Patents

Literature

1426results about "Scanning probe techniques" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Medical imaging, diagnosis, and therapy using a scanning single optical fiber system

InactiveUS6975898B2High resolutionEasy to viewEndoscopesSurgical instrument detailsFlexible endoscopyHigh resolution imaging

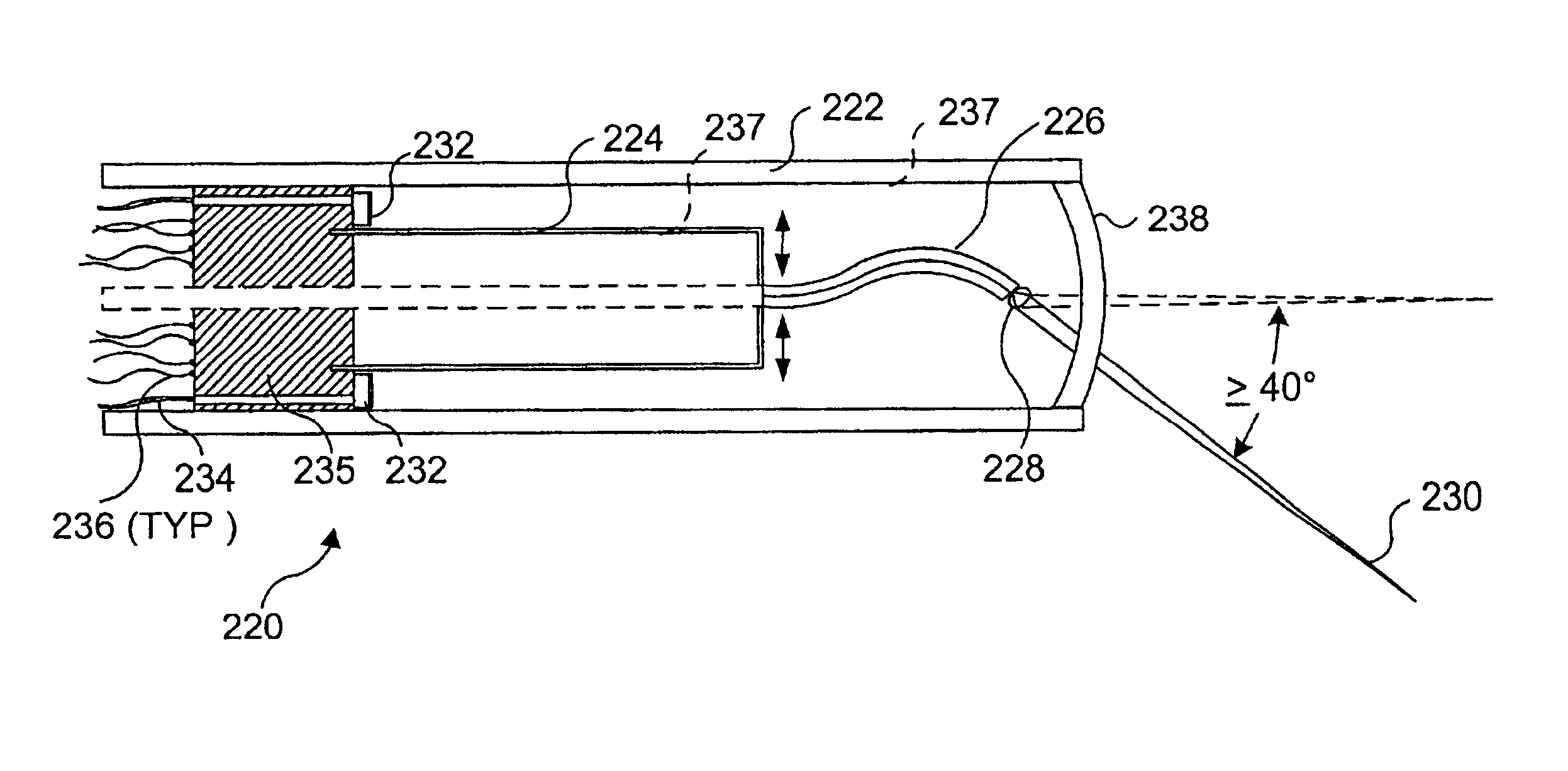

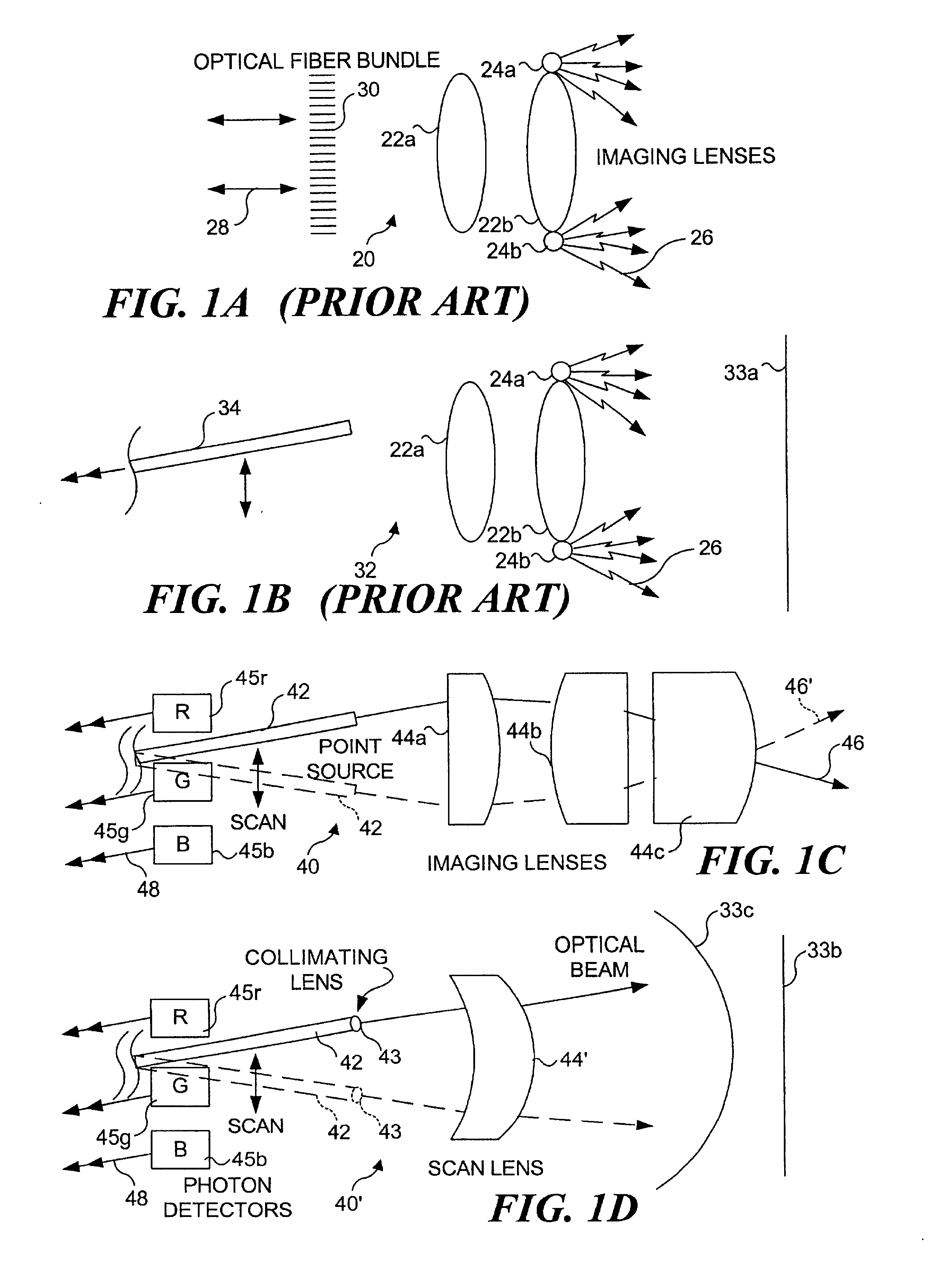

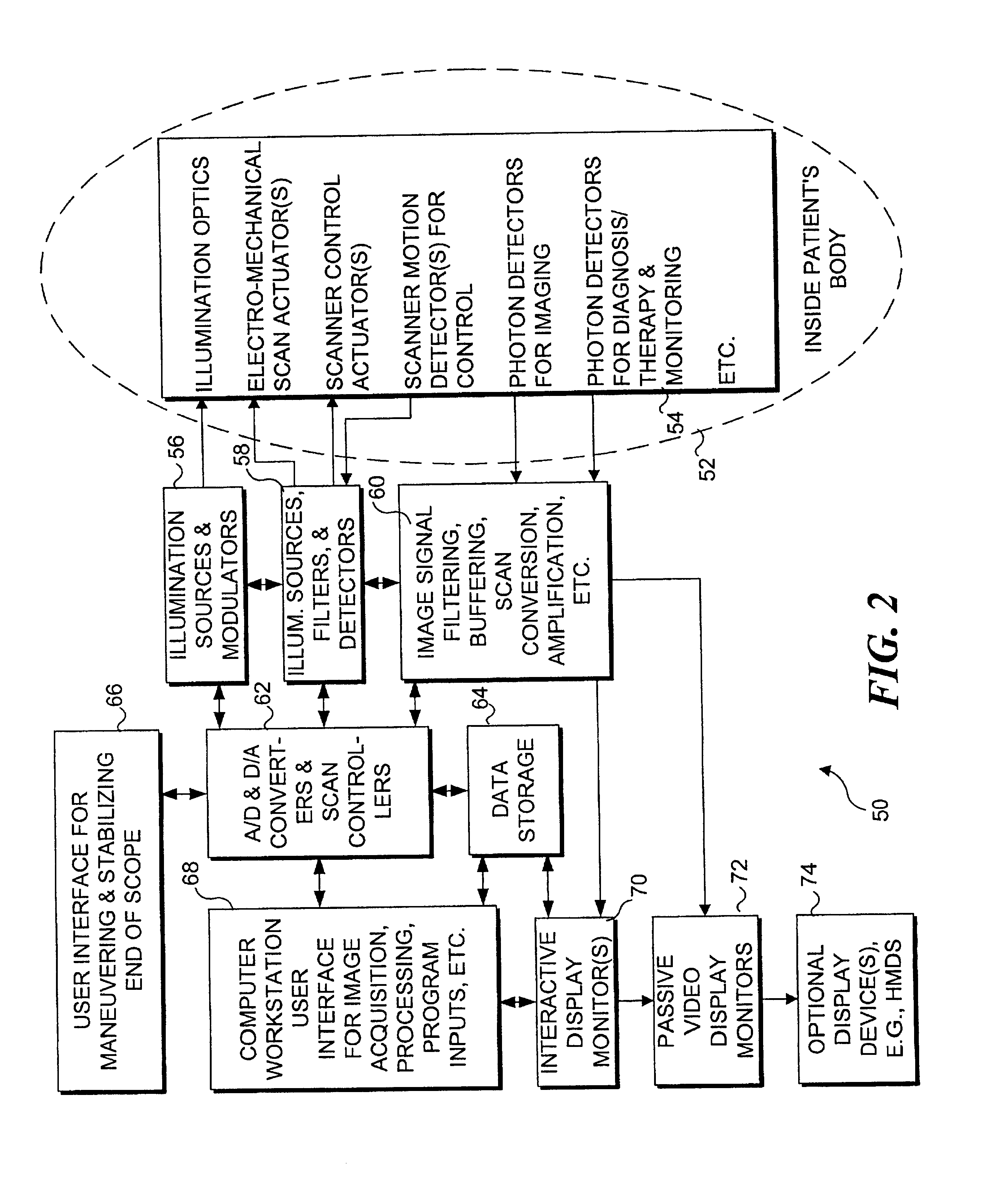

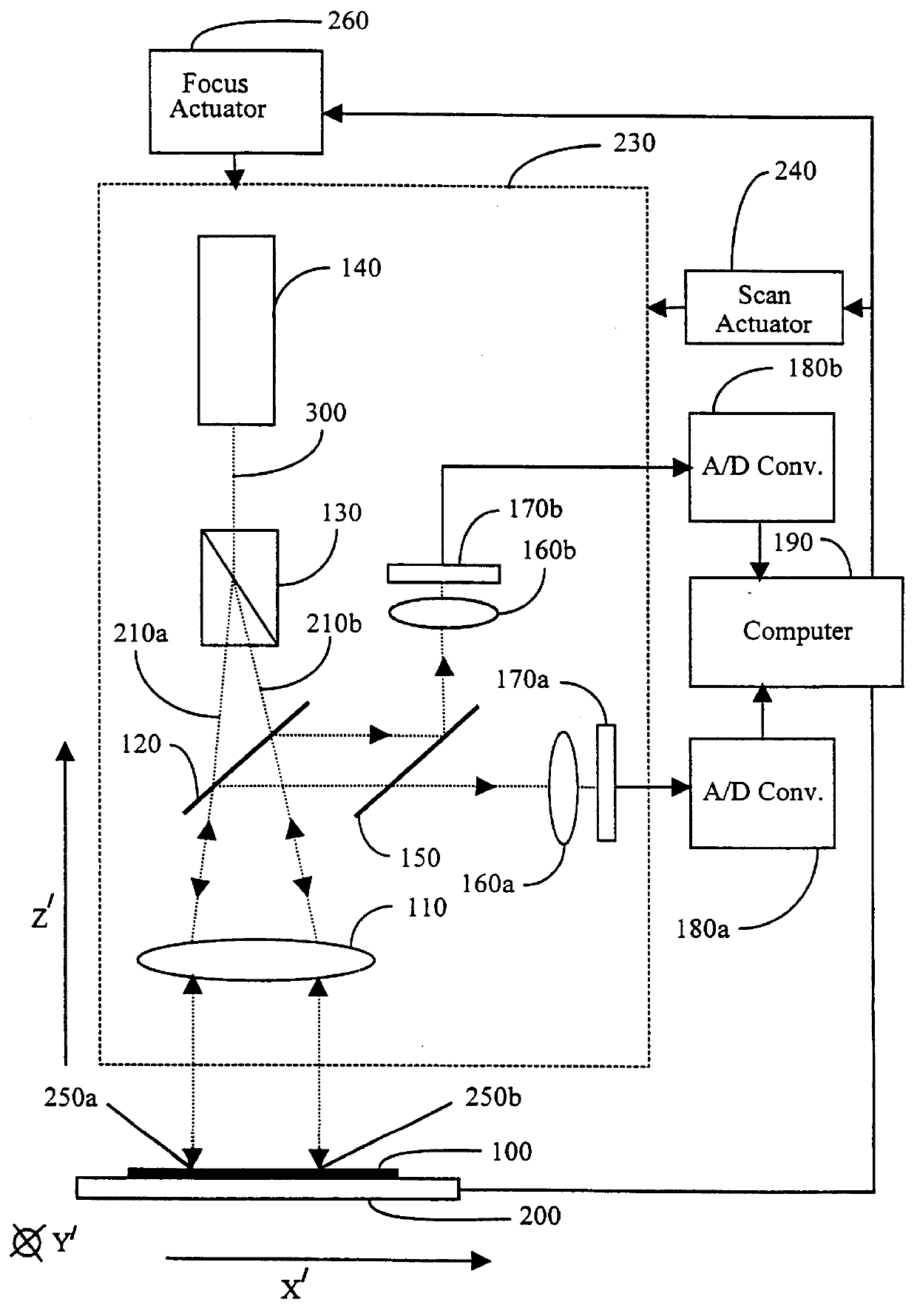

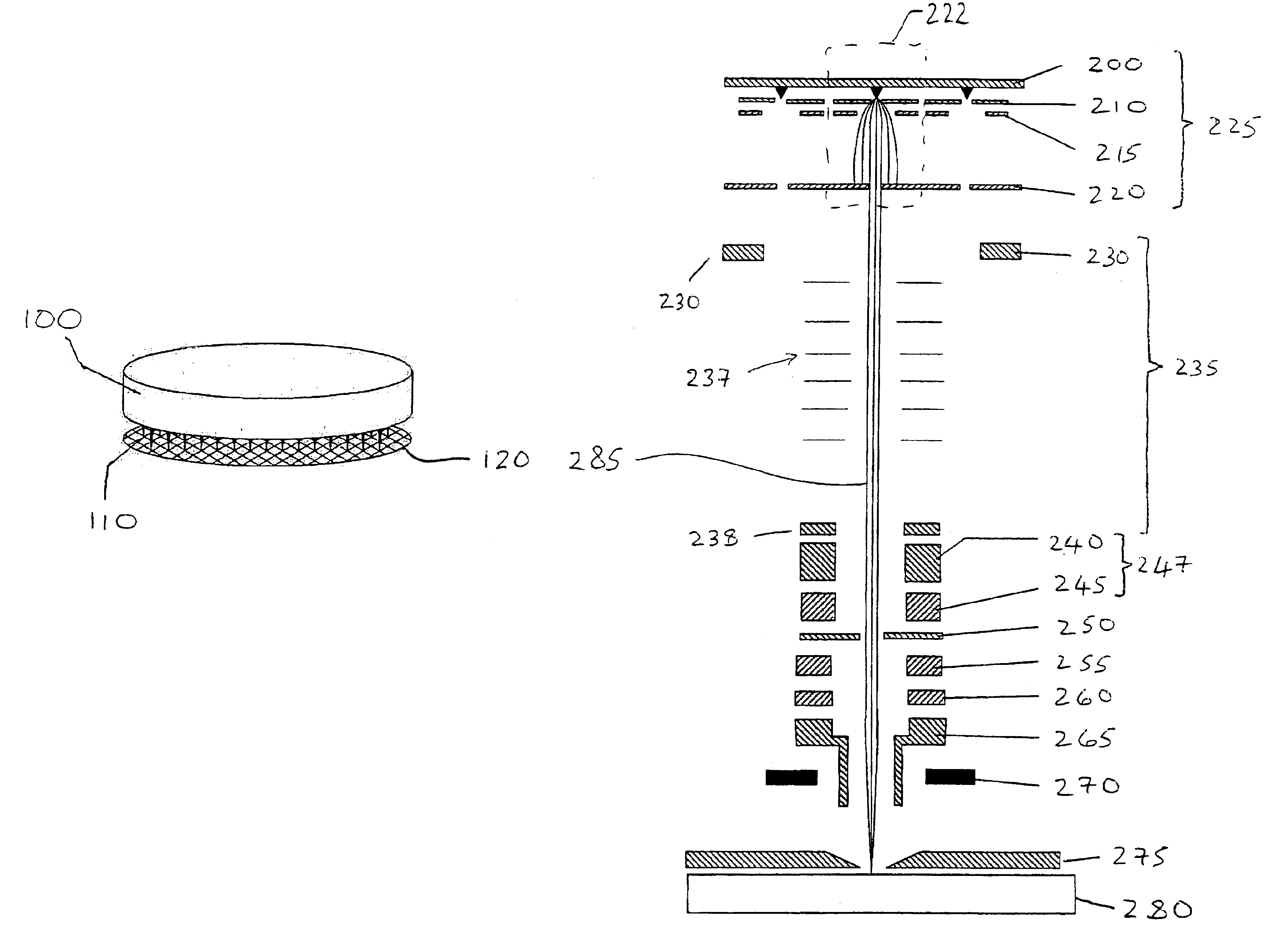

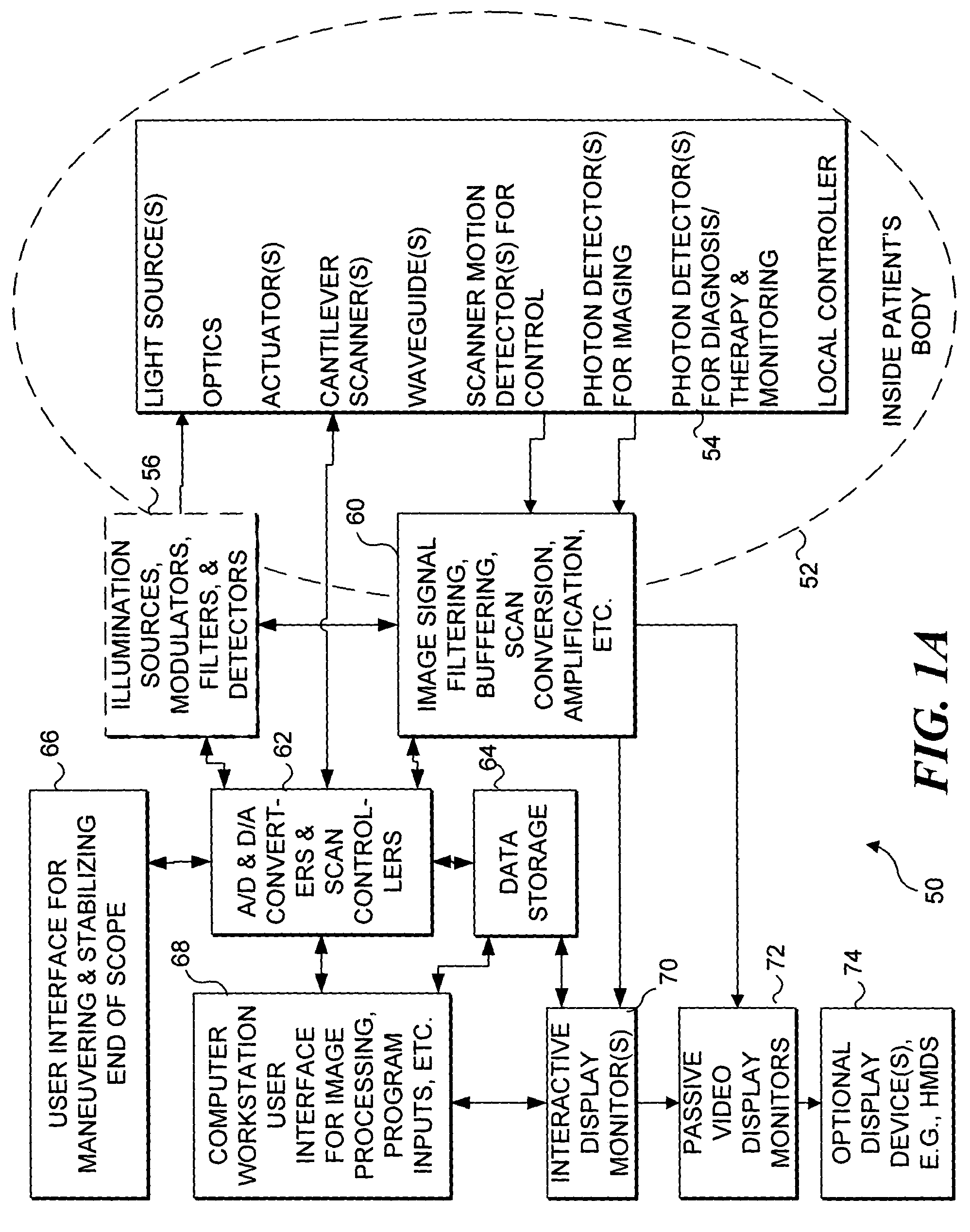

An integrated endoscopic image acquisition and therapeutic delivery system for use in minimally invasive medical procedures (MIMPs). The system uses directed and scanned optical illumination provided by a scanning optical fiber or light waveguide that is driven by a piezoelectric or other electromechanical actuator included at a distal end of an integrated imaging and diagnostic / therapeutic instrument. The directed illumination provides high resolution imaging, at a wide field of view (FOV), and in full color that matches or excels the images produced by conventional flexible endoscopes. When using scanned optical illumination, the size and number of the photon detectors do not limit the resolution and number of pixels of the resulting image. Additional features include enhancement of topographical features, stereoscopic viewing, and accurate measurement of feature sizes of a region of interest in a patient's body that facilitate providing diagnosis, monitoring, and / or therapy with the instrument.

Owner:UNIV OF WASHINGTON

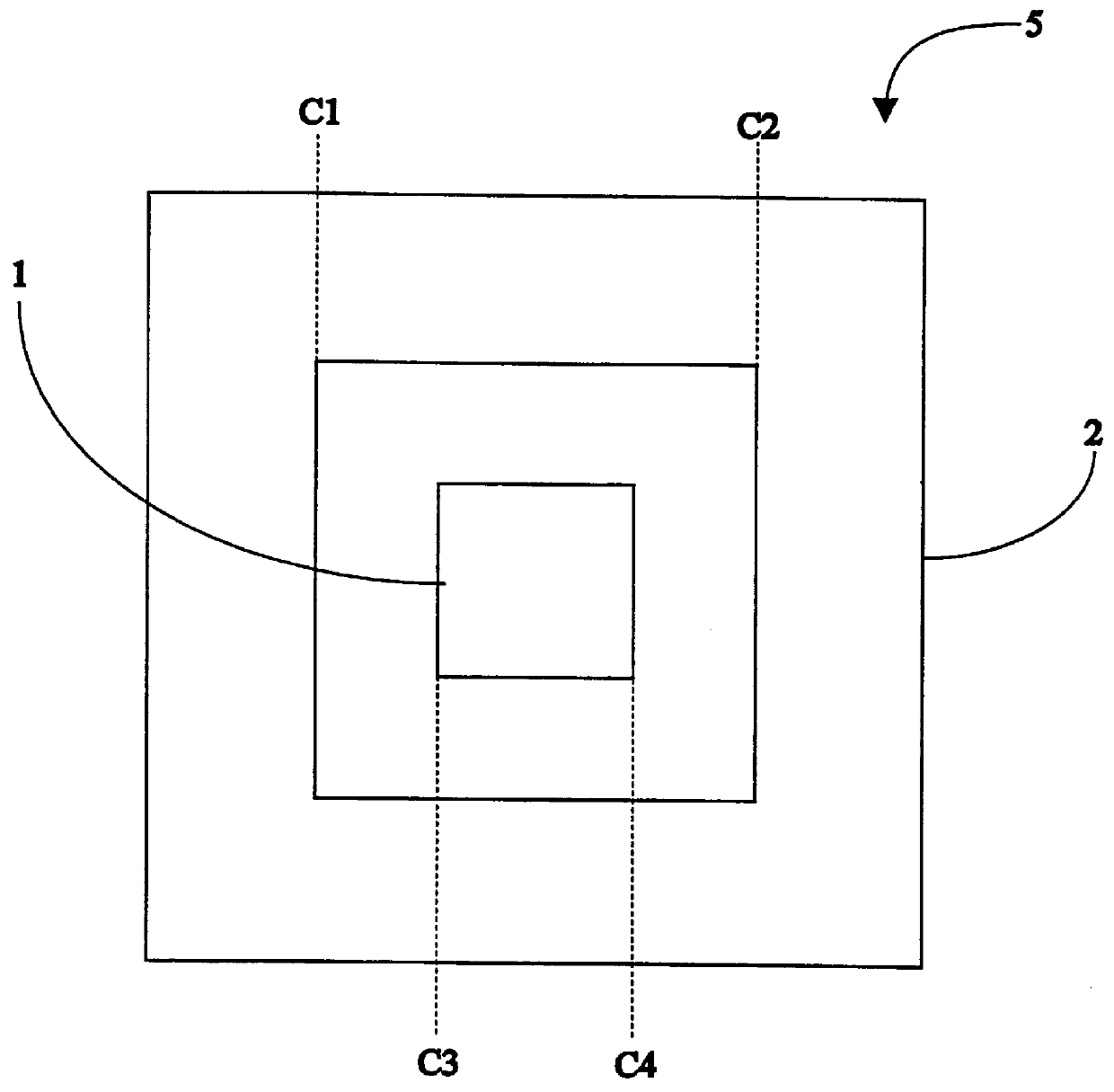

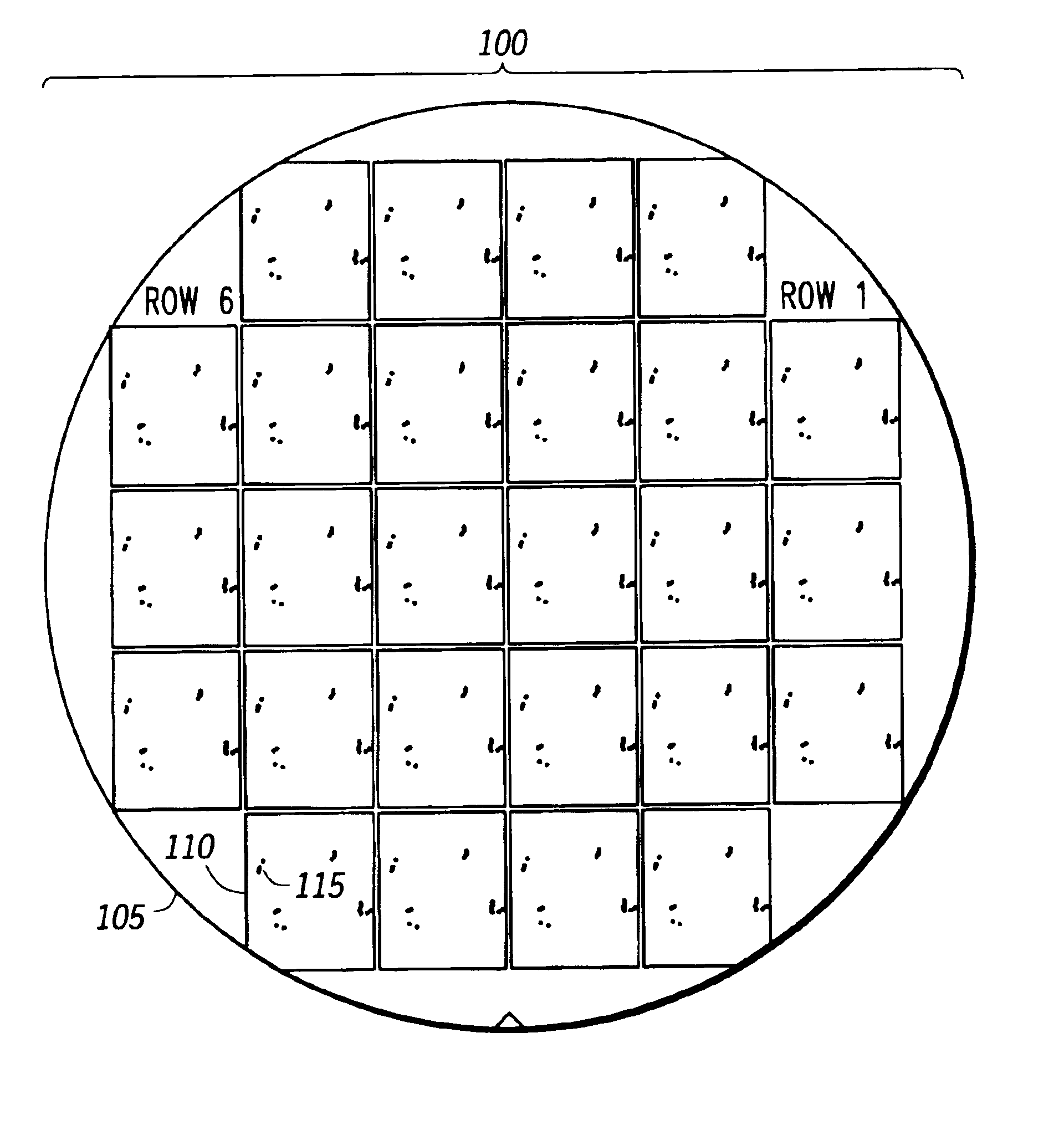

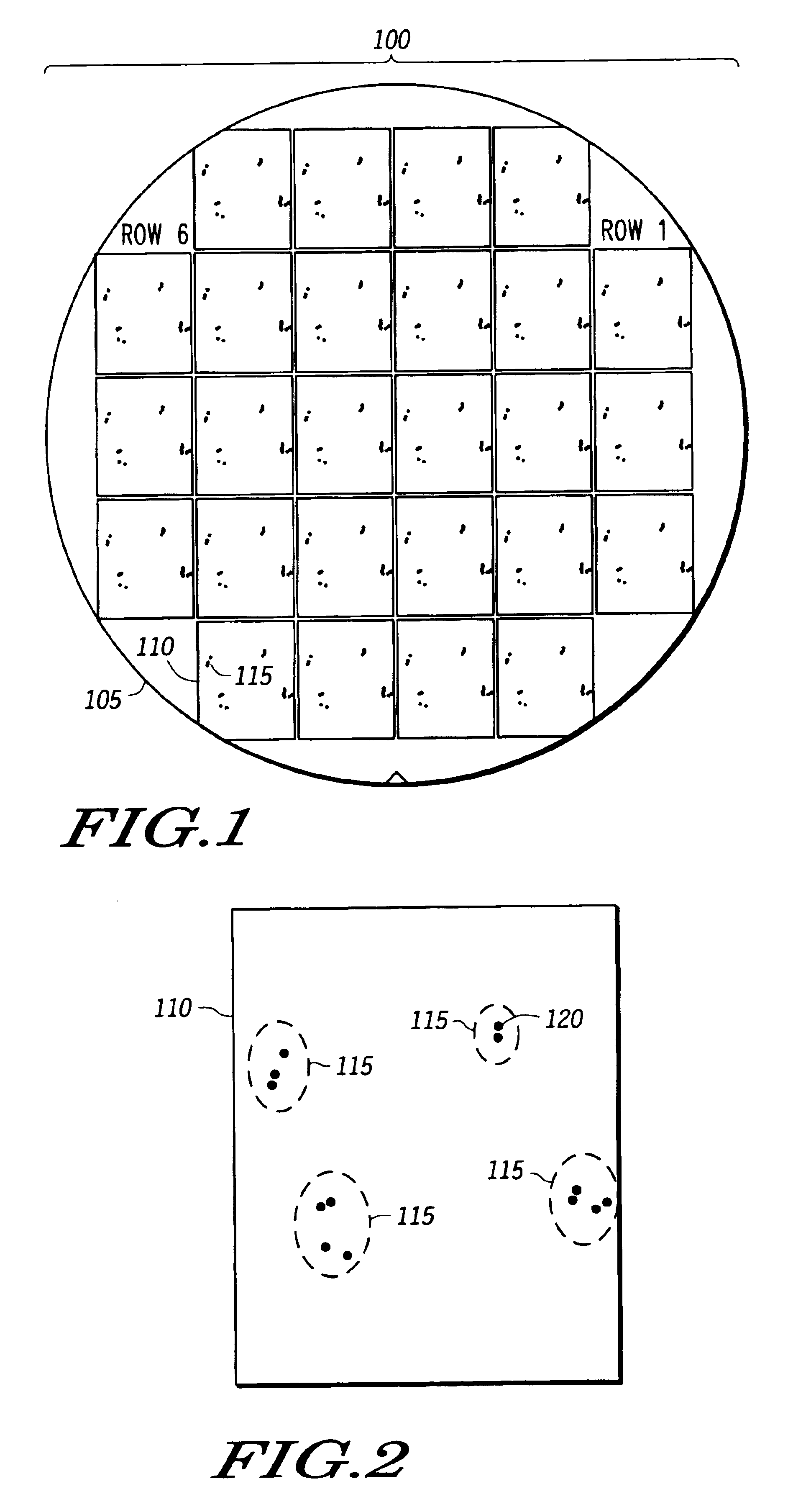

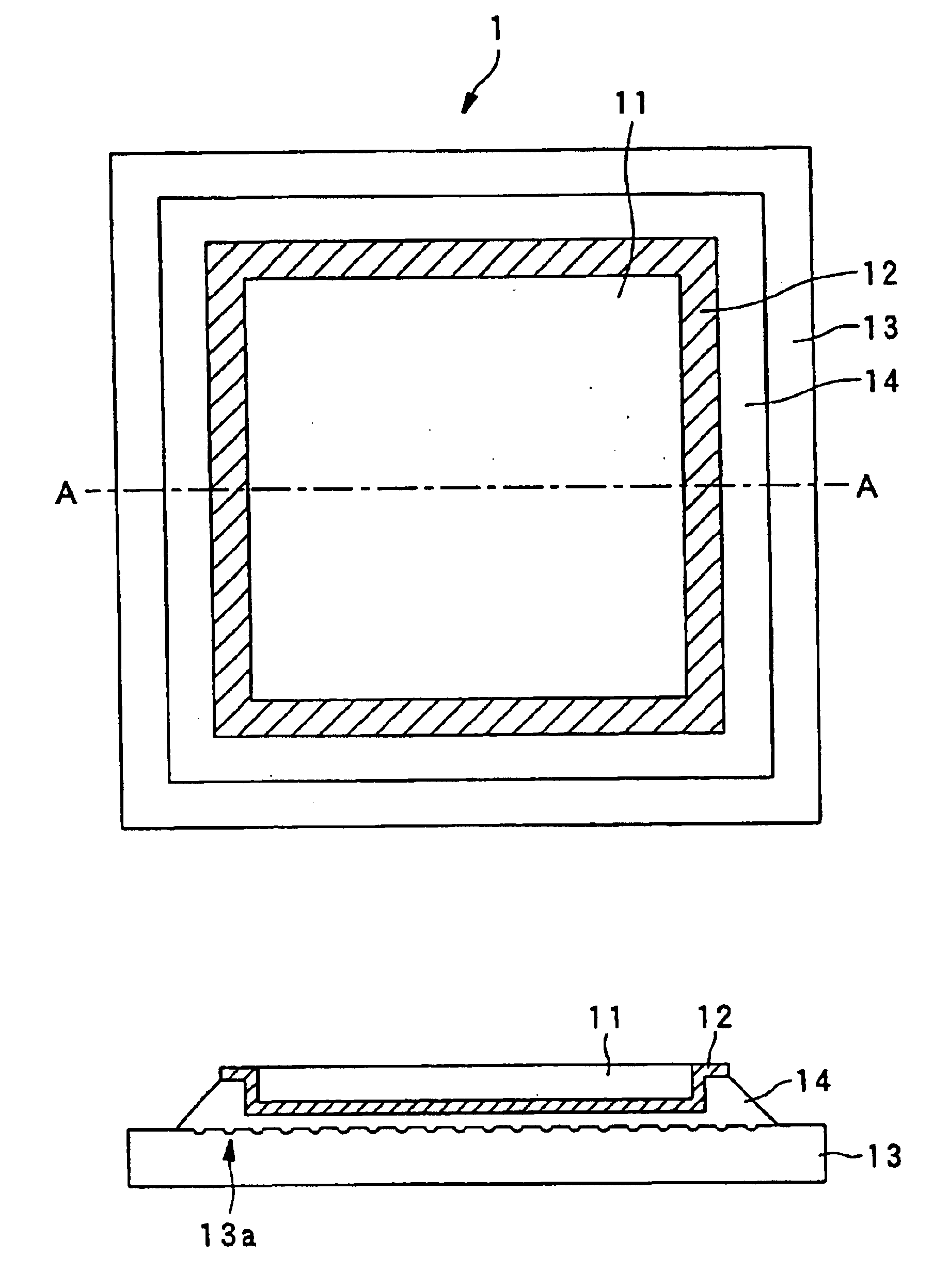

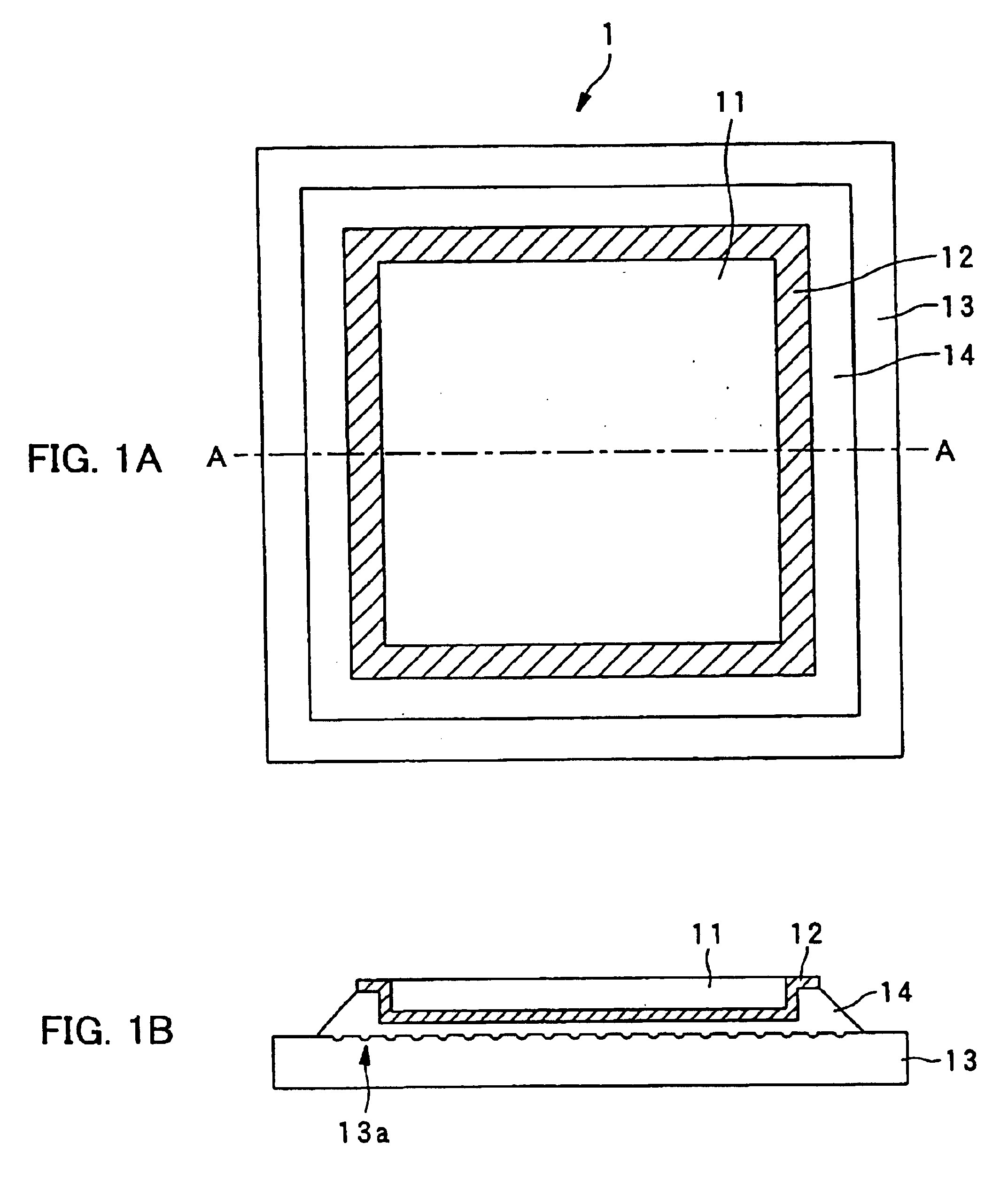

Overlay alignment measurement of wafers

InactiveUS6023338ASemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringElectron

