Patents

Literature

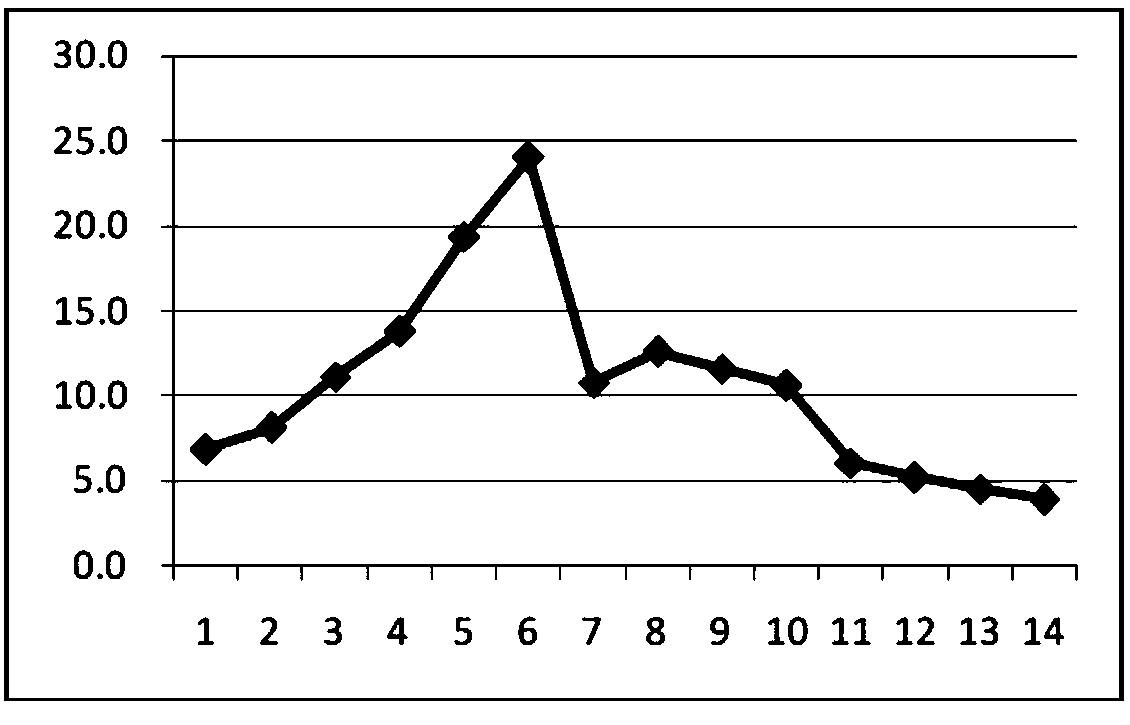

44 results about "Crack tip opening displacement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

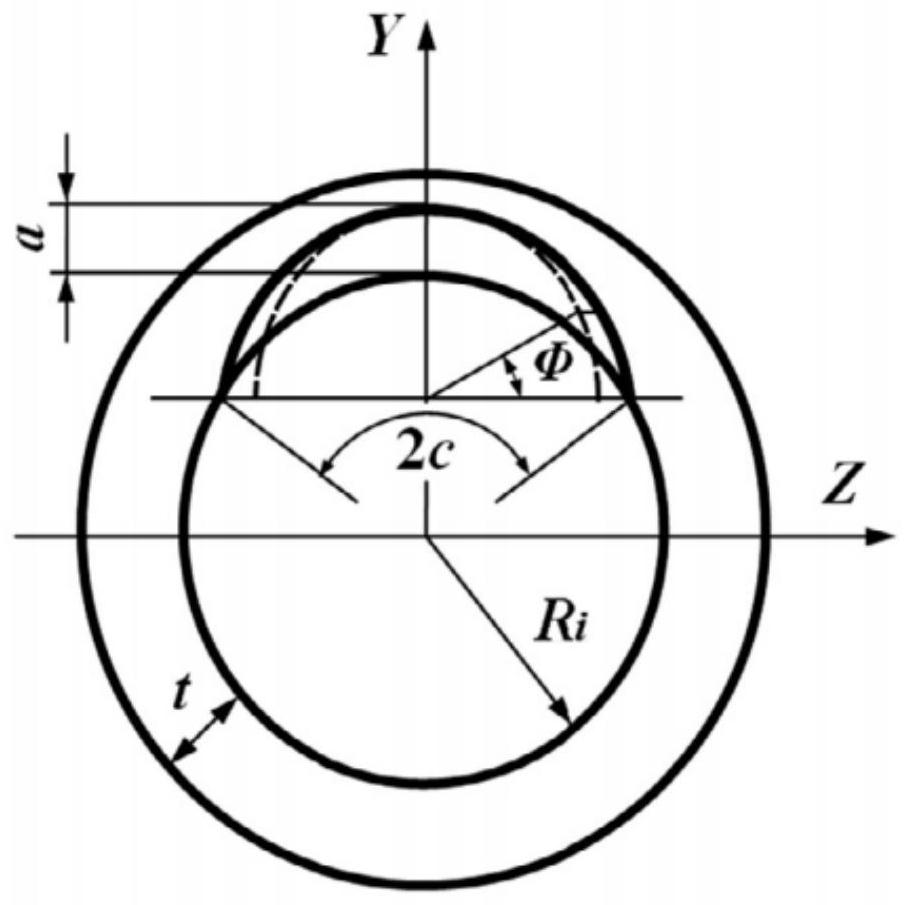

Crack tip opening displacement (CTOD) or δₜ is the distance between the opposite faces of a crack tip at the 90° intercept position. The position behind the crack tip at which the distance is measured is arbitrary but commonly used is the point where two 45° lines starting at the crack tip and intercepting the crack faces. The parameter is used in Fracture mechanics to characterise the loading on a crack and can be related to other crack tip loading parameters such as the stress intensity factor K and the elastic-plastic J-integral.

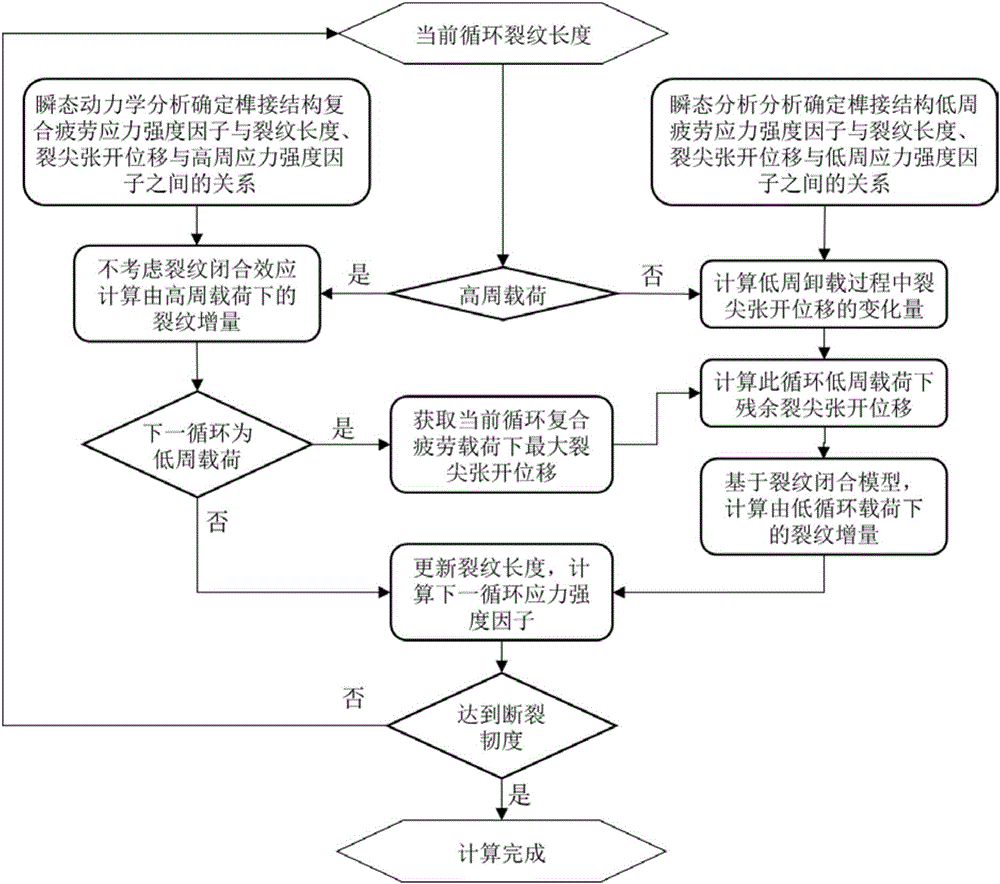

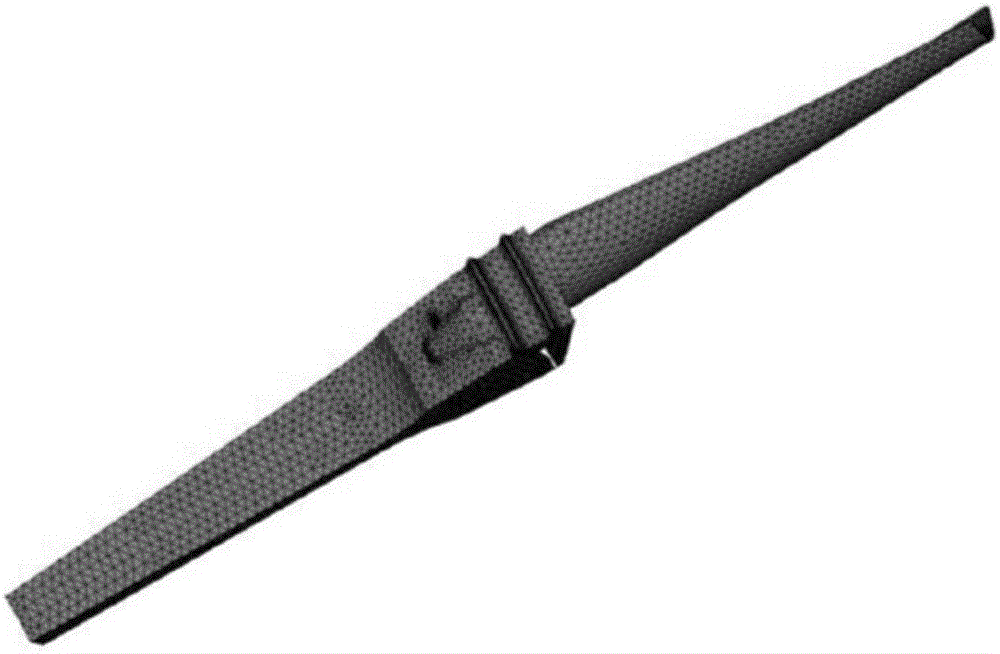

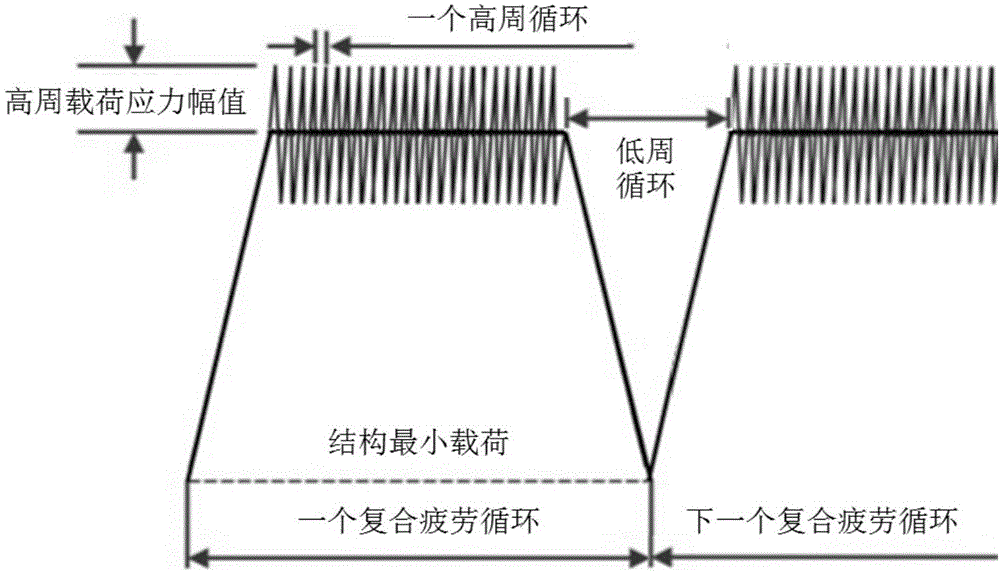

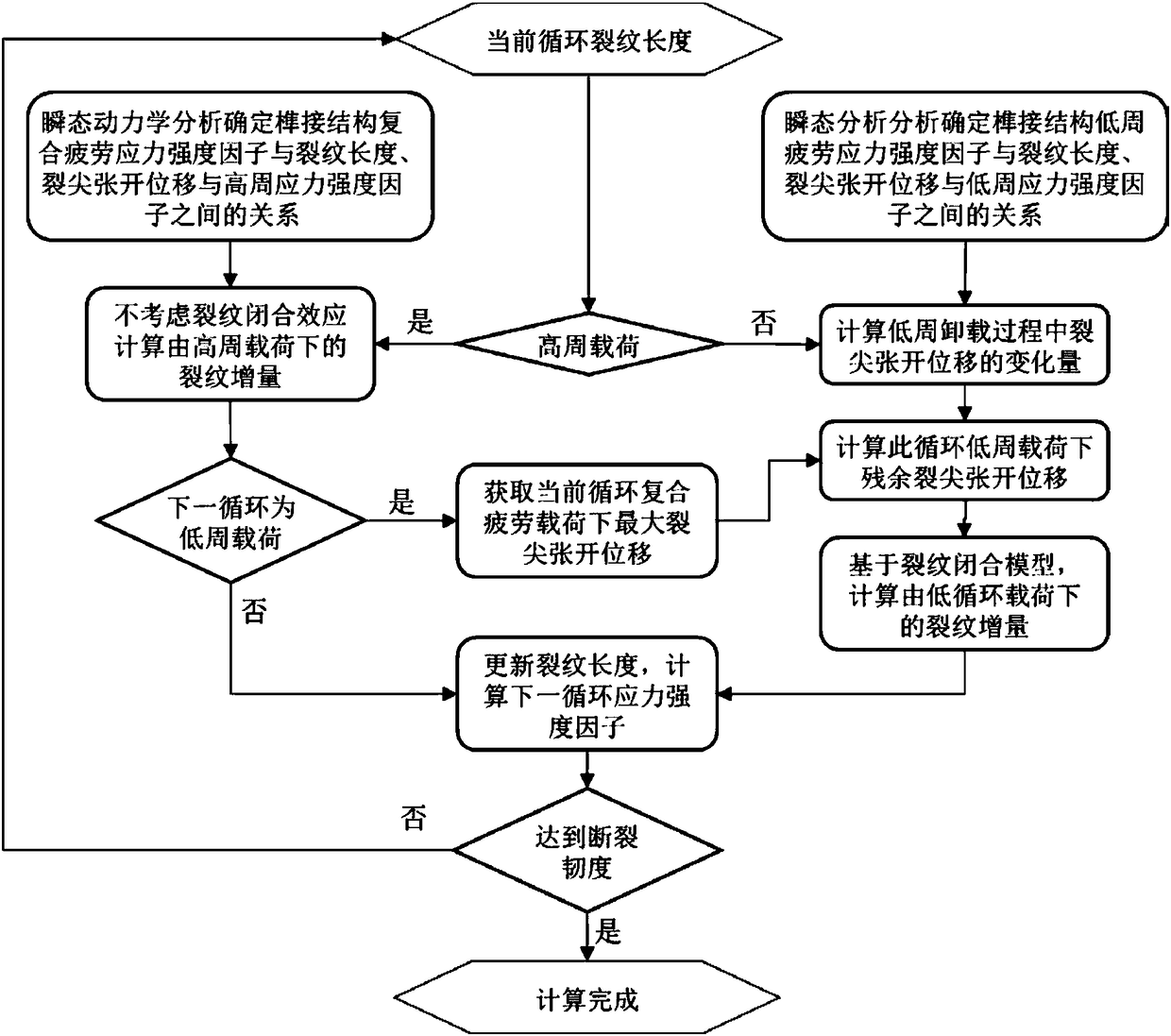

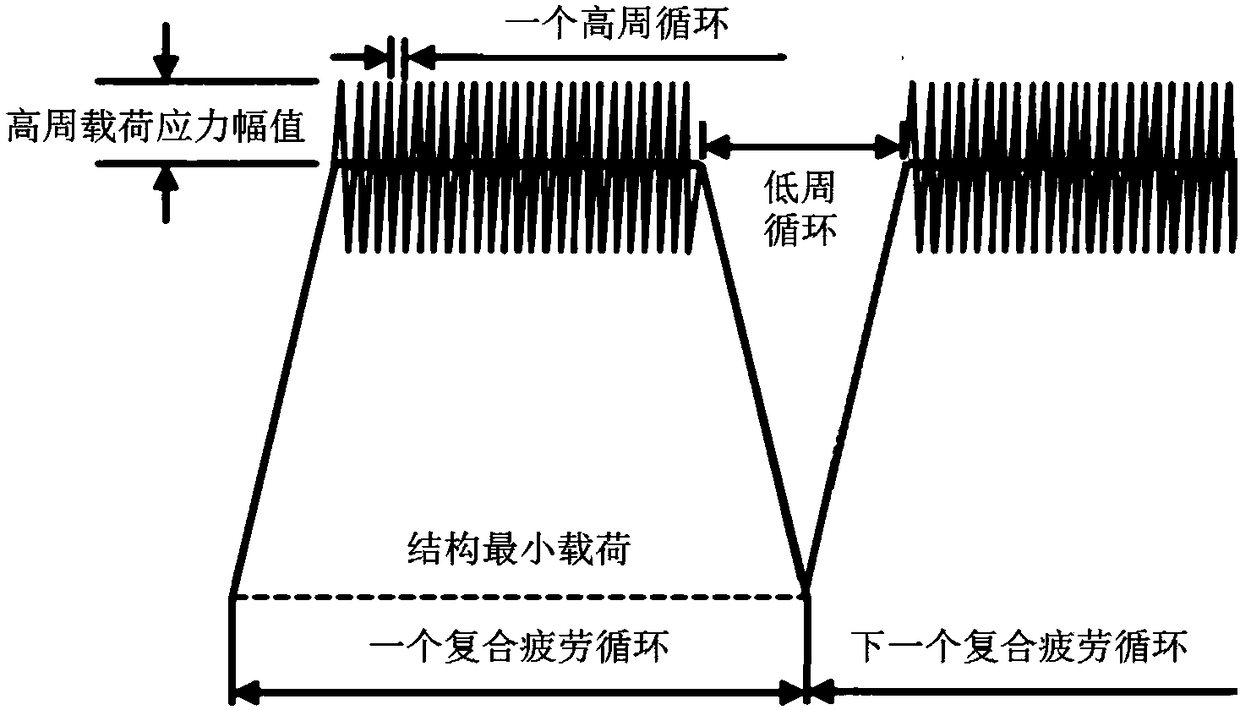

Method for predicting high-low-cycle composite fatigue crack growth life of turbine joggle structure

ActiveCN106644490AImprove scalabilityInhibit expansionEngine testingCrack tip opening displacementEngineering

The invention relates to a method for predicting the high-low-cycle composite fatigue crack growth life of a turbine joggle structure, and the method comprises the steps: (1), building a crack growth model giving consideration to a crack closure effect; (2), determining a high-cycle load stress intensity factor model; (3), determining a low-cycle load stress intensity factor model; (4), judging whether a current cycle is a high-cycle load or not: executing step (5) if the current cycle is the high-cycle load, or else executing step (6); (5), calculating a composite fatigue lower crack increment, judging whether a next cycle is a low-cycle fatigue load or not: obtaining the maximum crack tip opening displacement of the current cycle if the next cycle is the low-cycle fatigue load, and executing step (7), or else executing step (8); (6), calculating the variance of the low-cycle load lower crack tip opening displacement; (7), calculating the residual crack tip opening displacement and crack increment according to the results inputted at steps (5) and (6); (8), updating the crack length, repeatedly carrying out the steps (4)-(7) if the maximum stress intensity factor is less than the fracture toughness, or else completing the calculation, and obtaining the crack growth life.

Owner:BEIHANG UNIV

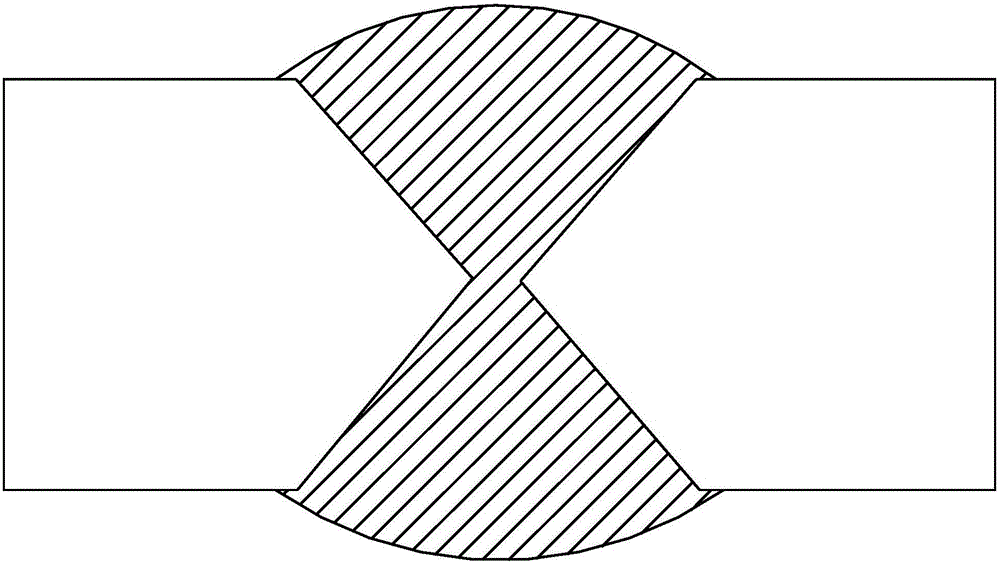

Novel welding repair CTOD (crack tip opening displacement) experimental method

ActiveCN105115802AHigh success rate of preparationExpanded bevel form rangePreparing sample for investigationStrength propertiesHeat-affected zoneExperimental methods

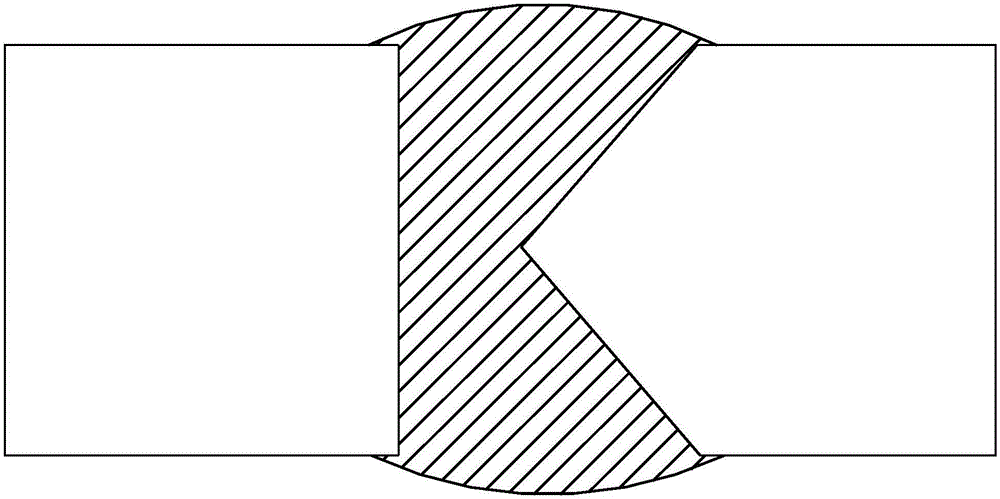

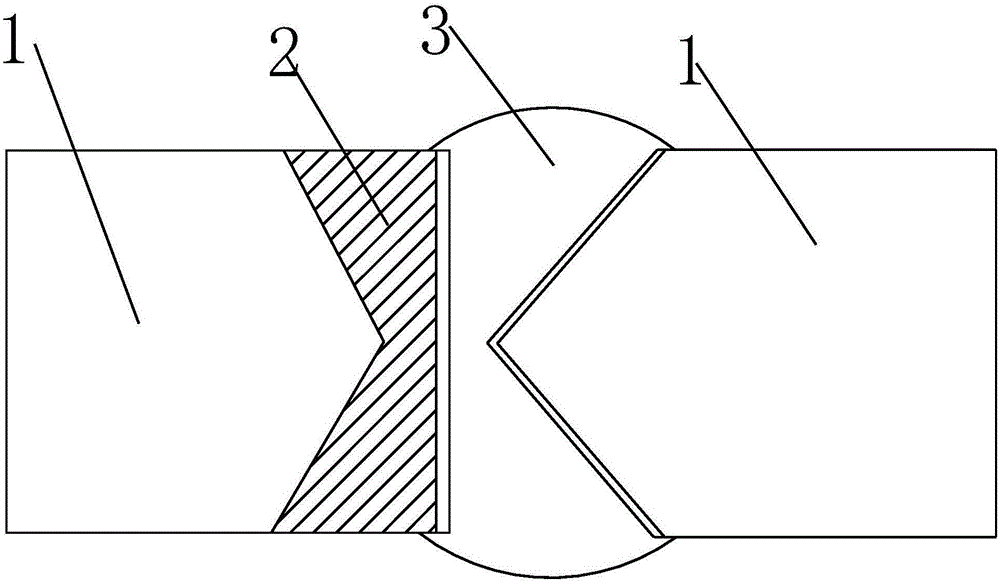

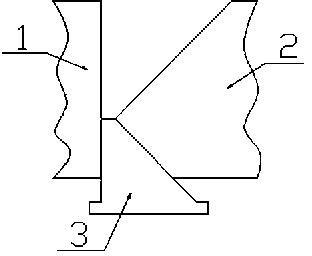

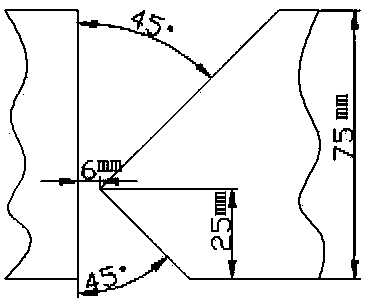

The invention discloses a novel welding repair CTOD (crack tip opening displacement) experimental method. The experimental method is characterized in that X and K type prefabricated weld grooves are adopted for welding of a prefabricated weld seam; a K type repair weld groove is adopted for the CTOD experiment of a welding heat affected zone; X and V type repair weld grooves are adopted for the CTOD experiment of a weld zone, the advantages of the two are combined, therefore the CTOD fracture toughness value of the most fragile part of a connector can be accurately evaluated, and the performance of a welded joint can be ensured. According to the novel welding repair CTOD (crack tip opening displacement) experimental method, provided by the invention, the form scope of a prefabricated weld groove is enlarged, the success rate of preparation of an effective CTOD sample for a welding heat affected zone can be increased, the application range is wider and the cost is lower.

