Catalyst for wet flue gas denitrification and application thereof

A catalyst and denitrification technology applied in the chemical industry to achieve the effects of easy recovery, high catalytic activity, and improved denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

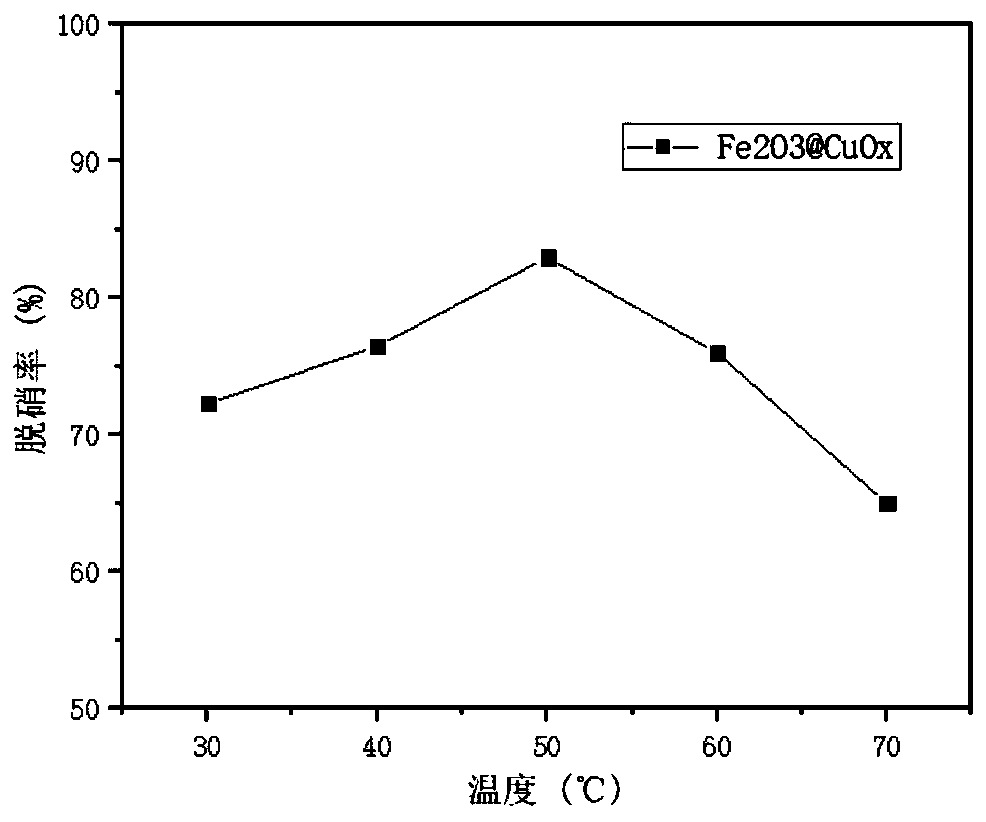

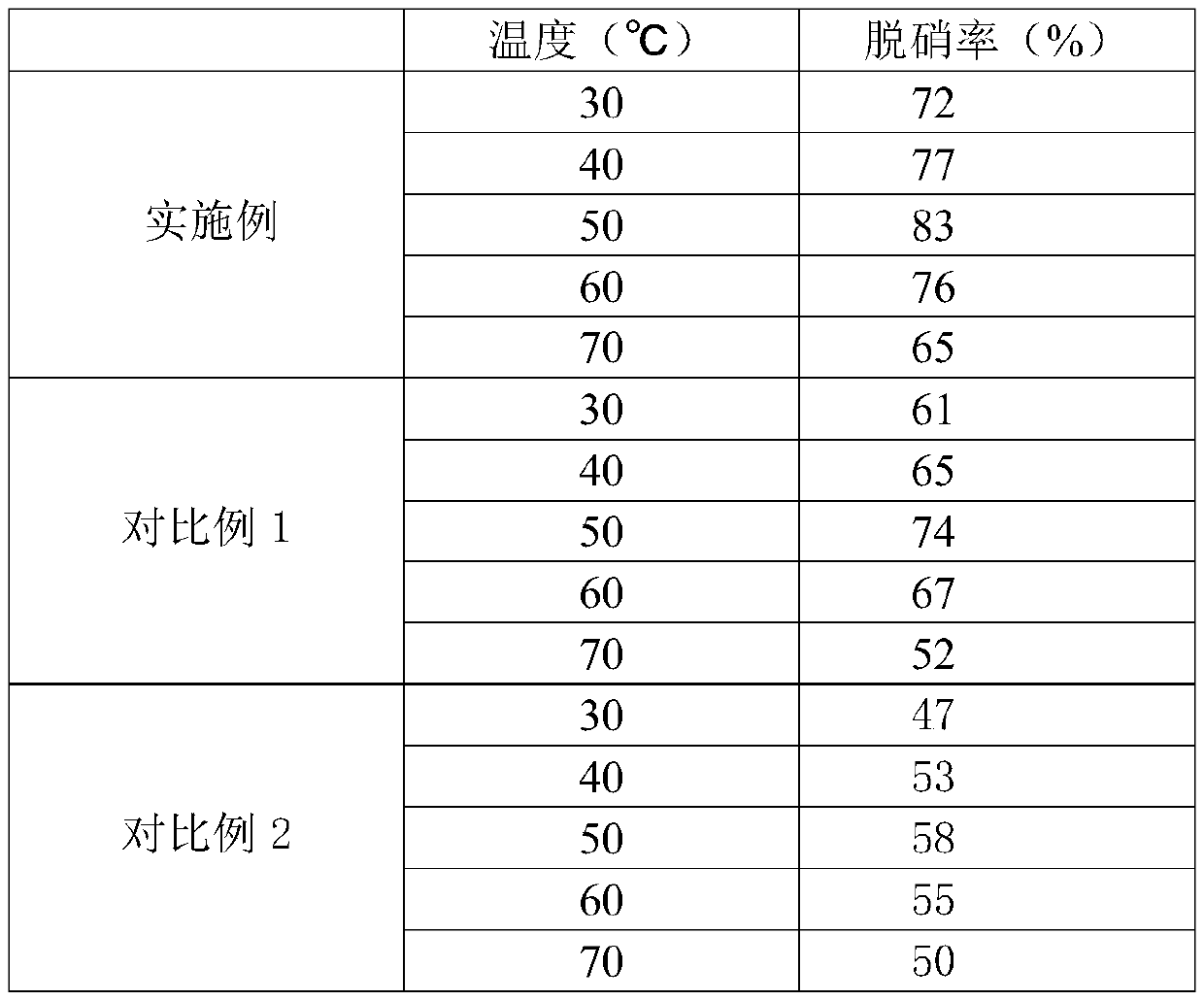

[0023] A catalyst for wet flue gas denitrification, the active ingredient of which is composed of iron oxide and foamed copper oxide (hereinafter referred to as Fe 2 o 3 @CuO x ), the preparation method of the catalyst is as follows:

[0024] Step 1, use 13.56mol / L acetone and 0.1mol / L dilute hydrochloric acid to remove dirt from the copper foam under ultrasonic vibration, and wash with deionized water to remove residual hydrochloric acid and acetone to obtain clean copper foam;

[0025] Step 2, roasting the clean foamed copper in air at 500°C for 6 hours to obtain foamed copper oxide;

[0026] Step 3, 1.4mmol FeSO 4 ·7H 2 O was dissolved in 70 ml deionized water with stirring to form FeSO 4 solution, then the solution and foamed copper oxide were transferred to a lined stainless steel autoclave, and 2.5 mmol of sodium hydroxide tablets were added quickly to obtain a mixed solution;

[0027] Step 4, place the high-pressure reaction kettle with the mixed solution in an ov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com