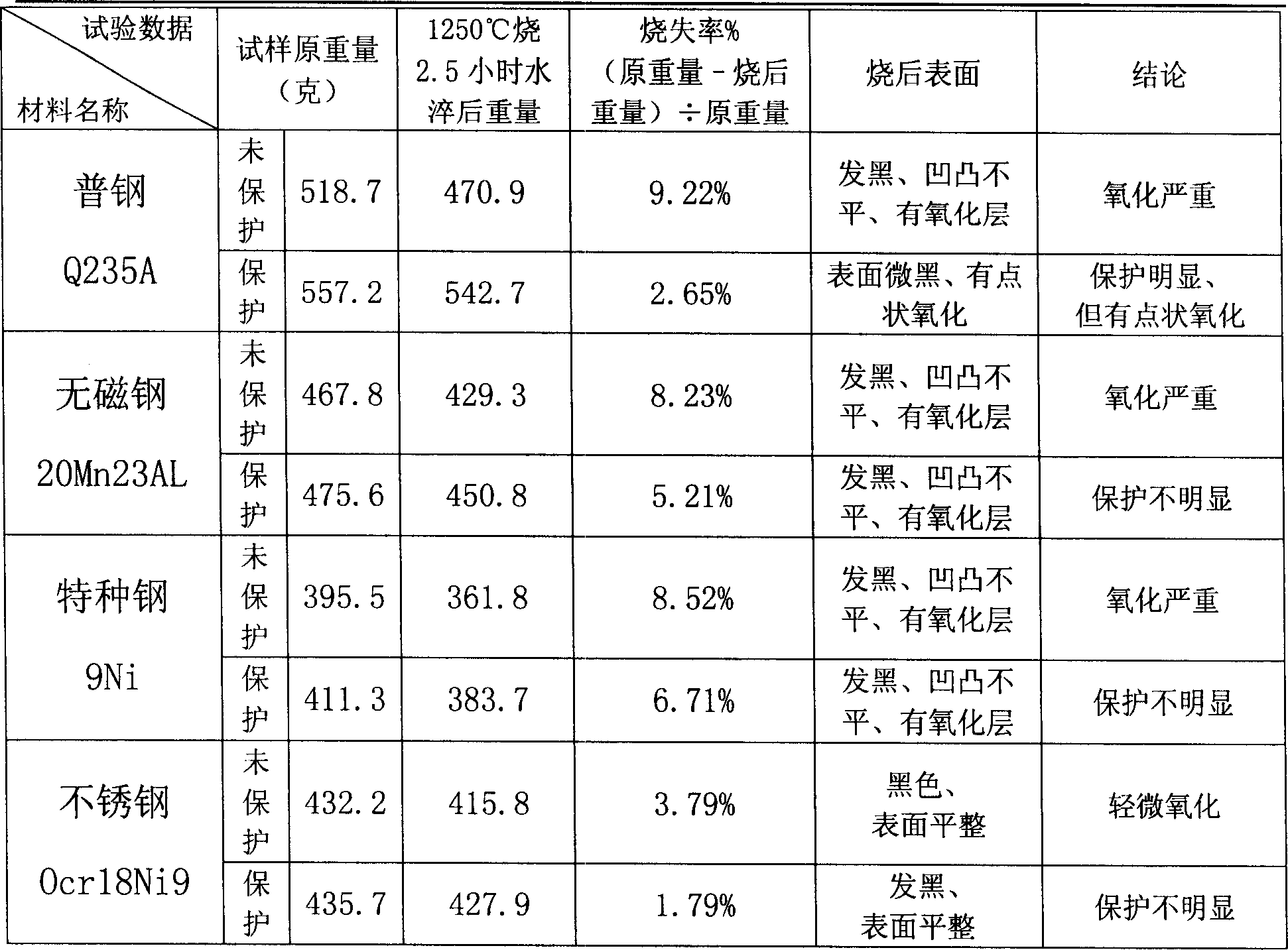

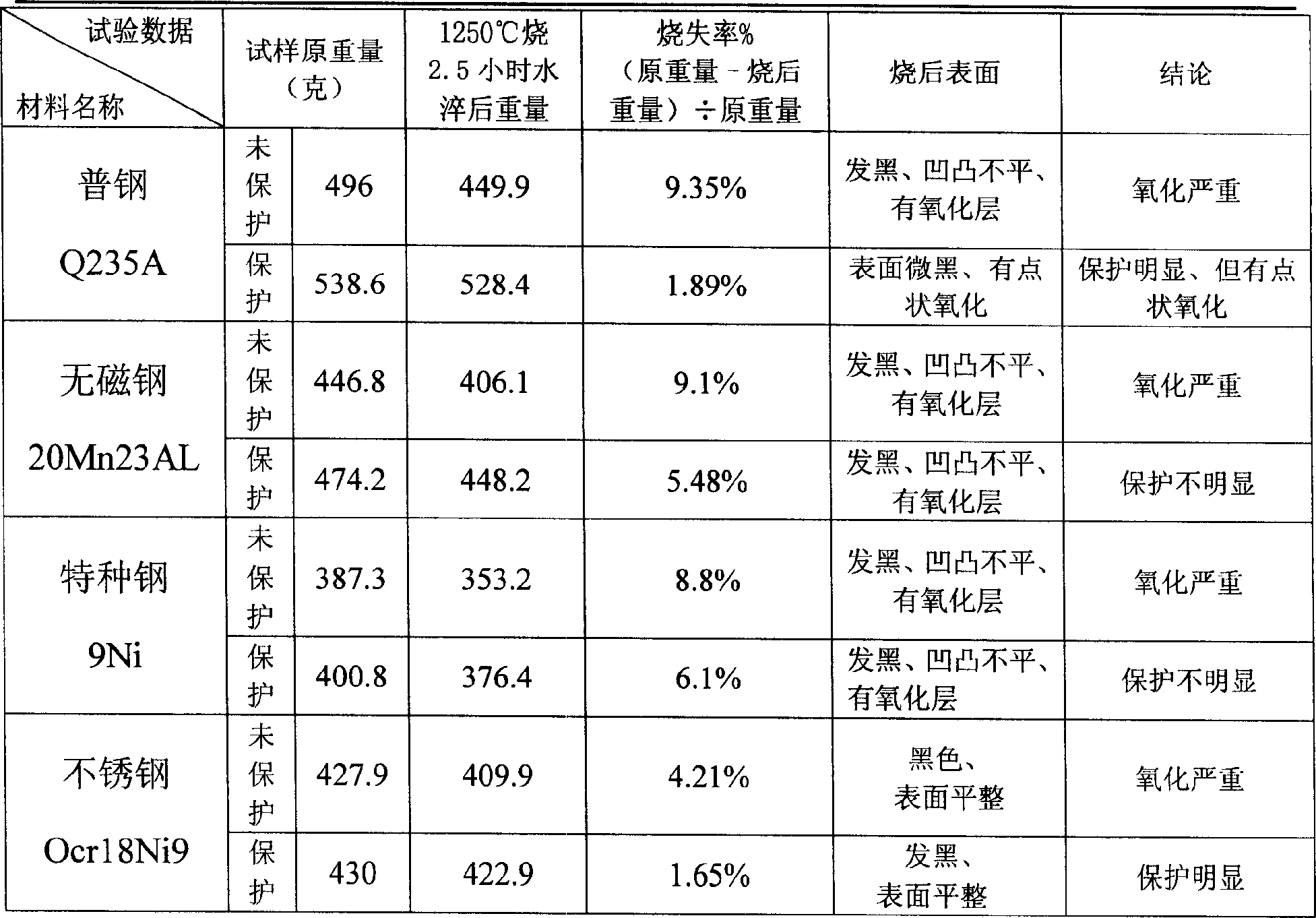

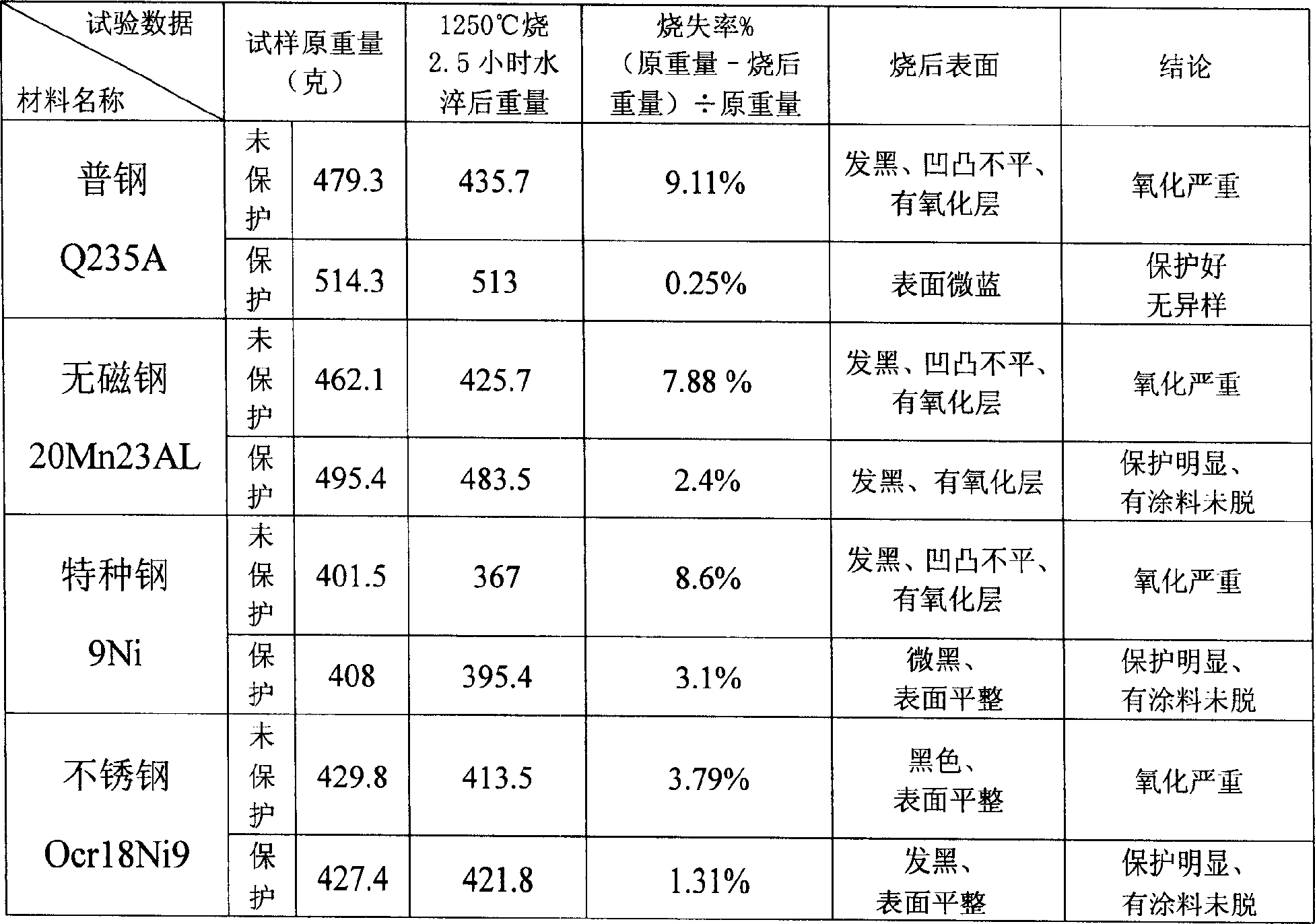

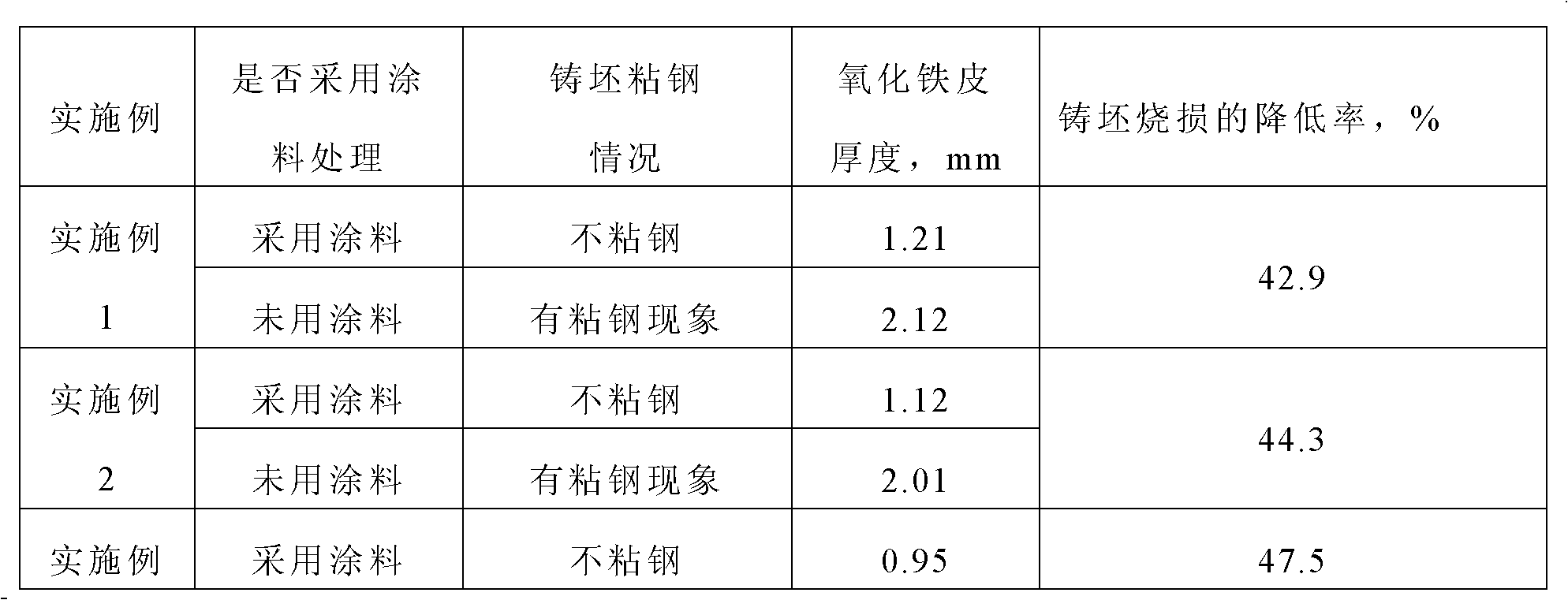

Antioxidation coating material of Nano silicate in use for annealing billet in series

This invention relates to nanoscale silicate anti-oxidation coating for steel billet annealing. The coating is composed of: composite binder 20-30 wt.%, composite phosphate curing agent 8-12 wt.%, and composite aluminosilicate filler 58-72 wt.%. The coating can resist 1500 deg.C high temperature. The coating does not need any surface treatment, and can be directly sprayed onto the surface of steel billet, and cured at normal temperature for 10 min. Before annealed and hot-rolled, the coated steel billet is water-quenched for