Owner:PENGLAI JUTAL OFFSHORE ENG HEAVY IND CO LTD

Welding method for steel plate of ocean platform

InactiveCN104384670AAvoid arcingImprove welding efficiencyWelding/soldering/cutting articlesMetal working apparatusCrack tip opening displacementEngineering

The invention provides a technical scheme for a welding method for a steel plate of an ocean platform. The welding method comprises the following steps: 1) processing an edge; 2) assembling the edge into a K-shaped edge and fixing a water-cooling copper strip on the rear side of the edge, wherein the water-cooling copper strip is used for lifting a molten pool during a front backing weld process; 3) during the front backing weld process, preventing the water-cooling copper strip from upward arcing at a welding moment; 4) performing rear backing weld; 5) performing filling welding: alternately performing front and rear filling welding by using flux cored wire gas shielded welding or submerged-arc welding according to the condition of angular deformation of a welded steel plate; 6) performing cosmetic welding: using the flux cored wire gas shielded welding or the submerged-arc welding. The K-shaped edge in asymmetrical depths is adopted; the water-cooling copper strip is used for lifting the molten pool during the front backing weld process; a distance from a welding wire to a straight edge side of the edge is strictly controlled by the filling welding; the lower welding heat input is adopted for the cosmetic welding, and a welding joint with the welding joint forming meeting the CTOD (crack tip opening displacement) test demand on the welding joint of the steel plate of the ocean platform is lastly acquired.

Owner:SHANDONG IRON & STEEL CO LTD

Ni-series low-temperature steel, manufacture method thereof, liquefied natural gas storage tank and ship body for transportation ship

The invention provides Ni-series low-temperature steel, a manufacture method thereof, a liquefied natural gas storage tank and a ship body for a transportation ship. The Ni-series low-temperature steel includes the following chemical compositions by mass percentage: 0.02-0.10% of C, 0.01-0.20% of Si, 0.50-0.75% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 8.50-9.50% of Ni, 0.005-0.40% of Al, 0.005-0.40% of Ti, 0.0005-0.003% of O, 0.0010-0.01% of N, 0.0005-0.004% of Ca, 0.001-1.50% of Cu, 0.001-0.16% of Mo and the balance being Fe. The manufacture method includes steps of: adopting a basic oxygen furnace (BOF)(or an electric arc furnace(EAF)) for smelting+ low frequency (LF)+ VD(or RH) refining technology for refining; adopting a secondary cold area weak cold+ stable low casting process to be matched for steel continuous casting; adopting low-temperature heating+ controlled rolling technology for steel rolling and directly quenching at the temperature above Ar3; and adopting the critical hardening+ tempering process for thermal treatment of steel. Through experiments of low-temperature impacting, non destructive testing (NDT), dark trace (DT), crack tip opening displacement (CTOD), K1a and the like, the Ni-series low-temperature steel is proved to have the advantages of having good obdurability matching and suitable for manufacturing ultra-large type liquefied natural gas (LNG) storage tanks, wherein manufacture volume of the LNG storage tanks exceeds 2*105m<3>, maximum wall thickness exceeds 50mm, and the LNG storage tanks are ultra-high in requirements for safety.

Owner:CENT IRON & STEEL RES INST

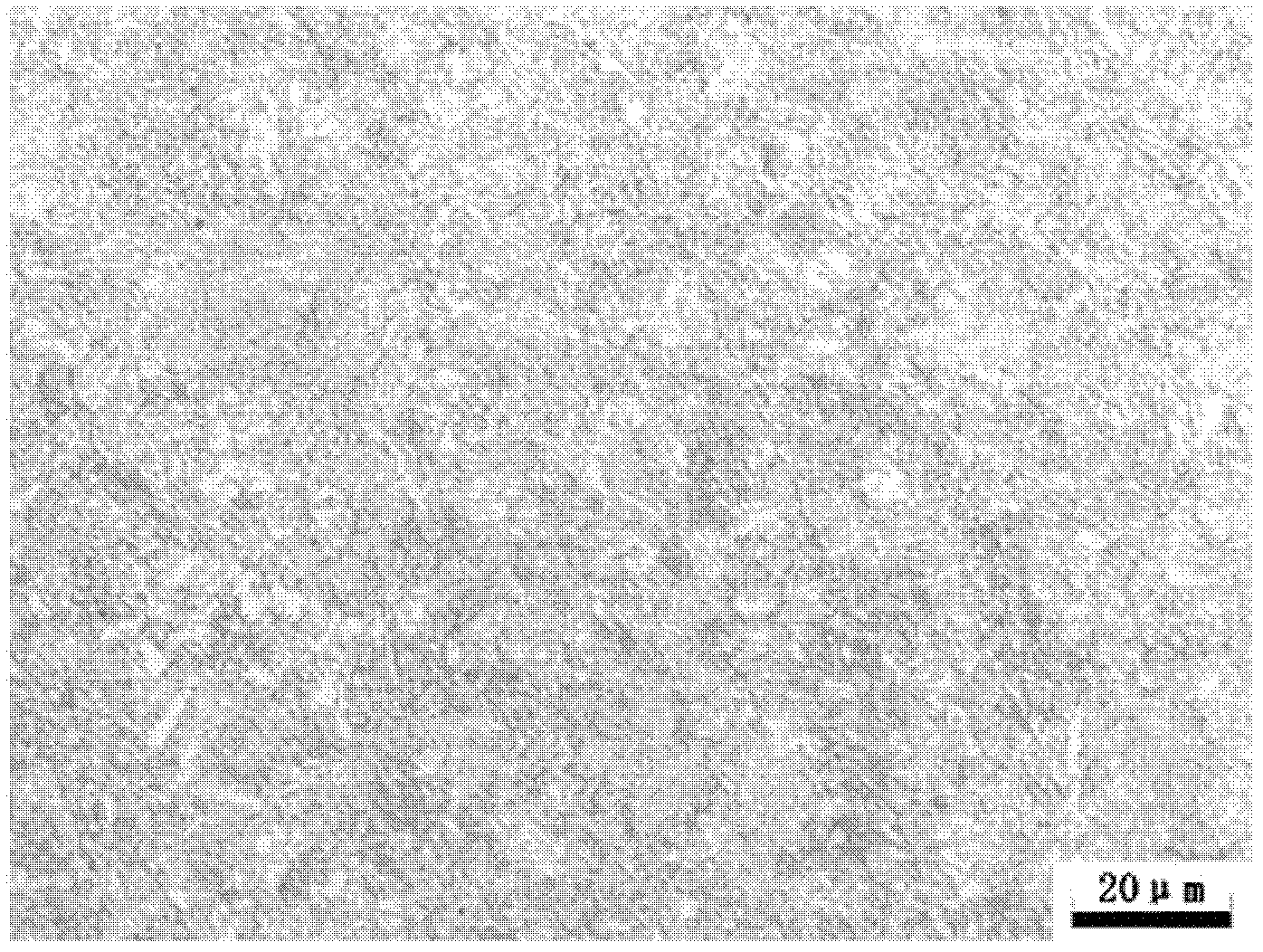

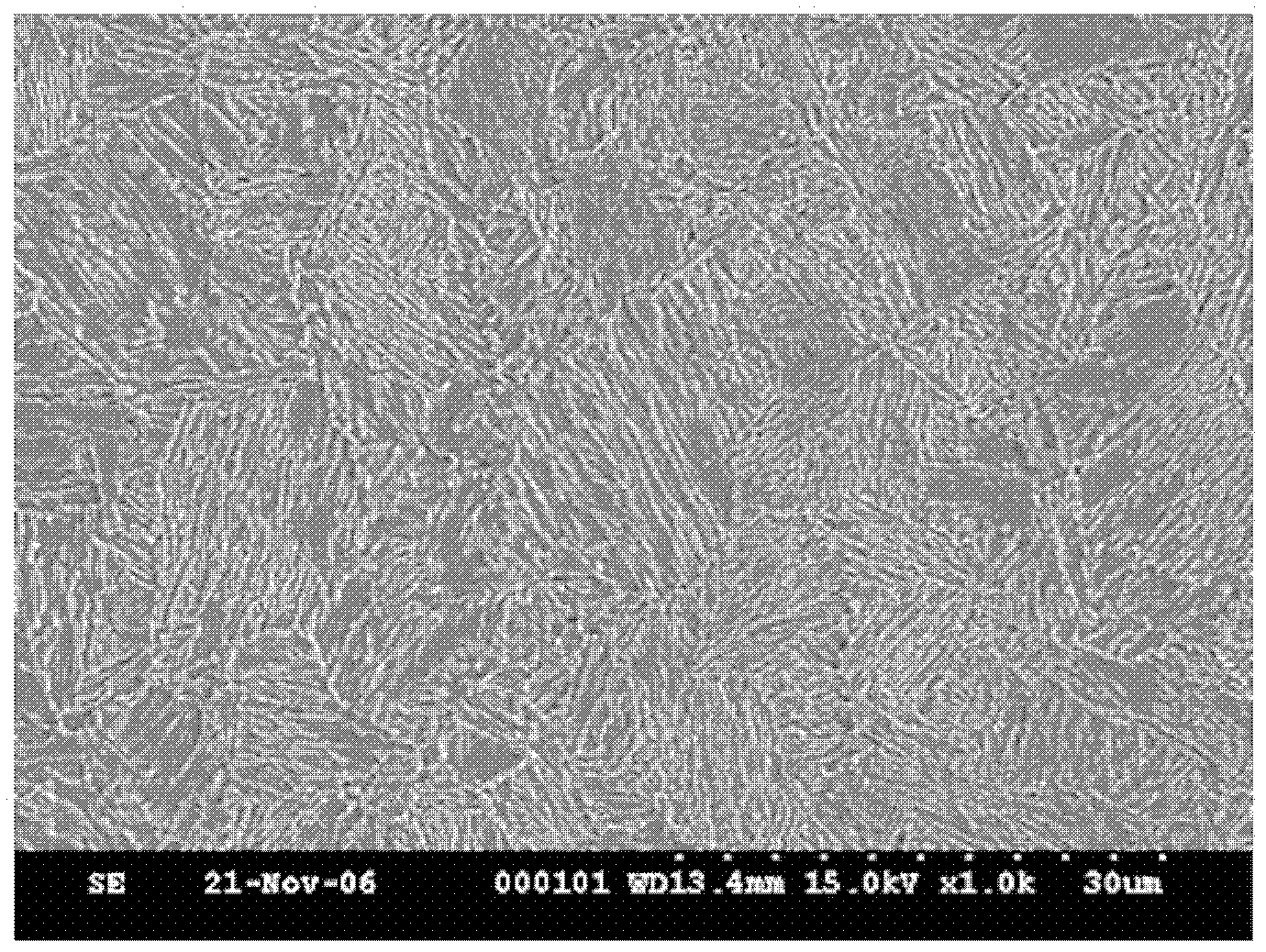

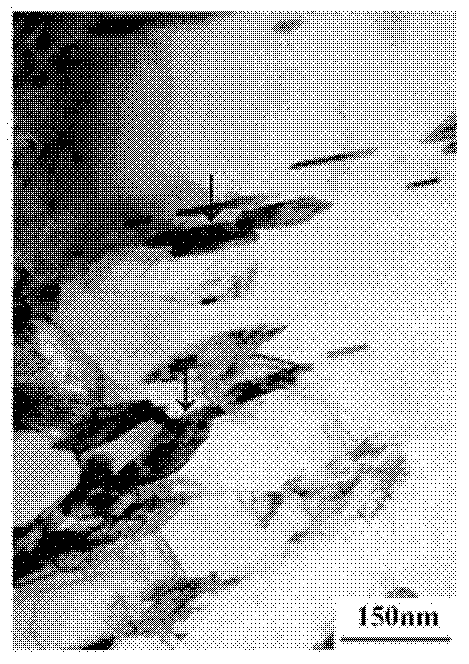

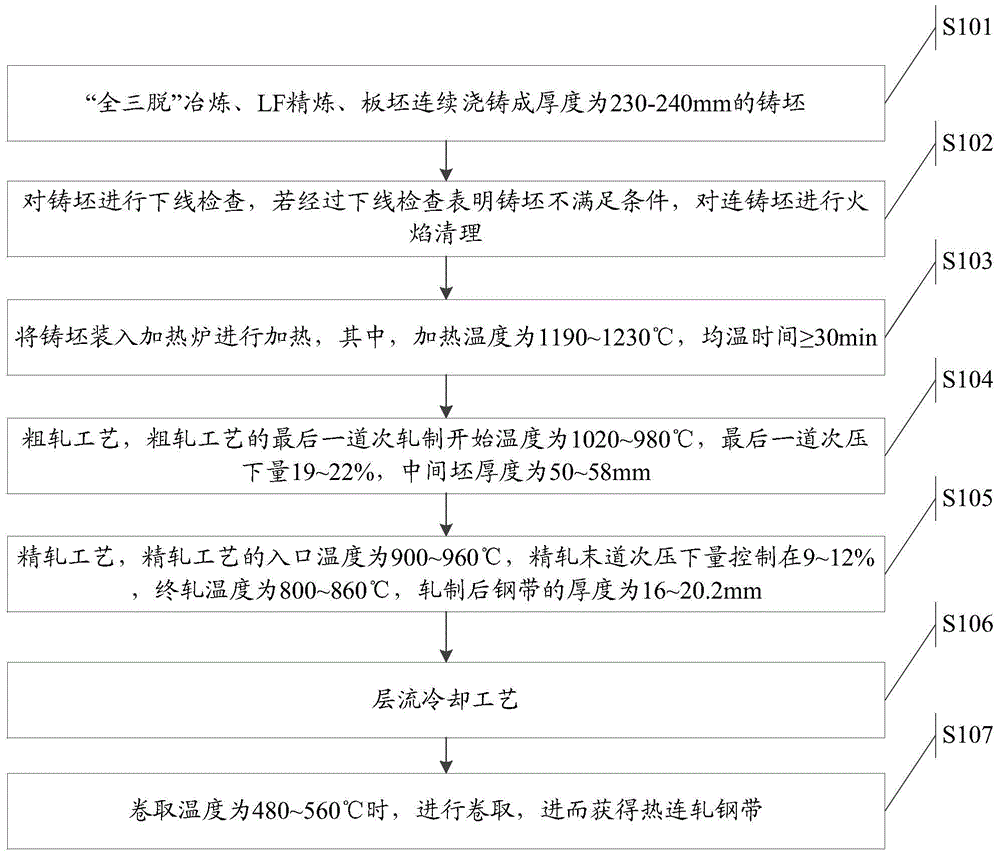

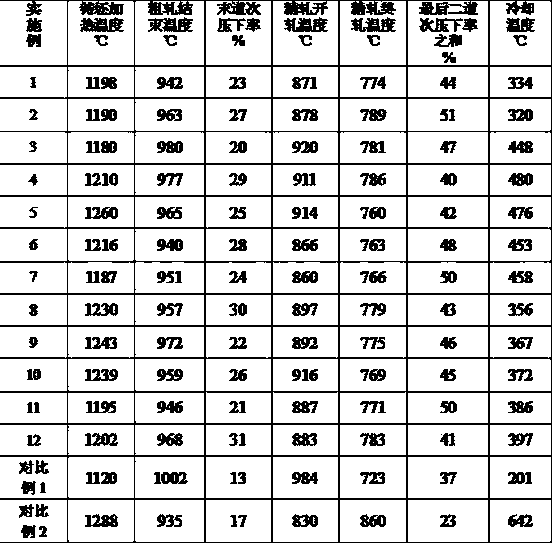

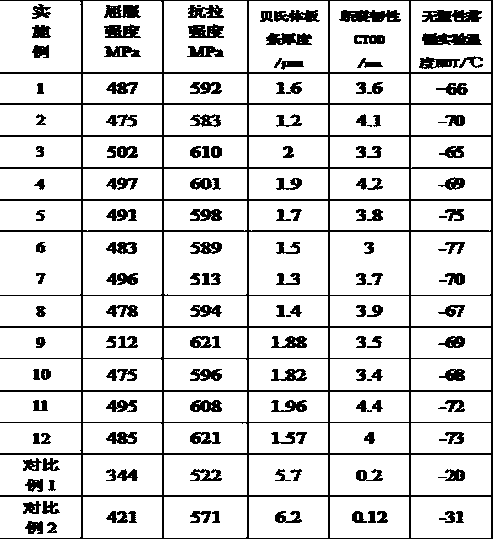

Thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and production method of thick-gauge hot continuous rolling steel belt

ActiveCN104561486AGuaranteed surface qualityImprove purityCrack tip opening displacementHeating furnace

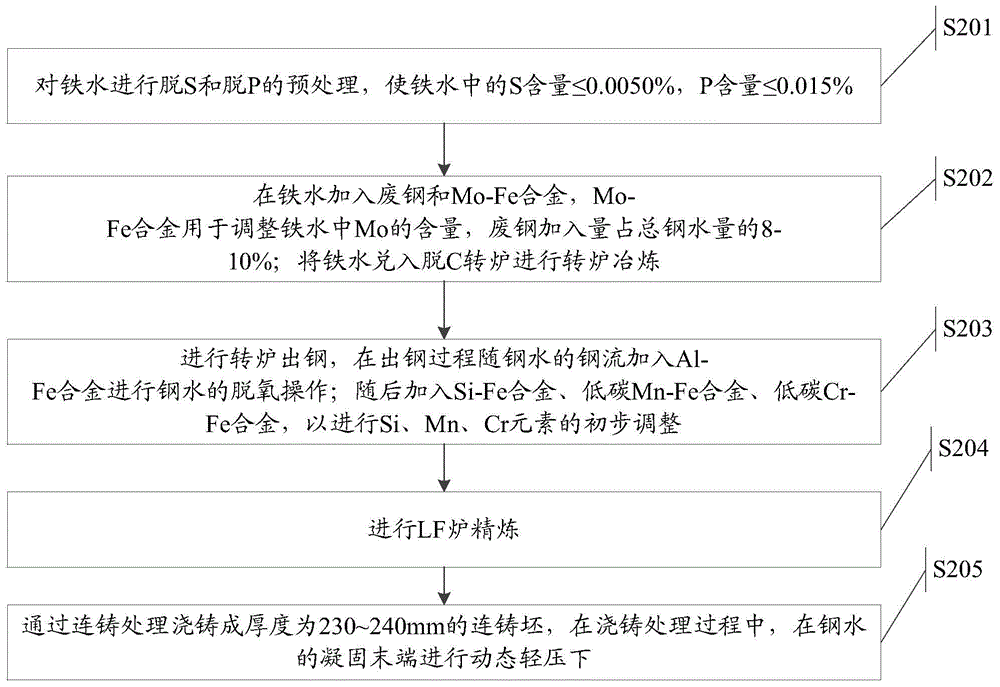

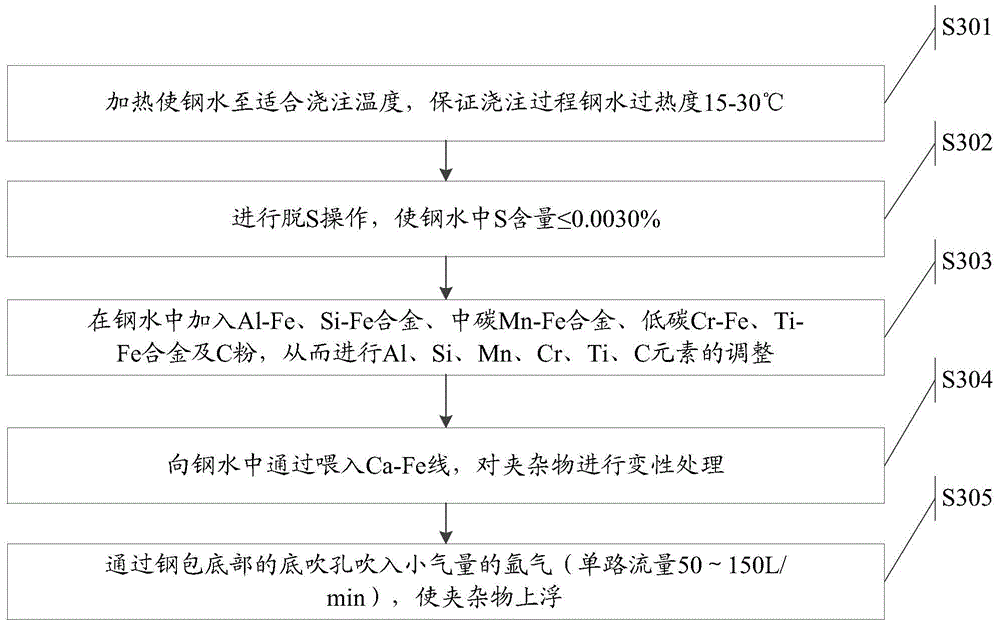

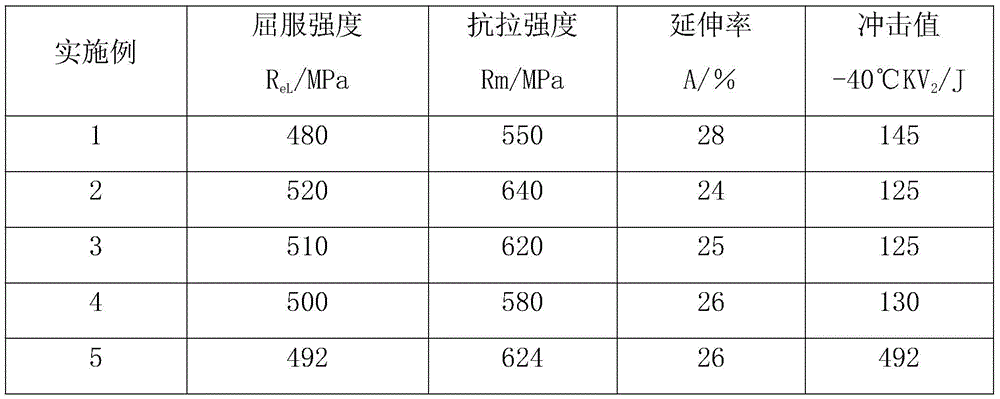

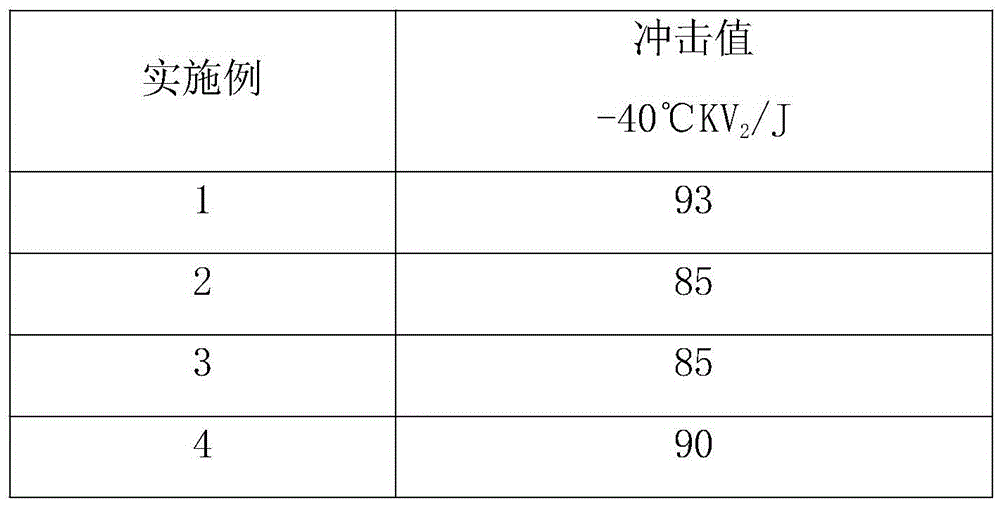

The invention relates to the technical field of hot continuous rolling steel belts for use in submarine oil / gas transmission pipelines and provides a thick-gauge hot continuous rolling steel belt with excellent ultralow temperature CTOD (Crack Tip Opening Displacement) performance and a production method of the thick-gauge hot continuous rolling steel belt. According to the thick-gauge hot continuous rolling steel belt and the production method, the technical problem of high technical difficulty in the production of the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD performance in the prior art is solved. The production method comprises the following steps: (1) continuously casting a plate blank into a casting blank with the thickness of 230mm-240mm by virtue of 'complete pretreatment' smelting and LF refining; (2) carrying out offline detection on the casting blank; (3) putting the casting blank in a heating furnace, and heating, wherein the heating temperature is 1190-1230 DEG C, and the temperature equalizing time is more than or equal to 30 minutes; (4) carrying out a rough rolling process; (5) carrying out a precision rolling process, wherein the thickness of the rolled steel belt is 16mm-20.2mm; (6) carrying out a laminar flow cooling process; and (7) reeling at the temperature of 480-560 DEG C. The production method can be used for producing the thick-gauge hot continuous rolling steel belt with the excellent ultralow temperature CTOD at relatively low difficulties.

