Patents

Literature

41results about How to "Achieving removal rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

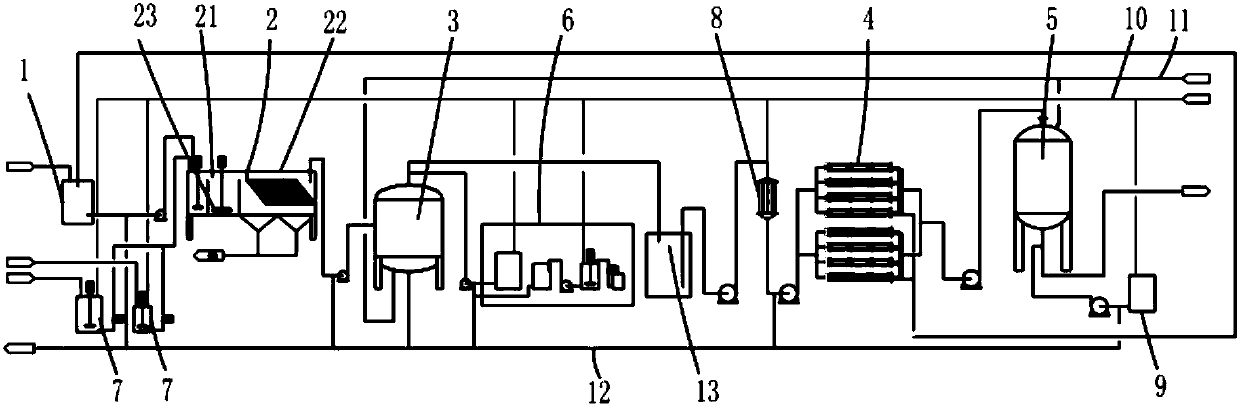

System and method for repairing polycyclic aromatic hydrocarbon contaminated soil

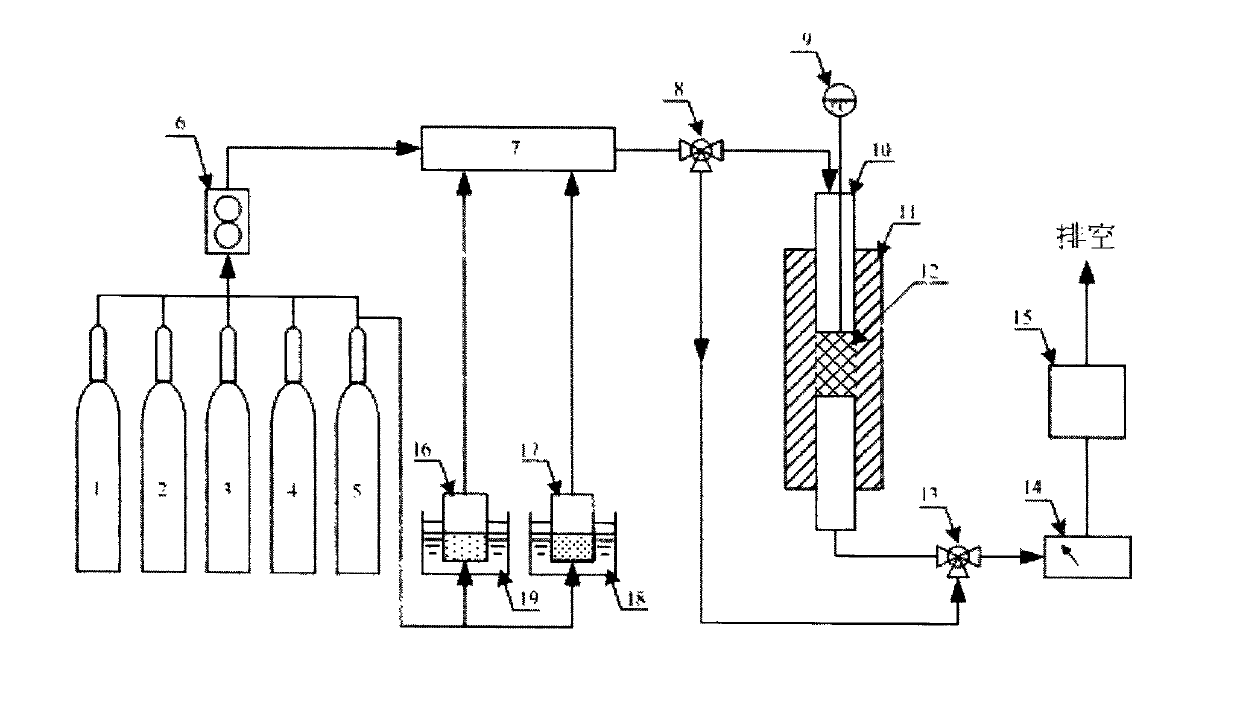

ActiveCN106363017AShorten the timeReduce competition effectContaminated soil reclamationPolycyclic aromatic hydrocarbonFlue gas

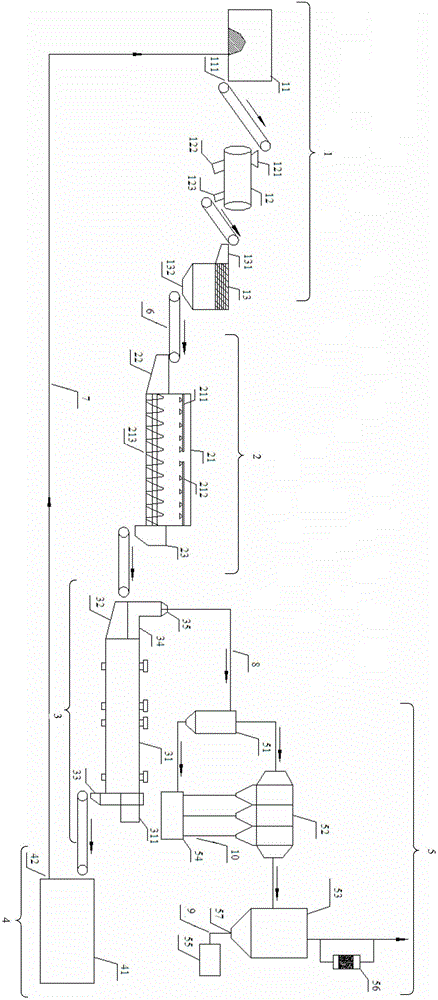

The invention provides a system for repairing polycyclic aromatic hydrocarbon contaminated soil. The system is provided with soil pretreatment equipment, chemical oxidation equipment, thermal desorption equipment, soil accumulation equipment and flue gas dust removal equipment in sequence. Conveying belts are arranged between the soil pretreatment equipment, the chemical oxidation equipment, the thermal desorption equipment and the soil accumulation equipment. The thermal desorption equipment communicates with the flue gas dust removal equipment through a pipeline. The soil accumulation equipment communicates with the soil pretreatment equipment through a pipeline. The invention further provides a method for repairing the polycyclic aromatic hydrocarbon contaminated soil. According to the system and method for repairing the polycyclic aromatic hydrocarbon contaminated soil, chemical oxidation and low-temperature thermal desorption are combined, and therefore the removal rate of polycyclic aromatic hydrocarbon of the soil can reach 99%, the repairing effect of the contaminated soil can be effectively improved, and the repairing period can be effectively shortened.

Owner:TONGJI UNIV +1

Adjusting method for A/O biological denitrification reactor and nitrification process, its on-line fuzzy controller and control thereof

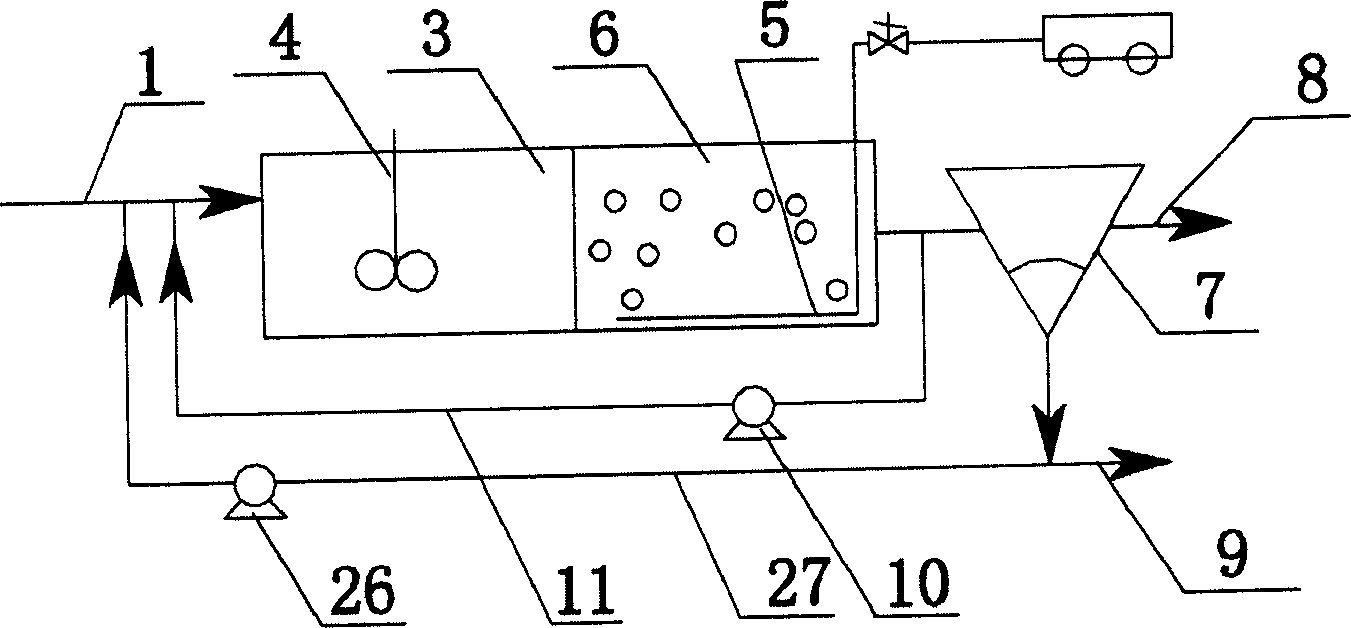

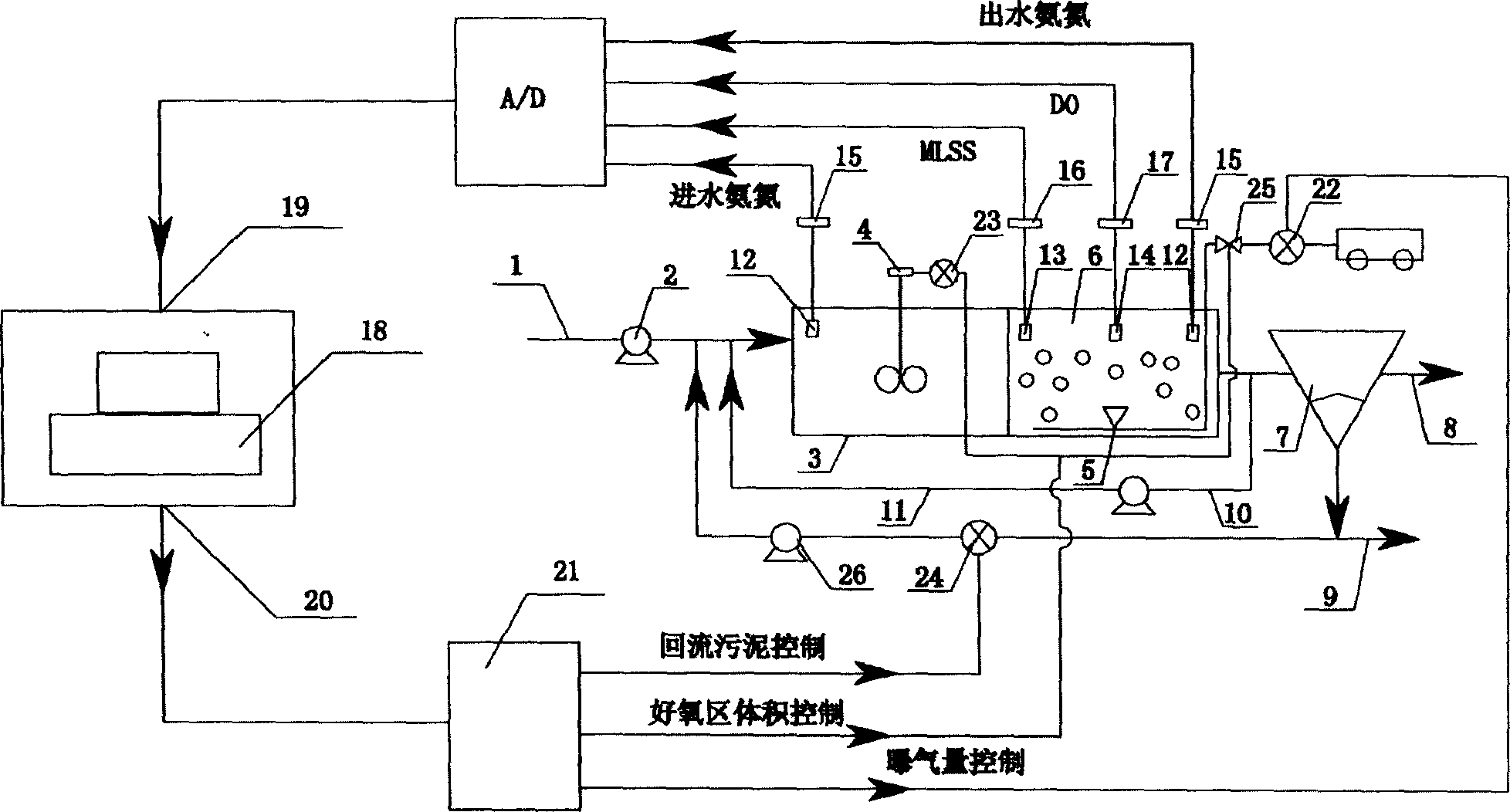

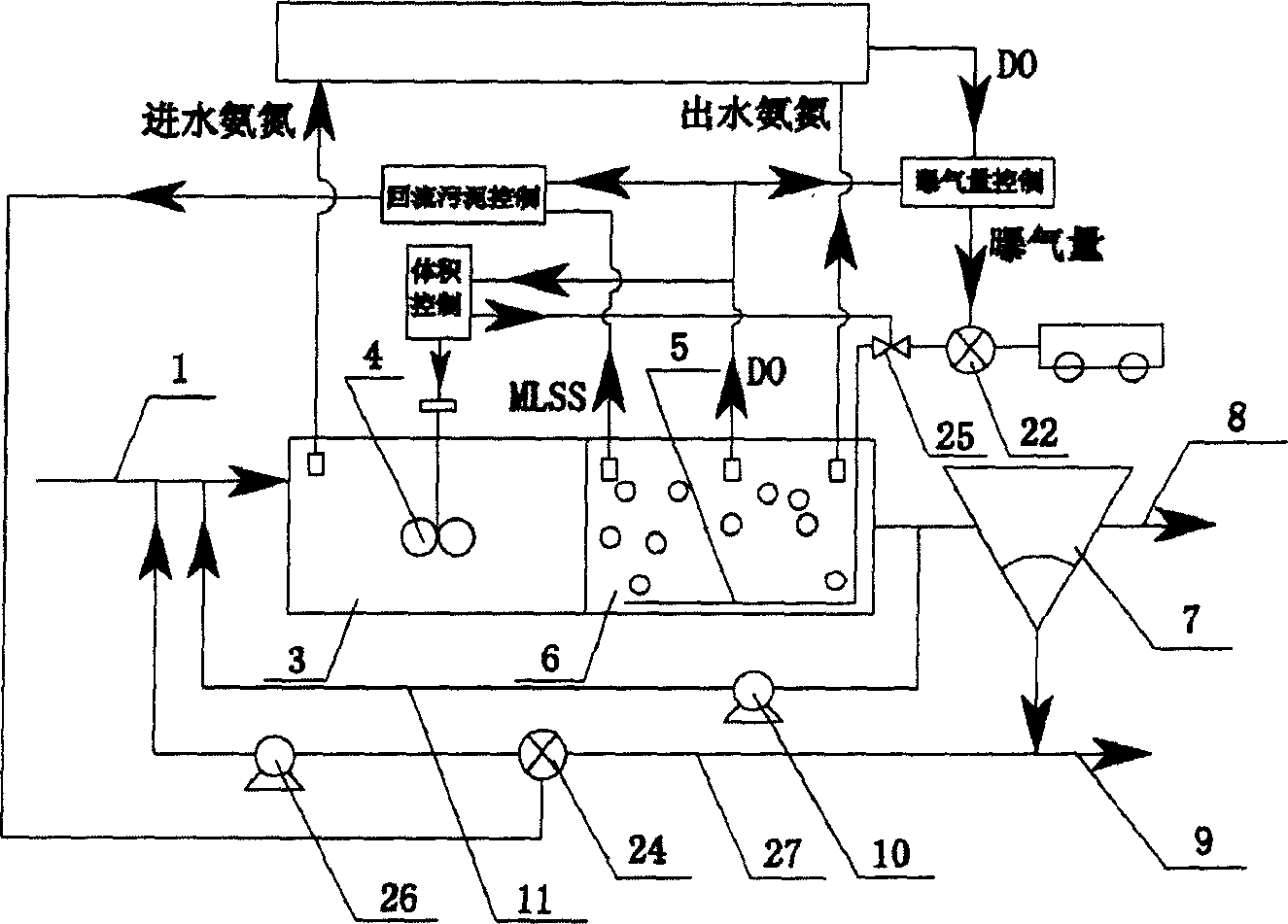

InactiveCN1778714ASave dosing costOrganic load reductionControlling ratio of multiple fluid flowsChemical variable controlSludgeMarine engineering

Owner:姚宏

Oxidative adsorbent for removing mercury from coal-burning flue gas

InactiveCN102553522AAchieving removal rateOther chemical processesDispersed particle separationSorbentSuspending Agents

The invention provides a preparation method of an oxidative adsorbent for removing mercury from coal-burning flue gas and an application condition thereof. The adsorbent is prepared by taking a mixture of montmorillonite and active carbon as a carrier, taking loaded copper chloride and manganese chloride as active ingredients and taking a mixed solution of water and acetone as a solution as well as a suspending agent through procedures including soaking, evaporative drying, baking, activating, grinding and the like. The adsorbent is used by injecting into flue gas of which the temperature is 60-340 DEG C. The preparation and use costs of the adsorbent are lower than those of an active carbon adsorbent, and over 85 percent of flue gas mercury removing rate can be reached.

