Carbon fiber with C-Si-Al coating on surface for gradient sintering protection of precursor as well as preparation method and application thereof

A c-si-al, carbon fiber technology, applied in coating, metal material coating process, ion implantation plating, etc., to achieve the effect of simple and easy-to-control preparation process, low substrate temperature, and guaranteed mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

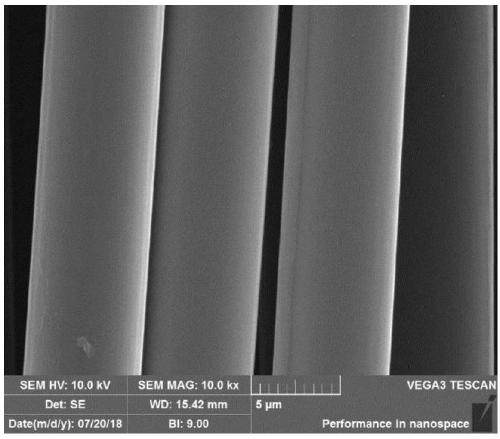

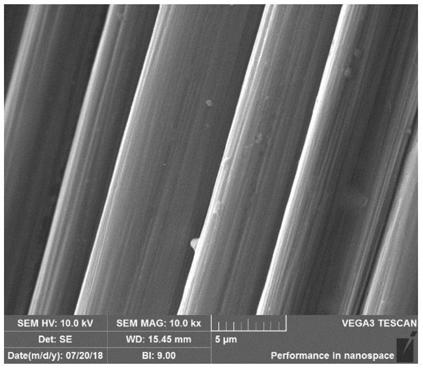

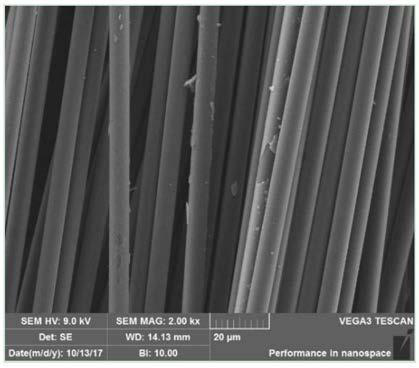

Image

Examples

preparation example Construction

[0044] A kind of preparation method that the surface has the carbon fiber of precursor gradient sintering protection C-Si-Al coating, comprises the following steps:

[0045] Step 1, CF cleaning to remove the glue on the surface of CF: In a digitally controlled ultrasonic cleaner, clean CF with pure water, absolute ethanol, acetone and distilled water at room temperature in sequence. During the cleaning process, the ultrasonic frequency is set to 60.0kHz, the power is set to 80.0W, and the ultrasonic cleaning time is 30.0min;

[0046] Step 2, mixed acid modification treatment: completely immerse the cleaned CF in nitric acid (HNO 3 ), hydrochloric acid (HCl) and sulfuric acid (H 2 SO 4 ) in a mixed acid solution composed of a certain proportion, after ultrasonic treatment at room temperature for 2 hours, take it out and wash it with distilled water, set the ultrasonic frequency and power to 60.0KHz and 80.0W respectively, to obtain mixed acid modified CF;

[0047] Step 3, al...

Embodiment 1

[0064] A kind of preparation method that the surface has the carbon fiber of precursor gradient sintering protection C-Si-Al coating, comprises the following steps:

[0065] Step 1, CF cleaning: In a digitally controlled ultrasonic cleaner, clean a certain quality of CF with pure water, absolute ethanol, acetone and distilled water at room temperature. During the cleaning process, the ultrasonic frequency is set to 60.0kHz, the power is set to 80.0W, and the ultrasonic cleaning time is 30.0min;

[0066] Step 2, mixed acid modification treatment: the CF after ultrasonic cleaning in step 1 was completely immersed in nitric acid (HNO 3 ), hydrochloric acid (HCl) and sulfuric acid (H 2 SO 4 ) in a mixed acid solution with a ratio of 1:1:1, after ultrasonic treatment at room temperature for 2 hours, take it out and wash it with distilled water, and the ultrasonic frequency and power are set to 60.0KHz and 80.0W, respectively.

[0067] Step 3, alkali treatment: The mixed acid-mod...

Embodiment 2

[0078] A kind of preparation method that the surface has the carbon fiber of precursor gradient sintering protection C-Si-Al coating, comprises the following steps:

[0079]Step 1, CF cleaning: In a digitally controlled ultrasonic cleaner, clean a certain quality of CF with pure water, absolute ethanol, acetone and distilled water at room temperature. During the cleaning process, the ultrasonic frequency is set to 60.0kHz, the power is set to 80.0W, and the ultrasonic cleaning time is 30.0min;

[0080] Step 2, mixed acid modification treatment: the CF after ultrasonic cleaning in step (1) was completely immersed in nitric acid (HNO 3 ), hydrochloric acid (HCl) and sulfuric acid (H 2 SO 4 ) in a mixed acid solution with a ratio of 1:1:1, after ultrasonic treatment at room temperature for 2 hours, take it out and wash it with distilled water, and the ultrasonic frequency and power are set to 60.0KHz and 80.0W, respectively.

[0081] Step 3, alkali treatment: completely immers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com