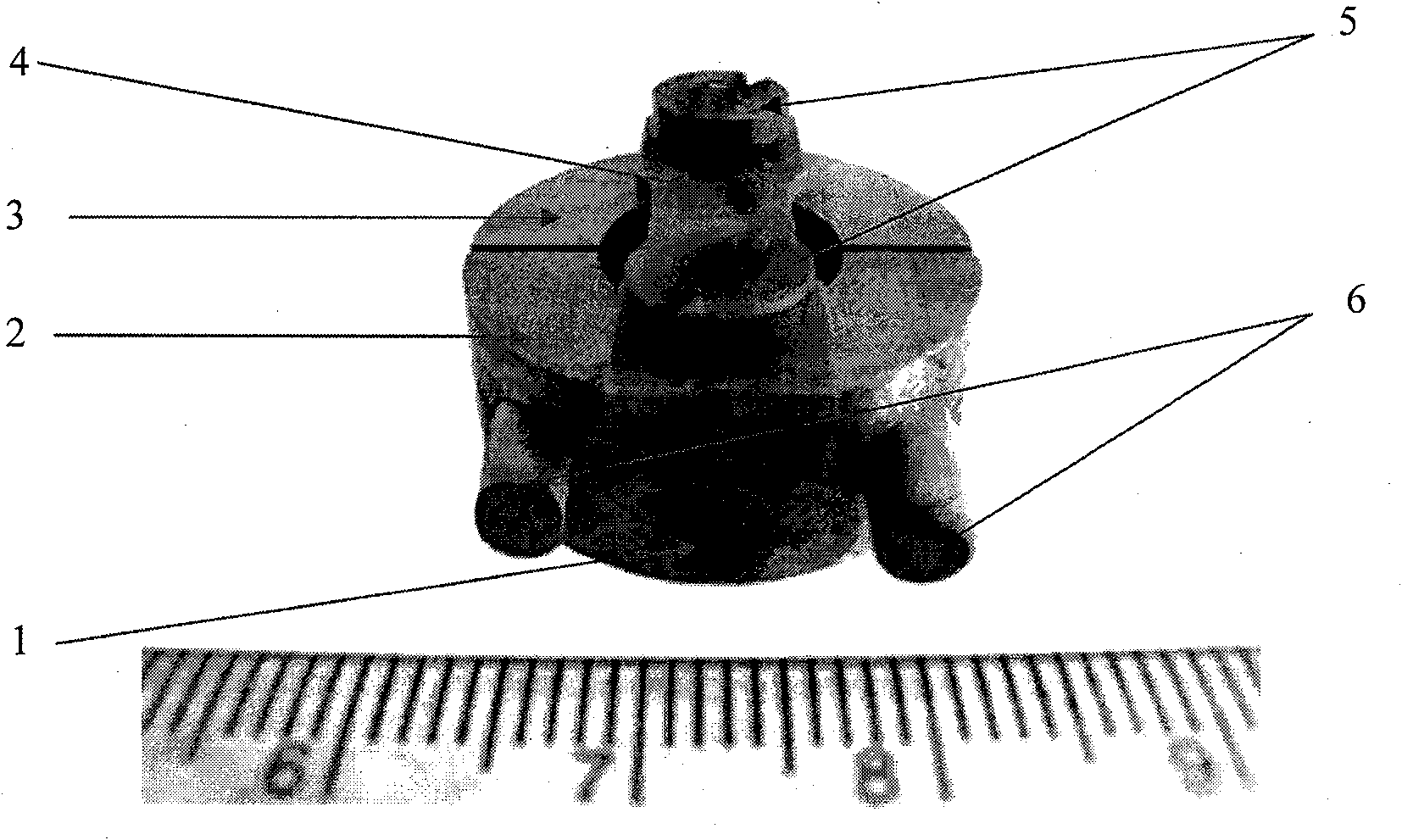

Sample table for scanning electron microscope in-situ observation of stress corrosion cracking of metal material

A technology of stress corrosion and metal materials, applied in the field of scanning electron microscope sample stage, which can solve the problems of limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

