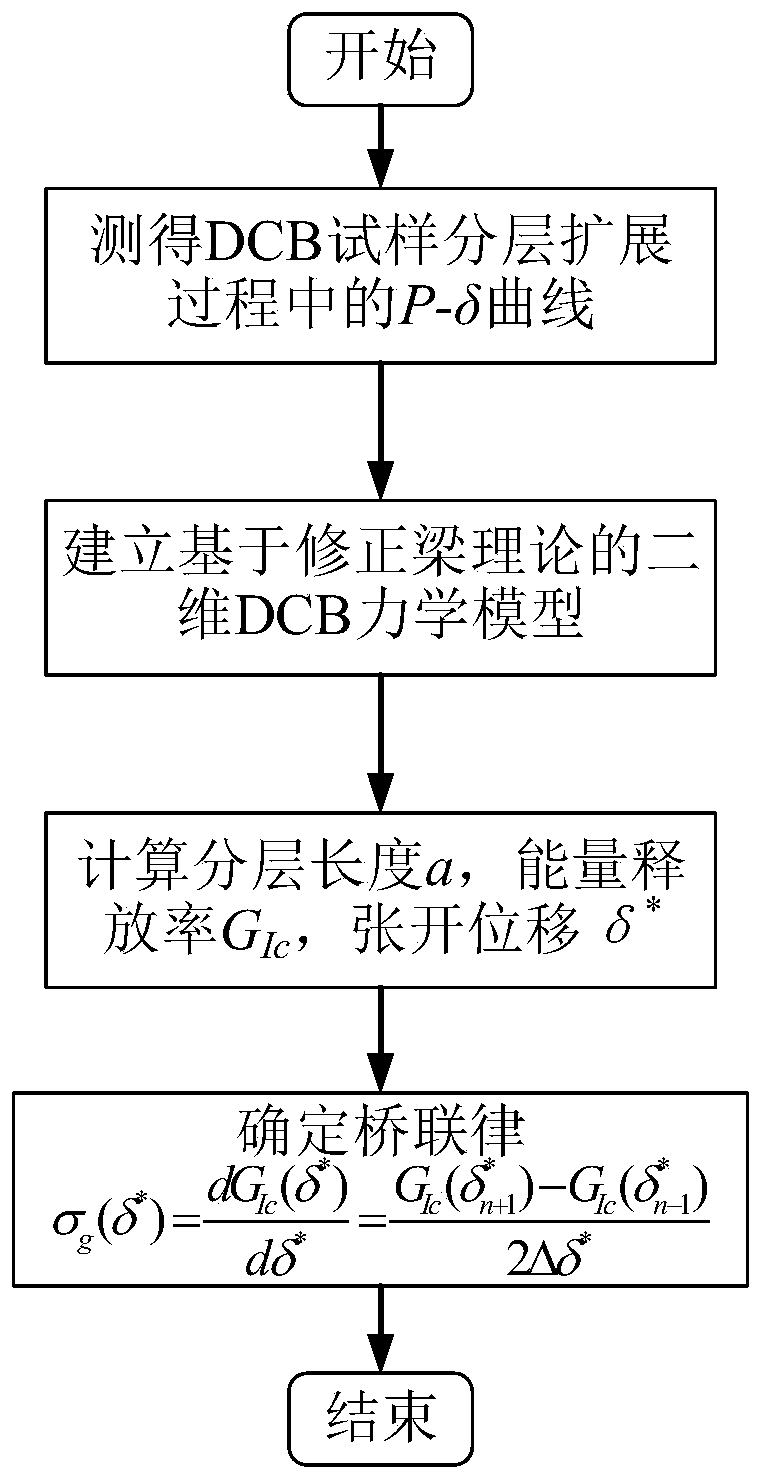

Composite material I-type layered bridging law determination method based on correction beam theory

A technology for composite materials and determination methods, applied in the fields of electrical digital data processing, instruments, computer-aided design, etc., can solve problems such as equipment errors and lack of versatility, and achieve the effect of avoiding calculation costs and reducing test devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