Owner:SHOUGANG CORPORATION +1

Gas protection welding wire for ocean engineering

InactiveCN105458550AStrong resistance to seawater corrosionImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSheet steelCrack tip opening displacement

The invention particularly provides a gas protection welding wire for ocean engineering. The gas protection welding wire for ocean engineering is composed of, by mass, 0.09-0.13% of C, 0.8-1.4% of Mn, 0.35-1.20% of Si, 0.08-0.20% of Cr, 0.6-1.3% of Ni, 0.1-0.4% of Mo, 0.01-0.03% of V, 0.20-0.25% of Cu, 0.015% or less of S, 0.025% or less of P, 0.06-0.20% of Ti, 0.002-0.008% of B, and the balance Fe. The composition matching of the welding wire and a welded steel board and influence of protective gas on alloy element burning loss and transition are comprehensively considered, on the basis of an Ni-Cu anti-corrosion alloy system, the compositions and content are controlled and adjusted, and therefore the welding wire has excellent impact toughness, welding performance, corrosion resistance, fatigue resistance, crack-tip opening displacement (CTOD) and other special properties, the board thickness center portion of an ultra-thick board has high strength and low-temperature toughness, and the welding wire can be matched with 460-MPa steel for ocean engineering for welding.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

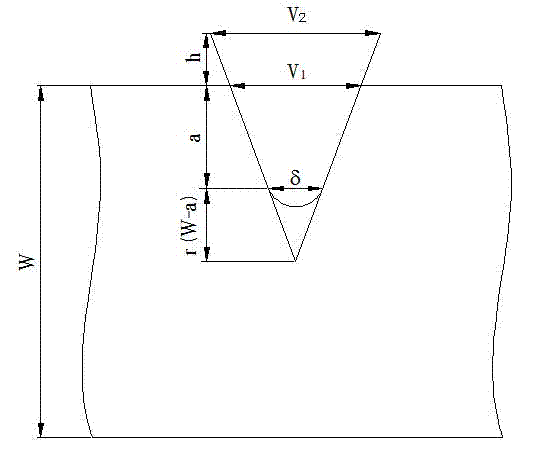

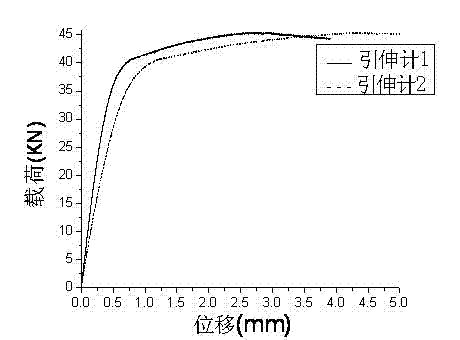

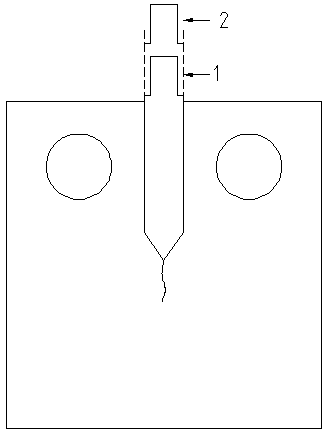

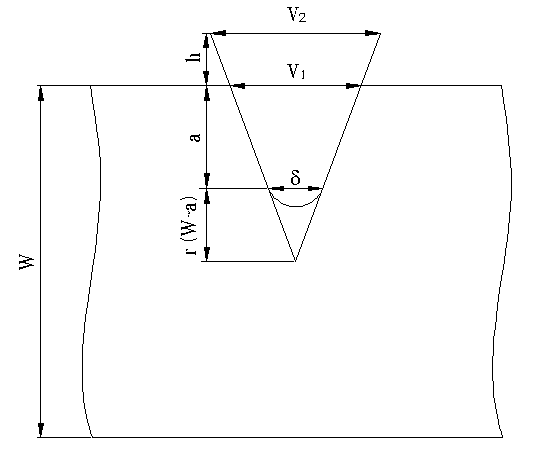

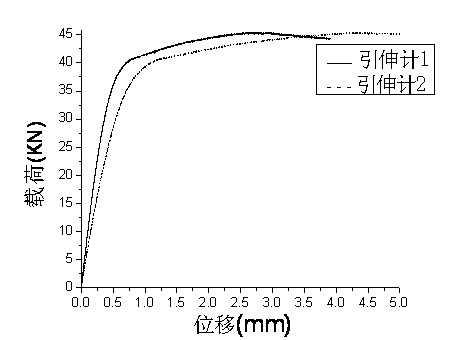

Method for measuring compact tension specimen fracture parameters by using double extensometers

ActiveCN102564844ASimple test methodData processing is simpleStrength propertiesCrack tip opening displacementInformation quantity

The invention discloses a novel method for measuring compact tension specimen fracture parameters by using double extensometers. The novel method comprises the following steps of: measuring two opening displacements by using the double extensometers; obtaining a crack tip opening displacement (CTOD) of a compact tension test through calculation by using a triangular relation; and calculating a CTOD value under each load and a nominal stress corresponding to the CTOD value, and obtaining a relation between the nominal stress and the CTOD, thereby obtaining a CTOD design curve of the compact tension test. The fracture parameter test method disclosed by the invention has the characteristics of simpleness, easy operation, simpleness for processing data, high precision of a critical CTOD value, comprehensive data, large information quantity, freeness from test precision influences of other parameters, such as strength, Young modulus, rotary factor and load, capabilities of obtaining the CTOD data of the whole test loading process and obtaining the CTOD design curve of the compact tension test under an actual board thickness condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

