Technique for preparing chromium zirconium copper alloy wire pole

A preparation process, a technology of chromium-zirconium copper, which is applied in the field of non-vacuum short-process preparation of chromium-zirconium alloy wire rods and chromium-zirconium-copper alloy wire rods, can solve problems such as difficult feeding, unfavorable feeding and observation, and inability to obtain component alloys. Achieve the effects of reducing liquid level fluctuations, significant economic benefits and social effects, and preventing melt convection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

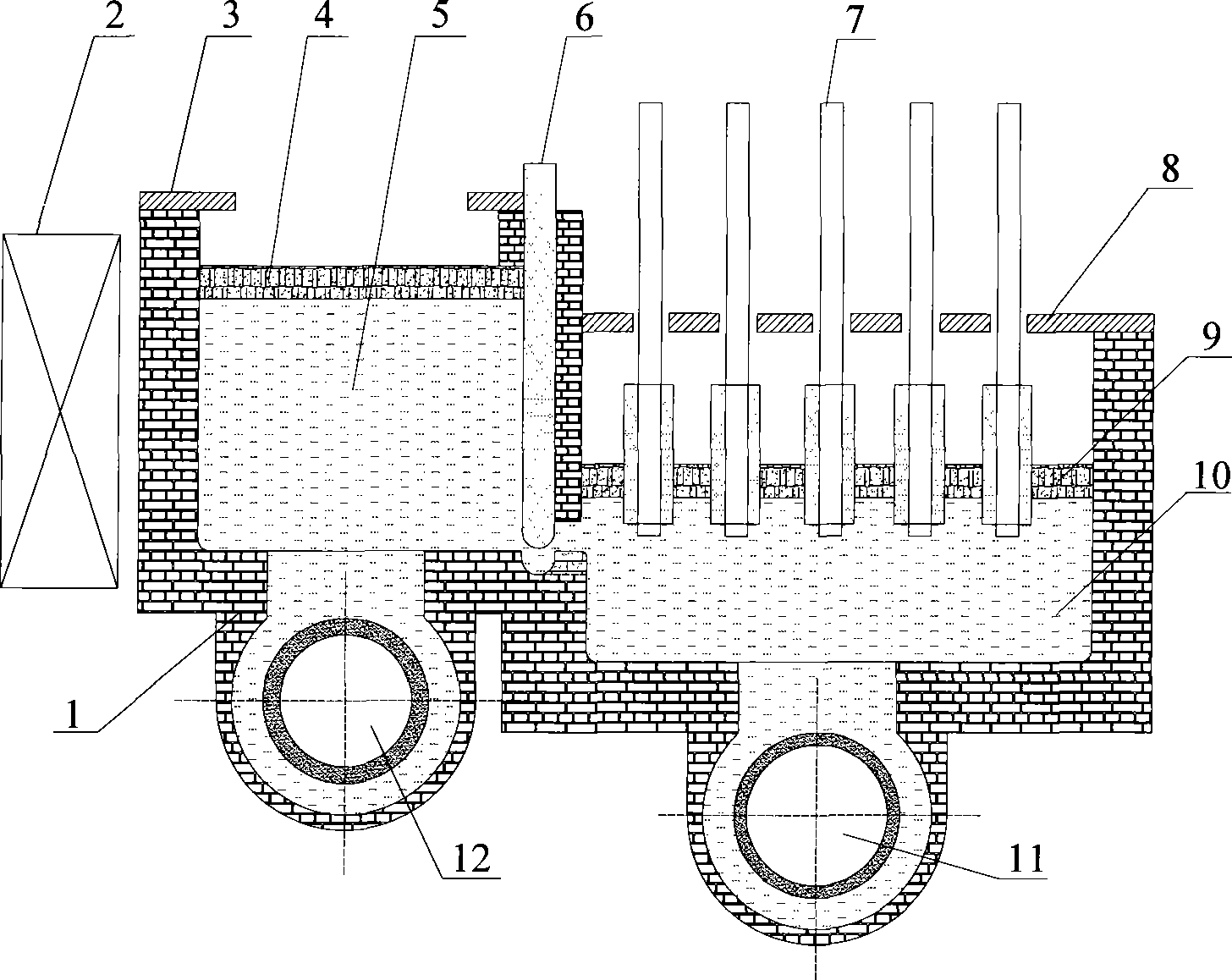

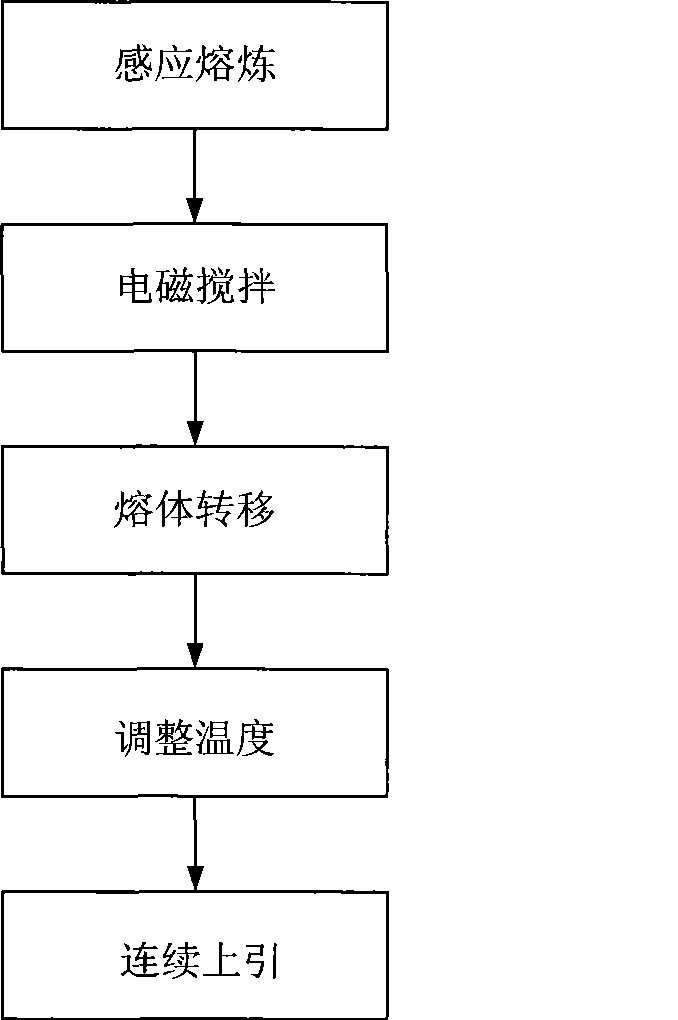

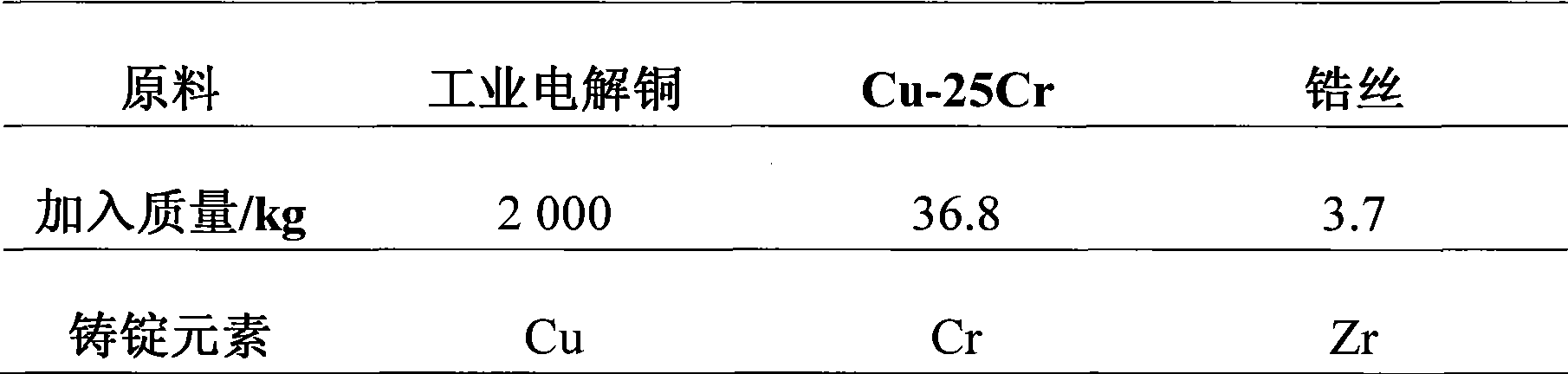

[0030] Take industrial electrolytic copper, copper-chromium master alloy and zirconium wire respectively according to Table 1, and prepare 2000kg furnace charge. First of all, induction melting, feed 2000kg and heat up to melt, cover with graphite powder and charcoal, start electromagnetic stirring after almost melting, assist deoxidation; after complete melting, add copper-chromium master alloy and zirconium wire to heat up and melt. And carry out electromagnetic stirring, not only when melting industrial electrolytic copper, but also after adding copper-chromium master alloy and zirconium wire, so that the composition of the added alloy melt is uniform. Then the melt is transferred, and after the composition reaches the standard, the melt is transferred to the holding furnace. After the official operation, new materials are generally added according to the ratio and burning loss rate, and it is not necessary to check the composition every time. Then adjust the temperature, a...

Embodiment 2