Owner:四川清源环境工程有限公司

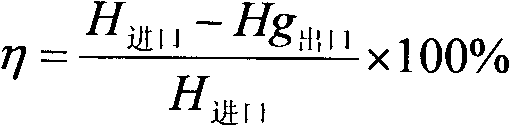

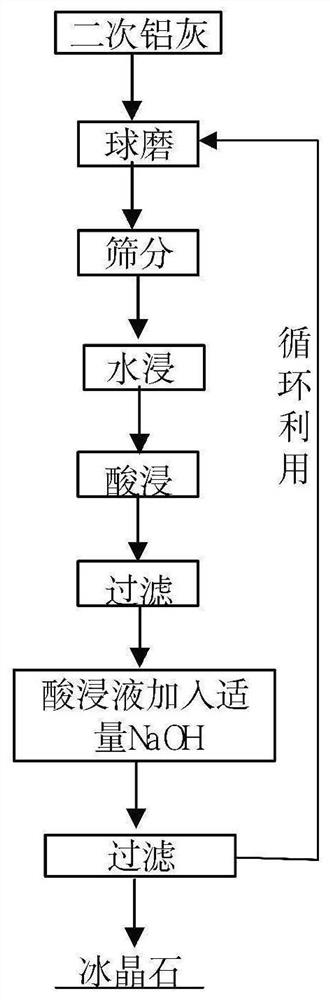

Method for defluorinating and preparing cryolite by secondary aluminum ash acid method

ActiveCN111333092AAchieving removal rateNo leaching toxicityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium fluoridesMetallic aluminumProcess engineering

The invention provides a method for defluorinating and preparing cryolite by a secondary aluminum ash acid method. The method comprises the following steps: carrying out ball milling on secondary aluminum ash, and screening to remove metal aluminum; taking the aluminum ash from which the metal aluminum is removed, adding water, heating and leaching; adding acid into the slurry subjected to water leaching for acid leaching; carrying out solid-liquid separation on the slurry subjected to acid leaching to obtain an acid leaching solution and acid leaching residues; mixing the acid leaching solution with NaF, and adjusting the pH value of the mixed solution to be neutral; heating and stirring the solution of which the pH value is adjusted, and then carrying out solid-liquid separation to obtain a cryolite product and residual liquid; and drying the obtained cryolite product to obtain a finished product, and returning the obtained residual liquid to the ball milling process for cyclic utilization. According to the method, harmless utilization of the secondary aluminum ash is achieved, recyclable products such as cryolite and high-purity aluminum oxide are produced, resource circulationis achieved, economic benefits of enterprises are improved, and the method has important practical significance and practical value.

Owner:CENT SOUTH UNIV +2

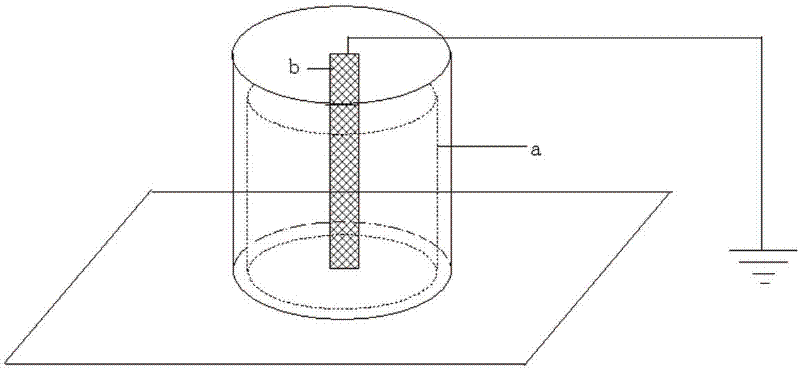

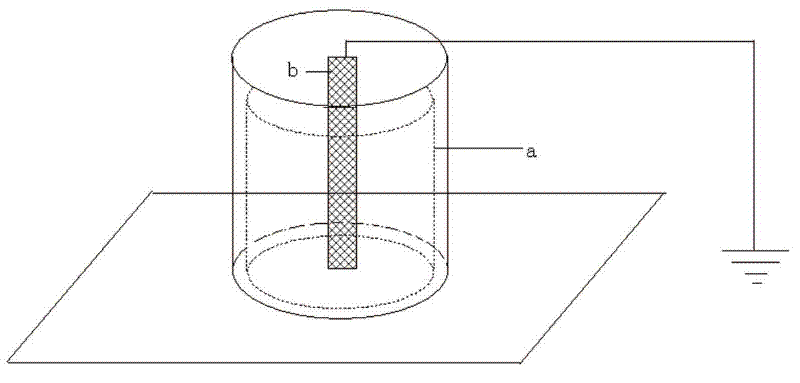

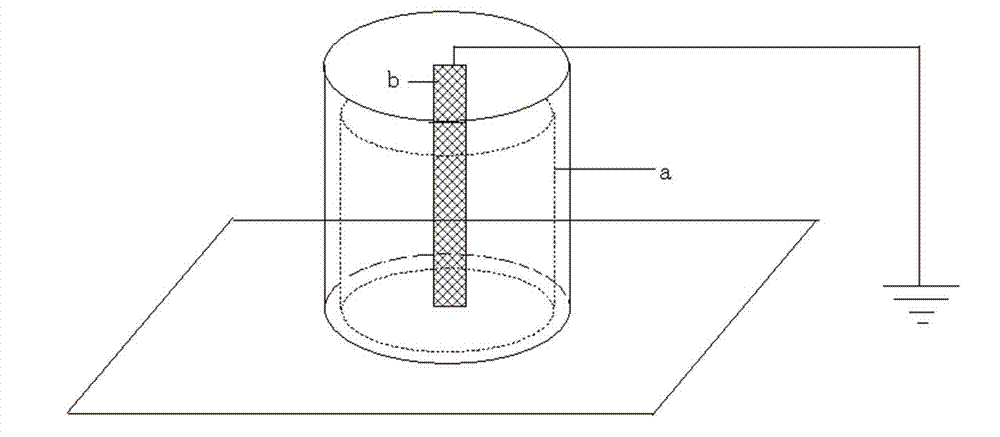

Method for preparing coal tar or coaltar pitch without quinoline insolubles

ActiveCN102229808AGood dispersionEasy to operateWorking-up pitch/asphalt/bitumenWorking-up tarDistillationQuinoline

The invention relates to a method for preparing coal tar or coaltar pitch without quinoline insolubles, comprising the following steps of: adding a solvent and a surfactant which can cause the quinoline insolubles to be positively charged into coal tar or coaltar pitch, placing a mixture into a container provided with an electrode, electrifying for 20-60 minutes under the conditions that the electric intensity is 7.5*10<4>-3.0*10<5>V / m and temperature is 10-90 DEG C, taking out the electrode adhered with sediments, and carrying out vacuum reduced pressure distillation on the coal tar or coaltar pitch in the container to remove the added solvent, thus coal tar or coaltar pitch without quinoline insolubles is obtained. The method provided by the invention has the characteristics of low energy consumption, mild conditions, simple process and environmental protection property and is easy for industrialization production.

Owner:宁夏鑫华威能源科技有限公司

Preparation method of special active carbon for adsorbing dioxin

ActiveCN103979536AReduce emission concentrationAchieving removal rateCarbon compoundsDispersed particle separationPotassium hydroxidePolyethylene glycol

The invention discloses a preparation method of special active carbon for adsorbing dioxin. The method disclosed by the invention comprises the steps of pre-oxidizing and carbonizing phenol formaldehyde resin to obtain a carbon precursor; mixing the carbon precursor, petroleum coke, polyethylene glycol and potassium hydroxide, wherein the alkaline-to-carbon ratio is 1-6; heating to 750-820 DEG C at the temperature rise speed of 10-30 DEG C / min; activating for 0.5-1.0h; cooling and drying to obtain active carbon with a high specific surface area. The special active carbon can be used for efficiently removing dioxin, realizing high removal rate (more than 92%) of dioxin in a waste incineration process and ensuring that the concentration of dioxin in the dioxin removed smoke is less than 0.1ngTEQ / Nm<3>; the preparation method has the advantages of simplicity in preparation, few process steps and high yield.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

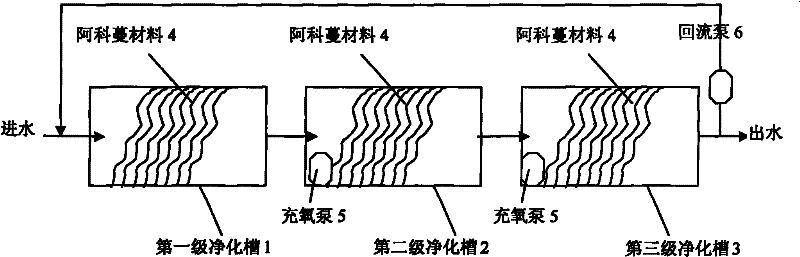

Stage purification method for black and odorous river water

InactiveCN102206016AEfficient removalGuaranteed uptimeWater/sewage treatment by irradiationTreatment with aerobic and anaerobic processesAmmoniacal nitrogenPurification methods

The invention provides a stage purification method for black and odorous river water. The method comprises the following steps: (1) carrying out first-stage preprocessing: adding photosynthetic bacteria and anaerobic ammonia oxidation bacteria in the black and odorous river water and enriching on surfaces of an Aquamats material to form biomembranes in natural light; (2) carrying out second-stageprocessing: adding sulfur-oxidizing bacteria in the black and odorous river water and enriching on the surfaces of the Aquamats material to carry out oxidation on sulphions and ferrousions under an aerobic condition; and (3) carrying out third-stage processing: adding nitrobacteria in the black and odorous river water and enriching on the surfaces of the Aquamats material to carry out nitration on ammonia nitrogen under the aerobic condition. The method has the advantages of high efficiency and stability of black and odorous river water purification, energy saving and low carbon.