several seconds so that the coating layer is removed without any trace, and the surface quality is improved. The coating can reduce the loss-on-ignition of various steels, thus can be used for surface protection of refractory materials used as furnace kiln lining. Besides, the coating can also be used as inner and outer wall coating, and metal surface (bridge, bridge pier and dam) coating with water, corrosion and oxidation resistance.

Owner:沁阳市皇甫喷射防腐技术有限公司

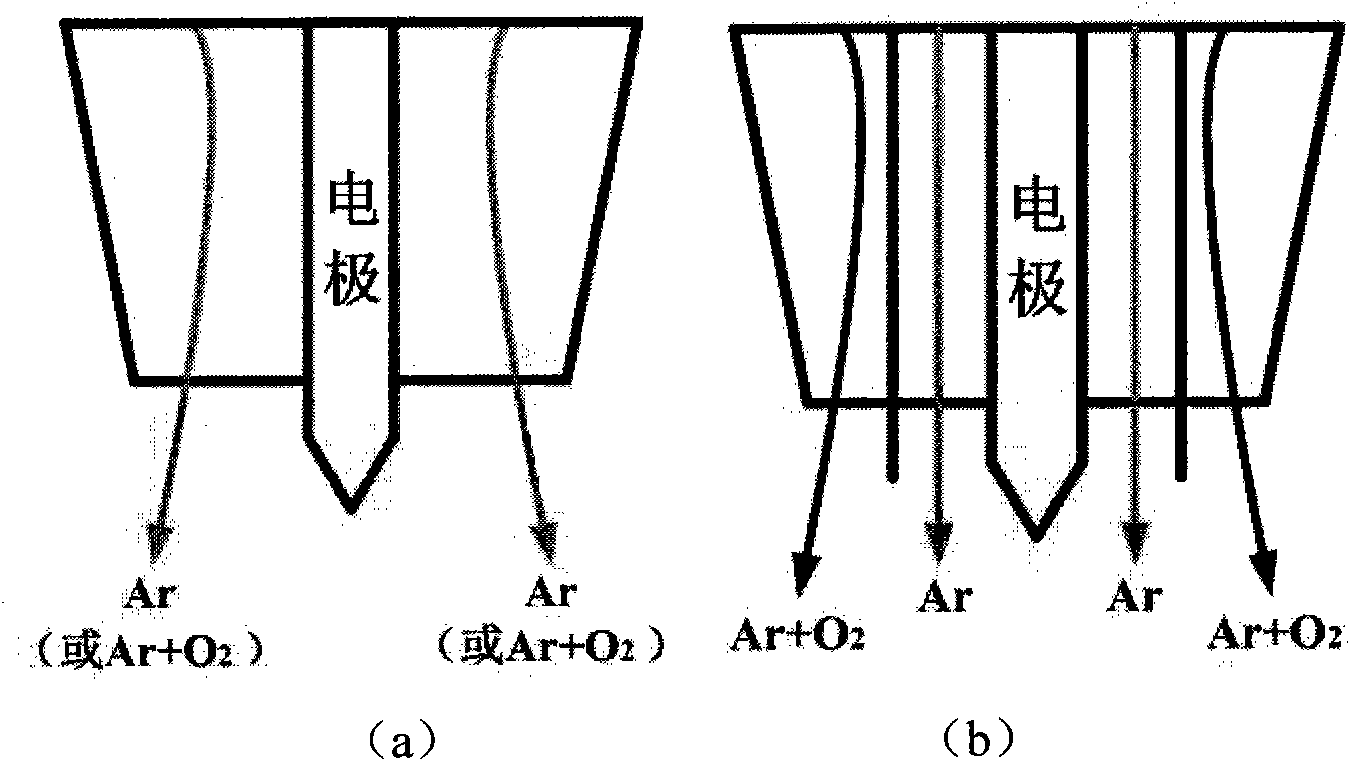

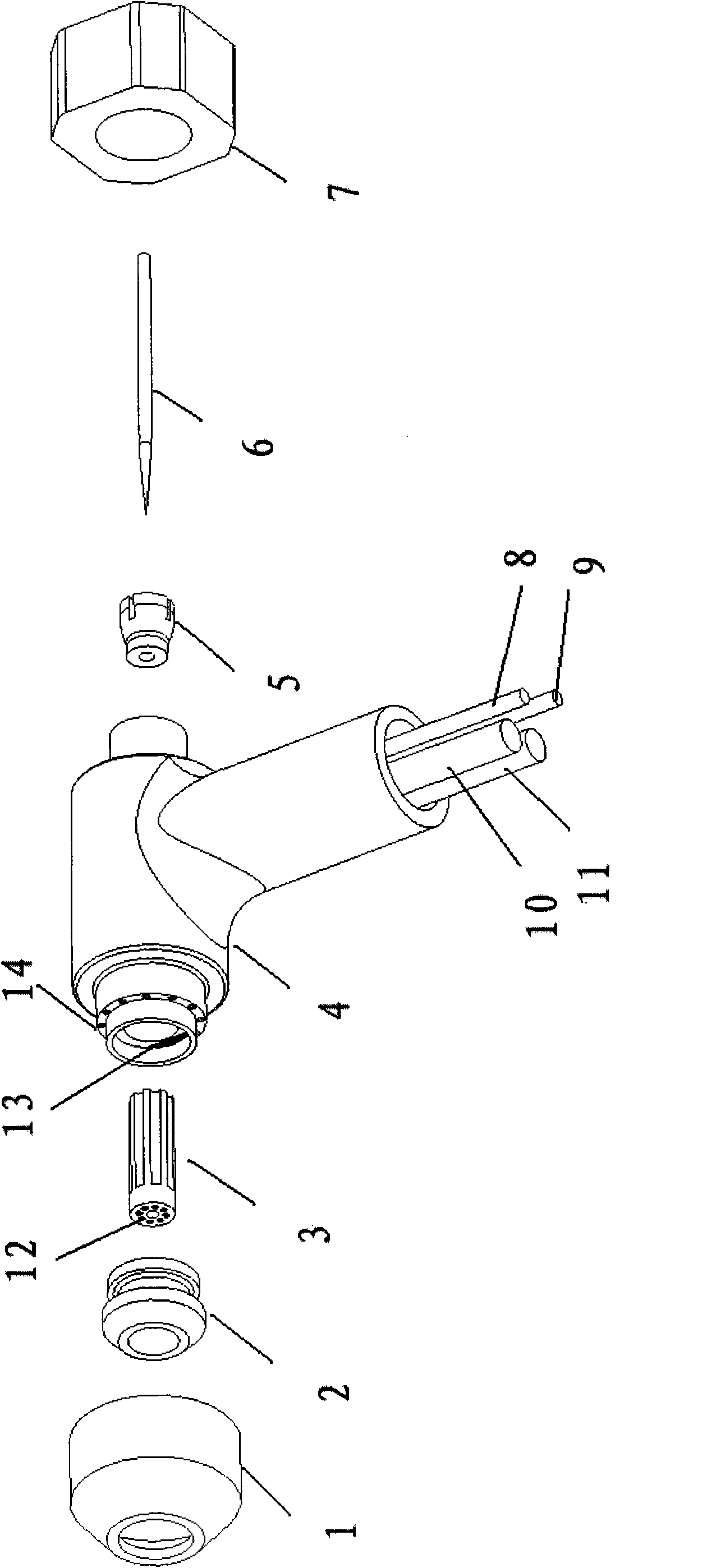

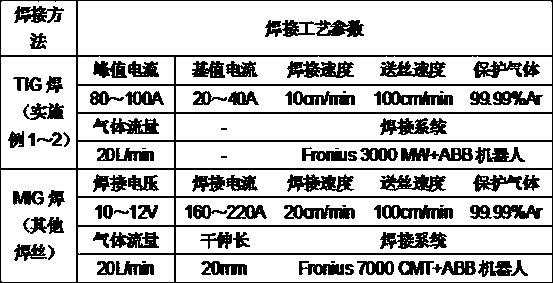

Tungsten electrode inert gas protected welding gun in double-layered airflow structure

ActiveCN101920384AAvoid oxidation burnAdjust oxygen contentElectrode supporting devicesEngineeringMixed gas

