Multifunctional optical micro-control device

A manipulation device and multi-functional technology, applied in the field of optical micromachining and measuring devices, can solve the problems of inconvenient use and achieve the effects of small thermal damage, compact system structure and large penetration depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

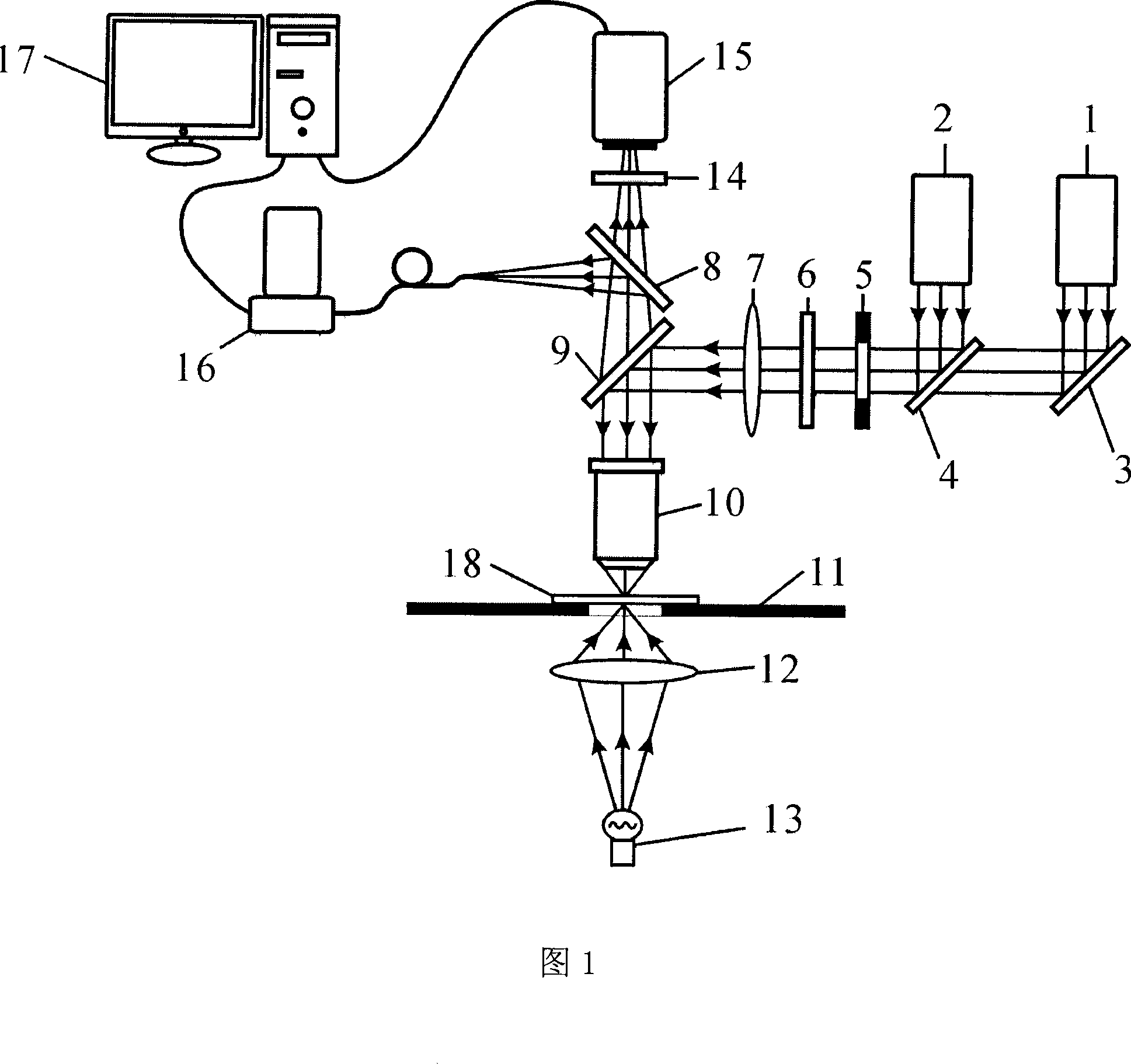

[0027]A multifunctional optical micro-manipulation device, referring to Fig. 1, includes a laser generator, an optical system, a stage 11 on which a sample 18 can be placed, a light source system, an imaging system, a spectral measurement system and a computer 17, and the laser generator includes a femtosecond Laser 1 and optical tweezers laser 2; the optical system includes a reflector 3 arranged in front of the femtosecond laser 1, a beam splitter 4 arranged in front of the optical tweezers laser 2, and a shutter 5, an attenuator 6, and a shutter arranged in sequence on the laser optical path. Focus lens 7, near-infrared reflector 9, microscope objective lens 10, reflector 3, beam splitter 4, shutter 5, attenuator 6, focusing mirror 7 coaxial settings, wherein beam splitter 4 is arranged on shutter 5 and Between the reflecting mirrors 3; the light source system includes an illumination source 13 and a condenser 12; the microscope objective lens is arranged above the stage to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com