Novel welding repair CTOD (crack tip opening displacement) experimental method

An experimental method and rework technology, applied in the field of welding, can solve the problems of invalid CTOD samples, welding test plate extension test costs, invalid samples, etc., and achieve the goal of improving the preparation success rate, increasing the preparation success rate, and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

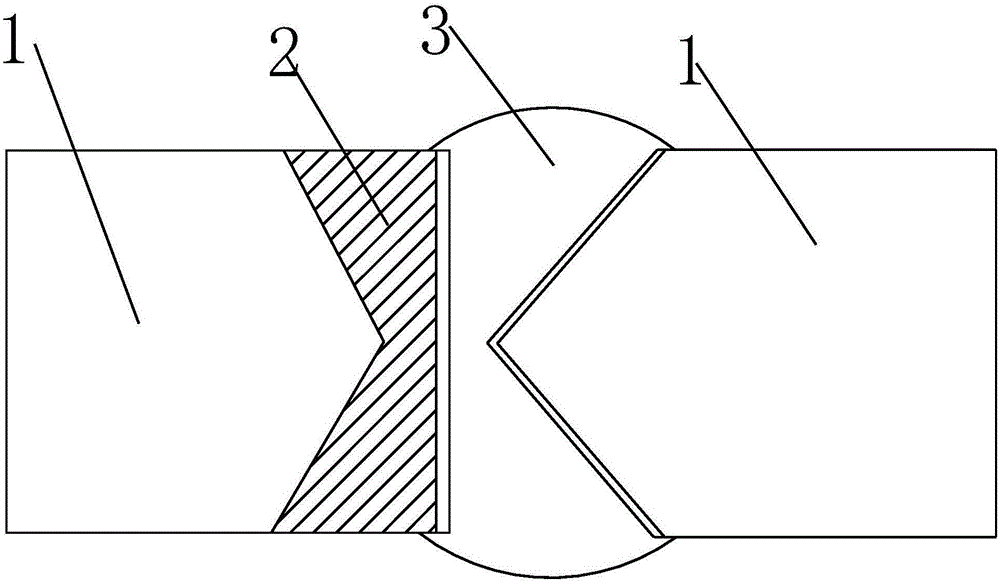

[0035] Such as Figure 1 to Figure 6 Shown, a kind of new welding repair CTOD experiment method provided by the present invention, specific implementation process is as follows: 1. Blanking

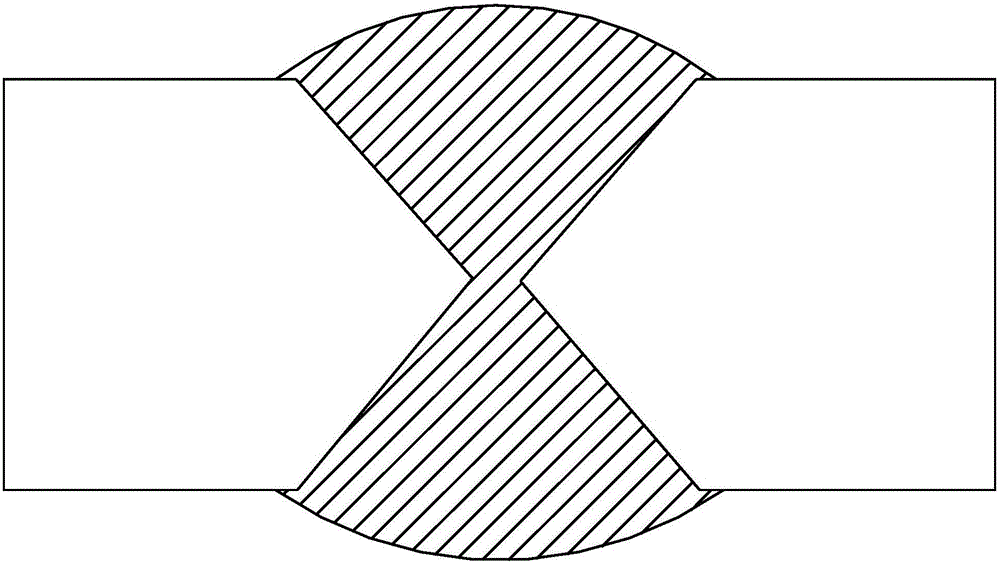

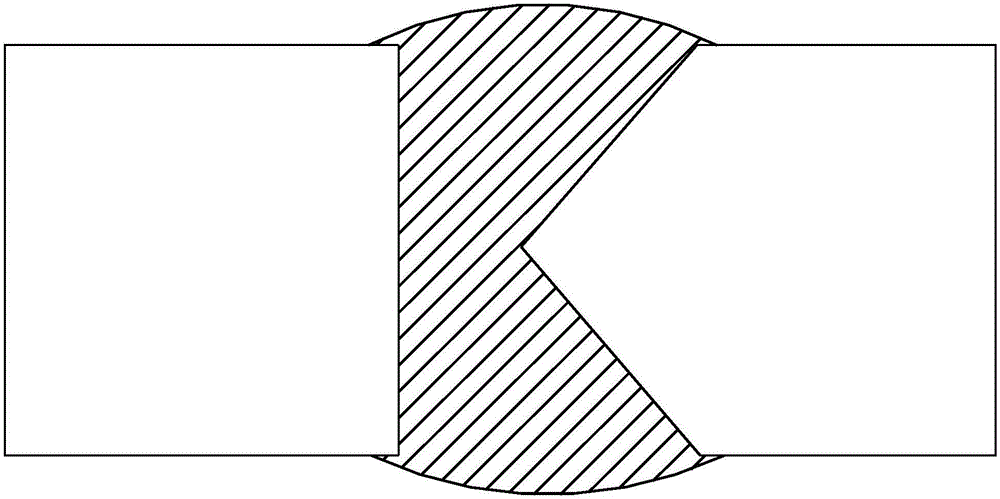

[0036] According to the material certificate of the steel plate, go to the material factory to find the corresponding steel plate, that is, the base material 1, and cut and process the test plate according to the processing drawing, two pairs of "X" type groove test plates, and two pairs of "K" type groove test plates.

[0037] 2. Train welders.

[0038] In order to ensure that the fusion line on the straight side of the "K" groove can be in the same plane as possible, it is necessary to train welders on skills and operating points. The parameters of the process are carefully adjusted and recorded.

[0039]

[0040] Table 1 Typical welding parameters of submerged arc welding

[0041]

[0042] Table 2 Typical welding parameters of carbon dioxide gas shielded welding (rework)

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com