A kind of production method of high strength and toughness bridge structure steel plate

A bridge structure and production method technology, applied in heat treatment equipment, manufacturing tools, heat treatment process control and other directions, can solve the problems of high carbon equivalent, poor welding performance, high residual stress of steel plates, prevent mixed crystals, improve tensile strength, The effect of reducing the yield ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

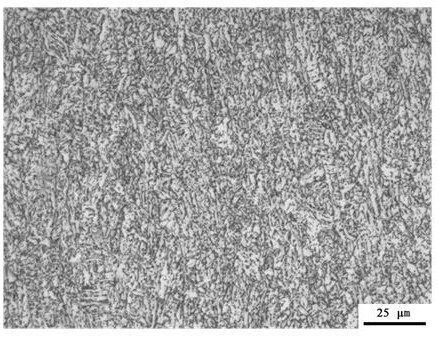

Image

Examples

Embodiment 1

[0016] Example 1: The production method of steel plate with a thickness of 32mm

[0017] The chemical composition and weight percentage of steel are C=0.05%, Si=0.40%, Mn=1.65%, P=0.010%, S=0.002%, Al=0.035%, Ti=0.016%, Nb=0.045%, Cr= 0.42%, Cu=0.12%, the balance is Fe and inevitable impurity elements; the key process steps include:

[0018] (1) Heating: The continuous casting billet is cooled to room temperature and then heated by cold loading. The soaking temperature is 1230℃ and the soaking time is 45min;

[0019] (2) Rolling: Two-stage controlled rolling is adopted, the finishing temperature of rough rolling is 1000℃, the starting temperature of finishing rolling is 900℃, the final rolling temperature of finishing rolling is 760℃, and the accumulative reduction rate of finishing rolling is 95.1%;

[0020] (3) Hot straightening: hot straightening is carried out after final rolling, the straightening speed is 0.5m / s, the straightening inlet roll gap is 29.2mm, and the outle...

Embodiment 2

[0025] Example 2: The production method of the steel plate with a thickness of 20mm

[0026] The chemical composition and weight percentage of steel are: C=0.05%, Si=0.45%, Mn=1.60%, P=0.008%, S=0.003%, Al=0.046%, Ti=0.012%, Nb=0.035%, Cr =0.40%, the balance is Fe and inevitable impurity elements; the key process steps include:

[0027] (1) Heating: The continuous casting billet is cooled to room temperature and then heated by cold loading. The soaking temperature is 1240℃ and the soaking time is 32min;

[0028] (2) Rolling: Two-stage controlled rolling is adopted, the finishing temperature of rough rolling is 980℃, the starting temperature of finishing rolling is 915℃, the final rolling temperature of finishing rolling is 765℃, and the accumulative reduction rate of finishing rolling is 112.3%;

[0029] (3) Hot straightening: hot straightening is carried out after final rolling, the straightening speed is 0.5m / s, the straightening inlet roll gap is 16.8mm, and the outlet rol...

Embodiment 3

[0033] Example 3: The production method of steel plate with a thickness of 50mm

[0034]The chemical composition and weight percentage of steel are: C=0.07%, Si=0.35%, Mn=1.72%, P=0.011%, S=0.002%, Al=0.038%, Ti=0.020%, Nb=0.051%, Cr =0.40%, Cu=0.15%, the balance is Fe and inevitable impurity elements; the key process steps include:

[0035] (1) Heating: The continuous casting billet is cooled to room temperature and then heated by cold loading. The soaking temperature is 1240°C and the soaking time is 50min;

[0036] (2) Rolling: Two-stage controlled rolling is adopted, the finishing temperature of rough rolling is 1030℃, the starting temperature of finishing rolling is 880℃, the final rolling temperature of finishing rolling is 770℃, and the accumulative reduction rate of finishing rolling is 73.8%;

[0037] (3) Hot straightening: hot straightening is carried out after final rolling, the straightening speed is 0.5m / s, the straightening inlet roll gap is 47.7mm, and the outl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com