[0036]Take industrial electrolytic copper, copper-chromium master alloy and zirconium wire respectively according to Table 1, and prepare 3000kg furnace charge. First of all, induction melting, feed 3000kg and heat up to melt, cover with graphite powder and charcoal, start electromagnetic stirring after almost melting, assist deoxidation; after complete melting, add copper-chromium master alloy and zirconium wire to heat up and melt. And carry out electromagnetic stirring, not only when melting industrial electrolytic copper, but also after adding copper-chromium master alloy and zirconium wire, so that the composition of the added alloy melt is uniform. Then the melt is transferred, and after the composition reaches the standard, the melt is transferred to the holding furnace. After the official operation, new materials are generally added according to the ratio and burning loss rate, and it is not necessary to check the composition every time. Then adjust the temperature, an...

Embodiment 3

[0041] Take industrial electrolytic copper, copper-chromium master alloy, and zirconium wire respectively according to Table 1, and prepare 4000 kg of charge. First of all, induction melting, feed 4000kg and heat up to melt, cover with graphite powder and charcoal, and start electromagnetic stirring after melting to assist deoxidation; after complete melting, add copper-chromium master alloy and zirconium wire to heat up and melt. And carry out electromagnetic stirring, not only when melting industrial electrolytic copper, but also after adding copper-chromium master alloy and zirconium wire, so that the composition of the added alloy melt is uniform. Then the melt is transferred, and after the composition reaches the standard, the melt is transferred to the holding furnace. After the official operation, new materials are generally added according to the ratio and burning loss rate, and it is not necessary to check the composition every time. Then adjust the temperature, and a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com