Light emitting display with high-low flat-arc polymerization independent door control tilted and closed hook face ring edge negative electrode structure

A light-emitting display, closed-surface technology, applied in cold cathode manufacturing, image/graphic display tube, cathode ray tube/electron beam tube, etc., can solve the problem of increasing power loss of light-emitting display, cathode-gate electrical breakdown, gate High working voltage problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to this embodiment.

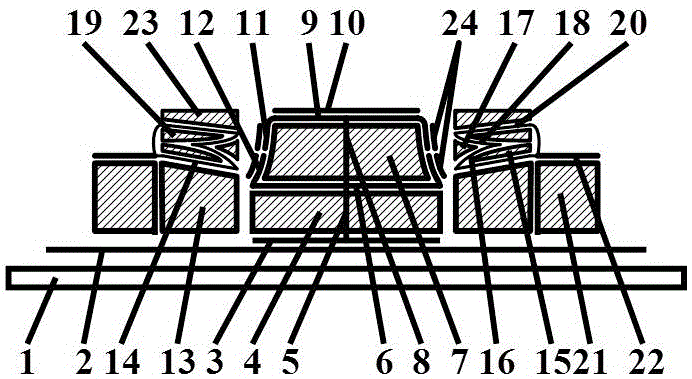

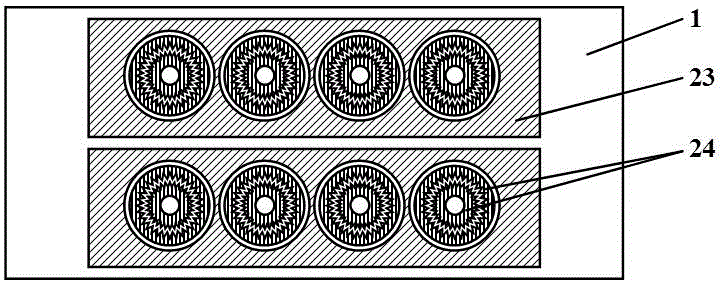

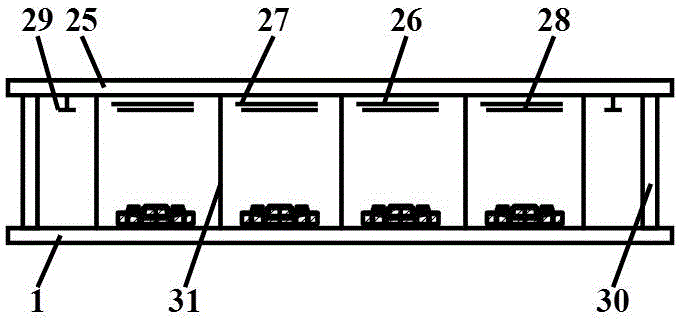

[0055] In this embodiment, the light-emitting display with high and low flat arc polymerization unique gate control obliquely placed closed curved surface ring edge cathode structure is as follows: figure 1 , figure 2 and image 3 Shown, comprise the vacuum chamber that is made of upper transparent hard anti-pressure plate 25, lower transparent hard anti-pressure plate 1 and surrounding glass frame 30; On upper transparent hard anti-pressure plate 25, anode low-resistance film electrode layer 26 is arranged, and The anode silver transfer line layer 27 connected to the anode low-resistance film electrode layer 26 and the phosphor layer 28 prepared on the anode low-resistance film electrode layer 26; on the lower transparent hard pressure-resistant plate 1, there are high and low flat arc poly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com