Ultra-pure smelting process for low-carbon ultra-low-titanium high-strength steel

An ultra-low titanium, high-strength steel technology, applied in the field of alloy steel special smelting process, can solve the problems of titanium burning loss, difficulty in controlling the uniform distribution of titanium elements, large differences in titanium chemical composition, etc., to ensure strong and toughness matching, large engineering The effect of chemical application value and uniform distribution of titanium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] In embodiment 1, embodiment 2, embodiment 3, the vacuum induction furnace batching is jointly pressed by 0.17% by carbon, by 0.9% by manganese, by 0.3% by silicon, by 1.7% by chromium, by 1.6% by nickel, by 0.1% by aluminum and entering, The dosage of titanium is 0.17%.

[0012] Example 1

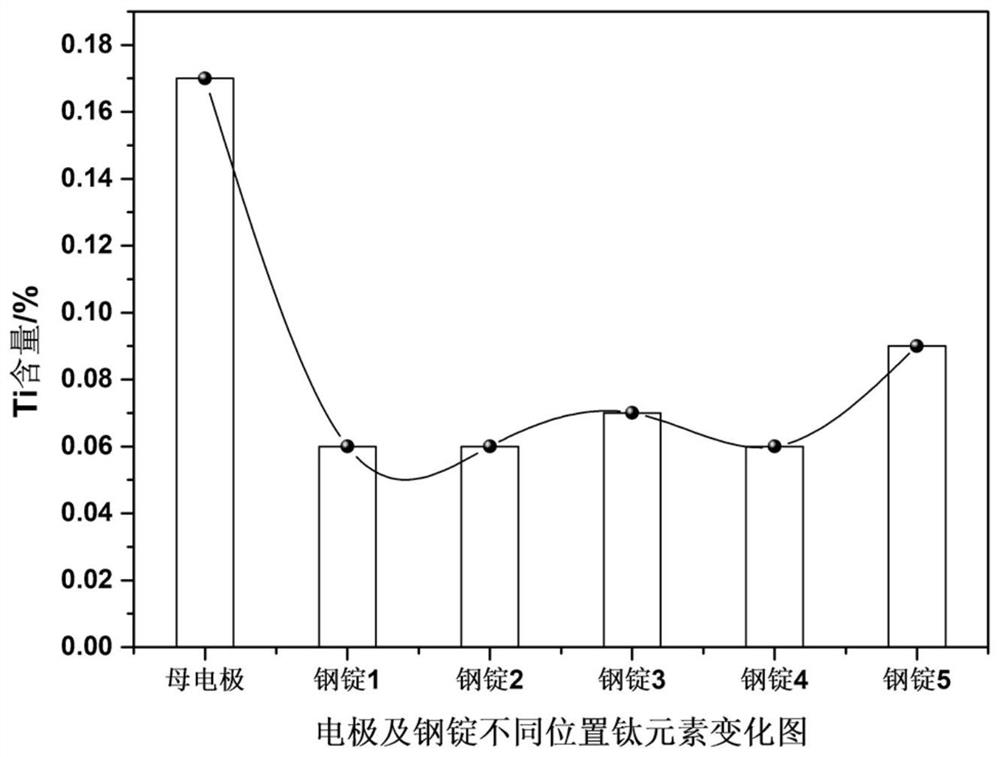

[0013] Ti-1 steel through vacuum induction + electroslag remelting Φ330 steel ingot specific steps: electrode titanium is 0.17%, [oxygen] is 10×10 -6 , [nitrogen] is 17×10 -6 ; During electroslag remelting, the electroslag furnace is filled with argon gas at a large flow half an hour in advance, and the flow rate of argon gas is added at 35L / min, and the purified slag-based Al 2 o 3 :CaF 2 = Add at 30:70, the amount of slag is 34kg, the melting speed of the steel ingot is controlled at 4.5kg / min, and titanium dioxide powder is added at 2g / min in the second half of electroslag remelting.

[0014] Chemical composition (%) of Ti-1 steel after remelting: carbon is 0.165 / 0.167, manga...