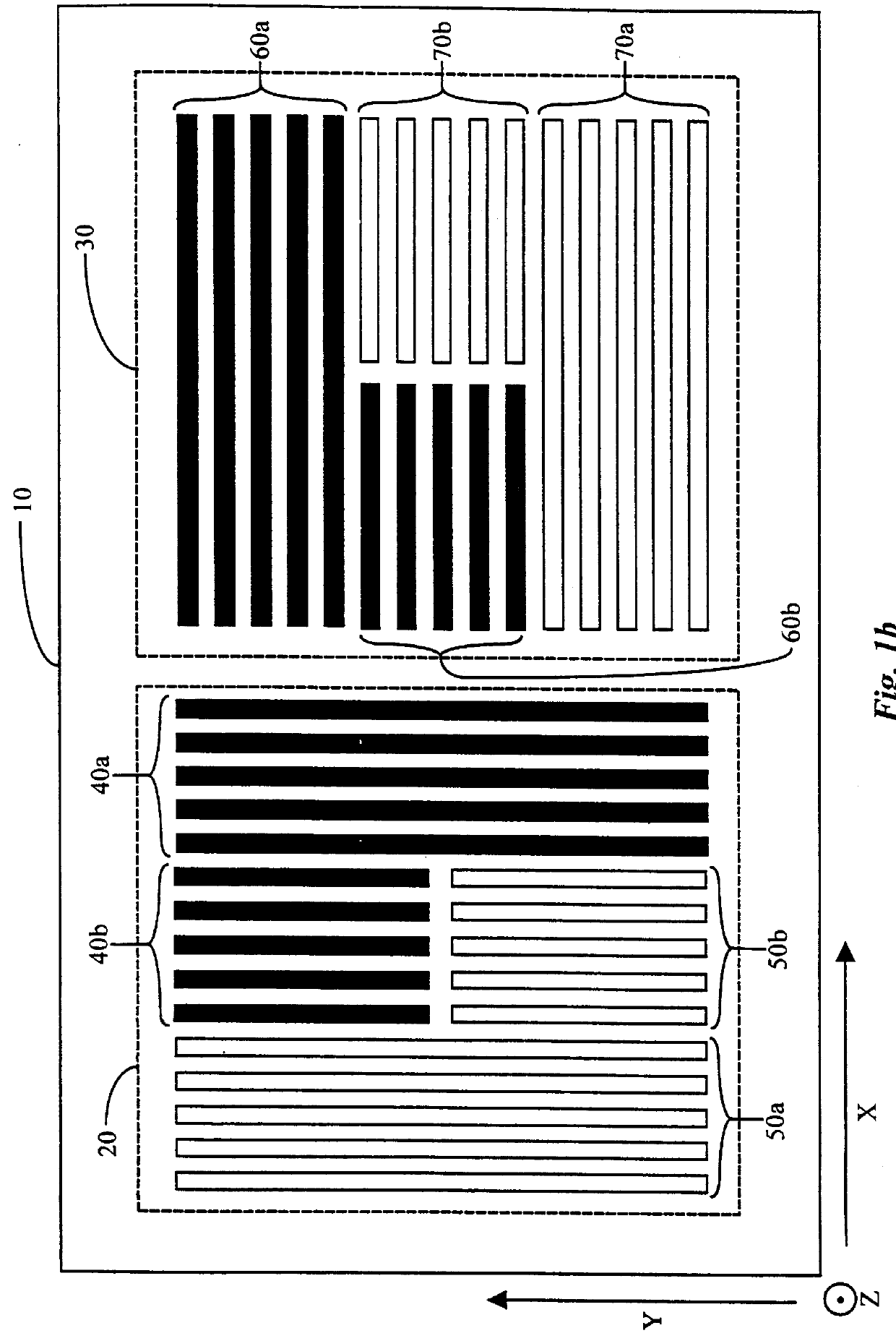

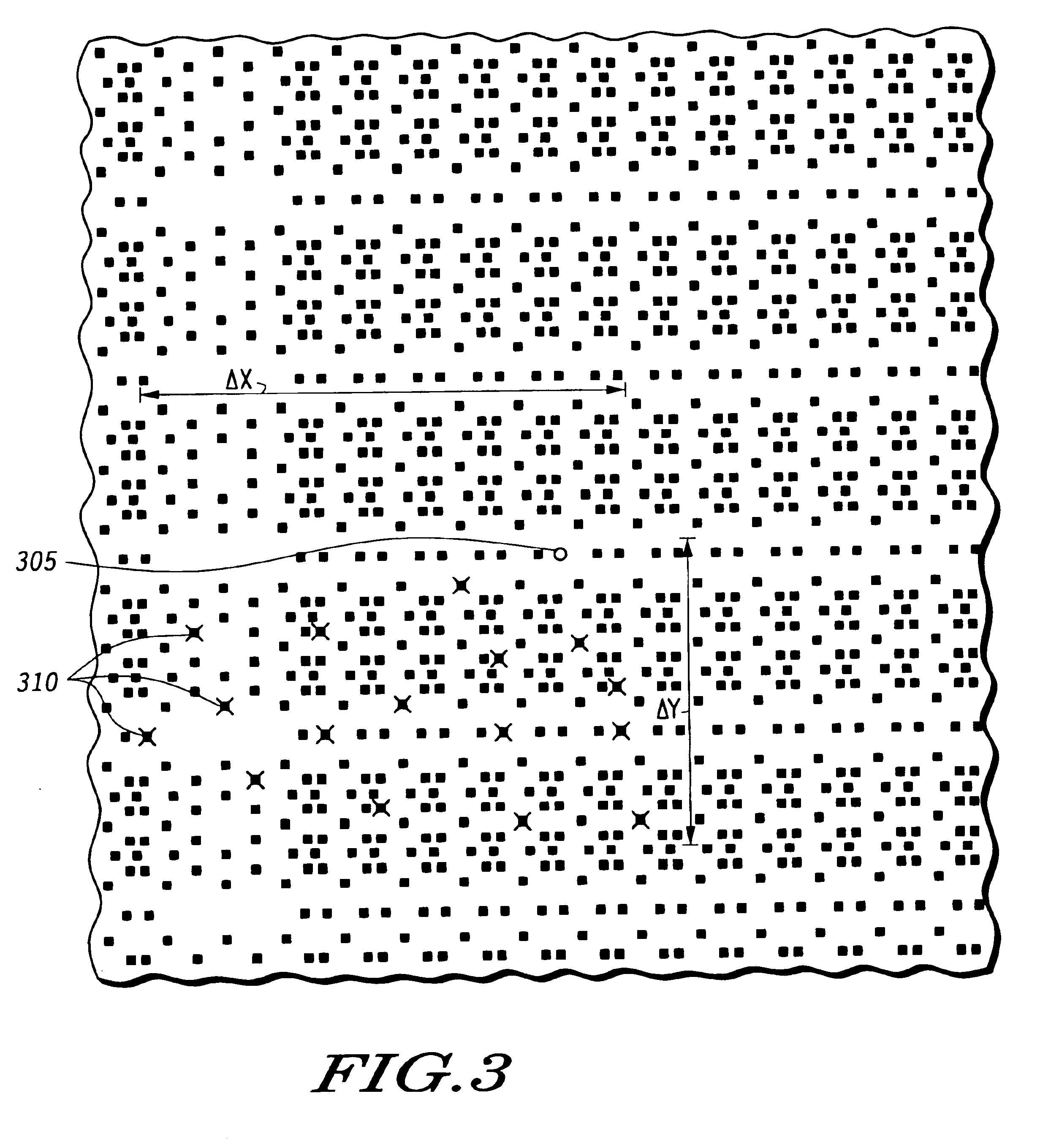

The present invention is a new target, and associated apparatus and methods, for determining offset between adjacent layers of a semiconductor device. The target disclosed here includes a first periodic structure to be placed on a first layer of the device and a second periodic structure, that complements the first periodic structure, placed on a second layer of the device at a location that is adjacent the first periodic structure when the second layer is placed on the first layer. Any offset that may occur is detected by the present invention either optically, micro-mechanically or with electron beams using any of various methods and system embodiments.

Owner:KLA INSTR

Overlay alignment measurement of wafers

InactiveUS6079256AMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementControl systemEngineering

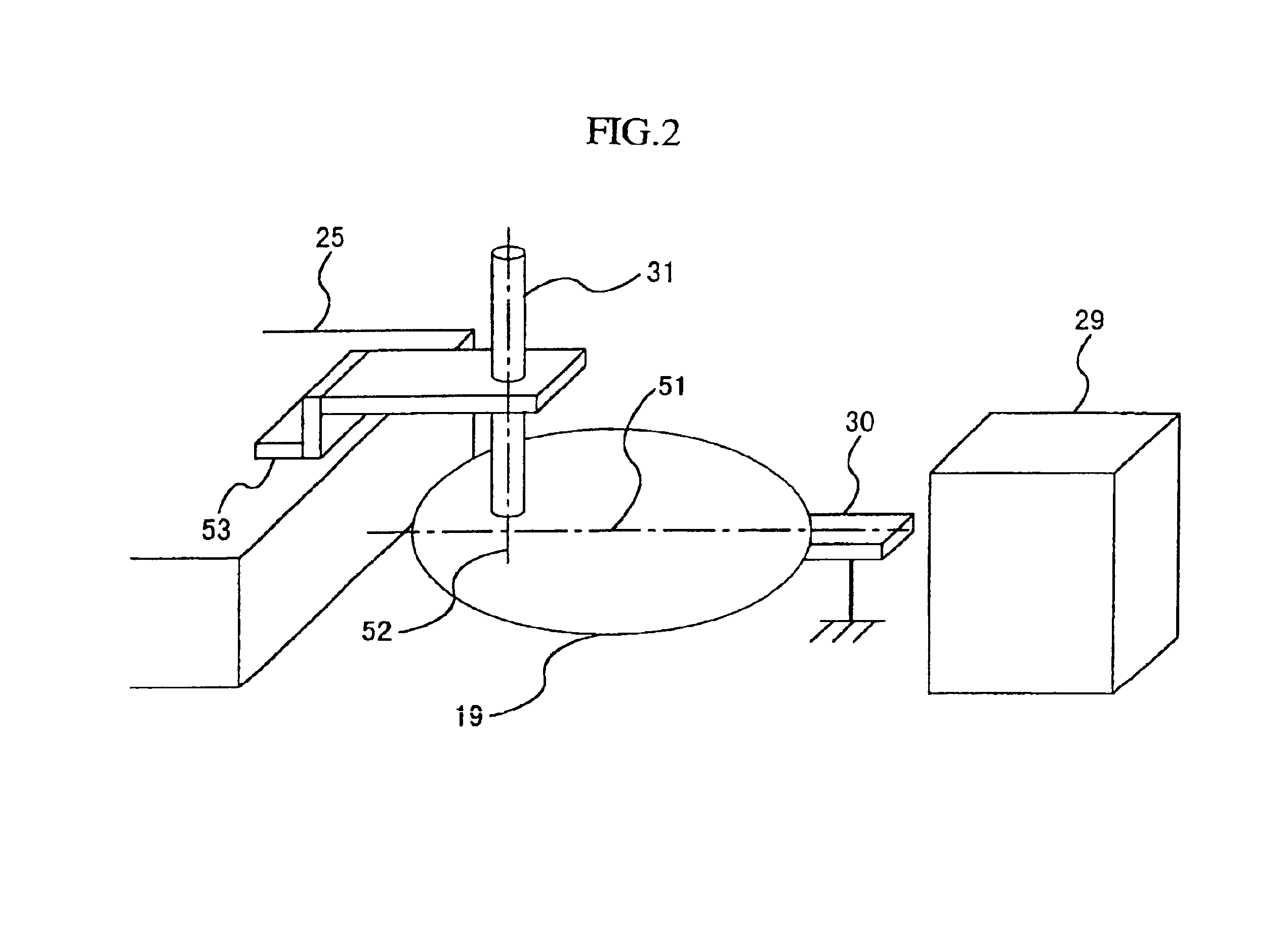

The present invention is a method and apparatus that uses a microscopic height variation positioned relative to a semiconductor device to scan a target on the device to produce an electrical signal representative of height variations of first and second periodic structures of the target in a selected path across the device, and a computing and control system to provide translation between the microscopic height variation detector and the target on the device in a selected path, and to calculate any offset between the first periodic structure and the second periodic structure of the target from the electrical signals from the microscopic height variation detector. The first periodic structure of the target is on a first layer of the device, and the second periodic structure, that complements the first periodic structure, is on a second layer of the device at a location that is adjacent the first periodic structure.

Owner:KLA INSTR

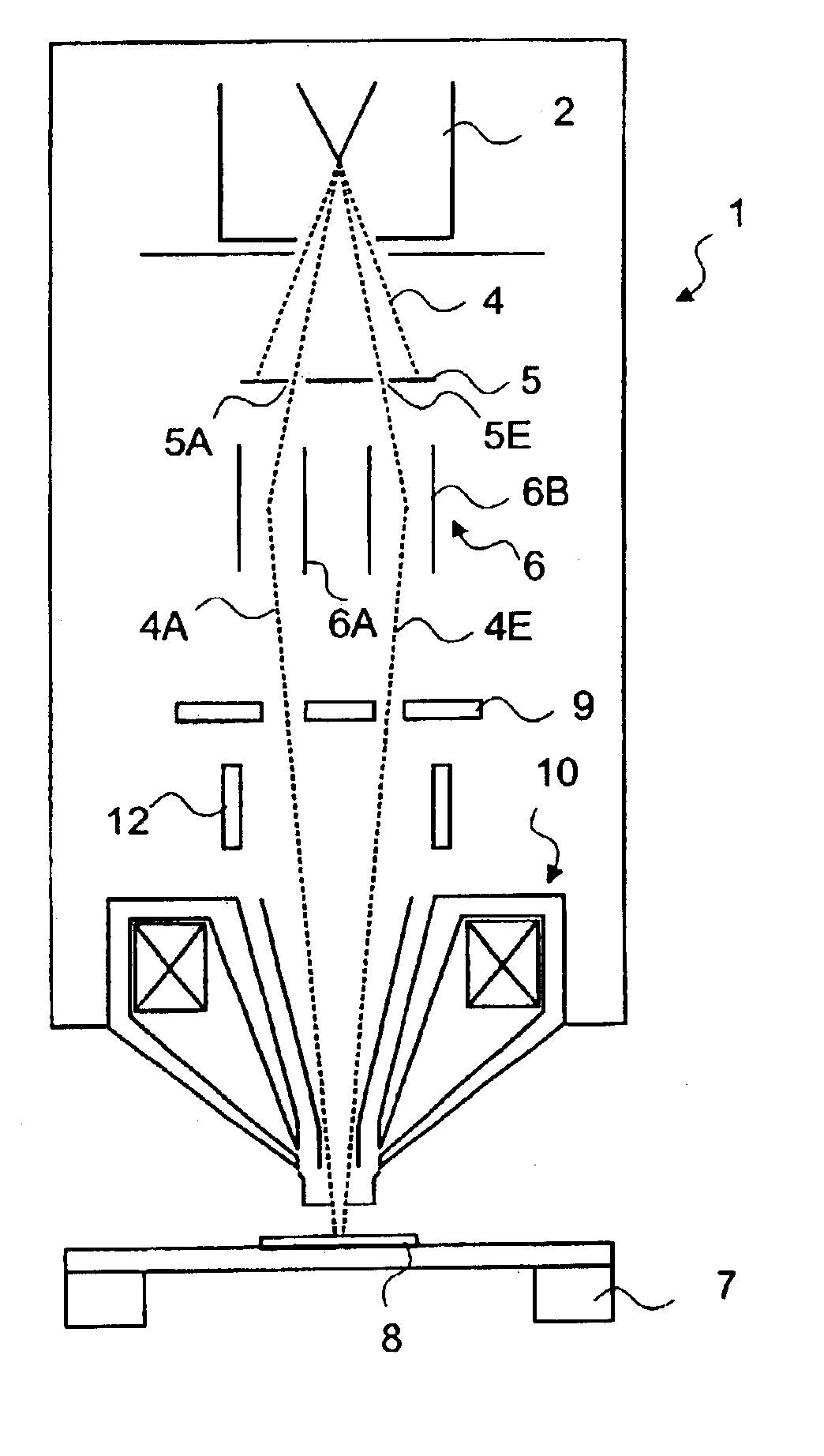

Multi-beam multi-column electron beam inspection system

InactiveUS6844550B1Material analysis using wave/particle radiationRadiation/particle handlingSystems designData stream

A multi-column electron beam inspection system is disclosed herein. The system is designed for electron beam inspection of semiconductor wafers with throughput high enough for in-line use. The system includes field emission electron sources, electrostatic electron optical columns, a wafer stage with six degrees of freedom of movement, and image storage and processing systems capable of handling multiple simultaneous image data streams. Each electron optical column is enhanced with an electron gun with redundant field emission sources, a voltage contrast plate to allow voltage contrast imaging of wafers, and an electron optical design for high efficiency secondary electron collection.

Owner:MULTIBEAM CORP

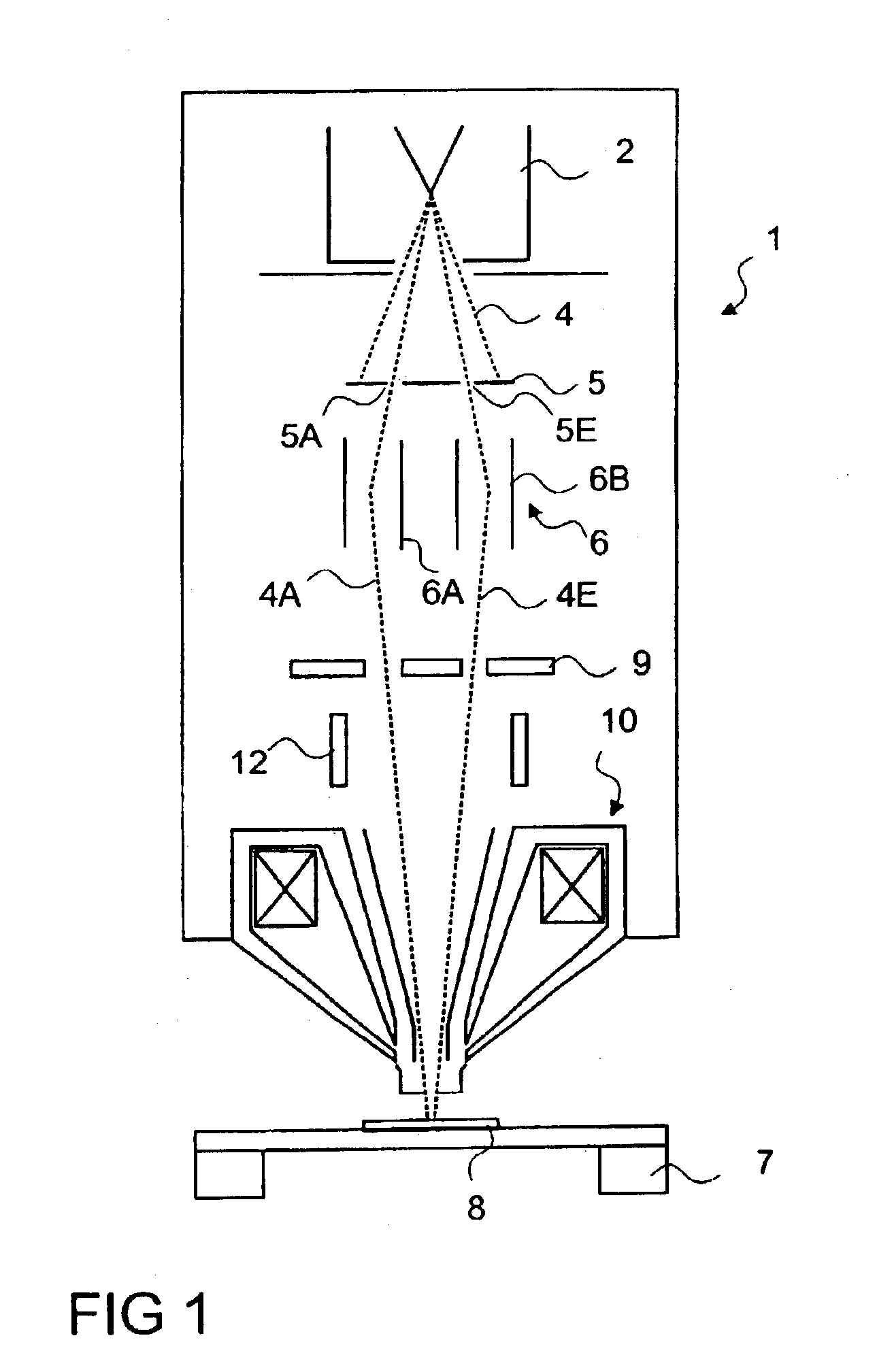

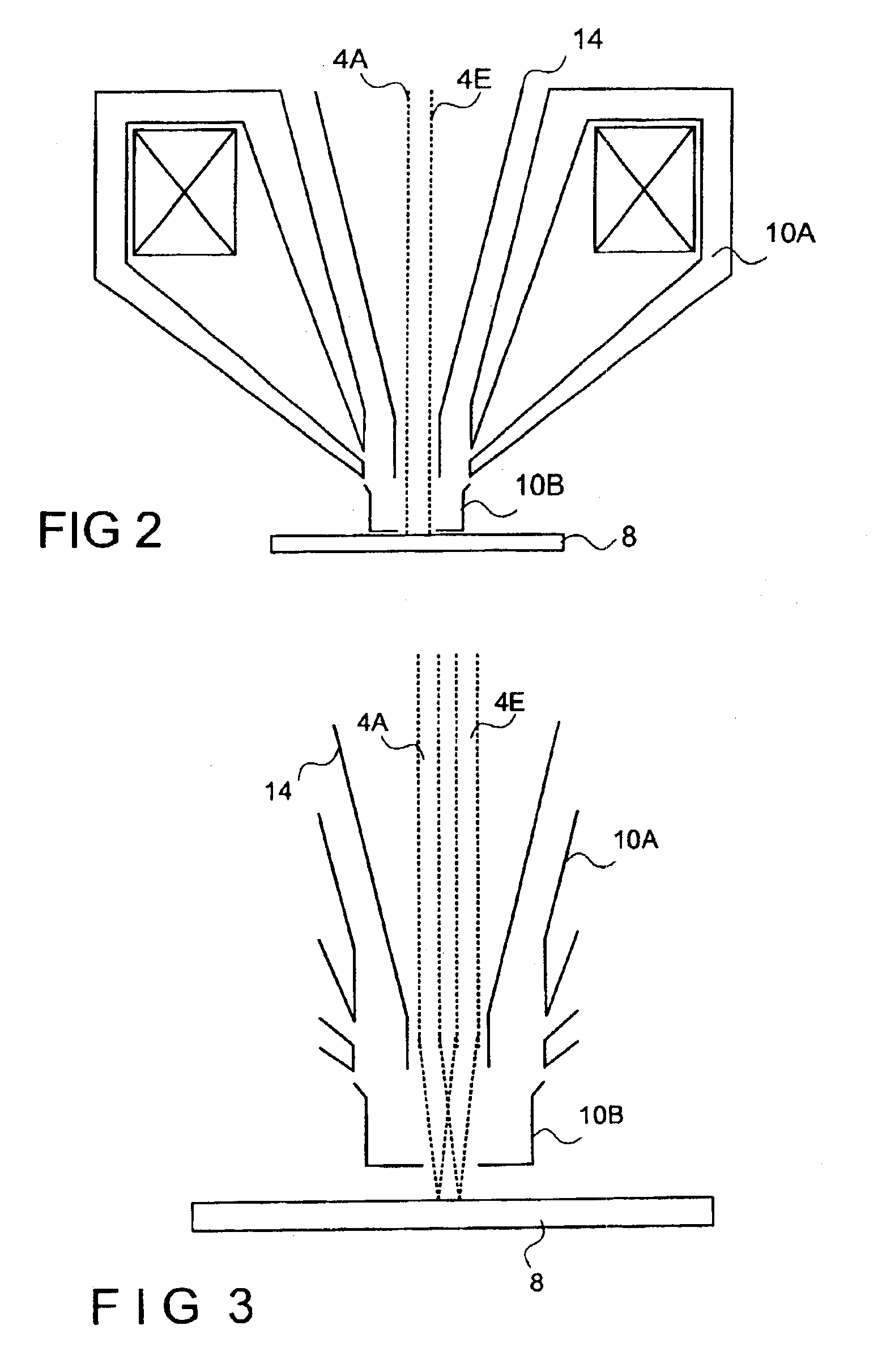

Multi beam charged particle device

InactiveUS6943349B2Improve data acquisition speedIncrease speedThermometer detailsStability-of-path spectrometersImage resolutionParticle beam

The present invention provides an improved column for a charged particle beam device. The column comprises an aperture plate having multiple apertures to produce multiple beams of charged particles and a deflector to influence the beams of charged particles so that each beam appears to come from a different source. Furthermore, an objective lens is used in order to focus the charged-particle beams onto the specimen. Due to the deflector, multiple images of the source are created on the surface of the specimen whereby all the images can be used for parallel data acquisition. Accordingly, the speed of data acquisition is increased. With regard to the focusing properties of the objective lens, the beams of charged particles can basically be treated as independent particle beams which do not negatively affect each other. Accordingly, each beam basically provides the same resolution as the beam of a conventional charged particle beam device.

Owner:ICT INTEGRATED CIRCUIT TESTING GESELLSCHAFT FUER HALBLEITERPRUEFTECHNIK GMBH

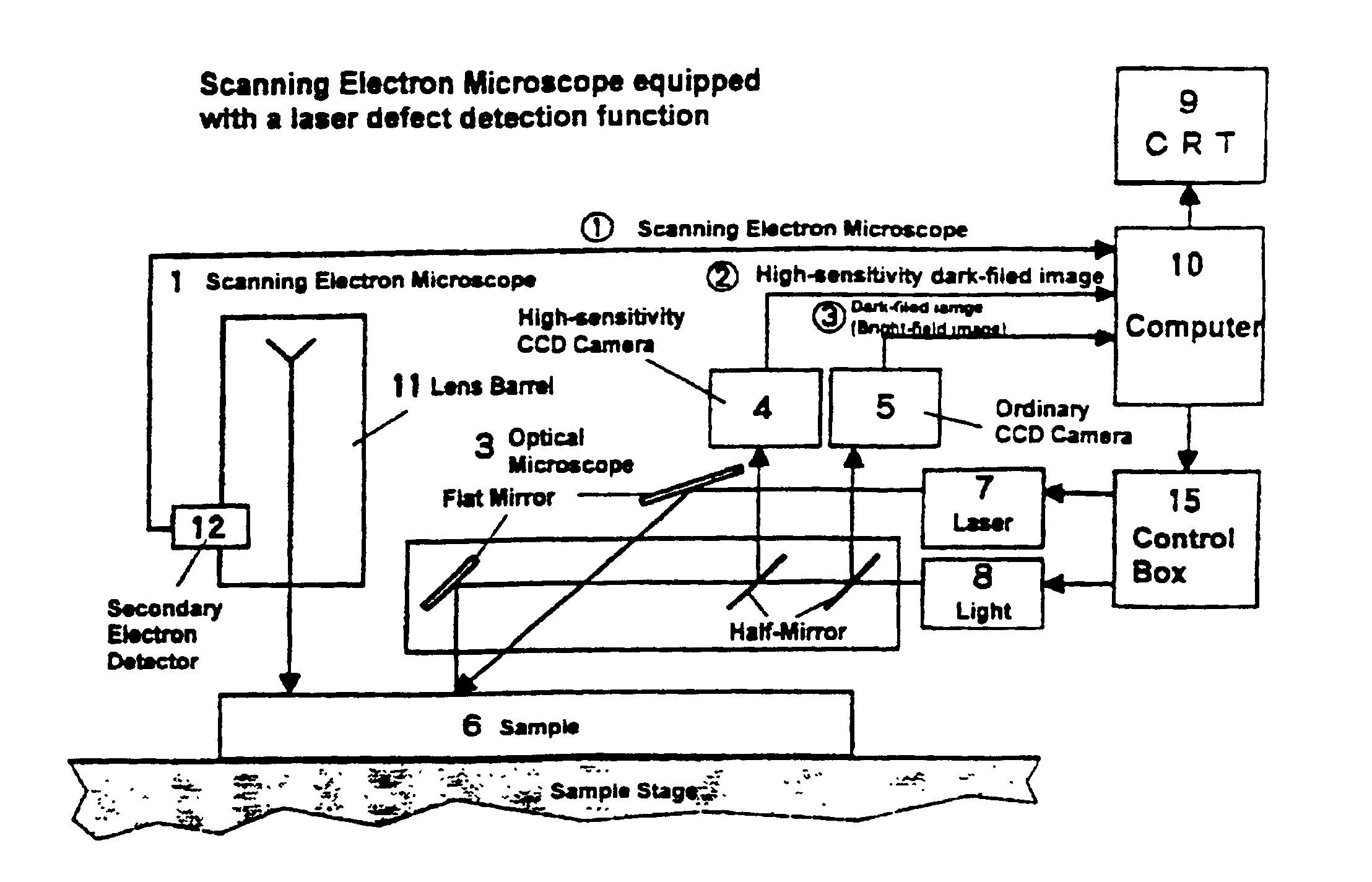

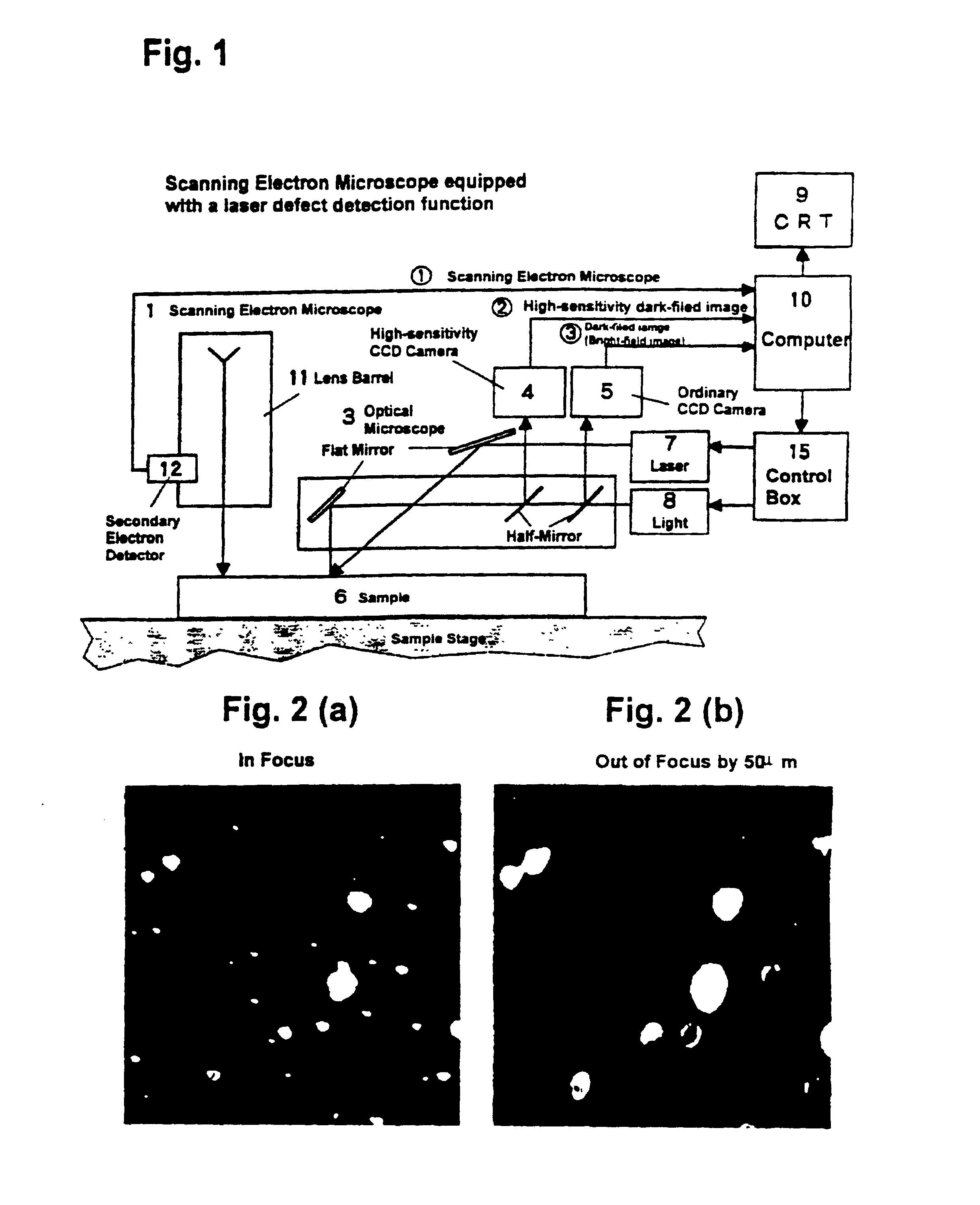

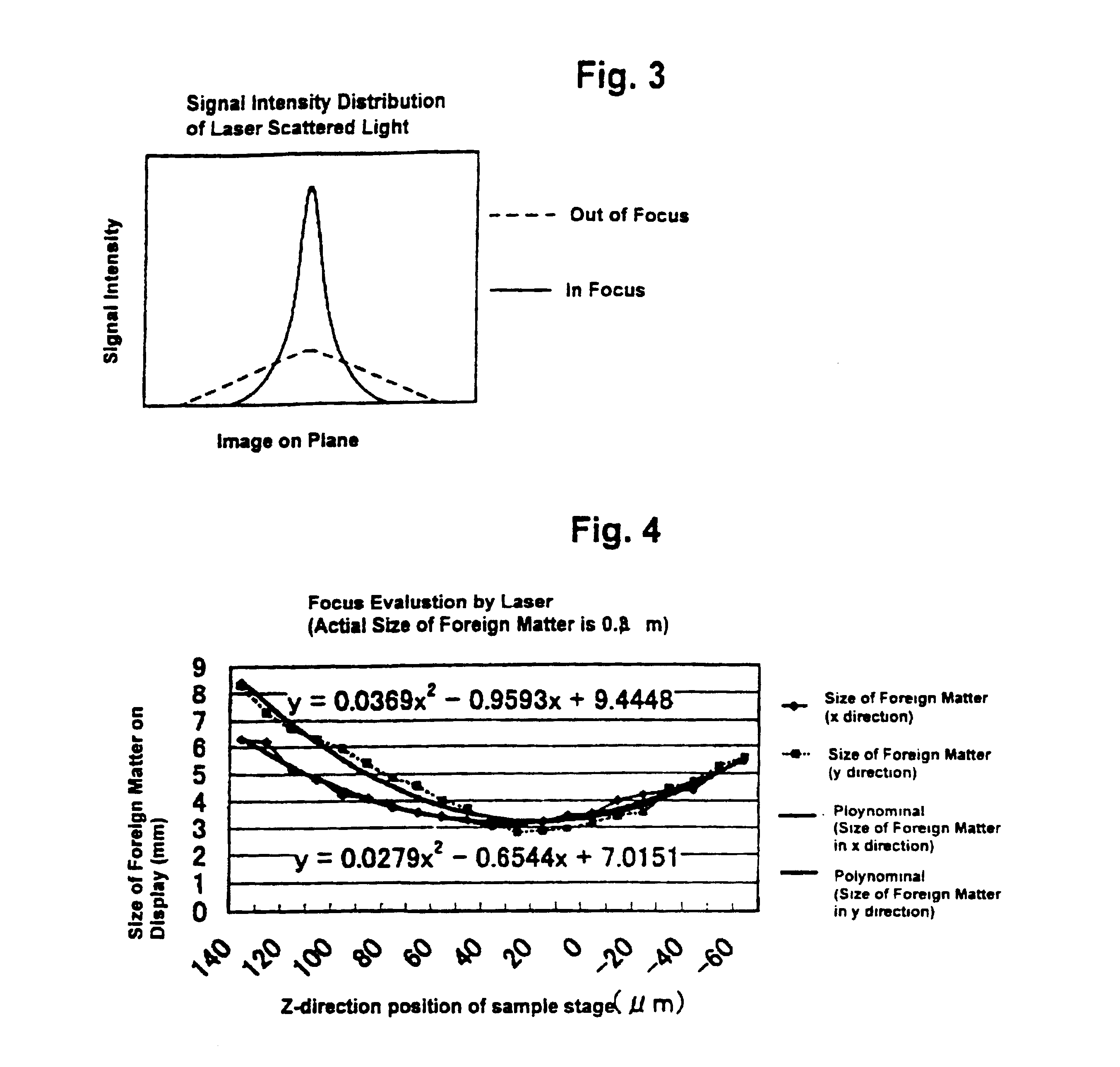

Automatic focusing system for scanning electron microscope equipped with laser defect detection function

InactiveUS6621082B2Material analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementImage detectionElectron microscope

A scanning electron microscope equipped with a laser defect detection function has an automatic focusing function that performs the steps of: obtaining a deviation (offset) amount between focal positions of an optical microscope and a scanning electron microscope; detecting a defect by a laser dark-field image of the optical microscope; analyzing the dark-field image to readjust a focus of the optical microscope to adjust a height of the optical microscope; and automatically adjusting a focus of the scanning electron microscope by adding a readjusted amount of the focus of the optical microscope to the offset amount before an observation is conducted by the scanning electron microscope.