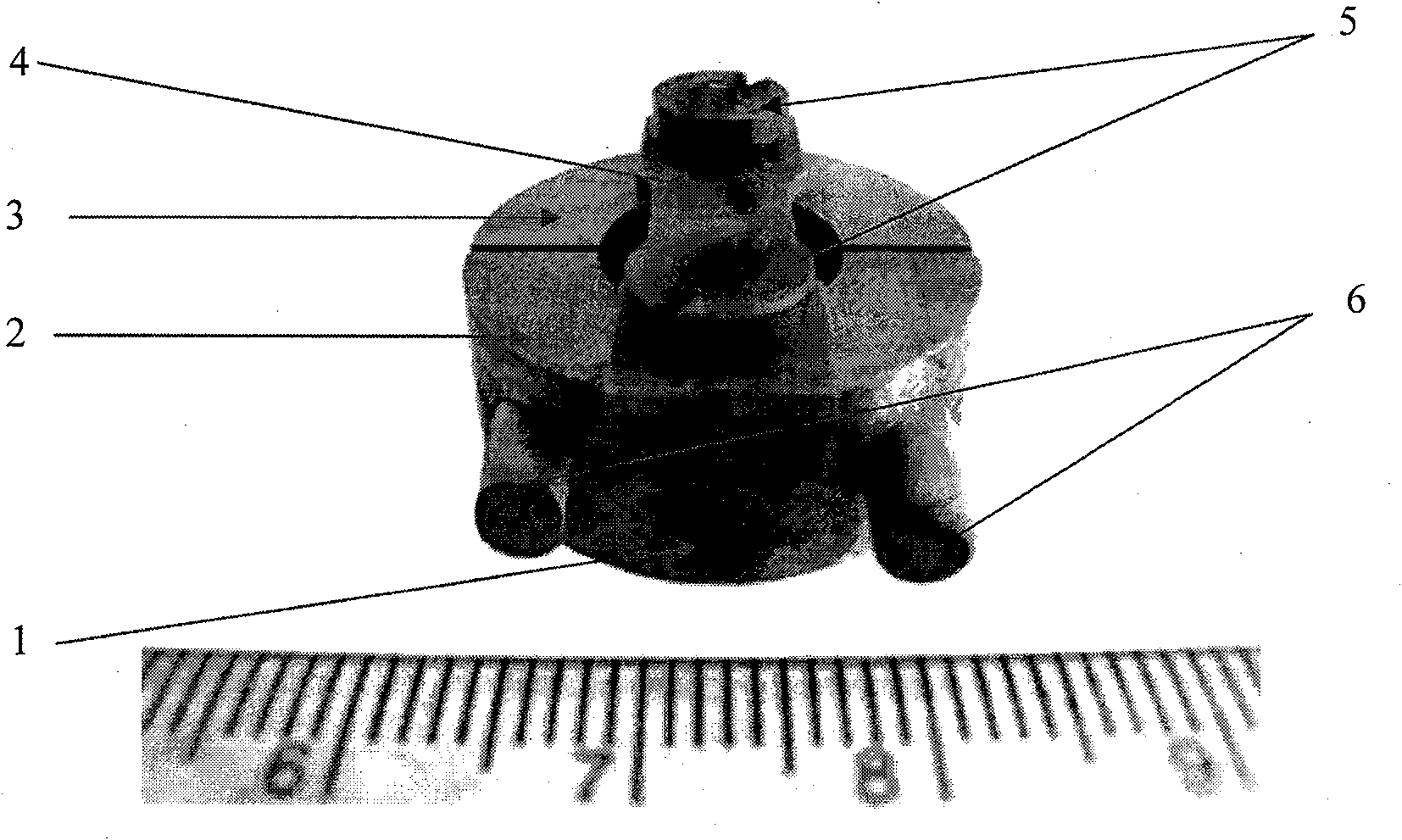

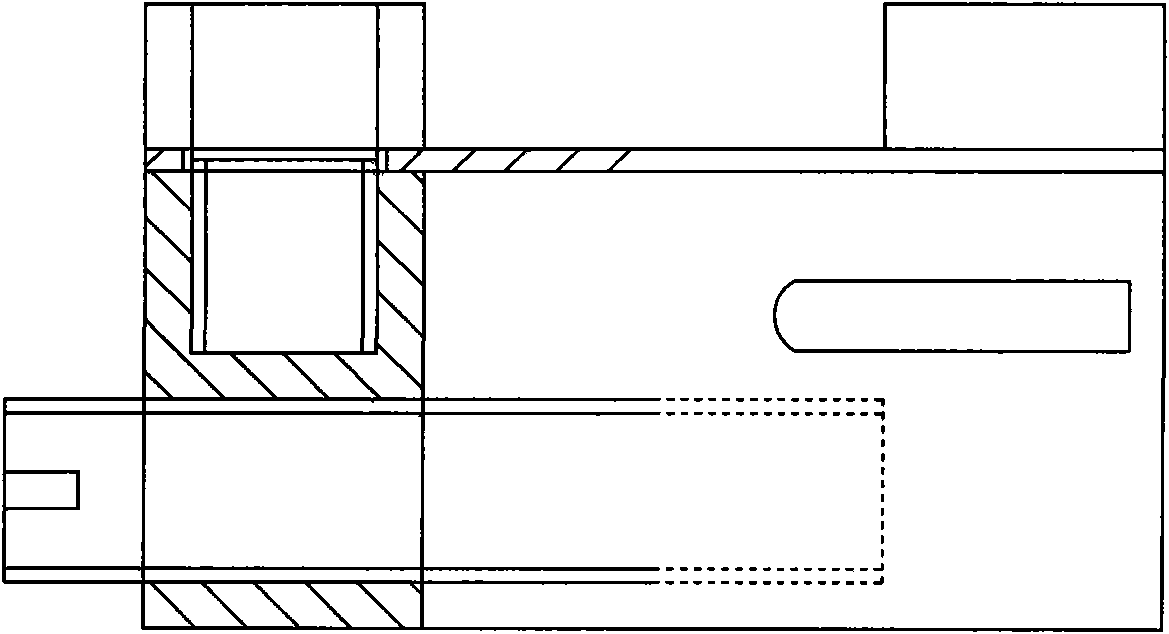

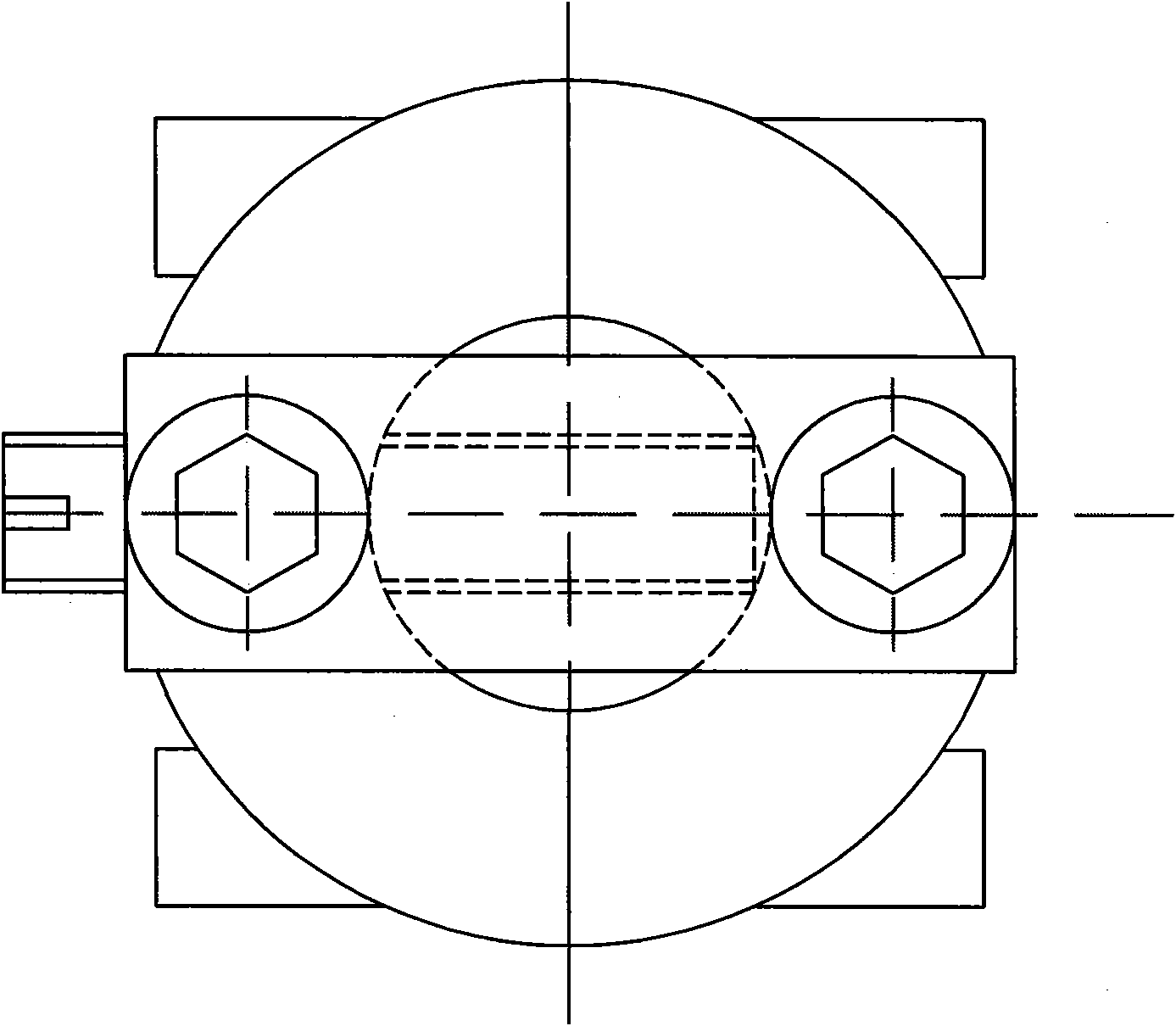

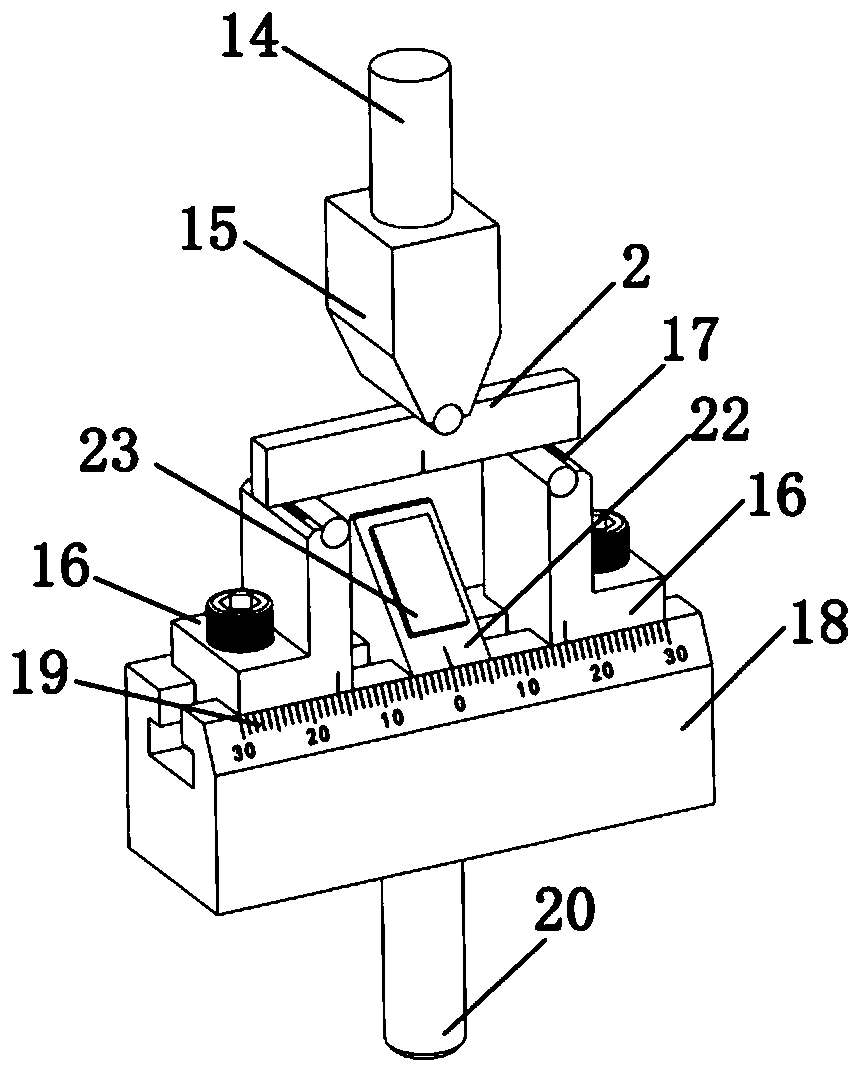

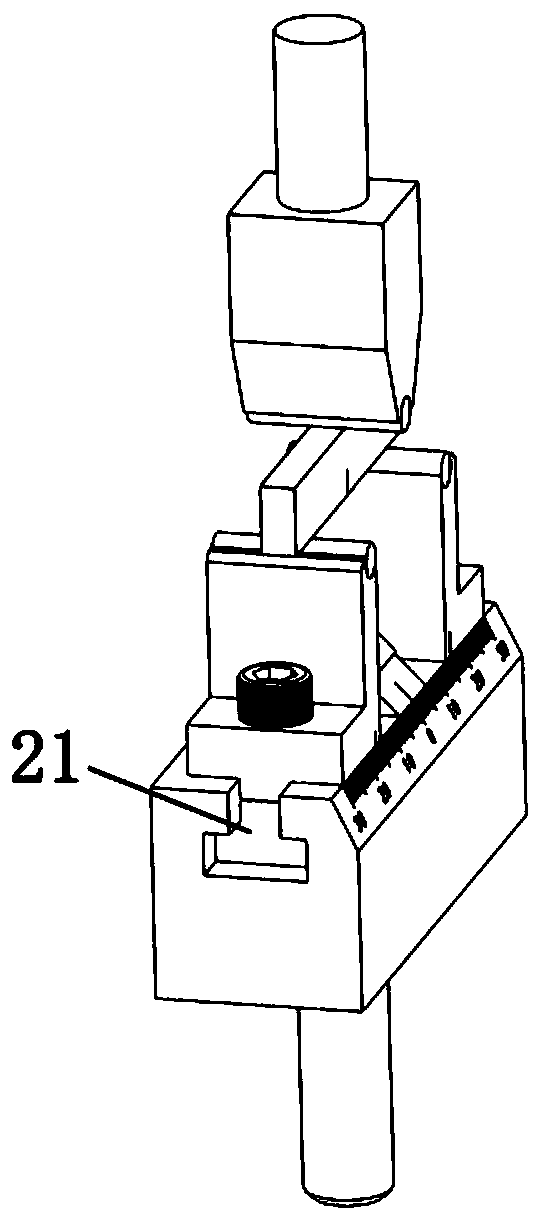

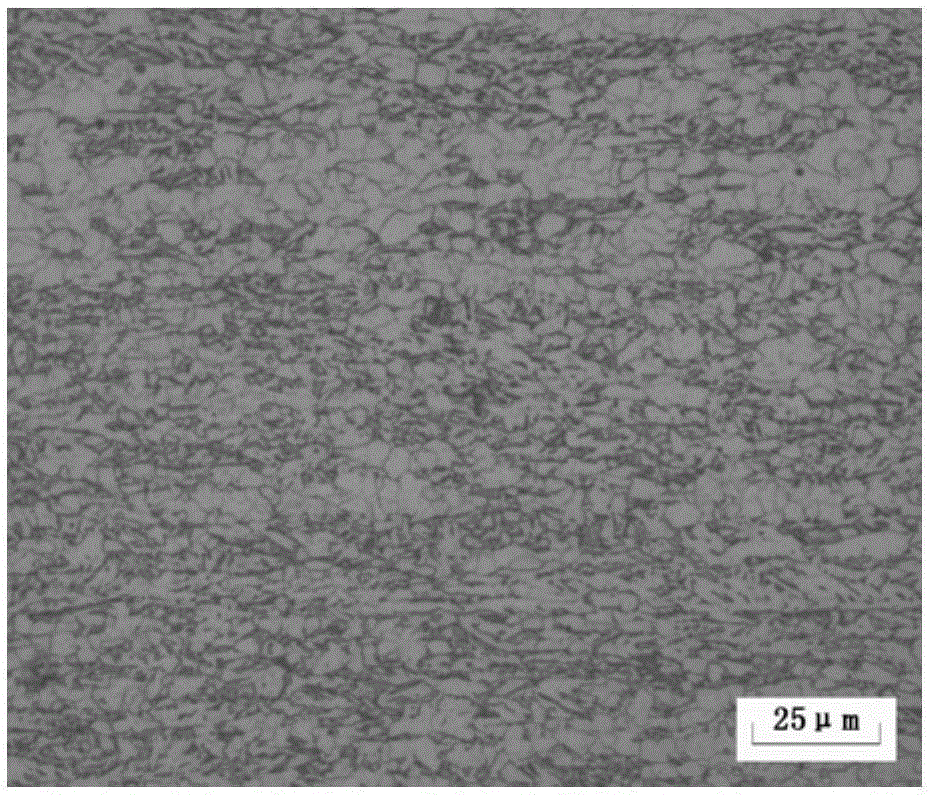

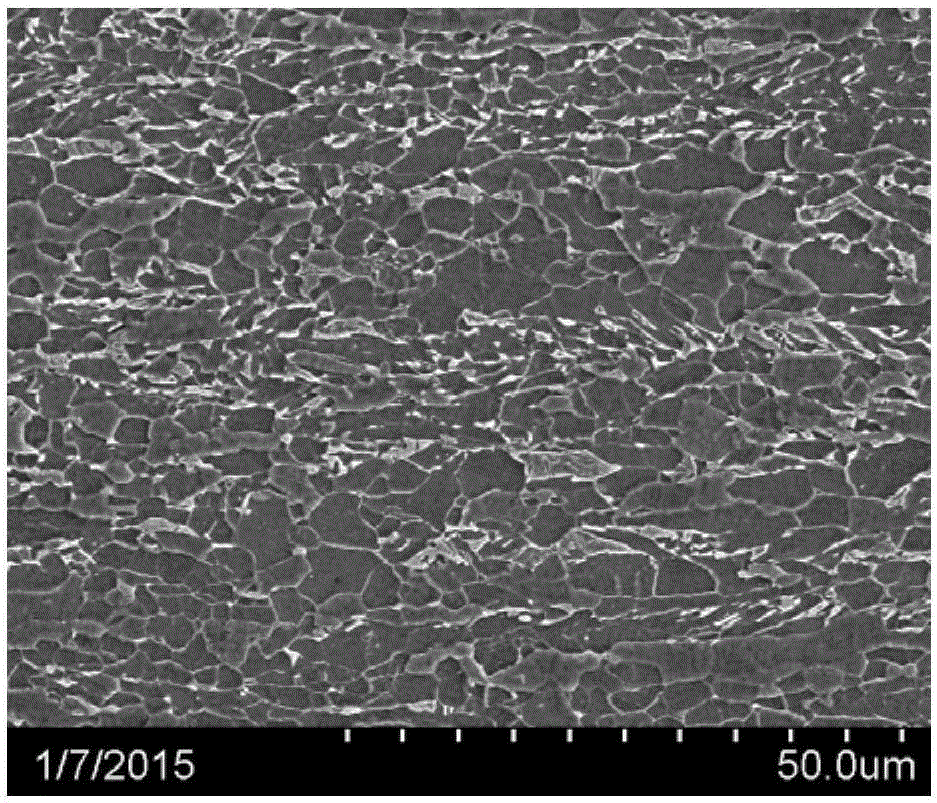

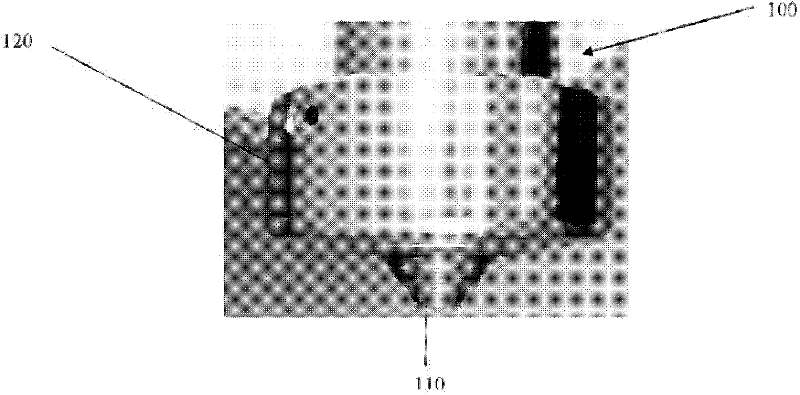

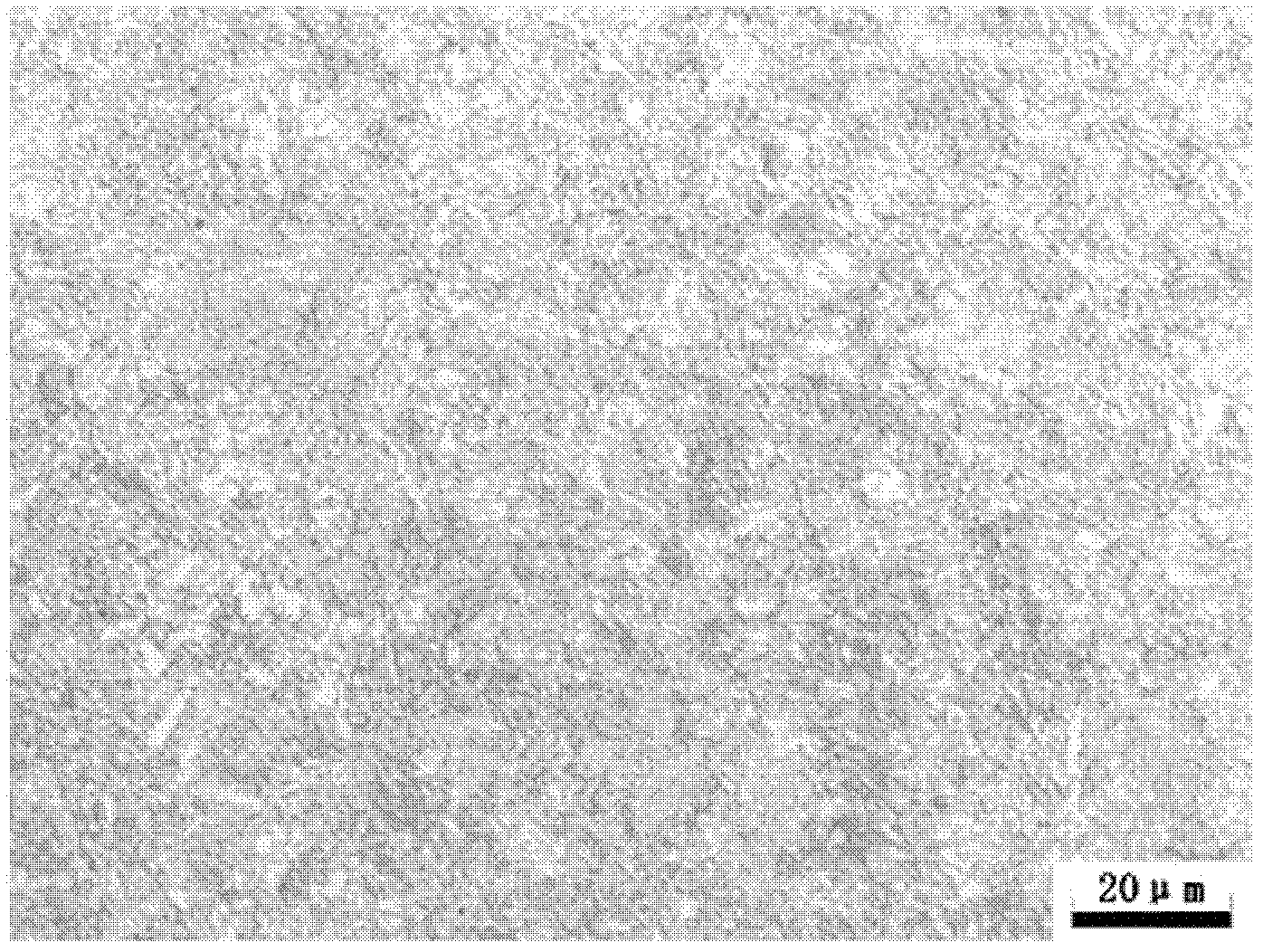

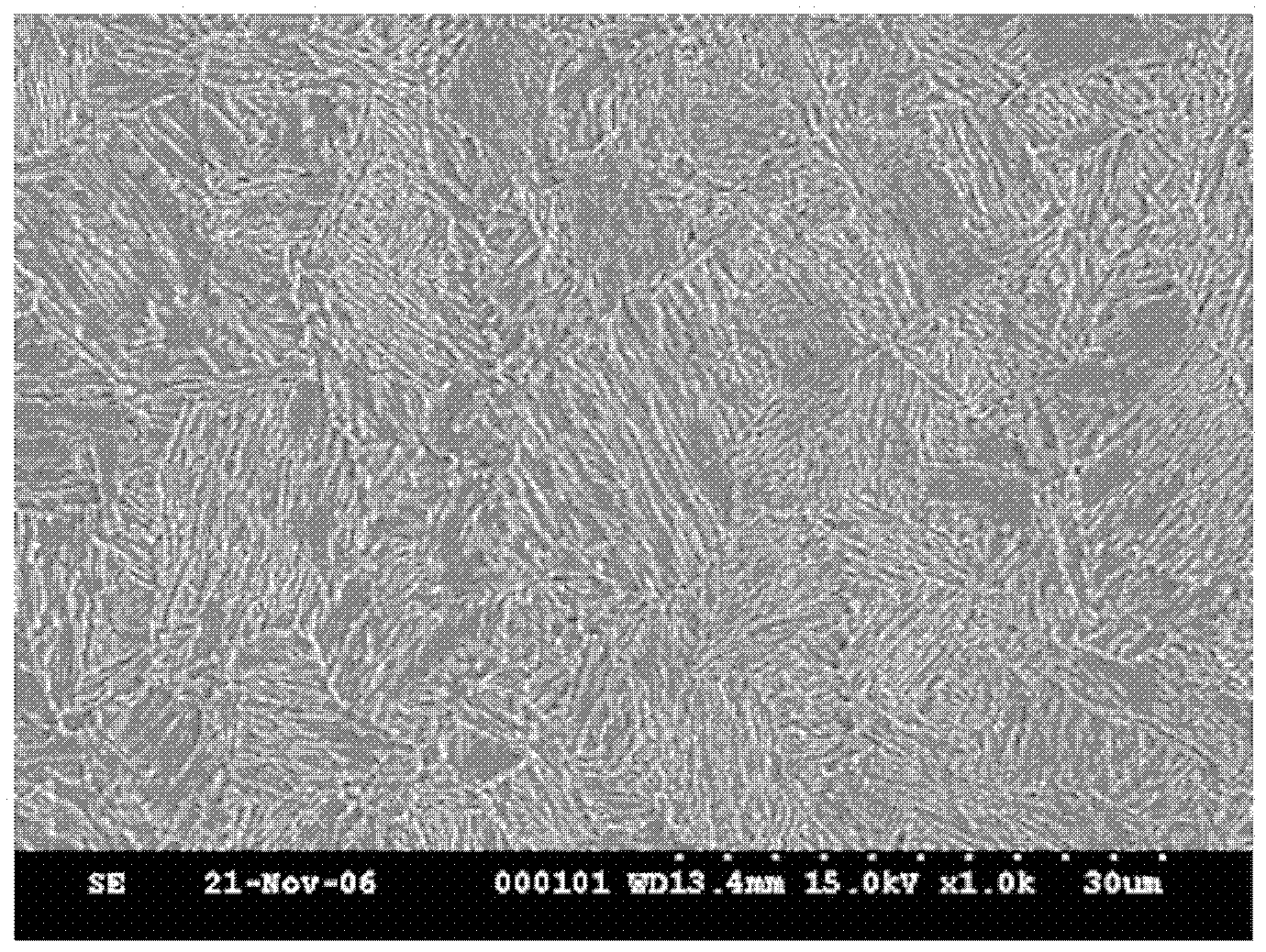

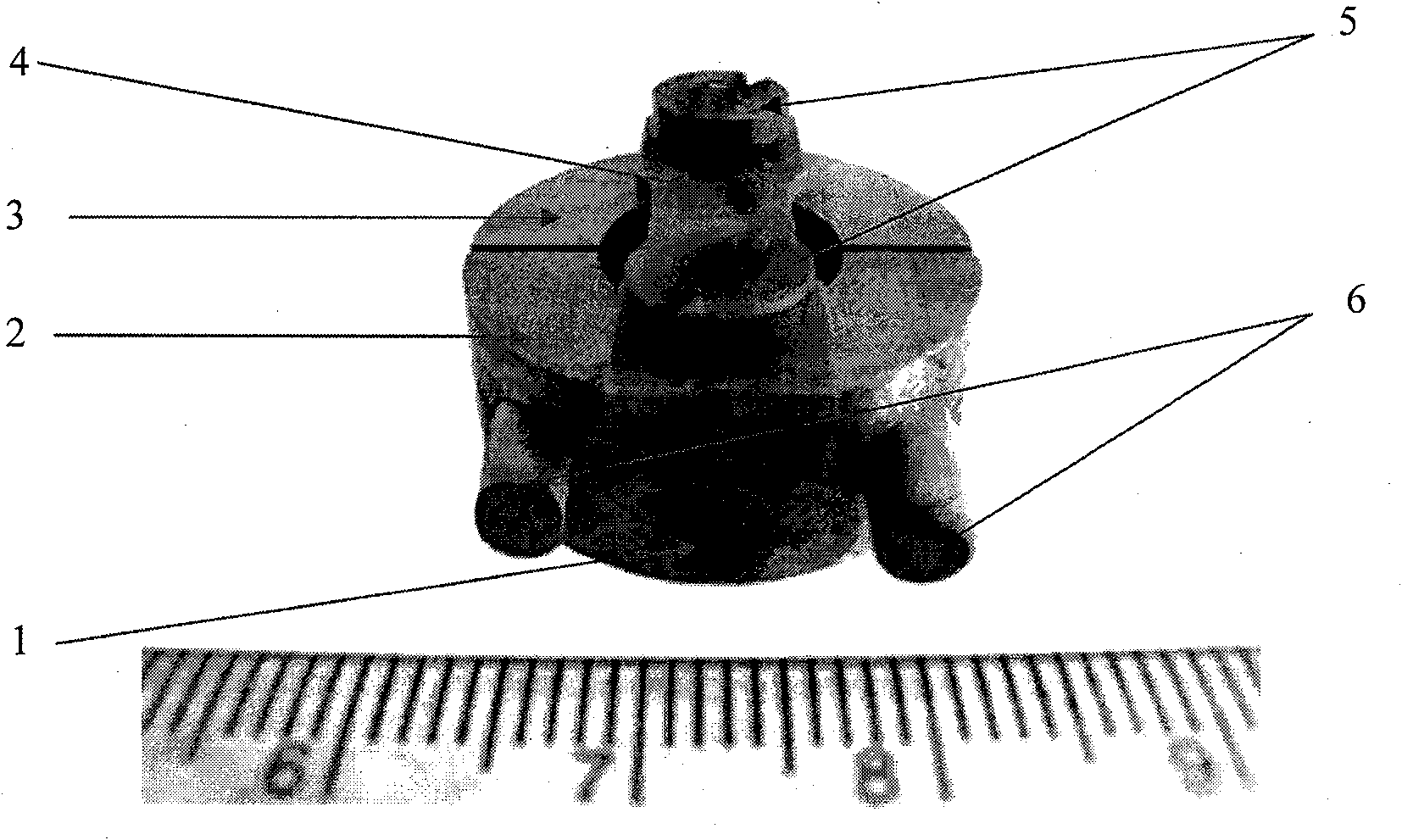

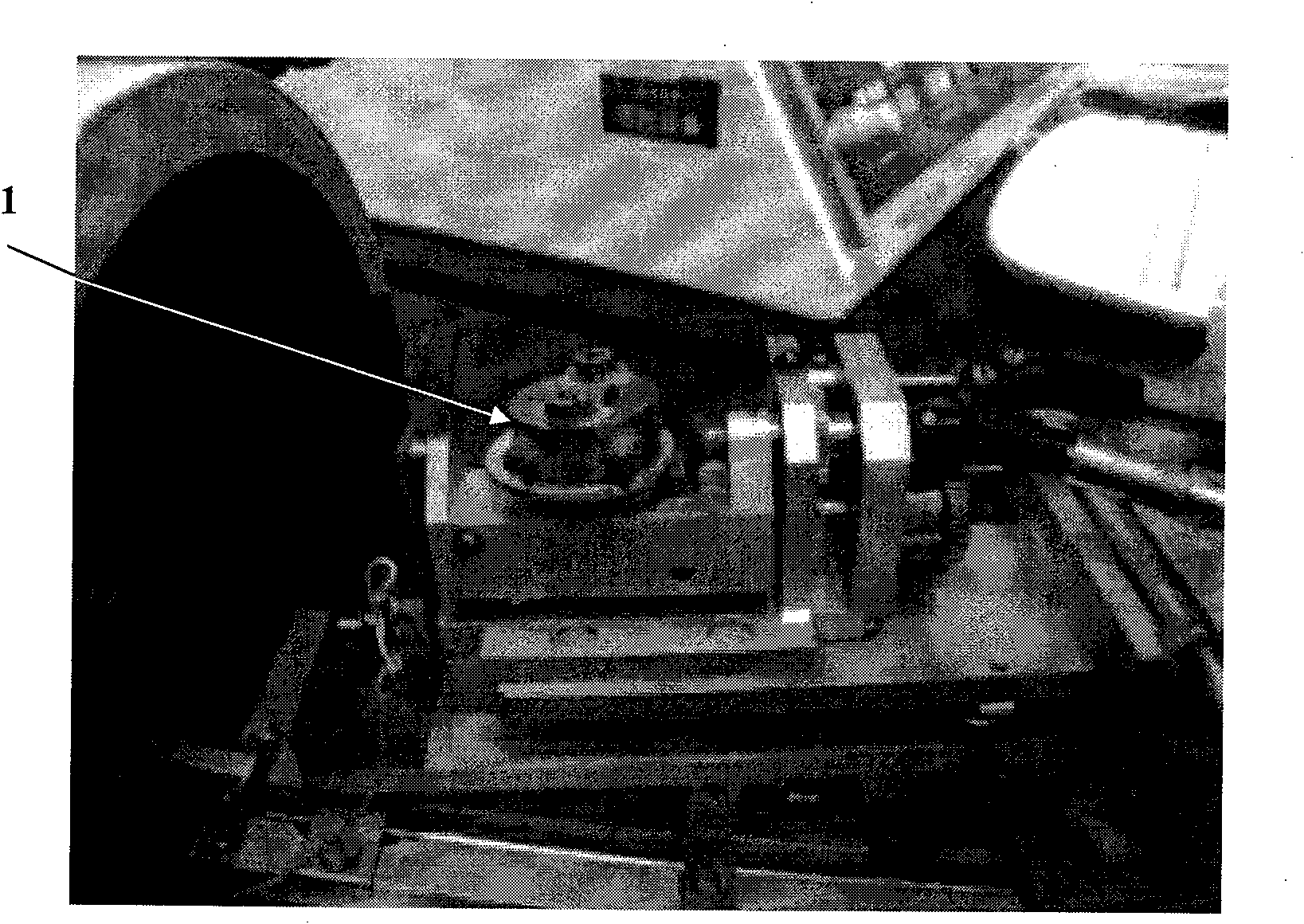

Sample table for scanning electron microscope in-situ observation of stress corrosion cracking of metal material

InactiveCN102103148AAccurate calculation of expansion rateScanning probe techniquesLiquid mediumCrack tip opening displacement

The invention belongs to the field of research of environmental cracking of materials, and provides a sample table for scanning electron microscope (SEM) in-situ observation of stress corrosion cracking, which can realize the SEM in-situ observation of the stress corrosion cracking of a metal material in a liquid medium. The sample table is designed according to a spatial size of an SEM sample room; a micro tension sample can be loaded and kept in a constant displacement state in the aspect of loading the sample; and the sample table is placed in the liquid medium together with a constant displacement sample to produce the stress corrosion cracking, is taken out of the medium and is arranged in the SEM sample room, so that a continuous process of stress corrosion crack propagation can be observed and recorded. Meanwhile, the crack propagation speed and crack tip opening displacement can be accurately calculated according to a stress corrosion cracking SEM image. Through the sample table, the problem that the stress corrosion cracking of the material in the liquid medium cannot be observed by an SEM is solved, and the sample table is an effective tool for researching a stress corrosion cracking micromechanism of the material.

Owner:YANSHAN UNIV

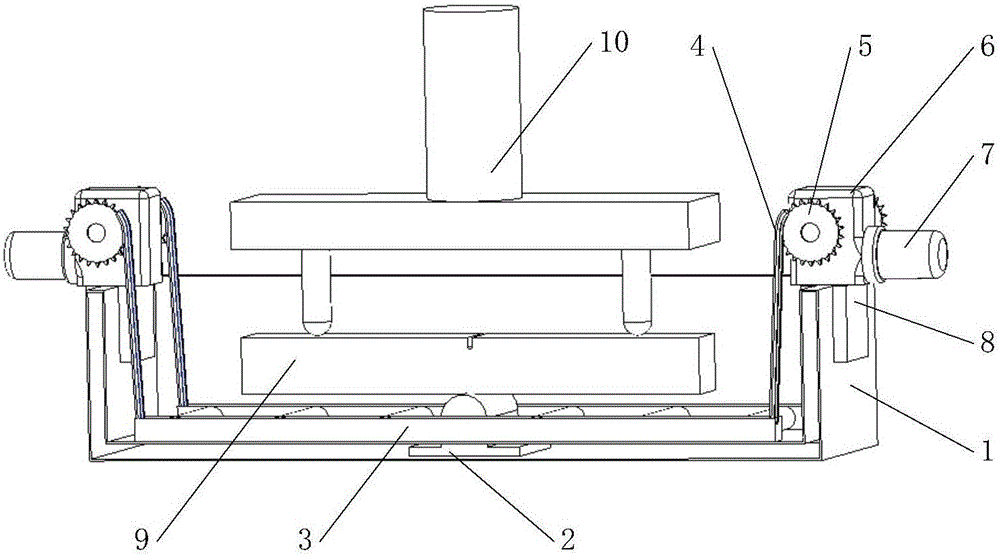

Non-contact crack opening displacement measuring device and method for bending fracture test

PendingCN110174315AEnabling Fracture Toughness MeasurementsRealize non-contact measurementMaterial strength using steady bending forcesMeasurement deviceEngineering

The invention belongs to the field of material performance test, and especially relates to a non-contact crack opening displacement measuring device and method for a bending fracture test. The non-contact crack opening displacement measuring device comprises a mechanical experimental machine; a bending test tooling including an upper pressing head and two lower pressing heads, and a sample is clamped between the upper pressing head and the lower pressing heads; a digital image acquisition system including an industrial camera, an imaging lens, an annular LED illuminating light source arrangedat the front end of the imaging lens, a camera support system and a reflecting mirror, wherein the reflecting mirror is arranged at the lower part of the sample at an inclined angle of 45 degrees; thereflecting mirror reflects light generated by the light source to a fracture surface of the sample, and meanwhile, a surface image of the fractured sample is reflected into the imaging lens; and a control system for displaying an image of the industrial camera in real time, and calculating the real-time crack opening displacement. According to the non-contact crack opening displacement measuringdevice for the bending fracture test provided by the invention, an optical imaging system is used for collecting images around a crack opening of the sample, and a digital image correlation algorithmis used for calculating the real-time crack opening displacement, so that non-contact measurement can be realized, and the measurement device does not have any influence on the sample.

Owner:NANJING UNIV OF SCI & TECH

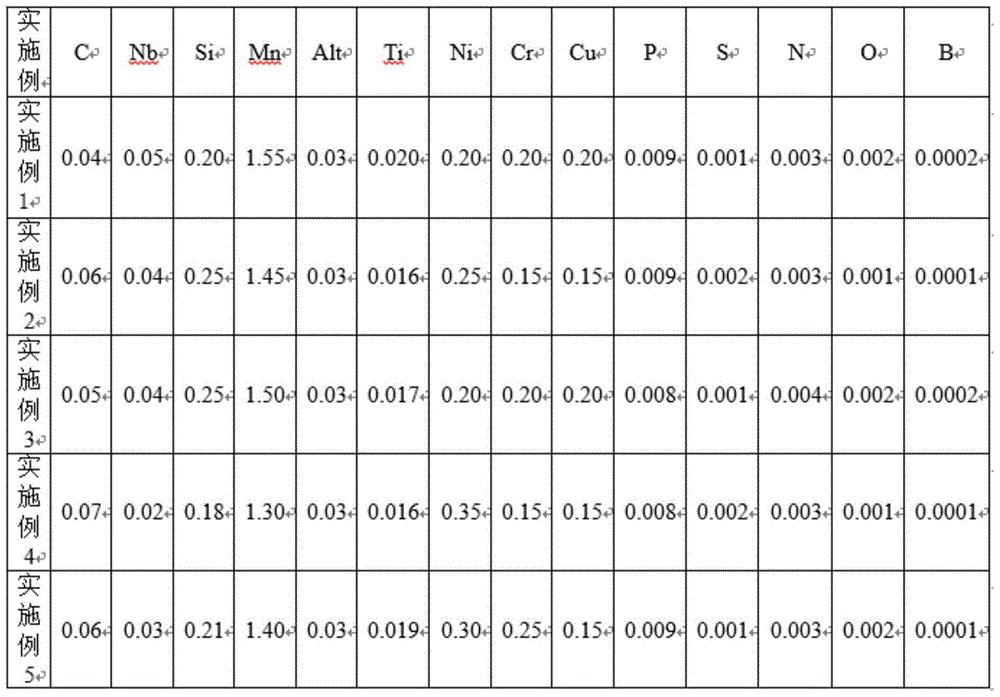

Strain design region based high-performance pipeline steel with high-deformation resistance and preparation method

InactiveCN105200336AExcellent resistance to large deformationImprove low temperature toughnessChemical compositionCrack tip opening displacement

The invention discloses strain design region based high-performance pipeline steel with high-deformation resistance and a preparation method and belongs to the technical field of high-strength pipeline steel. The chemical composition of the pipeline steel comprises components in percentage by weight as follows: 0.04%-0.07% of C, 0.02%-0.05% of Nb, 0.10%-0.30% of Si, 1.00%-1.60% of Mn, 0.01%-0.05% of Alt, 0.015%-0.025% of Ti, 0.15%-0.40% of Ni, 0.10%-0.30% of Cr, 0.10%-0.30% of Cu, smaller than or equal to 0.012% of P, smaller than or equal to 0.003% of S, smaller than or equal to 0.005% of N, smaller than or equal to 0.002% of O, smaller than or equal to 0.004% of B and the balance of Fe and inevitable impurities, wherein the content of C and Nb is 0.08%-0.10%, the content of Cr and Cu is 0.20%-0.40%, and the content of P, S, N, O and B is smaller than or equal to 0.016%. The high-performance pipeline steel has the advantages of excellent high-deformation resistance, low-temperature toughness, CTOD (crack tip opening displacement) fracture toughness and acid resistance.