Owner:EAST CHINA NORMAL UNIV

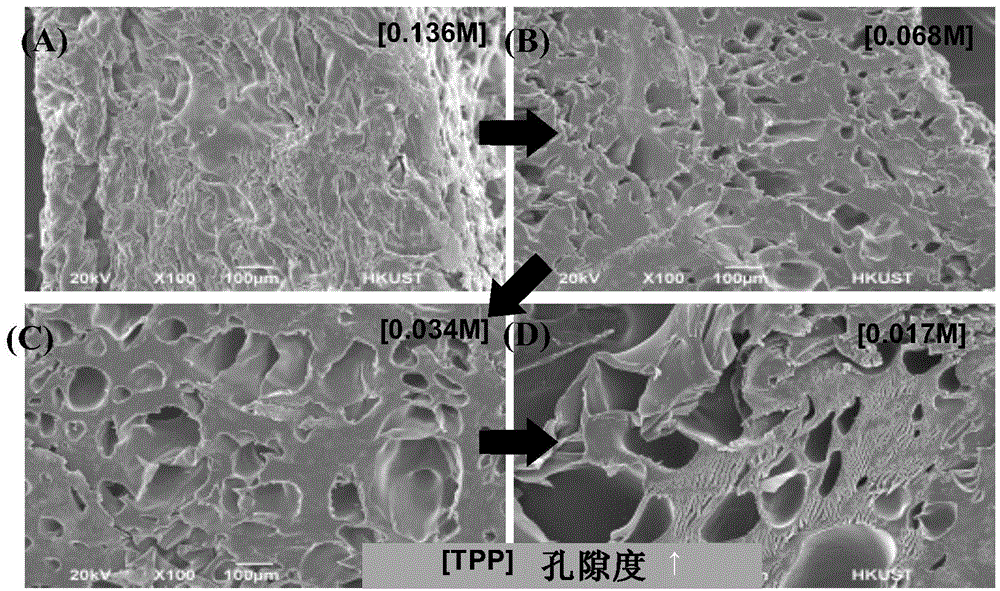

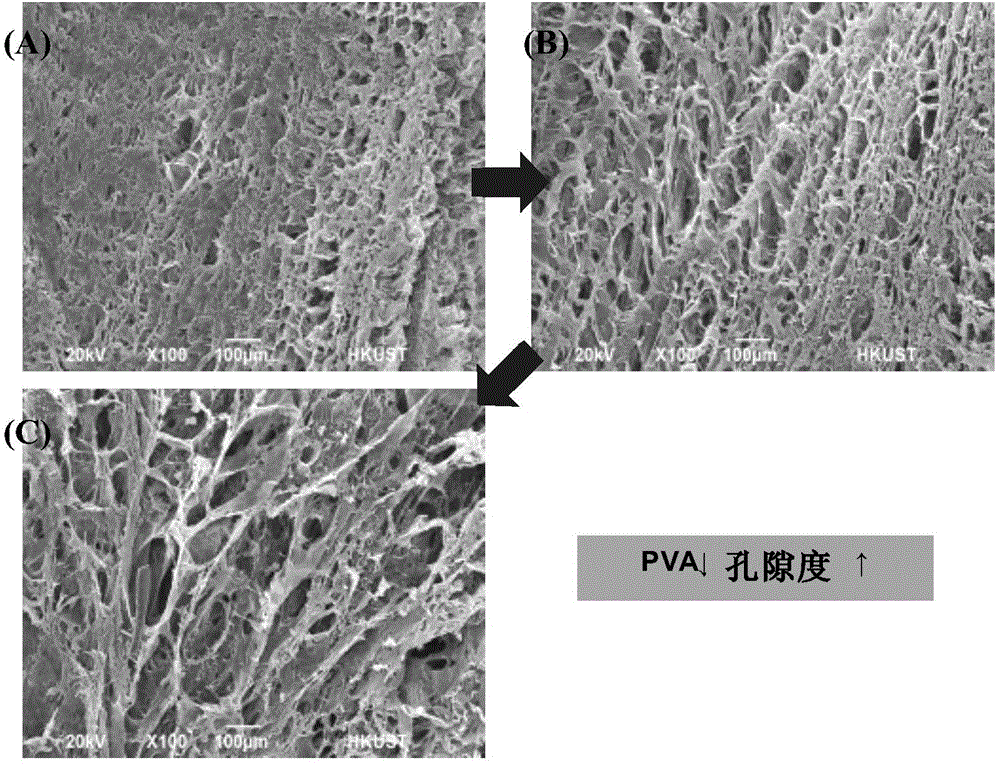

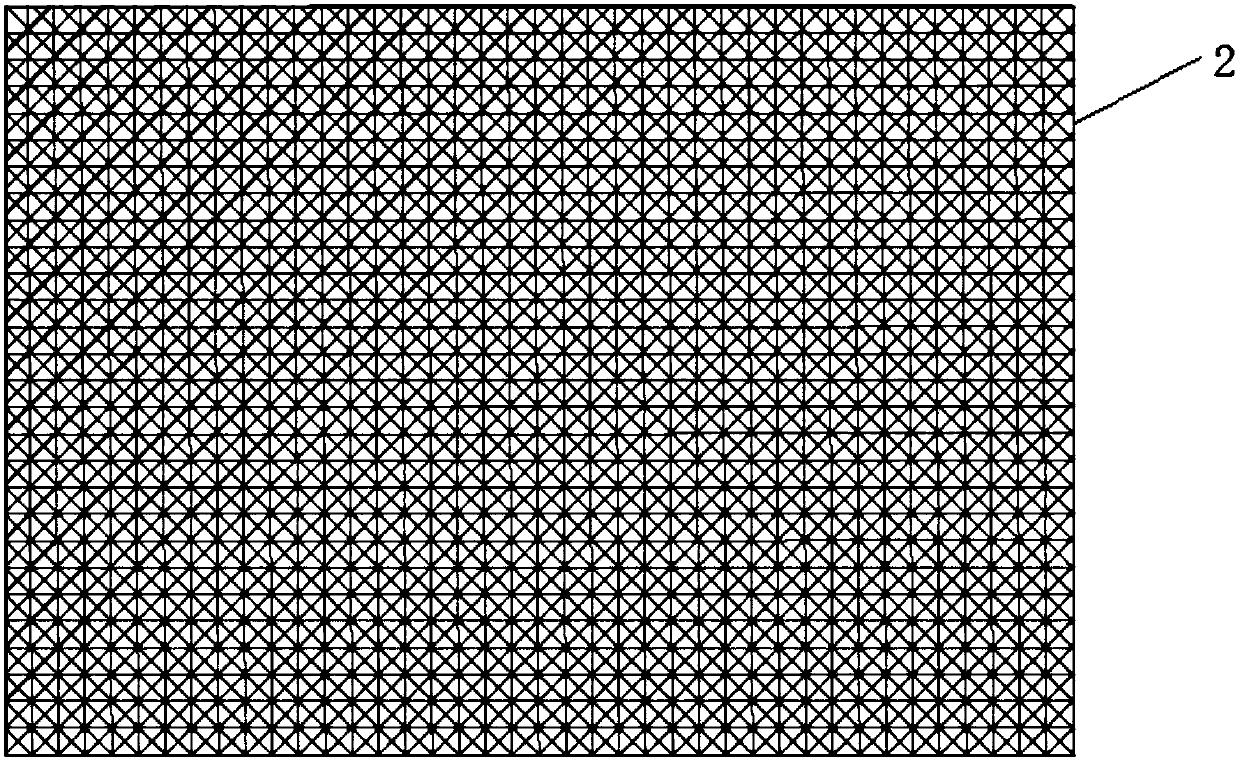

Chitosan based high performance filter with self-regenerating ability

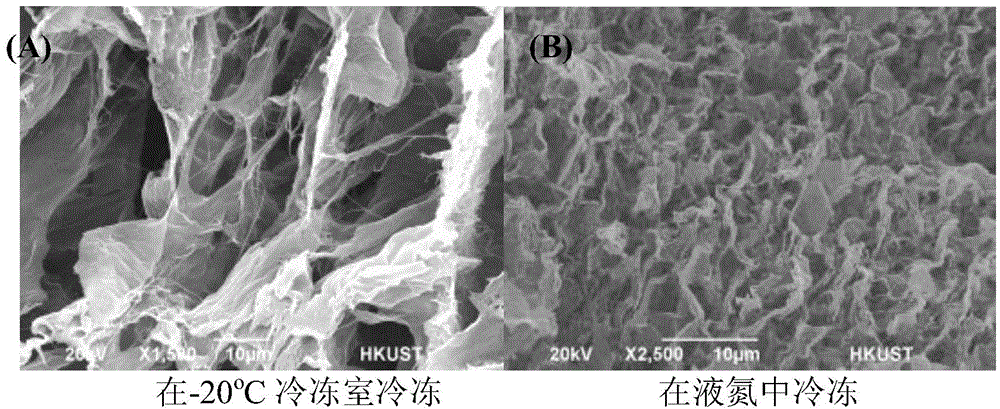

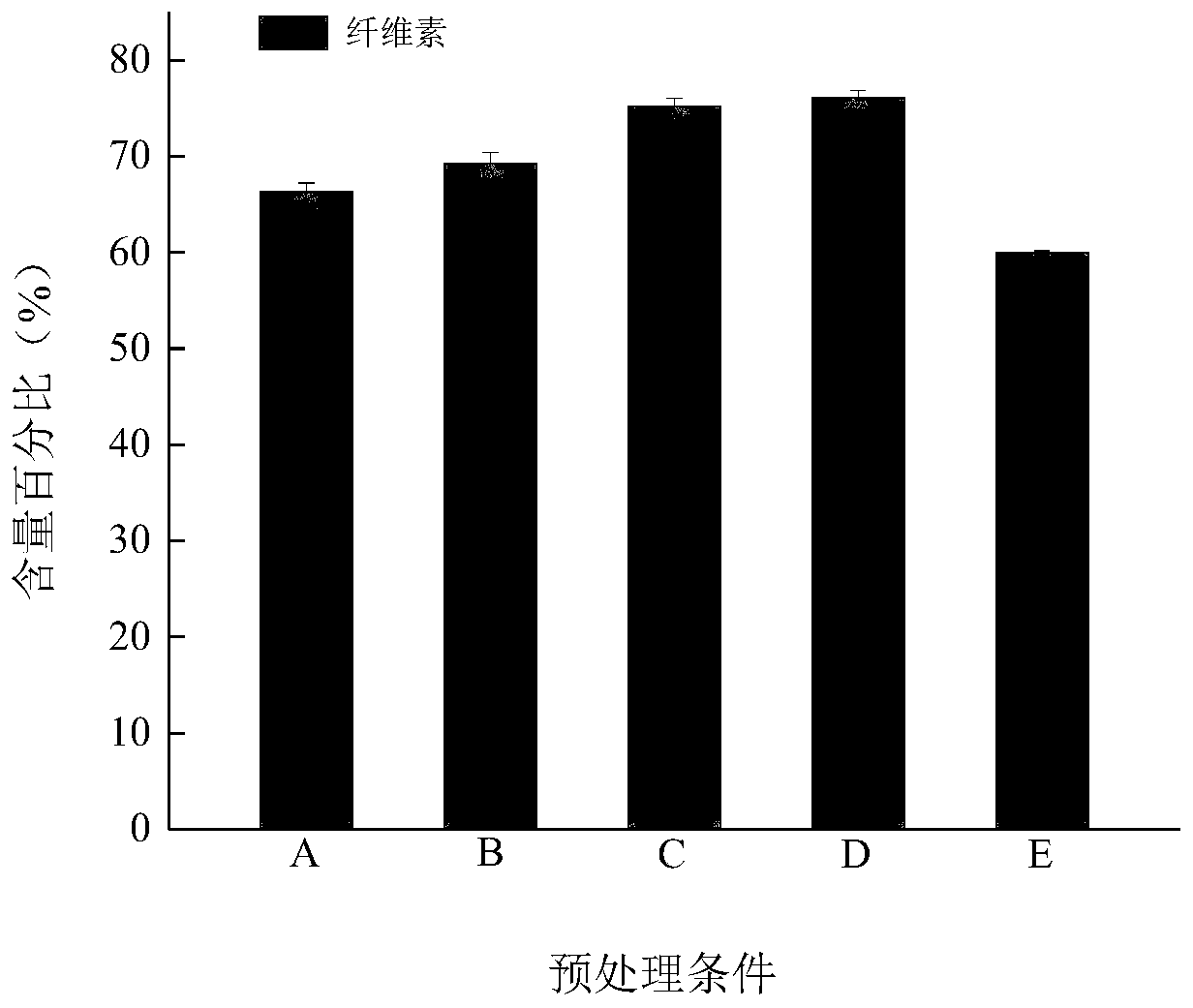

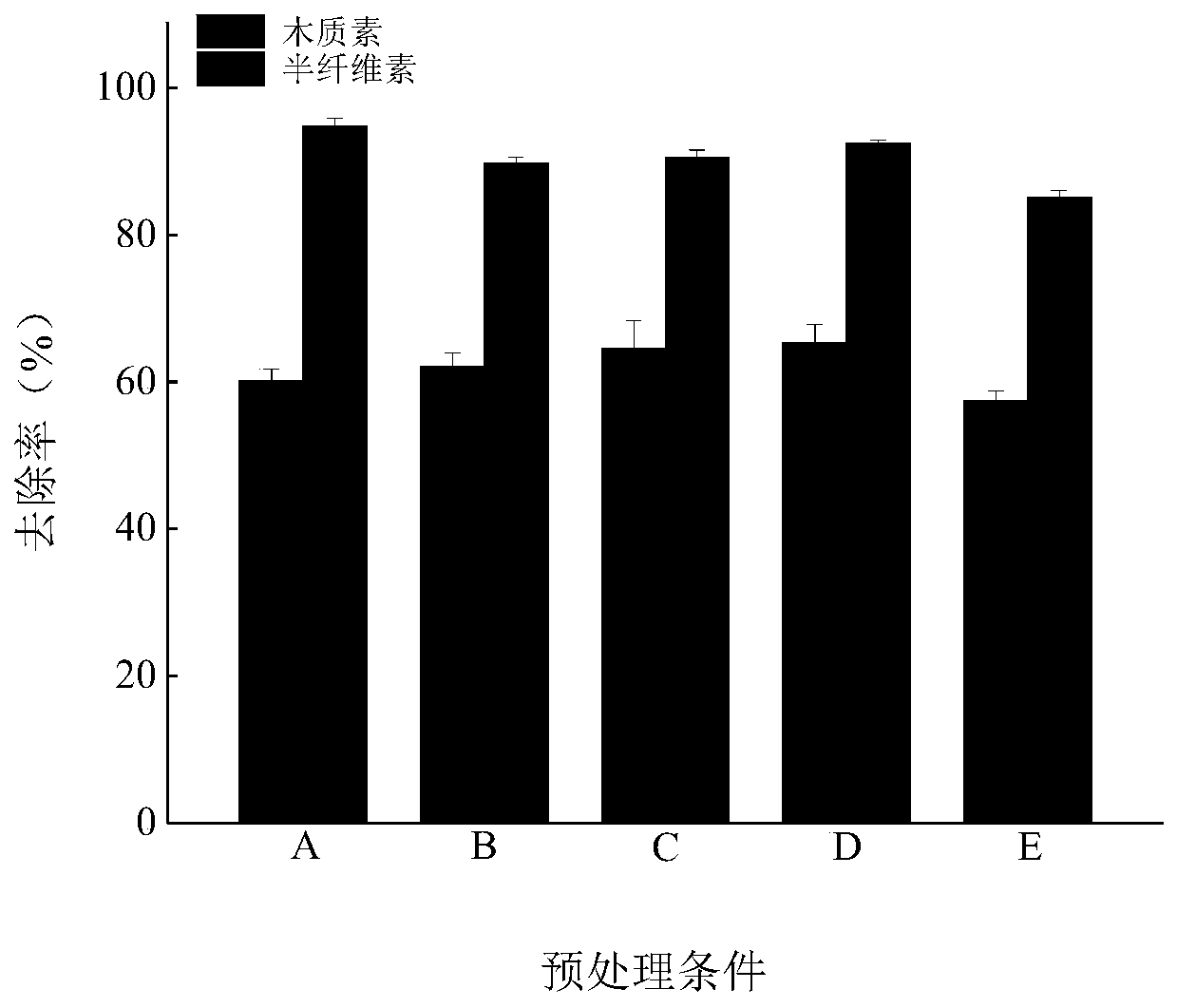

ActiveCN104548749AEfficient removalAchieving removal rateBiocideOrganic-compounds/hydrides/coordination-complexes catalystsFilter mediaCross linker

A self-regenerating chitosan based filter medium for disinfecting and purifying organic pollutants and other pollutants in a gas or liquid is disclosed herein. Porosity and surface charge of said filter medium is manipulative / tunable by varying one or more of the following parameter(s): concentration of chitosan, crosslinking density, amount of copolymers and additives, freezing temperature, freezing profile, and / or types of crosslinker used. The present filter medium is capable of self-regenerating under exposure to ultra-violet light for sufficient time and removing over 90% of the pollutants from each influent flowing through the filter medium.

Owner:NANO & ADVANCED MATERIALS INST

Method for dissociating corn stalks by utilizing ultrasonic microwave enhanced deep eutectic solvent

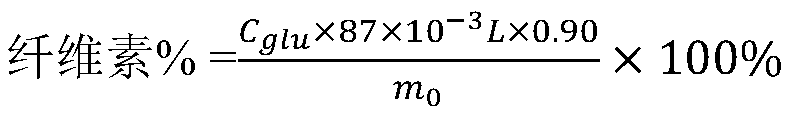

ActiveCN111321618ATo achieve the purpose of environmental protectionMeet the requirements of sustainable development of green chemistryPulping with organic compoundsOXALIC ACID DIHYDRATEGlycerol

The invention discloses a method for dissociating corn stalks by utilizing an ultrasonic microwave enhanced deep eutectic solvent, and belongs to the technical field of corn stalk component separation. The method comprises the following steps: synthesizing a deep eutectic solvent serving as a solvent by taking choline chloride, oxalic acid and glycerol as raw materials, mixing the deep eutectic solvent with corn stalks according to a certain proportion, putting the mixture into a multi-frequency combined ultrasonic emitter, processing the mixture in the ultrasonic emitter for a period of time,taking out the mixture, putting the mixture into a microwave digestion instrument to carry out digestion; after the reaction is finished, regenerating the corn stalks in the system, and measuring thecomponents. The constructed deep eutectic solvent is cheap, natural and pollution-free, and the selected ultrasonic microwave system not only has an outstanding effect, but also can realize the deconstruction of corn stalks under mild conditions. The method is a novel method for dissociating corn stalk components.

Owner:JIANGSU UNIV

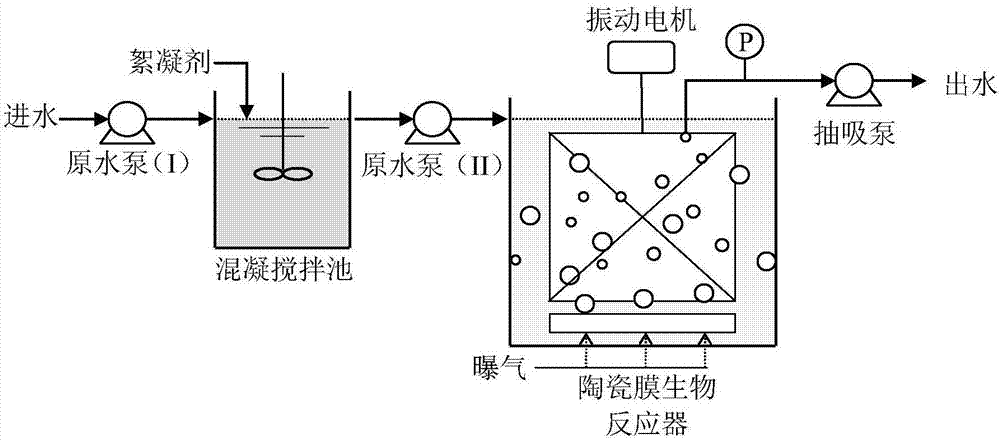

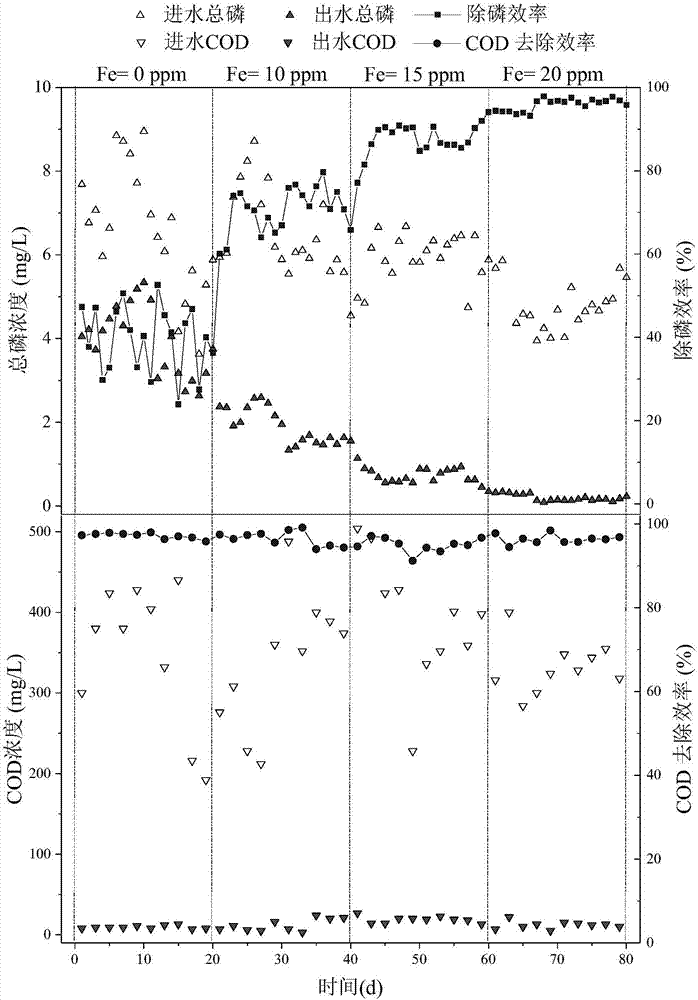

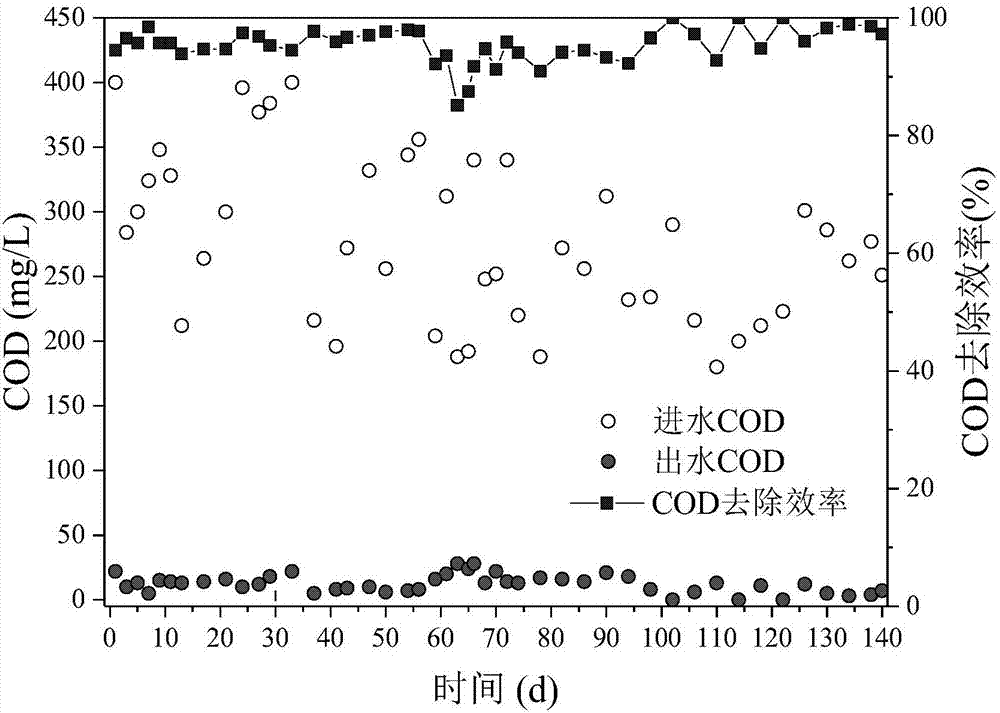

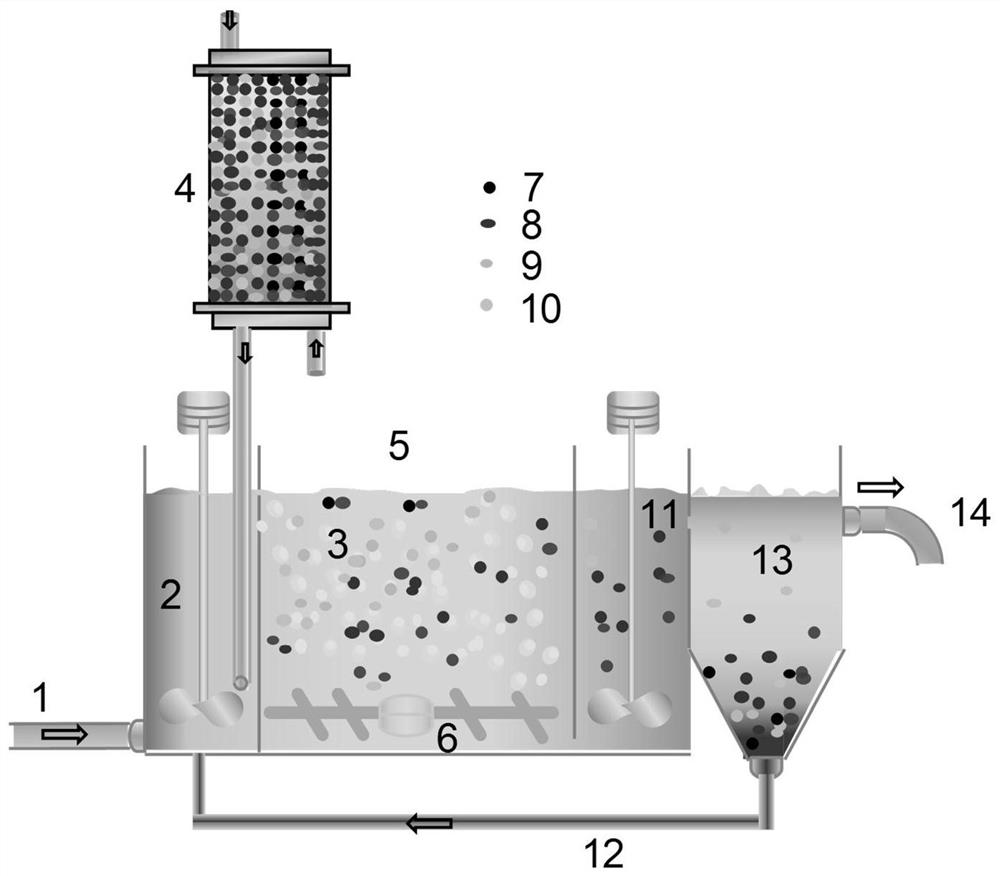

Vibrating flat plate ceramic membrane bioreactor technology for enhancing phosphorus removal, and sewage treatment system

InactiveCN107512823AAchieving removal rateMeet the process requirementsSemi-permeable membranesWater contaminantsMunicipal sewageEngineering

The invention is mainly applied to the technical field of municipal sewage treatment, and mainly relates to a vibrating flat plate ceramic membrane bioreactor technology for enhancing phosphorus removal, and a sewage treatment system and treatment method. The technology has excellent effects of sewage treatment and phosphorus removal. A membrane has the characteristics of long period of use, high anti-corrosion capability, good thermal stability, good stability of holes and the like. The device system involved by the technology has the advantages of small land occupation area, simple operation, high purification ability and wide application scope, and is suitable for various scales of sewage treatment systems.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