Owner:HITACHI HIGH TECH SCI CORP

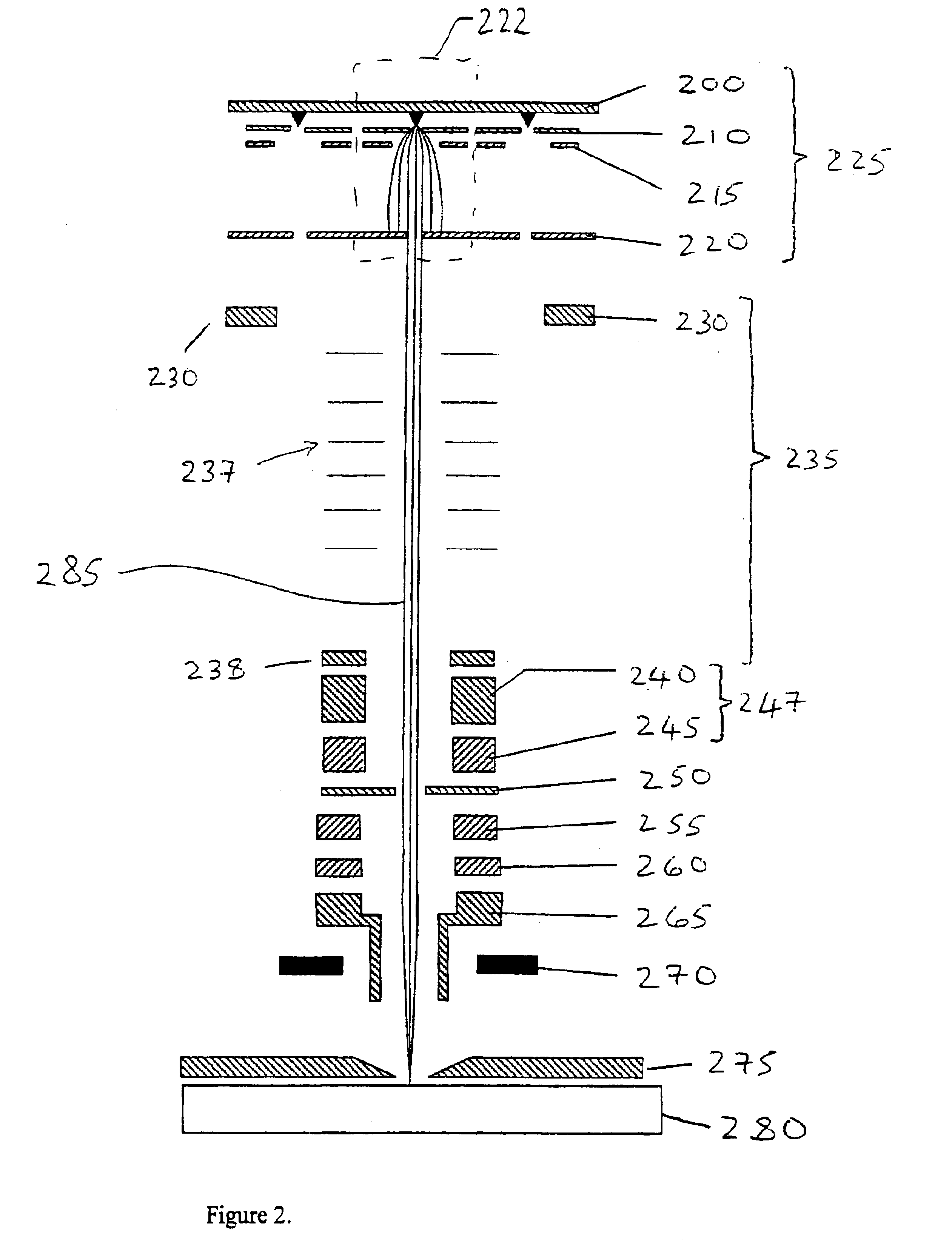

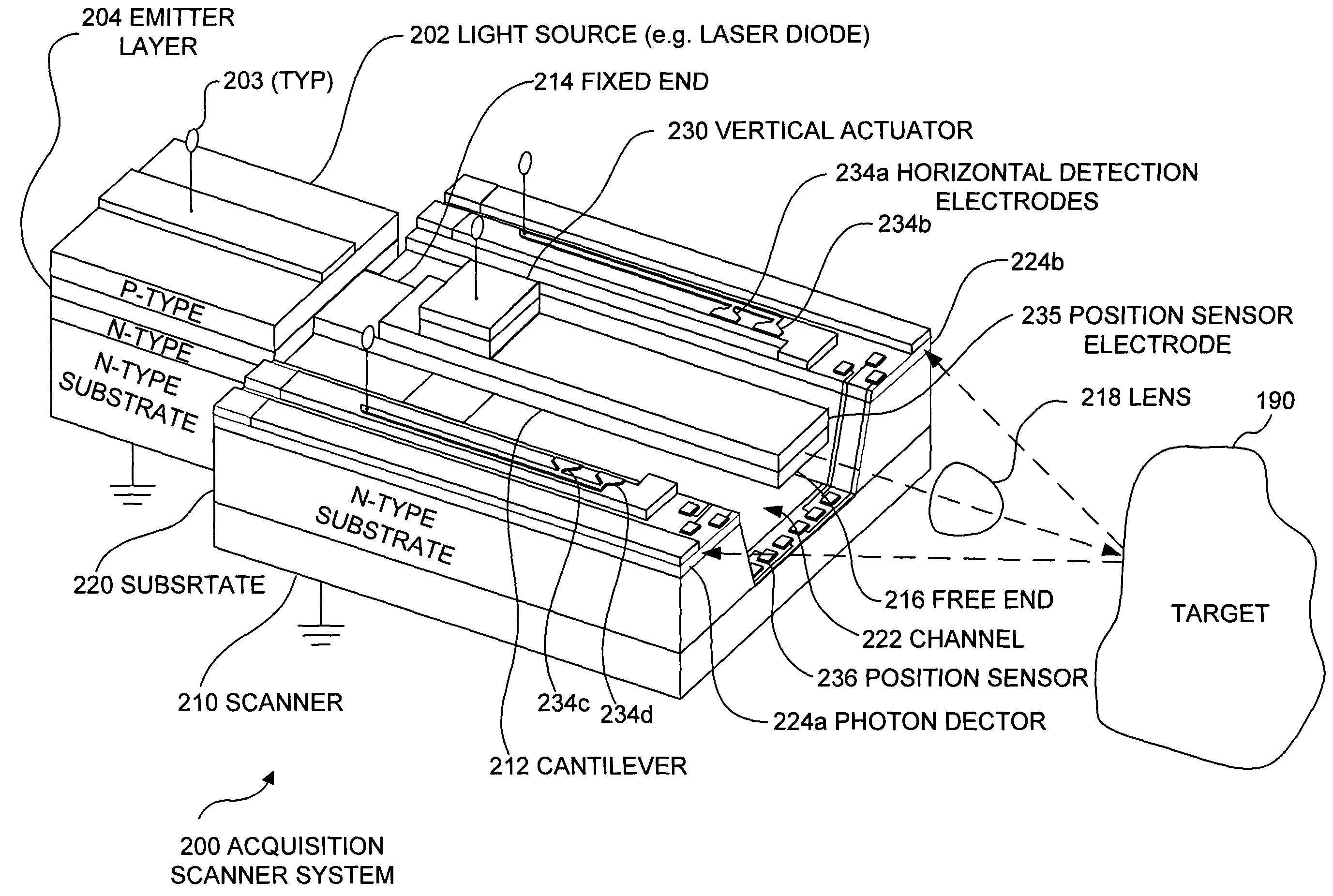

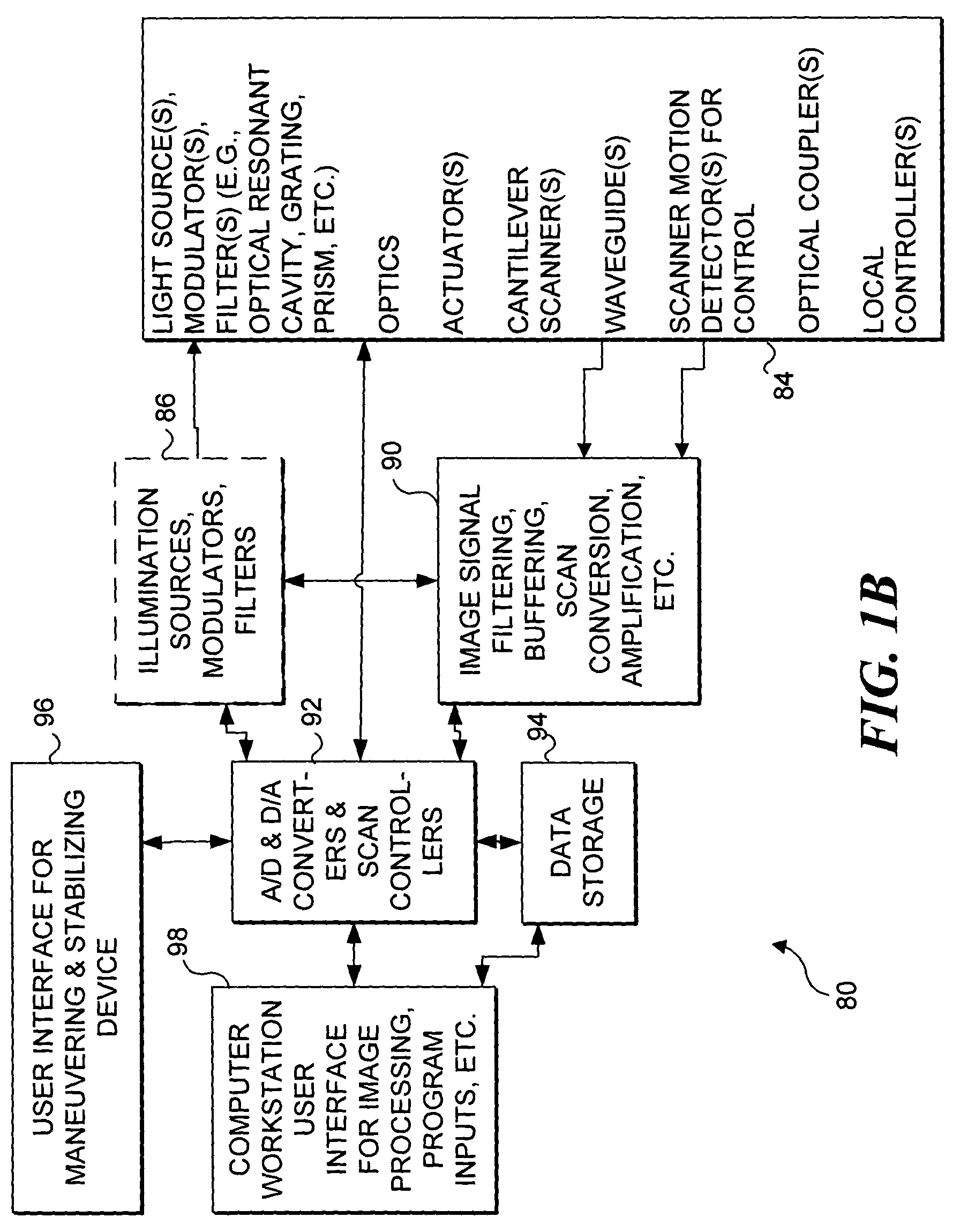

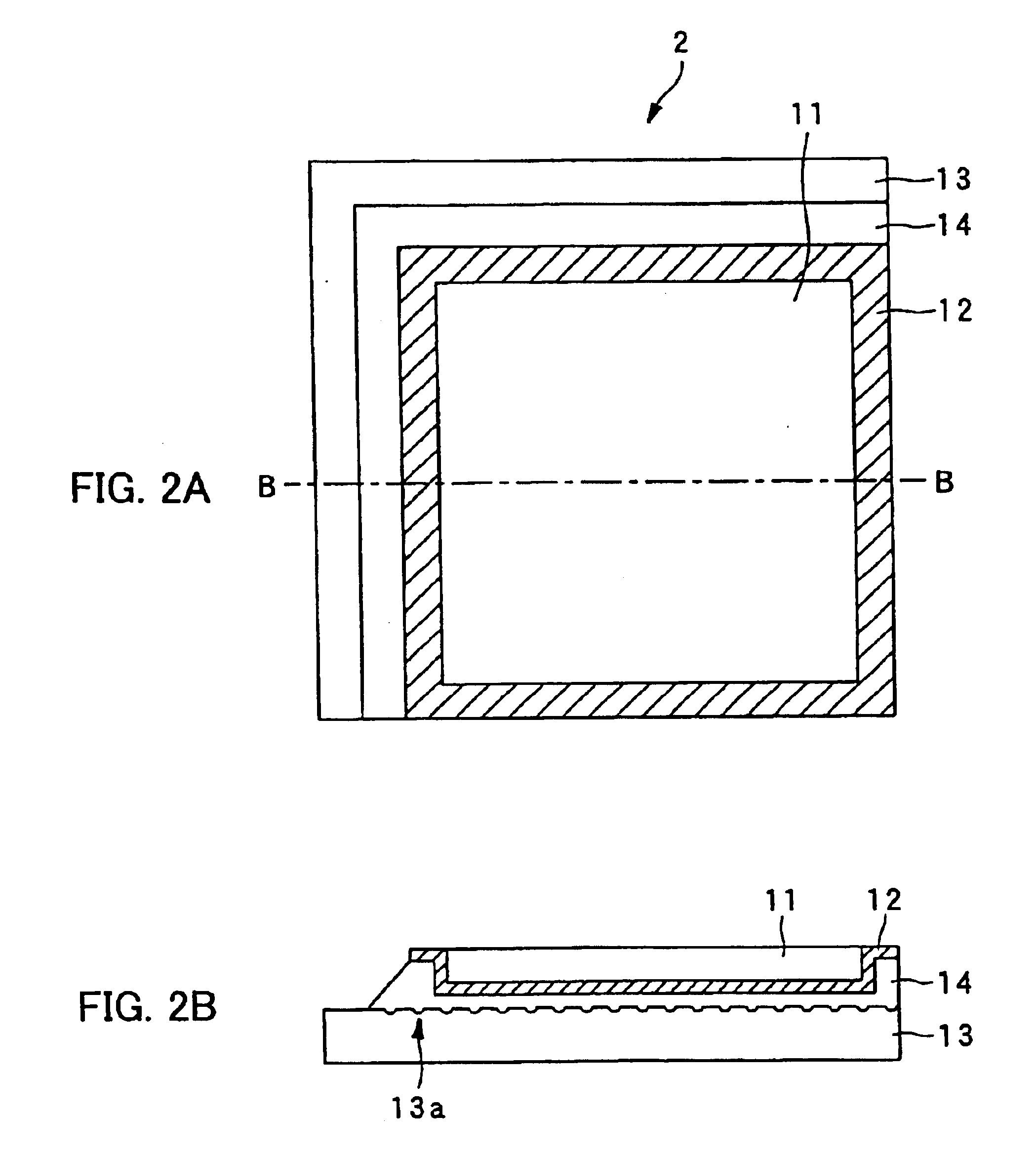

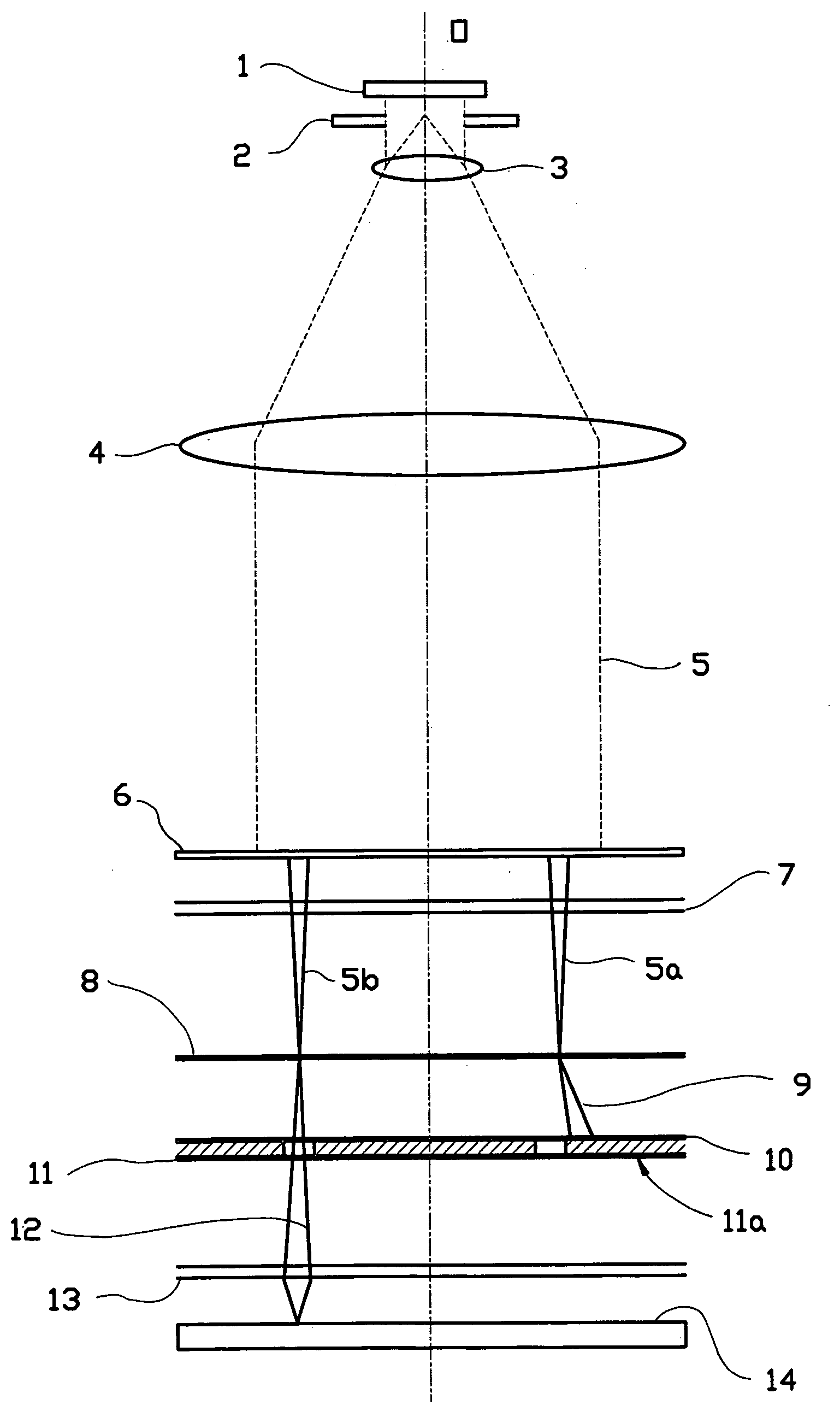

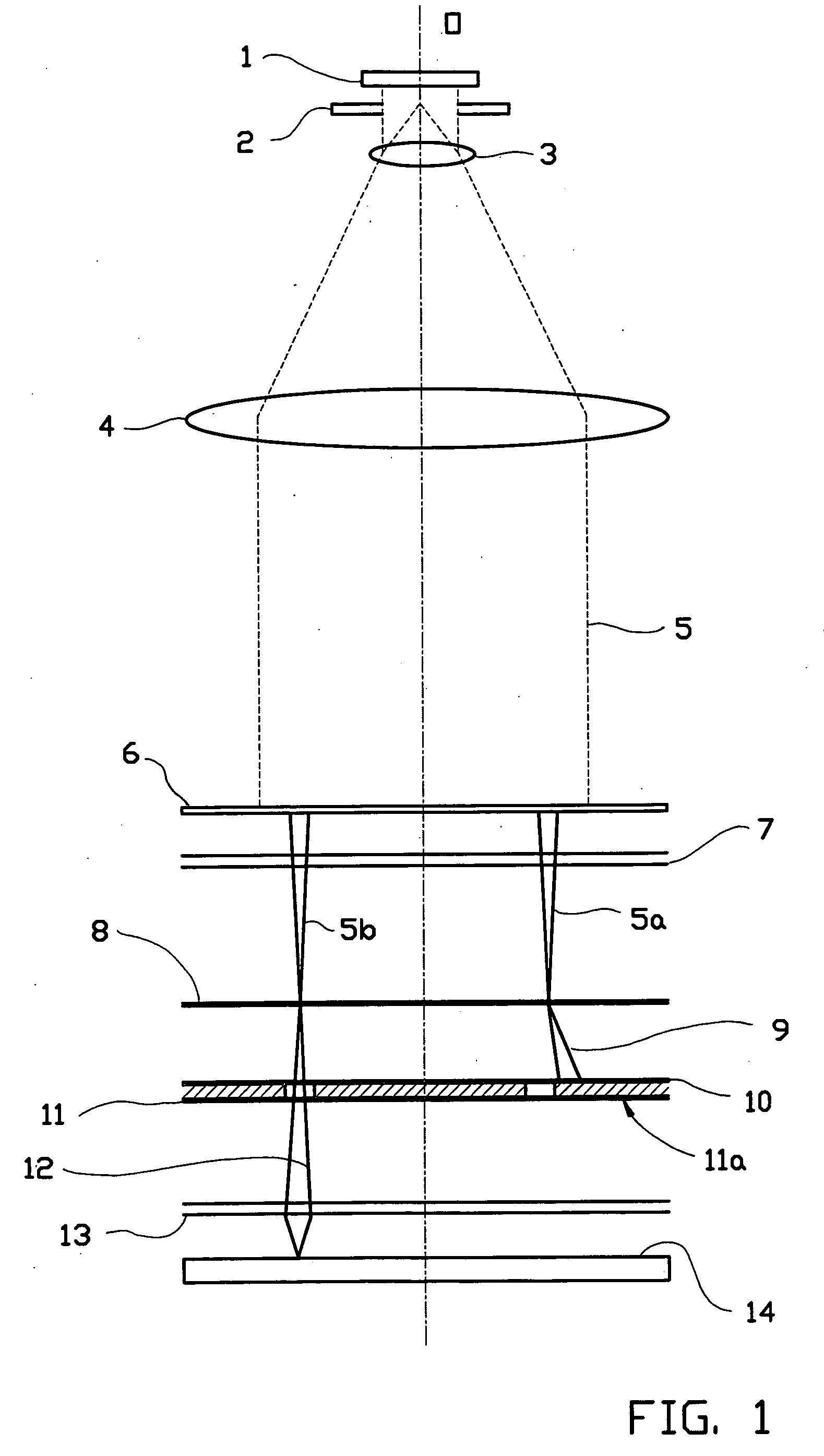

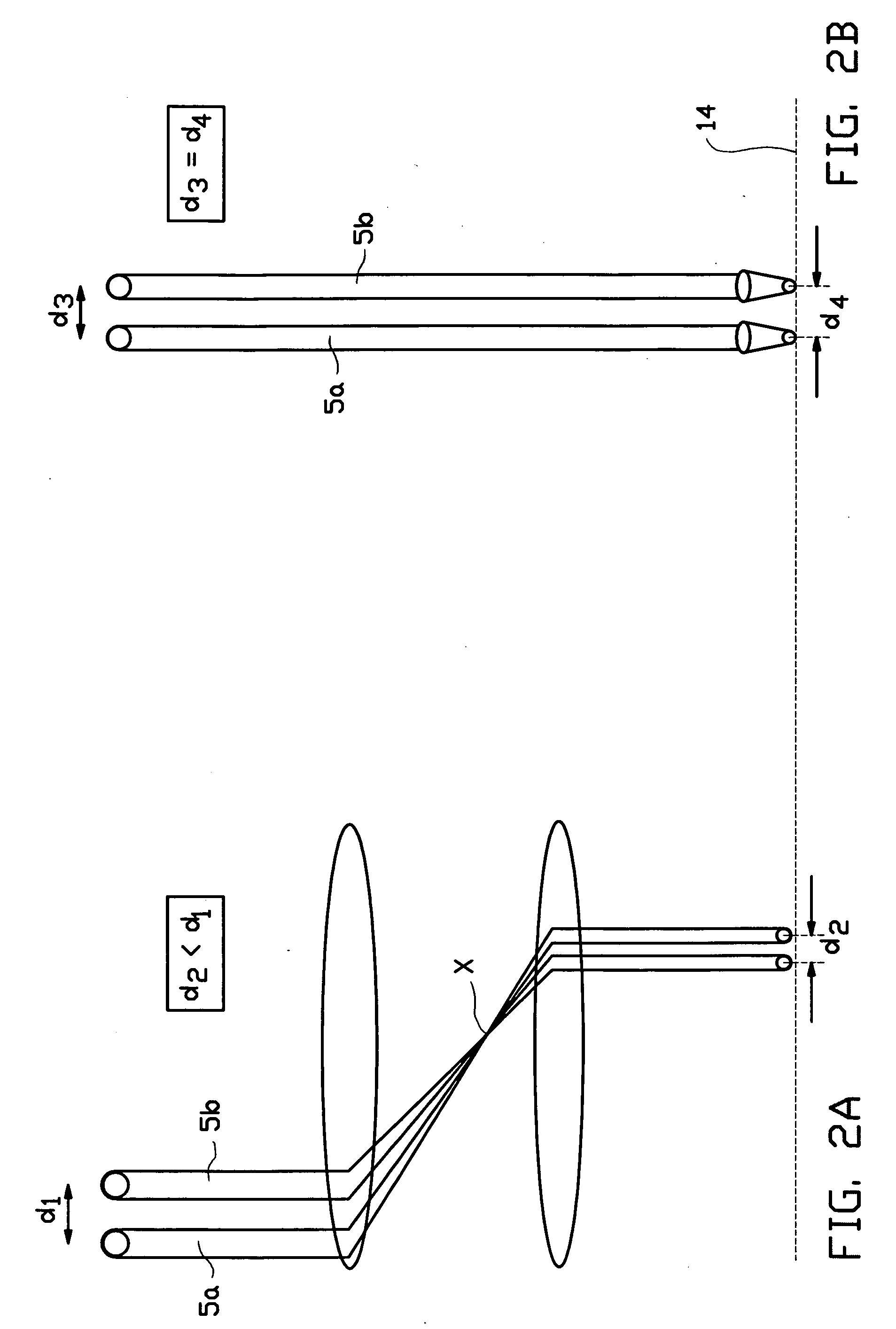

Integrated optical scanning image acquisition and display

An apparatus and method for providing image acquisition and / or image display in a limited region of interest (ROI). The apparatus comprises a micro electro-mechanical system (MEMS), preferably integrating a light source, a cantilever, a lens, an actuator, a light detector, and a position sensor. The light source provides light for illuminating the ROI, displaying an image, providing a therapy, and / or performing other functions. The cantilever comprises a resin waveguide with a fixed end attached to a substrate that supports many or all other components. A free end of the cantilever is released from the substrate during fabrication and includes the lens. The actuator scans the free end in orthogonal directions to illuminate the ROI or display an image. The position sensors detect the position of the free end for control. The light detector receives light backscattered from the ROI separate from, or at the fixed end the cantilever.

Owner:UNIV OF WASHINGTON +1

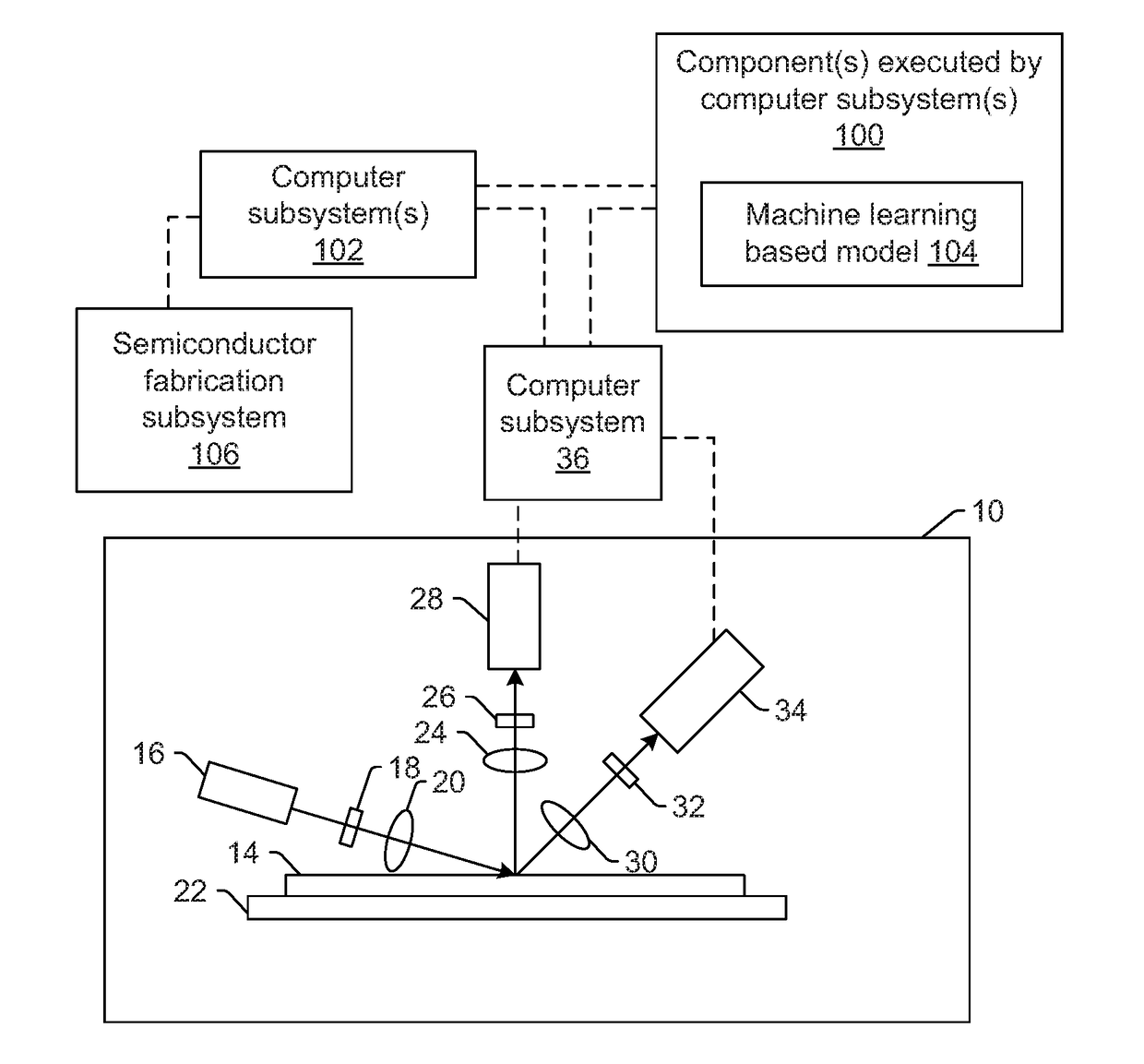

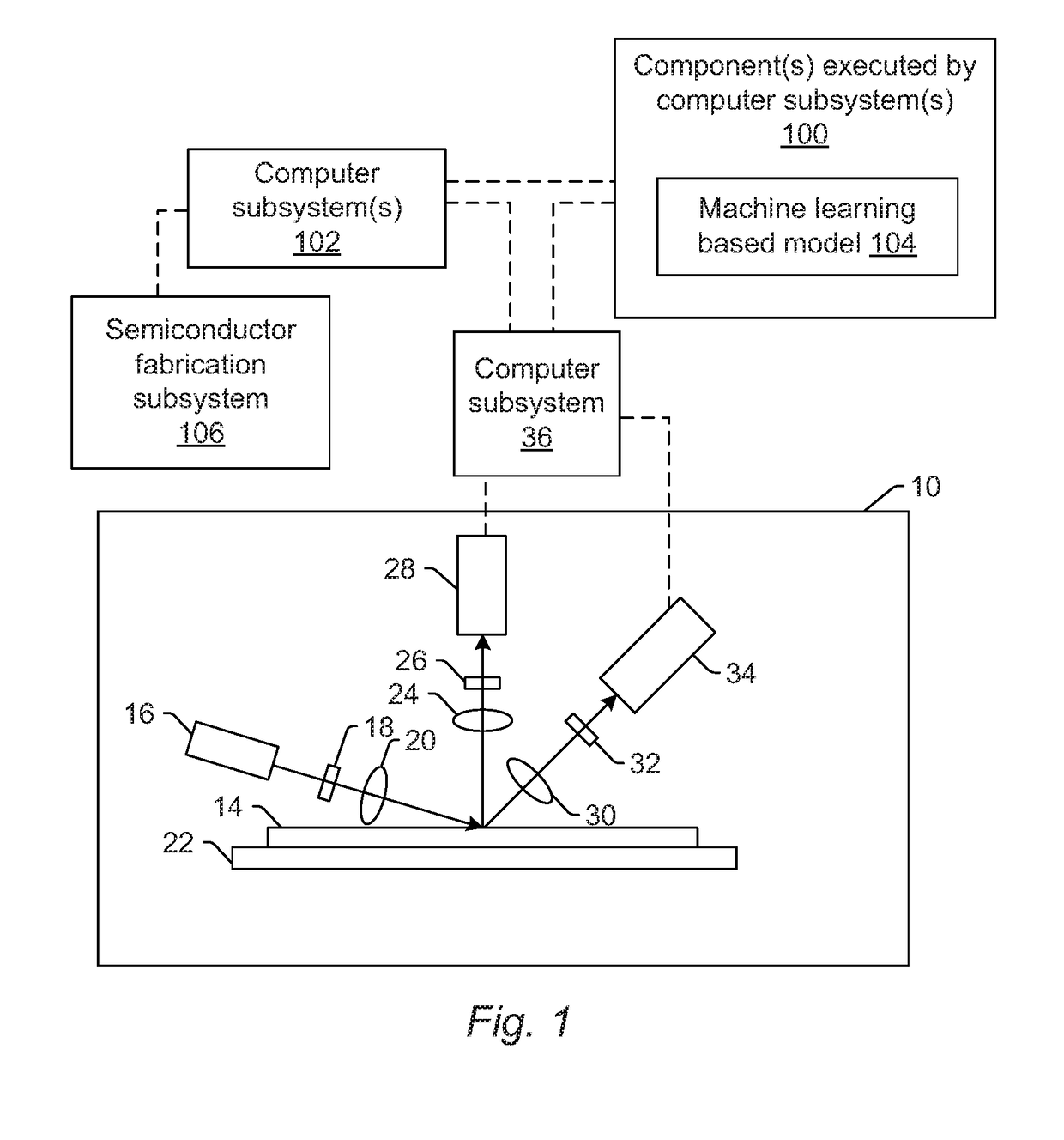

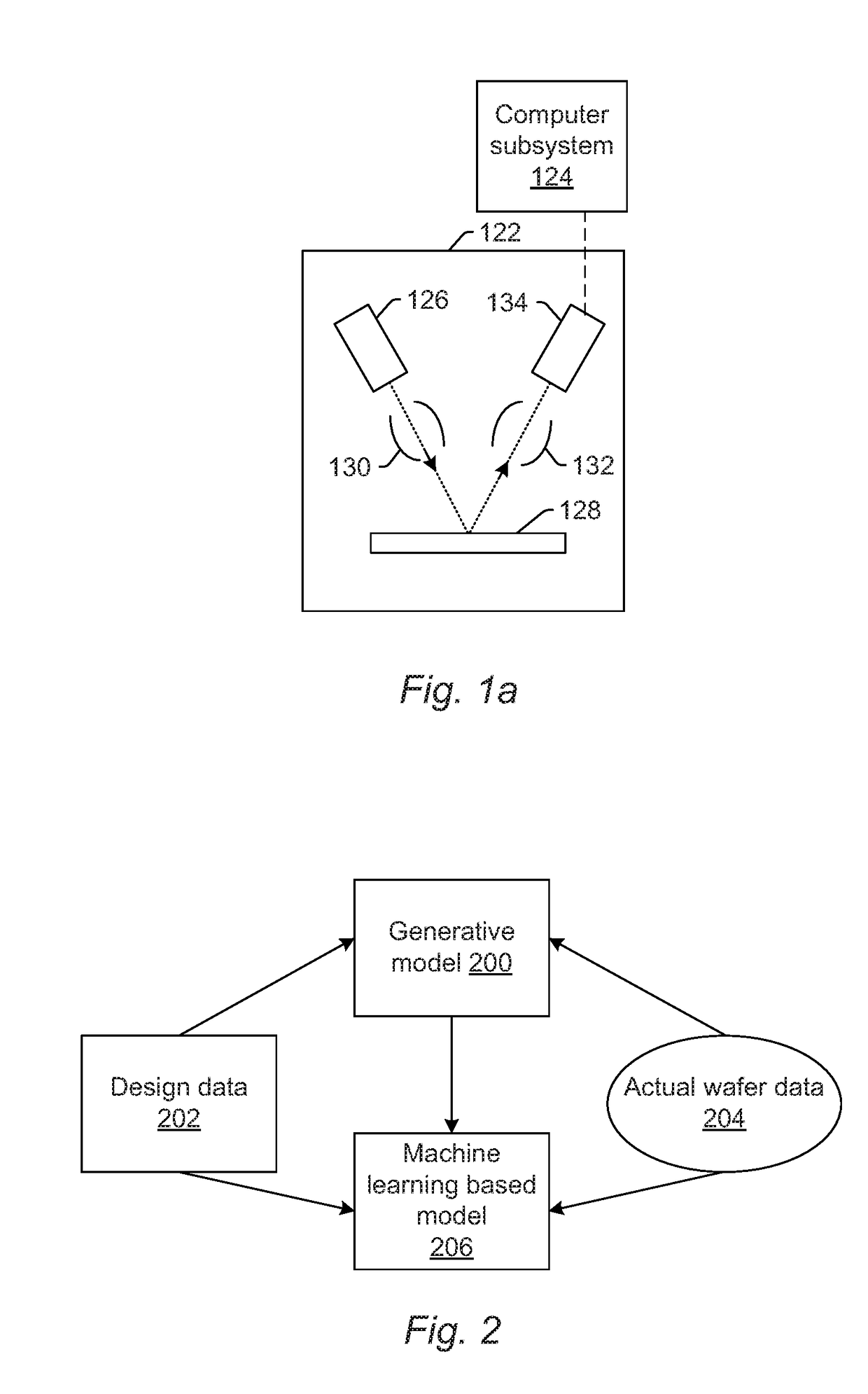

Accelerated training of a machine learning based model for semiconductor applications

Methods and systems for accelerated training of a machine learning based model for semiconductor applications are provided. One method for training a machine learning based model includes acquiring information for non-nominal instances of specimen(s) on which a process is performed. The machine learning based model is configured for performing simulation(s) for the specimens. The machine learning based model is trained with only information for nominal instances of additional specimen(s). The method also includes re-training the machine learning based model with the information for the non-nominal instances of the specimen(s) thereby performing transfer learning of the information for the non-nominal instances of the specimen(s) to the machine learning based model.