The invention belongs to the technical field of welding, in particular to a tungsten electrode insert gas protected welding gun in a double-layered airflow structure, which is suitable for a TIG (Tungsten Inert Gas) welding process and solves the problems of shallow weld penetration and easy tungsten electrode oxidation and burning under the protection of mixed gases of common TIG welding. A gun body of the welding gun is internally provided with a gas splitter which is internally provided with an inner layer gas passage, and an outer layer of the gun body is provided with an outer layer gas passage. The double-layered airflow structure of the welding gun is characterized in that a traditional TIG welding gun with a single gas passage is changed and designed into double layer air passages, a pure inert gas is adopted as the inner layer gas to protect the electrode, a mixed gas of the inert gas and an active gas is adopted as the outer layer gas, active components are transited to a melting bath to change a heat transfer convection mode of the melting bath and deepen the depth of the melting bath. The welding gun can increases the depth of the TIG welding melting bath by 2-3 times compared with the common arc welding, simultaneously avoid the tungsten electrode from being oxidized and burnt and improve the welding efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

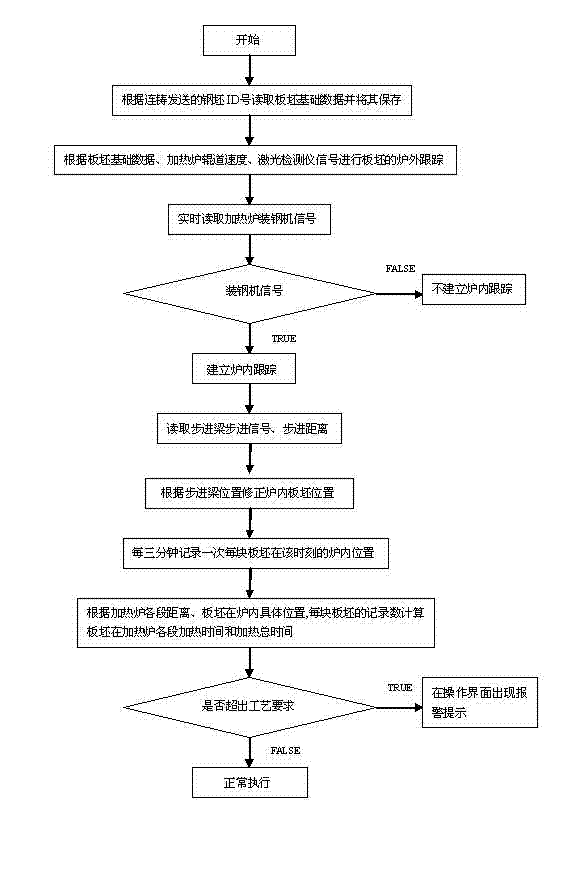

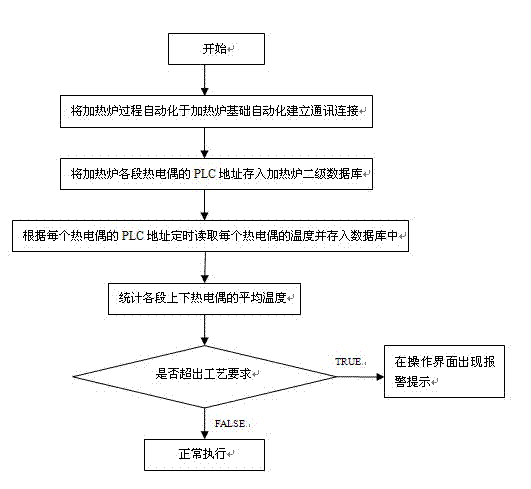

Monitoring method of heating time and heating temperature of heating furnace

InactiveCN103045847APrevent increased oxidative burning lossAvoid oxidation burnFurnace typesHeat treatment process controlLoss rateHeating temperature

The invention relates to a monitoring method of the heating time and the heating temperature of a heating furnace on a hot rolling production line, and belongs to the field of automation of the metallurgical hot rolling production line. According to the technical scheme, the method comprises the following steps: reading steel billet ID (Identification) signals sent to PLC (Programmable Logic Controllers) at the first stage in the heating furnace continuously; establishing a tracking of steel billets in the furnace by tracking the positions of the steel billets on a roller bed outside the furnace; reading the position of each steel billet in the heating furnace every three minutes from a secondary database of the heating furnace and accumulating the reading results; calculating the heating time of the steel billets at each stage in the heating furnace; contrasting the heating time with a technological requirement and alarming if the heating time exceeds the time specified by the technological requirement; storing the PLC address of each thermocouple in the heating furnace in the secondary computer database of the heating furnace; reading an average value of the temperature at each stage in the heating furnace; and finally, contrasting the heating temperature with the technological requirement and alarming if the heating temperature exceeds the temperature specified by the technological requirement. With the adoption of the method provided by the invention, the occurrence of inferior-quality products caused by an incomplete phosphorus removal on the surface of strip steel due to the long heating time and the high heating temperature at each stage in the heating furnace is avoided; the oxidation burning loss rate is decreased; the yield is increased; the cost of the steel per ton is reduced; and therefore the economic benefit is improved.

Owner:TANGSHAN GUOFENG IRON & STEEL

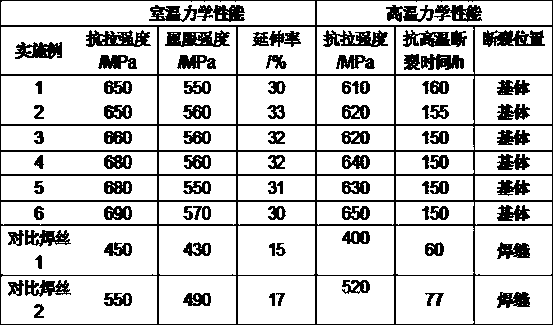

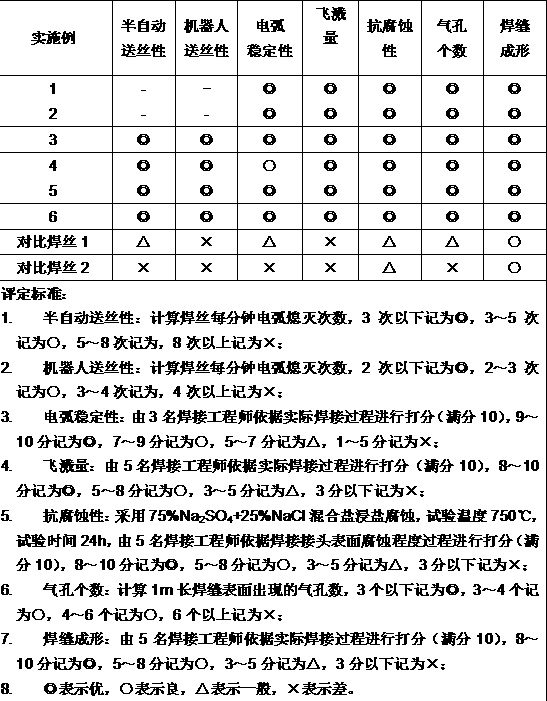

NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and preparation method thereof

InactiveCN109894770AAvoid oxidation burnAvoid welding requirements for high temperature and corrosion resistanceWelding/cutting media/materialsSoldering mediaAcid washingAlloy

The invention discloses a NiCrNb-Re high-temperature-resistance and corrosion-resistance welding wire for ethylene cracking furnace cast pipes and a preparation method thereof, and belongs to the field of welding materials. The welding wire comprises the following components in percentage by weight: 45-50% of Ni, 35-40% of Cr, 1.00-1.50% of Nb, 0.01-0.10% of Re, 0.30-0.55% of C, 0.50-2.00% of Si,1.00-2.00% of Mn, 0.01-0.10% of Al, 0.05-0.20% of Ti, 0.01-0.10% of Zr, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of alloy smelting-electroslag remelting-blooming by hot forging-hot-rolled annealing-mechanical stripping-diameter reduction by drawing-straightening and cutting or precise layer winding. The preparation method is environmentally friendly, free of acid washing pollution, stable in welding arc, free of splashing, beautiful in welding line molding, excellent in welding process and mechanical performance and dense in welding line structure, and can totally meet high-temperature-resistance and corrosion-resistance welding requirements of the ethylene cracking furnace cast pipes.