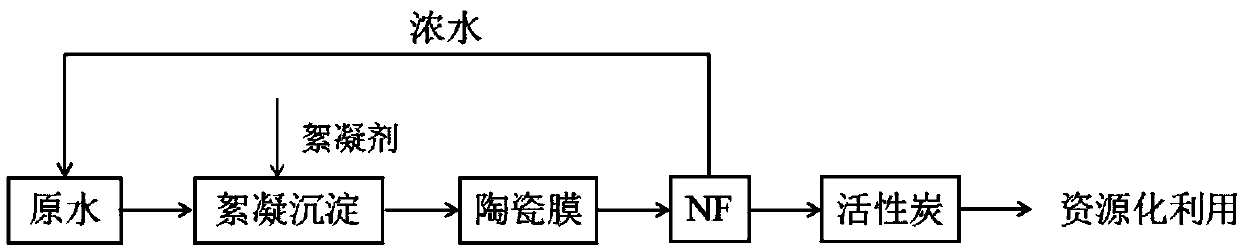

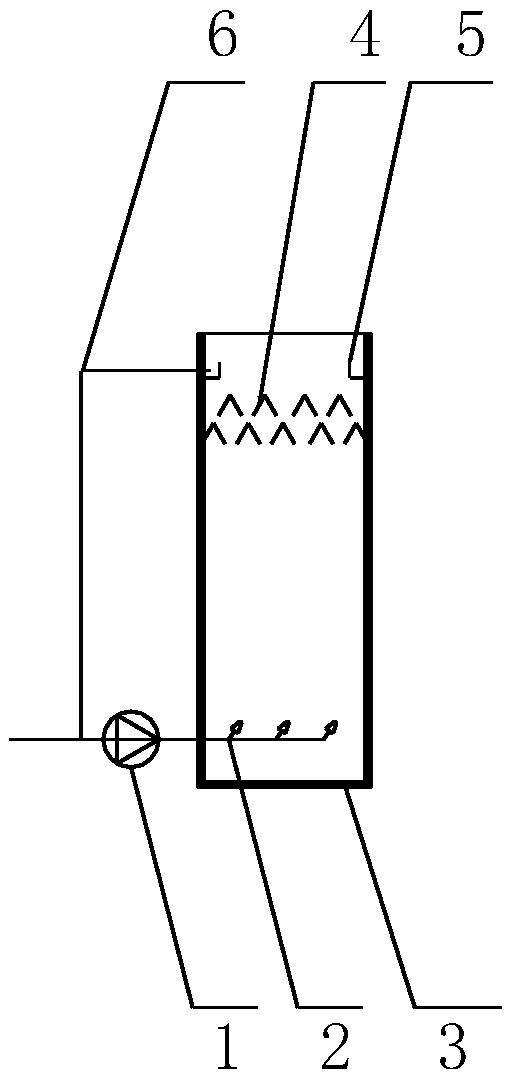

Hydrazine hydrate wastewater treatment device and technology thereof

PendingCN107721023ASolve the emission problemHigh removal rateSpecific water treatment objectivesWater/sewage treatment bu osmosis/dialysisActivated carbon filtrationSewage

The invention provides a hydrazine hydrate wastewater treatment device, and belongs to the technical field of wastewater or sewage treatment. The device comprises a raw water tank, a flocculent precipitate tank, a ceramic membrane filter, a nanofiltration filter and an active carbon filter, wherein a concentrated water pipe outlet of the nanofiltration filter is connected with the inlet of the rawwater tank; concentrated water is not discharged through overturn circulation and backflow circulation; the raw water tank, the flocculent precipitate tank, the ceramic membrane filter, the nanofiltration filter and the active carbon filter are all connected with a main drain. The invention further provides a treatment technology of the hydrazine hydrate wastewater treatment device. The hydrazinehydrate wastewater treatment device can solve negative effects, such as environmental pollution and ecological damage, by sewage of hydrazine hydrate factories, which is directly discharged, has goodsocial benefit, can further effectively solve key technical problem of hydrazine hydrate sewage treatment which restricts the development of hydrazine hydrate production enterprises, further expandsthe production capacity of the enterprises, saves energy, reduces environmental pollution, improves the labor productivity, improves the market competitiveness, and ensures that the enterprises becomeindustry leaders.

Owner:天津海泽惠科技发展有限公司

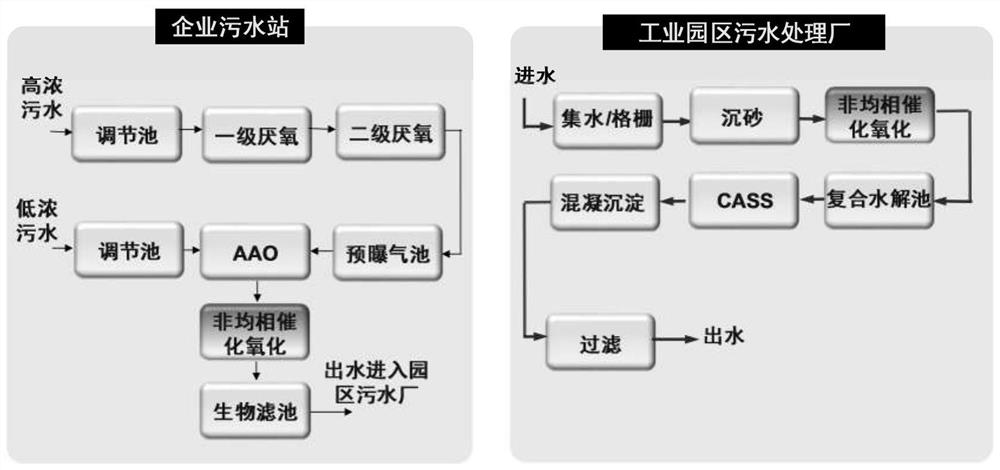

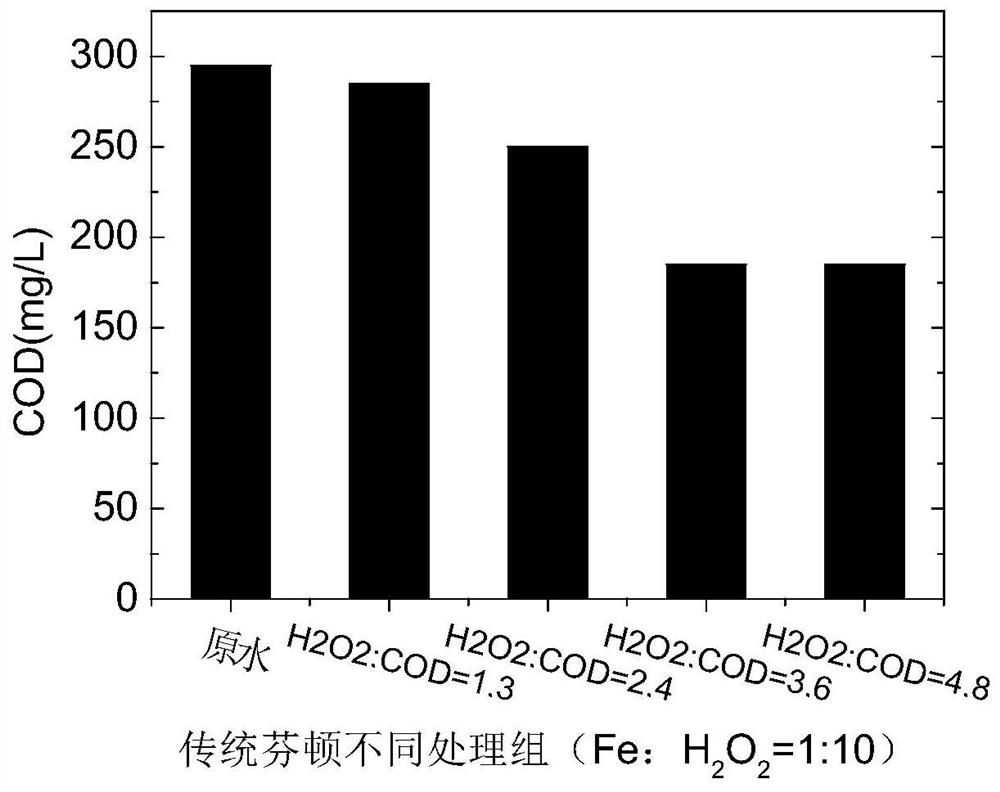

Catalytic oxidation purification device and method for high-chlorine degradation-resistant wastewater

PendingCN113003697AAchieving removal rateReduce usageWater treatment parameter controlWater treatment compoundsFlocculationPtru catalyst

The invention belongs to the technical field of wastewater purification, and particularly relates to a catalytic oxidation purification device and method for high-chlorine degradation-resistant wastewater. The device comprises a pH adjusting area, a main reaction area, a catalyst storage tank, a catalyst supplementing pipe, a pH callback flocculation area, a catalyst recycling pool and a catalyst backflow pipeline. The treatment method comprises the following steps: adding hydrogen peroxide into water to be treated to be acidic in the pH adjusting area, mixing the catalyst with the added hydrogen peroxide to react, adjusting the water to be slightly alkaline, carrying out self-flocculation and recovery on the catalyst, separating the catalyst from the treated water, and refluxing to the pH adjusting area to realize reuse. The method effectively realizes treatment of high-chlorine degradation-resistant wastewater, has the advantages of high removal efficiency, low operation cost, convenience in management and the like, and has a wide application prospect.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Method for preparing coal tar or coaltar pitch without quinoline insolubles

ActiveCN102229808BGood dispersionEasy to operateWorking-up pitch/asphalt/bitumenWorking-up tarDistillationQuinoline

Owner:宁夏鑫华威能源科技有限公司

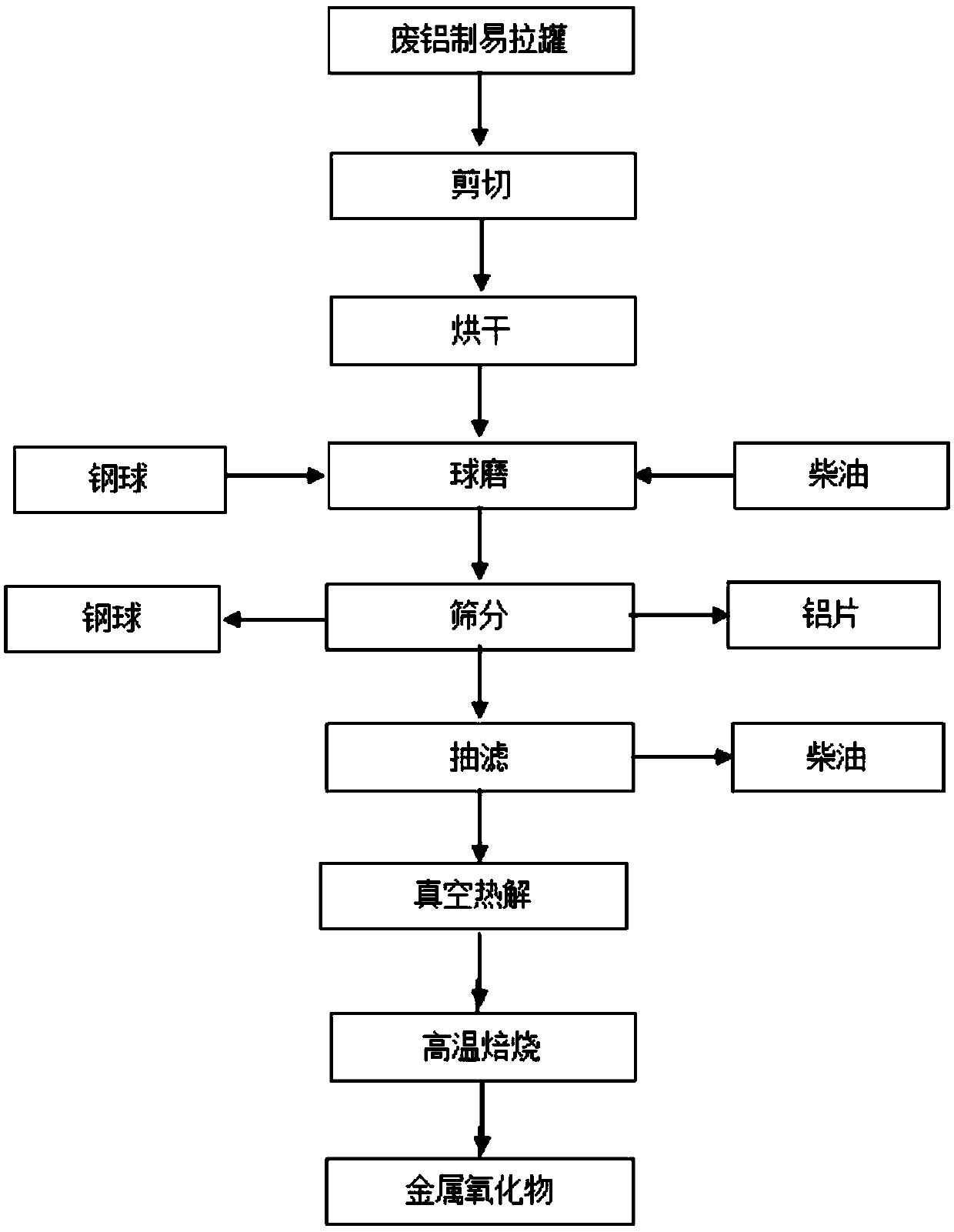

Recovery method for pop-tops made of waste aluminum

InactiveCN109097597AReduce aluminum lossImprove recycling efficiencyProcess efficiency improvementChemical industryMuffle furnace

The invention provides a recovery method for pop-tops made of waste aluminum. The recovery method comprises the following steps: firstly cutting out the pop-tops made of waste aluminum into aluminum pieces of which the area is 8-12cm<2> with a cutting machine, conveying the aluminum pieces into a drying machine, and removing water; performing ball milling on the aluminum pieces without water, steel balls and diesel fuel, and performing screening to obtain depainted aluminum pieces, steel balls and diesel fuel infiltrated with come-off paintcoats and aluminum powder; performing sucking filtration on the diesel fuel containing paintcoats and aluminum powder so as to obtain clean diesel fuel as a recycled material; performing vacuum pyrolysis on the paintcoats and the aluminum powder containing a little oil, and through condensation, collecting pyrolytic oil as an available fuel; and then conveying surplus pyrolysis residues in a muffle furnace, and performing high-temperature roasting treatment so as to obtain a mixed metallic oxide powder of which the main components include titanium dioxide and aluminum oxide. Due to the adoption of the recovery method disclosed by the invention, the stripping of the paintcoats of the pop-tops made of waste aluminum can be realized, organic resin and titanium dioxide in the paintcoats can be recovered, and a little scraped-away aluminum powdercan be converted into aluminium oxide to be used as chemical industry raw materials.

Owner:CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

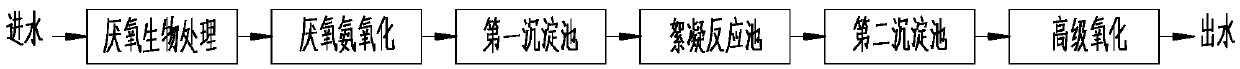

Anaerobic ammonia oxidation-based landfill leachate treatment device and use method thereof

ActiveCN105502811AAchieving "Zero Emissions"Achieve removalTreatment using aerobic processesWaste based fuelEmission standardPrecipitation

The invention relates to an anaerobic ammonia oxidation-based landfill leachate treatment device and a use method thereof. The device comprises a primary processing unit, a secondary processing unit and a tertiary processing unit which are connected in sequence through a pipeline system; the primary processing unit comprises a water inlet pump, a water distribution system, a first reactor, a three-phase separator, an effluent weir trough and an effluent return pipe; the secondary processing unit comprises a second reactor, a filler, an aerator and a first precipitation tank; the tertiary processing unit comprises a flocculation reaction tank, a second precipitation tank, a primary ozone-oxidation unit, a primary biological treatment unit, a secondary ozone-oxidation unit and a second biological treatment unit which are connected in sequence; the tertiary processing unit further comprises a flocculating agent adding device, an ozone generator, an ozone catalyst and an ozone aerator. The anaerobic ammonia oxidation-based landfill leachate treatment device has the advantages that the structure is simple, the design is reasonable, the wastewater treatment cost is low, an effluent can meet the national emission standards, and aeration energy consumption is reduced, so that zero emission of a landfill leachate is realized.

Owner:BEIJING DRAINAGE GRP CO LTD

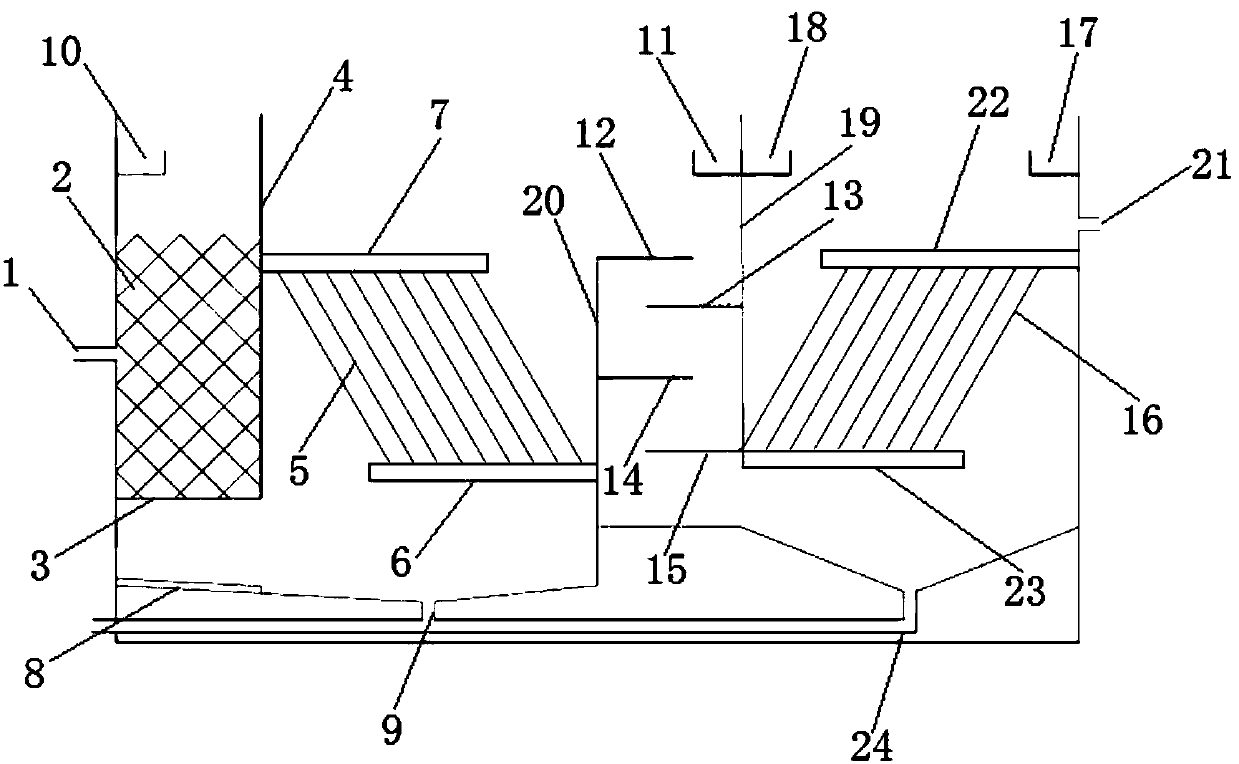

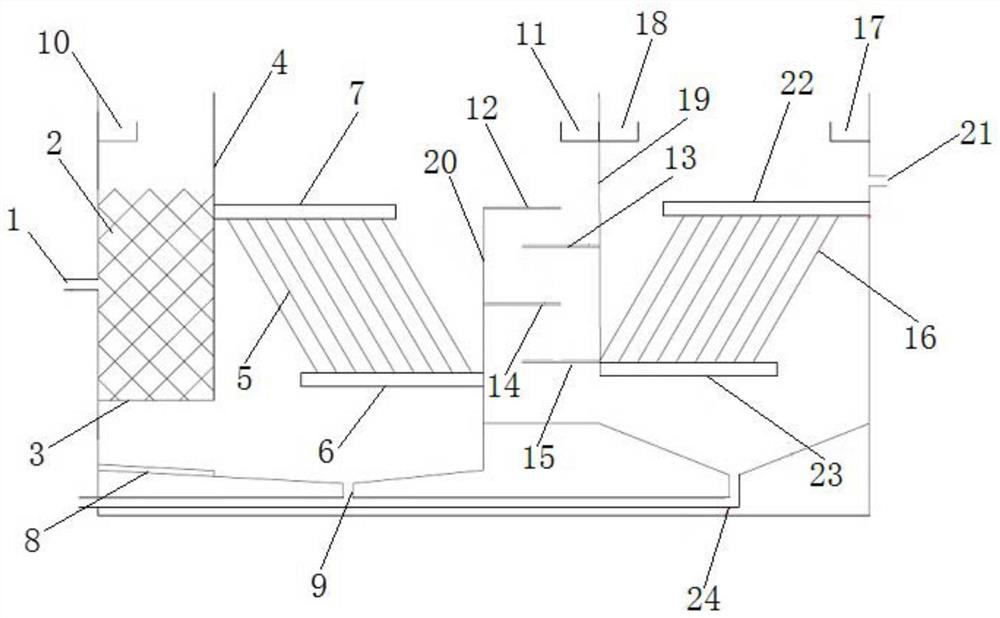

Oil-containing sewage treatment apparatus and oil-containing sewage treatment method

ActiveCN109553241AReduce drug costsReduced sludge productionWaste water treatment from quariesFatty/oily/floating substances removal devicesSewage treatmentSewage

The invention discloses an oil-containing sewage treatment apparatus and an oil-containing sewage treatment method. The oil-containing sewage treatment apparatus comprises a water inlet, a water outlet, an oil stain removal part and a suspended matter removal part, wherein the oil stain removal part comprises an oil stain aggregation unit and an oil stain inclination plate precipitation unit, a first baffle is arranged between the oil stain aggregation unit and the oil stain inclination plate precipitation unit, the suspended matter removal part comprises an electric flocculation unit, a suspended matter inclination plate sedimentation unit and a sludge sedimentation concentration unit, a second baffle is arranged between the electric flocculation unit and the suspended matter inclinationplate sedimentation unit, the sludge sedimentation concentration unit is arranged on the lower portion of the suspended matter inclination plate sedimentation unit, and a third baffle is arranged between the oil stain inclination plate precipitation unit and the electric flocculation unit. With the apparatus and the method of the present invention, the removal rate of oil and suspended matter in sewage can achieve more than 95% without the adding of agents.