Owner:KLA TENCOR TECH CORP

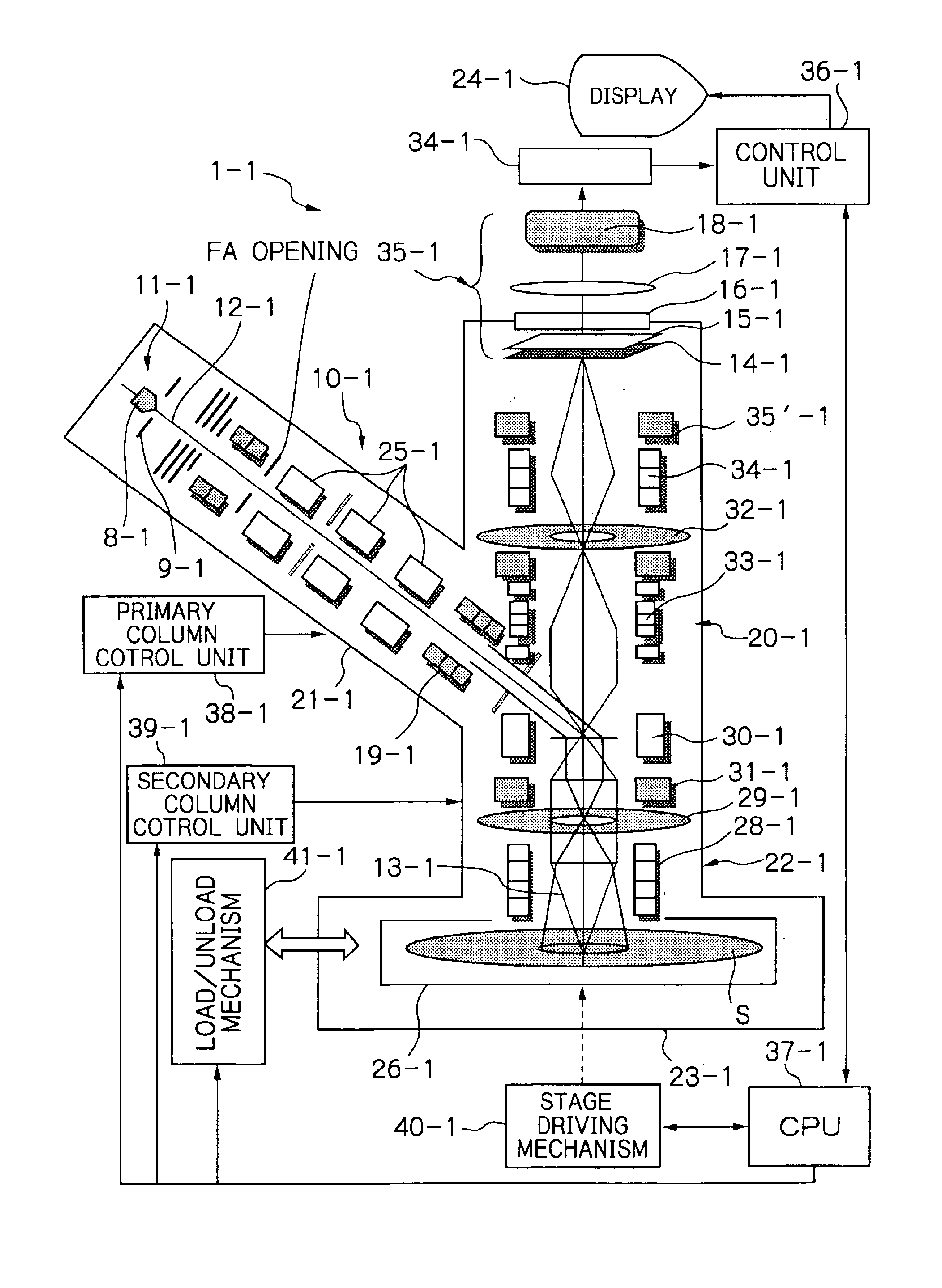

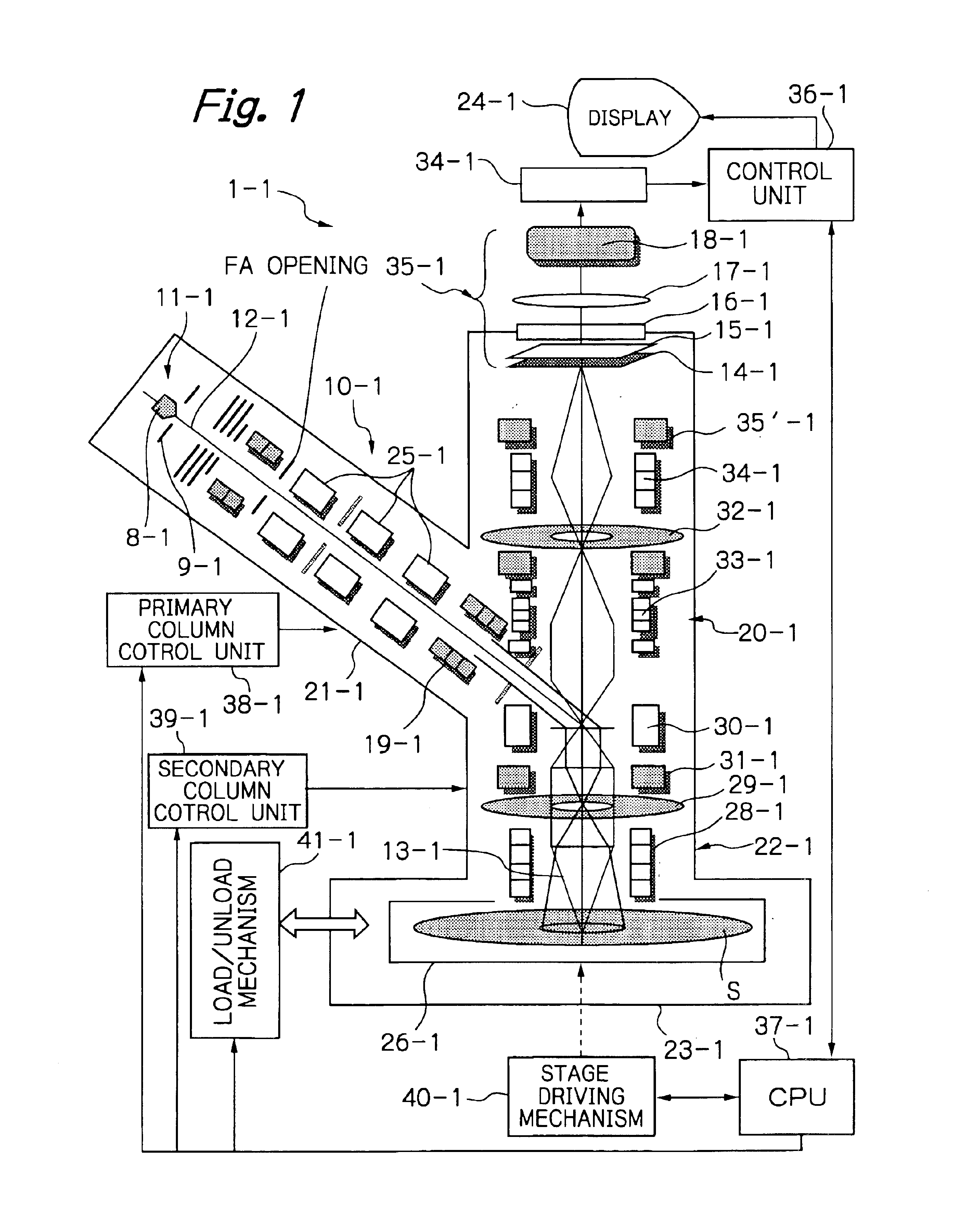

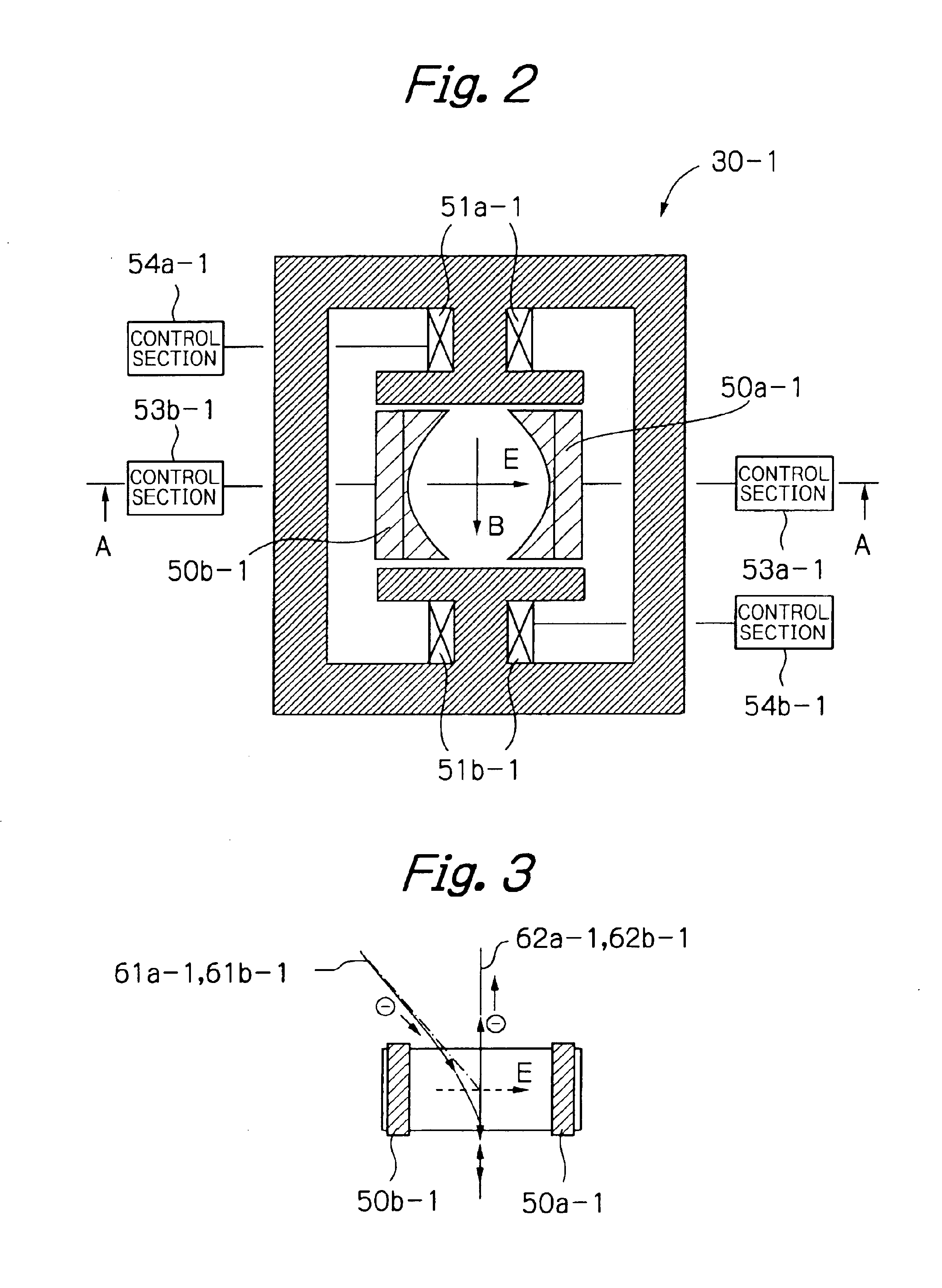

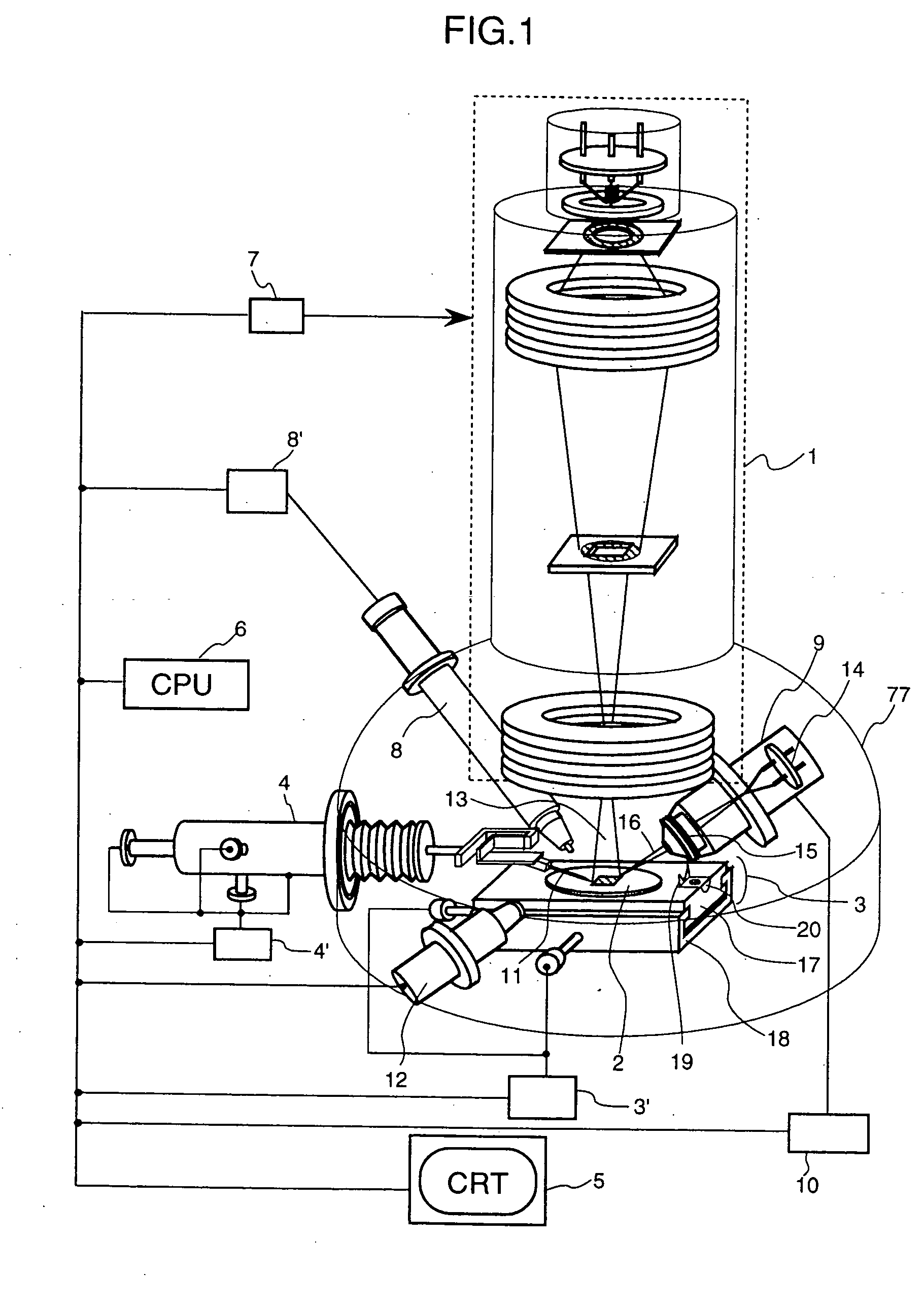

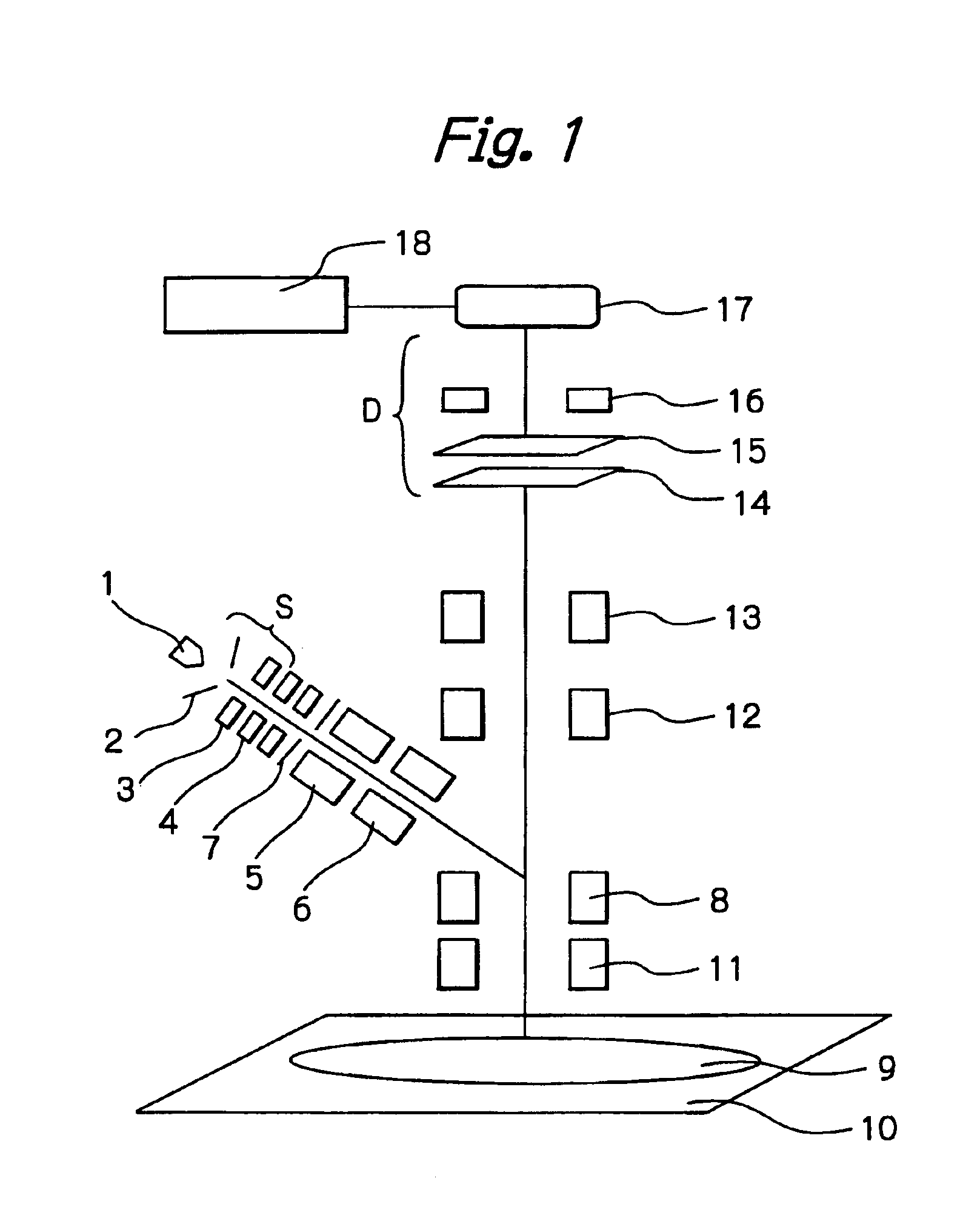

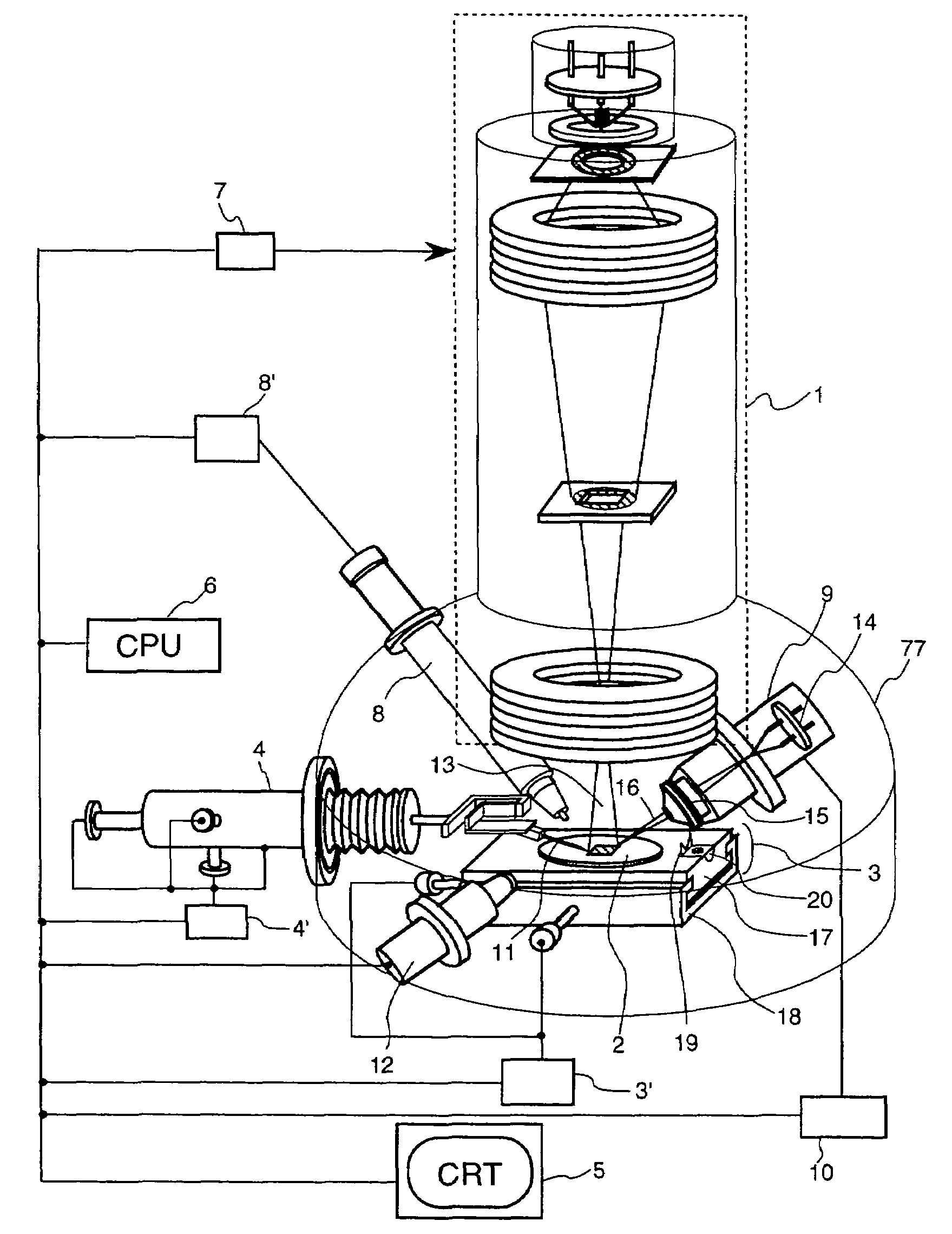

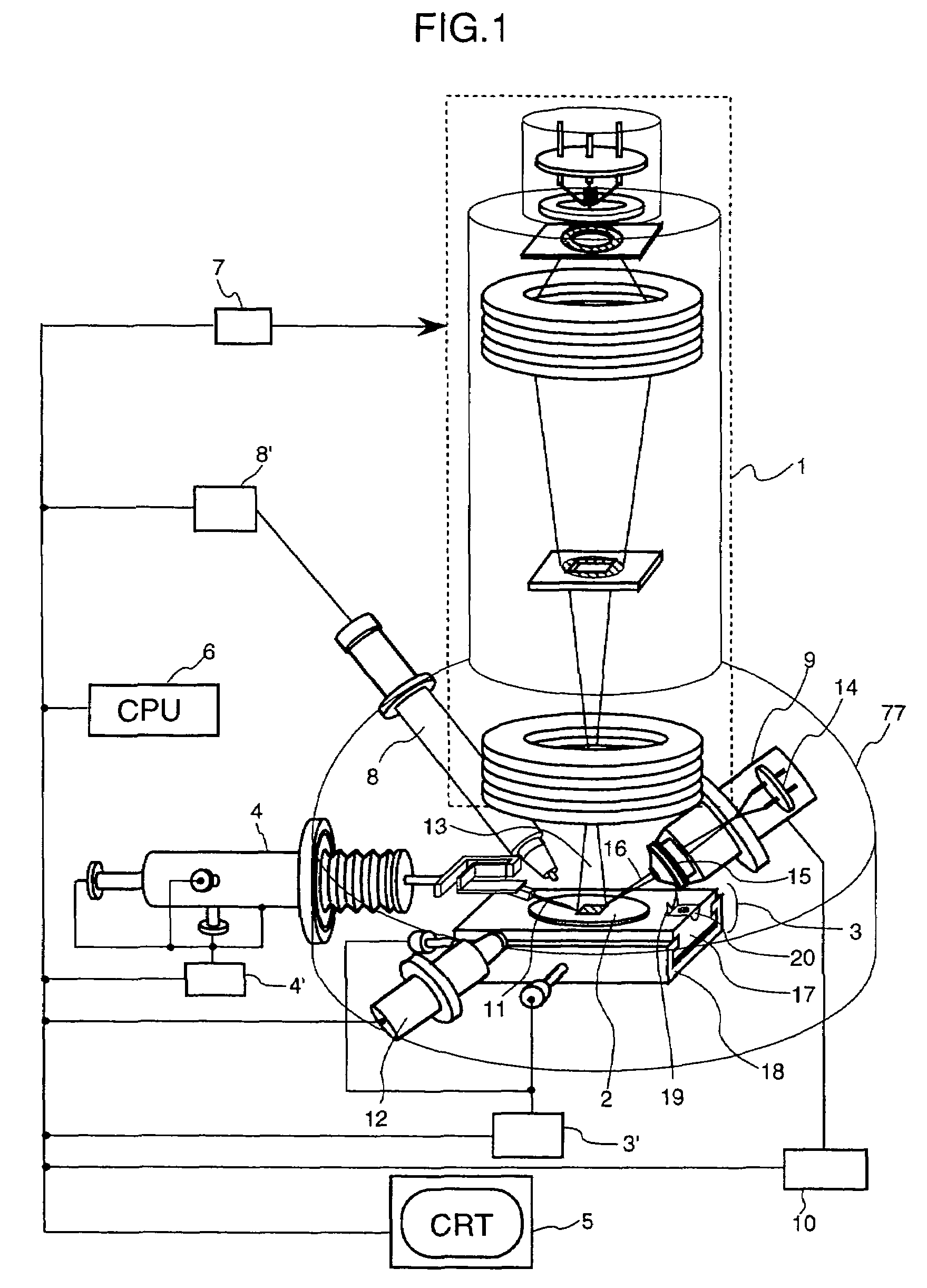

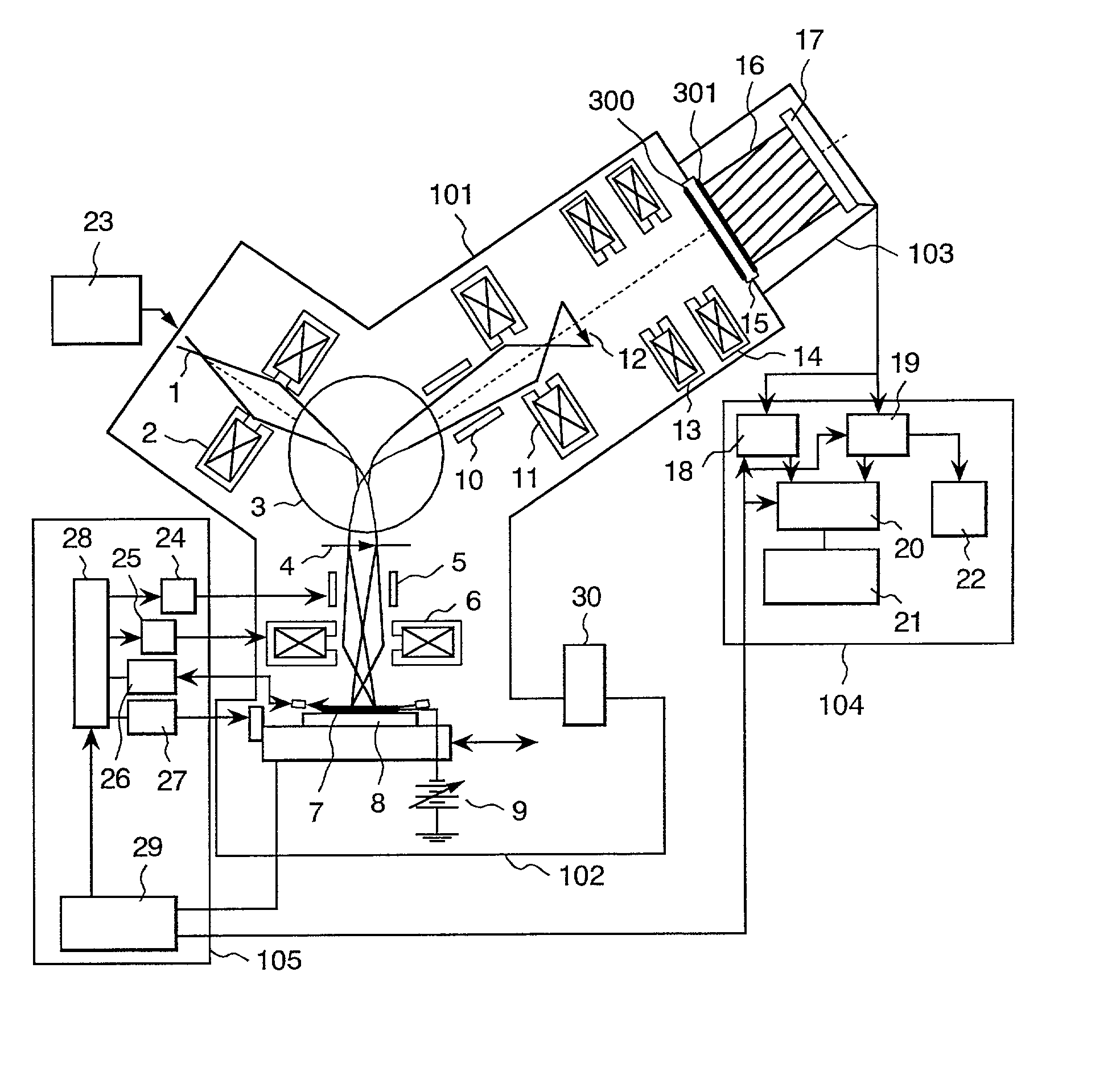

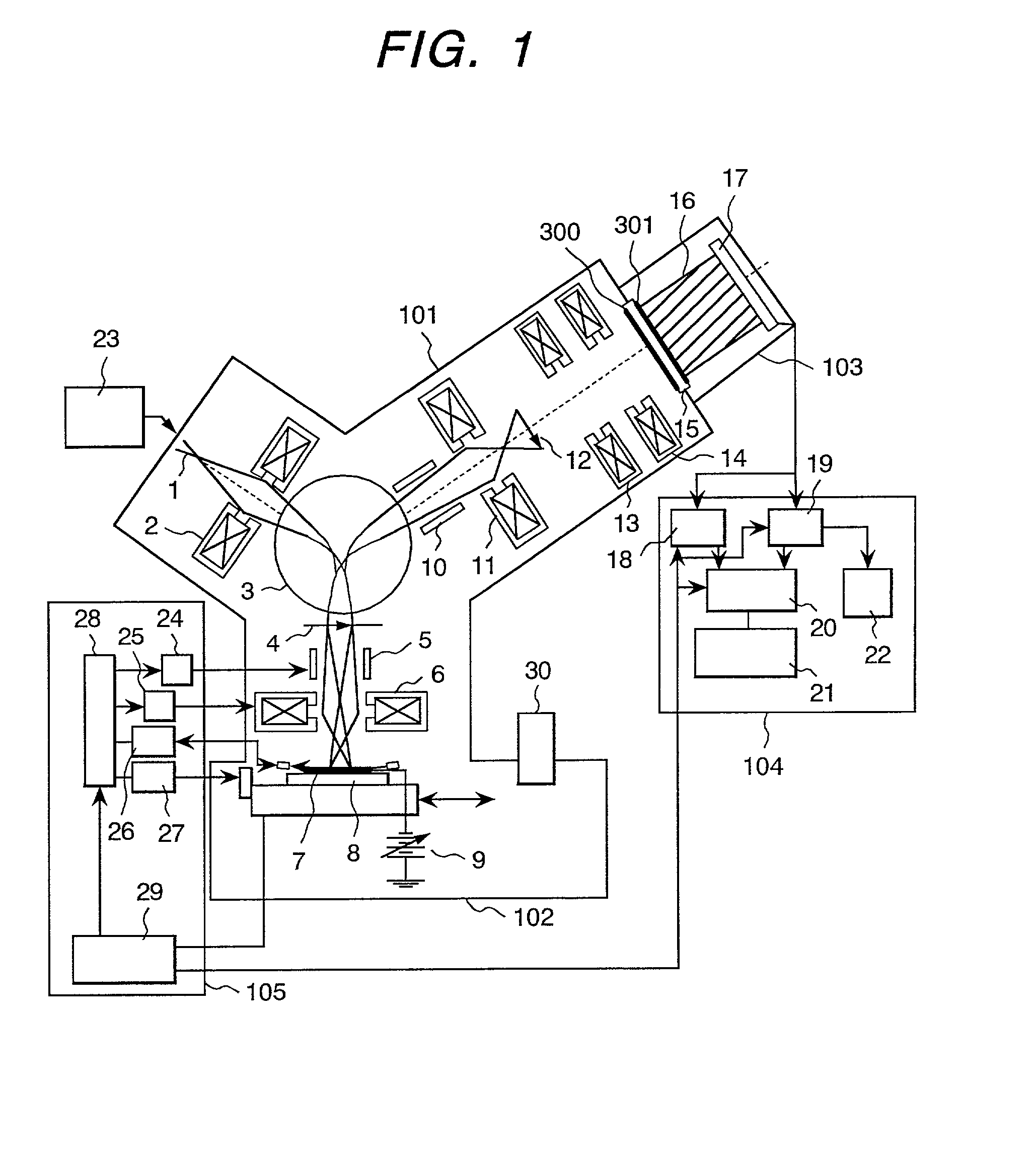

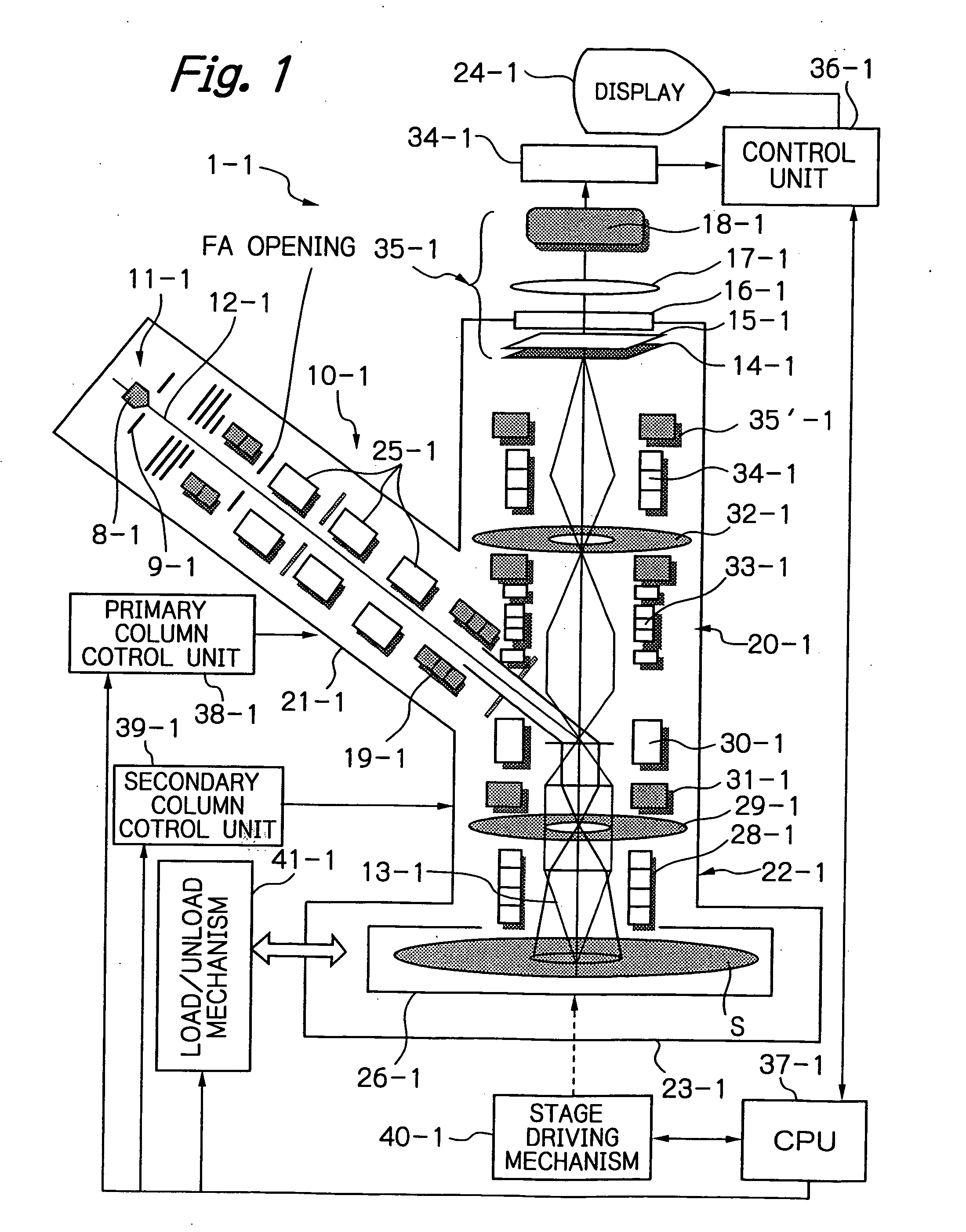

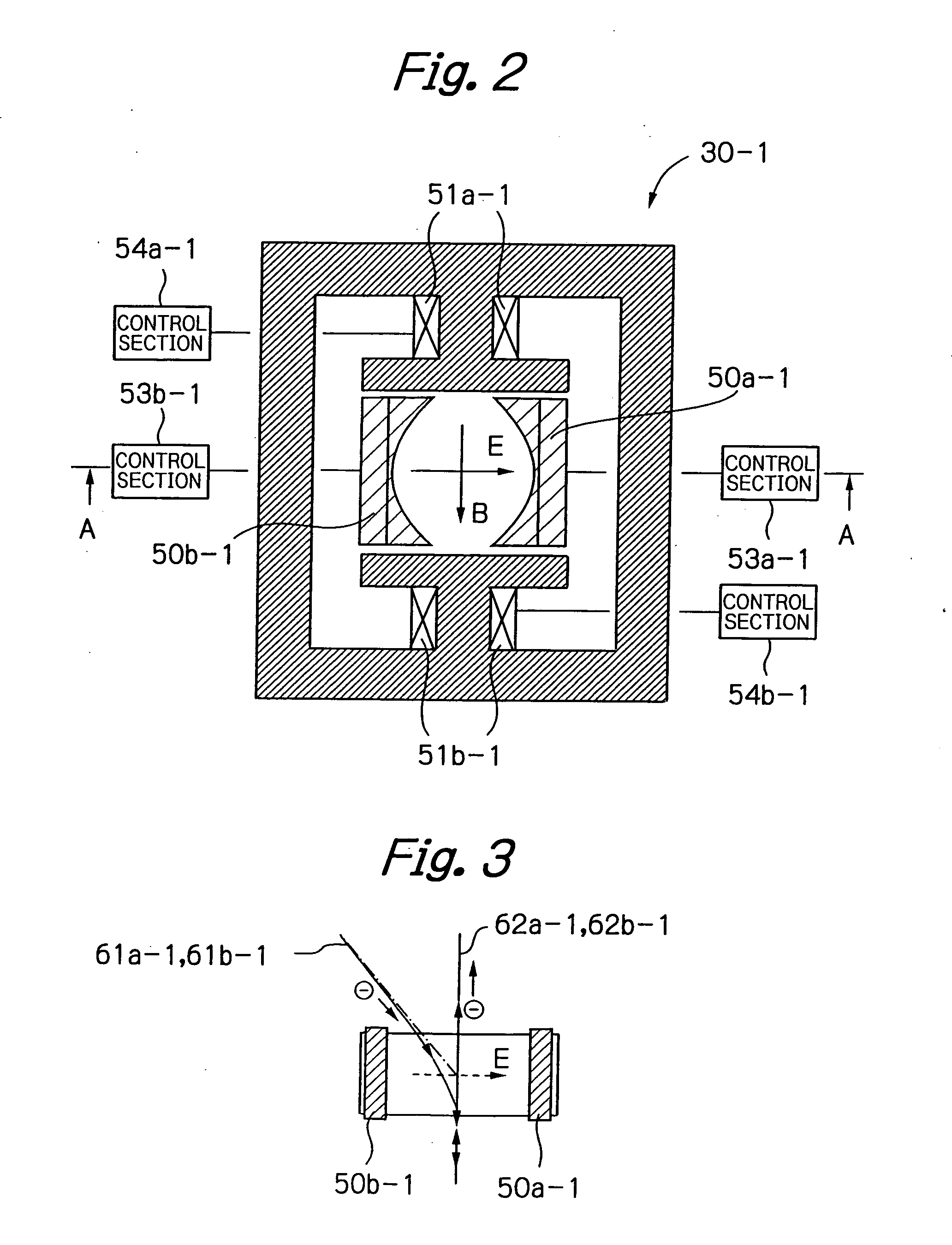

Apparatus for inspection with electron beam, method for operating same, and method for manufacturing semiconductor device using former

InactiveUS6855929B2Avoid low detection accuracyAvoid mistakesElectric discharge tubesSolid-state devicesImaging processingSecondary electrons

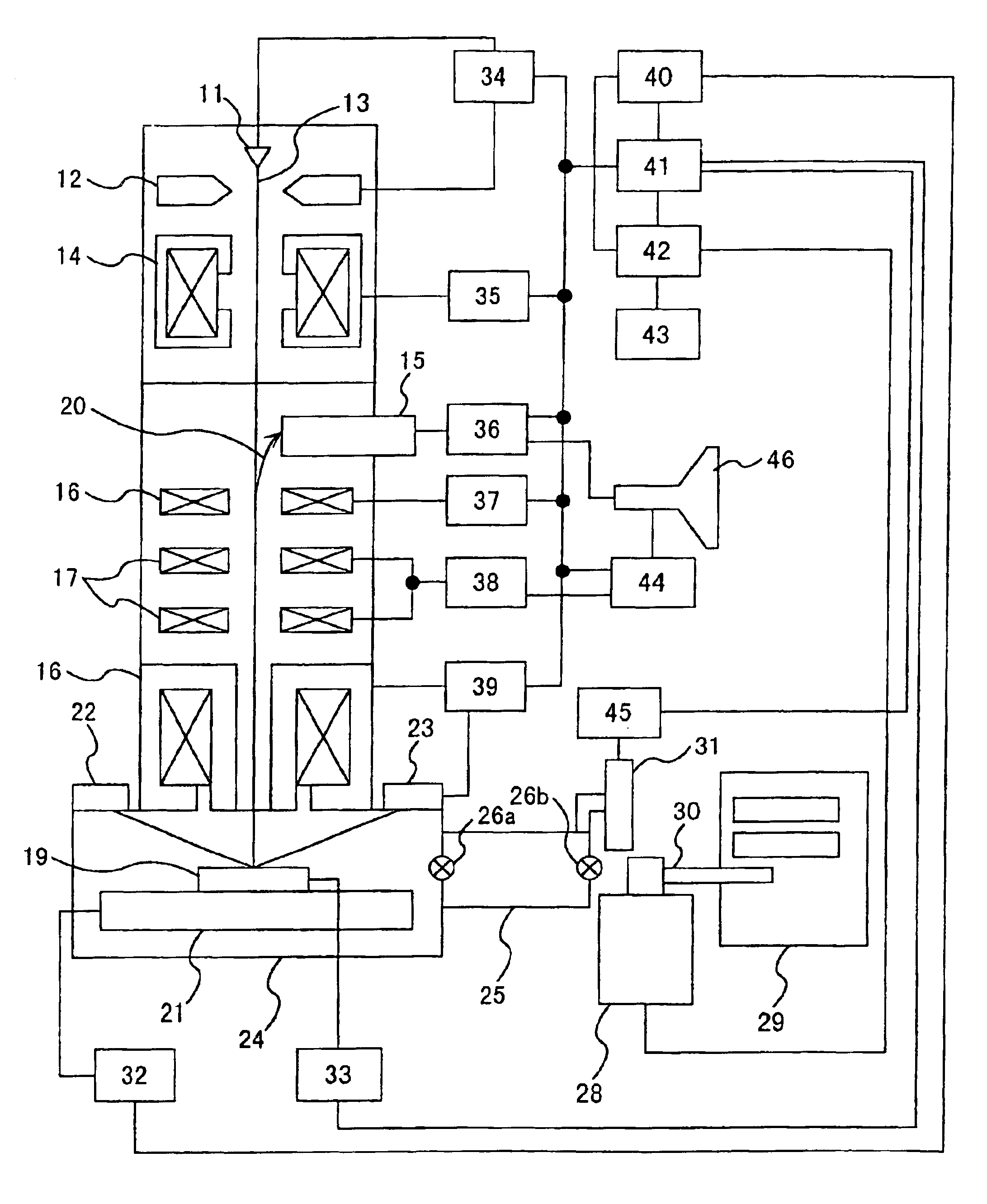

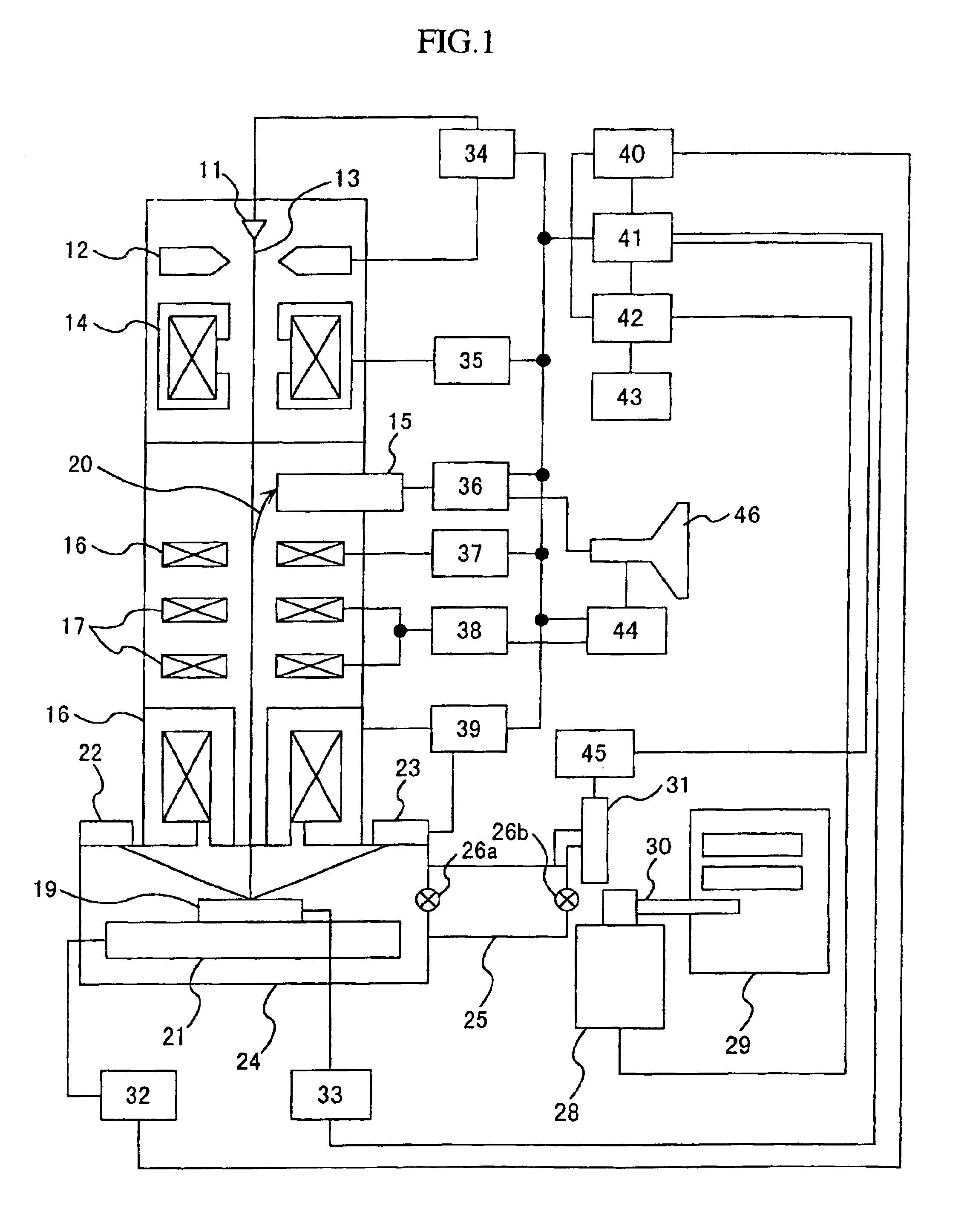

A substrate inspection apparatus 1-1 (FIG. 1) of the present invention performs the following steps of: carrying a substrate “S” to be inspected into an inspection chamber 23-1 maintaining a vacuum in said inspection chamber; isolating said inspection chamber from a vibration; moving successively said substrate by means of a stage 26-1 with at least one degree of freedom; irradiating an electron beam having a specified width; helping said electron beam reach to a surface of said substrate via a primary electron optical system 10-1; trapping secondary electrons emitted from said substrate via a secondary electron optical system 20-1 and guiding it to a detecting system 35-1; forming a secondary electron image in an image processing system based on a detection signal of a secondary electron beam obtained by said detecting system; detecting a defective location in said substrate based on the secondary electron image formed by said image processing system; indicating and / or storing said defective location in said substrate by CPU 37-1; and taking said completely inspected substrate out of the inspection chamber. Thereby, the defect inspection on the substrate can be performed successively with high level of accuracy and efficiency as well as with higher throughput.