Owner:DANYANG XINHANG SPECIAL ALLOY

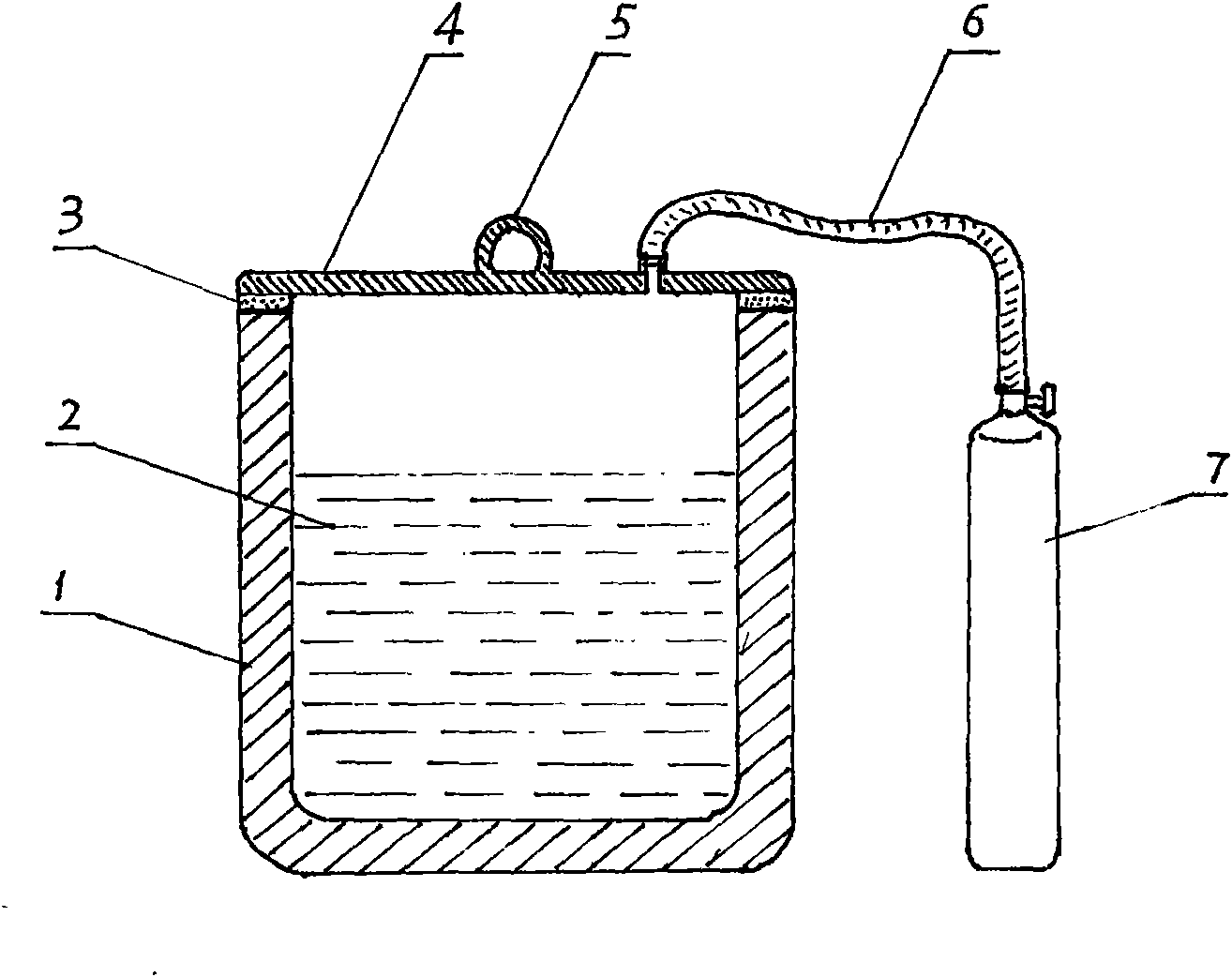

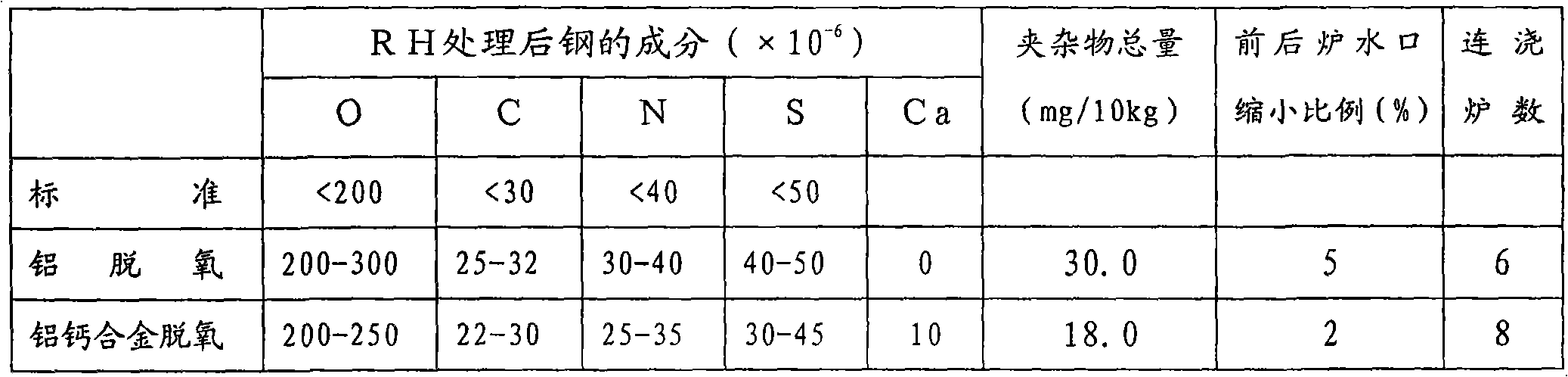

Preparation method of aluminum-calcium alloy used for vacuum refining molten steel deoxidation and device thereof

The invention discloses a preparation method of aluminum-calcium alloy used for vacuum refining molten steel deoxidation and a device thereof; the high-purity aluminum and calcium are used as the raw material and are prepared according to the weight percent as follows: 70-90 percent of aluminum and 10-30 percent calcium; the calcium is added to the aluminum which is molten by a low-frequency sensing induction furnace, the aluminum and the calcium are molten for 30-40 minutes under the protection of argon gas and then cast into an ingot; after being cooled, the ingot is broken into blocks to prepare the aluminum-calcium alloy. The invention has the advantages that the alloy has high purity and high calcium content and is used for vacuum refining molten steel deoxidation; the deoxidation and calcium can be completed in one step; the O, C, N, S ingredients in the steel are ensured not to exceed the standard requirement; meanwhile, the Al2O3 inclusion content in the steel is greatly reduced, thereby having the obvious effects of reducing nodulation at a pouring water gap and improving steel quality.

Owner:郭庆成

Aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and manufacturing method of aluminum iron alloy

The invention belongs to the technical field of metallurgy and particularly relates to an aluminum iron alloy with ultra-low carbon, ultra-low titanium and high silicon contents for deoxidizing aluminum silicon killed steel and a manufacturing method of the aluminum iron alloy. The alloy contains aluminum, iron, silicon and impurities, and is characterized in that the alloy comprises the following components by weight percentage: 20%-30% of aluminum, 45%-55% of silicon, 22%-28% of iron and the balance of impurities. The impurities comprise the components by weight percentage: less than 0.008% of carbon, less than 0.02% of phosphorus, less than 0.02% of sulfur, less than 0.05% of copper, less than 0.005% of titanium, less than 1.0% of manganese and less than 0.05% of nitrogen. The manufacturing method comprises the steps of burdening, melting and casting. The alloy has the advantages of ultra-low titanium content, ultra-low carbon content, low impurity content and the like, and particularly meets the requirement of the aluminum iron killed steel on the ultra-low titanium and ultra-low carbon contents of a deoxidier.

Owner:江苏江南铁合金有限公司

A356 aluminum alloy efficient modifier and preparation method thereof

The invention relates to an A356 aluminum alloy efficient modifier and a preparation method thereof. The modifier consists of the following components in percentage by mass: 2-10% of Nd, 1-5% of Mg, 1-5% of Sb and the balance of Al. The preparation method for the modifier comprises the following steps of: (1) providing an Al-Nd intermediate alloy, an Al-Sb intermediate alloy, an aluminum ingot anda pure magnesium ingot; (2) pre-treating the intermediate alloys and the magnesium ingot, grinding, polishing and removing surface oxide skin, and drying and weighing after cleaning; (3) heating theweighed dried intermediate alloys and the magnesium ingot to a temperature being 730-750 DEG C to melt in a graphite crucible, and keeping the temperature for 5 minutes or more; (4) after the intermediate alloys are completely molten, stirring for 10 minutes by a graphite stirring rod; (5) cooling a furnace temperature to 710-720 DEG C, adding a slag remover into molten alloy, and leading argon gas into melt to refine; and (6) preserving heat and staying for 15-20 minutes, removing surface scum, and pouring alloy into a metal mould to cool to obtain the alloy.

Owner:QINHUANGDAO XINGLONG WHEEL HUB

Boron-containing alloy smelting process with high yield

InactiveCN101736123AHigh yieldReduce oxygen contentElectric furnaceProcess efficiency improvementSocial benefitsSmelting process

The invention discloses a boron-containing alloy smelting process with high yield. The process is characterized in that firstly boron-containing alloy is smelted in an electric furnace, when the temperature of the alloy is 180-230 DEG C higher than liquidus temperature, 0.2-0.5 % of calcium-silicon is added for preliminary deoxygenation, then 0.12-0.18% of aluminium is added for final deoxygenation, and then 0.2-0.3% of ferrotitanium is added for fixing nitrogen in metal solution, and finally ferrotitanium and ferroboron tightly wrapped by an aluminium plate are added into metal liquid together, when the temperature of boron-containing alloy is 200-260 DEG C higher than the liquidus temperature, boron-containing alloy liquid is discharged and can be used for pouring of cast or cast ingot. The invention is adopted to smelt boron-containing alloy, yield of boron element is over 90%, consumption of boron element can be obviously reduced, and boron-containing alloy production cost can be reduced, thus the invention has better economic and social benefits.

Owner:BEIJING UNIV OF TECH

Bearing steel high temperature heating protective coating and using method thereof

The invention discloses a bearing steel high temperature heating protective coating and a using method thereof. The protective coating comprises the following components in percentage by weight: 55 to 75 percent of MgO, 6 to 25 percent of CaO, 10 to 30 percent of TiO2, 4 to 10 percent of P2O5 and 2.5 to 7.5 percent of Na2O. The protective coating can effectively prevent bearing steel from being adhered to a pusher-type heating furnace or subjected to oxidation burning loss, and the using method of the protective coating is simple, easy to operate and good in effect.

Owner:武汉钢铁有限公司

Nodular cast iron used for crankshafts and preparation method thereof

The invention relates to the field of nodular cast iron and in particular relates to nodular cast iron used for crankshafts and a preparation method thereof. The nodular cast iron used for crankshafts comprises the following elements by mass percent: 3.6-3.8% of C, 1.9-2.2% of Si, 0.4-0.6% of Mn, 0.4-0.7% of Cu, 0.03-0.035% of Mg, 0.02-0.03% of Sn, 0.04-0.06% of Ni, 0.005-0.015% of Ge, 0.004-0.005% of Sb, not more than 0.03% of P, not more than 0.01% of S and the balance of Fe. The preparation method mainly comprises the following steps: raw material smelting, spheroidizing, inoculation and heat treatment. The nodular cast iron and the preparation method have the beneficial effects that by reasonably allocating the elements, the prepared nodular cast iron used for crankshafts has high strength and toughness, has higher rigidity and wear resistance, has the effect of improving the bearing capacities and reliability of the crankshafts, and has prolonged service life; and meanwhile, by optimizing the preparation method, the production cost is reduced and the production efficiency is improved.

Owner:HANSHAN COUNTY XINGDA DUCTILE IRON FACTORY

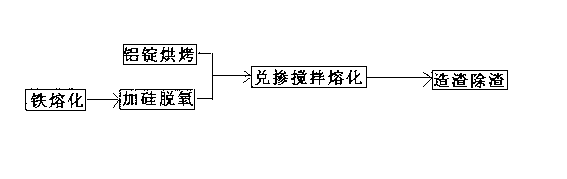

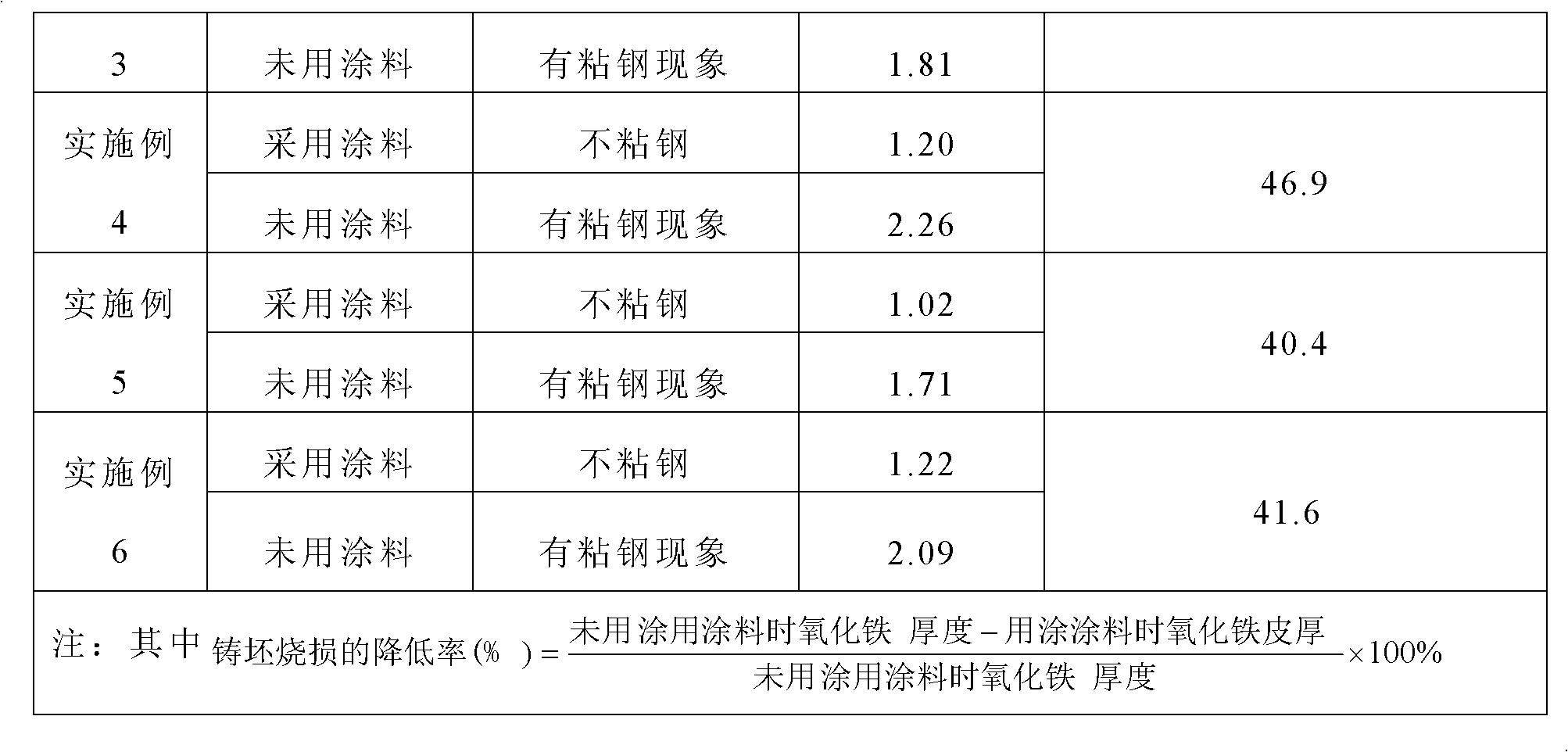

Method for adding additive for electroslag remelting alloy tool and die steel

The invention relates to an adding method of additives of electroslag remelting alloy tool and die steel and the method comprises the following steps: (1) the additives are packed up by using metal pipes and rolled into metal cored-wire; and (2) the metal cored-wire is directly hung in a consumable electrode steel mould. The adding method can avoid the oxidation loss of active modification elements caused by steel slag mixing and molten slag oxidation, the yielding rate is high (over 30 percent) and the modification effect of steel is good.