Owner:CHINA PETROLEUM & CHEM CORP +1

Treatment method for leachate in garbage landfill

InactiveCN104341078AReduce leachate water volumeStrong resistance to shock loadsMultistage water/sewage treatmentRaw waterReduction rate

The invention discloses a treatment method for leachate in garbage landfill. According to the treatment method, in order to accelerate the stabilization of fresh garbage and simultaneously improve the biodegradability of leachate, the tail water can also be back-filled by virtue of an underdrain or in a spraying and flooding way so as to infiltrate into a fresh garbage landfill heap body and the effluent water is then back-filled by virtue of an underdrain to infiltrate into an old garbage heap body. The leachate raw water is simply precipitated by virtue of a precipitation tank and an underdrain back-filling engineering, the underdrain is formed by embedding pipes of which middles are provided with holes in gravel or sand, each pipe has the diameter of generally 100-200mm and a plurality of holes with aperture of 5-15mm are formed in both sides of each pipe. The pipes are embedded in a way that the holes of the pipes are aligned to the horizontal direction, gravel or sand is arranged at both sides of the pipes and soil-covering layers are arranged at the upper and lower parts of the pipes. According to climatic conditions and the concentration of leachate raw water, the back-filling hydraulic load is controlled, the height of garbage in each garbage landfill heap body is not less than 1m, the thickness of the surface covering soil is not less than 0.5 meter, generally 0.5-0.8 meter, and the cycle frequency or the number of stages in series connection is determined according to the removal rate of leachate contaminants or an evaporation reduction rate.

Owner:蒋寿悟

A device and method for treating oily sewage

ActiveCN109553241BAchieve removalLow costWaste water treatment from quariesFatty/oily/floating substances removal devicesSludgeElectro flocculation

The invention discloses an oily sewage treatment device and method. The device comprises: a water inlet, a water outlet, an oil stain removal part and a suspended matter removal part; wherein, the oil stain removal part includes an oil stain coalescing unit and an oil stain inclined plate precipitation unit , a first baffle is arranged between the oil pollution coalescing unit and the oil pollution sloping plate sedimentation unit; the suspended solids removal unit includes an electroflocculation unit, a suspended solids sloping plate settling unit and a sludge sedimentation concentration unit, the A second baffle is arranged between the electroflocculation unit and the suspended matter inclined plate settling unit, and the sludge settling and concentrating unit is arranged at the lower part of the suspended matter inclined plate settling unit; the oil pollution inclined plate settling unit and the A third baffle is arranged between the electrocoagulation units. The device and method provided by the invention can realize a removal rate of more than 95% of oil and suspended matter in sewage without adding chemicals.

Owner:CHINA PETROLEUM & CHEM CORP +1

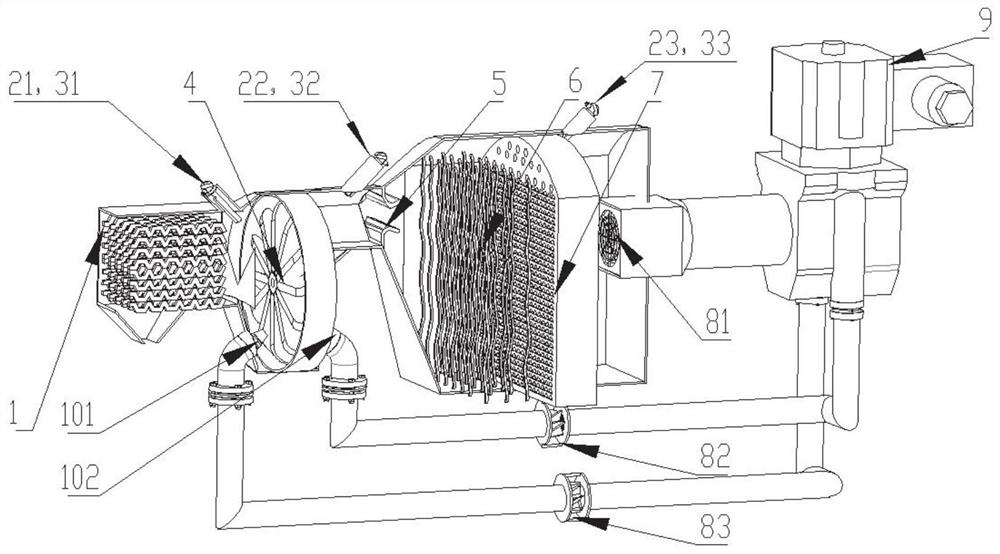

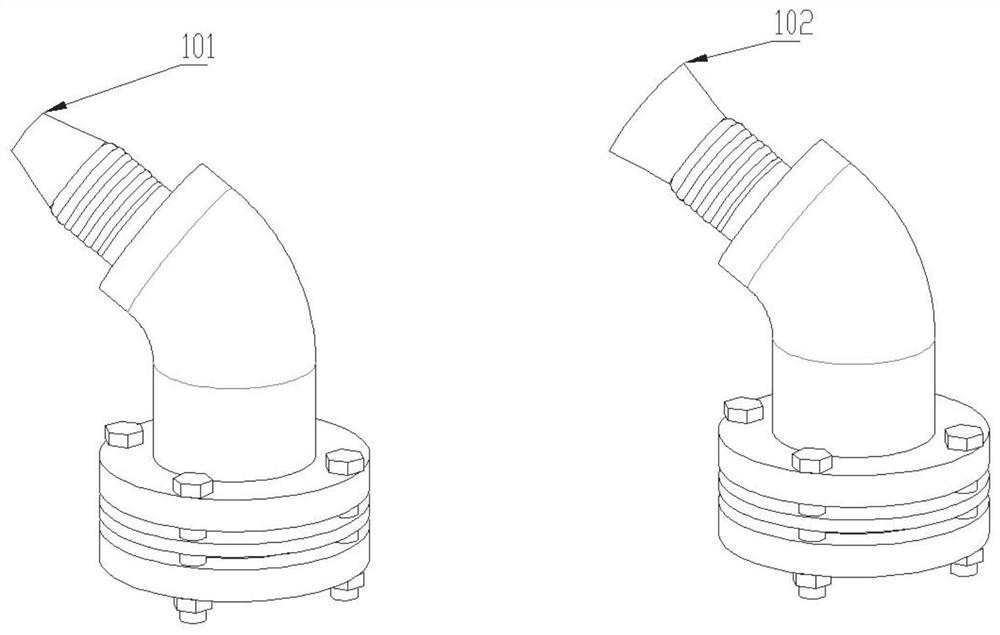

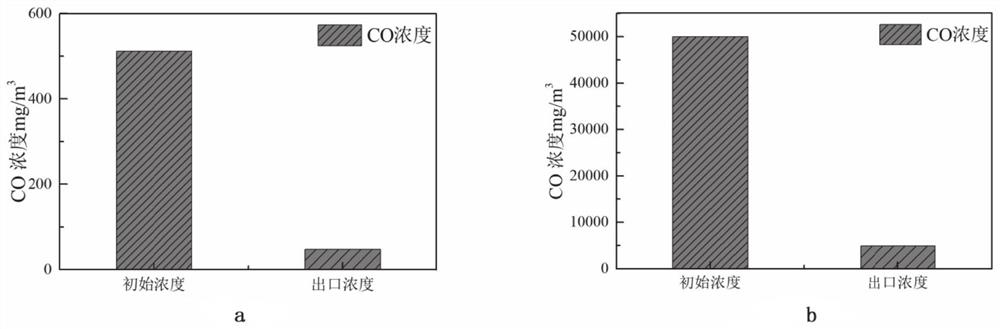

Catalyst, preparation method of catalyst, and flue gas CO removal-white smoke elimination system and method

ActiveCN112058274AIncrease temperatureEasy to cleanDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsThermodynamicsPtru catalyst

The invention provides a catalyst, a preparation method of the catalyst, a flue gas CO removal and white smoke elimination system and a flue gas CO removal and white smoke elimination method. The system comprises a demister, a dehumidification rotating wheel, an intelligent gas detection module, a flow guide module, a heating module, a catalytic oxidation module and a flue gas backflow module; thedemister is arranged at a flue gas inlet, and a dehumidification rotating wheel, a flow guide module, a flue gas heating module, a catalytic oxidation module and a flue gas backflow module are sequentially arranged on a flue of the dust remover. The system is located behind wet desulphurization, dry denitration or semi-dry desulphurization and in front of a chimney, the flue gas treatment processis not changed, the transformation degree is small, the spatial applicability is high, the energy consumption in the operation process is low, efficient CO removal and flue gas white elimination canbe completed automatically, and the operation cost is low. According to the system, the CO and CO2 concentration sensors are installed at the flue gas inlet and the flue gas outlet, whether the catalytic oxidation module works normally or not can be intelligently evaluated, meanwhile, the flue gas temperature in the system can be evaluated, and the white smoke eliminating effect is guaranteed.

Owner:SHANDONG UNIV

A kind of secondary aluminum lime acid method defluorination and the method for preparing cryolite

ActiveCN111333092BAchieving removal rateNo leaching toxicityAluminates/aluminium-oxide/aluminium-hydroxide purificationAluminium fluoridesMetallic aluminumPhysical chemistry

The invention provides a method for defluorinating and preparing cryolite by secondary aluminum ash acid method, comprising the following steps: ball milling and sieving secondary aluminum ash to remove metallic aluminum; taking the aluminum ash after removing metallic aluminum, adding water , heating leaching; adding acid to the slurry after water leaching for acid leaching; separating the solid and liquid from the slurry after acid leaching to obtain acid leaching solution and acid leaching residue; mixing the acid leaching solution with NaF to adjust the mixed The pH of the solution is neutral; the pH-adjusted solution is heated and stirred, and then solid-liquid separation is carried out to obtain cryolite products and raffinate; the obtained cryolite products are dried to obtain finished products, and the obtained raffinate is returned to the ball milling process for recycling. The invention realizes the harmless utilization of secondary aluminum ash, and produces reusable products such as cryolite and high-purity alumina, realizes resource recycling, improves the economic benefits of enterprises, and has important practical significance and practicality. value.

Owner:CENT SOUTH UNIV +2

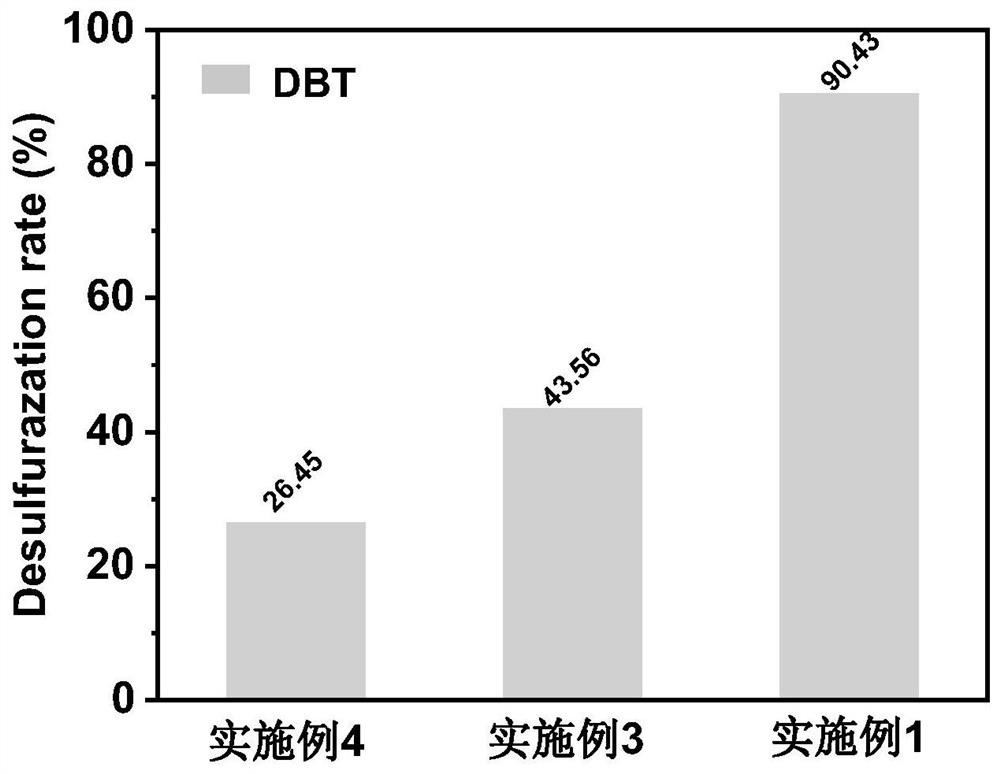

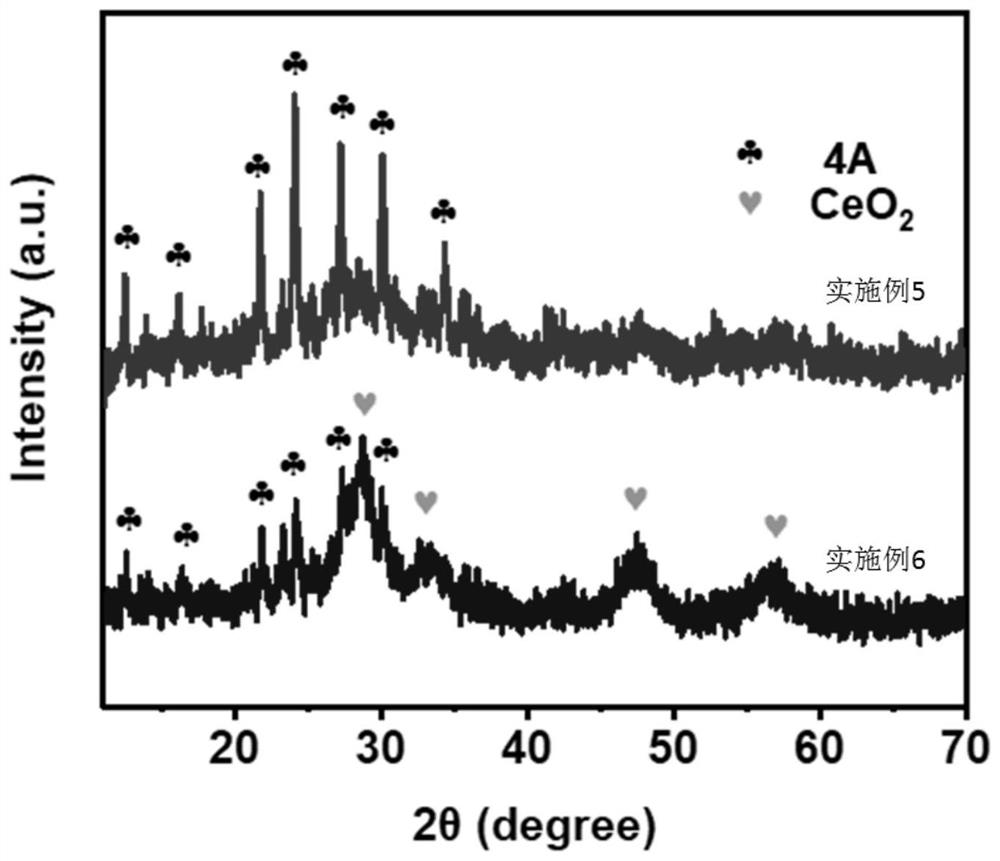

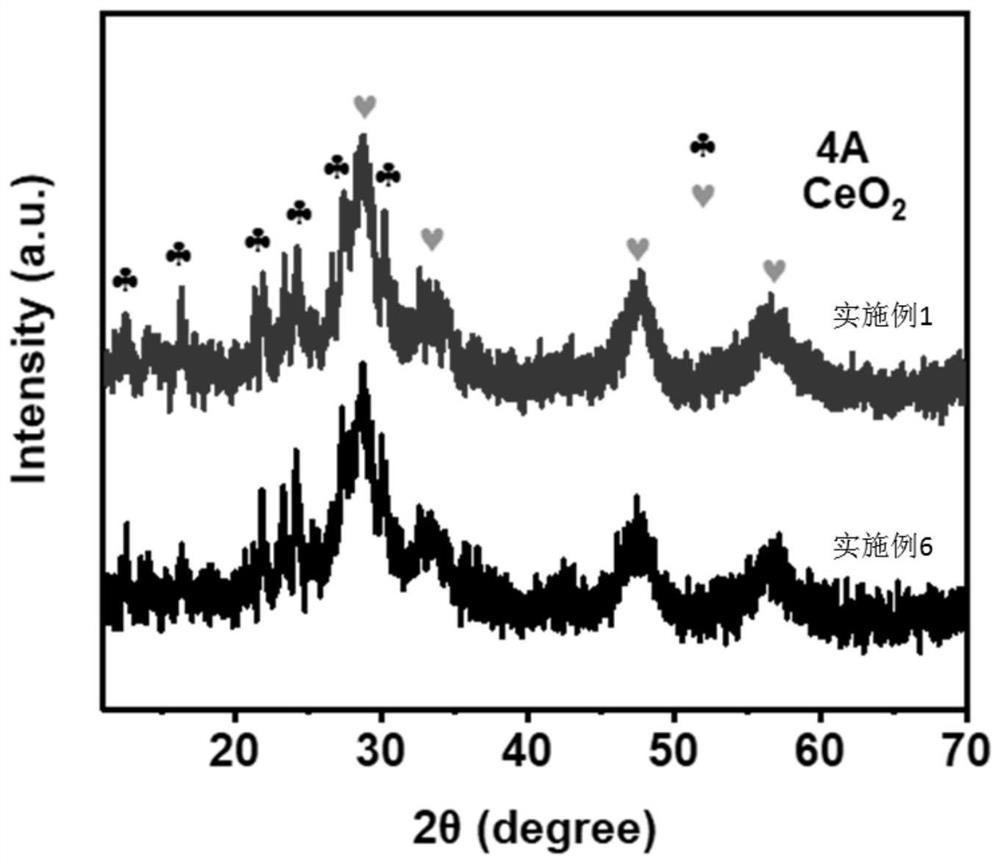

Copper-cerium double-metal modified 4A molecular sieve desulfurization adsorbent as well as preparation method and application thereof

ActiveCN112934173ASolve the steric hindrance effectGood adsorption and desulfurization performanceOther chemical processesHydrocarbon oils refiningMolecular sieveFuel oil

The invention relates to a copper-cerium double-metal modified 4A molecular sieve desulfurization adsorbent as well as a preparation method and application thereof. The adsorbent takes copper and cerium as active components and takes a 4A molecular sieve synthesized by kaolin as a carrier material. The method comprises the following steps: (1) preparing a copper source solution, carrying out copper impregnation modification on a 4A molecular sieve through a water bath, and calcining after centrifugal drying to obtain a copper modified molecular sieve; and (2) preparing a cerium source solution, performing cerium impregnation modification on the copper modified molecular sieve through a water bath, and calcining after centrifugal drying to obtain the copper-cerium double-metal modified 4A molecular sieve desulfurization adsorbent. The adsorbent is applied to the field of fuel oil deep desulfurization. Compared with the prior art, thedsorbent provided by the invention has the advantages of capability of realizing excellent desulfurization performance under normal temperature and normal pressure conditions, small influence on components in the fuel, high octane number, low investment, low operation cost, low energy consumption, high desulfurization rate and the like.

