Method for testing CTOD-delta resistance curve of metal

A CTOD- and resistance curve technology, applied in the field of CTOD-Δa resistance curve testing, can solve the problems of single-sample method relying on testing instruments and operating skills, large data dispersion, waste of materials, time and manpower, etc. Low cost, wide application prospect, high accuracy effect

Active Publication Date: 2022-05-06

CHINA UNIV OF PETROLEUM (BEIJING)

View PDF9 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The multi-sample method needs to test more than 6 samples, which not only wastes materials, time and manpower, but also usually results in a large dispersion of data due to different sampling locations

The single-sample method can better avoid the defects of the multi-sample method, but the single-sample method relies too much on testing instruments and operating skills

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

[0114] The detection method of the present embodiment comprises the following steps:

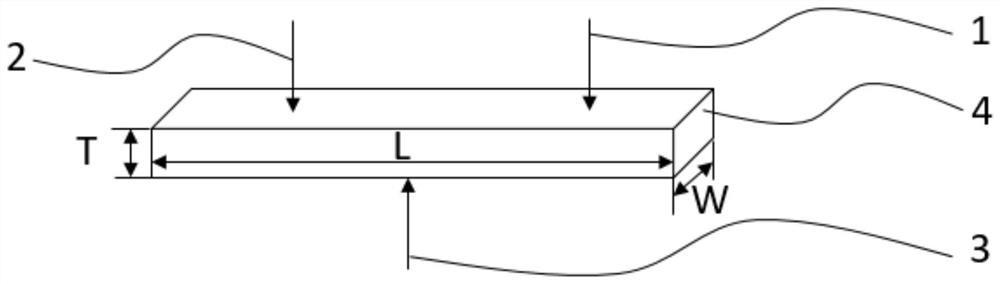

[0115] S100: cutting the metal to be evaluated in the width direction of the metal to be evaluated to obtain the metal to be evaluated;