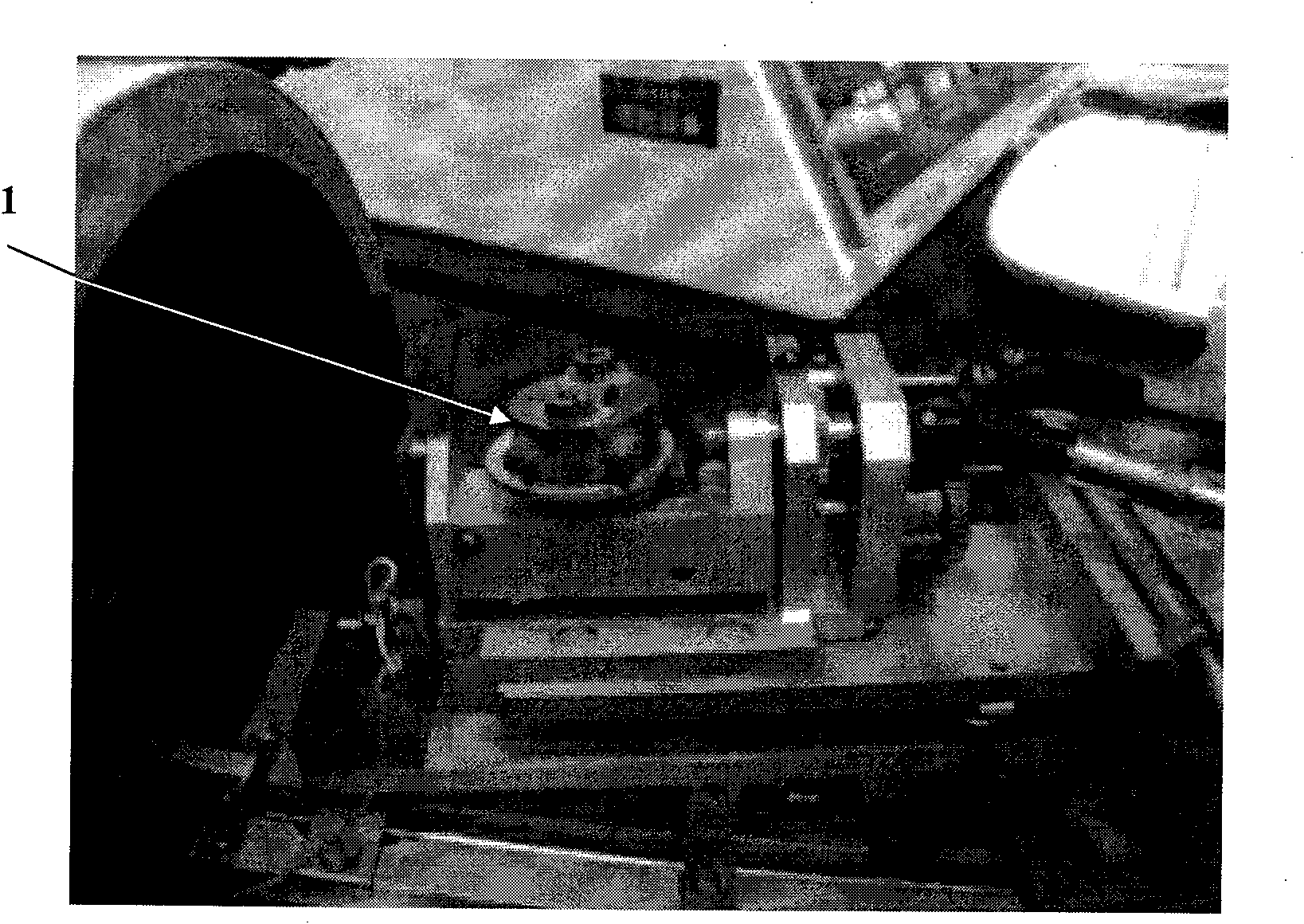

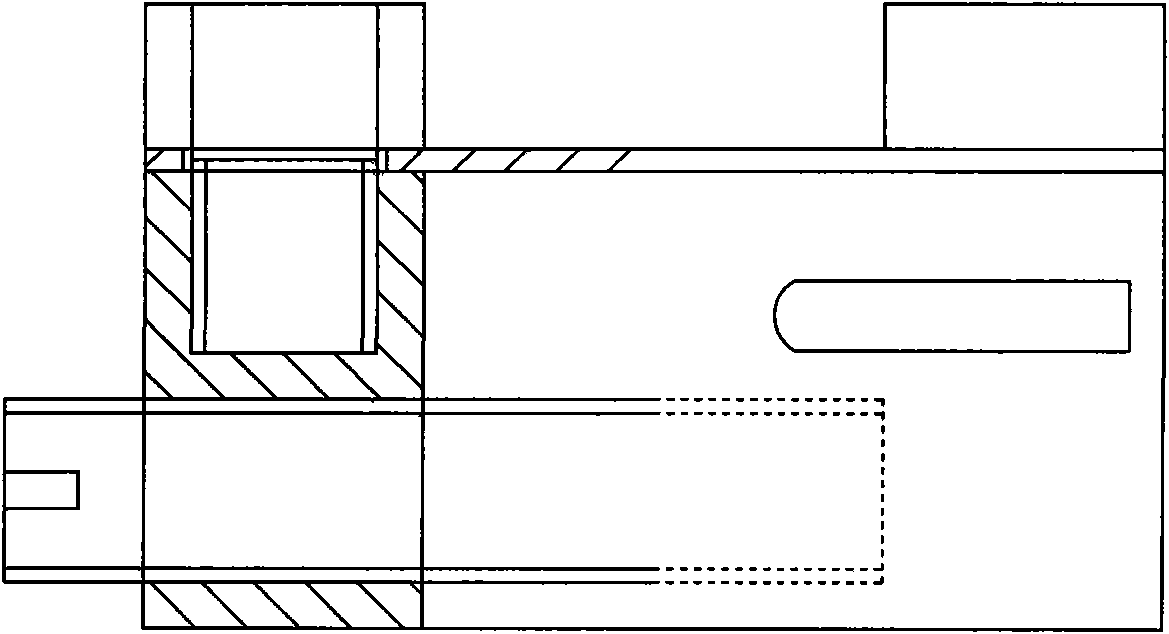

Method used

Image

Examples

Embodiment 1

[0030] Using the present invention, the SEM in-situ observation process of stress corrosion cracking of U75V steel in a 1.0% HCl aqueous solution was recorded. The process is given by 4 SEM images: the topography of the prefabricated crack maintained in a constant displacement state; the topography of the prefabricated crack maintained in a 1.0% HCl aqueous solution for 20 hours, it can be seen that the surface corrodes and the crack propagates; maintained for 40 hours The morphological image, crack propagation, and passivation of the crack tip; maintaining the morphological image for 60 hours, the corrosion is aggravated, the crack is extended, and the micro-crack connection before the crack tip. The crack propagation was increased from 20 hours to 40 hours, and the measured crack tip opening displacement was increased by 3.13 μm from 5.0 μm to 8.13 μm. That is: 6=3.13 μm.

Embodiment 2

[0032] H62 brass at 0.5MNH recorded using the present invention 4 SEM in situ observation process of stress corrosion cracking in OH aqueous solution. The process is given by two SEM images, which are: the prefabricated crack morphology image that maintains a constant displacement state, and the crack tip forms a slip line; at 0.5MNH 4 The morphology image of the OH aqueous solution kept under load for 5 minutes shows that a small amount of corrosion products appeared on the surfaces of both sides of the crack. It was measured that the crack length expanded from 116.0 μm in the initial state to 130.0 μm, an increase of 14.0 μm. The crack growth rate was calculated: da / dt=14.0 / 5=2.8 μm / min.

Embodiment 3

[0034]The present invention records the SEM in-situ observation process of stress corrosion cracking of 7075-T6 aged aluminum alloy in 0.5M NaCl aqueous solution. The process is given by two SEM images, which are the stress corrosion fracture image of the crack in 0.5M NaCl aqueous solution for 1.0h, the magnification is 30 times; the surface of the sample is corroded, and a step crack appears at the crack tip; the crack growth morphology after 2.0h , the magnification is 200 times, and the step crack expands, showing the effect of precipitation relative to crack expansion. The length of the front end of the step crack extends from 179.0 μm to 320.0 μm, an increase of 141.0 μm. Calculate the crack growth rate: da / dt=141.0 / 60=2.33 μm / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com