Owner:SHOUGANG CORPORATION

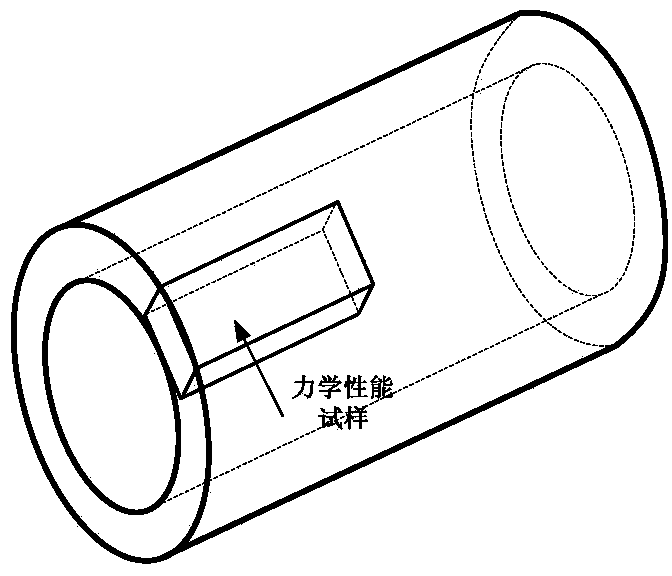

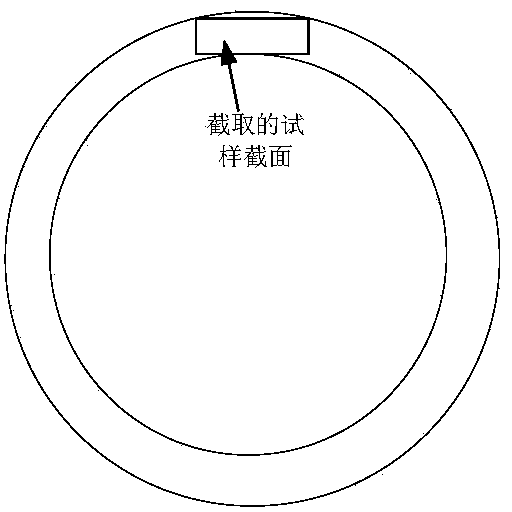

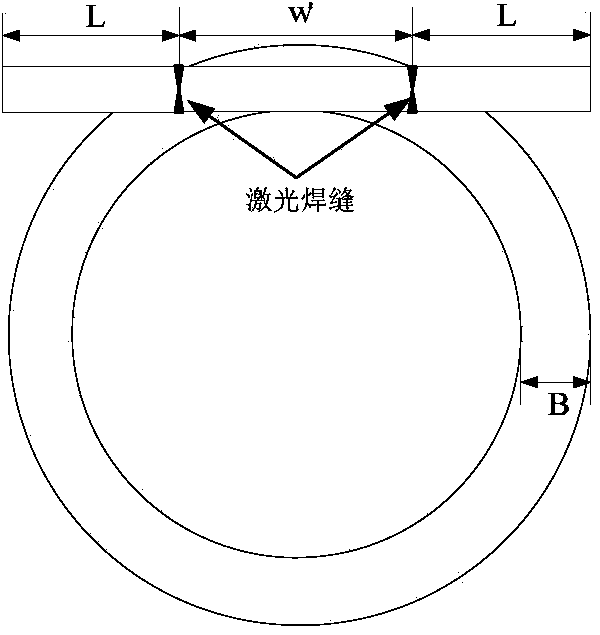

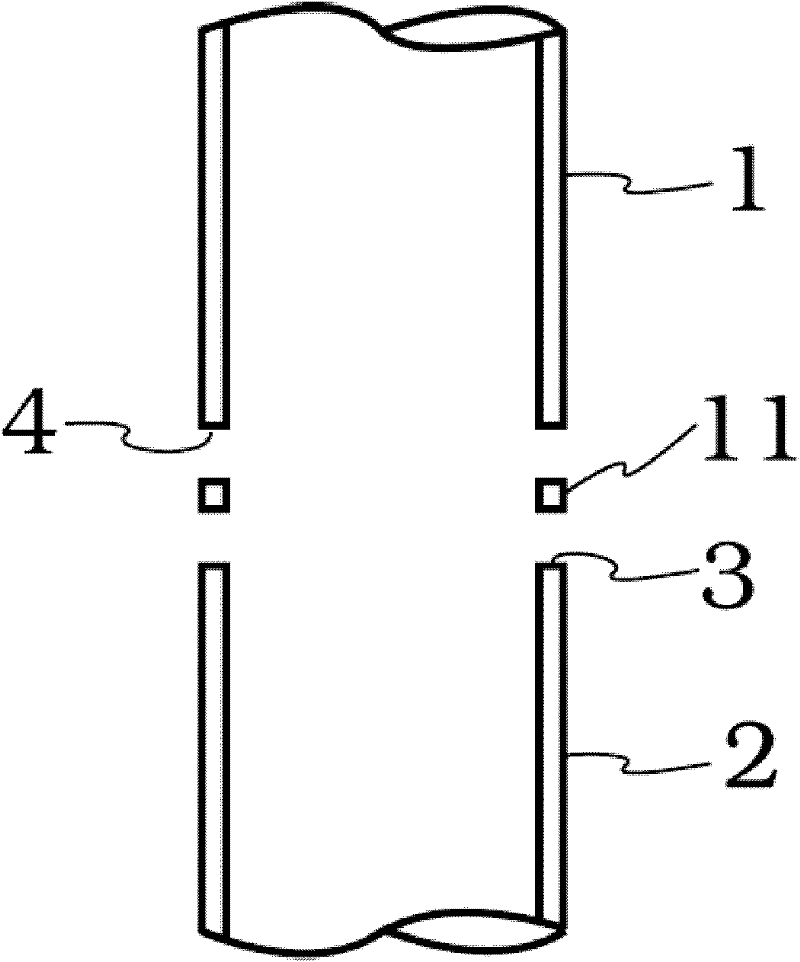

Method for preparing specimens used in testing of mechanical properties of thin-walled and small-diameter petroleum and natural gas pipelines

ActiveCN103884557AIncrease profitSave materialPreparing sample for investigationGreen manufacturingPetroleum

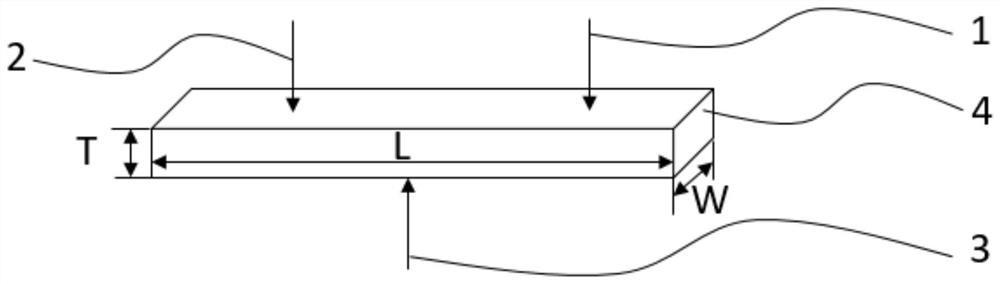

The present invention discloses a method for preparing specimens used in testing mechanical properties of thin-walled and small-diameter petroleum and natural gas pipelines, which comprises the following steps: (1) cutting specimens having width of W mm and thickness of B mm from the circumferential direction of thin-walled and small-diameter petroleum and natural gas pipelines to be tested; and (2) carrying out laser welding on two lengthening blocks on both sides of specimens to obtain test specimens, wherein the width of the lengthening block is L, the thickness of the lengthening block is larger than or equal to B, the sum of L, W and L is greater than or equal to the minimum length of the test specimens required for testing the tensile, impact, CTOD (crack tip opening displacement) fracture toughness or crack propagation rate. Mechanical properties data, which are uneasily acquired by conventional methods, can be measured by virtue of the method disclosed by the invention and have an important practical significance on improvement of the safety evaluation of petroleum and natural gas pipelines. The laser penetration fusion welding technology is applied in preparation of small specimens to effectively increase the utilization rate of specimens, thereby saving materials, saving energy and reducing consumption. The method disclosed by the invention has a nature of green manufacture.

Owner:湖州双林建设发展有限公司

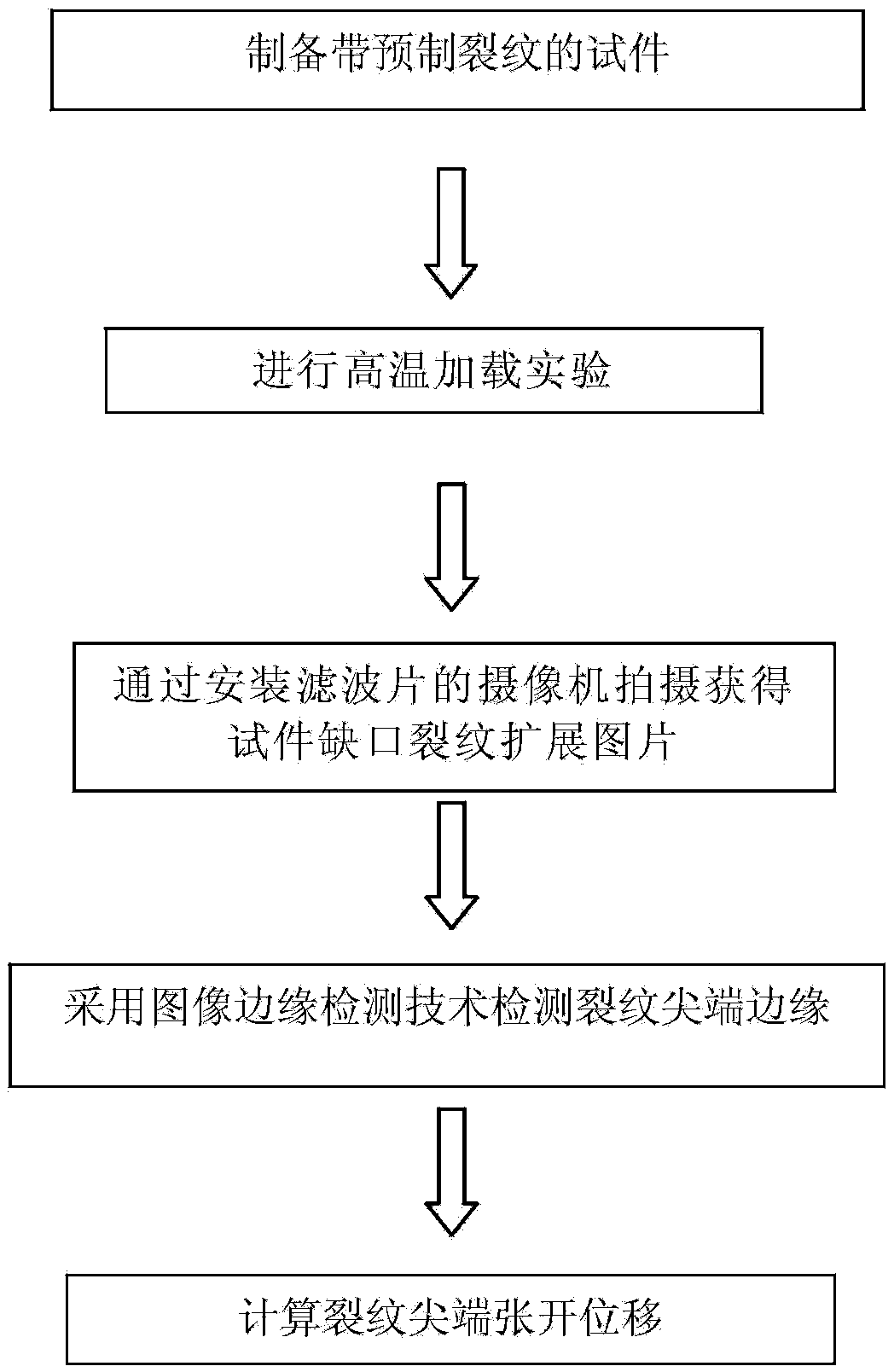

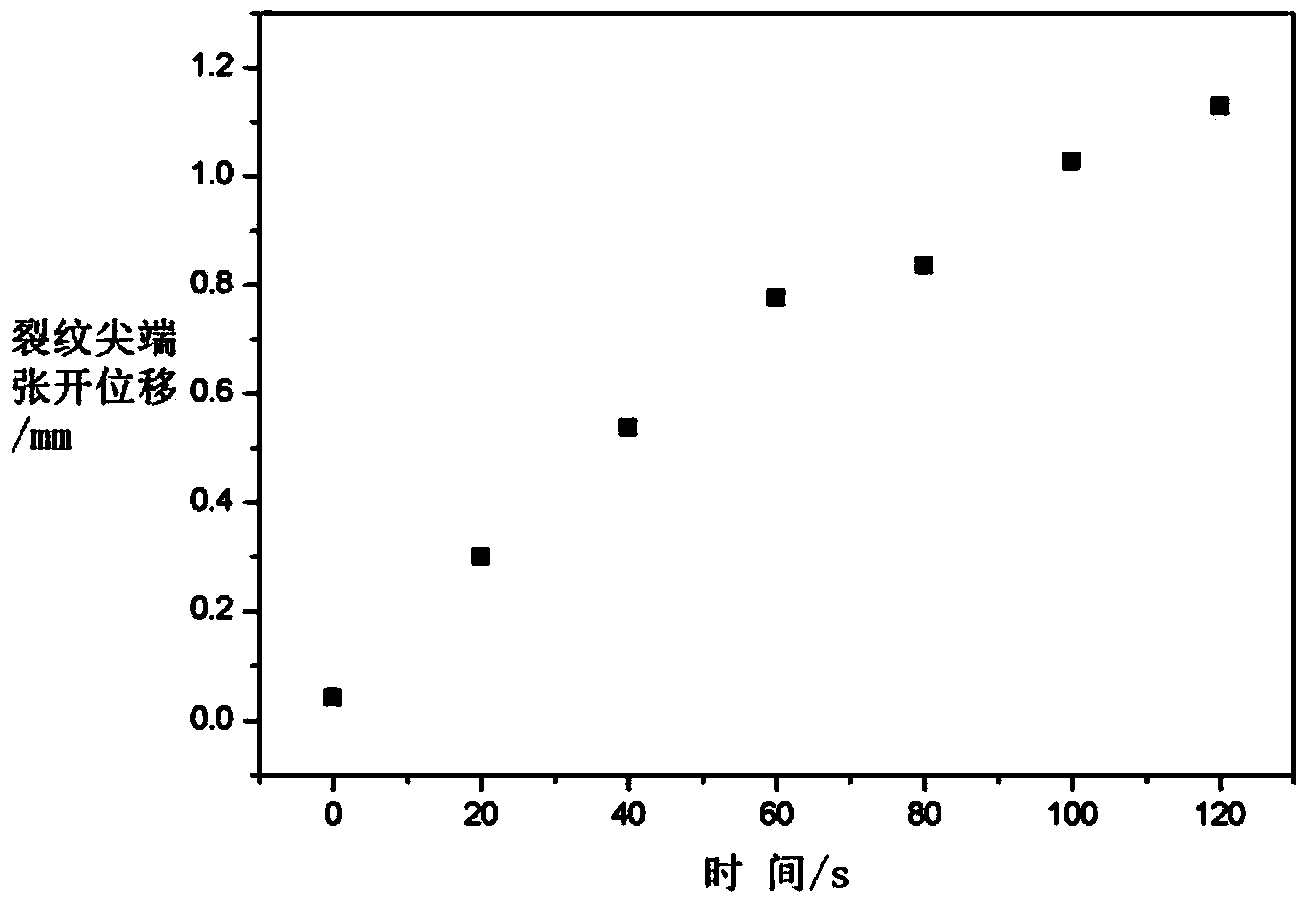

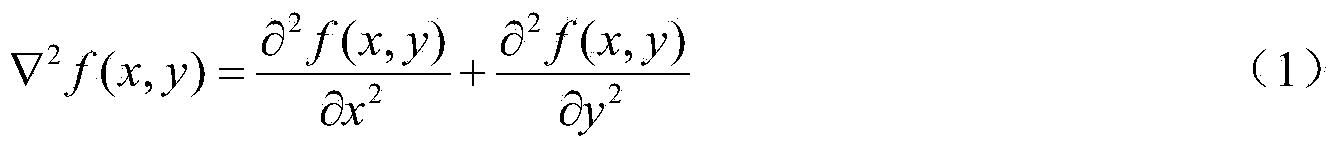

CTOD (crack-tip opening displacement) measurement method based on high-temperature image processing

ActiveCN104266900AReduce mistakesEasy to operateUsing optical meansStrength propertiesImaging processingCrack tip opening displacement

The invention discloses a CTOD (crack-tip opening displacement) measurement method based on high-temperature image processing, and belongs to the technical field of engineering materials, structure deformation and mechanical experiments. The CTOD measurement method is technically characterized in that a test piece provided with precracks is subjected to high-temperature mechanical loading experiment, a camera equipped with a filter device is used for shooting the propagation process of cracks on the surface of the test piece, , cracks of a notch of the test piece are subjected to positioning detection with an edge detection method on an acquired image, and the open displacement of a crack tip is calculated, so that CTOD in the high-temperature environment of the material is acquired. According to the method, the CTOD is directly calculated through an image processing technology; and compared with a conventional method for obtaining the CTOD of the material through a stress-displacement curve, the method is simple and direct, a result can be directly obtained through auxiliary calculation of software, and conventional errors of the stress-displacement curve due to human judgment are reduced.

Owner:TSINGHUA UNIV

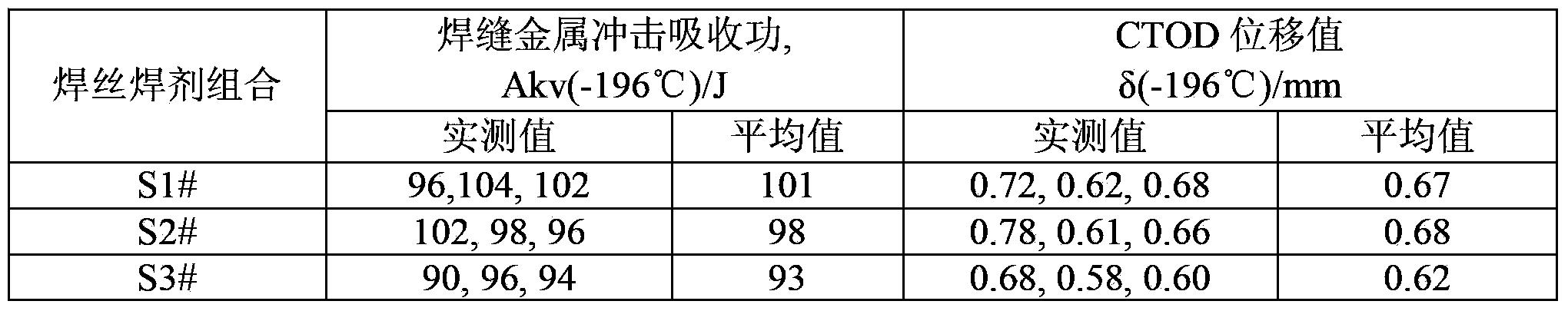

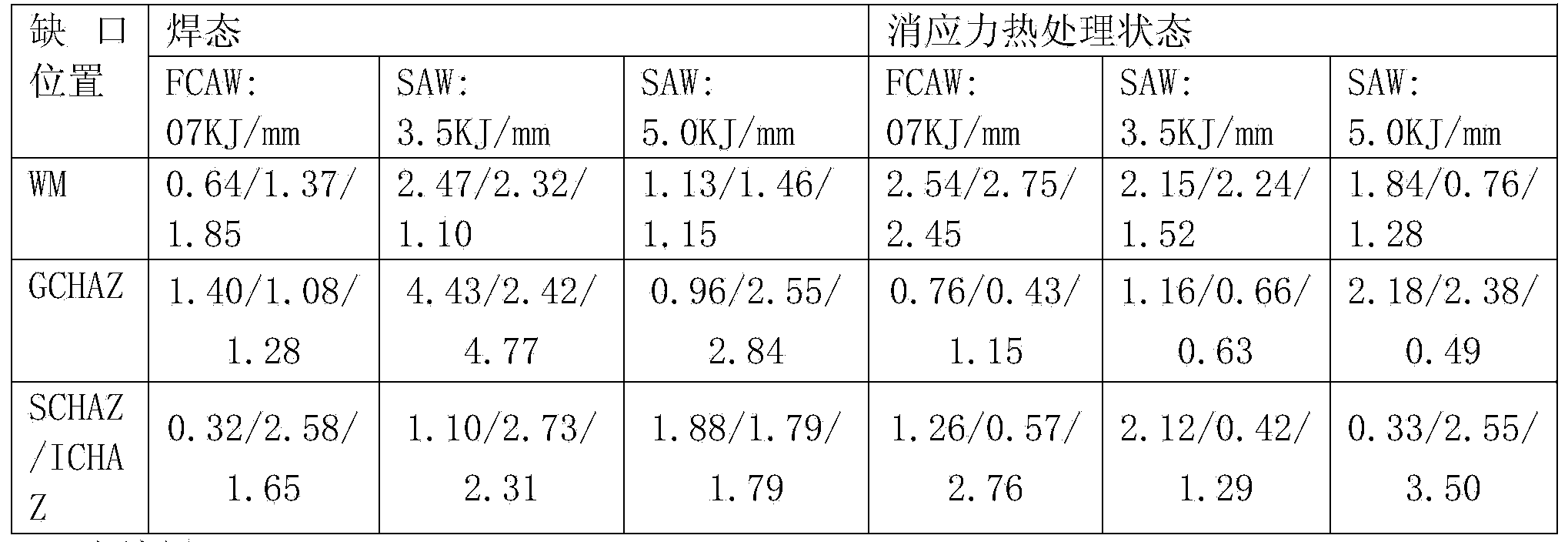

Welding wire and welding flux for 9Ni low-temperature steel submerged arc welding as well as application of welding wire and welding flux

ActiveCN103464930AOvercome the disadvantage that it can only be used for horizontal butt weldingWeld firmlyArc welding apparatusWelding/cutting media/materialsAlkalinityCrack tip opening displacement

The invention discloses a welding wire and a welding flux for 9Ni low-temperature steel submerged arc welding as well as application of the welding wire and the welding flux. The welding wire comprises the following chemical ingredients in percentage by weight: at most 0.04 percent of C, at most 0.10 percent of Si, at most 0.10 percent of Mn, 15 to 25 percent of Mo, 2.0 to 6.0 percent of W, 0.10 to 0.50 percent of Al and the balance of Ni and inevitable impurities. The welding flux comprises the following ingredients in percentage by weight: 5 to 20 percent of Ti2O3, 15 to 35 percent of MgO, 15 to 35 percent of CaF2, 15 to 25 percent of A12O3 and the balance Na2O, and the alkalinity is 2.2 to 4.2. The welding wire and the welding flux are adopted, submerged arc weld metal with excellent comprehensive performance can be obtained, the yield strength of the weld metal is greater than or equal to 516MPa, the tensile strength is greater than or equal to 725MPa, the impact power at minus 196 DEG C is greater than or equal to 90J, and the CTOD (crack tip opening displacement) displacement value at minus 196 DEG C is greater than or equal to 0.58mm. The welding wire and the welding flux can provide solutions for the welding assembly of LNG (liquefied natural gas) low-temperature storage tanks in China.

Owner:HAINING RUIAO METAL TECH CO LTD

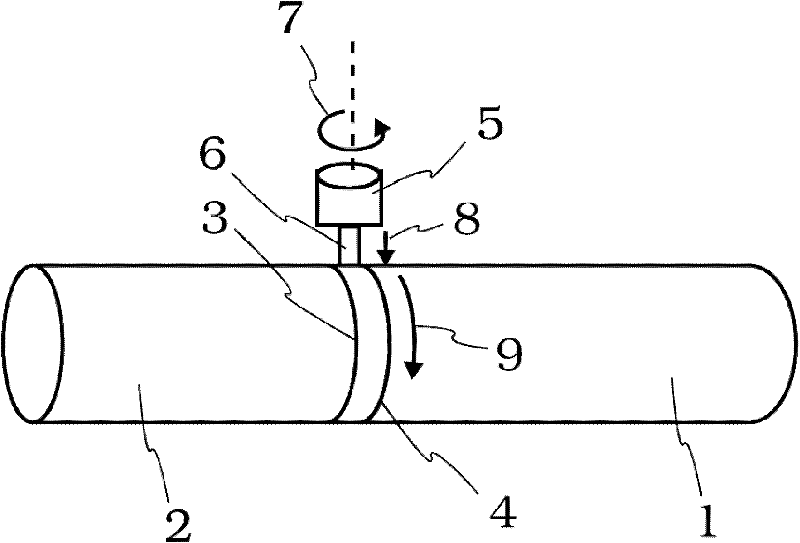

High strength and toughness steel structures by friction stir welding

InactiveCN102216483AWelding/soldering/cutting articlesThin material handlingCrack tip opening displacementAustenite grain

Provided are steel structures methods of making such steel structures including structural steel components bonded by friction stir weldments with advantageous microstructures to yield improved weldment strength and weldment toughness. In one form of the present disclosure, the steel structure includes: two or more structural steel components produced by conventional melting or secondary refining practices and friction stir weldments bonding faying surfaces of the components together, wherein the chemistry and grain size of the starting structural steel satisfies one or more of the following criteria:; a) 0.02 wt% < Ti + Nb < 0.12 wt%, b) 0.7 < Ti / N <3.5, c) 0.5 wt% < Mo + W + Cr + Cu + Co + Ni < 1.75 wt%, d) 0.01 wt% < TiN + NbC + TiO / MgO < 0.1 wt%, e) average grain size of at least 2 microns, wherein the friction stir weldments have a prior austenite grain size of between 5 and 60 microns and less than 50 vol% of martensite-austenite constituent, and wherein the friction stir weldment strength is greater than the starting structural steel and the friction stir weldment toughness as measured by the crack tip opening displacement test at less than or equal to 0 DEG C is greater than or equal to 0.05 mm or by the Charpy V-notch impact test at less than or equal to 0 DEG C is greater than 40 J. The steel structures find application in linepipe for oil and gas production.