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Login to View More

Abstract

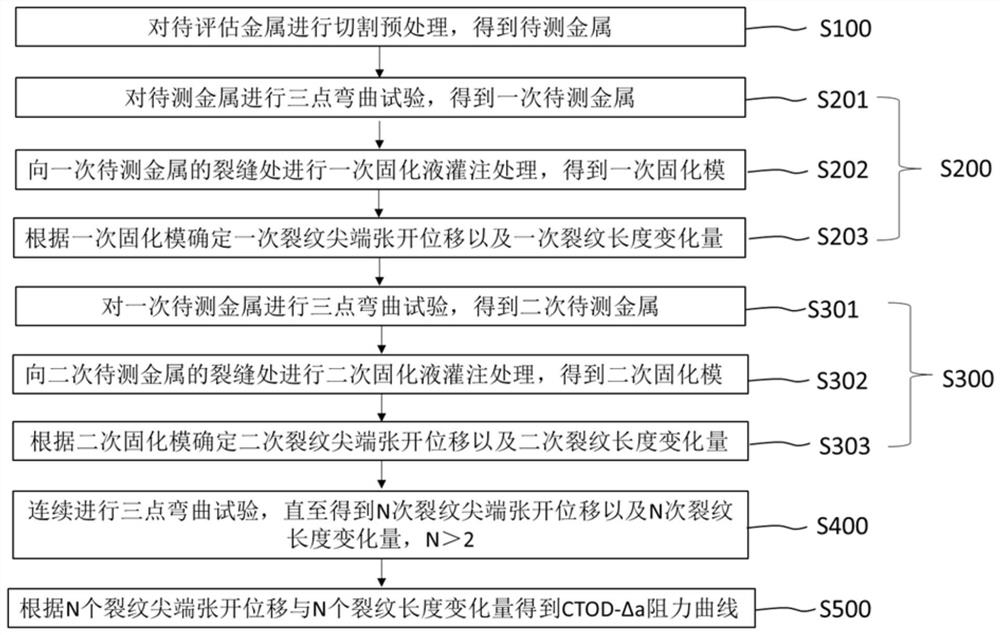

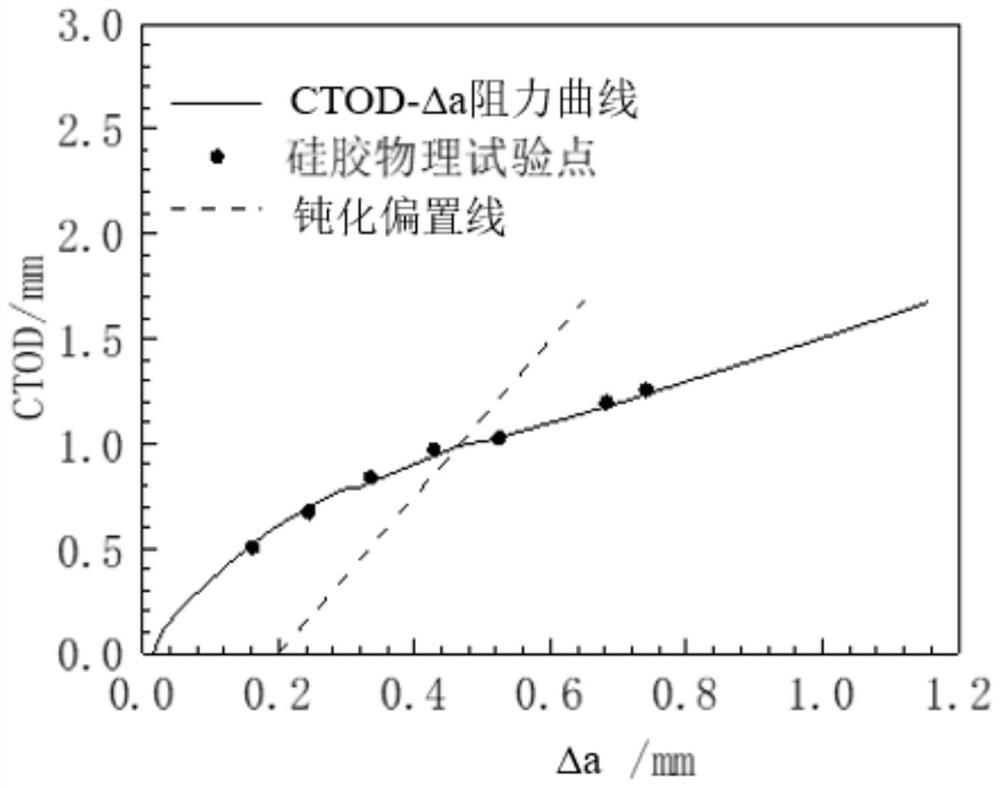

The invention provides a method for testing a CTOD-delta a resistance curve of metal, which comprises the following steps of: performing cutting pretreatment on to-be-evaluated metal to obtain to-be-tested metal; performing a three-point bending test on the to-be-tested metal to obtain primary to-be-tested metal; performing primary curing liquid filling treatment on the crack of the primary to-be-detected metal to obtain a primary curing mold; according to the primary curing mold, primary crack tip opening displacement and primary crack length variation are determined; the three-point bending test is continuously carried out until N times of crack tip opening displacement and N times of crack length variation are obtained, and N is larger than 2; and obtaining a CTOD-delta a resistance curve of the to-be-evaluated metal according to the tip opening displacement of the N cracks and the length variation of the N cracks. The method for testing the CTOD-delta a resistance curve of the metal, provided by the invention, is simple to operate, low in cost and high in accuracy, and has a wide application prospect.

Description

technical field [0001] The invention relates to the technical field of testing the fracture mechanical properties of metal materials, in particular to a testing method for the CTOD-Δa resistance curve of metals. Background technique [0002] The R-resistance curve is a curve in which the R-resistance changes with the crack extension length, which can characterize the dynamic change process of the elastic-plastic material resistance to crack extension during the test. Using the R-resistance curve can not only judge the crack growth state of elastic-plastic materials and guide the experimental research of elastic-plastic materials, but also use the R-resistance curve to evaluate the fracture toughness of industrial pipelines and guide the application process of industrial pipelines. [0003] The methods for testing the R-resistance curve in the prior art mainly include the multi-sample method and the single-sample method. The multi-sample method needs to test more than 6 samp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N3/20G01N1/28G01N33/20G01B21/02

CPCG01N3/20G01N1/28G01N33/20G01B21/02G01N2203/0003G01N2203/0023G01N2203/0066G01N2203/0676G01N2203/0682G01N2001/2873

Inventor 刘啸奔张东张宏吴锴江金旭杨悦武学健

Owner CHINA UNIV OF PETROLEUM (BEIJING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com