Owner:内蒙古包钢和发稀土有限公司 +1

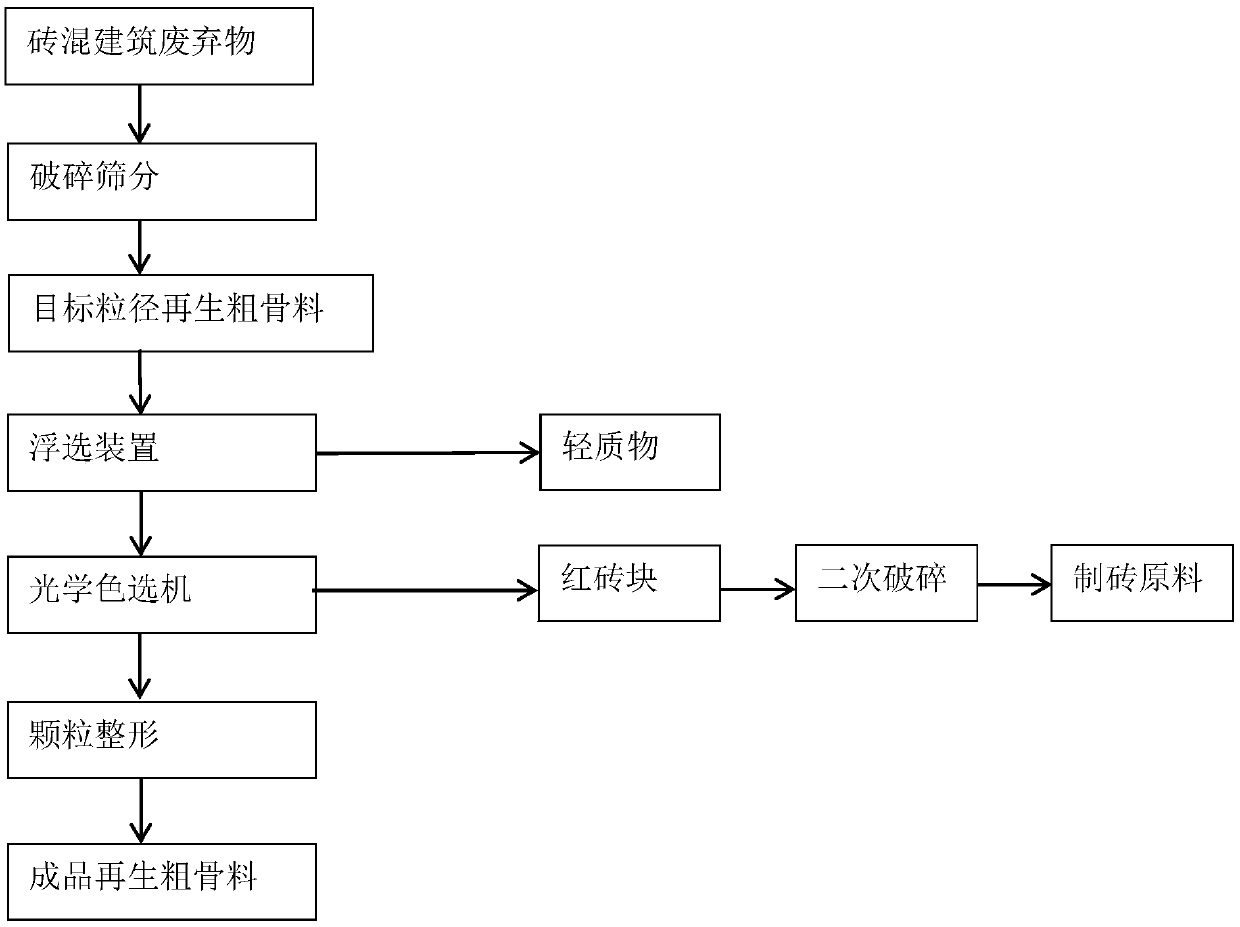

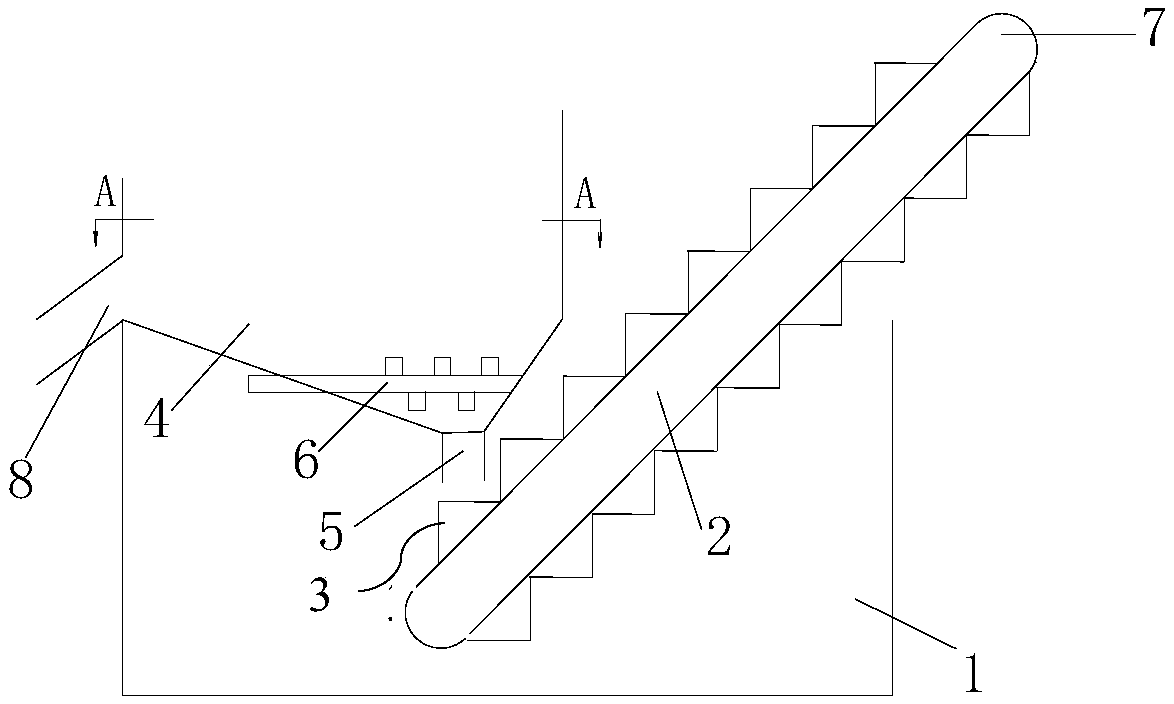

Brick-concrete building waste treatment technology

InactiveCN109604299AAchieving removal rateGuaranteed removal rateConstruction waste recoverySolid waste disposalBrickPrill

The invention relates to a brick-concrete building waste treatment technology which comprises the following steps of A, crushing brick-concrete building wastes, and performing sieving to obtain recycled coarse aggregates in a target particle size range; B, removing light matters in the recycled coarse aggregates through a flotation device; C, sorting and removing red bricks in the recycled coarseaggregates through an optical color selector; and D, shaping particles of the recycled coarse aggregates after removal of the red bricks by utilizing a particle shaping machine to obtain a finished recycled coarse aggregate product with a mellow and full particle shape, and removing mortar blocks and aerated blocks in the recycled coarse aggregates at the same time. In the brick-concrete buildingwaste treatment technology provided by the invention, the removal rate of the light matters is 95 percent or above, the removal rate of the low-intensity red bricks is 90 percent or above, removal ofthe low-intensity mortar blocks and aerated blocks can be realized, the high-quality recycled coarse aggregates, approaching natural aggregates, are acquired, breakthrough of the technical barrier ofpopularization and application of the recycled coarse aggregates of the building wastes is facilitated, and comprehensive utilization of building waste resources is promoted.

Owner:深圳市绿志新型建材研究院有限公司

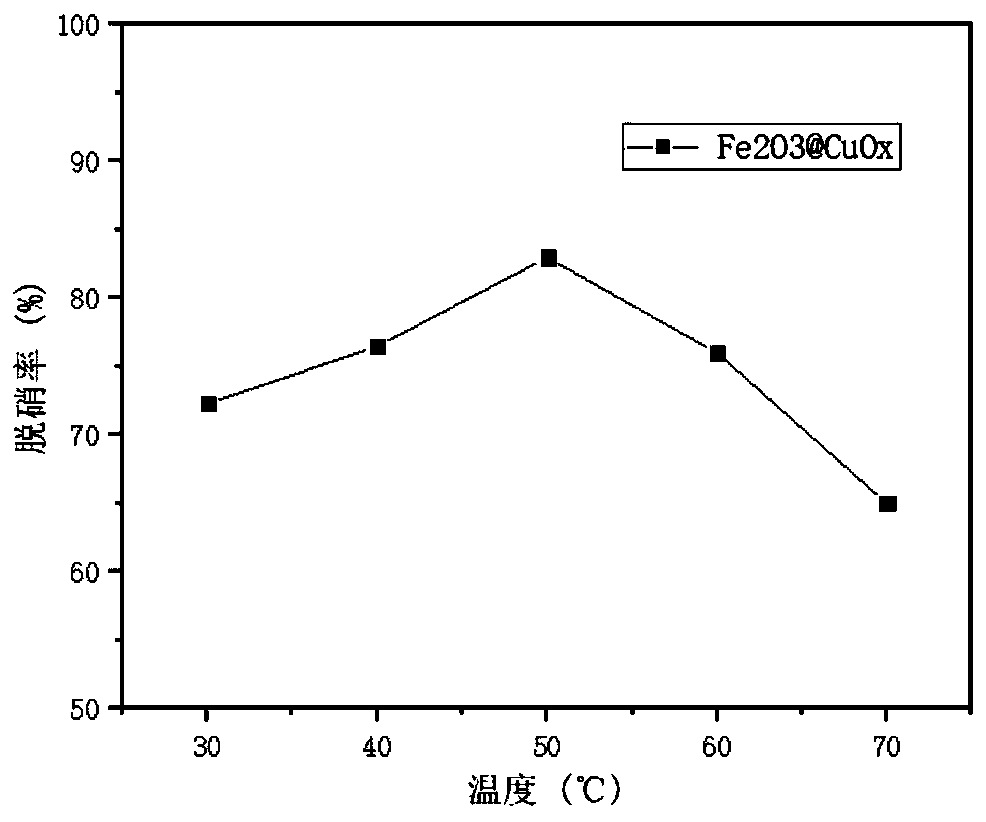

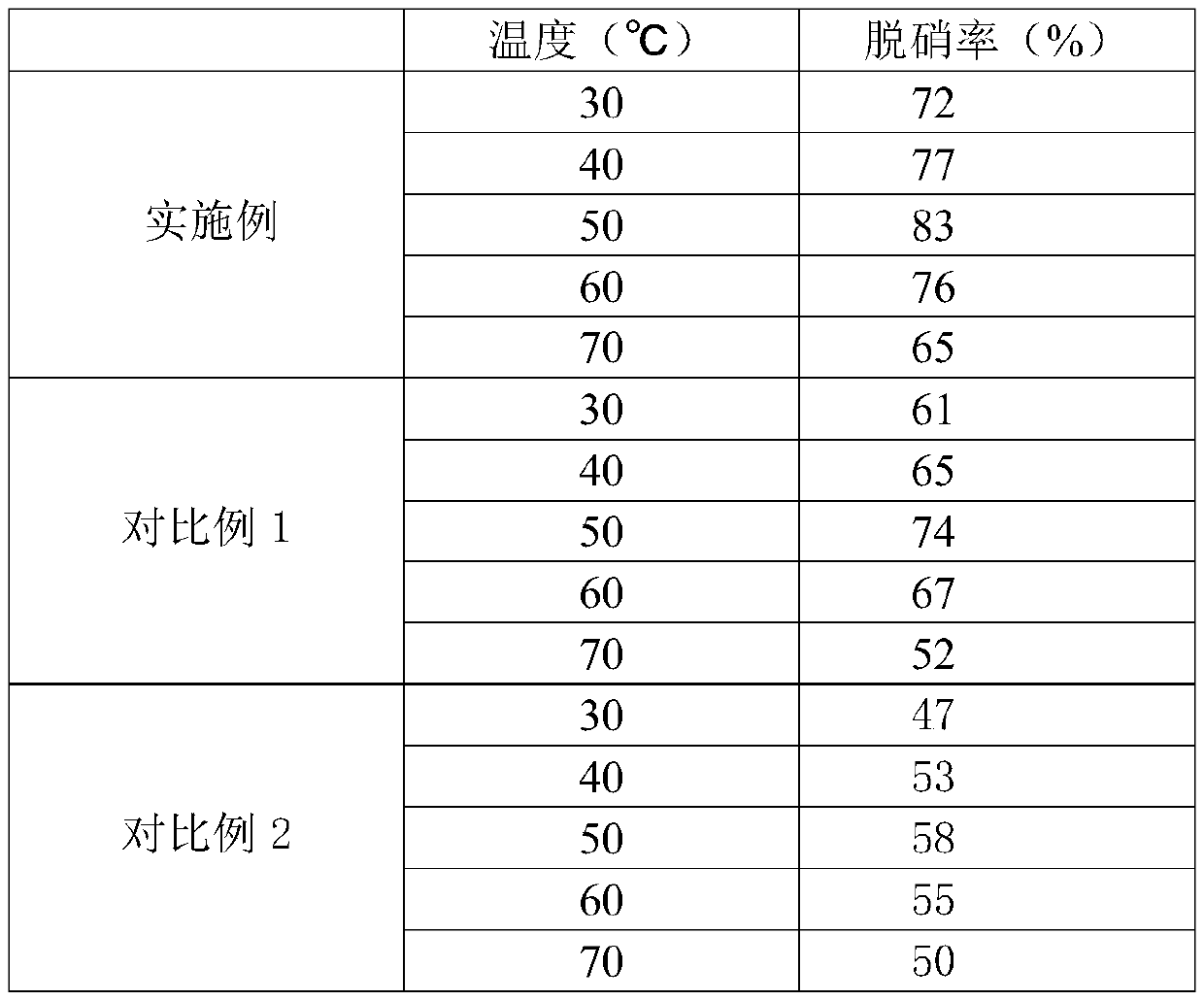

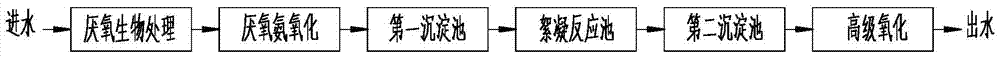

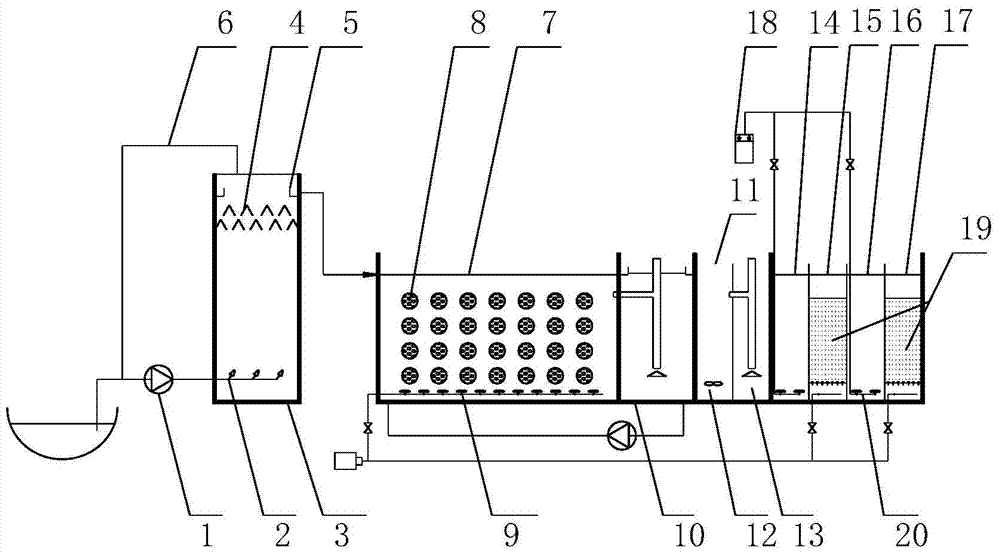

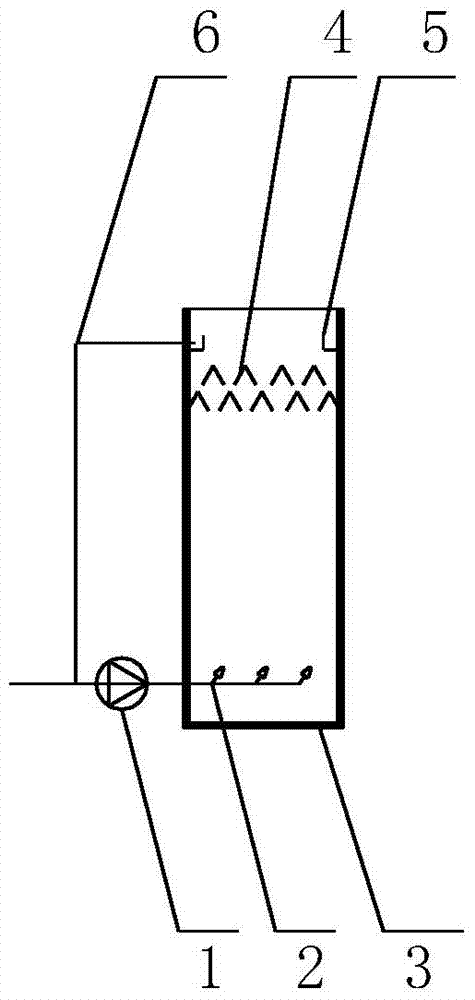

Catalyst for wet flue gas denitrification and application thereof

InactiveCN111203220AHigh catalytic activityAchieving removal rateGas treatmentDispersed particle separationPtru catalystFlue gas