Owner:EXXON RES & ENG CO

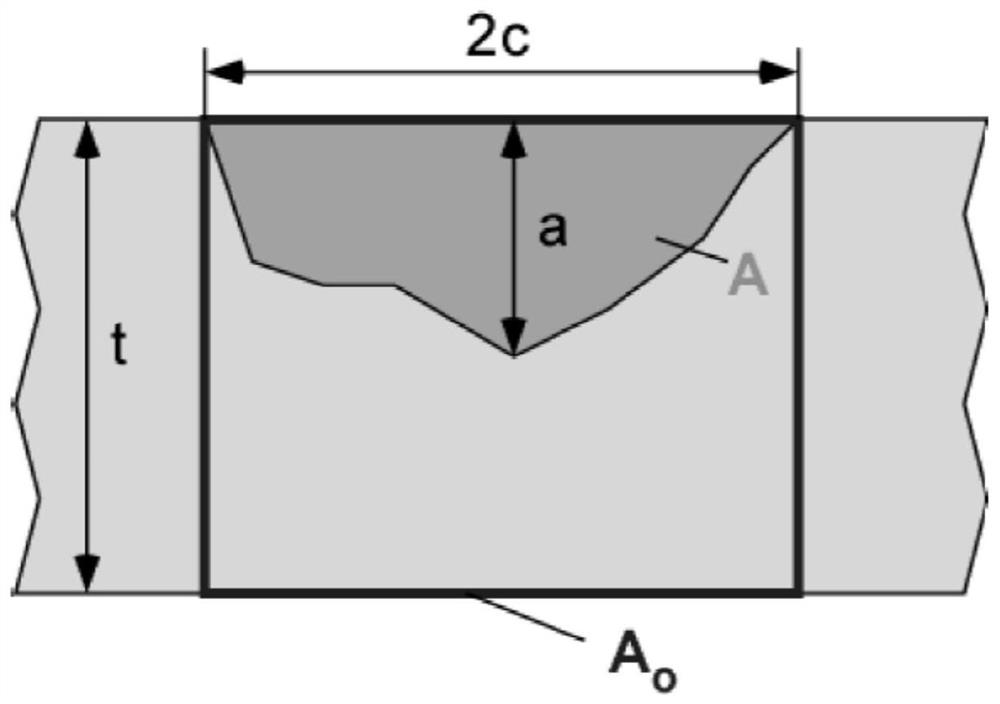

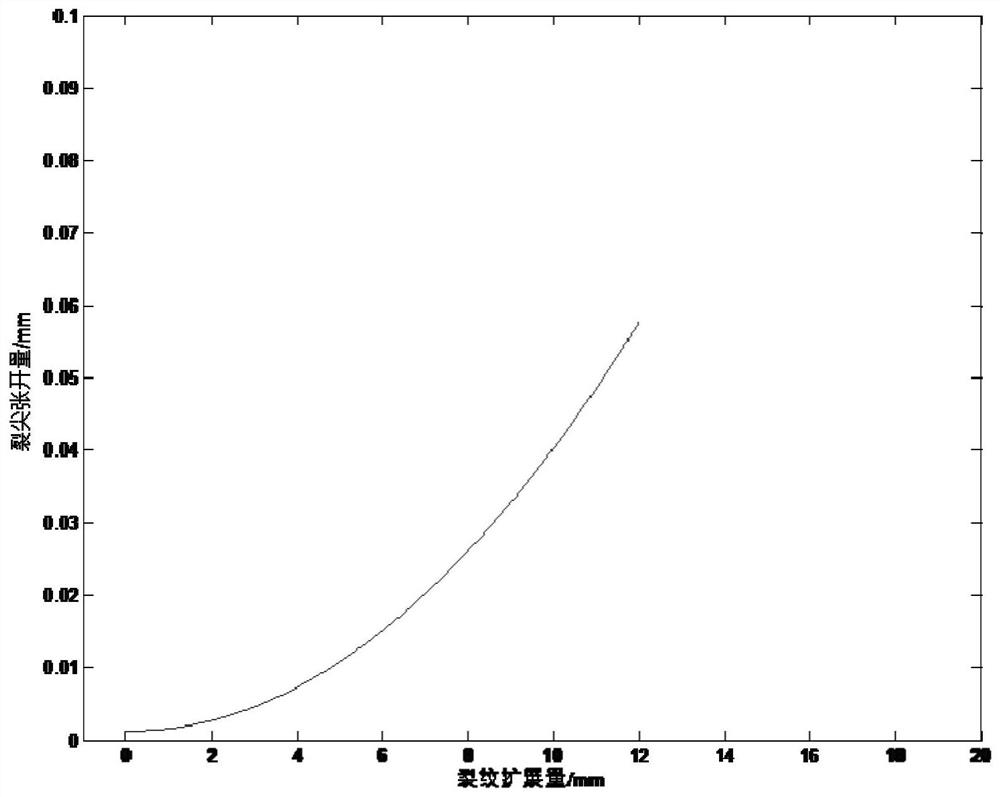

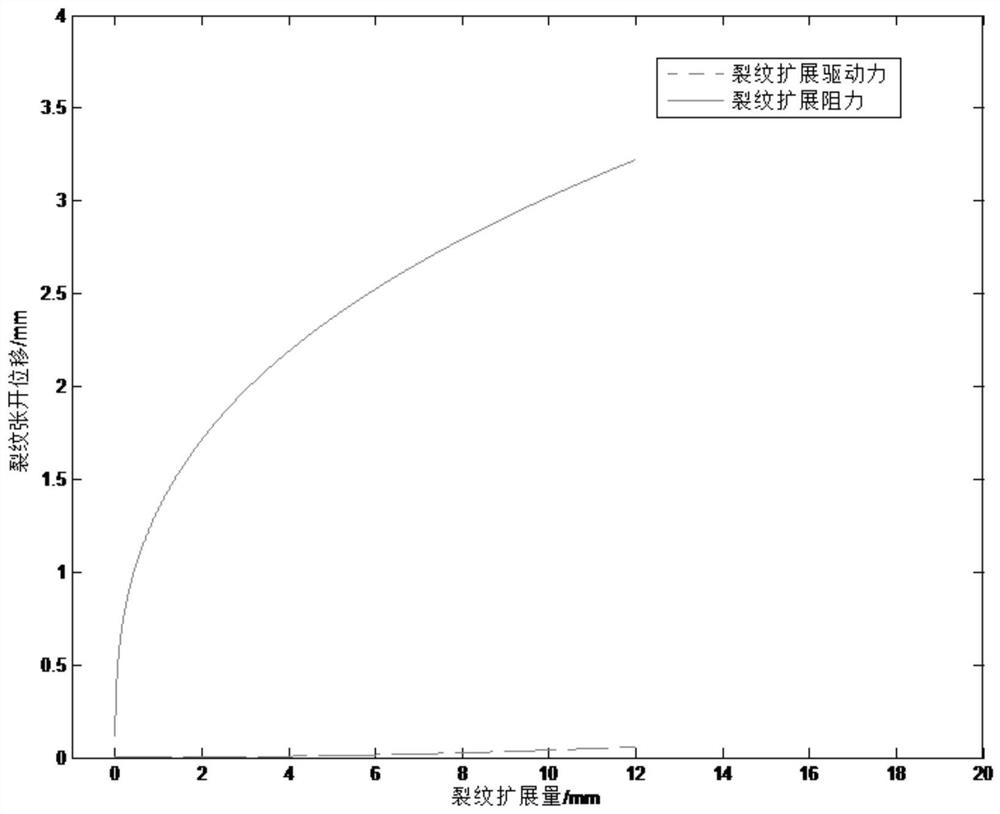

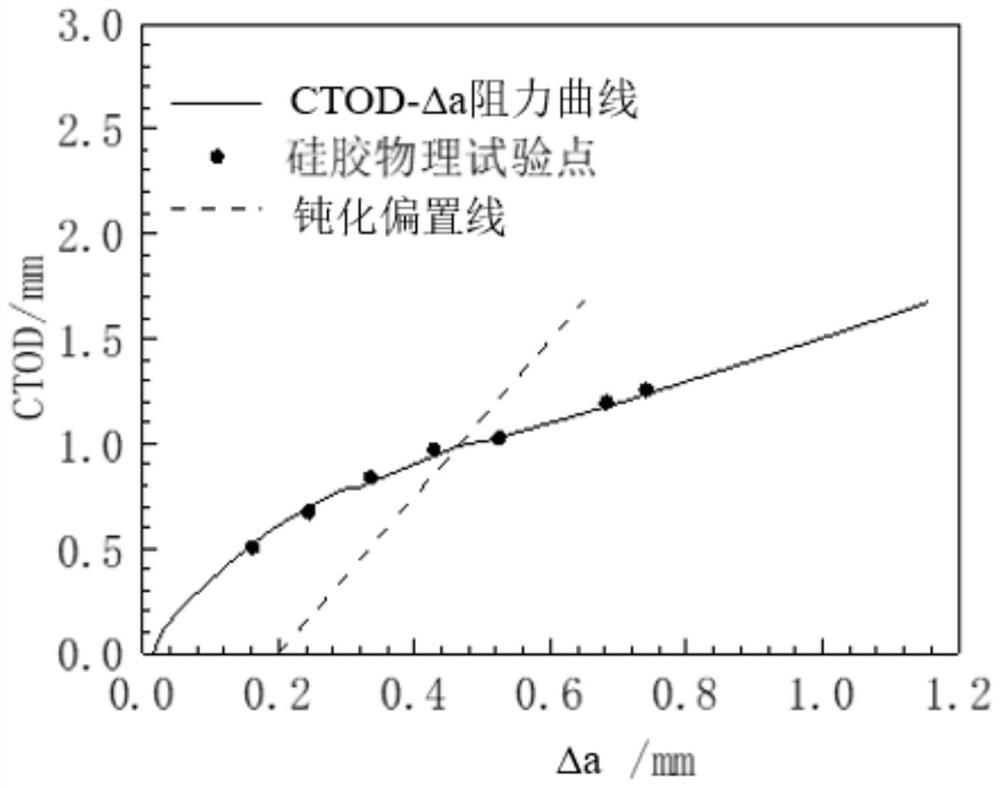

High-pressure natural gas pipeline fracture critical dimension and service life evaluation method

PendingCN111859616AAccurate calculationEasy to understandMaterial strength using tensile/compressive forcesDesign optimisation/simulationCrack tip opening displacementCrack growth resistance curve

The invention discloses a high-pressure natural gas pipeline fracture critical dimension and service life evaluation method; the method includes obtaining a crack propagation resistance curve of the to-be-tested natural gas pipeline through a fracture resistance test; obtaining the yield strength and the tensile strength of the to-be-tested natural gas pipeline through a tensile property test; calculating the parameters of the fracture toughness of the material according to the crack propagation resistance curve of the natural gas pipeline to be measured, the parameters of the resistance curve, yield strength and tensile strength; establishing a crack tip opening displacement relation; obtaining crack tip opening displacement under different crack depths under the action of fixed internalpressure; determining the critical dimension of the crack when the pipeline fails according to the competitive relationship between the crack propagation driving force and the resistance; and reflecting the whole service process from the growth of failure cracks of the pipeline. According to the invention, the material crack propagation resistance of the pipeline is considered in the calculation process, the calculation process is more accurate, tests required by the method belong to conventional tests and are easy to carry out, the treatment process is simple and convenient, and time and economic cost are saved.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Ni-series low-temperature steel, manufacture method thereof, liquefied natural gas storage tank and ship body for transportation ship

The invention provides Ni-series low-temperature steel, a manufacture method thereof, a liquefied natural gas storage tank and a ship body for a transportation ship. The Ni-series low-temperature steel includes the following chemical compositions by mass percentage: 0.02-0.10% of C, 0.01-0.20% of Si, 0.50-0.75% of Mn, less than or equal to 0.010% of P, less than or equal to 0.004% of S, 8.50-9.50% of Ni, 0.005-0.40% of Al, 0.005-0.40% of Ti, 0.0005-0.003% of O, 0.0010-0.01% of N, 0.0005-0.004% of Ca, 0.001-1.50% of Cu, 0.001-0.16% of Mo and the balance being Fe. The manufacture method includes steps of: adopting a basic oxygen furnace (BOF)(or an electric arc furnace(EAF)) for smelting+ low frequency (LF)+ VD(or RH) refining technology for refining; adopting a secondary cold area weak cold+ stable low casting process to be matched for steel continuous casting; adopting low-temperature heating+ controlled rolling technology for steel rolling and directly quenching at the temperature above Ar3; and adopting the critical hardening+ tempering process for thermal treatment of steel. Through experiments of low-temperature impacting, non destructive testing (NDT), dark trace (DT), crack tip opening displacement (CTOD), K1a and the like, the Ni-series low-temperature steel is proved to have the advantages of having good obdurability matching and suitable for manufacturing ultra-large type liquefied natural gas (LNG) storage tanks, wherein manufacture volume of the LNG storage tanks exceeds 2*105m<3>, maximum wall thickness exceeds 50mm, and the LNG storage tanks are ultra-high in requirements for safety.

Owner:CENT IRON & STEEL RES INST

High-strength and high-toughness submerged arc welding wire for deep-sea pipeline welding

InactiveCN104107988AImprove mechanical propertiesInsufficient improvementArc welding apparatusWelding/cutting media/materialsSocial benefitsCrack tip opening displacement

Disclosed is a high-strength and high-toughness submerged arc welding wire for deep-sea pipeline welding. The welding wire is prepared from, by mass, 0.04-0.09% of C, 0.1-0.3% of Si, 1.6-1.8% of Mn, 0.3-0.5% of Mo, 0.15-0.5% of Ni, 0.04-0.12% of Ti, 0.004-0.001% of B, less than 0.012% of P, less than 0.003% of S and the balance ferrum. The welding wire has the advantages of reasonable components and reliable performance. The high-strength and high-toughness submerged arc welding wire for deep-sea pipeline welding belongs to an Mn-Mo-Ti-B alloy system, has the features of multi-component alloy, and can adjust components weld metal and improve mechanical properties of welds. When the welding wire is applied to thick-walled deep-sea pipeline welding, low-temperature impact toughness and low-temperature CTOD (crack tip opening displacement) performance of the welds are good, Charpy impact absorption of the welds and welding lines can meet requirements, and margin is large. The defects of an existing deep-sea pipeline build-up welding material are overcome, and the welding wire has good economic and social benefits.

Owner:HUBEI KMK WELDING MATERIALS

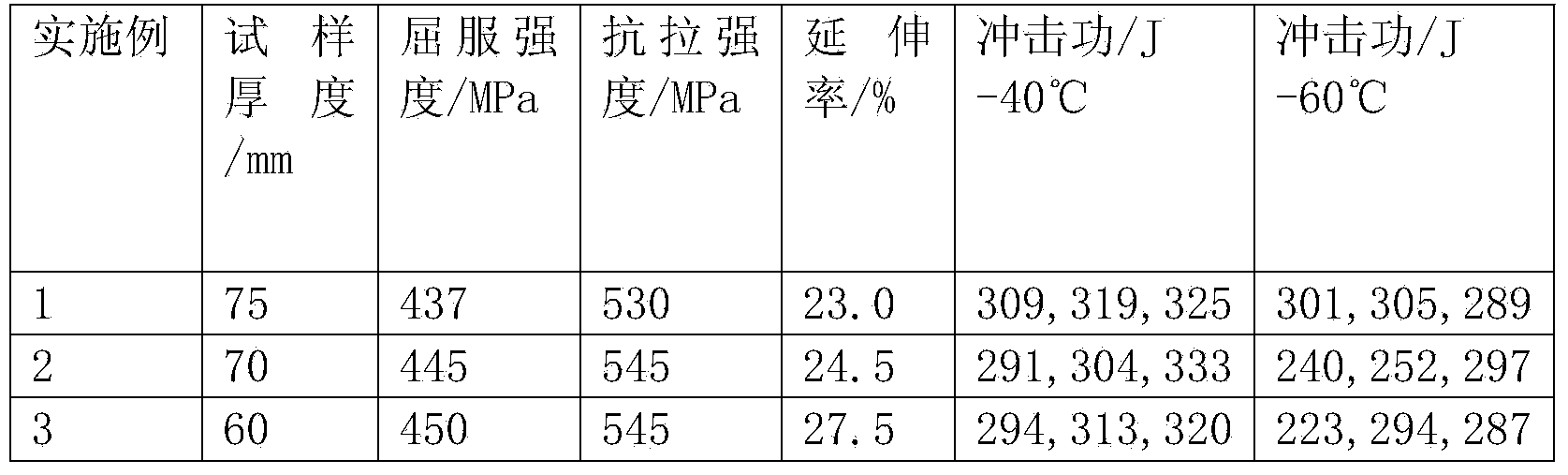

50-75 mm-thick 355MPa-grade fracture toughness protecting steel and production method thereof

InactiveCN104264050AAchieve recrystallization refinementGuaranteed low temperature impact performanceHigh fractureCrack tip opening displacement

The invention belongs to the technical field of steel and iron material production and particularly relates to 50-75 mm-thick 355MPa-grade fracture toughness protecting steel and a production method thereof. The 50-75 mm-thick 355MPa-grade fracture toughness protecting steel comprises the following chemical components in percentage by weight: 0.04-0.13 percent of C, 0.2-0.5 percent of Si, 1.0-1.6 percent of Mn, less than 0.018 percent of P, less than 0.005 percent of S, 0.3-0.7 percent of Ni, 0.02-0.05 percent of Nb, 0.02-0.04 percent of V, 0.08-0.020 percent of Ti and the balance of Fe and inevitable impurities. The 50-75 mm-thick 355MPa-grade fracture toughness protecting steel and the production method thereof have the benefits that the fracture toughness protecting steel is low in cost, is easy to weld and can reach 75 mm thickness under the condition of realizing 355MPa-grade high toughness of the steel; the CTOD (Crack Tip Opening Displacement) characteristic value of a welded joint at a temperature of 10 DEG C blew zero can be ensured, and the fracture toughness protecting steel with high strength, high toughness and high fracture toughness is realized under the condition of low carbon content.

Owner:SHANDONG IRON & STEEL CO LTD

Ocean engineering steel with welded joint CTOD (crack tip opening displacement) greater than 0.5mm and preparation method

ActiveCN103741027AGuaranteed Low Temperature ToughnessImprove low temperature toughnessCrack tip opening displacementEngineering

The invention discloses ocean engineering steel with welded joint CTOD (crack tip opening displacement) greater than 0.5mm and a preparation method, belonging to the technical field of ocean engineering steel. The ocean engineering steel comprises the following chemical components in percentage by weight: 0.05-0.12% of C, 0.10-0.40% of Si, 1.0-1.50% of Mn, 0.03-0.04% of Alt, 0.02-0.06% of Nb, 0.010-0.02% of Ti, 0.1-0.5% of Ni, less than 0.01% of P, less than 0.005% of S and the balance of Fe and unavoidable impurities. The alloy content is adjusted according to the effect of the alloy element in the steel, the parameters of the controlled-rolling and controlled-cooling process are strictly controlled, and the obtained 10-80mm steel plate has comprehensive mechanical properties that the welded joint CTOD is greater than 0.5mm at -10 DEG C under 420MPa and the lamellar tearing resistance is greater than 35% and the like. The ocean engineering steel disclosed by the invention has excellent comprehensive properties and can be widely applied to the key parts of the stationary, semi-submersible and self-elevating platforms.

Owner:SHOUGANG CORPORATION

Method for calculating power hardening elastic-plastic bending crack opening displacement under the action of dynamic load

PendingCN108804829ACreate a function change relationshipDesign optimisation/simulationSpecial data processing applicationsShear stressCrack tip opening displacement

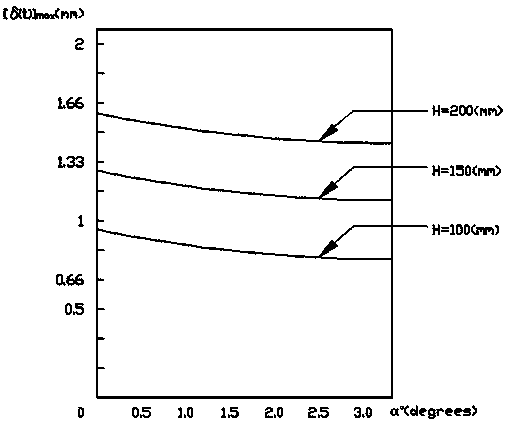

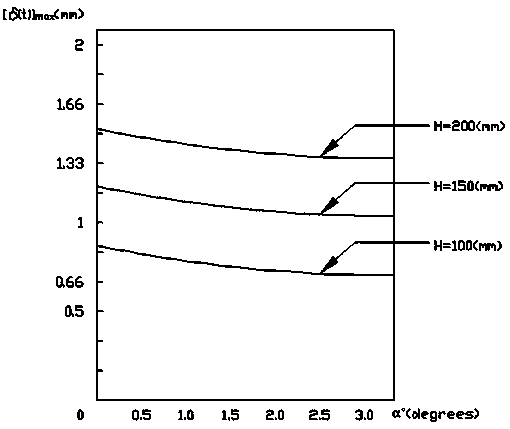

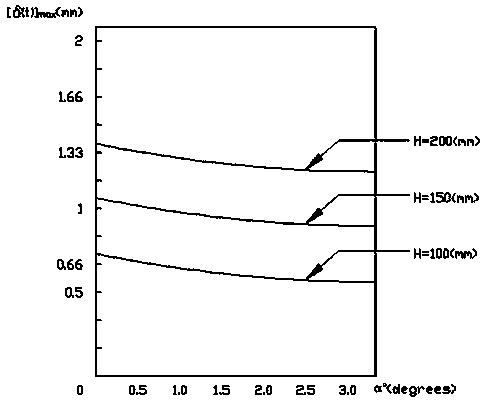

The invention discloses a method for calculating power hardening elastic-plastic bending crack opening displacement under the action of dynamic load. According to the calculation method, the dynamic action stress, the normal stress and the shear stress on the boundary of a plastic region are comprehensively considered, and the opening displacement of a tip point of an elastic-plastic bending crackof a hardened material is calculated by using the Castigliano's theorem. The variation relationship between the maximum value of the dynamic opening displacement of the elastic-plastic bending crackand a material hardening exponent is analyzed by drawing. In a power hardening material, the maximum value of the dynamic opening displacement of the tip point of the elastic-plastic bending crack decreases with the increase of the material hardening exponent n, when the n increases uniformly at a constant velocity, the maximum value of the dynamic opening displacement of the tip point of the elastic-plastic bending crack decreases in an acceleration manner, and the reduction amplitude becomes bigger and bigger. When the hardening index of the material is the same, the maximum value of the dynamic opening displacement of the tip point of the elastic-plastic bending crack gradually decreases with the continuous decrease of the external load.