Owner:EBARA CORP

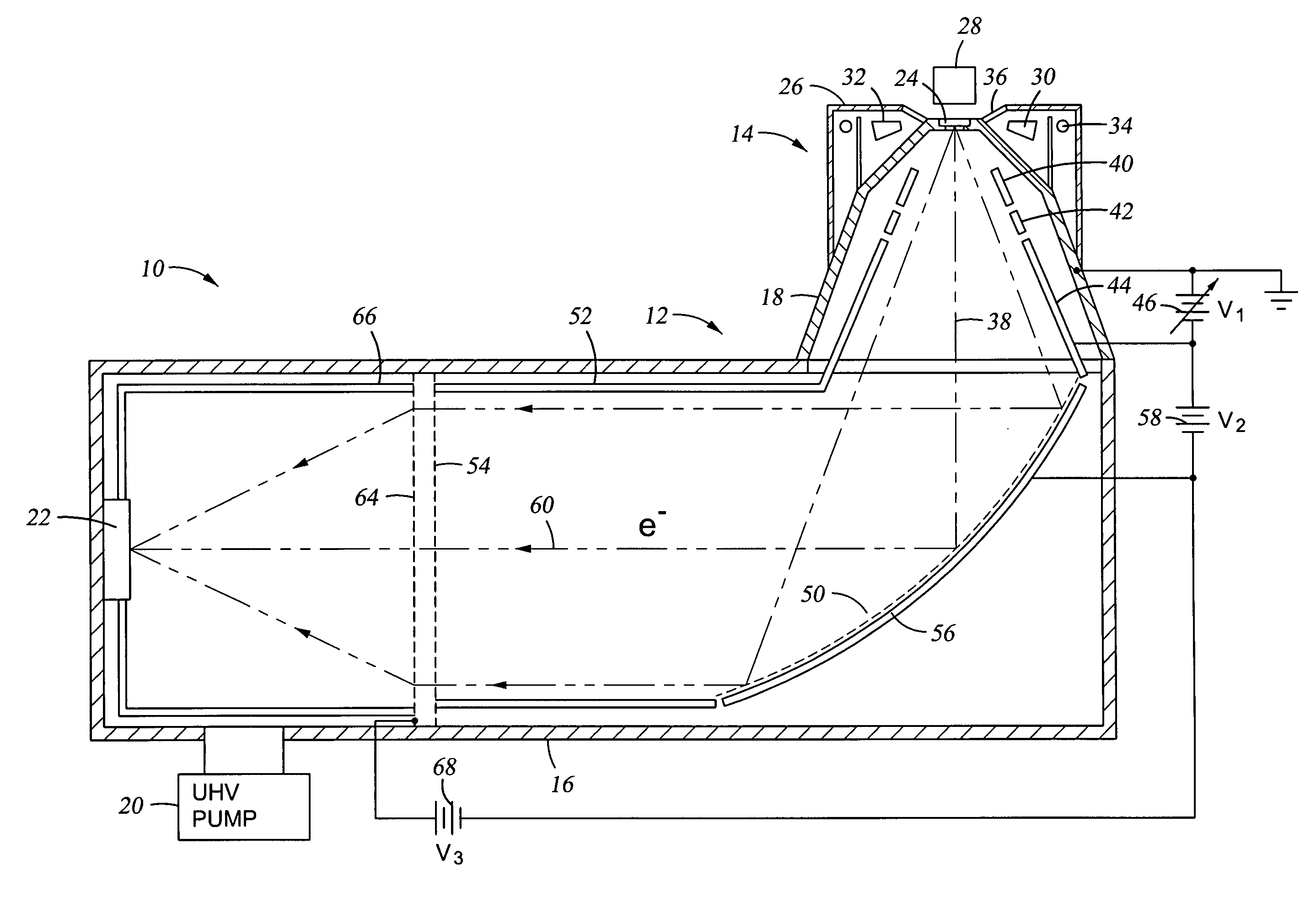

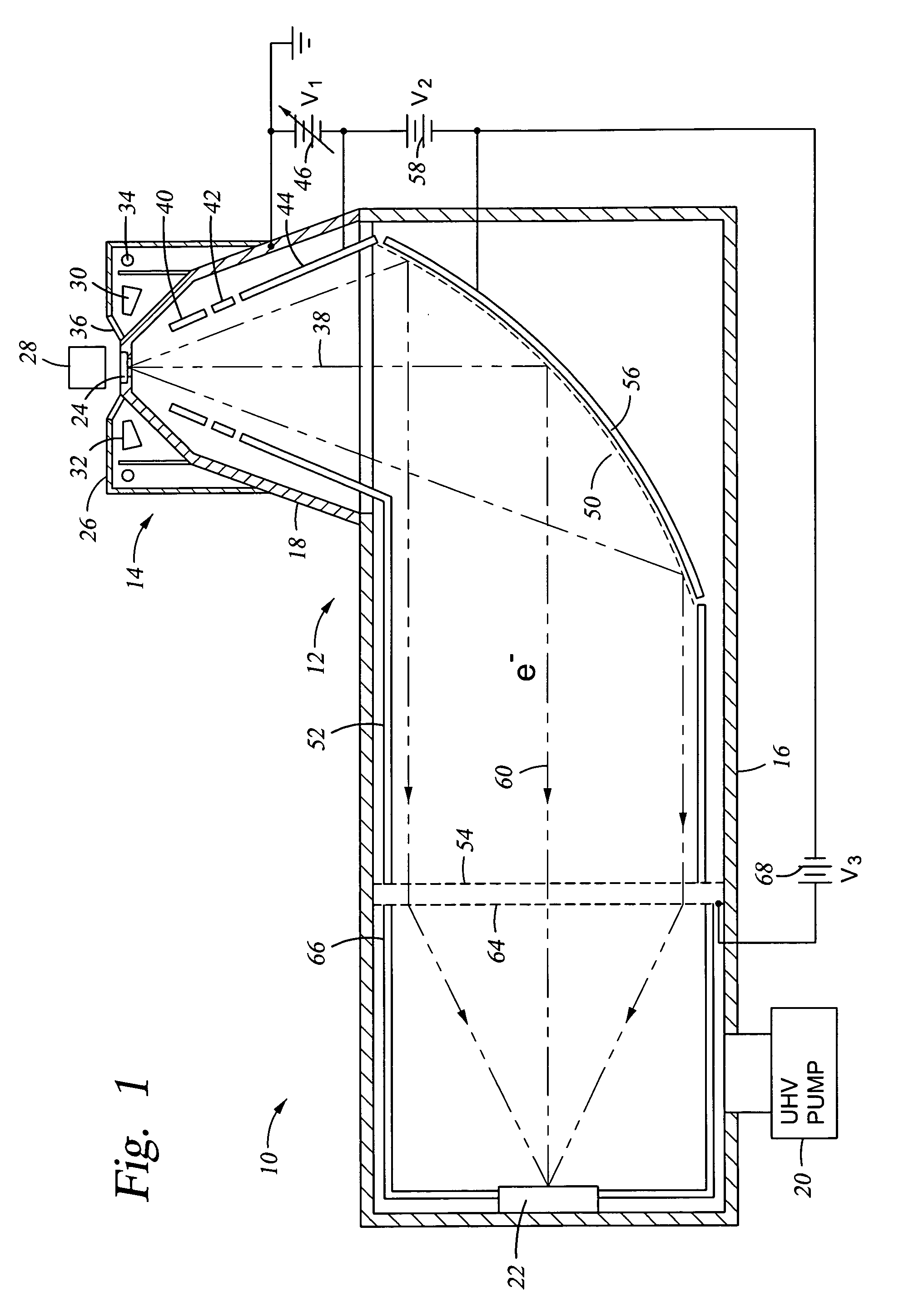

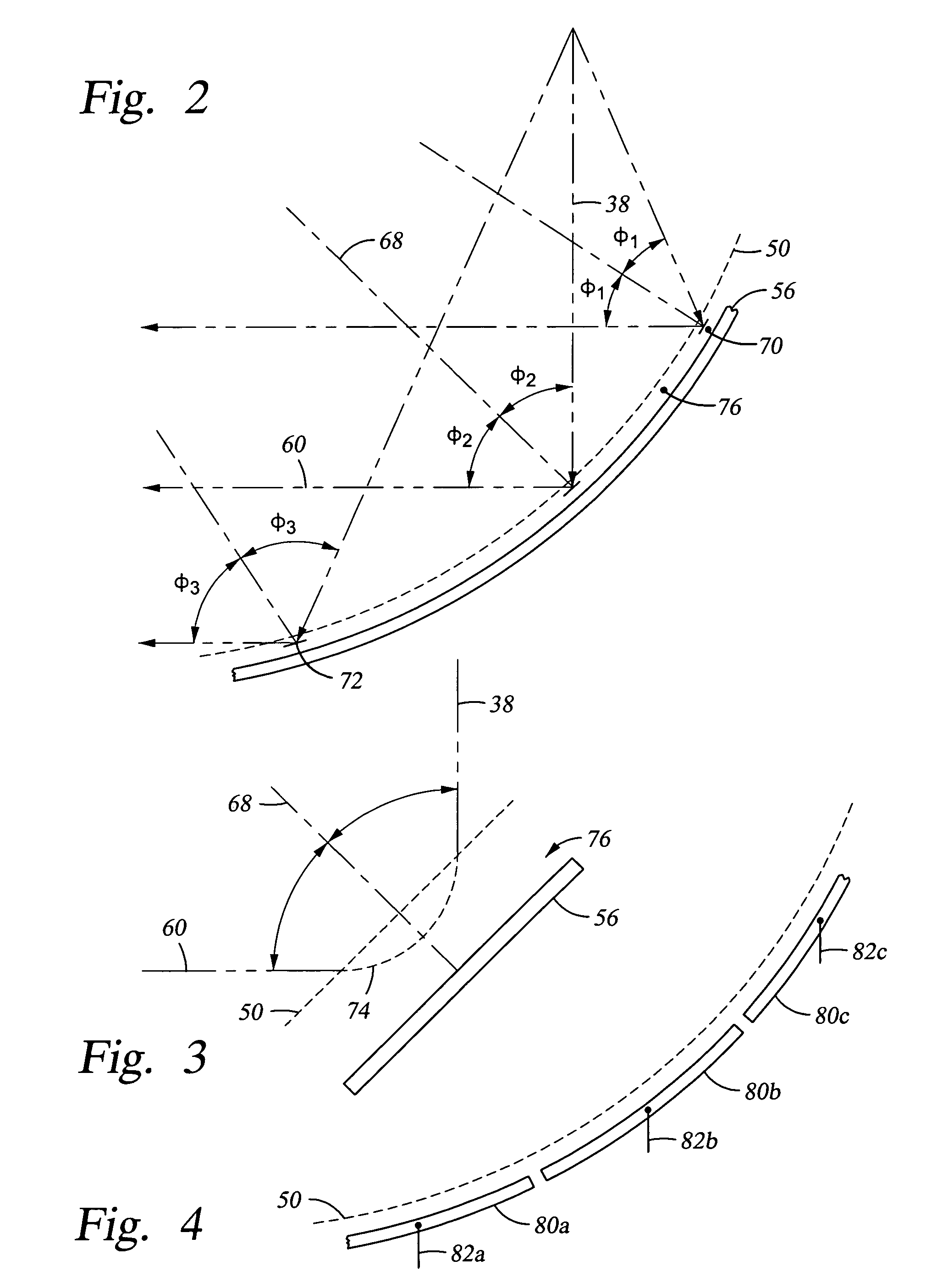

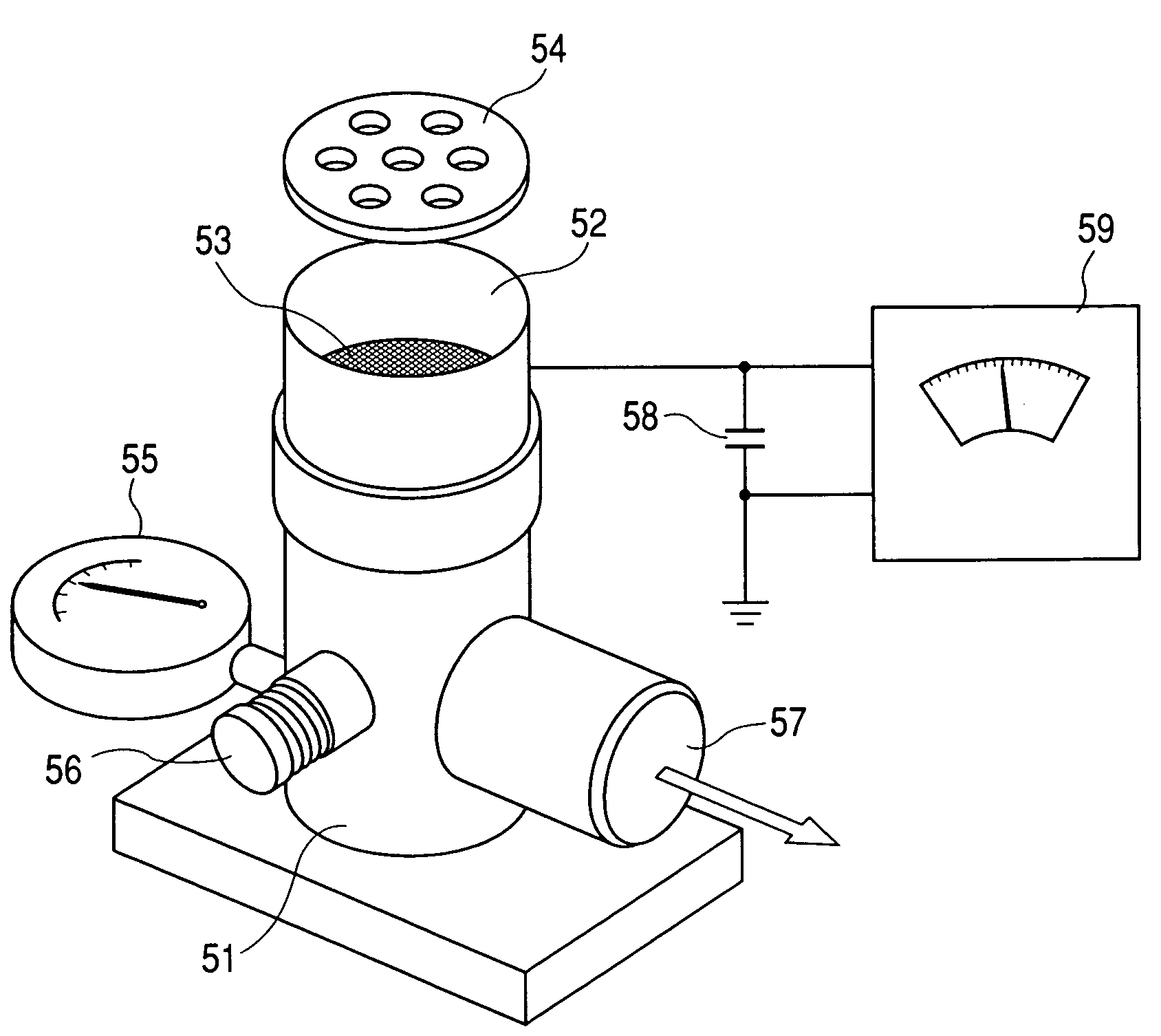

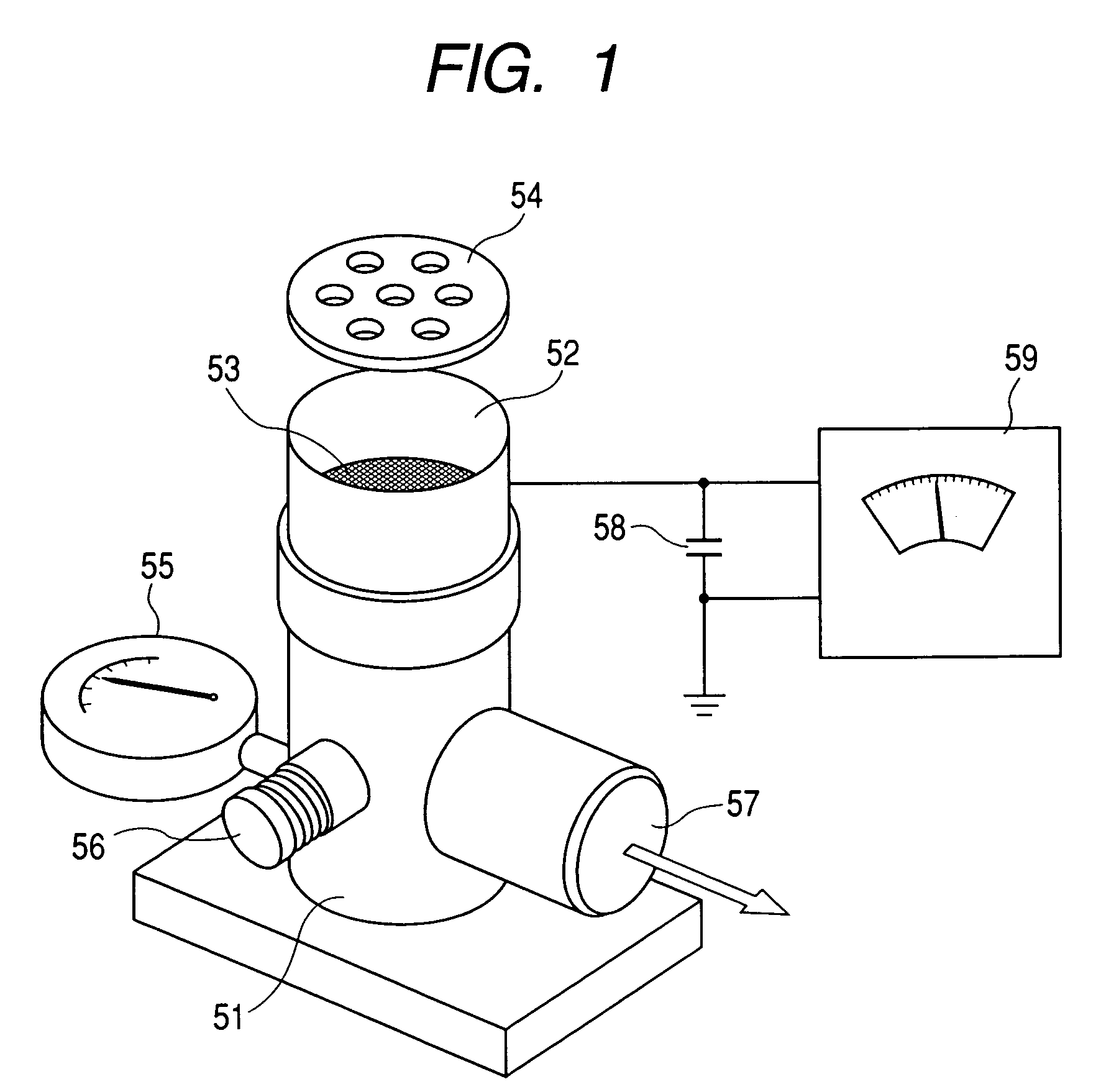

Non-dispersive charged particle energy analyzer

InactiveUS20050045832A1Thermometer detailsStability-of-path spectrometersElectron sourceEnergy analyser

An electron energy analyzer including a curved electrostatic low-pass reflector and a high-pass electrostatic transmissive filter. The reflector comprises a curved grid, preferably ellipsoidal, and an absorber electrode placed in back of the curved grid with respect to the electron source and biased negatively to the curved grid to act as a reflective low-pass filter and a collimating optics for the reflected beam. The transmissive filter includes first and second flat grids extending across the collimated reflected beam. The second grid on the side of the first grid opposite the curved grid is biased negatively to the first grid and the absorber electrode. A field free region is created by applying the same bias to the curved grid, the first grid, and chamber sidewall sleeve. An electron detector detects all electrons passed by the second grid in an energy band in the overlap of the high-pass and low-pass bands.

Owner:BRYSON III CHARLES E

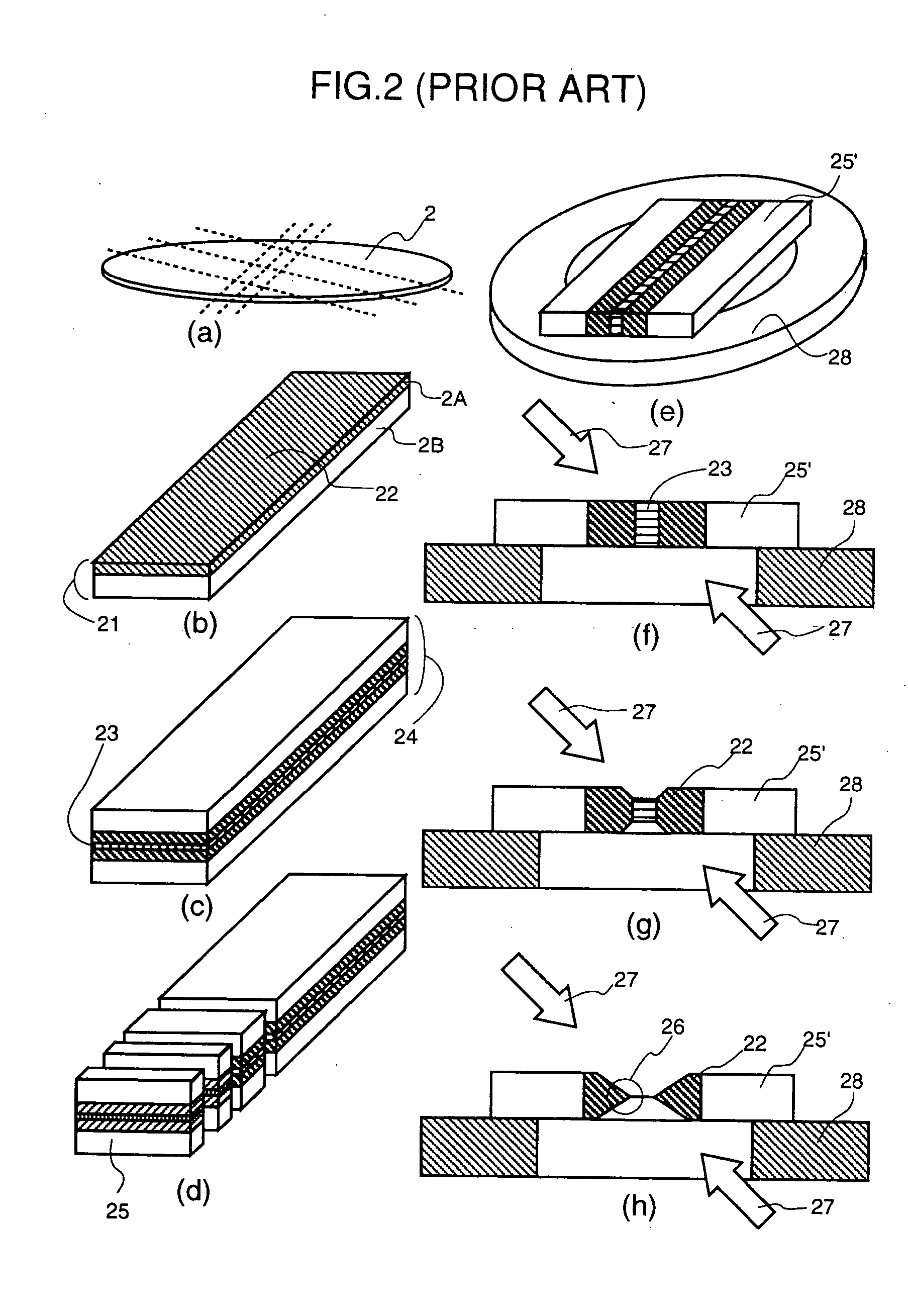

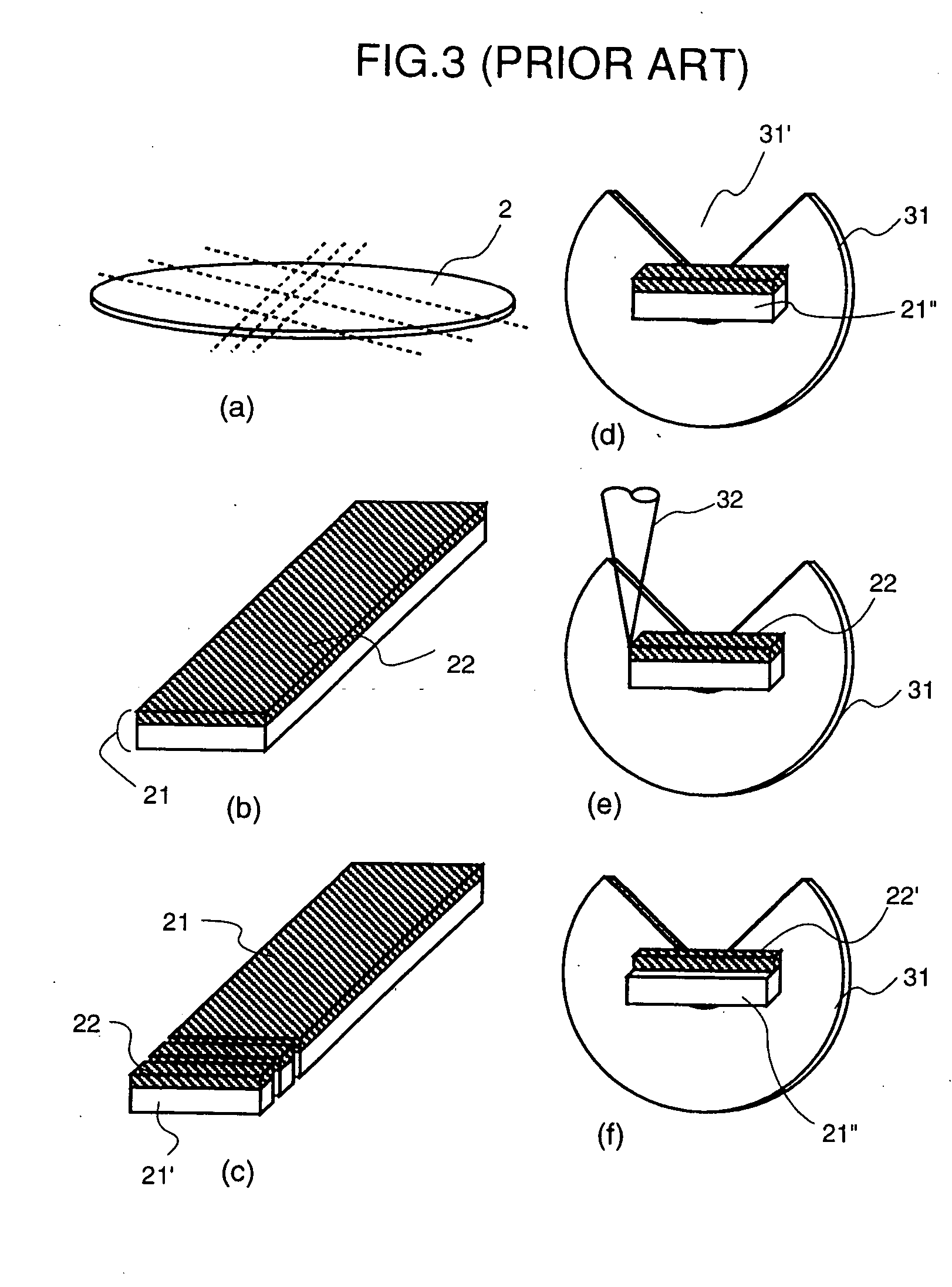

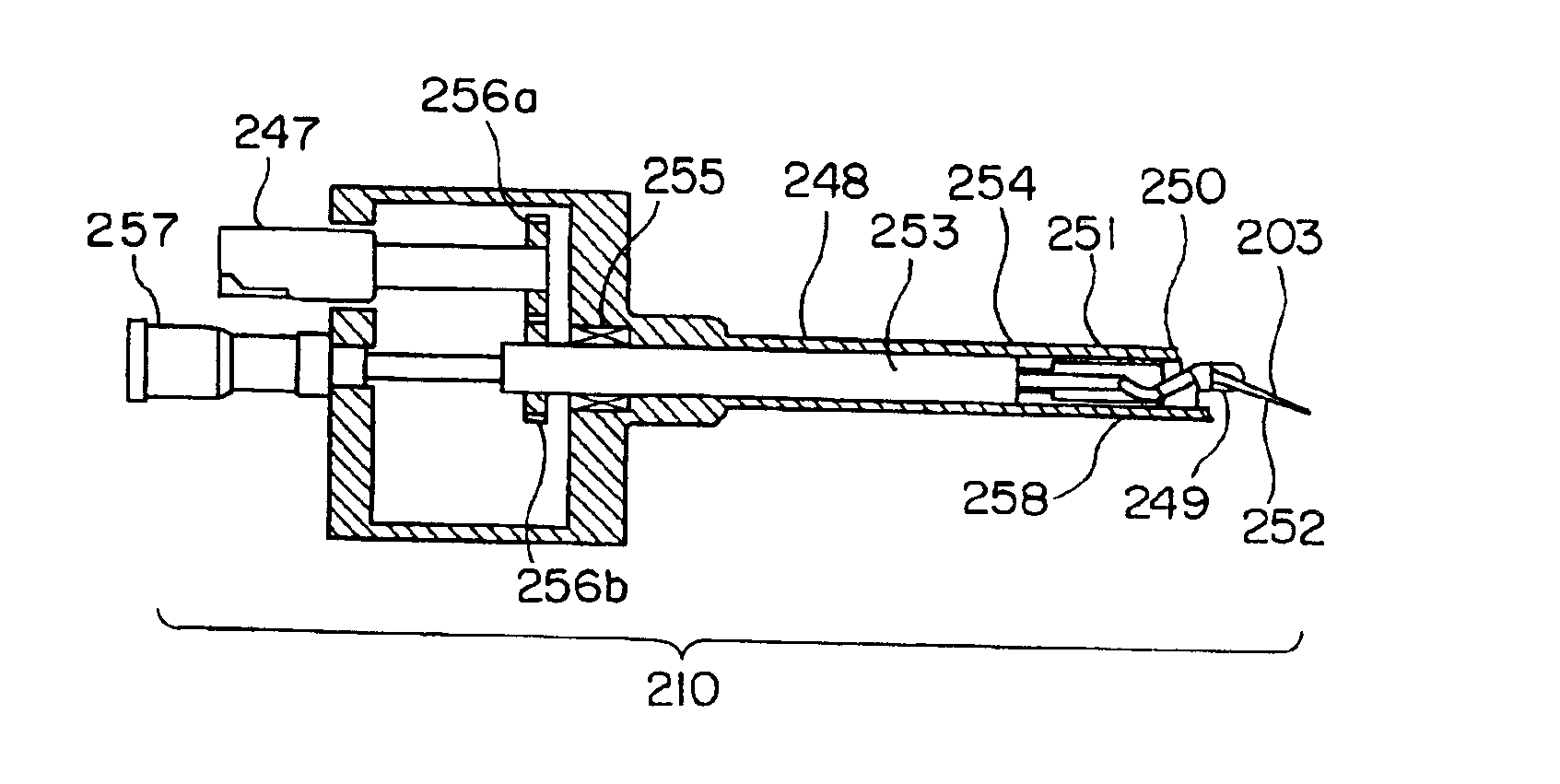

Method and apparatus for specimen fabrication

InactiveUS20050054029A1Great fabricationSolve the quick positioningBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMaterials science

Owner:HITACHI LTD

Method and apparatus for translating detected wafer defect coordinates to reticle coordinates using CAD data

Systems and methods are described for translating detected wafer defect coordinates to reticle coordinates using CAD data. A wafer inspection image is provided and coordinates of potential defects in the wafer are determined. Then the wafer inspection image is converted into a predetermined image format. CAD data for the device under test is then used to produce a second image, also in the predetermined image format. The CAD-derived image and the wafer-derived image are then aligned, and the coordinates of potential defects in the wafer are converted into CAD coordinates. The CAD coordinates are then used to navigate through the reticle for the wafer in order to locate reticle defects corresponding to the detected wafer defects.

Owner:NXP USA INC

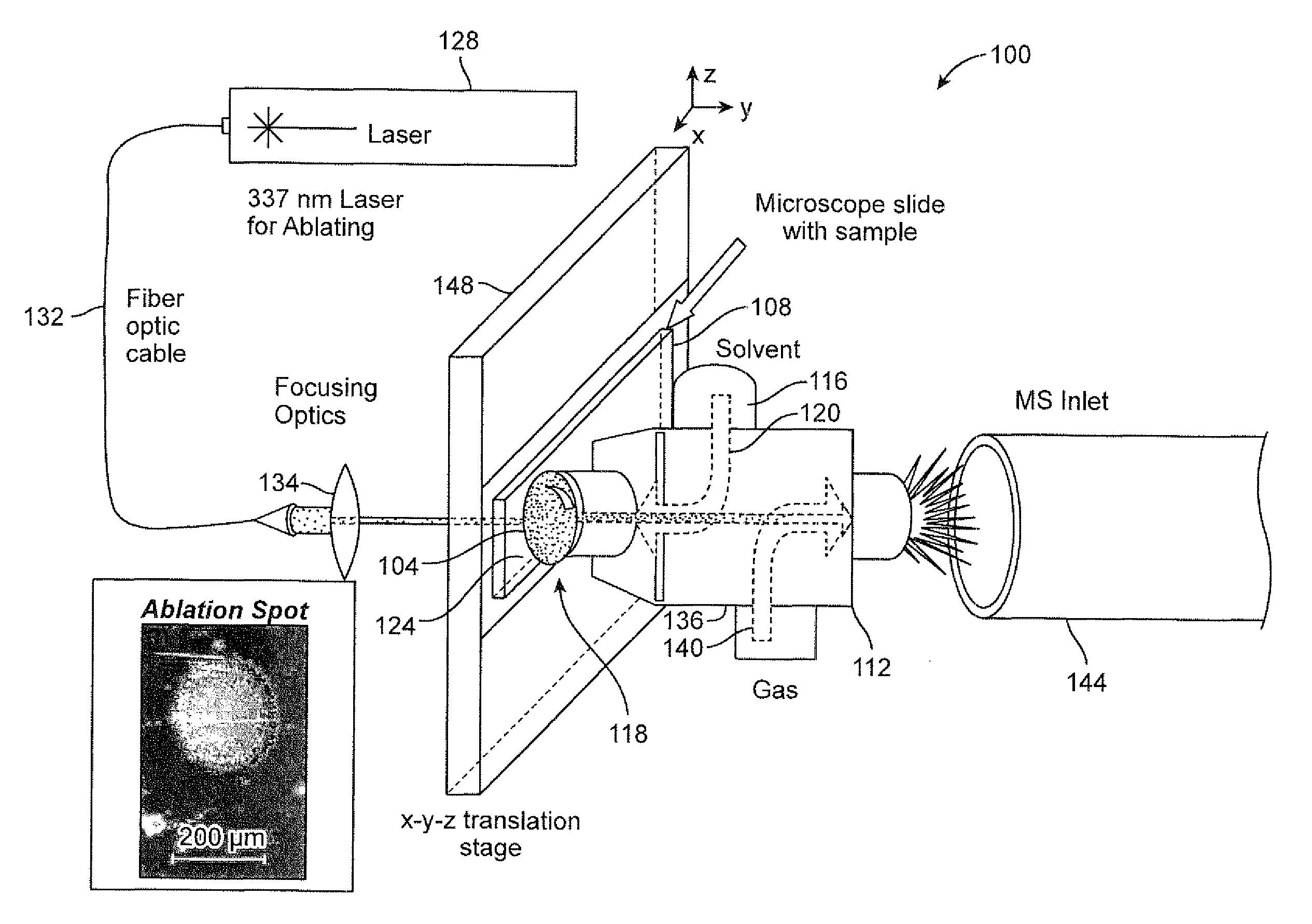

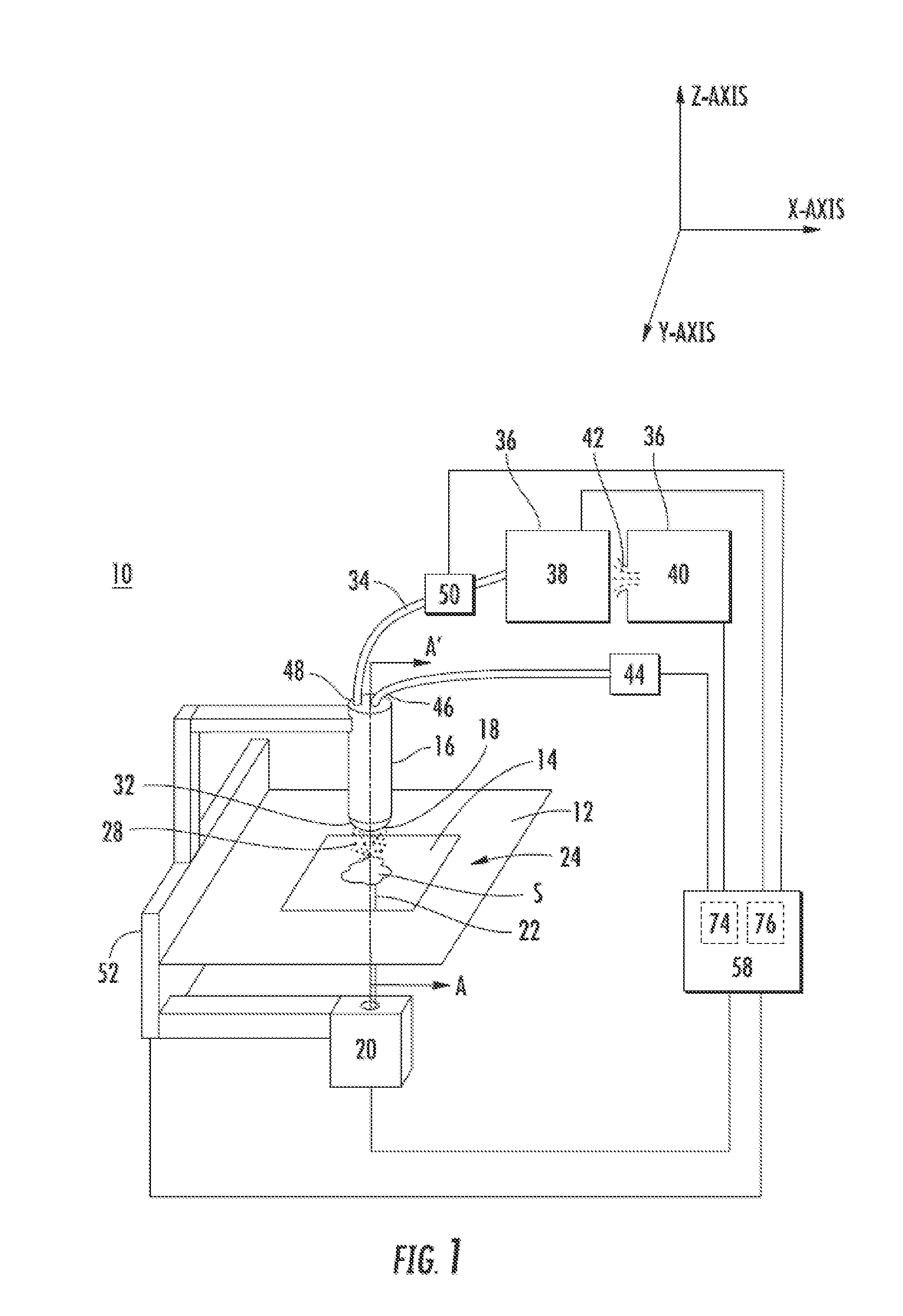

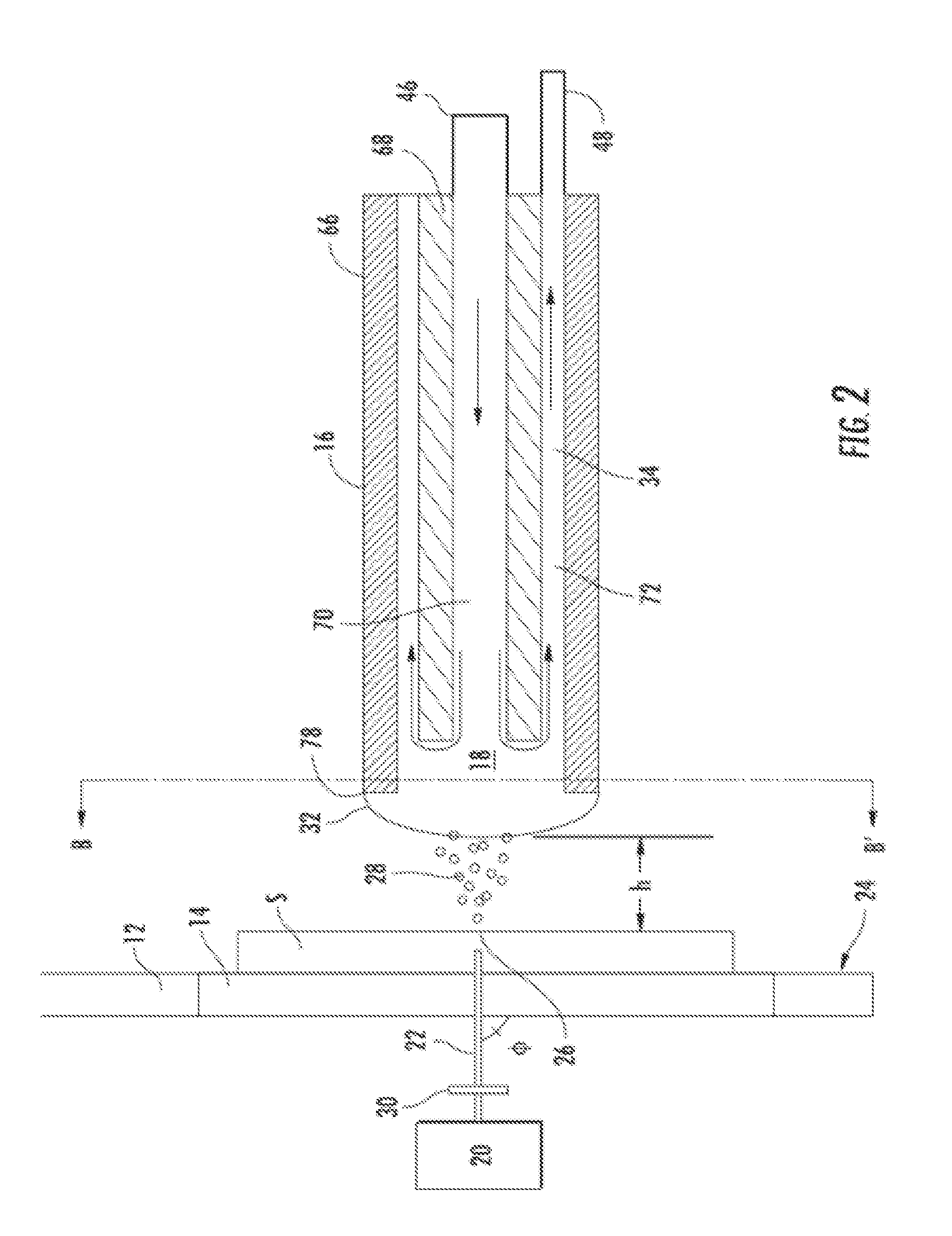

Systems and methods for laser assisted sample transfer to solution for chemical analysis

ActiveUS20120079894A1Stop the flowParticle separator tubesWithdrawing sample devicesAtomic force microscopyAnalyte

Systems and methods are described for laser ablation of an analyte from a specimen and capturing of the analyte in a dispensed solvent to form a testing solution. A solvent dispensing and extraction system can form a liquid microjunction with the specimen. The solvent dispensing and extraction system can include a surface sampling probe. The laser beam can be directed through the surface sampling probe. The surface sampling probe can also serve as an atomic force microscopy probe. The surface sampling probe can form a seal with the specimen. The testing solution including the analyte can then be analyzed using an analytical instrument or undergo further processing.