Owner:ZHEJIANG ZHENGDA MOLD

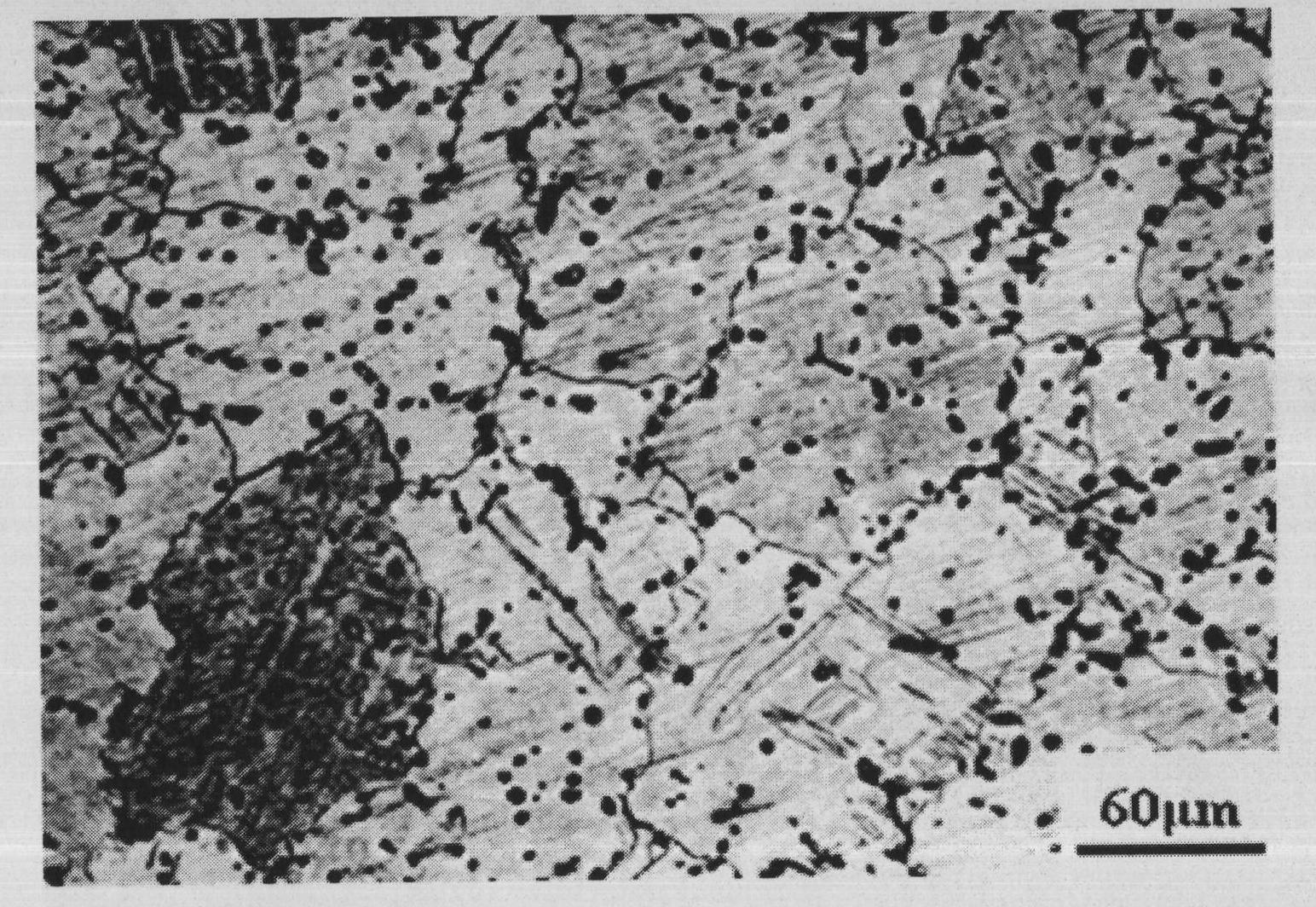

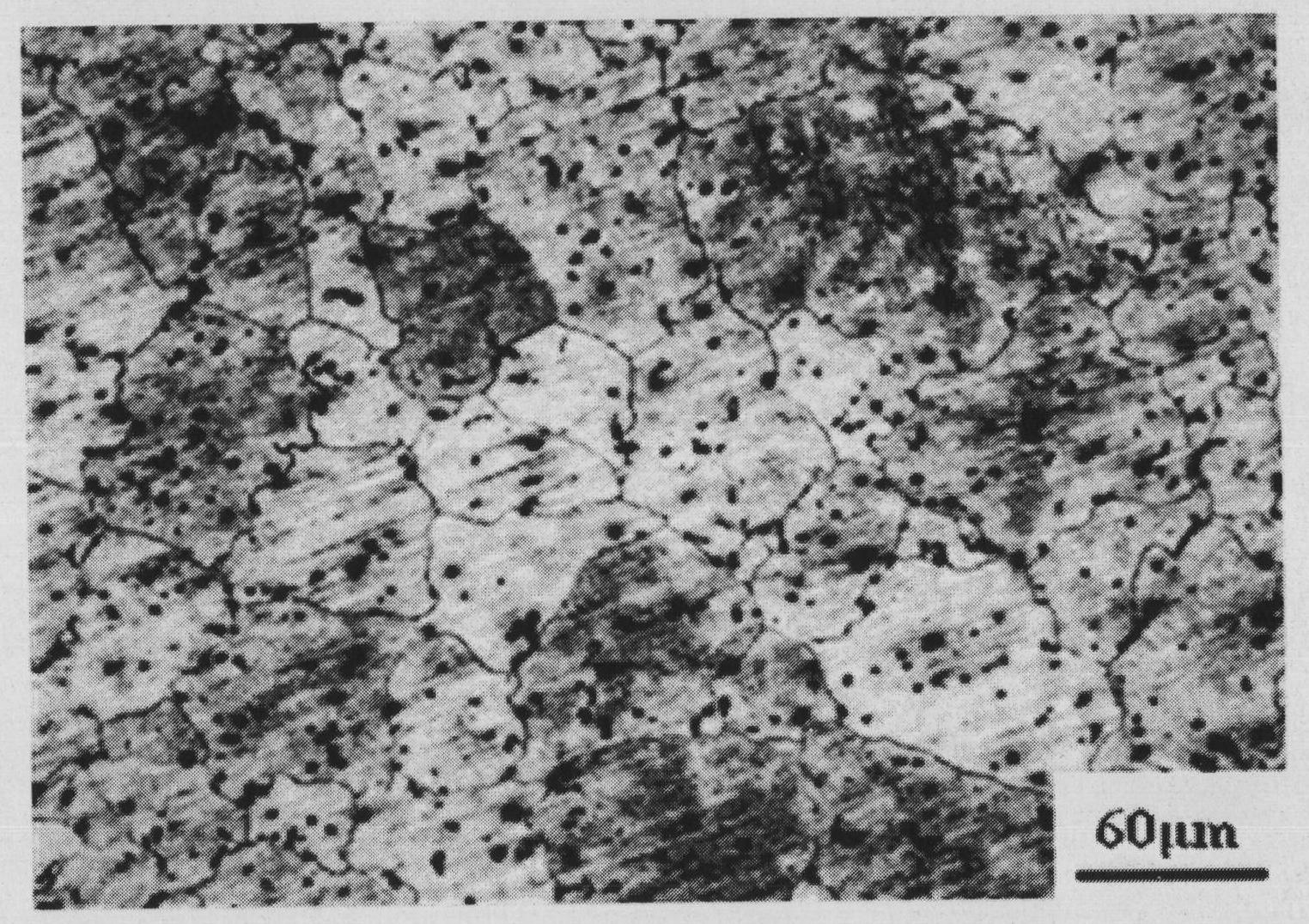

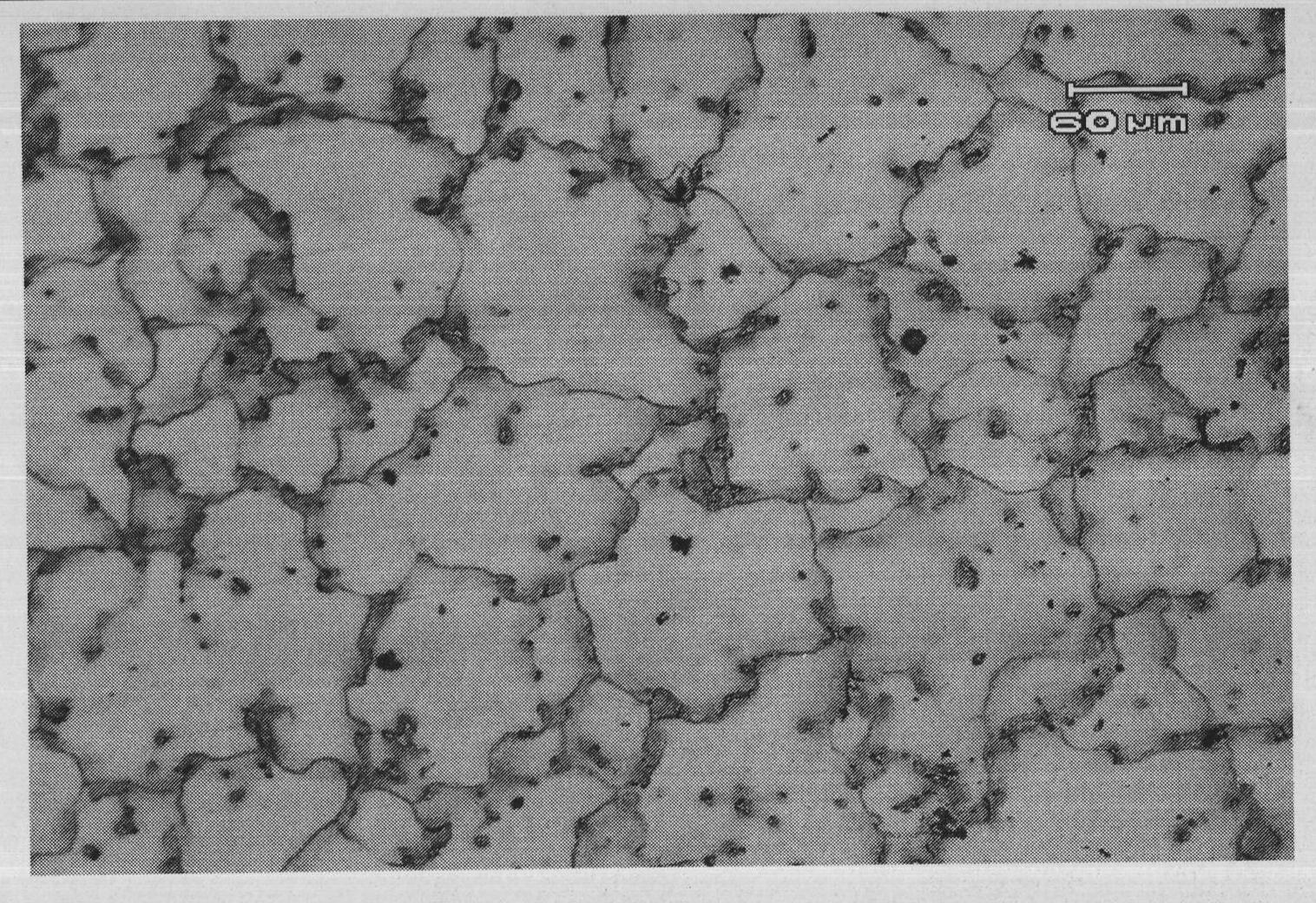

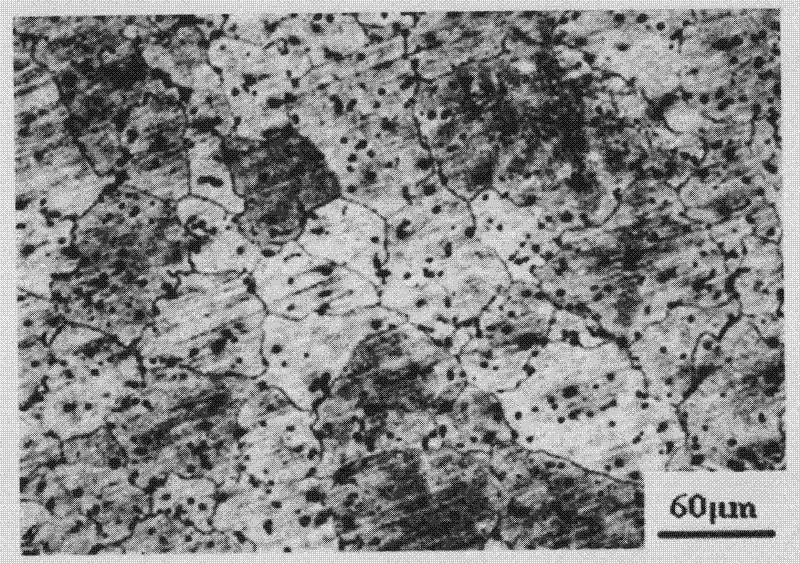

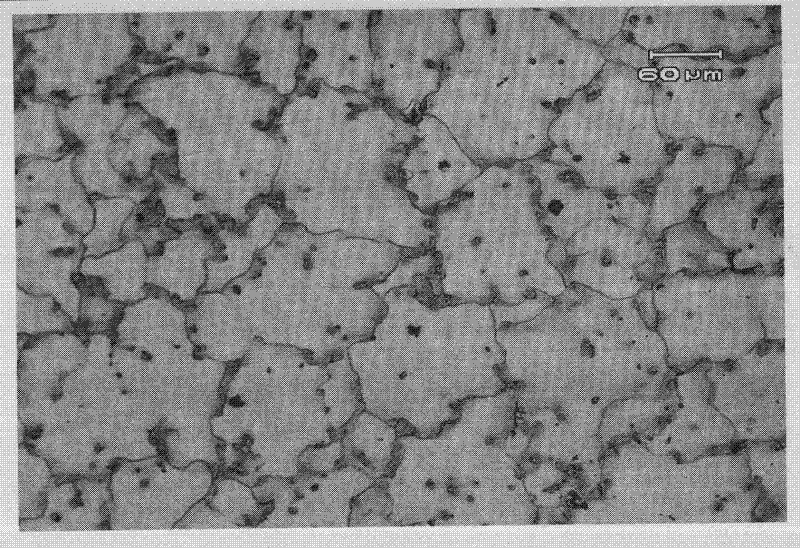

Fe-x-c grain refiner and preparation method thereof

An Fe-X-C grain refiner in the technical field of metal materials and a preparation method thereof. Fe-X-C grain refiner, its composition and mass percentage are: Fe 35-99.4%, C 0.1-15%, X 0.5-50%; wherein, X is one or more of Ti, V and Nb kind. The preparation method of Fe-X-C grain refiner comprises the following steps: step 1, take Fe-C alloy, mix with metal X; Or, take pure iron and graphite, mix with metal X afterwards; The melt is melted in the furnace; in the mixture, Fe is 35-99.4%, C is 0.1-15%, and the balance is X; step 2, when the temperature of the melt is 1550-1650°C, feed argon into the melt , the time is 10s ~ 3h; Step 3, stop feeding argon, cut off the power, and get the Fe-X-C grain refiner. The grain refiner of the invention is easy to prepare; adding the grain refiner of the invention to the steel melt can refine the grains of the steel and increase the ratio of the equiaxed grain area of the as-cast structure of the billet to more than 60%.

Owner:SHANGHAI JIAO TONG UNIV +1

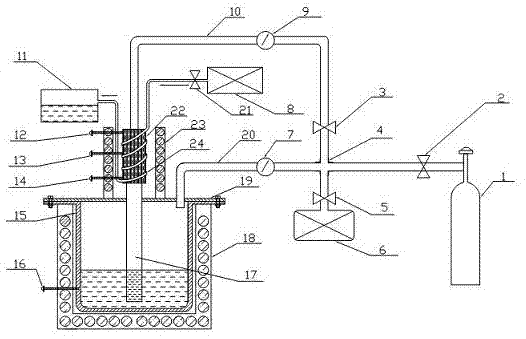

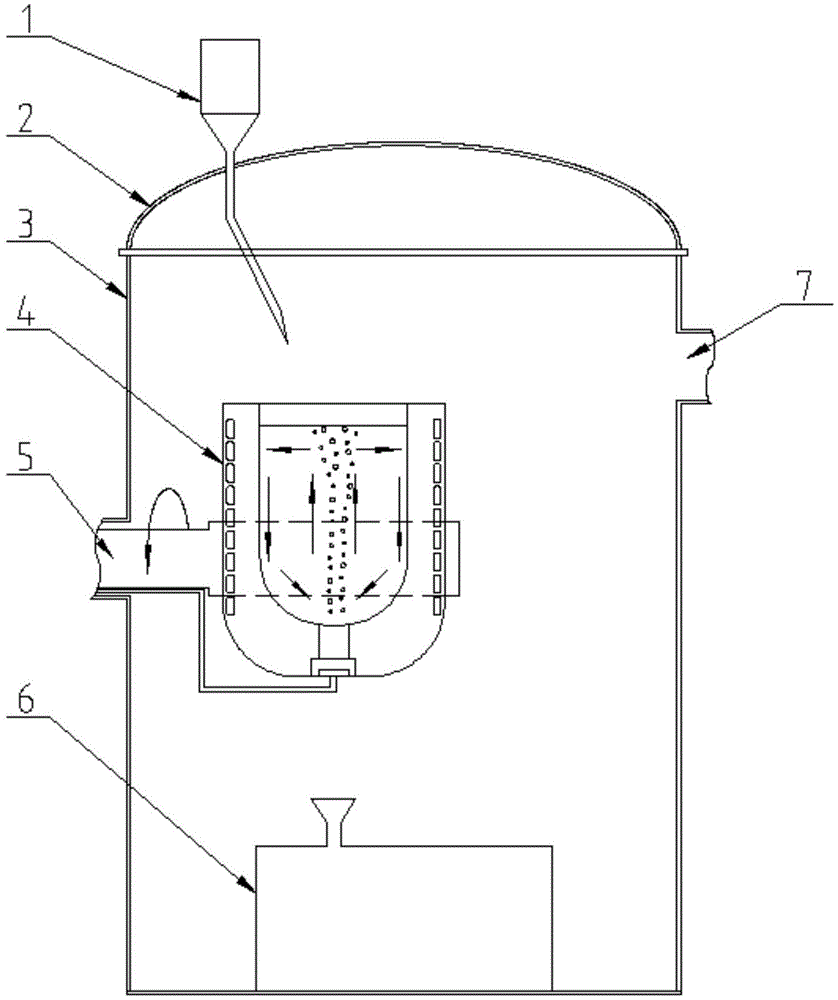

