Steel for 440MPa-grade polar ship body and preparation method thereof

A hull and ferrite technology, applied in manufacturing tools, temperature control, heat treatment equipment, etc., can solve problems such as high strength, high toughness, good weldability, impact resistance, etc. at the same time, achieve excellent mechanical properties, and inhibit growth , good weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0023] The invention provides a 440MPa polar hull steel suitable for polar environment and its preparation method. The marine steel has the characteristics of high strength, high and low temperature toughness and easy welding, etc., and is used to solve the problem that the existing steel plates cannot meet the use conditions of the polar environment temperature The problem.

[0024] The steel for the 440MPa polar ship hull provided by the invention has yield strength ≥ 440MPa, tensile strength ≥ 550MPa, elongation ≥ 26%, impact energy at -60°C ≥ 200J, section fiber % ≥ 90%.

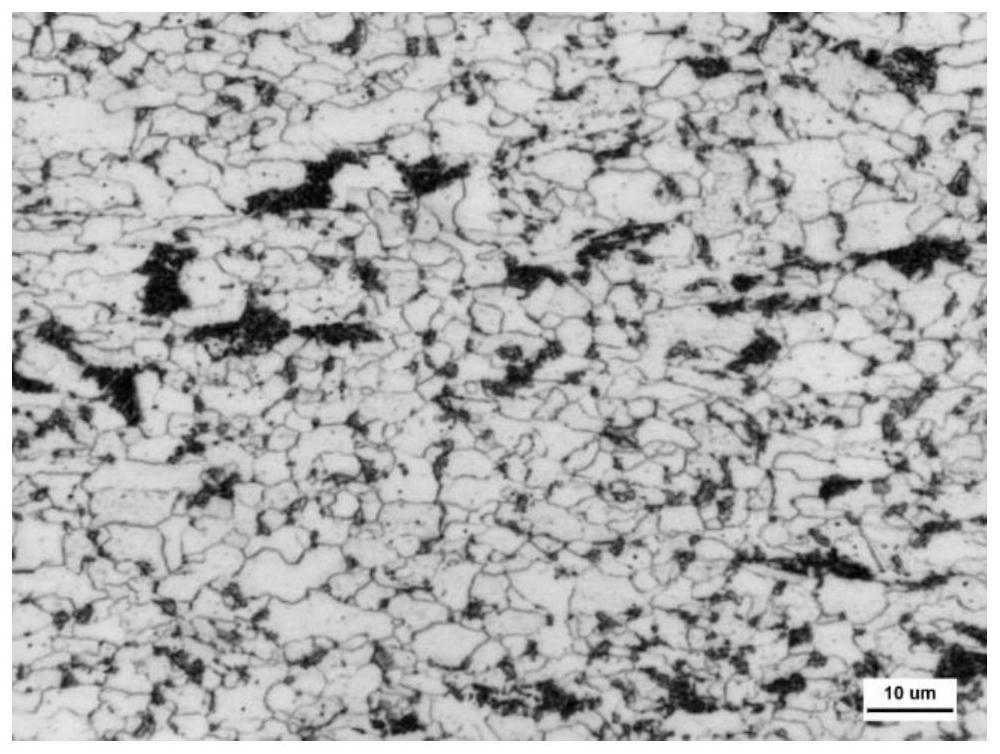

[0025] Specifically, the microstructure of the steel is ferrite and pearlite, and the average ferrite grain size is ≤8 μm.

[0026] It should be noted that the ferrite content is not less than 75%. The strength of ferrite is lower, but its plasticity and toughness are better. The strength of pearlite is higher than that of ferrite, but its plasticity and toughness are lower than that of ferrite. Guaran...

Embodiment 1

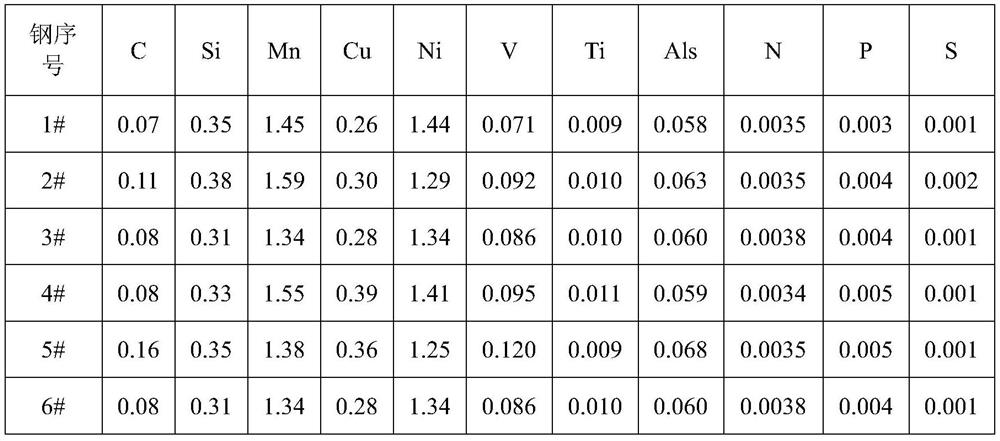

[0050] This embodiment discloses six kinds (1#-6# steel) of 440MPa grade ship hull steel suitable for polar environment.

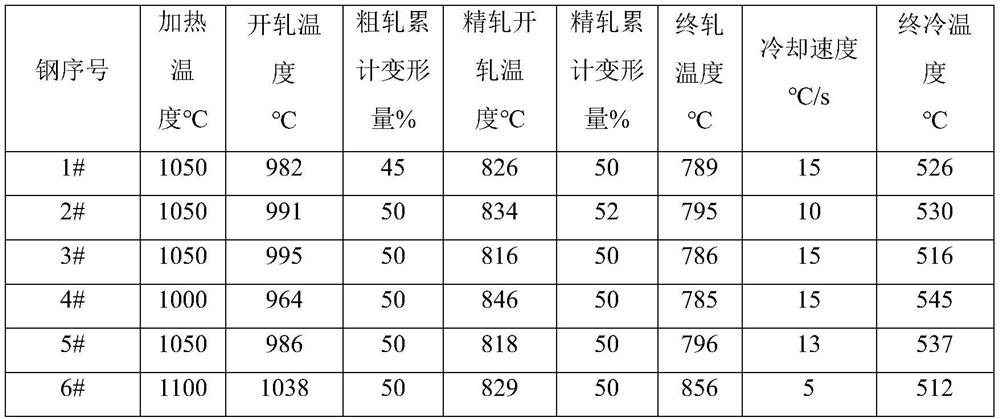

[0051] 1#-5# all adopt the same process: (1) after KR desulfurization; (2) converter smelting + LF refining; (3) continuous casting: target superheat of tundish molten steel ≤ 25 ℃, enter slow cooling pit after continuous casting (4) Controlled rolling and controlled cooling: the slab is heated at a low temperature, the heating temperature is between 1000-1050°C, the heating time is 180-240min, and the controlled rolling adopts a two-stage rolling method: the first stage is recrystallization Zone rolling, the rolling start temperature is 964-995°C, the cumulative deformation is 45%-50%, and the recrystallization of coarse austenite grains is promoted through deformation. The second stage is rolling in the non-recrystallized zone. The starting rolling temperature is 816-846°C, the cumulative deformation is 50%-52%, and the final rolling temperature is 785°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Impact energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com