Owner:UNIV OF TENNESSEE RES FOUND +1

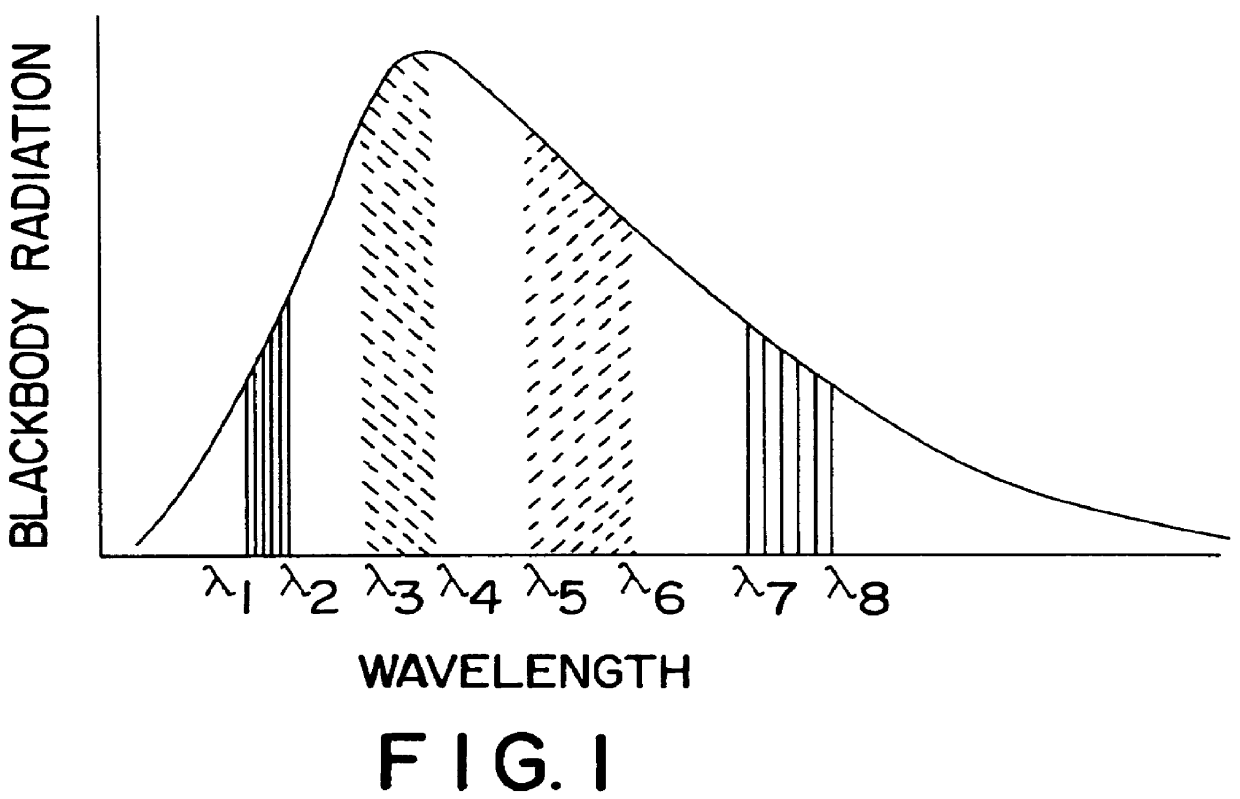

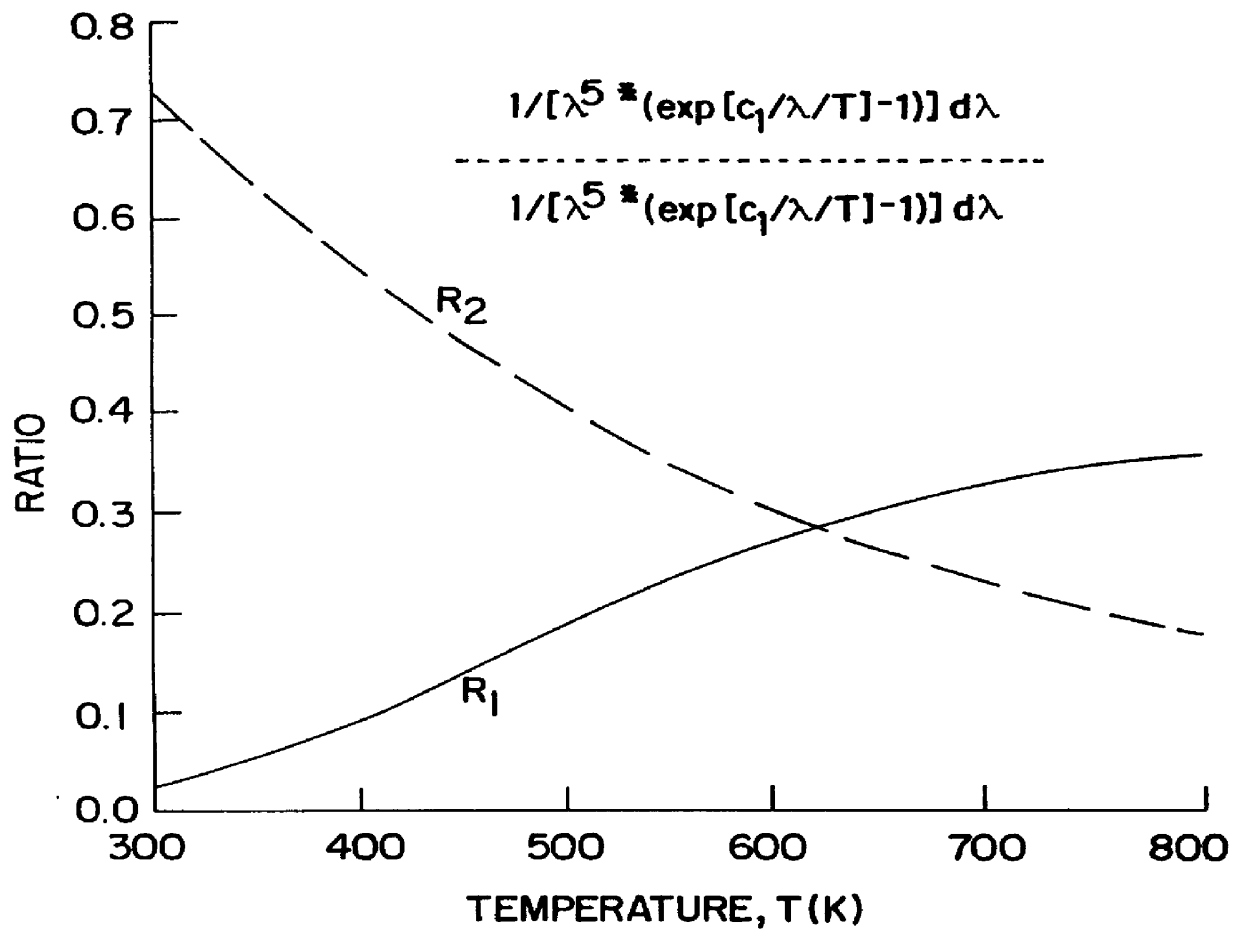

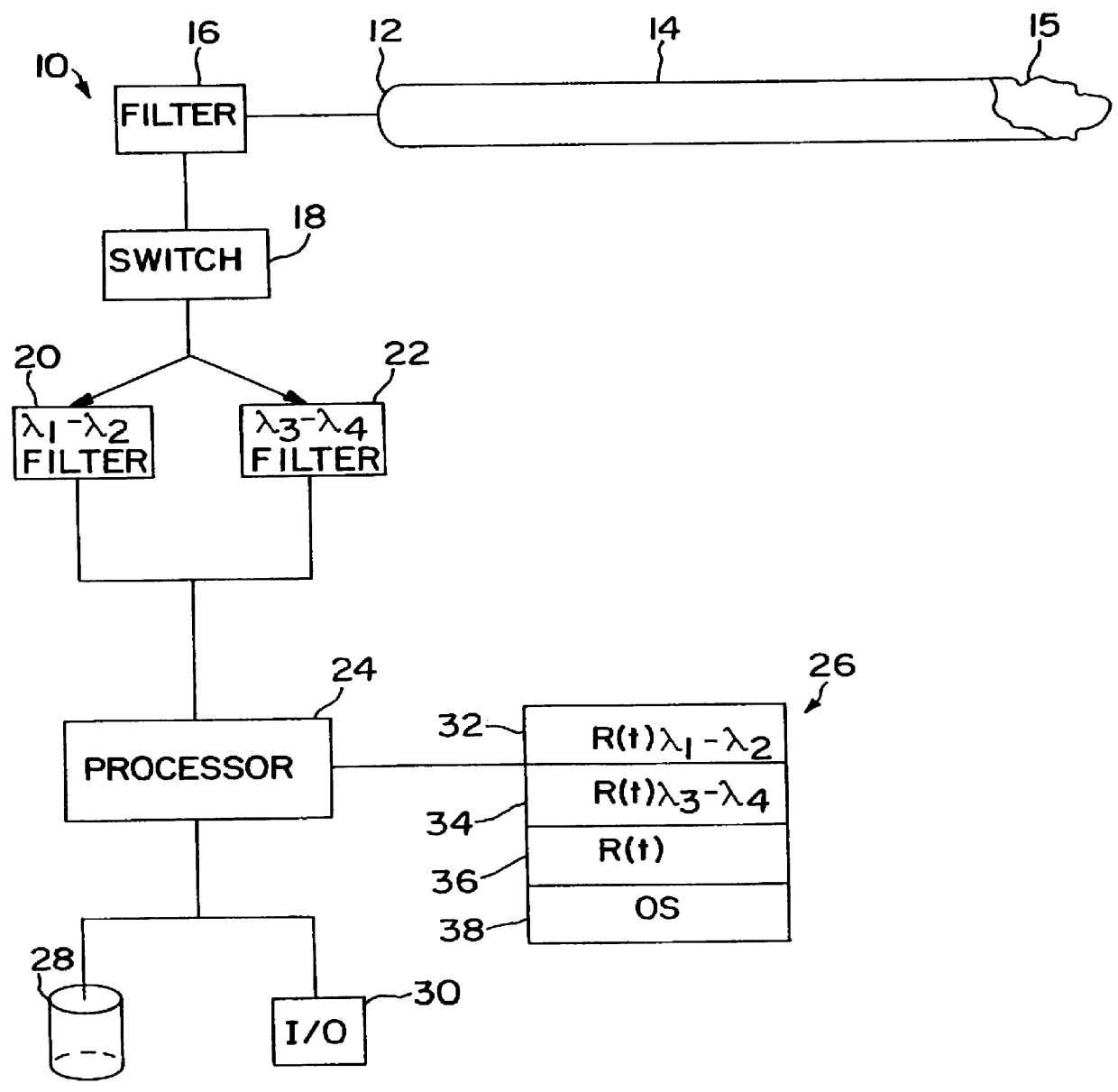

Non-contact passive temperature measuring system and method of operation using micro-mechanical sensors

InactiveUS6050722AAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesThermal energyEmissivity

A non-contact infrared thermometer measures target temperatures remotely without requiring the ratio of the target size to the target distance to the thermometer. A collection means collects and focusses target IR radiation on an IR detector. The detector measures thermal energy of the target over a spectrum using micromechanical sensors. A processor means calculates the collected thermal energy in at least two different spectral regions using a first algorithm in program form and further calculates the ratio of the thermal energy in the at least two different spectral regions to obtain the target temperature independent of the target size, distance to the target and emissivity using a second algorithm in program form.

Owner:LOCKHEED MARTIN ENERGY SYST INC

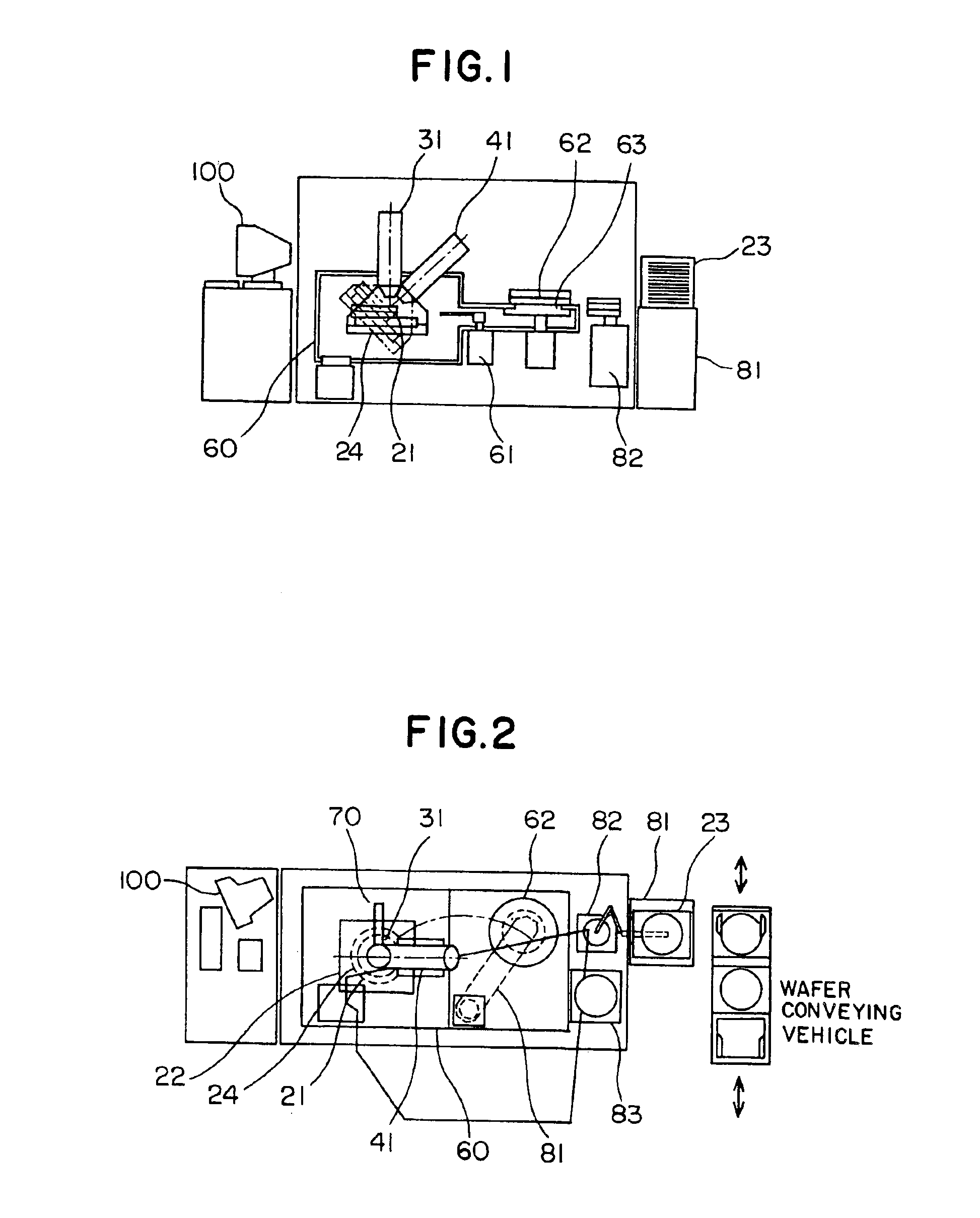

Electron beam apparatus and device manufacturing method using same

InactiveUS6909092B2Reduce image distortionLess aberrationThermometer detailsBeam/ray focussing/reflecting arrangementsElectron sourceImaging processing

A defect inspecting apparatus is provided for generating a less distorted test image to reliably observe a surface of a sample for detecting defects thereon. The defect detecting apparatus comprises a primary electron beam source for irradiating a sample, electrostatic lenses for focusing secondary electrons emitted from the surface of the sample irradiated with the primary electron beam, a detector for detecting the secondary electrons, and an image processing unit for processing a signal from the detector. Further, a second electron source may be provided for emitting an electron beam irradiated to the sample, wherein the sample may be irradiated with the electron beam from the second electron source before it is irradiated with the primary electron beam from the first electron source for observing the sample. A device manufacturing method is also provided for inspecting devices under processing with high throughput using the defect detecting apparatus.

Owner:EBARA CORP

Method and apparatus for processing a micro sample

InactiveUS6927391B2Reduce resolutionGood for observationMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementHigh fluxIon beam

Owner:HITACHI LTD

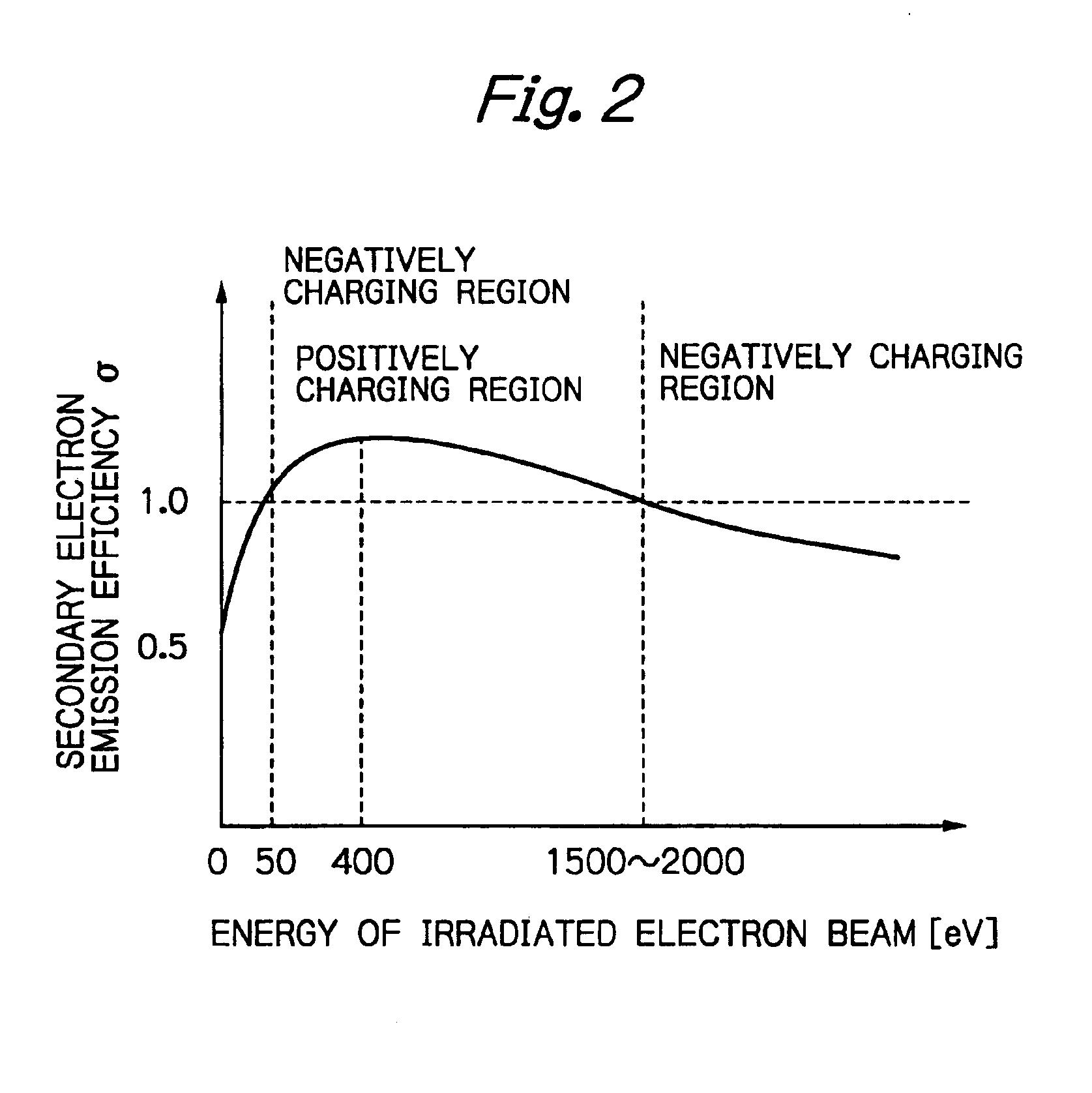

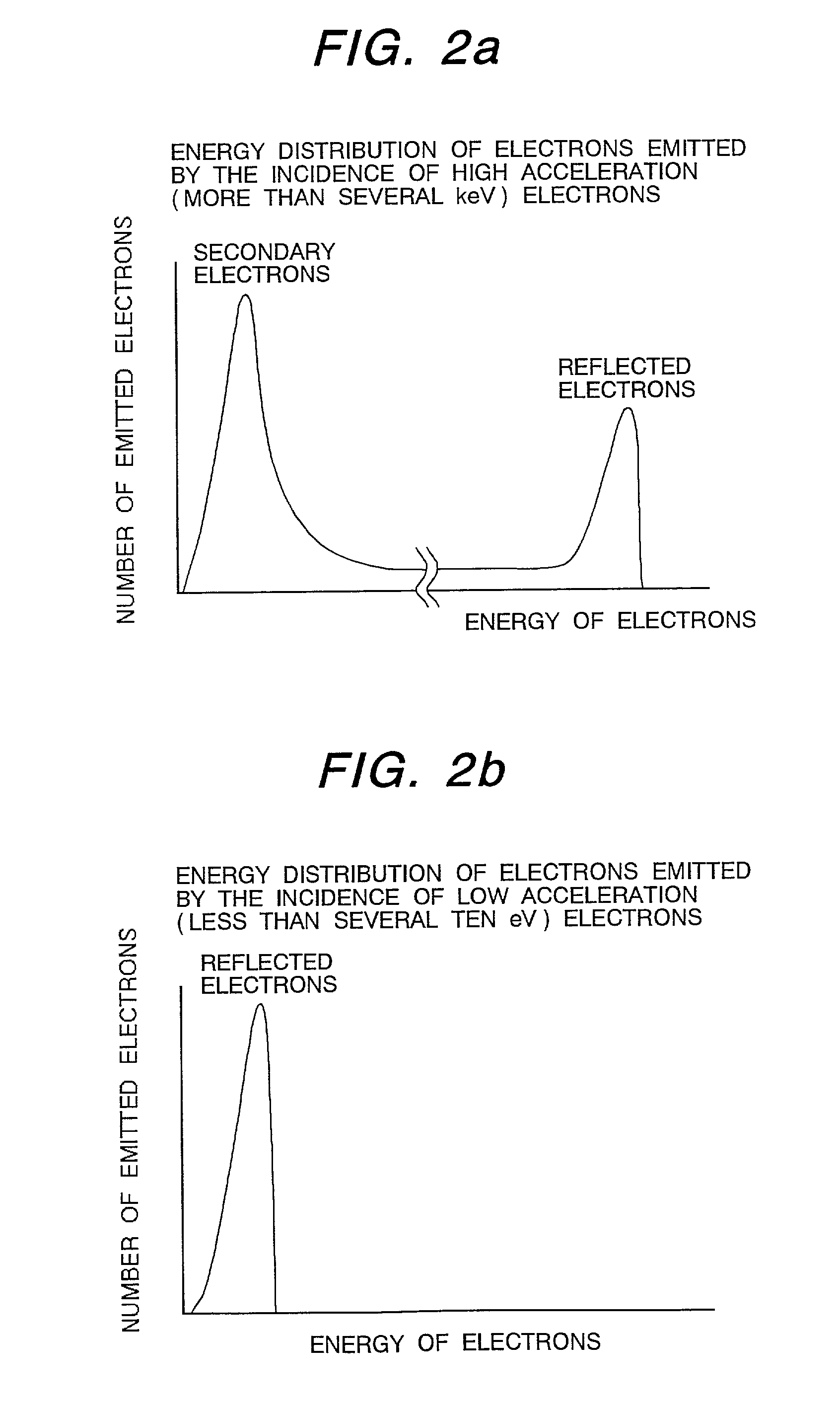

Sample electrification measurement method and charged particle beam apparatus

InactiveUS6946656B2Reduce errorsReduce fluctuationMaterial analysis using wave/particle radiationElectric discharge tubesMagnificationElectrometer

The present invention has the object of providing a charged particle beam irradiation method ideal for reducing the focus offset, magnification fluctuation and measurement length error in charged particle beam devices.To achieve these objects, a method is disclosed in the invention for measuring the electrical potential distribution on the sample with a static electrometer while loaded by a loader mechanism. Another method is disclosed for measuring the local electrical charge at specified points on the sample, and isolating and measuring the wide area electrostatic charge quantity from those local electrostatic charges. Yet another method is disclosed for correcting the measurement length value or magnification based on fluctuations found by measuring the amount of electrostatic charge at the specified points under at least two charged particle optical conditions, and then using a charged particle beam to measure fluctuations in measurement dimensions occurring due to fluctuations in the electrostatic charge at the specified locations.

Owner:HITACHI LTD

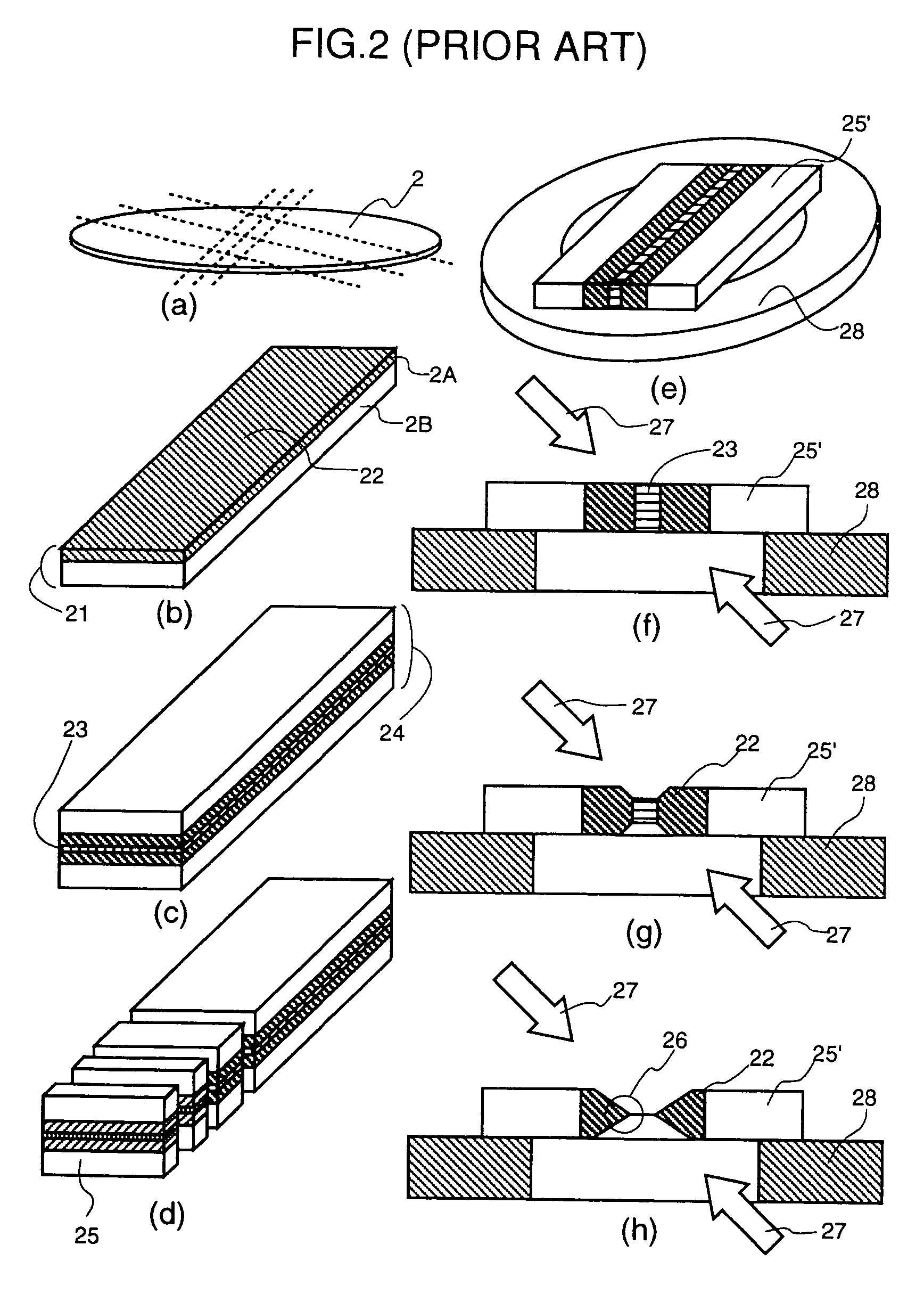

Dielectric recording medium, and method of and apparatus for producing the same

InactiveUS6841220B2Remove electric charge on the recording surface rapidlyImprove abilitiesNanoinformaticsFerroelectric carrier recordingSingle crystalOptoelectronics

The dielectric recording medium is provided with a dielectric material, a conductive thin film, and a substrate. The conductive thin film and the substrate are bonded by a resin adhesive. The dielectric material is constructed of a ferroelectric single crystal having a uniform thickness, and its one surface is used for a recording and / or reproducing surface, on the order of mm on a side and about 5000 Å thick. The conductive thin film, about 1000 to 2000 Å thick, is placed on a surrounding portion and a back surface of the recording and / or reproducing surface of the dielectric material. The substrate is intended to preserve the thin dielectric material and maintain the planarity, and concave portions are formed on the adhesive surface. The concave portions absorb excessive resin adhesive when the dielectric material is bonded onto the substrate, which makes the adhesive surface uniform and flat.

Owner:PIONEER CORP +1

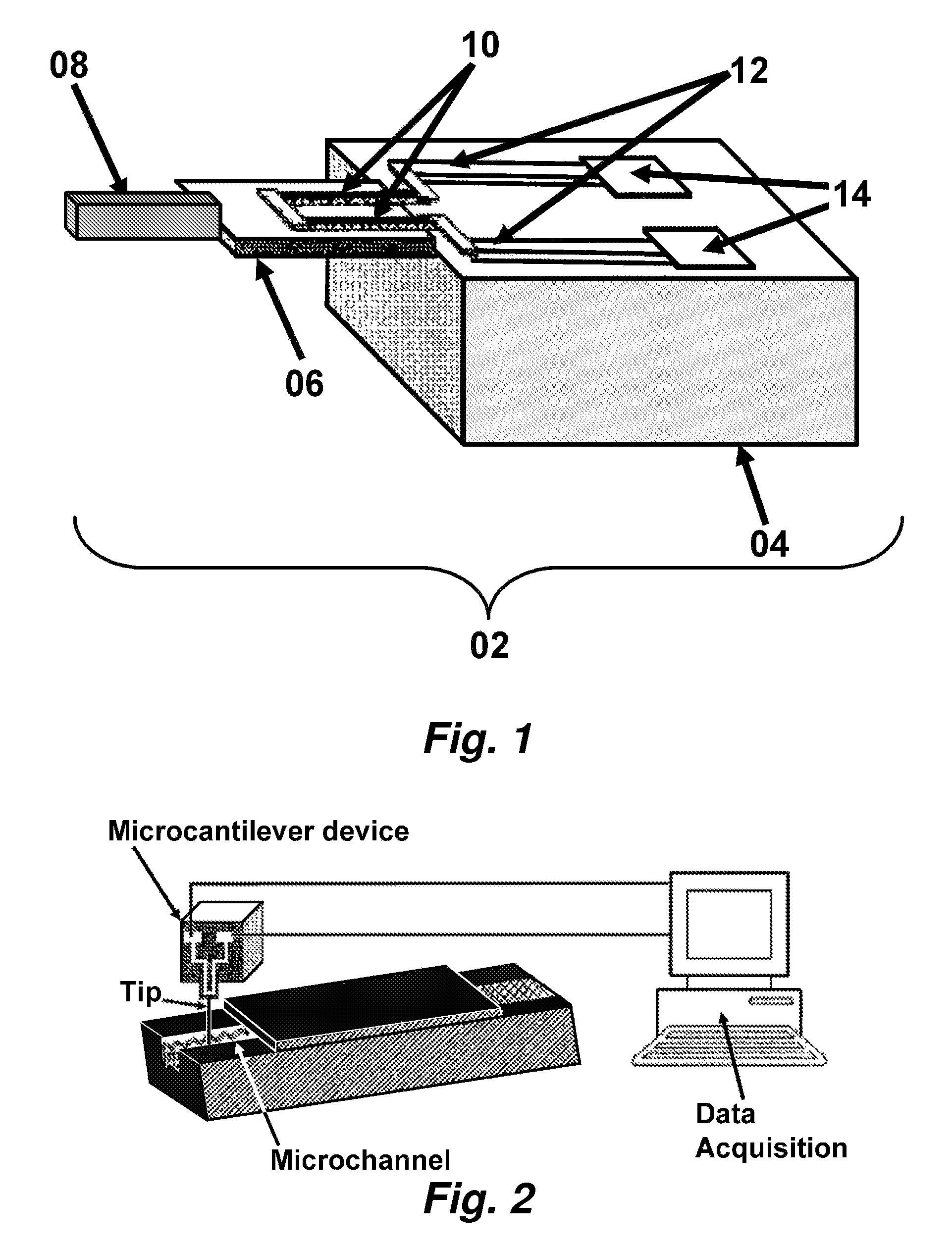

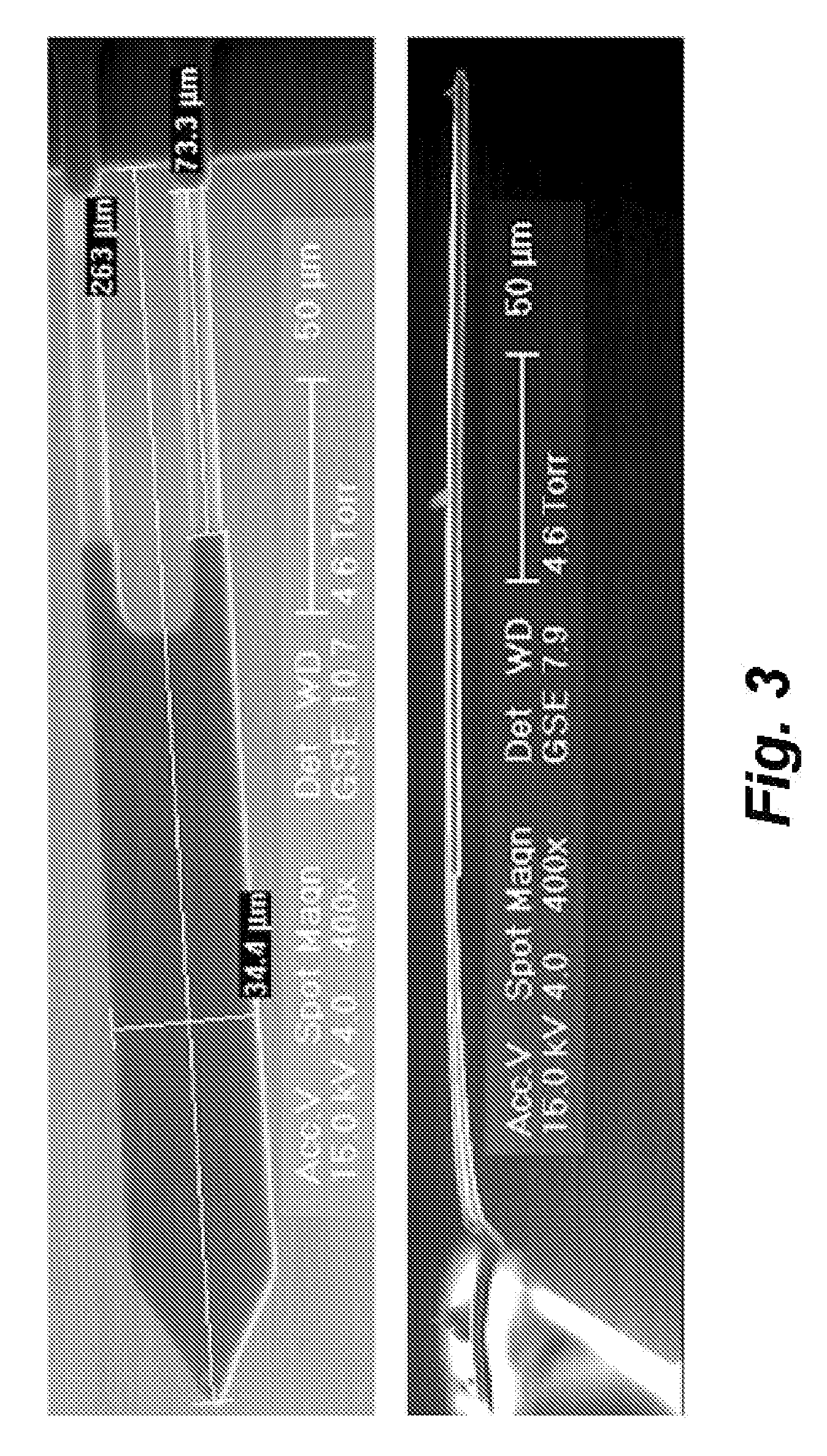

Piezoresistive cantilever based nanoflow and viscosity sensor for microchannels

InactiveUS20080011058A1Material analysis using sonic/ultrasonic/infrasonic wavesFlow propertiesAnalyteEngineering

This invention provides a sensor to measure physical and / or chemical properties of viscous fluids. The sensor is based on microfabricated piezoresistive cantilevers. Deflection of these cantilevers is read out using, e.g., a wheatstone bridge to amplify and convert the deflection into a voltage output. The cantilevers and / or tips attached thereto, can be chemically or physically modified using reagents specific to interact with analytes to be detected in the fluid. The cantilevers can be integrated in a microfluidic system for easy fluid handling and the ability to manage small quantities of fluids.