Owner:ZHENGZHOU TECHN COLLEGE

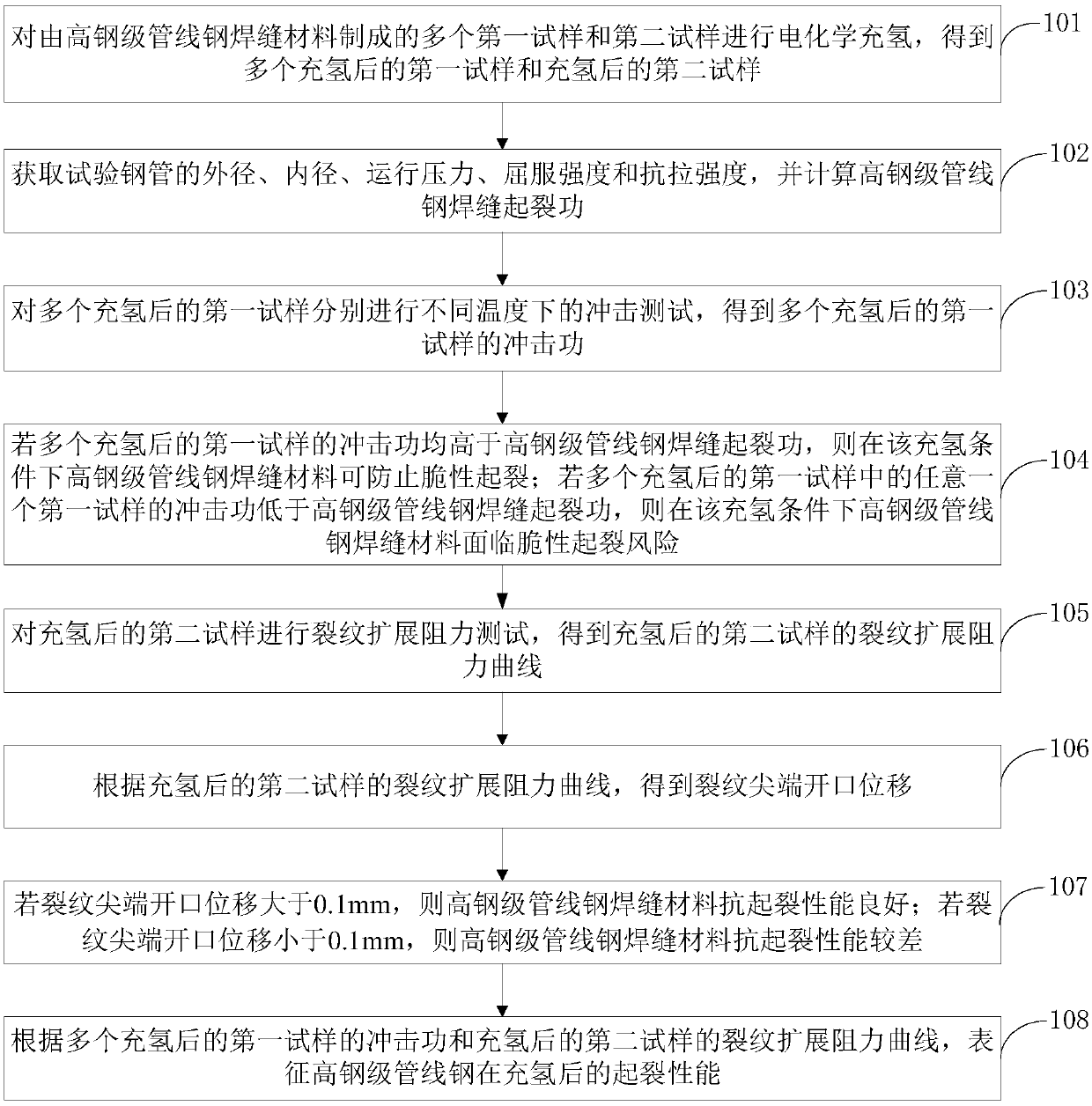

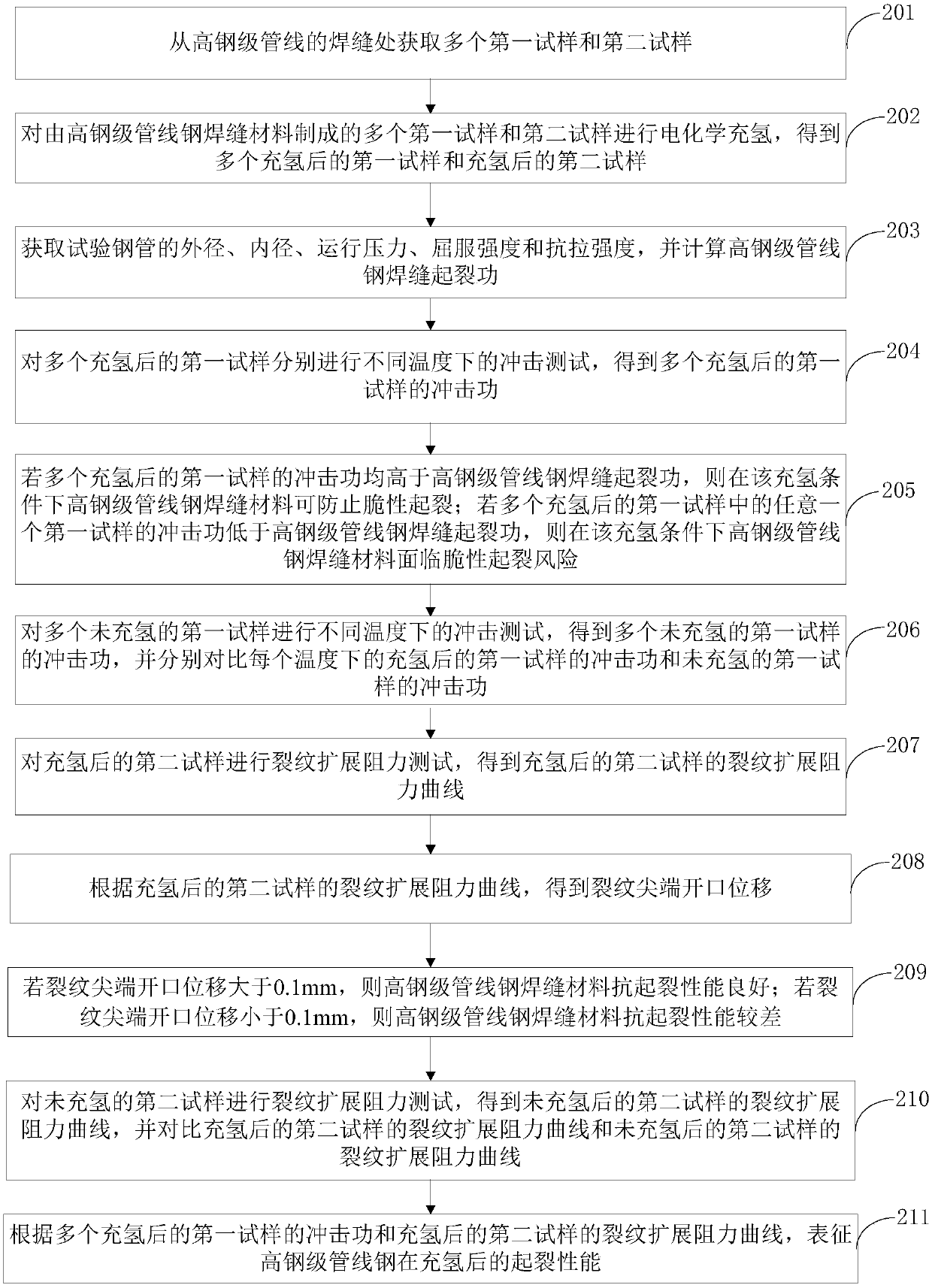

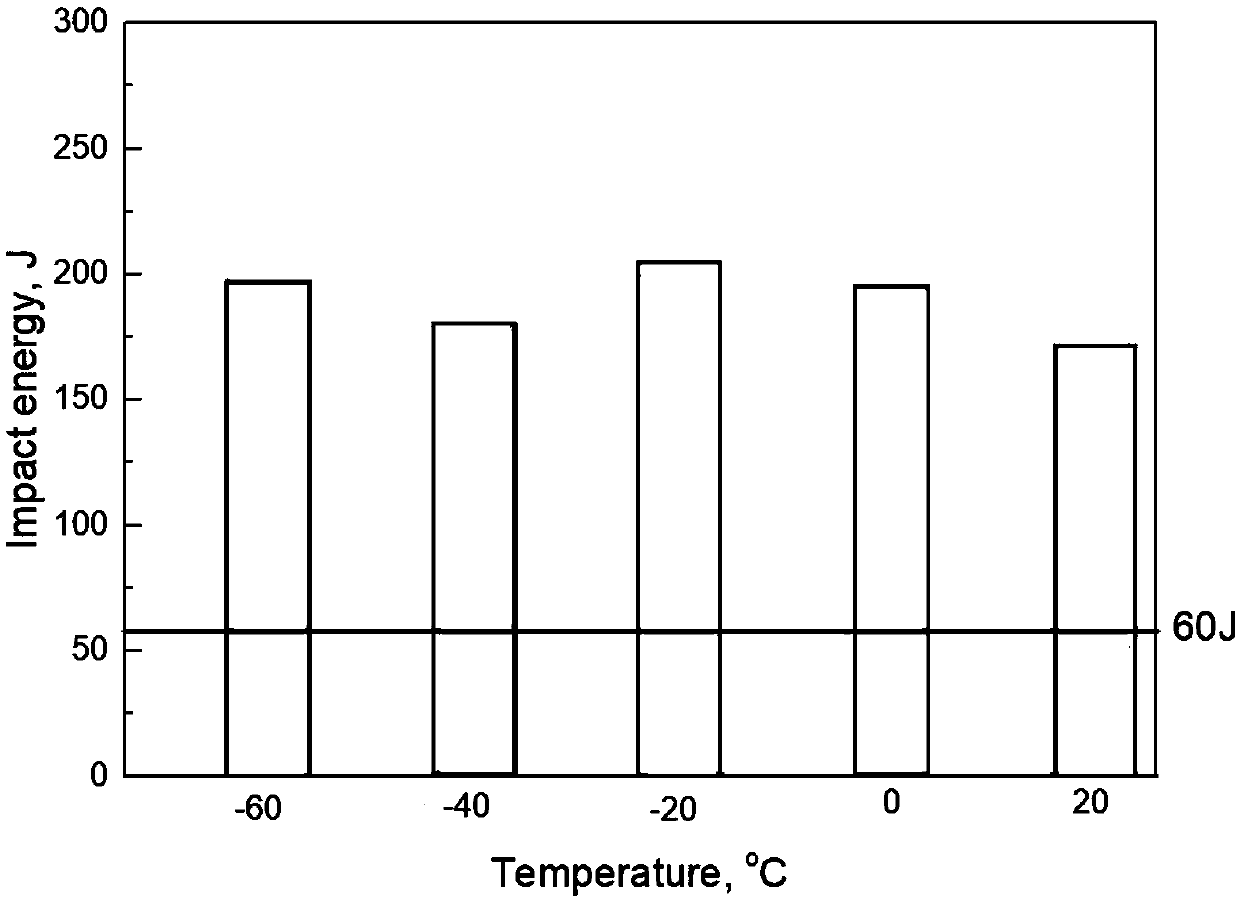

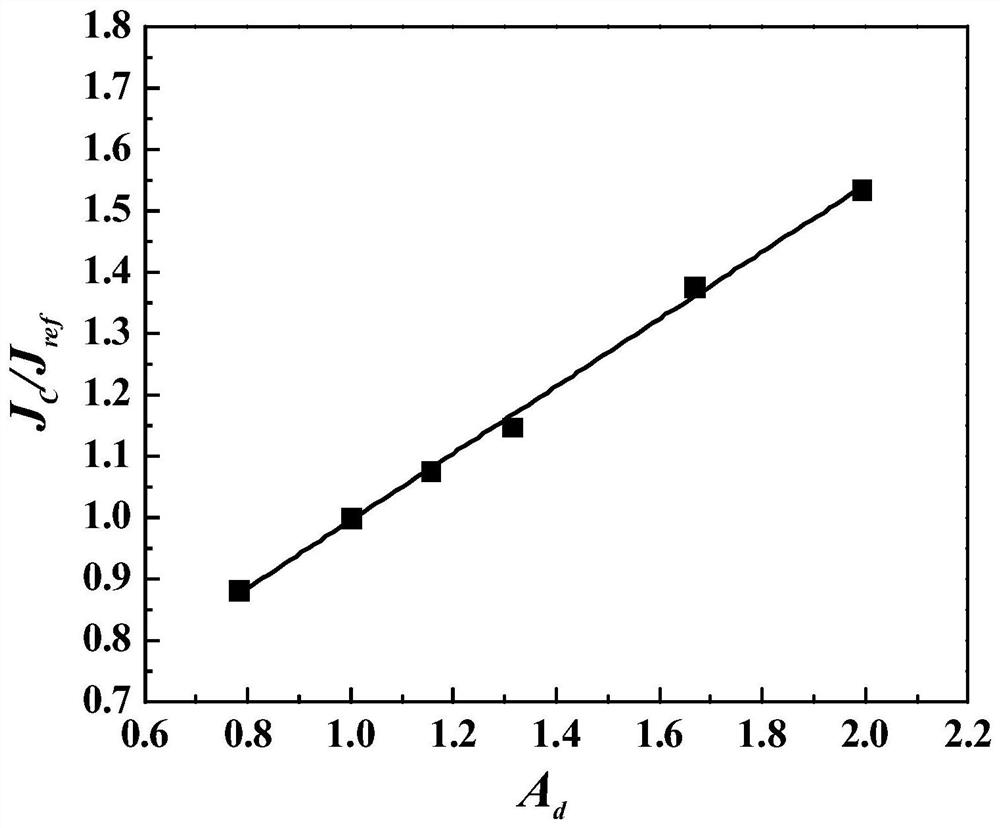

Test method for representing influence of hydrogen on crack initiation performance of high-steel-grade pipeline steel

ActiveCN111366483AMaterial strength using repeated/pulsating forcesCrack tip opening displacementCrack growth resistance curve

The invention discloses a test method for representing influence of hydrogen on crack initiation performance of high-grade pipeline steel. The method comprises steps that electrochemical hydrogen charging of a plurality of first samples and second samples which are made of a high-steel-grade pipeline steel weld joint material is conducted; after hydrogen filling is finished, impact tests at different temperatures are conducted on the multiple first samples obtained after hydrogen filling, the impact work of the multiple first samples obtained after hydrogen filling is obtained, and the impactwork of the multiple first samples obtained after hydrogen filling is compared with the crack initiation work of a high-steel-grade pipeline steel weld joint; a crack propagation resistance test on the second samples after hydrogen filling is conducted, a crack propagation resistance curve of the second samples is obtained after hydrogen filling, the crack tip opening displacement is obtained, whether a value of the crack tip opening displacement is larger than 0.1 mm or not is judged, the crack initiation resistance of the high-steel-grade pipeline steel weld joint material is determined, anda basis is provided for judging the crack initiation performance of the high-steel-grade pipeline steel after the high-steel-grade pipeline steel bears the hydrogen environment of a certain degree.

Owner:PETROCHINA CO LTD

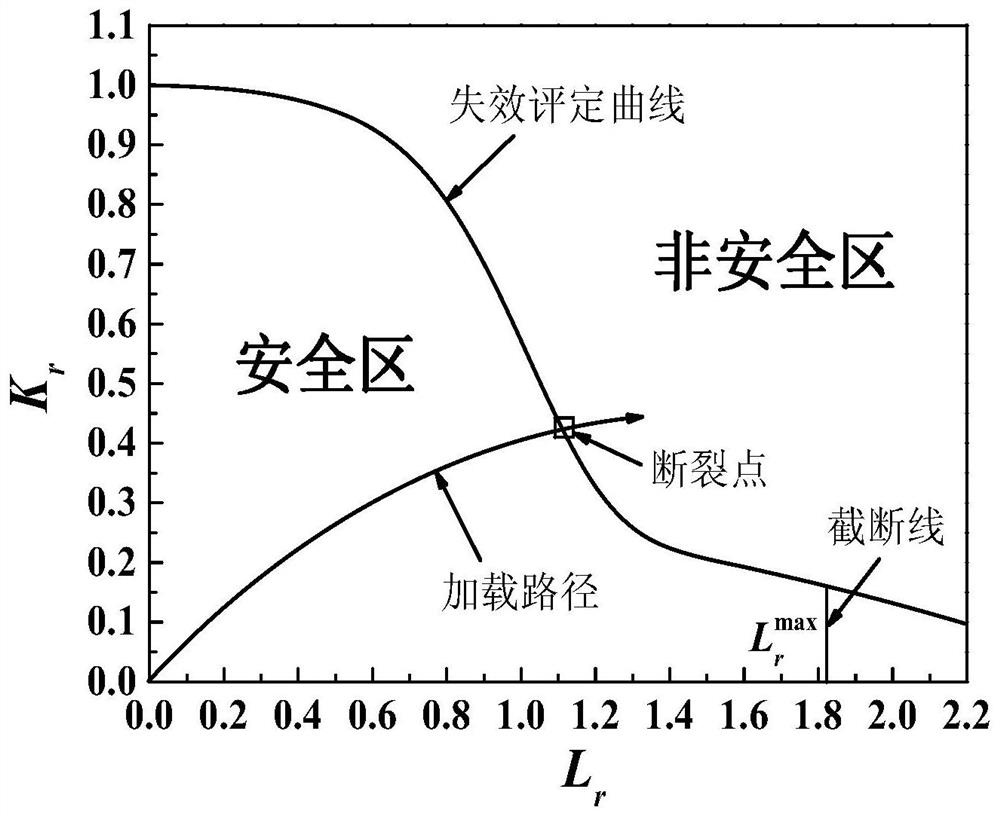

Structural integrity evaluation method incorporating in-plane and out-plane unified constraint

PendingCN112287577AEasy to calculateEfficient use ofDesign optimisation/simulationSpecial data processing applicationsReference sampleCrack tip opening displacement

The invention provides a structural integrity evaluation method incorporating in-plane and out-plane unified constraint. The method comprises the following steps: establishing a correlation between nominal fracture toughness of a material and a unified constraint parameter, wherein the unified constraint parameters is the ratio of the crack tip opening displacement of other samples or a to-be-evaluated structure to the crack tip opening displacement value of a reference sample under the fracture load; representing the geometric dimension and the defect dimension of the structure; determining astructure limit load and unified constraint parameters under different load ratios; constructing a failure evaluation graph of the defects; determining evaluation point coordinates under each load ratio to form a loading path line; when the fracture ratio of the coordinates of the evaluation point is calculated, substituting the constraint parameters under different load ratios into the correlation, and determining the fracture toughness related to material constraint; and performing defect safety evaluation and fracture prediction. According to the evaluation method, unified constraint parameters based on crack tip opening displacement are provided, so that in-plane constraint and out-plane constraint are unified, engineering calculation and application are facilitated, and the evaluation precision is improved.

Owner:EAST CHINA UNIV OF SCI & TECH

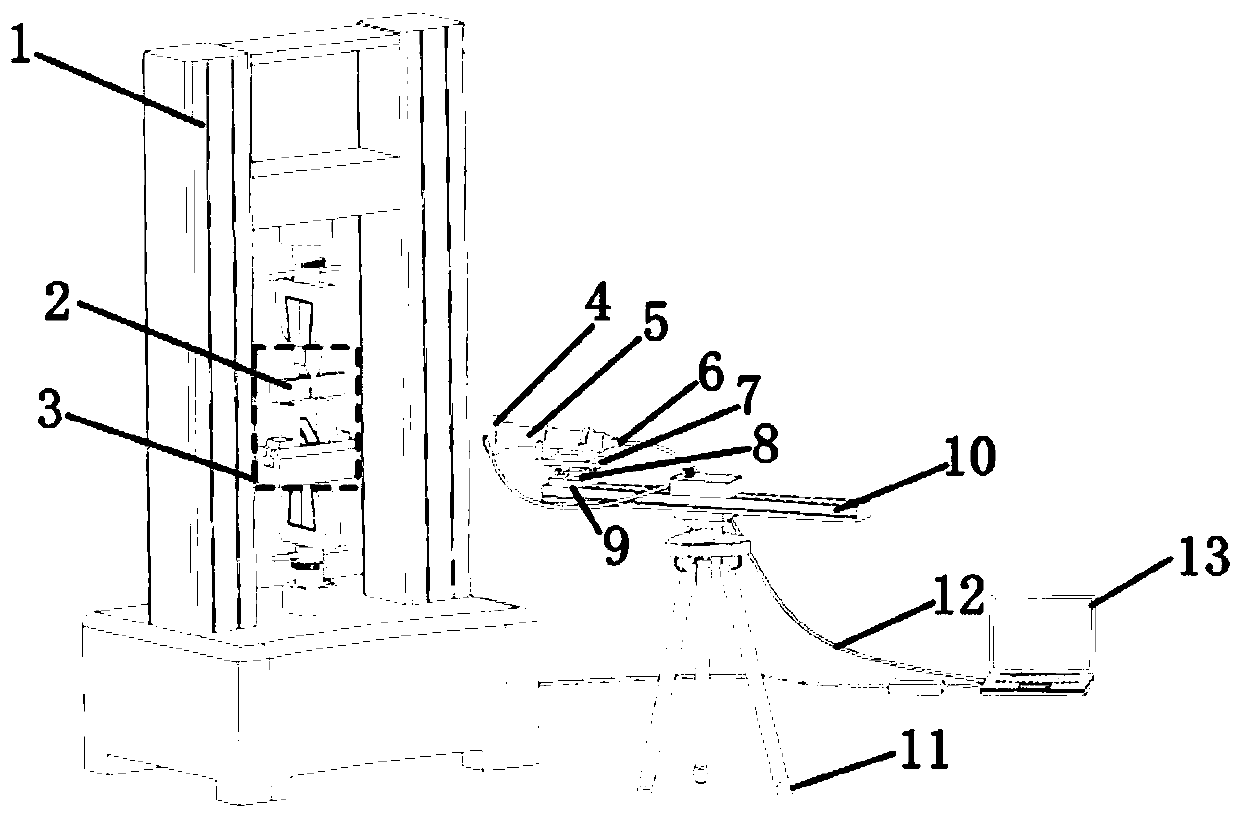

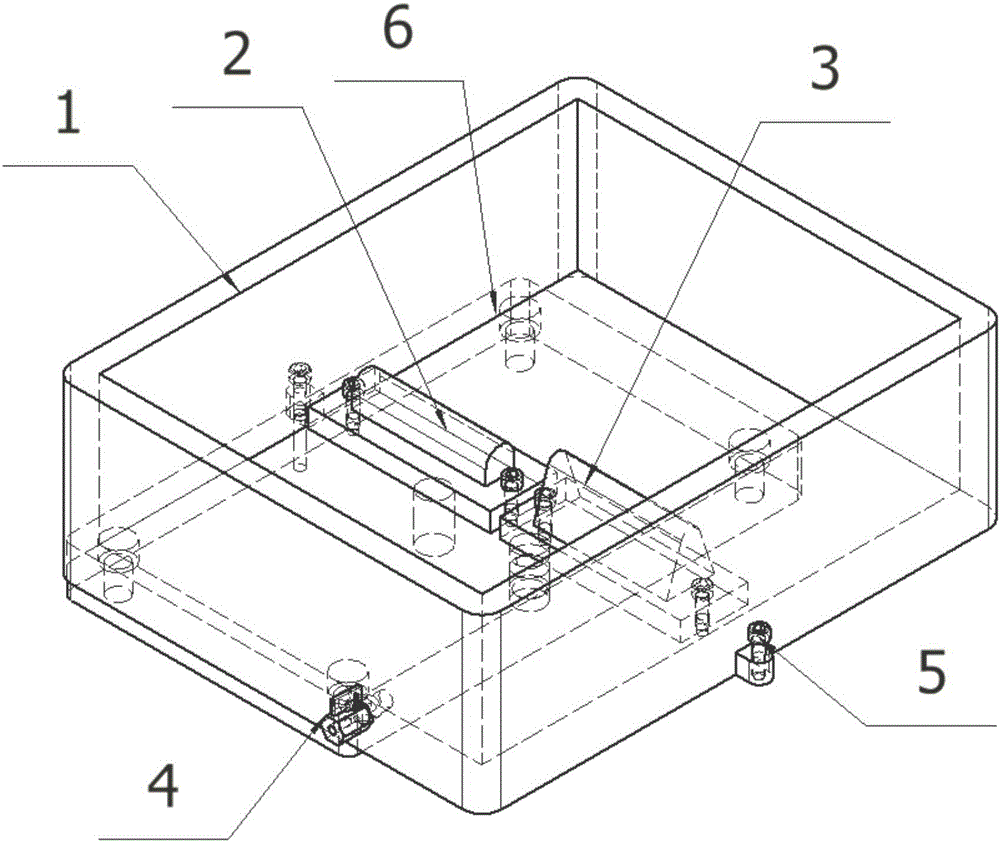

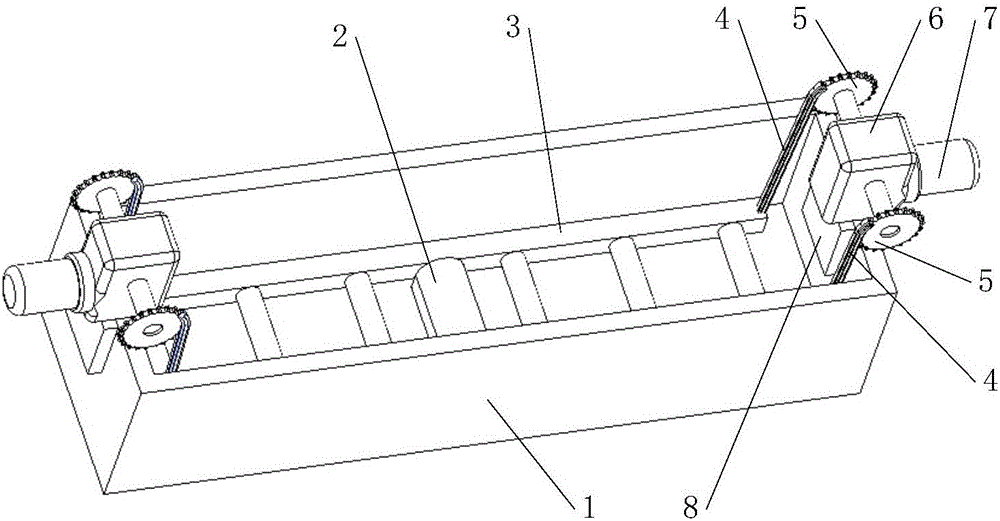

Double-propping head incubator for low-temperature CTOD (Crack Tip Opening Displacement) tests

ActiveCN105865901APrecise positioningSimple structureMaterial strength using tensile/compressive forcesCrack tip opening displacementEngineering

The invention discloses a double-propping head incubator for low-temperature CTOD (Crack Tip Opening Displacement) tests. The double-propping head incubator comprises a rotational low-temperature tank, a buckling failure propping head, a breaking propping head, a liquid discharge micro ball valve, limiting screws and a test machine connecting plate, wherein the rotational low-temperature tank is a tank body of which the upper end is opened; the buckling failure propping head and the breaking propping head are arranged inside the rotational low-temperature tank; the liquid discharge micro ball valve is mounted on a side wall of the rotational low-temperature tank; two sides of the rotational low-temperature tank are positioned by using the limiting screws; the test machine connecting plate is arranged at the bottom of the rotational low-temperature tank. Therefore, when low-temperature CTOD tests are implemented, rapid and accurate positioning of a double-point pressing head and two single-point propping heads can be achieved, so that two test steps of buckling failure loading and breaking of a test piece can be continuously completed by using one universal test machine, the working efficiency and the precision of tests are improved, and the working intensity of testers can be alleviated.