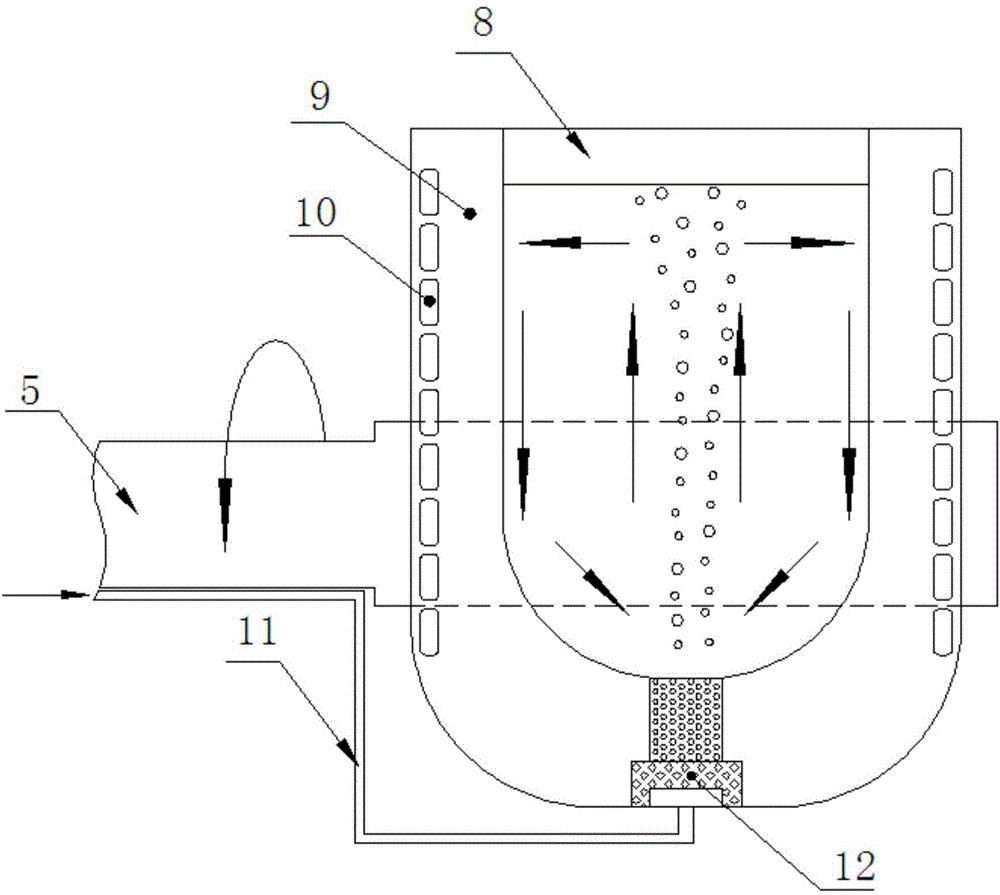

High phosphorous cast iron inoculating treatment method device in vacuum induction furnace

The invention discloses a high phosphorous cast iron inoculating treatment method device in a vacuum induction furnace, and belongs to the technical field of metallurgy process. The high phosphorous cast iron inoculating treatment method in the vacuum induction furnace comprises the steps of loading industrial pure iron into a hearth of the induction furnace; sealing the induction furnace in a vacuum chamber; exhausting air in the vacuum chamber, and maintaining in a vacuum state; heating for melting industrial pure iron in the induction furnace, and alloying molten iron; adding a nucleating agent into the alloyed molten iron, introducing inert gas to the bottom of the hearth, and stirring the molten iron with the nucleating agent by virtue of the inert gas; stopping the blowing of the inert gas after the nucleating agent is completely molten, and pouring the molten iron. By adopting the high phosphorous casts iron inoculating treatment method and device in the vacuum induction furnace, the oxidation burning of an alloy and nucleating agent can be effectively prevented, the yield is high, the inoculating treatment effect can be rapidly completed, and the uniformity in the inoculating treatment can be improved.