The invention relates to a catalyst for wet flue gas denitrification and application thereof, and belongs to the field of chemical engineering. The active components of the composite catalyst for wetflue gas denitrification comprise ferric oxide and foamed copper oxide, and the mass ratio of ferric oxide to foamed copper oxide is (1.8-2.3):1. The catalyst for wet flue gas denitrification providedby the invention can maintain a denitrification rate of 75% or more at a temperature of 40-60 DEG C and a hydrogen peroxide concentration of 1.5 mol / L. The catalyst is relatively stable, has relatively high industrial utilization value, and can be widely applied to wet-process simultaneous desulfurization and denitrification in the future.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Landfill leachate treatment device based on anaerobic ammonium oxidation and its application method

ActiveCN105502811BAchieving "Zero Emissions"Achieve removalTreatment using aerobic processesWaste based fuelEmission standardPrecipitation

The invention relates to an anaerobic ammonia oxidation-based landfill leachate treatment device and a use method thereof. The device comprises a primary processing unit, a secondary processing unit and a tertiary processing unit which are connected in sequence through a pipeline system; the primary processing unit comprises a water inlet pump, a water distribution system, a first reactor, a three-phase separator, an effluent weir trough and an effluent return pipe; the secondary processing unit comprises a second reactor, a filler, an aerator and a first precipitation tank; the tertiary processing unit comprises a flocculation reaction tank, a second precipitation tank, a primary ozone-oxidation unit, a primary biological treatment unit, a secondary ozone-oxidation unit and a second biological treatment unit which are connected in sequence; the tertiary processing unit further comprises a flocculating agent adding device, an ozone generator, an ozone catalyst and an ozone aerator. The anaerobic ammonia oxidation-based landfill leachate treatment device has the advantages that the structure is simple, the design is reasonable, the wastewater treatment cost is low, an effluent can meet the national emission standards, and aeration energy consumption is reduced, so that zero emission of a landfill leachate is realized.

Owner:BEIJING DRAINAGE GRP CO LTD

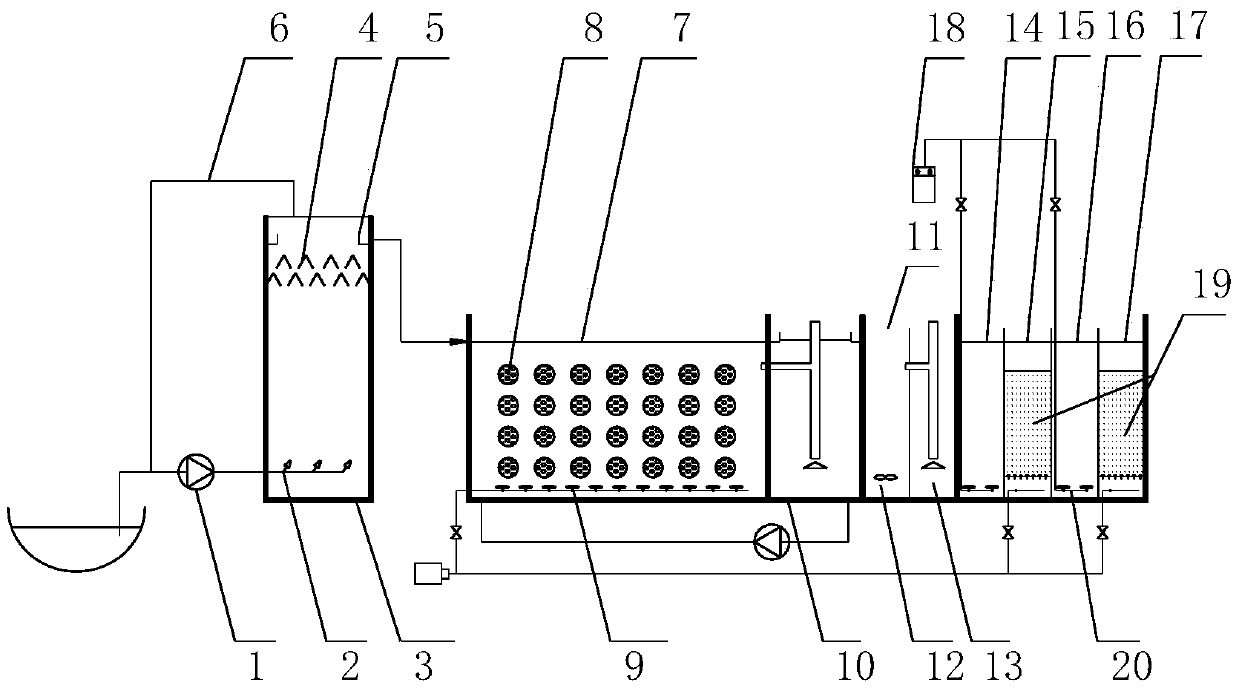

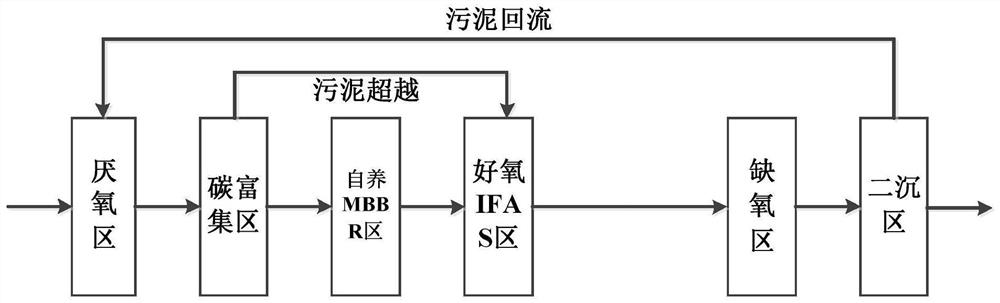

CANON-MBBR enhanced AOA water treatment method and system based on BFM form

ActiveCN114772730AReduce denitrification pressureReduce loadWater contaminantsTreatment with aerobic and anaerobic processesAmmoniacal nitrogenWater treatment system

The invention discloses a CANON-MBBR enhanced AOA water treatment method and a CANON-MBBR enhanced AOA water treatment system based on a BFM form, and belongs to the technical field of sewage treatment. The method comprises the following steps: sewage to be treated enters an anaerobic zone, and effluent of the anaerobic zone enters a carbon enrichment zone; supernate obtained in the carbon enrichment area enters the autotrophic MBBR area, and obtained sludge is discharged from an outlet end at the bottom of the carbon enrichment area and is conveyed to the aerobic IFAS area through a pipeline connected with a sludge overrunning pump; the effluent of the aerobic IFAS zone enters the anoxic zone, and the effluent of the anoxic zone enters the secondary sedimentation zone. The autotrophic MBBR area serves as a nitrification and denitrification main body, it is guaranteed that the ammoxidation rate is 80-90%, the aerobic IFAS area conducts targeted removal on a small amount of ammonia nitrogen carried by effluent of the autotrophic MBBR area and part of ammonia nitrogen caused by sludge exceeding, and the method has the advantages of being excellent in denitrification effect and nitrification effect, high in impact resistance, small in occupied area and the like.

Owner:QINGDAO SPRING WATER TREATMENT

A kind of preparation method of activated carbon special for dioxin adsorption

ActiveCN103979536BReduce emission concentrationAchieving removal rateCarbon compoundsDispersed particle separationActivated carbonPolyethylene glycol

The invention discloses a preparation method of special active carbon for adsorbing dioxin. The method disclosed by the invention comprises the steps of pre-oxidizing and carbonizing phenol formaldehyde resin to obtain a carbon precursor; mixing the carbon precursor, petroleum coke, polyethylene glycol and potassium hydroxide, wherein the alkaline-to-carbon ratio is 1-6; heating to 750-820 DEG C at the temperature rise speed of 10-30 DEG C / min; activating for 0.5-1.0h; cooling and drying to obtain active carbon with a high specific surface area. The special active carbon can be used for efficiently removing dioxin, realizing high removal rate (more than 92%) of dioxin in a waste incineration process and ensuring that the concentration of dioxin in the dioxin removed smoke is less than 0.1ngTEQ / Nm<3>; the preparation method has the advantages of simplicity in preparation, few process steps and high yield.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

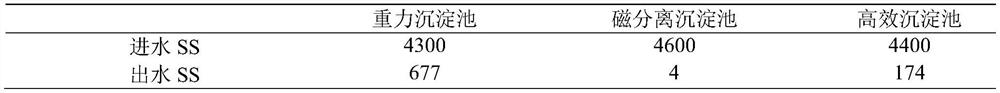

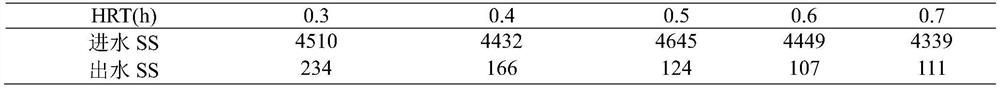

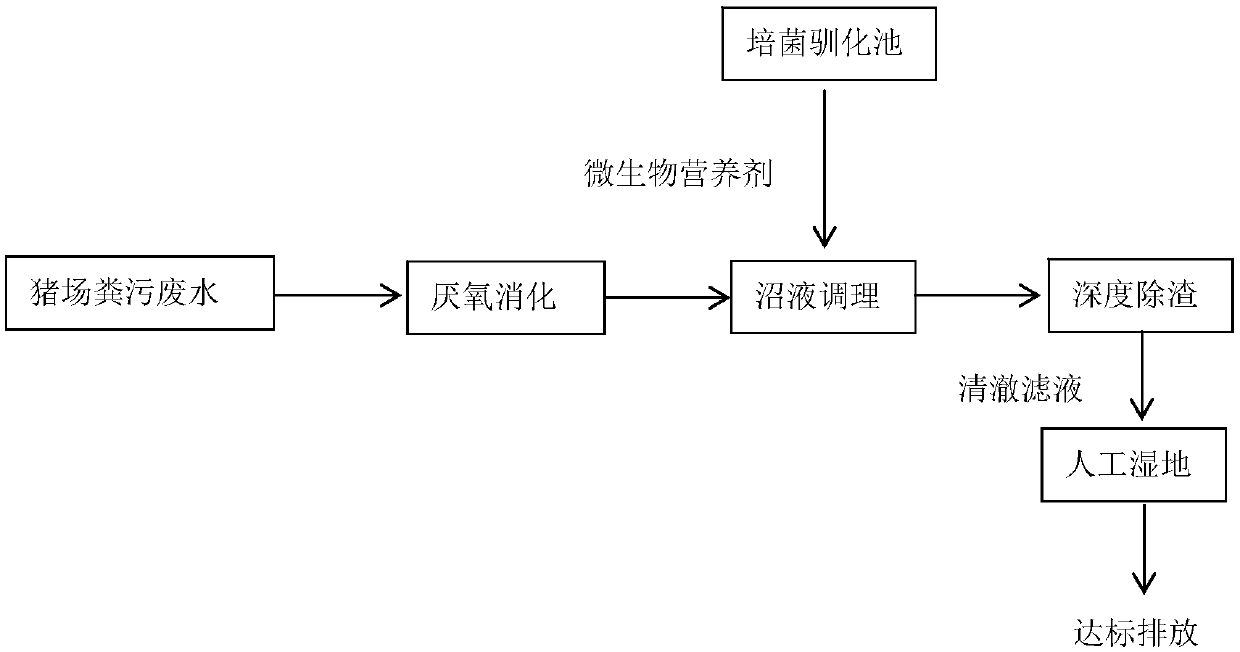

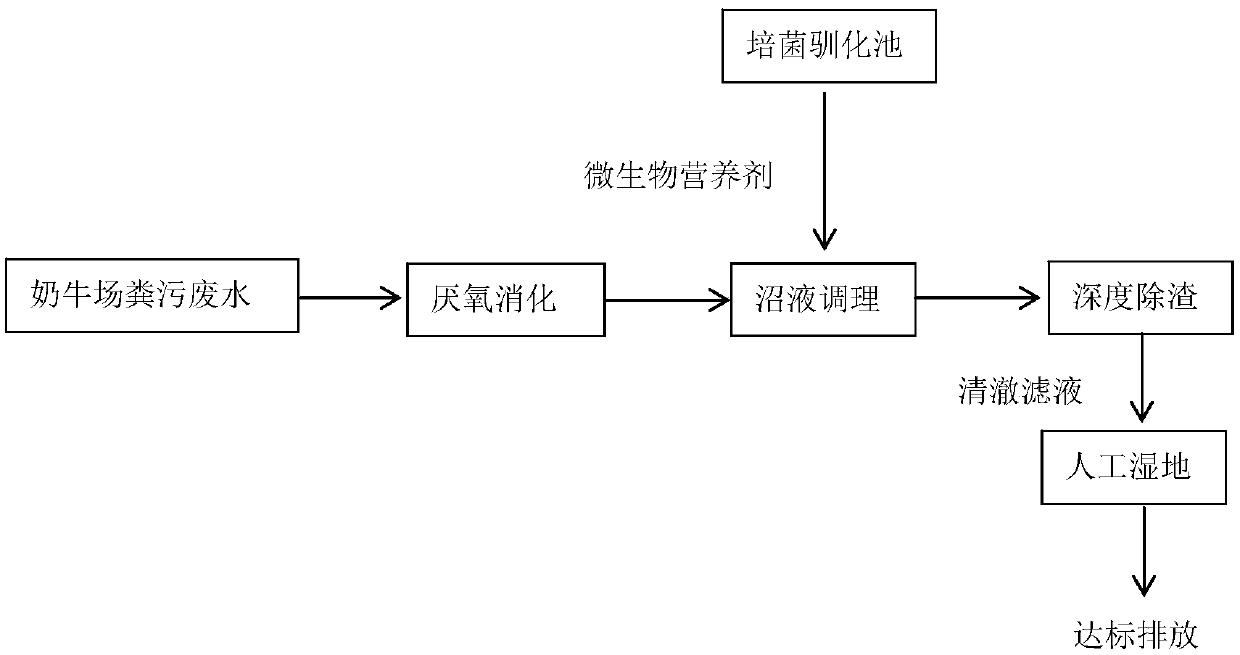

Deep slag removing method for biogas slurry with high solid content

InactiveCN109574398AReduce loadDeep slag removal is fast and efficientWater contaminantsTreatment involving filtrationPOLYMER SUBSTANCESlag

The invention discloses a deep slag removing method for biogas slurry with high solid content, and belongs to the field of environment protection. The deep slag removing method includes: cultivating and acclimating compound microorganisms; applying the acclimated compound microorganisms to condition fresh biogas slurry with high solid content; subjecting the conditioned biogas slurry to solid-liquid separation through deep slag removing equipment so as to realize deep slag removing. The deep slag removing method for the biogas slurry with high solid content has the advantages that the difficulty in treatment of the biogas slurry with high solid content is solved, extracellular polymeric substances among particles of the biogas slurry can be peeled off by means of a microorganism method, inert pollutants are enabled to be destabilized, deep slag removal and biogas slurry pollution load reduction are realized by a mechanical dehydration technology, and then the biogas slurry can be conveniently subjected to subsequent simple biochemical treatment before standardized discharging.