Owner:RGT UNIV OF CALIFORNIA

Method and apparatus for specimen fabrication

InactiveUS7071475B2Great fabricationSolve the quick positioningBioreactor/fermenter combinationsBiological substance pretreatmentsEngineeringMicroprobe

Owner:HITACHI LTD

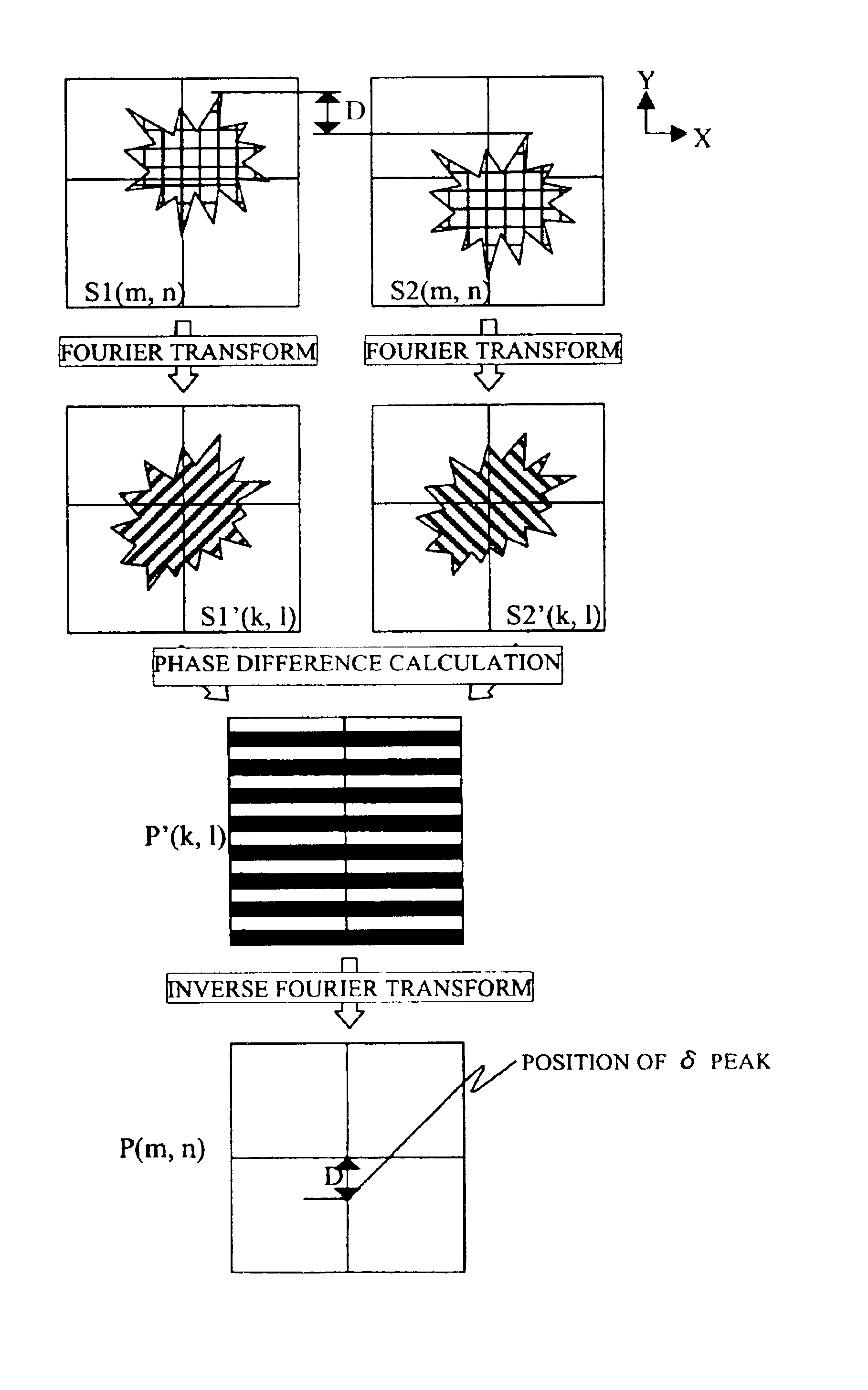

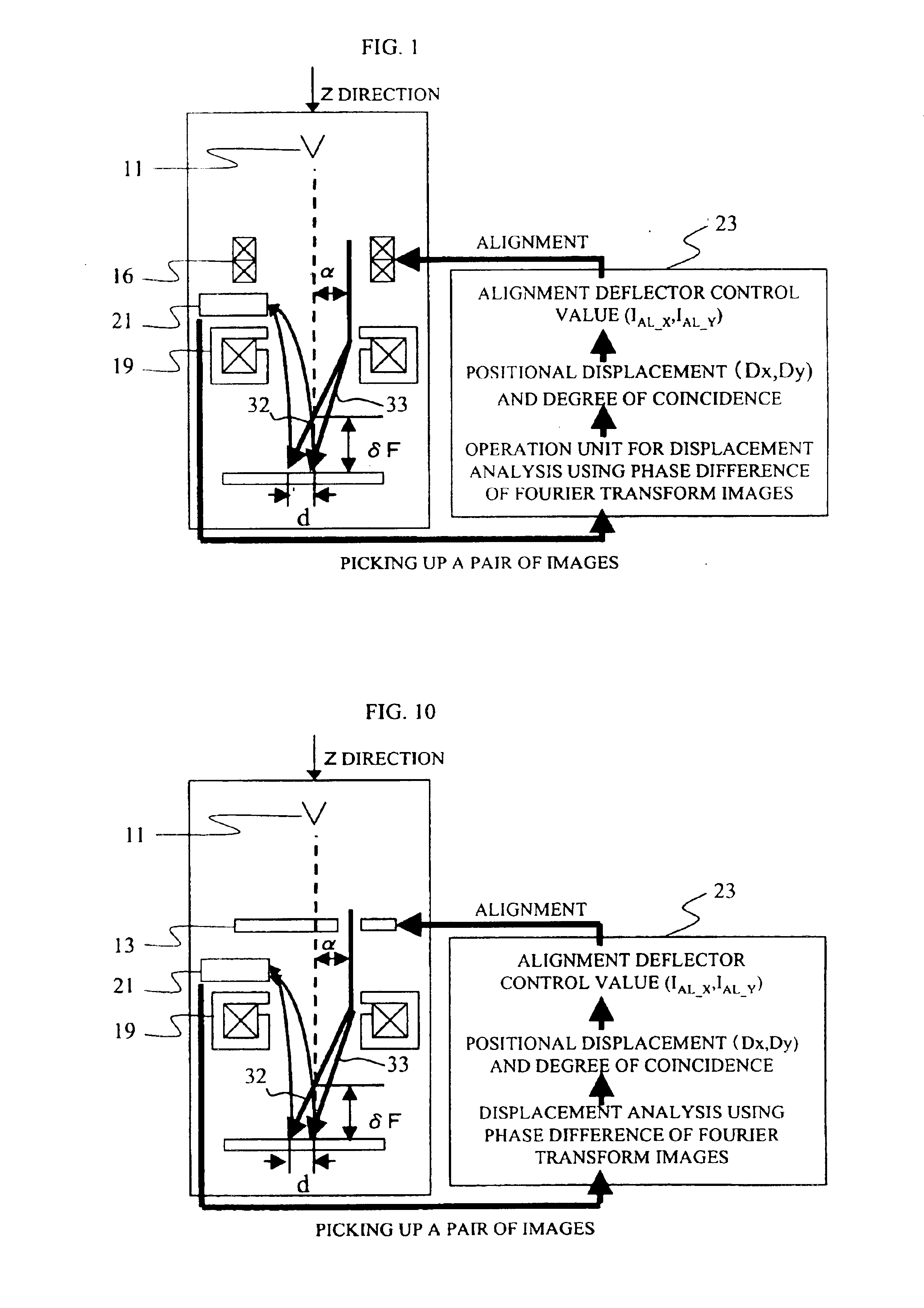

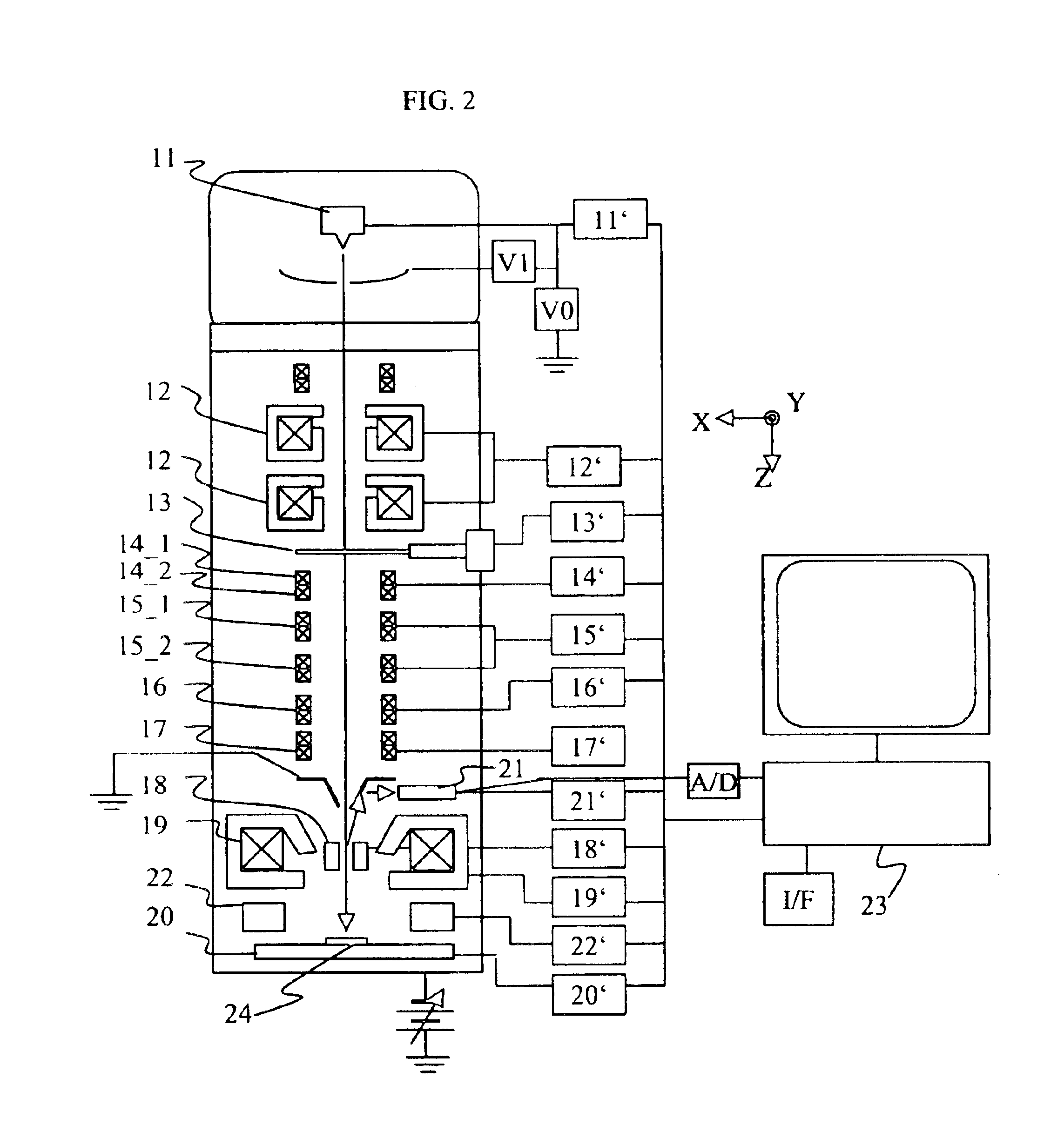

Method and apparatus for charged particle beam microscopy

InactiveUS6838667B2Material analysis using wave/particle radiationElectric discharge tubesParallaxPhase difference

By use of charged particle beam images picked up in different conditions, a positional displacement caused by parallax is analyzed, and an optics of an apparatus for charged particle beam microscopy is corrected automatically. An analysis method using phase difference of Fourier transform images and having analytic accuracy lower than that for one pixel is adopted for the displacement analysis. In addition, a degree of coincidence between images calculated in this analysis method is used as a criterion for evaluating the reliability of an analysis result. Since the analysis method based on parallax is low in specimen dependency, the operation range is expanded. In addition, by adopting a high-accuracy displacement analysis method, the apparatus correction accuracy is improved by one digit. A malfunction preventing flow is added using the degree of coincidence as a judgement criterion. Thus, the apparatus can deal with unmanned operation. In addition, the degree of coincidence can be used as a monitor of inspection states or a record of states in an inspection apparatus.

Owner:HITACHI LTD

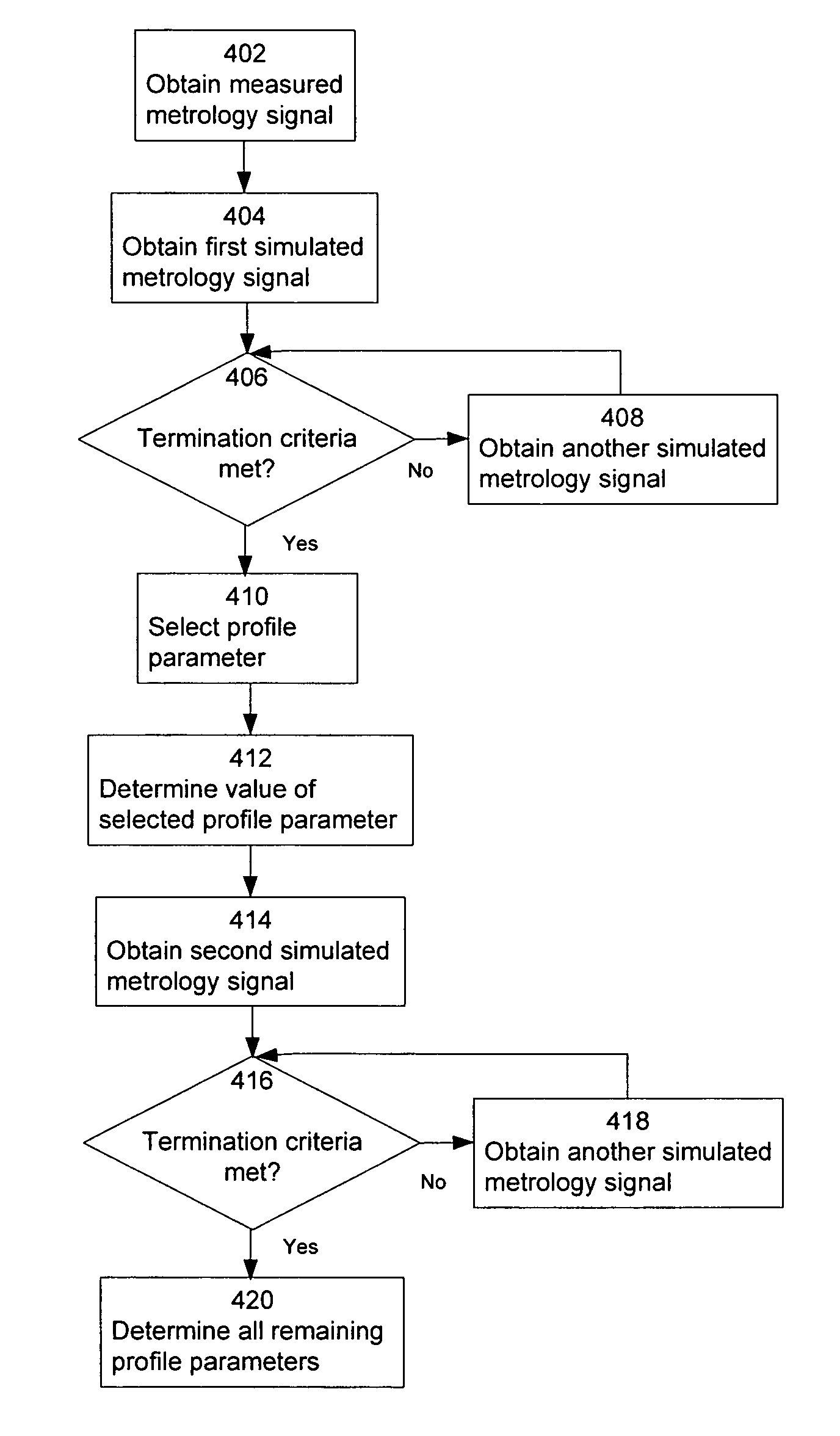

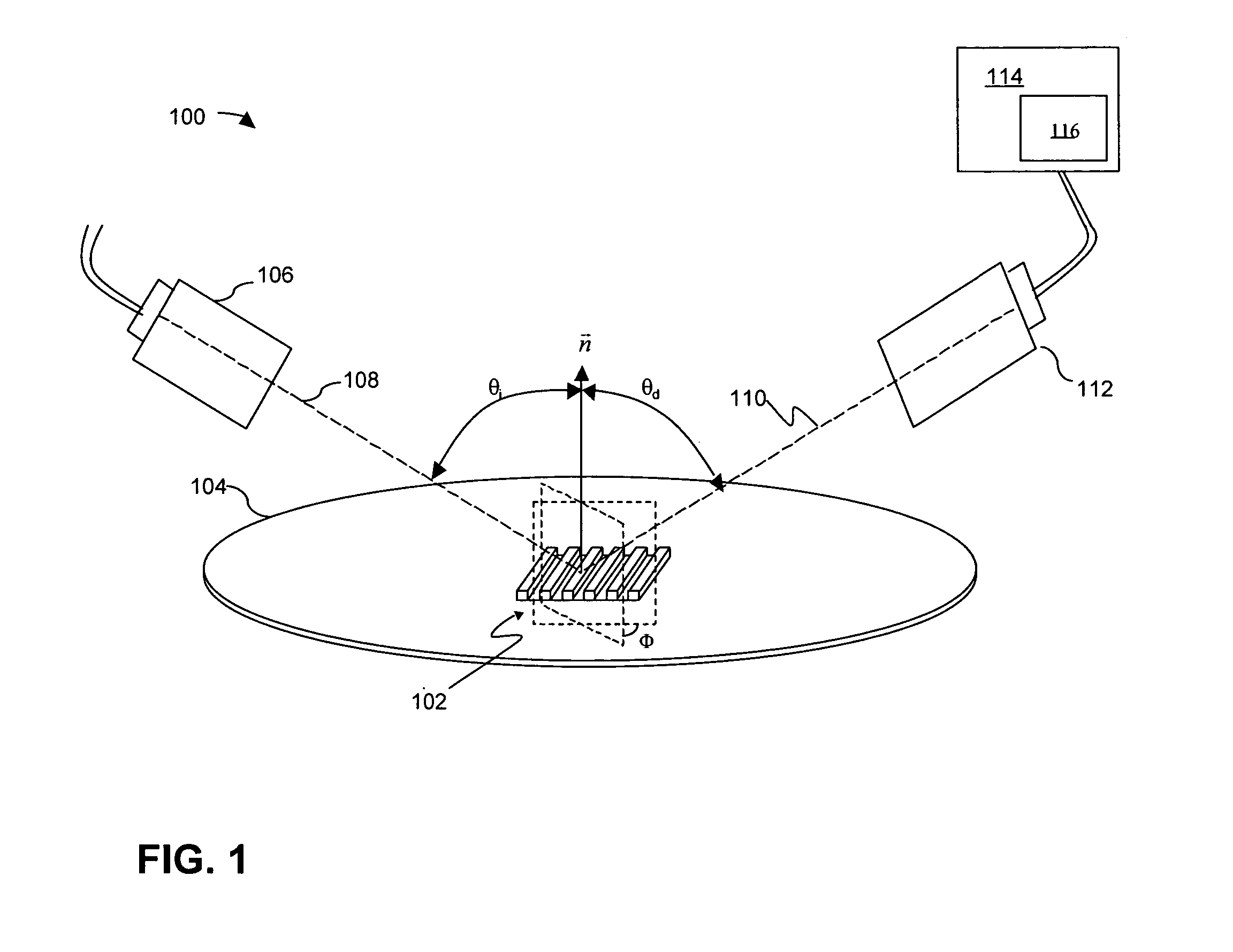

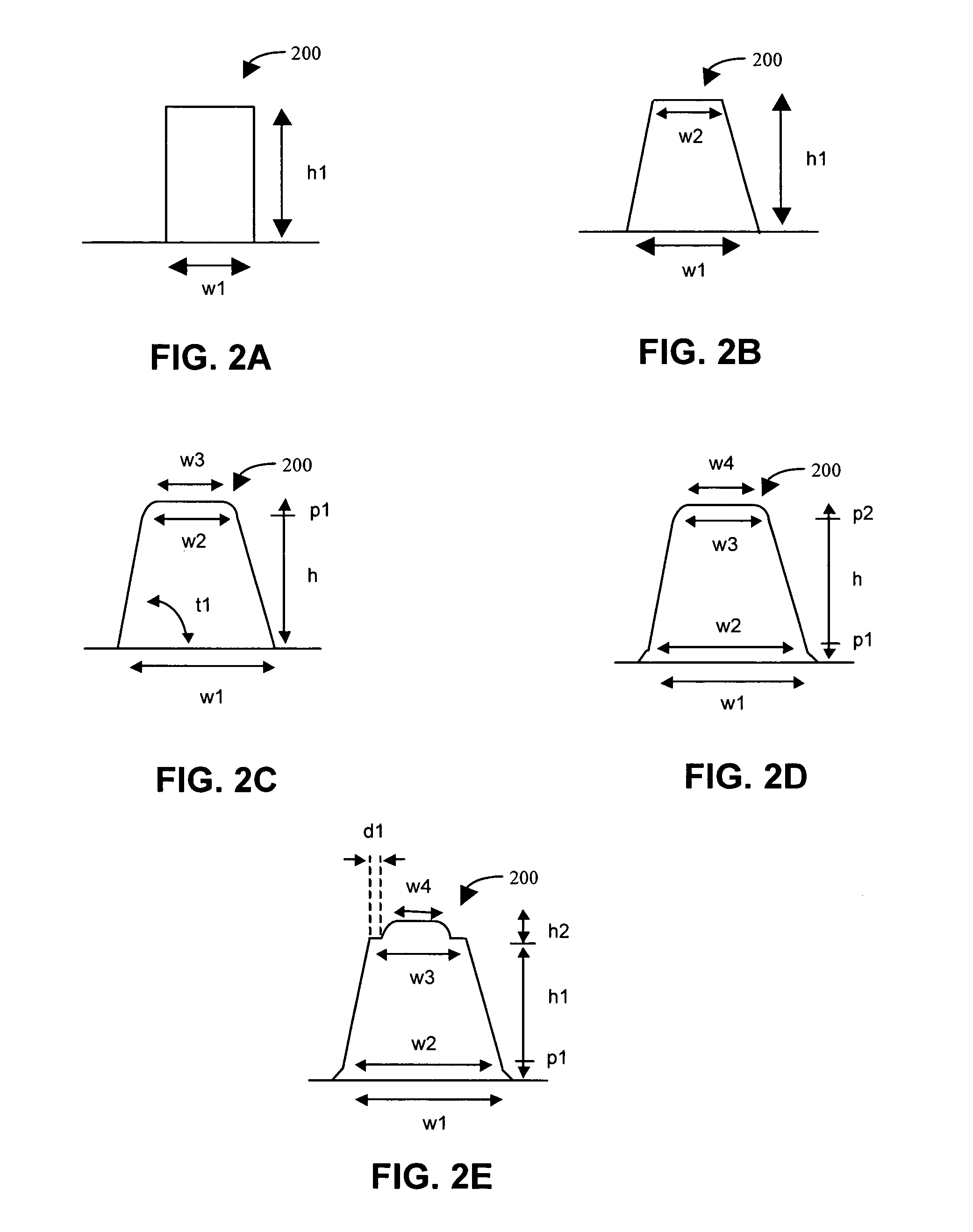

Parametric optimization of optical metrology model

InactiveUS7126700B2Semiconductor/solid-state device testing/measurementAmplifier modifications to reduce noise influenceSignal correlationOptical metrology

The profile of an integrated circuit structure is determined by obtaining a measured metrology signal and a first simulated metrology signal, which has an associated profile model of the structure defined by a set of profile parameters. When the two signals match within a first termination criterion, at least one profile parameter is selected from the set of profile parameters. A value for the selected profile parameter is determined. A second simulated metrology signal having an associated profile model of the structure defined by a set of profile parameters with at least one profile parameter equal or close to the determined value for the selected profile parameter is obtained. When the measured and the second simulated metrology signals match within a second termination criterion, values for one or more remaining profile parameters are determined from the set of profile parameters associated with the second simulated metrology signal.

Owner:TOKYO ELECTRON LTD

Patterned wafer inspection method and apparatus therefor

InactiveUS20020117635A1Shorten inspection timeDefect can be speededBus-bar/wiring layoutsElectric motor controlForeign matterLight beam

An electron beam (area beam) having a fixed area is irradiated onto the surface of a semiconductor sample, and reflected electrons from the sample surface are imaged by the imaging lens, and images of a plurality of regions of the surface of the semiconductor sample are obtained and stored in the image storage unit, and the stored images of the plurality of regions are compared with each other, and the existence of a defect in the regions and the defect position are measured. By doing this, in an apparatus for testing a pattern defect of the same design, foreign substances, and residuals on a wafer in the manufacturing process of a semiconductor apparatus by an electron beam, speeding-up of the test can be realized.

Owner:HITACHI LTD

Color toner

ActiveUS7288348B2Improve transmission performanceImprove performanceScanning probe techniquesDevelopersWaxEngineering

In a color toner having toner particles which have toner base particles containing a binder resin, a colorant and a wax, and inorganic fine particles, (i) in the toner base particles, particles having a circle-equivalent diameter of 3.00 μm or more as measured with a flow type particle image analyzer have an average circularity of from 0.920 or more to less than 0.950, (ii) in the particles having a circle-equivalent diameter of 3.00 μm or more in the toner base particles, particles having a circularity of 0.960 or more are in a number frequency cumulative value of 40% or less; and (iii) in the particles having a circle-equivalent diameter of 3.00 μm or more in the toner base particles, particles having a circularity of 0.920 or less are in a number frequency cumulative value of 30% or less. Also disclosed is a full-color image forming method making use of the toner.

Owner:CANON KK

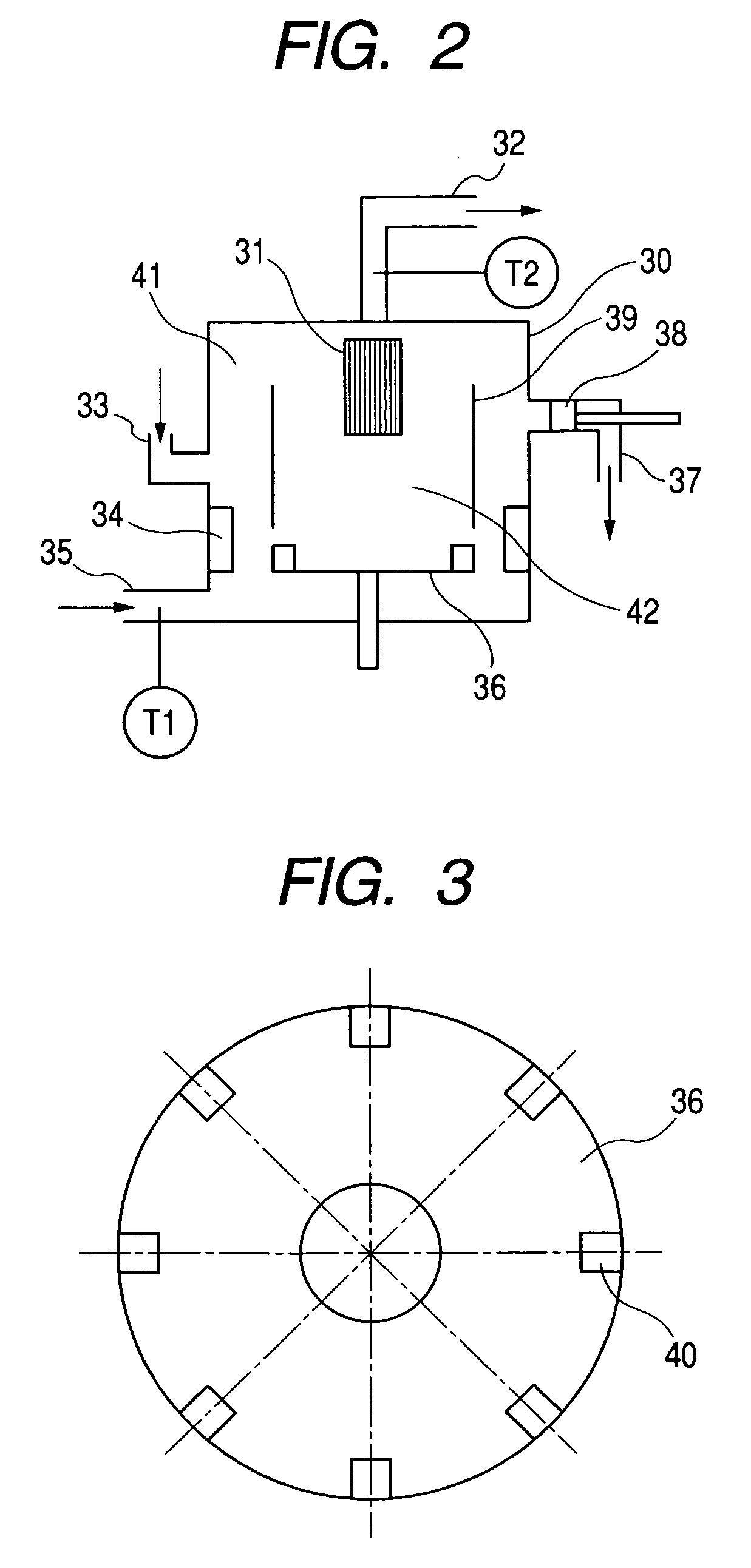

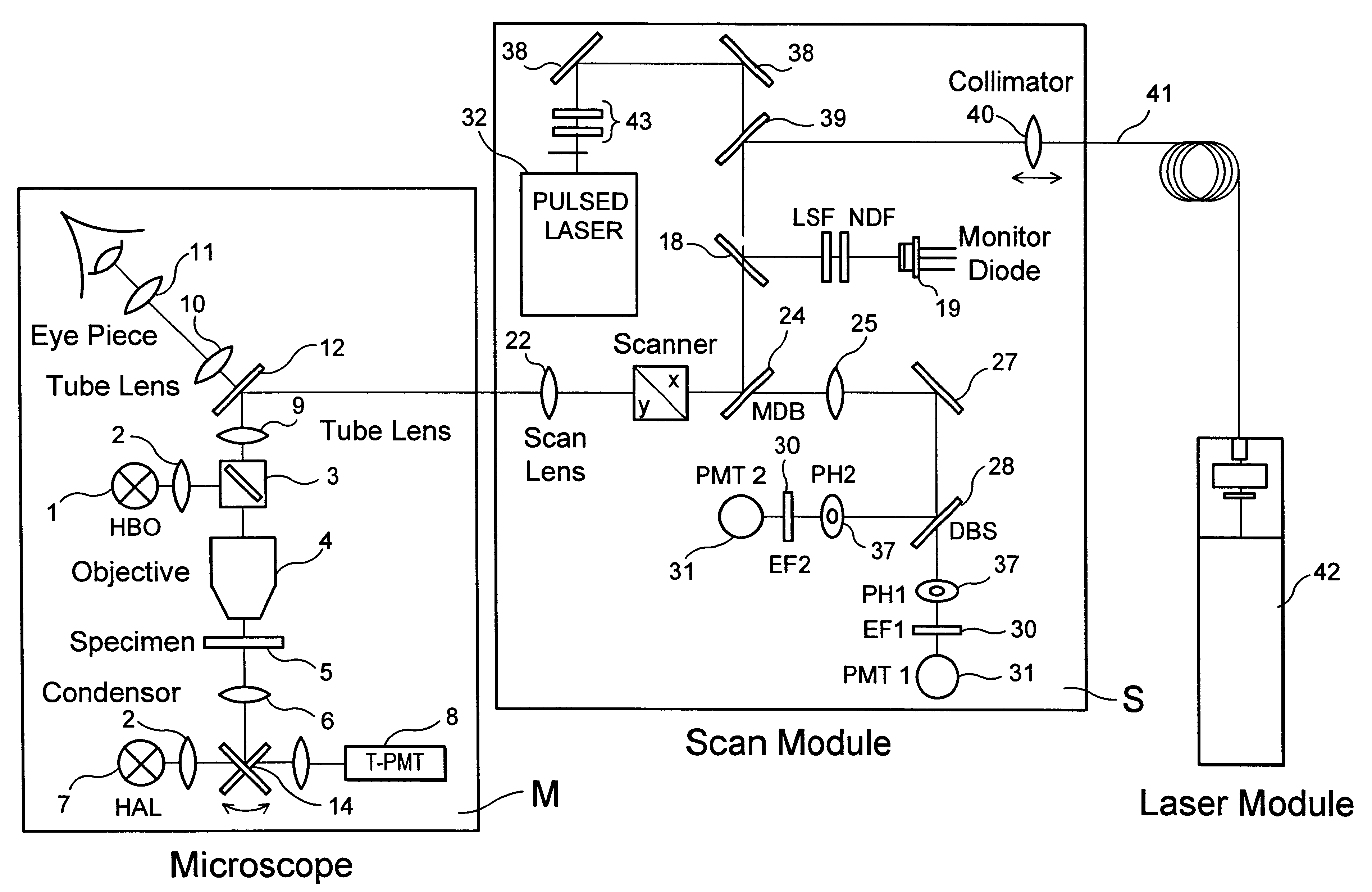

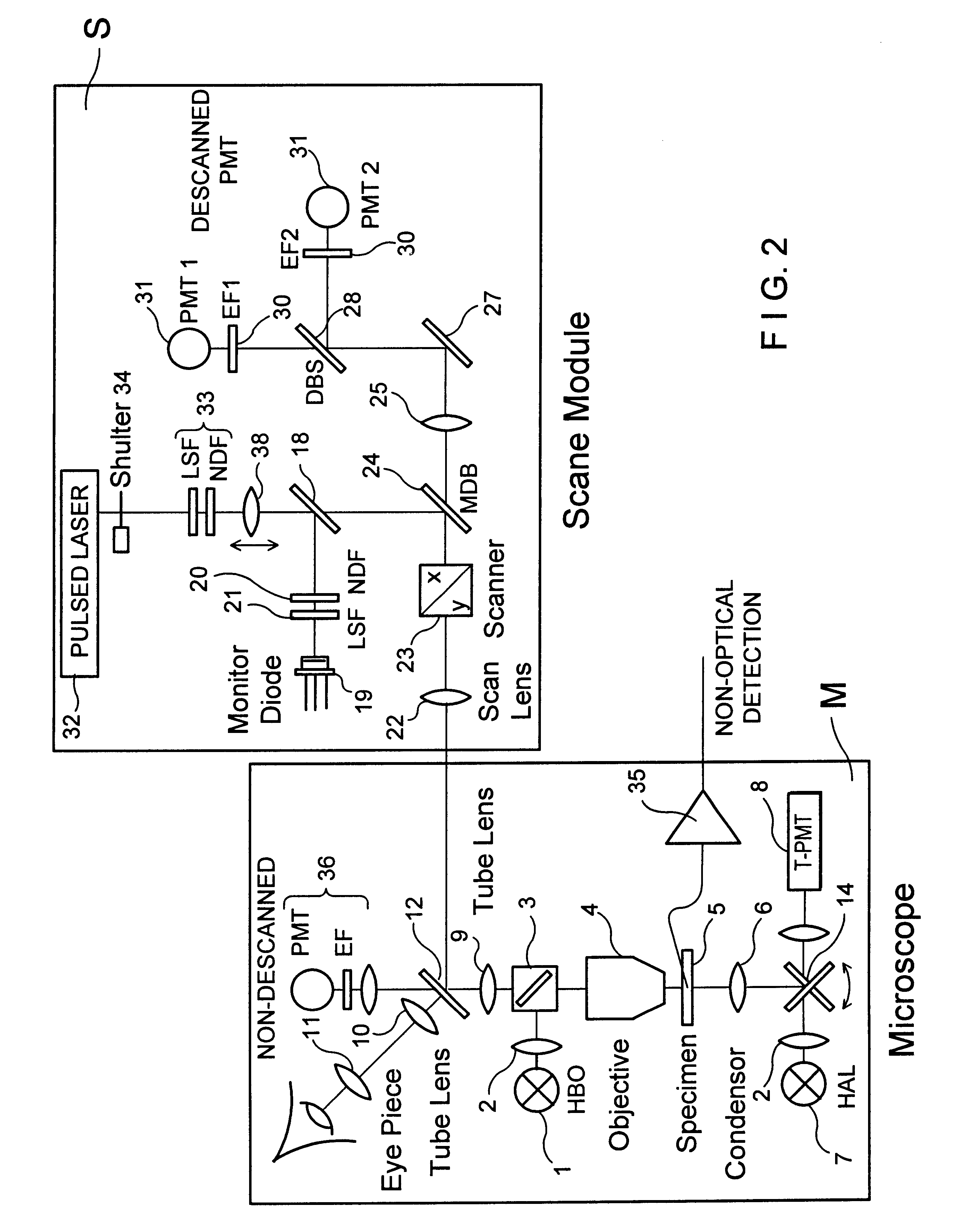

Highly compact laser scanning microscope with integrated short-pulse laser

InactiveUS6356088B1Improve signal-to-noise ratioAttenuation bandwidthMaterial analysis using wave/particle radiationScanning probe techniquesLaser scanning microscopeDirect coupling

The invention describes a highly compact laser scanning microscope with integrated short-pulse laser. Direct coupling or a fiber coupling of the short-pulse laser with the laser scanning microscope is advantageously circumvented with this arrangement. This compact arrangement of the laser in the scan module of the laser scanning microscope can be used in a particularly advantageous manner, for example, in multiphoton microscopy for three-dimensionally resolved microscopic analysis, e.g., of biological specimens. Because of the inherent depth discrimination of the multiphoton technique, confocal pinholes can be entirely omitted in the detection beam path. Accordingly, the microscope system can be realized in a very simple manner with respect to engineering and is particularly simple to handle with respect to application. Through the use of a short-pulse laser system in which a plurality of wavelengths are available simultaneously, diverse applications can be realized in one and the same compact microscope system.