Owner:武钢集团有限公司

High-strength magnesium alloy and die-casting method thereof

The invention provides a high-strength magnesium alloy. The high-strength magnesium alloy comprises Zn, Al, Cr, Mn, La, Ce, Nd, Yb, Y, VC, ZrC, WC, TiC, TiB2, ZrB2 and Mg. The invention further provides a die-pressing method of the high-strength magnesium alloy. According to the high-strength magnesium alloy, rare earth elements like La are added in the alloy and have high solubility in the magnesium alloy, the dispersion strengthening effect and the great solution strengthening can both be achieved, besides, the rare earth elements can also have a high bonding effect with impurities elements,such as oxygen, hydrogen, nitrogen, sulfur and iron in a raw material alloy, gas and inclusions in the alloy can be reduced, the form of the inclusions is improved, the inclusions tend to be spheroidized, the inclusions and gas can be removed advantageously, and a melt purifying effect is also achieved; and in addition, the added rare earth elements differ in content, and the synergistic effect of the different rare earth elements greatly improves the strength and corrosion resistance of the magnesium alloy.

Owner:仝仲盛

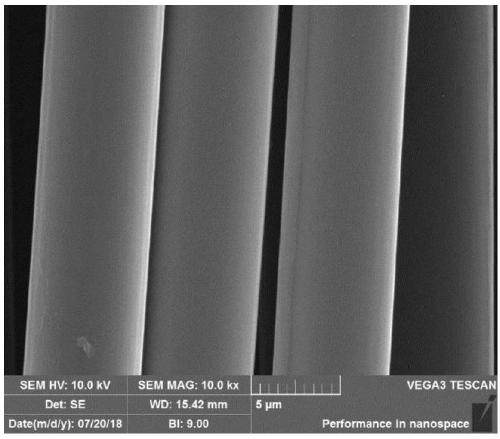

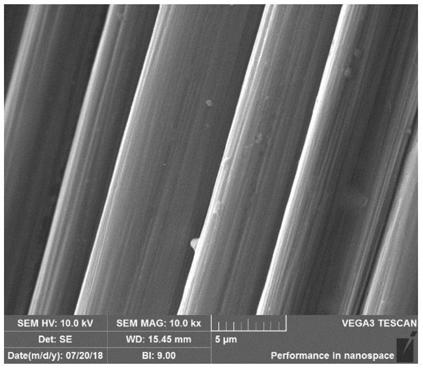

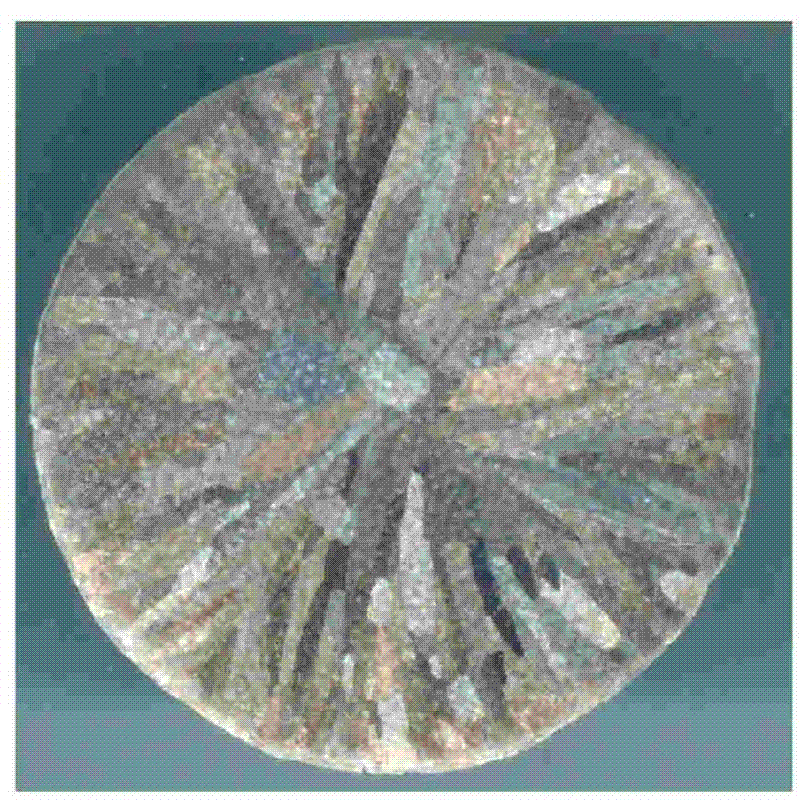

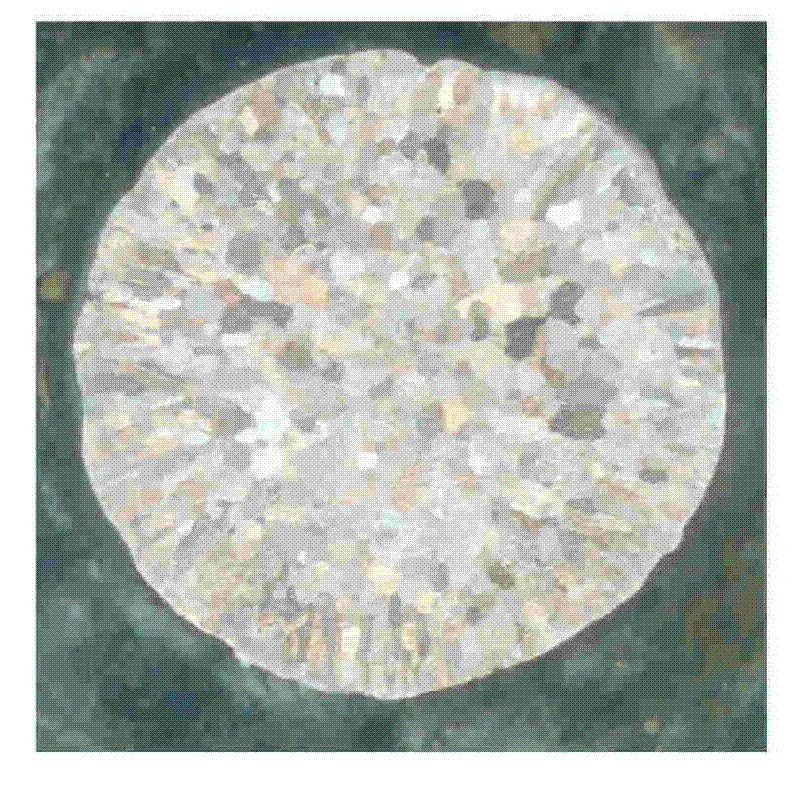

Carbon fiber with C-Si-Al coating on surface for gradient sintering protection of precursor as well as preparation method and application thereof

ActiveCN109161859AGood high temperature oxidation resistanceImprove efficiencyVacuum evaporation coatingSputtering coatingSputteringFiber

The invention discloses a carbon fiber with a C-Si-Al coating on the surface for gradient sintering protection of a precursor as well as a preparation method and application thereof. The C-Si-Al coating for gradient sintering protection of the precursor is designed and constructed on the surface of the carbon fiber (CF) with certain thickness and morphology by adopting the magnetron sputtering method; the C layer serves as the innermost layer to protect the CF and reduce the damage to the CF during the sputtering process; the Si layer serves as a transition layer to play the action of blockingand prevent the CF and the Al layer from being in contact reaction to form the brittle phase of Al4C3; the Al layer serves as a precursor coating for subsequent anodic oxidation of nanoporous Al2O3;and the gradient C-Si-Al coating is enabled to be dense and homogeneous in structure by heat treatment after sputtering. The C-Si-Al coating prepared by the invention has high strength in bonding withthe CF substrate and good stability in long-term implantation, and can prevent the coating from falling off and getting failed, thereby laying a certain research foundation for the application of C-Si-Al / CF in clinic.

Owner:SHAANXI UNIV OF SCI & TECH

High-strength and high-conductivity refining agent for smelting chromium-zirconium-copper alloy and application method for refining agent

The invention discloses a high-strength and high-conductivity refining agent for smelting a chromium-zirconium-copper alloy. The refining agent comprises a covering component and a purifying component, wherein the purifying component comprises calcium hexaboride, fluorotitanate, fluoborate, chlorine metal salt and rare earth. The invention further discloses an application method for the high-strength and high-conductivity refining agent for smelting the chromium-zirconium-copper alloy. According to the refining agent and the application method thereof, the cooperation function of the covering component and the purifying component is adopted so that the good impurity removal and purification effect on chromium-zirconium-copper alloy melt can be achieved, in addition, the oxidation burning loss in the smelting process can be effectively avoided, and therefore the strength and the conductivity of the material can be improved, and no pollution can be caused to the copper alloy melt.

Fe-X-C grain refiner and preparation method thereof

The invention discloses a Fe-X-C grain refiner and a preparation method thereof, belonging to the technical field of metal materials. The Fe-X-C grain refiner comprises the following components by weight percent: 35-99.4 percent of Fe, 0.1-15 percent of C and 0.5-50 percent of X, wherein X is one or more selected from Ti, V and Nb. The preparation method of the Fe-X-C grain refiner comprises the following steps : firstly, taking an alloy of Fe and C to mix with a metal X; or taking a pure iron and graphite to mix with the metal X; and smelting a mixture in vacuum in a frequency induction furnace to obtain a fusant, wherein the mixture contains 35-99.4 percent of Fe, 0.1-15 percent of C and X of the balance; secondly, leading argon into the fusant for 10s-3h when the fusant is at 1550-1650DEG C; and thirdly, stopping leading the argon and switching off the electricity to obtain the Fe-X-C grain refiner. The grain refiner has simple preparation; and the grain refiner can be added into a steel fusant to refine the grains of the steel so that the proportion of a billet steel casting tissue equiaxed grain zone is improved by 60 percent.

Owner:SHANGHAI JIAO TONG UNIV +1

Preparing method for anti-dezincification leadless bismuth arsenic extruded brass rod

The invention relates to the field of copper alloys for the bathroom and kitchen industry and provides a preparing method for an anti-dezincification leadless bismuth arsenic extruded brass rod. The preparing method comprises the step of smelting 61-63% of Cu, 0.5-0.9% of Bi, 0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, smaller than 0.1% of Pb, the balance Zn and smaller than or equal to 0.25% of impurities to obtain the solid brass rod by the processes of lead casting and extruding.

Owner:龙岩市鸿航金属科技有限公司

Production method of anti-dezincification and unleaded lead-cast brass ingot

The invention relates to the field of copper alloys for kitchenware industries, and provides a production method of an anti-dezincification and unleaded lead-cast brass ingot which is good in anti-dezincification corrosion property, high in strength, and good in machining property. The production method comprises the steps that the following raw materials of, by mass, 61-63% of Cu, 0.5-0.9% of Bi,0.07-0.12% of As, 0.5-0.8% of Al, 0.08-0.24% of Sn, less than 0.1% of Pb and the balance Zn and impurities with the total amount being less than or equal to 0.25% are smelted, and then subjected to lead casting, and the brass ingot is prepared.

Owner:龙岩市鸿航金属科技有限公司

Fusion casting production process capable of improving compressive strength of aluminium profile

ActiveCN110484792AReduce pollutionDoes not impair corrosion resistanceRare-earth elementCompressive strength

The invention relates to a fusion casting production process capable of improving compressive strength of an aluminium profile. The problem that the compressive strength of the aluminium profile is not sufficient in the prior art can be solved. The process comprises the following steps of firstly, preparing, wherein the aluminum profile comprises, by mass percent, 0.18 to 0.25% of Si, 0.28 to 0.32% of Fe, 0.01 to 0.03% of Be, 0 to 0.1% of Mn, 0.03 to 0.06% of Cr, 0.05 to 0.09% of Ti, 0.15 to 0.25% of rare earth element, 0.1 to 0.3% of Zn, 1.8 to 3.6% of Cu, 2.2 to 2.8% of Mg, and the balance Al; secondly, smelting; thirdly, refining; fourthly, standing and sampling analysis; fifthly, deslagging; and sixthly, casting, wherein the melt obtained after deslagging is casted to form a casting bar, the casting temperature is 695 to 710 DEG C, and the casting speed is 35 to 65 mm / min; and seventhly, homogenization annealing.