Owner:南京贝克特环保科技有限公司

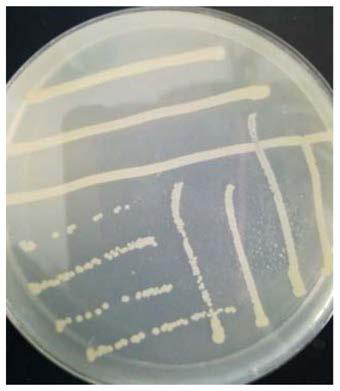

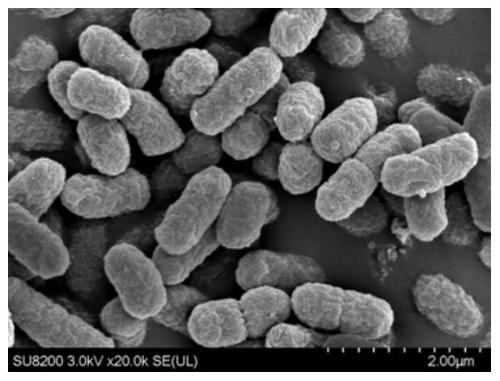

Triazole-degrading bacteria and its application in the treatment of triazole-containing wastewater

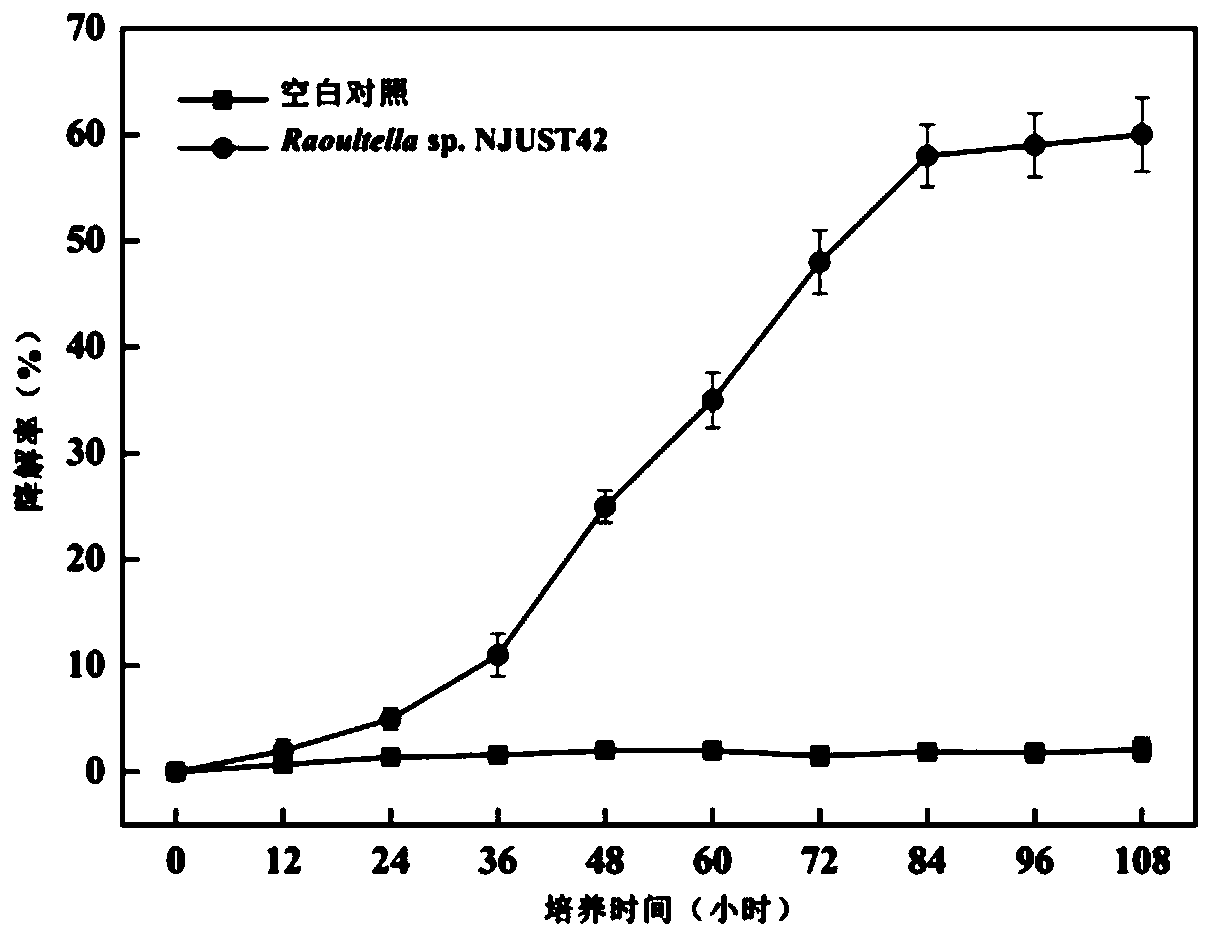

The invention discloses a triazole-degrading bacterium and its application in the treatment of triazole-containing wastewater. In the present invention, the activated sludge in the activated sludge reactor for removing triazole is used as the screening bacteria source, and the screening medium using triazole as the only carbon source and nitrogen source is used for enrichment, and the medium is used for marking According to the method of separation and purification, a triazole-degrading strain was obtained, which was identified as Raoultella by molecular biology, named Raoultella sp. NJUST42, and the preservation number was CCTCC NO: M 2018050. The triazole-degrading bacteria of the present invention can use triazole as the sole carbon source and nitrogen source for metabolism and growth. When Raoultellasp.NJUST42 is inoculated into the actual industrial wastewater containing triazole, the removal rate of triazole can reach more than 50% within 108 hours, and it has a good application prospect in the wastewater treatment of triazole.

Owner:NANJING UNIV OF SCI & TECH

Ag+-Fe2+ activated persulfate, method for degrading pollutants and application

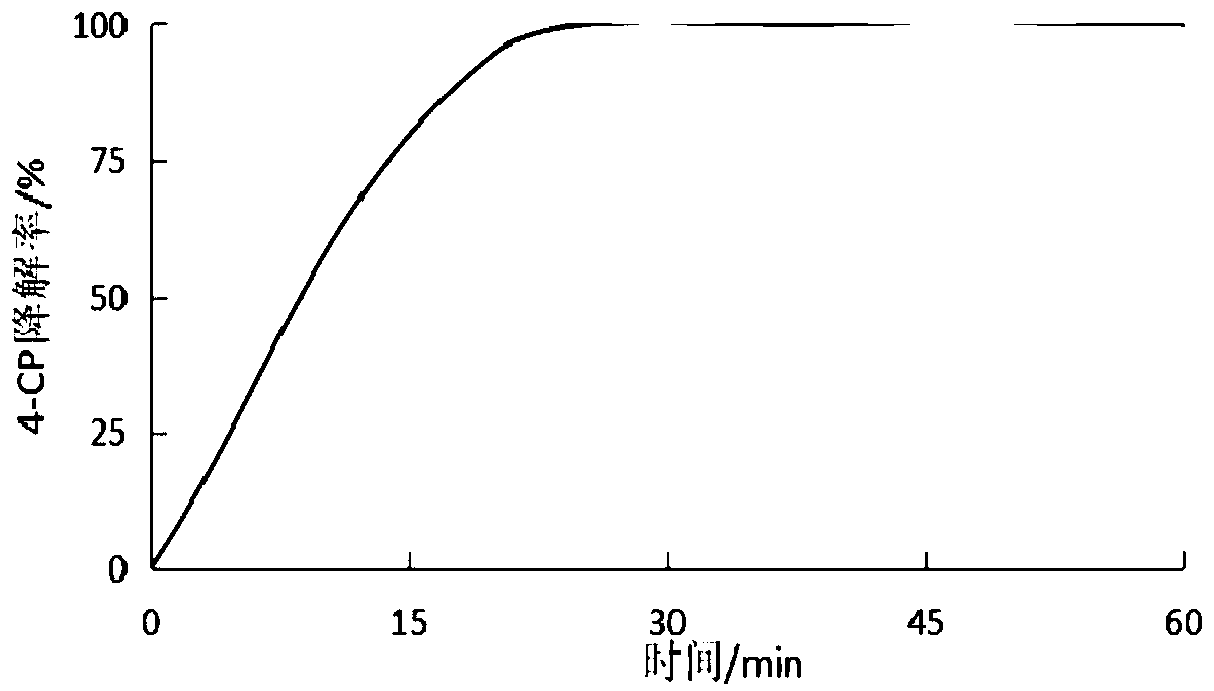

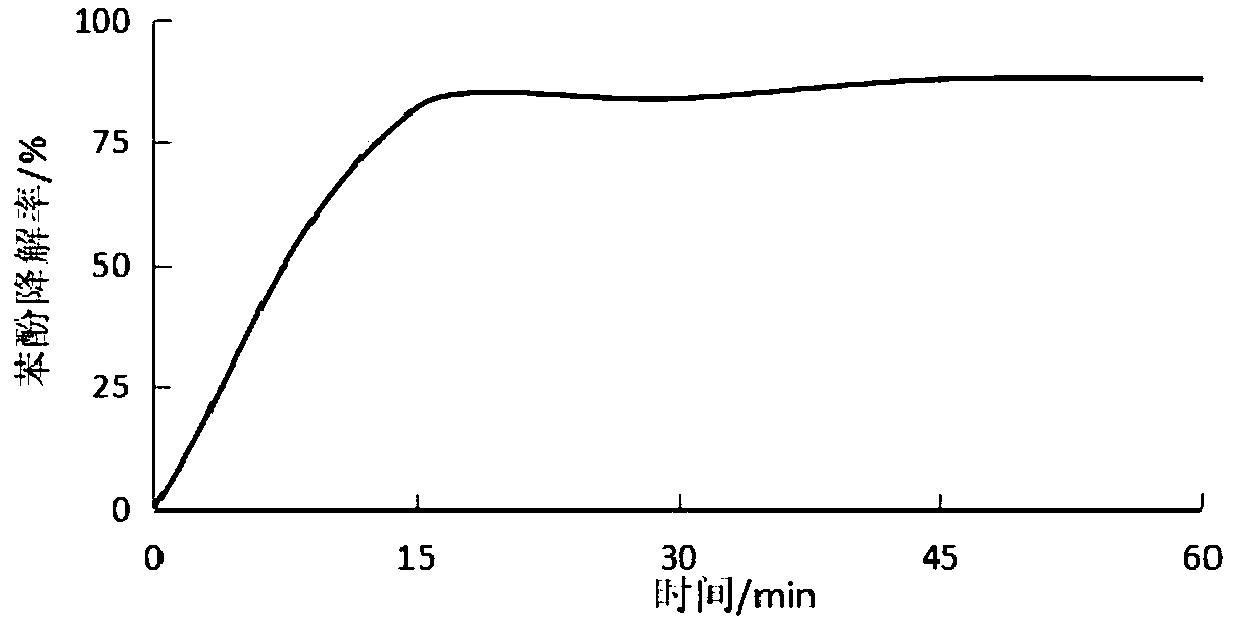

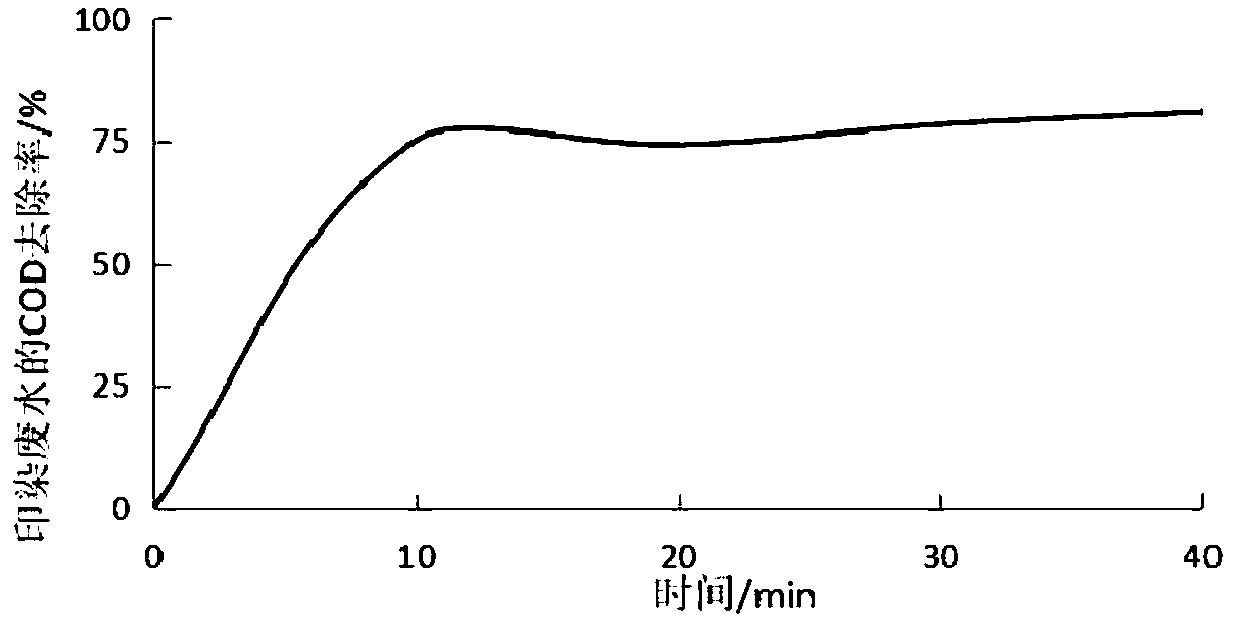

ActiveCN109052617AImprove degradation efficiencySave operating timeWater treatment compoundsWater contaminantsPollutantEnvironmental chemistry

The invention provides an Ag+-Fe2+ synergistic persulfate activating system and a method for degrading organic pollutants thereof. The synergistic activating system is composed of Ag+, Fe2+ and persulfate; the method for degrading the organic pollutants by means of the persulfate comprises the steps that 1, the Ag+-Fe2+ synergistic persulfate activating system is added into a to-be-treated compound aqueous solution and wastewater containing the organic pollutants, and a pH value of a reaction system is controlled to be 3-7; 2, at 15-50 DEG C, degradation treatment is conducted for 5-60 min. The Ag+-Fe2+ synergistic persulfate activating system forms a compound persulfate activation system, through Ag+-Fe2+ synergistic action, the purpose of activating the persulfate jointly is achieved, the reaction rate is improved, the degradation effect is improved, and advanced degradation of the pollutants is achieved.

Owner:BEIJING UNIV OF AGRI +1

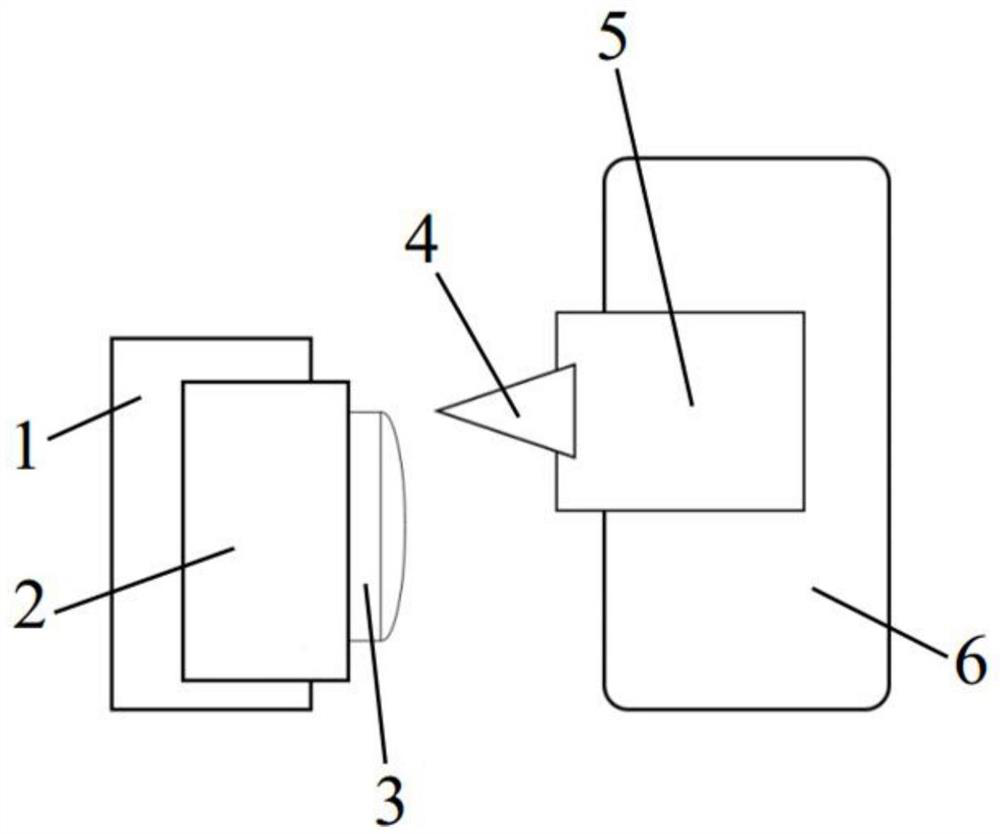

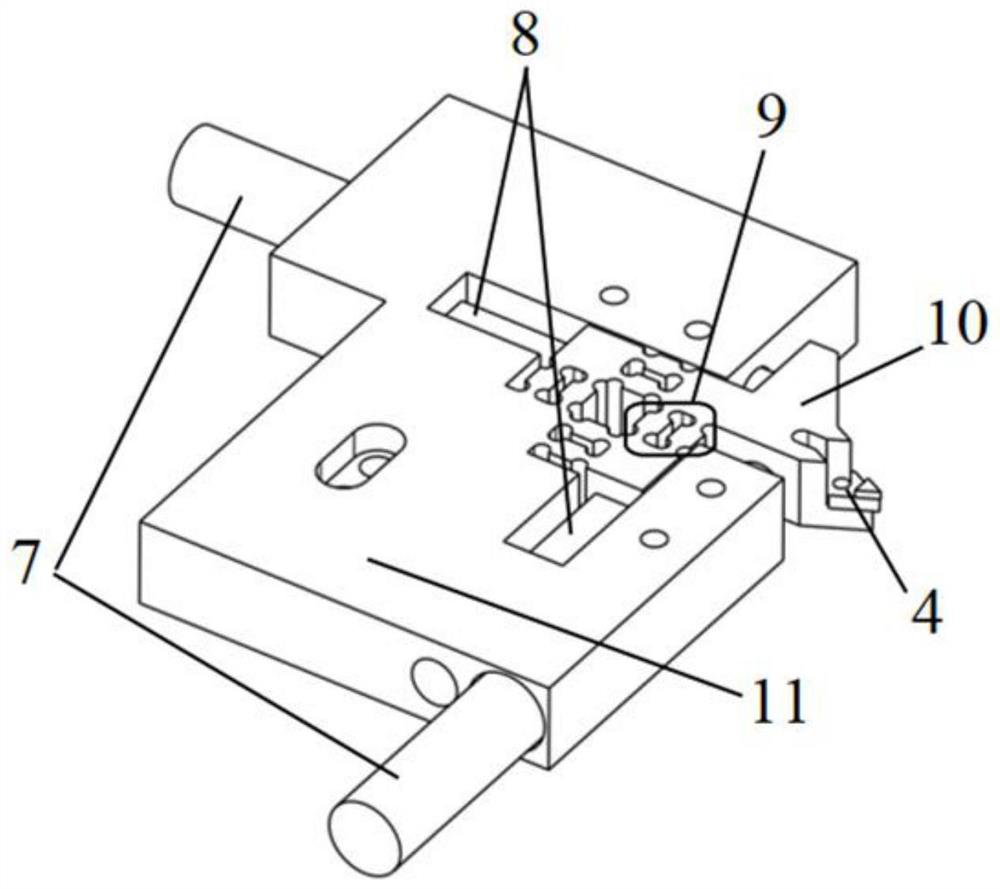

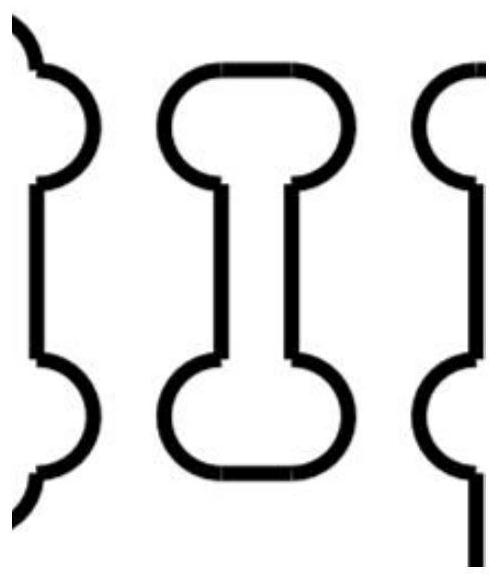

Diamond tuned cutting method and equipment for complex optical surfaces of brittle materials

ActiveCN109968548BAchieving removal rateImprove cutting efficiencyWorking accessoriesStone-like material working toolsNumerical controlMaterial removal

The invention discloses a diamond tuning cutting method and diamond tuning cutting equipment for a complex optical surface of a fragile material. The equipment comprises a spindle of a triaxis numerical control machine tool for mounting a workpiece, an X-axis guide rail of the machine tool, two-axle tool servo equipment mounted on the X-axis guide rail of the machine tool and a tool mounted on thetwo-axle tool servo equipment. The two-axle tool servo equipment comprises a piezoelectric stack driver, a flexible guiding mechanism, a capacitive displacement sensor, a substrate and a control system. The method maximizes a material removal rate at any moment under plastic region cutting constraint by self-adaptively adjusting the lateral feeding amount of the tool in any cutting position, so that the cutting efficiency is improved.

Owner:NANJING UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com