Owner:CARL ZEISS MICROSCOPY GMBH

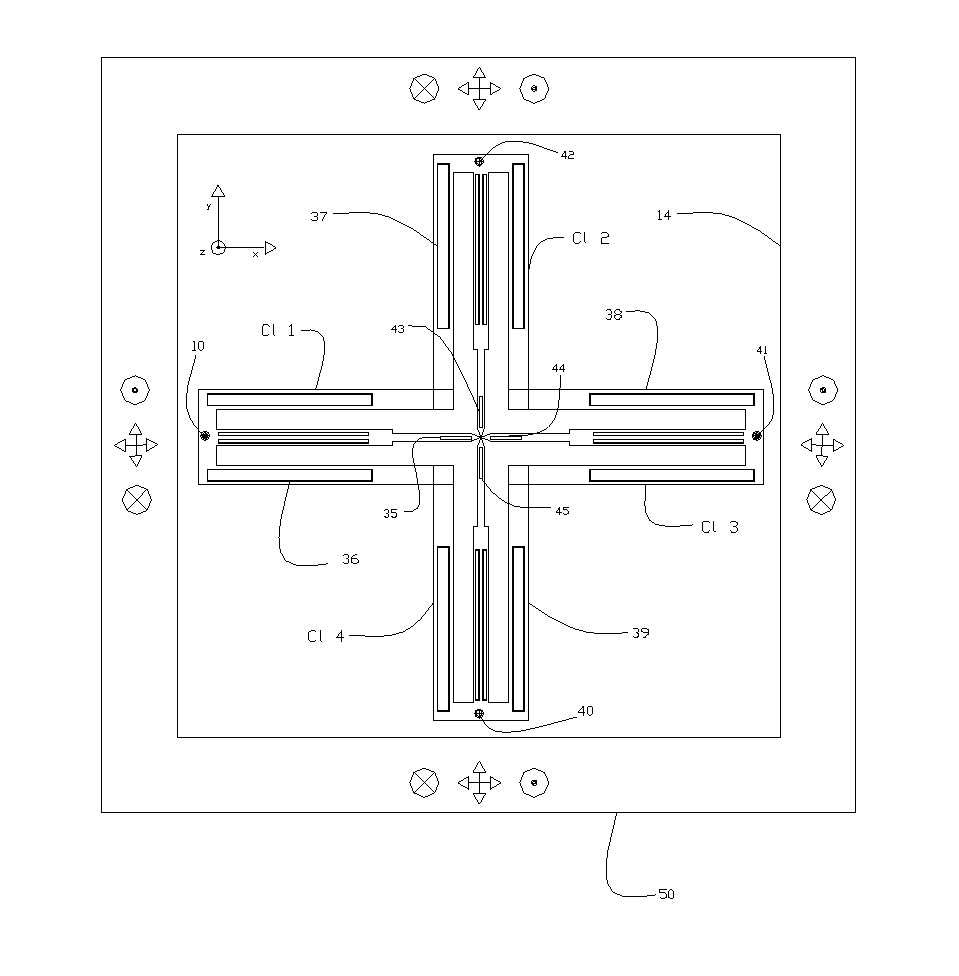

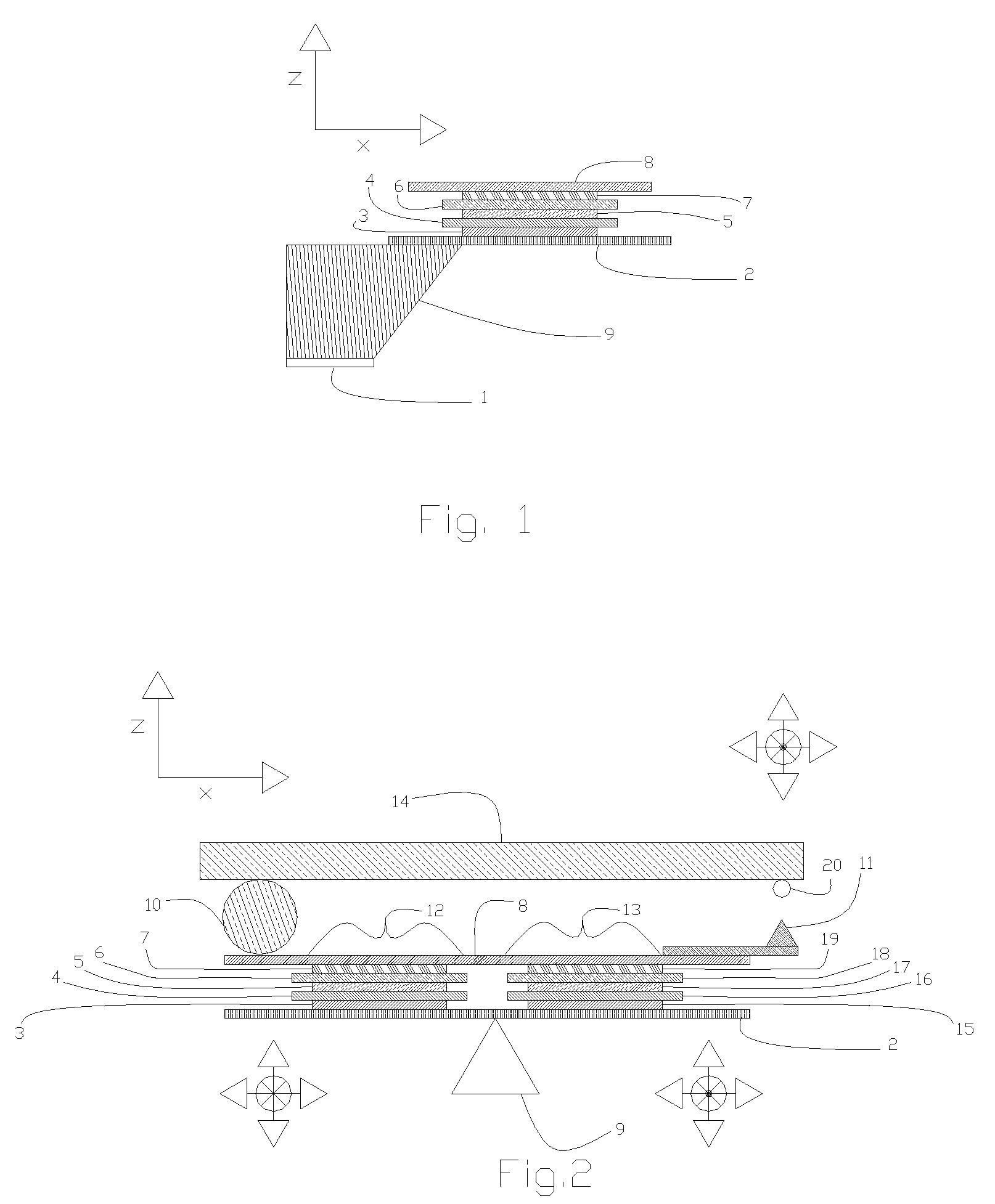

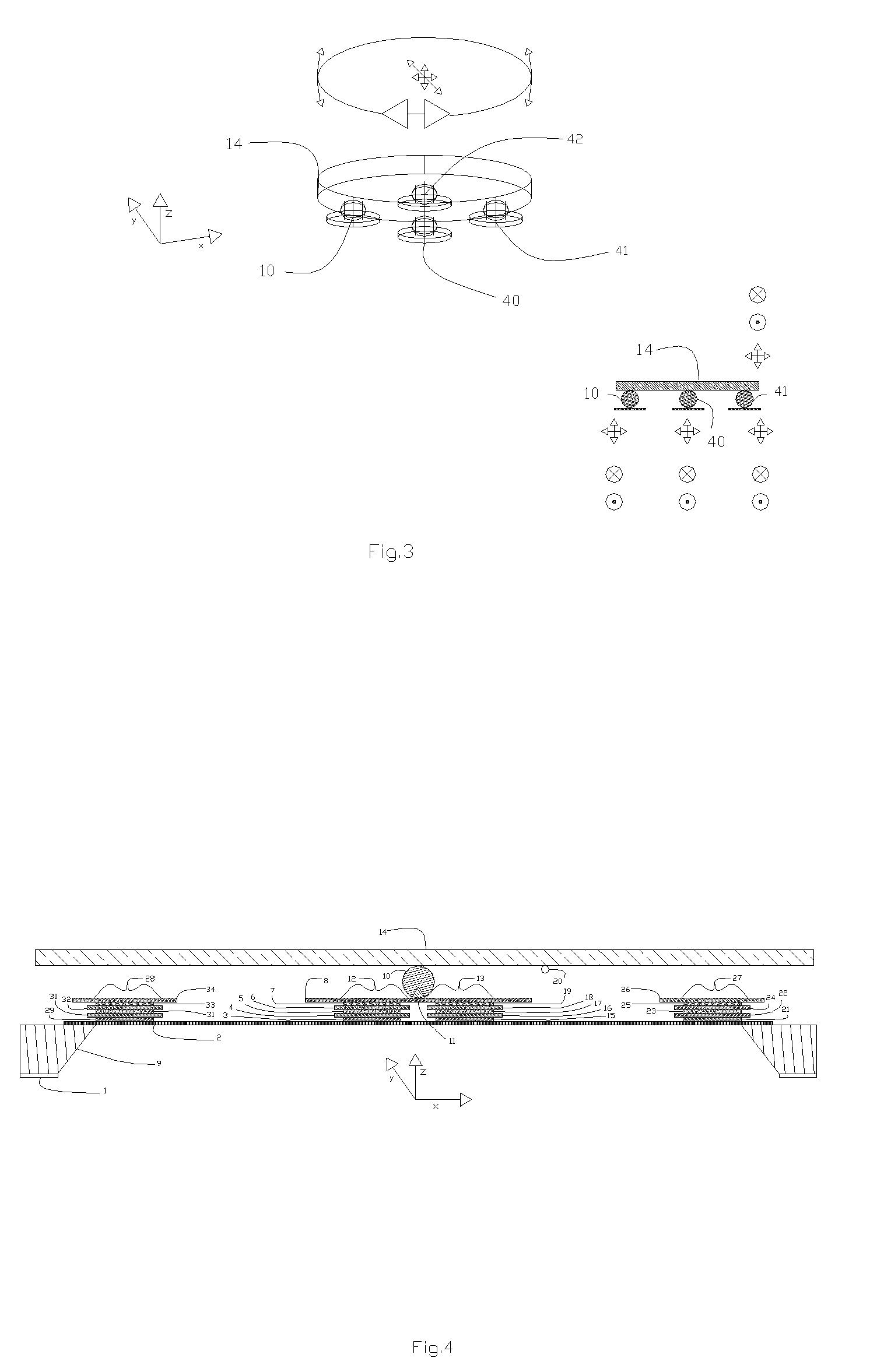

Scanning Probe Microscope, Nanomanipulator with Nanospool, Motor, nucleotide cassette and Gaming application

InactiveUS20080149832A1Material analysis using wave/particle radiationNanotechnologyNucleotideScanning probe microscopy

This invention has applications as a scanning probe microscope / nanomanipulator with consumer gaming applications. An integrated compound lever cantilever which can function simultaneously as both a sample substrate actuator and probe tip scanner actuator for modulation of one or more probe tip. In one embodiment a piezoelectric multimorph MEMS structure is fabricated which serves as a Scanning Probe Microscope cantilever probe tip scanner and allows for the substrate to be moved in more than 1 Degree of freedom with subnanometer resolution. Nanomanipulation means such as nanotweezer, nanopore and nanomachine embodiments are possible uses for the device in addition to data storage. Parallel array operation of many sets of cantilevers is a preferred embodiment which can be used as a nanoscale manipulation and fabrication means. In addition an embodiment where the actuation effects of the device are used to propel the scanner can allow for a programmable drivable MEMS / NEMS based autonomous or semi-autonomous robotic scanner, manipulator and assembler. The device has embodiments where it is essentially a planarized MEMS / NEMS derivative version of a Besocke type scanner. The invention also discloses uses for scanning probe microscopes and nanomanipulators as means for gaming systems, erector set and chemistry kit for entertainment and educational applications. Other applications include rotational actuation, linear motion and spooling of material on rotational bodies through coordination of the actuator probe or probes.

Owner:ZORN MIGUEL

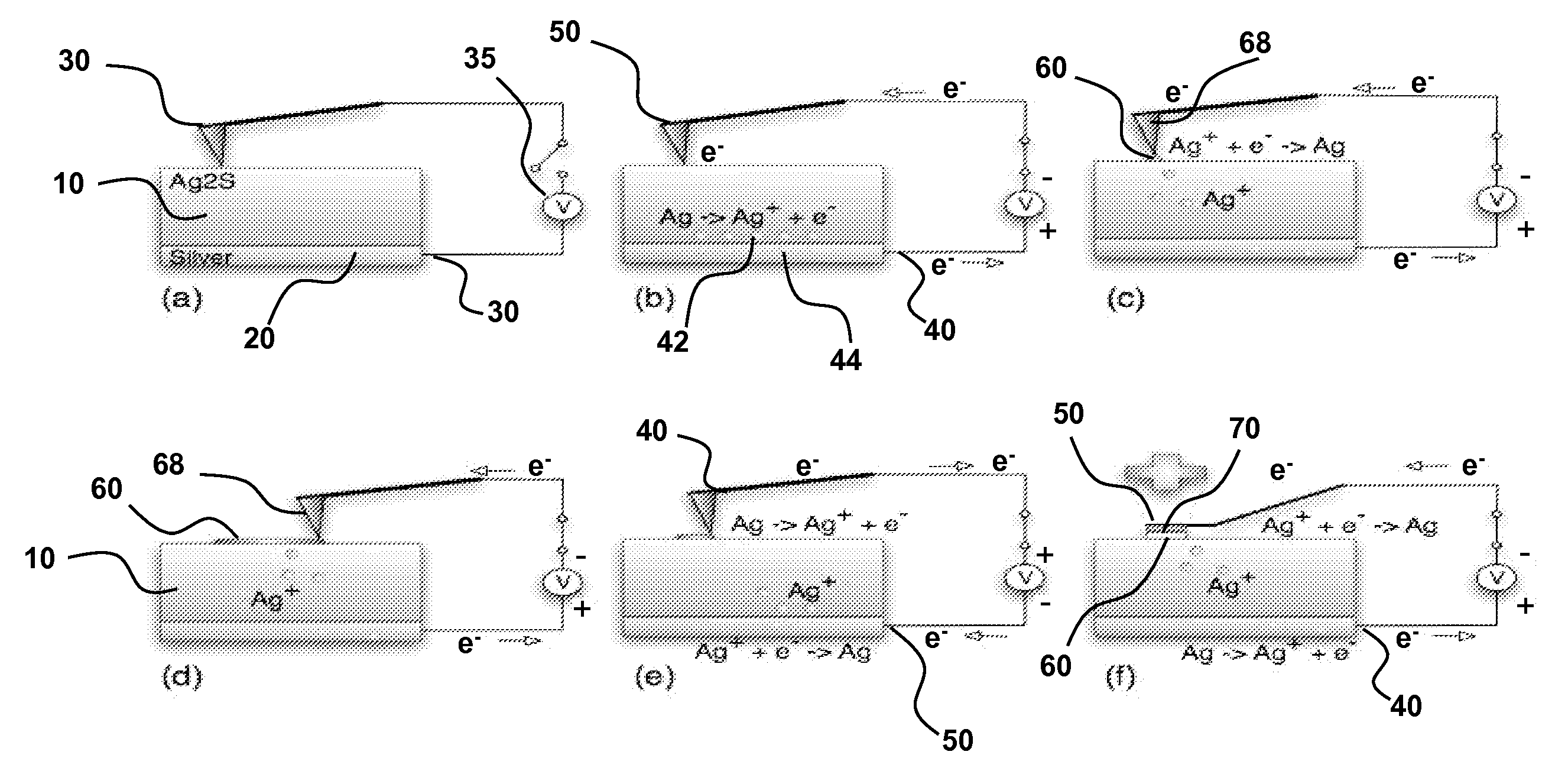

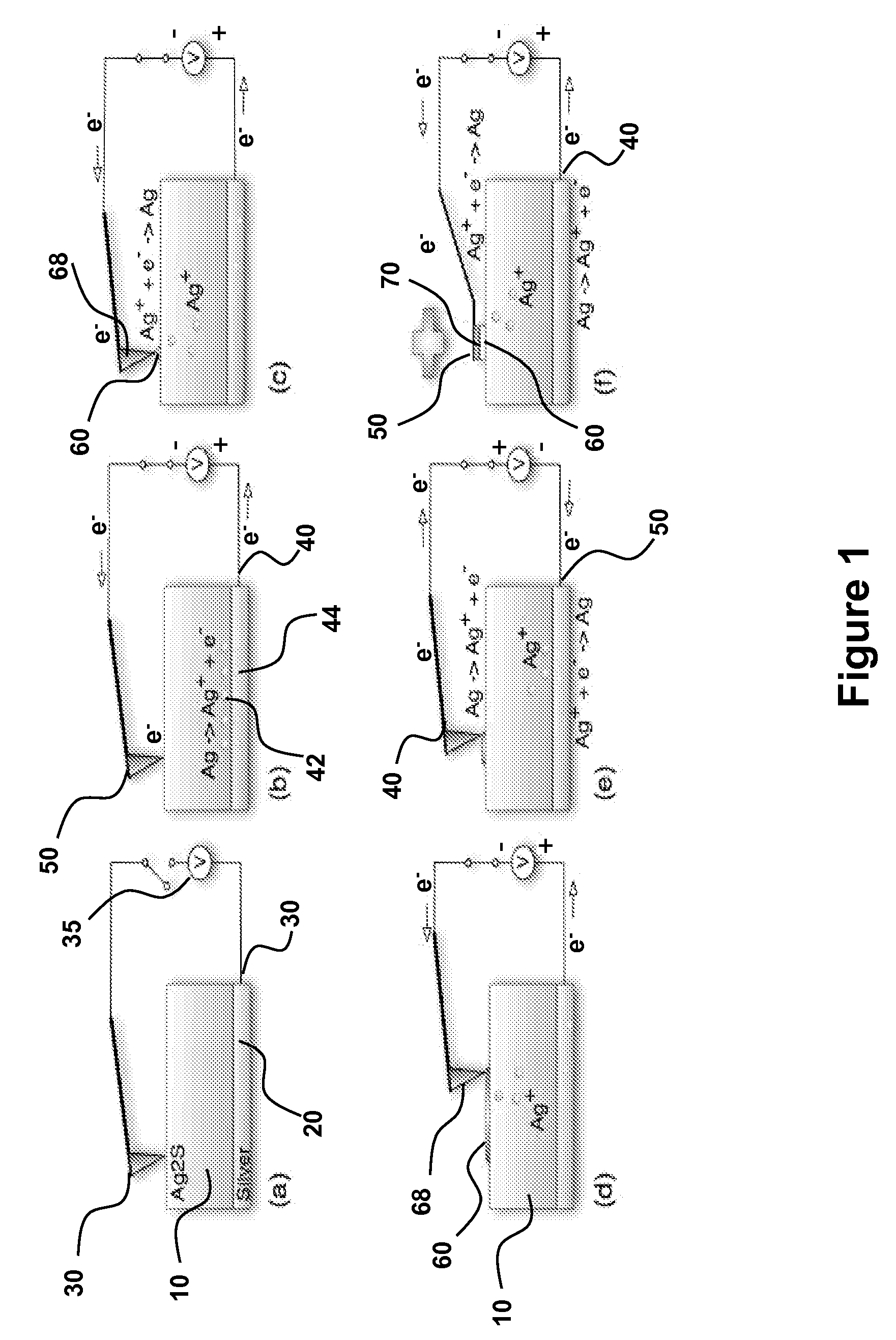

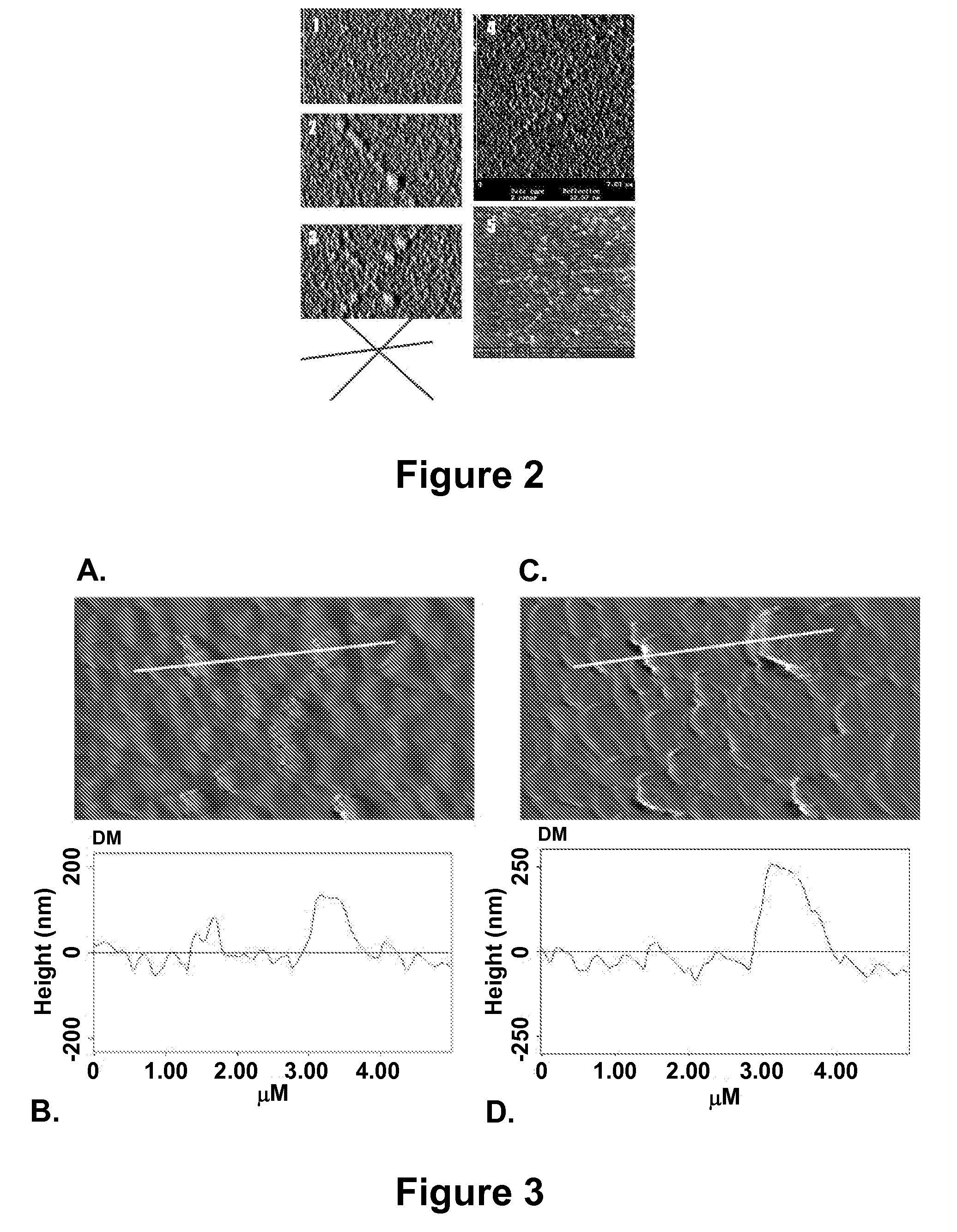

Direct Nanoscale Patterning of Metals Using Polymer Electrolytes

InactiveUS20090050487A1Improve throughputRobust and commercially attractive manufacturing pathwayMachining electrodesMaterial nanotechnologySpatial OrientationsElectrical conductor

Disclosed herein are electrochemical fabrication platforms for making structures, arrays of structures and functional devices having selected nanosized and / or microsized physical dimensions, shapes and spatial orientations. Methods, systems and system components use an electrochemical stamping tool such as solid state polymeric electrolytes for generating patterns of relief and / or recessed features exhibiting excellent reproducibility, pattern fidelity and resolution on surfaces of solid state ionic conductors and in metal. Electrochemical stamping tools are capable high throughput patterning of large substrate areas, are compatible with commercially attractive manufacturing pathways to access a range of functional systems and devices including nano- and micro-electromechanical systems, sensors, energy storage devices, metal masks for printing, interconnects, and integrated electronic circuits.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

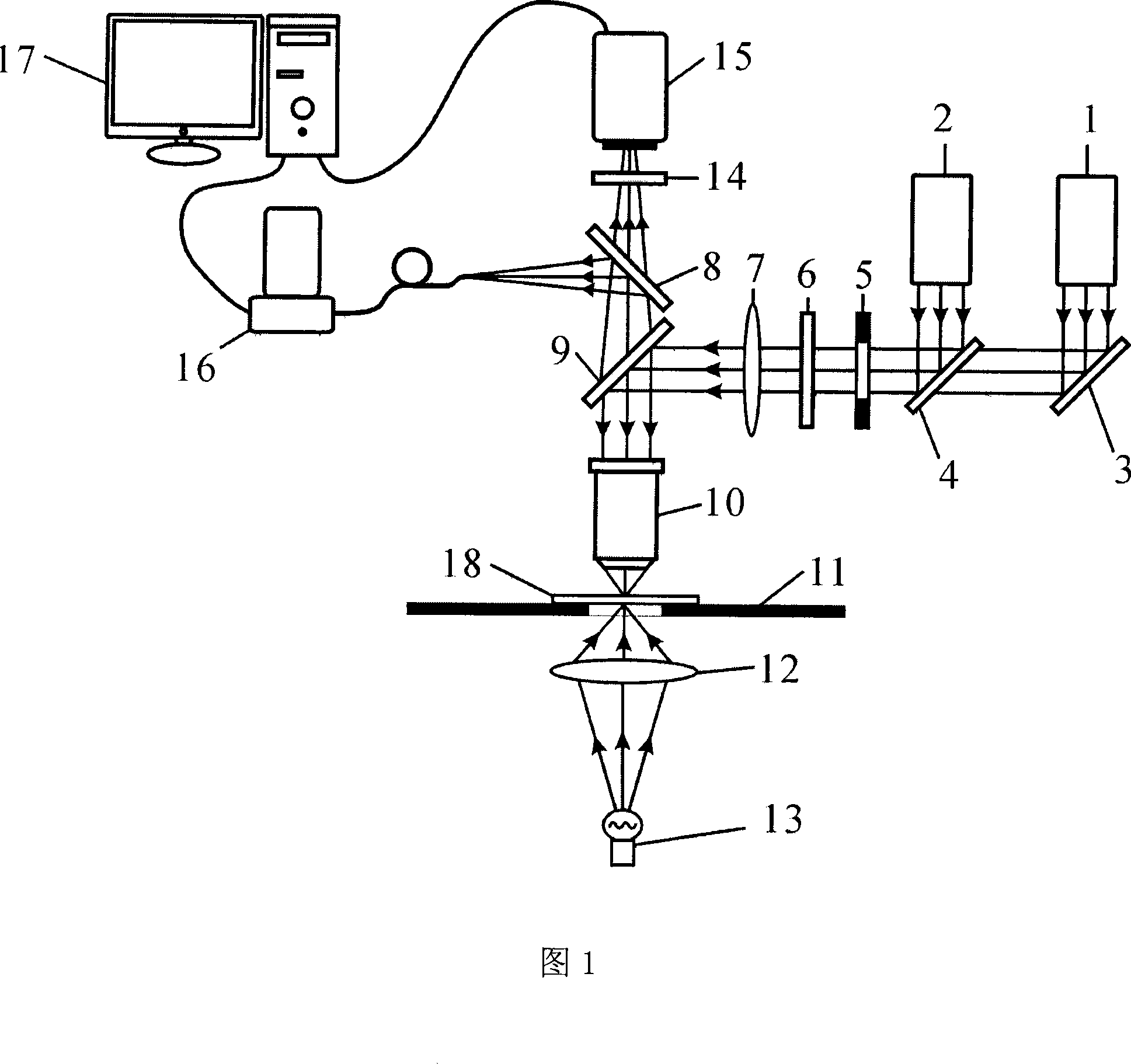

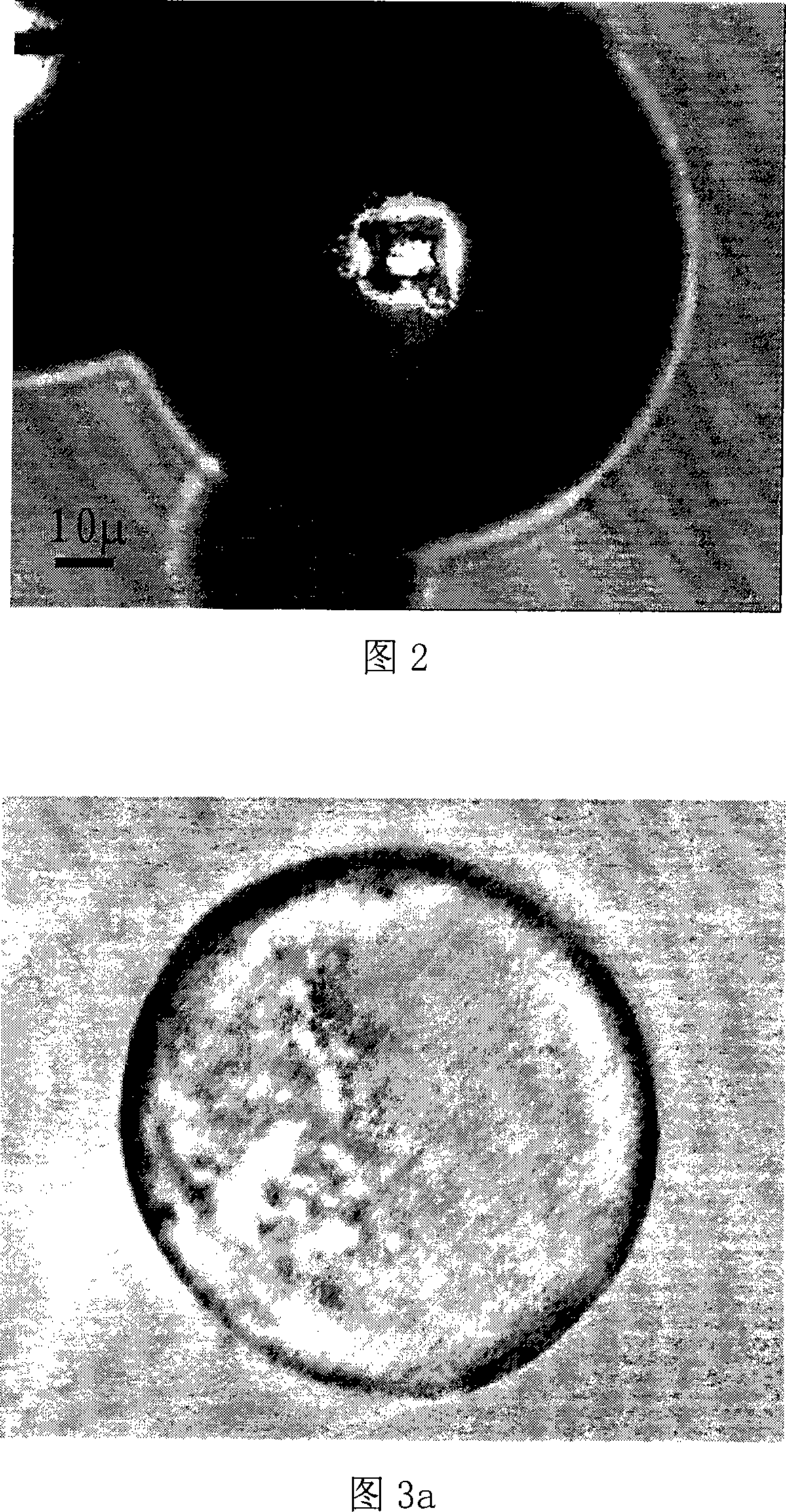

Multifunctional optical micro-control device

InactiveCN101216414AOvercome singleOvercome deficienciesSurface/boundary effectMaterial analysis by optical meansFemto second laserCcd camera

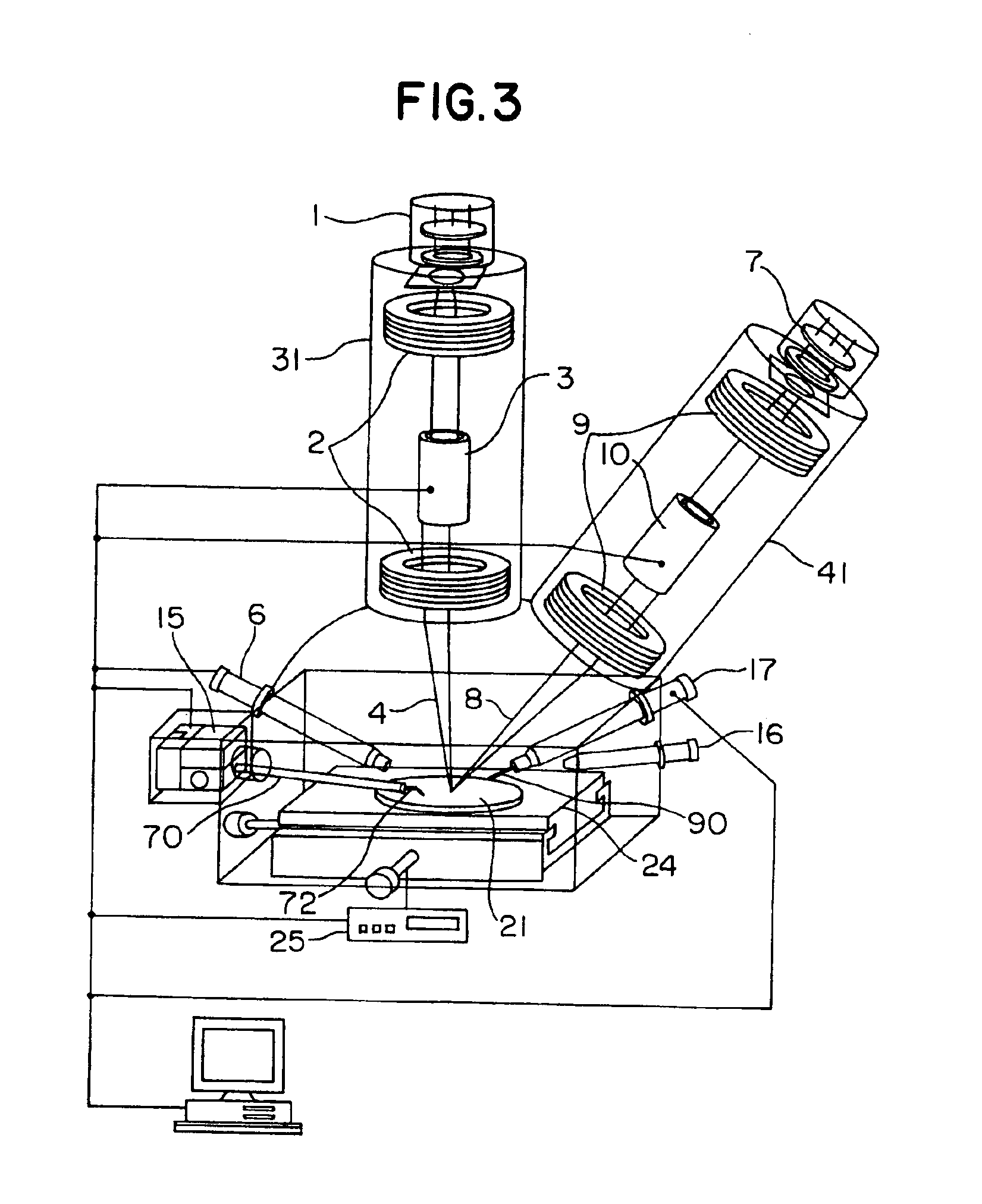

A multifunctional optical micro-manipulation device comprises a femtosecond laser, an optical tweezers laser, an optical system, a stage, a light source system, an imaging system, a spectral measurement system and a computer, wherein the optical system comprises a shutter, an attenuator, a focusing lens, a near IR reflector and a microscopic objective lens; the light source system comprises an illumination light source and a condenser lens; the microscopic objective lens is arranged on the stage for condensing a laser beam emitted by a laser generator onto a sample; the condenser lens is arranged below the stage for condensing a visible light emitted by the illumination light source onto the sample; and the imaging system includes an IR filter and CCD camera sequentially disposed on the projection light path of the near IR reflector. By integrating three functions of laser tweezers, femtosecond laser scissors and microspectrometer in one system, the invention can overcome the singleness and the disadvantages of the prior laser micro-beam technology and can be widely used for studying in biological, medical, biophysical, material chemistry and nano-technology fields.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

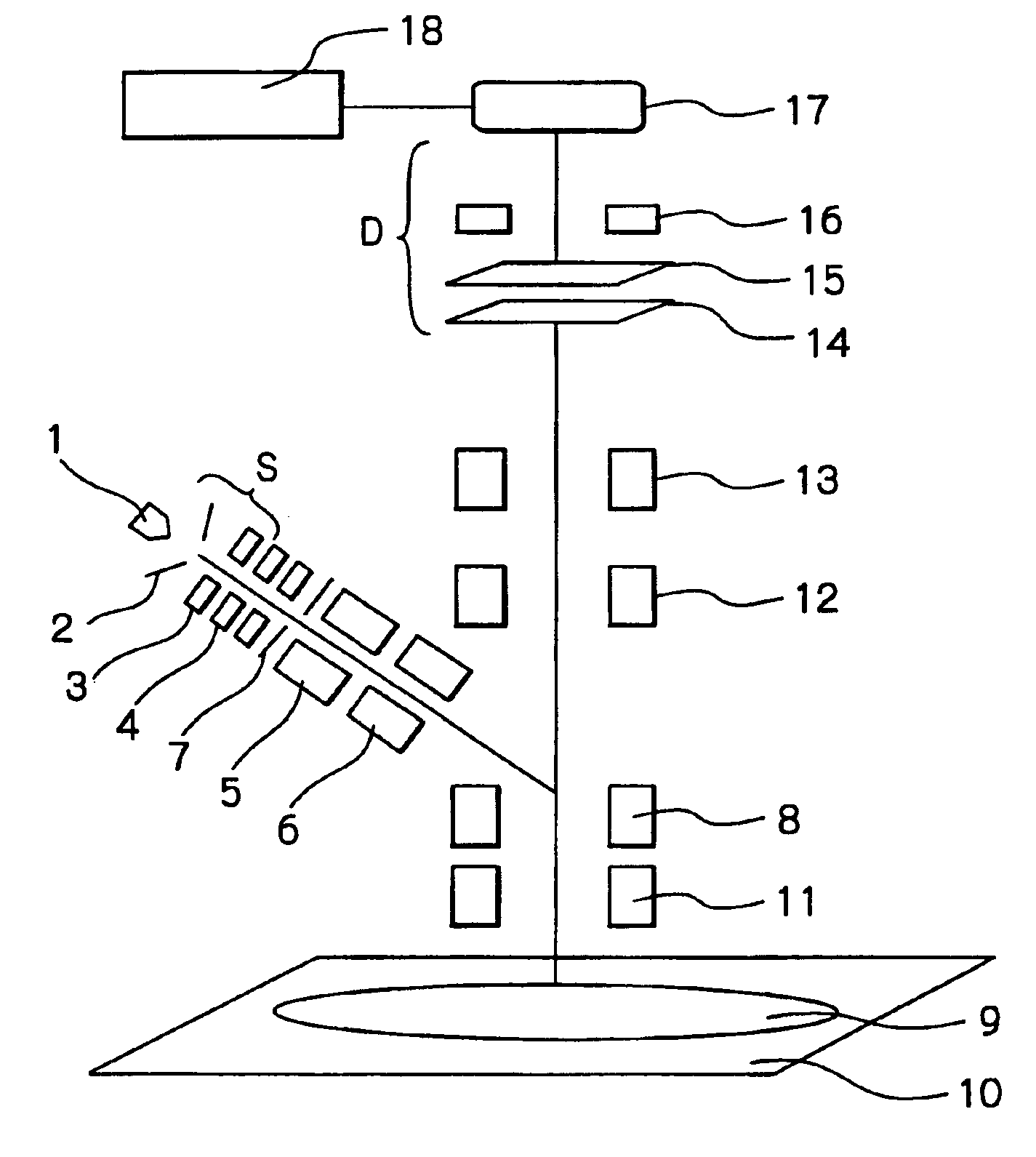

Apparatus for inspection with electron beam, method for operating same, and method for manufacturing semiconductor device using former

InactiveUS20050121611A1Improve throughputImprove efficiencyMaterial analysis using wave/particle radiationElectric discharge tubesImaging processingDevice material

A substrate inspection apparatus 1-1 (FIG. 1) of the present invention performs the following steps of: carrying a substrate “S” to be inspected into an inspection chamber 23-1; maintaining a vacuum in said inspection chamber; isolating said inspection chamber from a vibration; moving successively said substrate by means of a stage 26-1 with at least one degree of freedom; irradiating an electron beam having a specified width; helping said electron beam reach to a surface of said substrate via a primary electron optical system 10-1; trapping secondary electrons emitted from said substrate via a secondary electron optical system 20-1 and guiding it to a detecting system 35-1; forming a secondary electron image in an image processing system based on a detection signal of a secondary electron beam obtained by said detecting system; detecting a defective location in said substrate based on the secondary electron image formed by said image processing system; indicating and / or storing said defective location in said substrate by CPU 37-1; and taking said completely inspected substrate out of the inspection chamber. Thereby, the defect inspection on the substrate can be performed successively with high level of accuracy and efficiency as well as with higher throughput.

Owner:EBARA CORP

Electron beam exposure system

InactiveUS20050211921A1Improve performanceHigh resolutionThermometer detailsNanoinformaticsTarget surfaceControl signal

The invention relates to an electron beam exposure apparatus for transferring a pattern onto the surface of a target, comprising: a beamlet generator for generating a plurality of electron beamlets; a modulation array for receiving said plurality of electron beamlets, comprising a plurality of modulators for modulating the intensity of an electron beamlet; a controller, connected to the modulation array for individually controlling the modulators, an adjustor, operationally connected to each modulator, for individually adjusting the control signal of each modulator; a focusing electron optical system comprising an array of electrostatic lenses wherein each lens focuses a corresponding individual beamlet, which is transmitted by said modulation array, to a cross section smaller than 300 nm, and a target holder for holding a target with its exposure surface onto which the pattern is to be transferred in the first focal plane of the focusing electron optical system.

Owner:ASML NETHERLANDS BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com