Owner:FUJIAN MINFA ALUMINUM

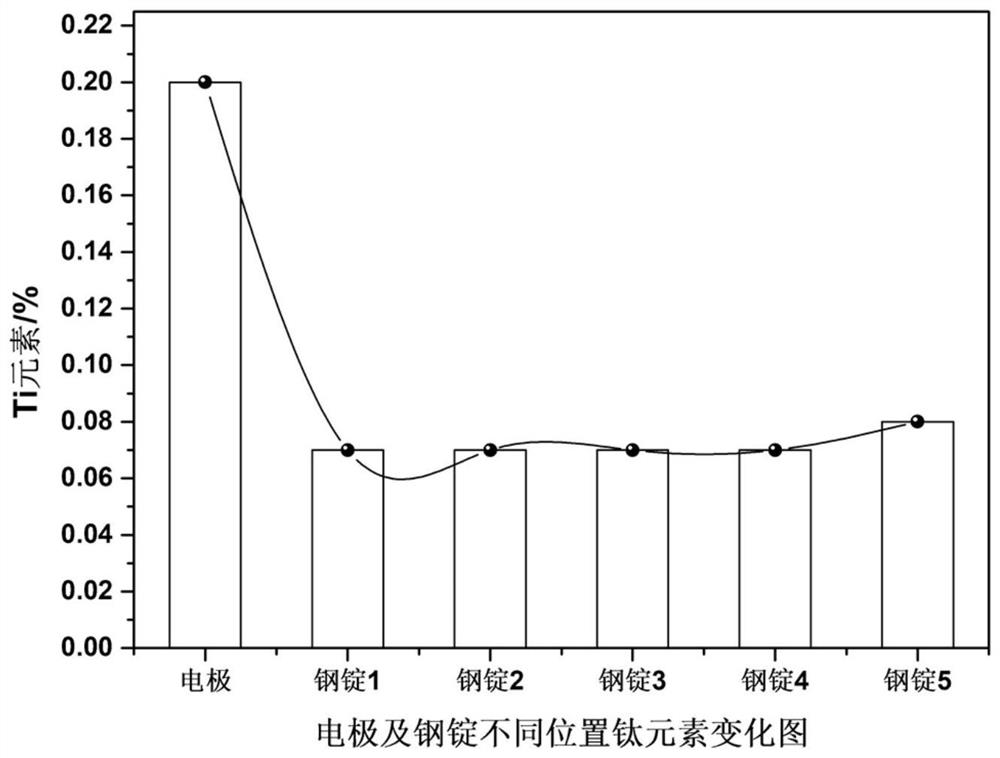

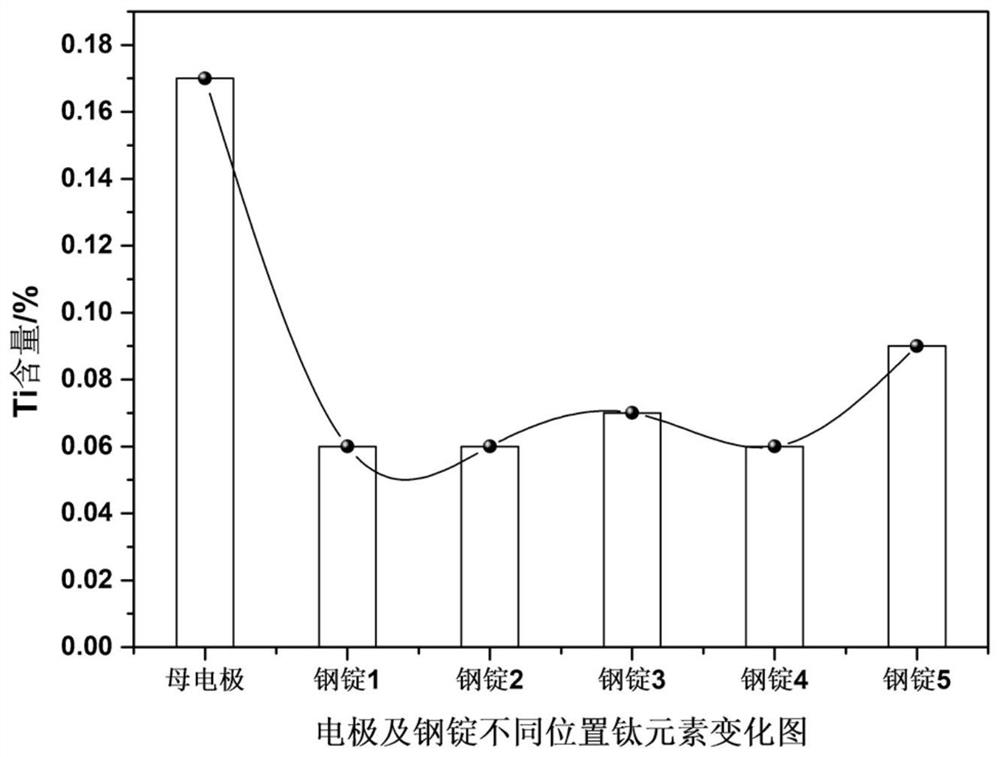

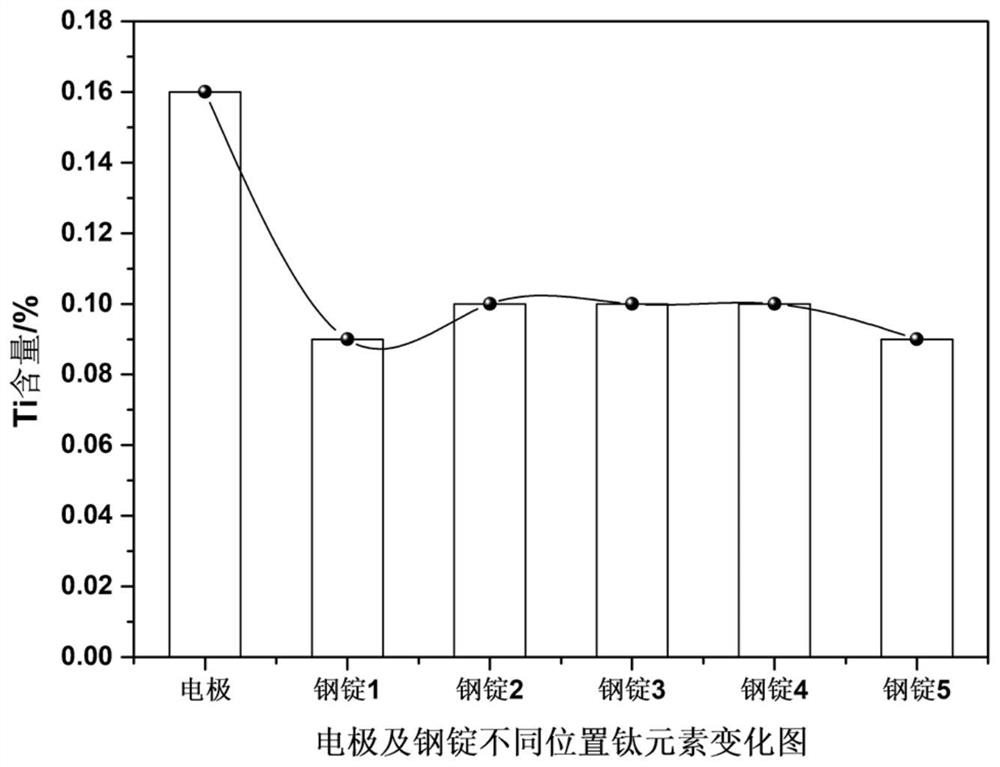

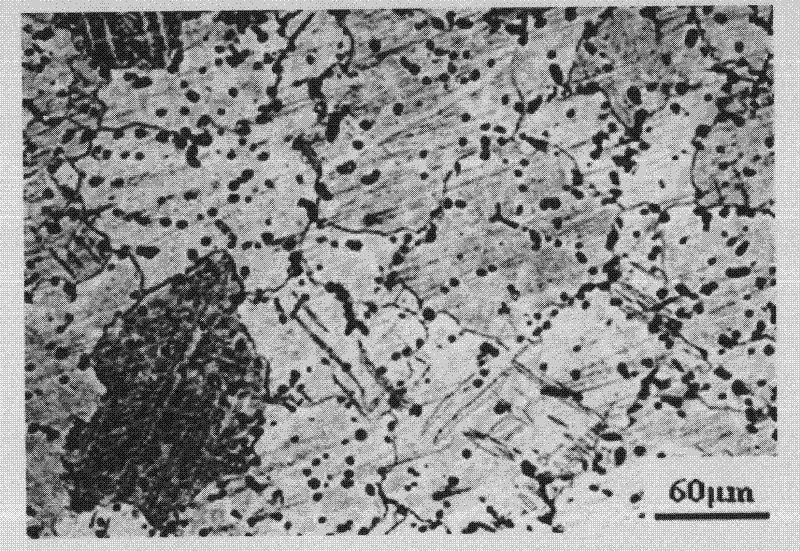

Ultra-pure smelting process for low-carbon ultra-low-titanium high-strength steel

InactiveCN112458303AStrength and toughness matchingUniform distribution of titanium contentIncreasing energy efficiencySmelting processTitanium

The invention discloses an ultra-pure smelting process for low-carbon ultra-low-titanium high-strength steel. The ultra-pure smelting process comprises the following steps: controlling the oxygen content of an electroslag metal molten pool, controlling the oxygen content of a primary electrode, adding a certain amount of aluminum element of which the activity is higher than that of titanium into the electrode, adding a certain amount of titanium dioxide powder into the rear half section of the electroslag remelting process, and the like. It is ensured that the titanium content after electroslag remelting reaches the technical standard and is uniformly distributed. The ultra-pure smelting process has the implementation effects that aluminum is burnt and titanium is protected in the electroslag remelting process, the titanium content deviation at the head and the tail of an electroslag ingot is + / -0.02%, the overall titanium content of the steel ingot is uniformly distributed, and the strength and toughness matching of the steel is ensured. The ultra-pure smelting process has greater engineering application value for component control of the alloy structural steel with ultra-low content of active alloy elements narrow in component control.

Owner:FUSHUN SPECIAL STEEL SHARES

Magnesium alloy refiner and preparation method thereof

The invention discloses a magnesium alloy refiner and a preparation method thereof, and relates to a grain refiner and a preparation method thereof. The method solves the problems that an overheating treatment method of the existing magnesium alloy refining method has strict condition requirement, the oxidation burning loss of magnesium is serous, a carbon-containing material treatment method hashigh temperature and produces harmful gases such as Cl2, HCl and the like, a ferric chloride method reduces the corrosion resistance of the magnesium alloy, an alloying method has high cost, a granular graphite or aluminium carbide granule method is easy to produce segregation on the grain boundary and a Zr element method has narrow application range. The magnesium alloy refiner is prepared from a calcium metal and a primary magnesium ingot. The preparation method comprises the following steps: heating and melting the primary magnesium ingot under atmospheric protection, then adding the calcium metal into the melted primary magnesium ingot, dissolving the calcium metal and stirring the mixture uniformly, and casting the mixture to form the magnesium alloy refiner. The magnesium alloy refiner has no burning loss, does not produce the harmful gases, has no influence on the corrosion resistance of the magnesium alloy, has low cost, is uniformly distributed in the alloy, can improve the mechanical property of the alloy, and is used for refining the magnesium alloy.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com