Embodiment 2

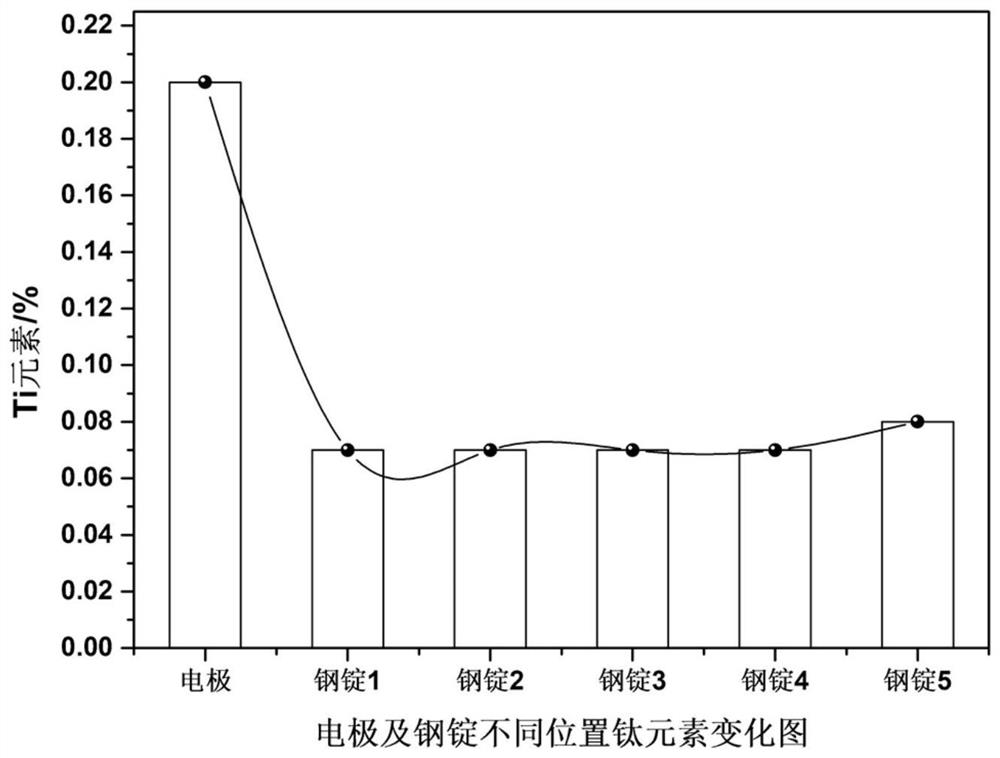

[0017] Ti-2 steel vacuum induction + electroslag remelting Φ330 steel ingot specific steps: electrode titanium is 0.20%, [oxygen] is 8×10 -6 , [Nitrogen] is 15×10 -6 ; During electroslag remelting, the electroslag furnace is filled with argon gas at a large flow rate half an hour in advance, and the flow rate of argon gas is added at 30L / min, and the purified slag-based Al 2 o 3 :CaF 2 = Add at 30:70, the amount of slag is 34kg, the melting speed of the steel ingot is controlled at 5.0kg / min, and titanium dioxide powder is added at 2g / min in the second half of electroslag remelting.

[0018] Chemical composition (%) of Ti-2 steel after remelting: carbon is 0.173 / 0.168, manganese is 0.87 / 0.88, silicon is 0.32 / 0.29, sulfur is 0.001, phosphorus is 0.005, nickel is 1.63, chromium is 1.72, aluminum is 0.04 / 0.03, titanium is 0.08 / 0.07, [oxygen] is 14×10 -6 , [Nitrogen] is 26×10 -6 , [Hydrogen] is 1×10 -6 ; The head, tail and middle of the Φ330 steel ingot are divided into 5 p...

Embodiment 3

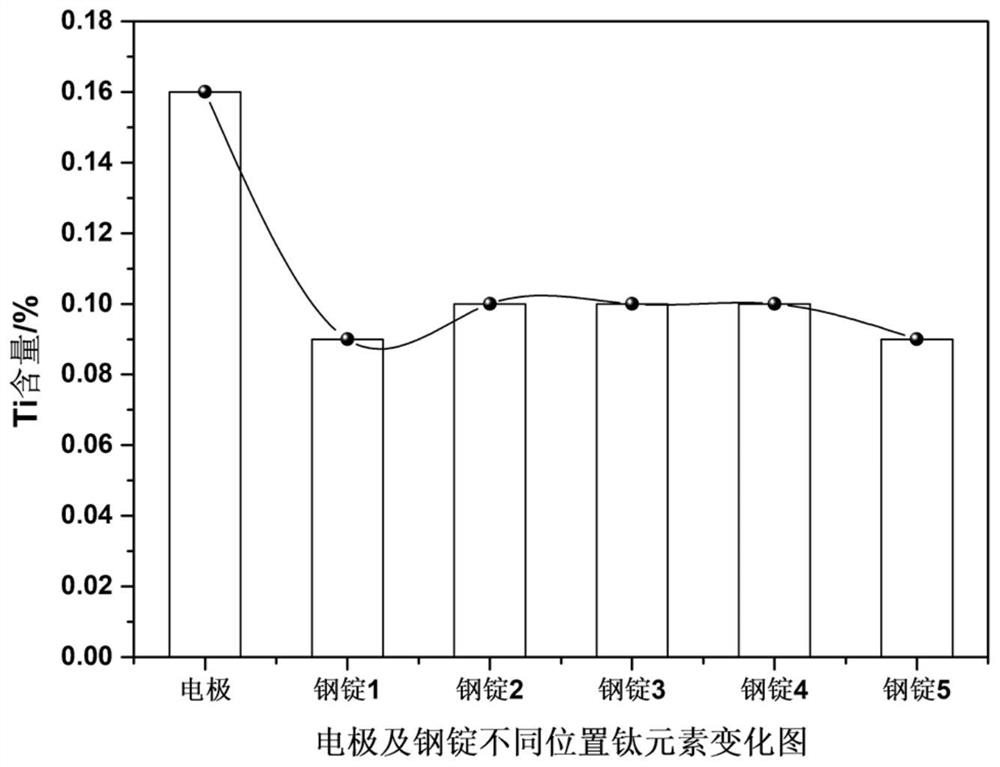

[0021] Ti-3 steel vacuum induction + electroslag remelting Φ330 steel ingot specific steps: electrode titanium is 0.16%, [oxygen] is 10×10 -6 , [Nitrogen] is 15×10 -6 ; During electroslag remelting, the electroslag furnace is filled with argon gas at a large flow half an hour in advance, and the flow rate of argon gas is added at 35L / min, and the purified slag-based Al 2 o 3 :CaF 2 = Add at 30:70, the amount of slag is 34kg, the melting speed of the steel ingot is controlled at 4.5kg / min, and titanium dioxide powder is added at 2g / min in the second half of electroslag remelting.

[0022] Chemical composition (%) of Ti-1 steel after remelting: carbon is 0.162 / 0.155, manganese is 0.84 / 0.89, silicon is 0.36 / 0.29, sulfur is 0.001, phosphorus is 0.004, nickel is 1.62, chromium is 1.67, aluminum is 0.05 / 0.03, titanium is 0.09 / 0.09, [oxygen] is 18×10 -6 , [Nitrogen] is 22×10 -6 , [Hydrogen] is 1×10 -6 ; The head, tail and middle of the Φ330 steel ingot were sampled at 5 points...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Impact absorption energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com