Owner:CNPC OFFSHORE ENG

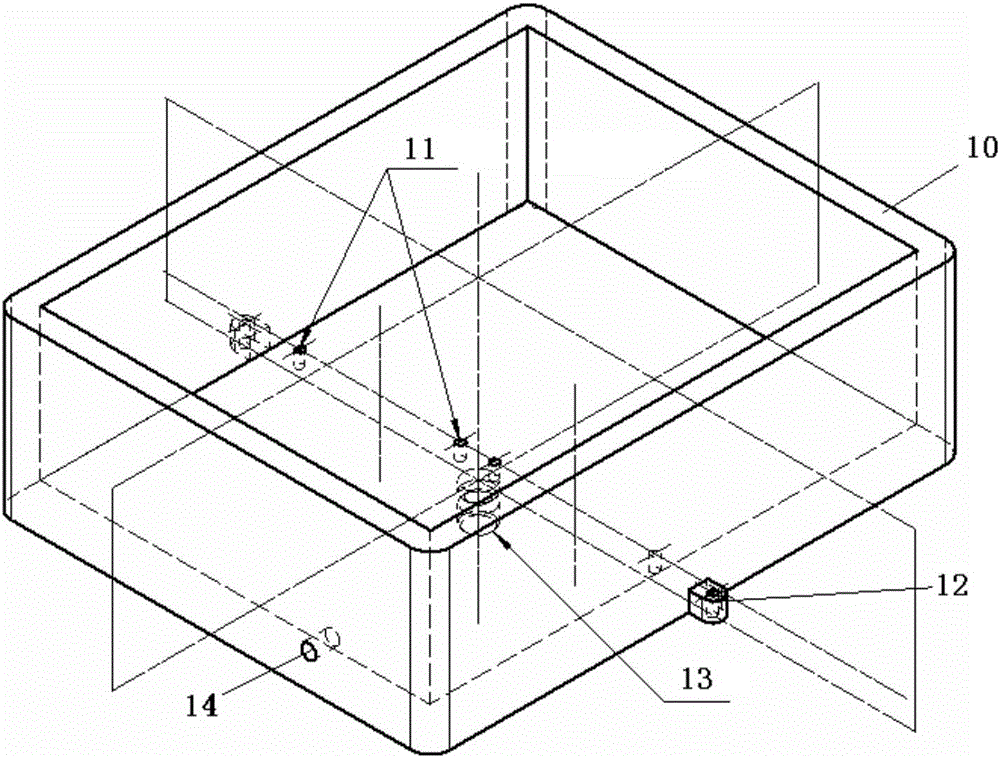

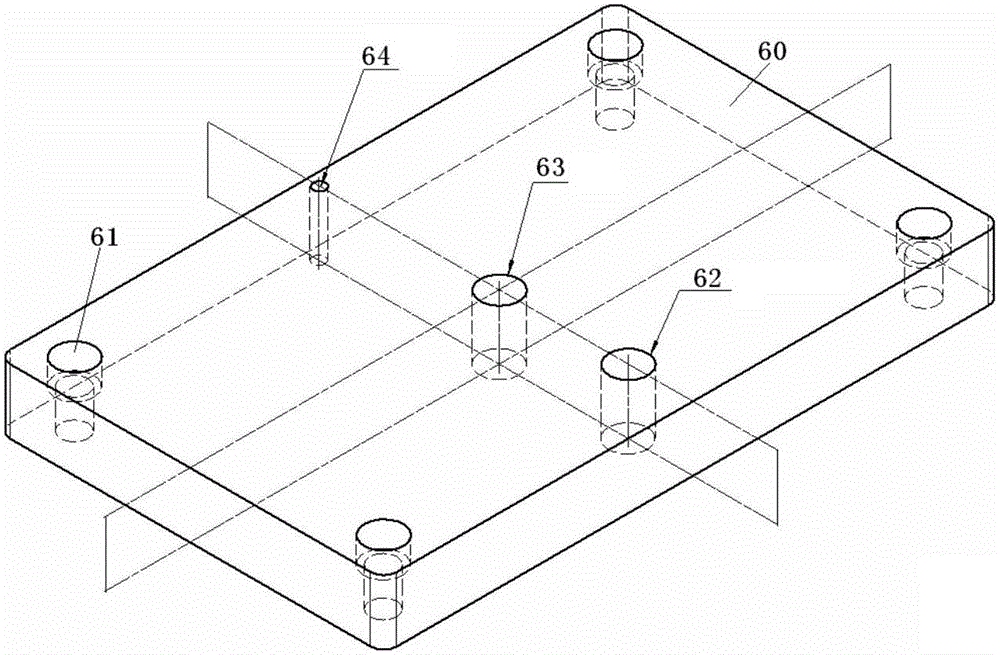

Cooling box for CTOD (crank tip opening displacement) test and operating process of cooling box

ActiveCN106018118APrevent splashInhibit sheddingMaterial strength using tensile/compressive forcesCrack tip opening displacementEngineering

The invention provides a cooling box for a CTOD (crank tip opening displacement) test and an operating process of the cooling box. The cooling box for the CTOD test comprises a box body, an ejecting head, a lifting frame and lifting mechanisms, wherein the box body is rectangular, and an opening is formed in the upper end of the box body and allows a sample to be placed in; the ejecting head is arranged in the middle of the bottom of the box body; the lifting frame is movably arranged in the box body, the two lifting mechanisms are located on two side walls of the box body respectively and connected to two sides of the lifting frame respectively to allow the lifting frame to move up and down in the box body. Therefore, the cooling box is safe, reliable and simple to operate, a cryogenic liquid can be effectively prevented from injuring an operator in a test link, the safety of the test is improved, and orderly and smooth implementation of the test can be guaranteed.

Owner:CNPC OFFSHORE ENG

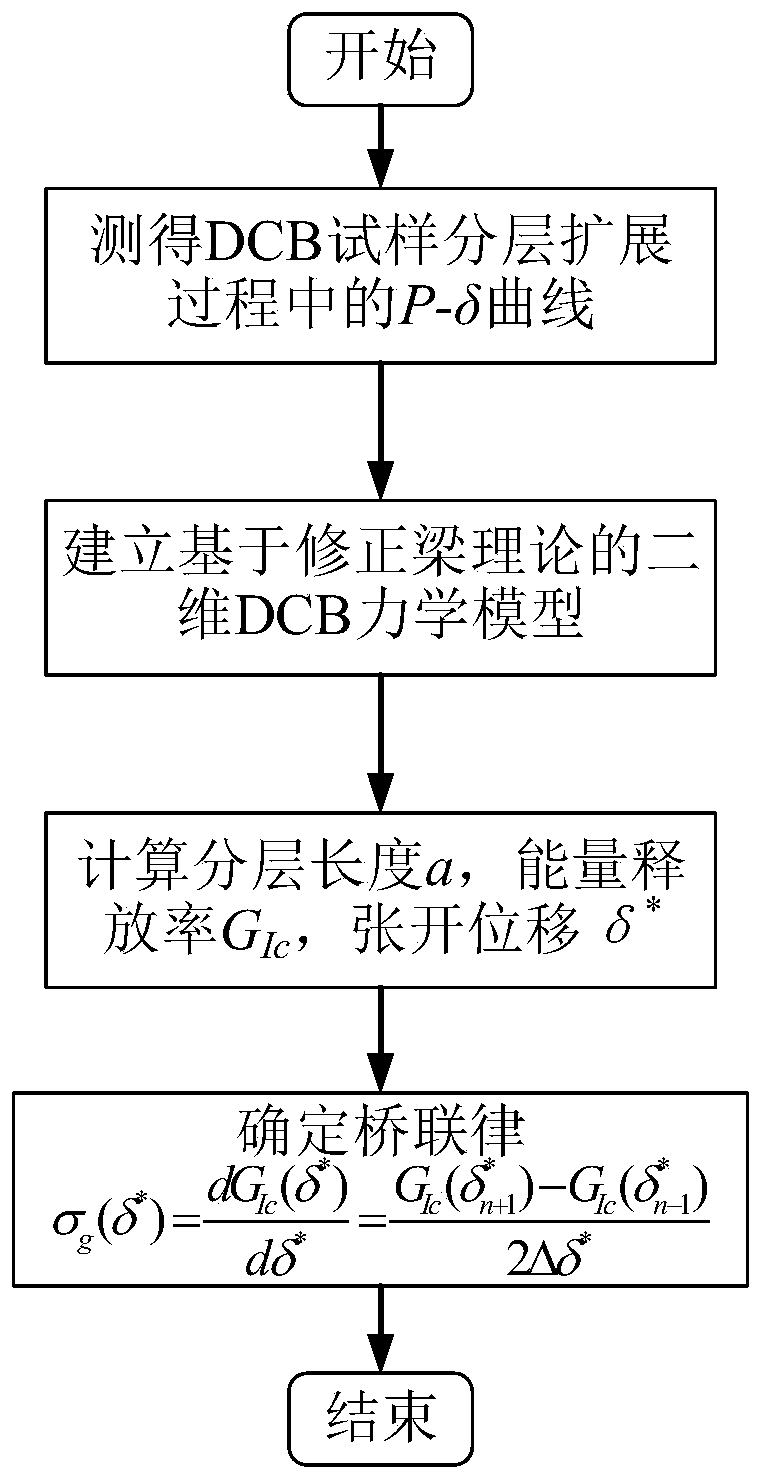

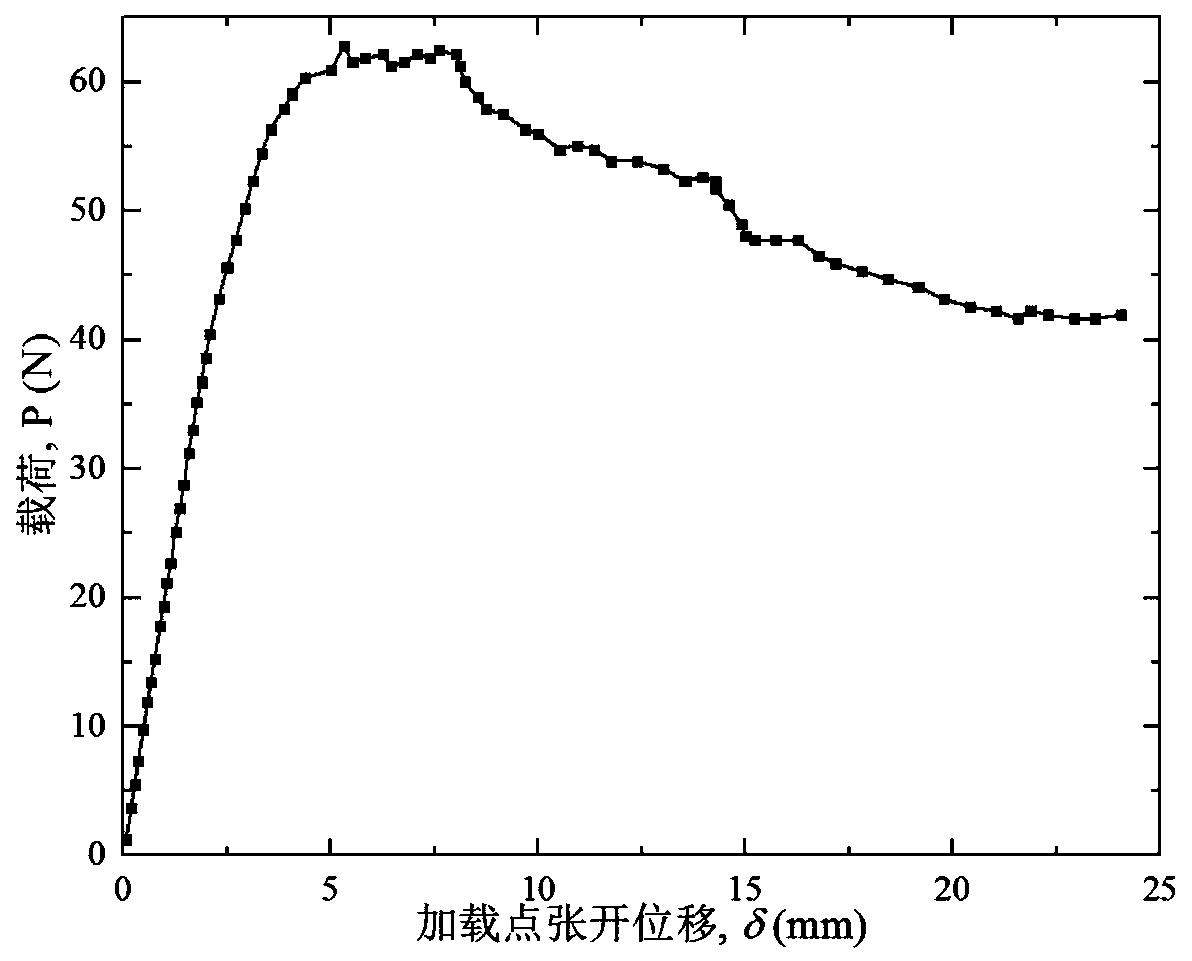

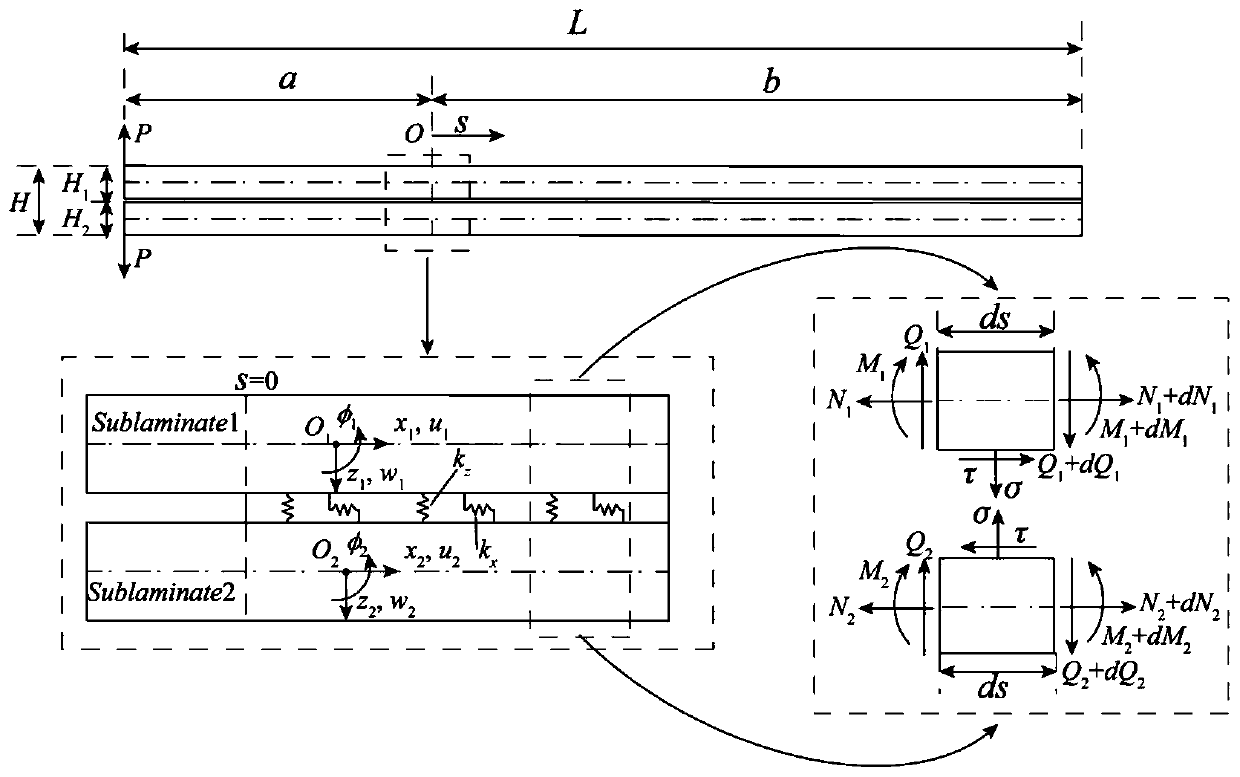

Composite material I-type layered bridging law determination method based on correction beam theory

ActiveCN111339697ASolve lengthResolve accuracyDesign optimisation/simulationCrazingCrack tip opening displacement

The invention relates to a composite material I-type layered bridging law determination method based on a modified beam theory, which comprises the following steps: (1) carrying out a composite material laminated plate I-type layered test, and measuring a P-delta curve of the composite material laminated plate I-type layered test; (2) establishing a two-dimensional correction beam mechanical modelof the sample under the I-type load; (3) inputting the P-delta curve, the material basic attribute and the geometric dimension into the model calculation program, performing iterative calculation inMatlab software, and determining a layering length a, an initial crack tip opening displacement delta * and an energy release rate GIc; and (4) establishing a relationship between GIc and delta * to obtain a bridging law sigma g (delta *). The method is suitable for determining the bridging law in the I-type layered expansion process of the composite laminate at any laying angle, and has the advantages that (1) the method only needs to take the P-delta curve of the sample as input, the crack position does not need to be observed, and test devices are reduced; (2) the method is realized by using a Matlab program, so that the calculation cost is relatively low; and (3) the method can be used for determining the I-type bridging law of the composite laminate at high temperature.

Owner:BEIHANG UNIV

Steel for large container hull box board and preparation method thereof

ActiveCN108546886ASimple production processProcess parameters are easy to controlChemical compositionCrack tip opening displacement

Steel for a large container hull box board is provided. The steel includes, by weight, 0.06-0.14% of C, 0.20-0.25% of Si, 2.51-2.79% of Mn, not more than 0.015% of P, not more than 0.005% of S, 0.09-0.18% of Mo, and 0.095-0.22% of Ce. A preparation method includes continuous casting after smelting to obtain a billet; rough rolling; finish rolling to the thickness of a product; cooling; and pit cooling to room temperature. The chemical composition and a production process of the steel are relatively simple, process parameters are easy to control; the thickness of a slab is not more than 2 [mu]munder the optical metallographic morphology; the yield strength is not less than 475 MPa; the crack tip opening displacement CTOD which is a fracture toughness index is not less than 3 mm; and the non-plastic drop test NDT is not more than -65 DEG C. Large container hull box boards made of the steel are free of breakage, and can safely sail in the extremely cold Arctic region, and the service lifetime can be 45 years.

Owner:武汉钢铁有限公司

Sample table for scanning electron microscope in-situ observation of stress corrosion cracking of metal material

InactiveCN102103148BAccurate calculation of expansion rateScanning probe techniquesCrack tip opening displacementLiquid medium

The invention belongs to the field of research of environmental cracking of materials, and provides a sample table for scanning electron microscope (SEM) in-situ observation of stress corrosion cracking, which can realize the SEM in-situ observation of the stress corrosion cracking of a metal material in a liquid medium. The sample table is designed according to a spatial size of an SEM sample room; a micro tension sample can be loaded and kept in a constant displacement state in the aspect of loading the sample; and the sample table is placed in the liquid medium together with a constant displacement sample to produce the stress corrosion cracking, is taken out of the medium and is arranged in the SEM sample room, so that a continuous process of stress corrosion crack propagation can be observed and recorded. Meanwhile, the crack propagation speed and crack tip opening displacement can be accurately calculated according to a stress corrosion cracking SEM image. Through the sample table, the problem that the stress corrosion cracking of the material in the liquid medium cannot be observed by an SEM is solved, and the sample table is an effective tool for researching a stress corrosion cracking micromechanism of the material.

Owner:YANSHAN UNIV

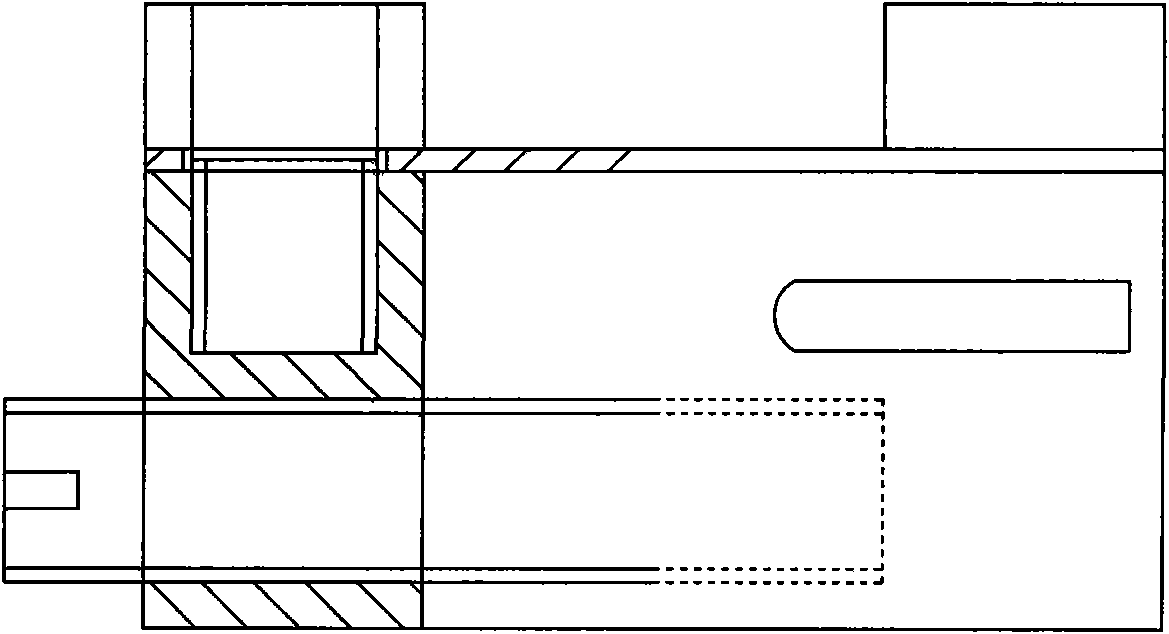

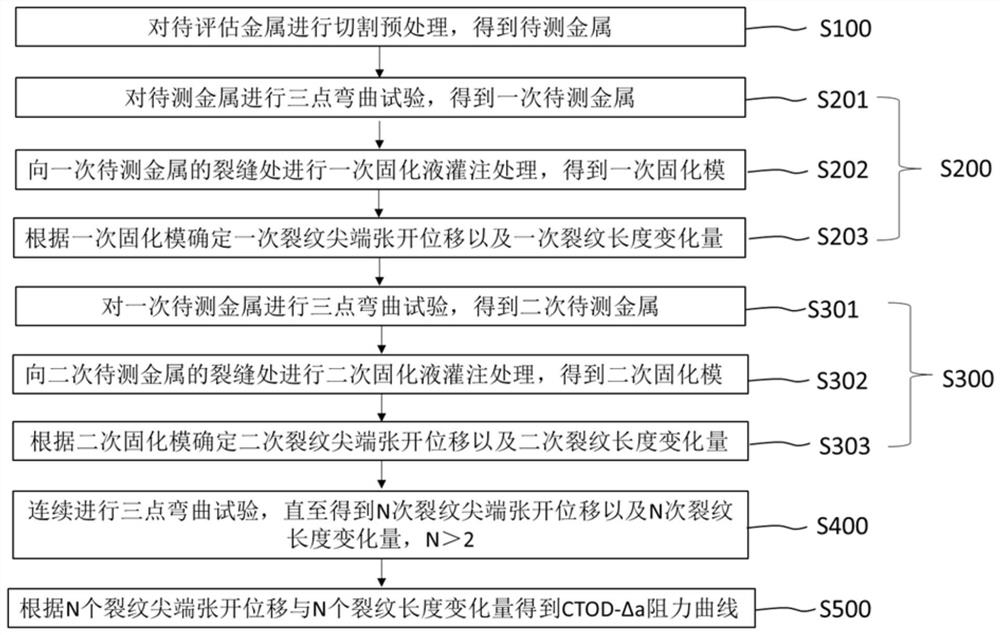

Method for testing CTOD-delta resistance curve of metal

ActiveCN114441336AEasy to operateReduce testing costsPreparing sample for investigationMaterial strength using steady bending forcesCrack tip opening displacementStructural engineering

The invention provides a method for testing a CTOD-delta a resistance curve of metal, which comprises the following steps of: performing cutting pretreatment on to-be-evaluated metal to obtain to-be-tested metal; performing a three-point bending test on the to-be-tested metal to obtain primary to-be-tested metal; performing primary curing liquid filling treatment on the crack of the primary to-be-detected metal to obtain a primary curing mold; according to the primary curing mold, primary crack tip opening displacement and primary crack length variation are determined; the three-point bending test is continuously carried out until N times of crack tip opening displacement and N times of crack length variation are obtained, and N is larger than 2; and obtaining a CTOD-delta a resistance curve of the to-be-evaluated metal according to the tip opening displacement of the N cracks and the length variation of the N cracks. The method for testing the CTOD-delta a resistance curve of the metal, provided by the invention, is simple to operate, low in cost and high in accuracy, and has a wide application prospect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for measuring compact tension specimen fracture parameters by using double extensometers

ActiveCN102564844BHigh measurement accuracyData processing is simpleStrength propertiesCrack tip opening displacementInformation quantity

The invention discloses a novel method for measuring compact tension specimen fracture parameters by using double extensometers. The novel method comprises the following steps of: measuring two opening displacements by using the double extensometers; obtaining a crack tip opening displacement (CTOD) of a compact tension test through calculation by using a triangular relation; and calculating a CTOD value under each load and a nominal stress corresponding to the CTOD value, and obtaining a relation between the nominal stress and the CTOD, thereby obtaining a CTOD design curve of the compact tension test. The fracture parameter test method disclosed by the invention has the characteristics of simpleness, easy operation, simpleness for processing data, high precision of a critical CTOD value, comprehensive data, large information quantity, freeness from test precision influences of other parameters, such as strength, Young modulus, rotary factor and load, capabilities of obtaining the CTOD data of the whole test loading process and obtaining the CTOD design curve of the compact tension test under an actual board thickness condition.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

A life prediction method for high and low cycle composite fatigue crack growth of turbine tenon joint structure

ActiveCN106644490BImprove scalabilityInhibit expansionEngine testingCrack tip opening displacementEngineering

The invention relates to a method for predicting the high-low-cycle composite fatigue crack growth life of a turbine joggle structure, and the method comprises the steps: (1), building a crack growth model giving consideration to a crack closure effect; (2), determining a high-cycle load stress intensity factor model; (3), determining a low-cycle load stress intensity factor model; (4), judging whether a current cycle is a high-cycle load or not: executing step (5) if the current cycle is the high-cycle load, or else executing step (6); (5), calculating a composite fatigue lower crack increment, judging whether a next cycle is a low-cycle fatigue load or not: obtaining the maximum crack tip opening displacement of the current cycle if the next cycle is the low-cycle fatigue load, and executing step (7), or else executing step (8); (6), calculating the variance of the low-cycle load lower crack tip opening displacement; (7), calculating the residual crack tip opening displacement and crack increment according to the results inputted at steps (5) and (6); (8), updating the crack length, repeatedly carrying out the steps (4)-(7) if the maximum stress intensity factor is less than the fracture toughness, or else completing the calculation, and obtaining the crack growth life.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com