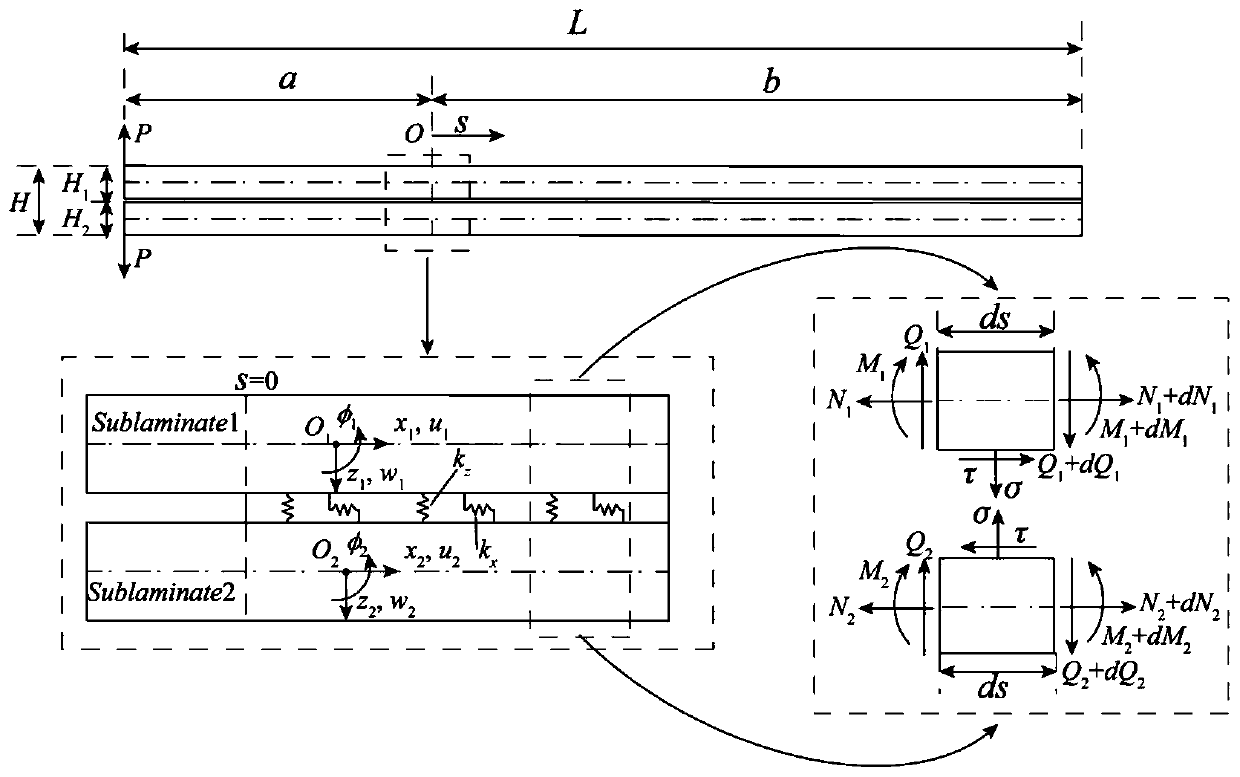

Method used

Image

Examples

Embodiment

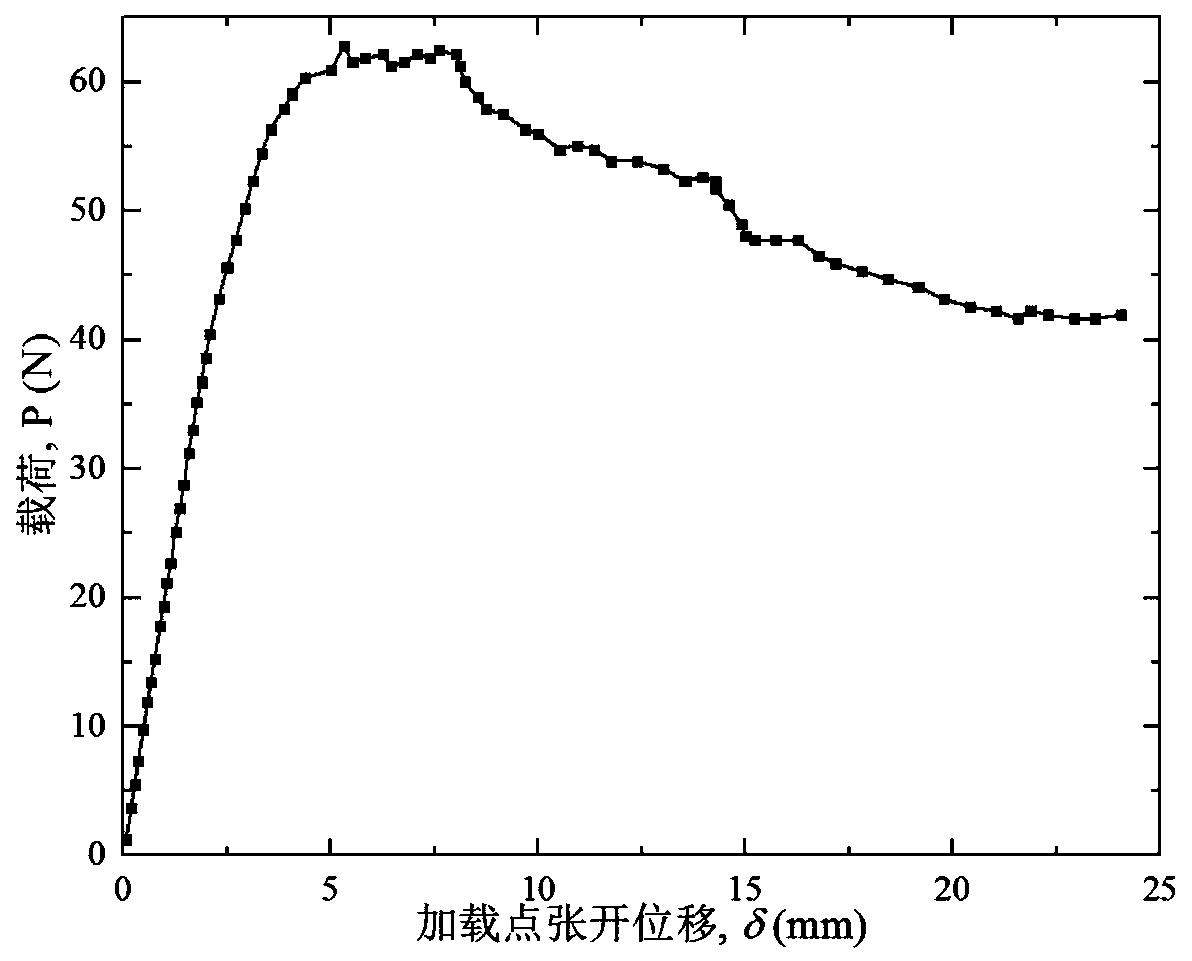

[0029] Implementation example: Determination of type I delamination bridging law of unidirectional laminate test piece using glass fiber / EPON 828 resin matrix composite material

[0030] 1. Geometric description

[0031] The thickness of the unidirectional laminate DCB test piece is 4.45mm, the width is 25mm, and the length is 150mm. The initial prefabricated delamination length is 35mm, and the initial delamination position is located at the middle thickness of the test piece. The ply order of the laminate is [0°] 24 , the material property of the unidirectional belt is: E 1 =35.25GPa,E 2 =E 3 =10.82GPa,G 12 =G 13 =G 23 =4.28GPa, ν 12 = ν 13 = ν 23 = 0.47.

[0032] 2. Carry out type I delamination test of composite material laminates, and measure its P-δ curve;

[0033] (A) Use the fast clamping hinge clamp to clamp the DCB sample to the MTS testing machine. After the clamping is completed, ensure that the sample is in a straight state as much as possible without a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com