Deep slag removing method for biogas slurry with high solid content

A technology with high solid content and biogas slurry, applied in chemical instruments and methods, multi-stage water/sewage treatment, water pollutants, etc., can solve the problems of long biochemical treatment cycle, difficult to meet discharge standards, pH buffer enhancement, etc., to achieve Reduce the difficulty of biochemical treatment, promote the precipitation of pollutants, and reduce the effect of pollutant load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

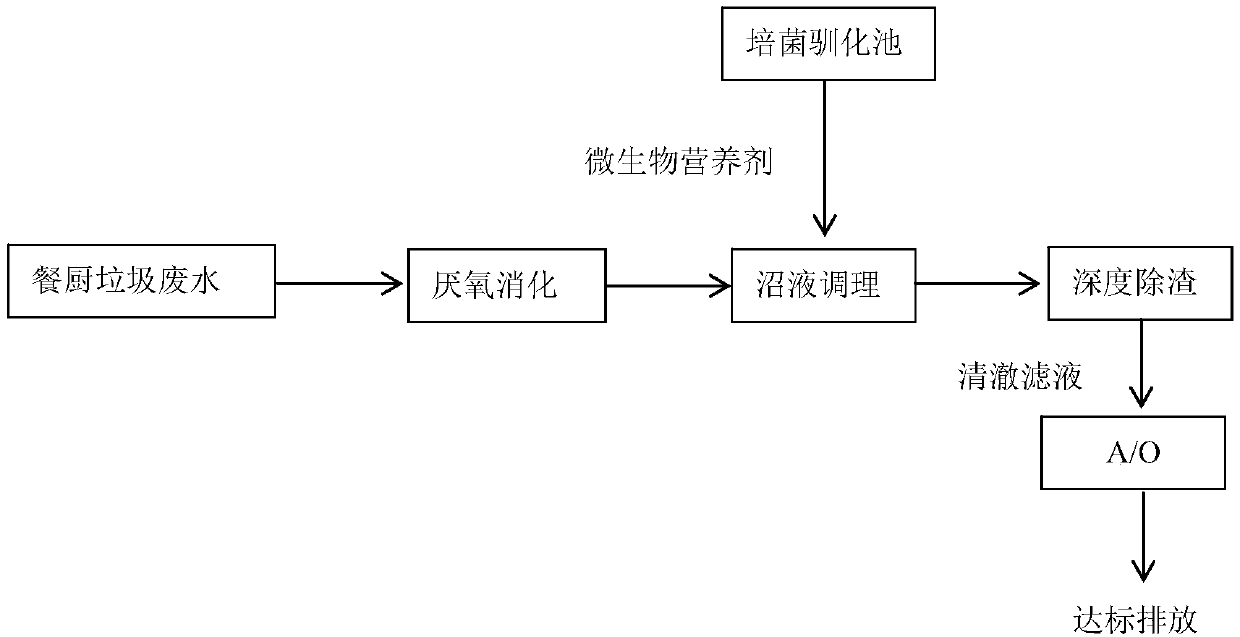

[0040] Anaerobic digestion and fermentation biogas slurry advanced slag removal treatment of kitchen waste wastewater

[0041] The relevant water quality indicators of the biogas slurry produced by the anaerobic digestion treatment of the waste water obtained from pre-treatment processes such as filtration, sorting, crushing, pulping, and three-phase separation of food waste are: COD 18500mg / L, SS 40000mg / L , ammonia nitrogen 2580mg / L, total phosphorus 350mg / L. Its deep slag removal treatment such as figure 1 shown, including the following steps:

[0042] (1) Cultivation and domestication of complex microorganisms: inoculate Bacillus F7 and acidophilus JZ6 isolated from sludge into their respective culture media (g / L of Bacillus F7 medium: glucose 20, peptone 0.5, yeast Paste 0.5, (NH 4 ) 2 SO 4 0.2,K 2 HPO 4 5. KH 2 PO 4 2. MgSO 4 0.2, NaCl 0.1, sterilized at 115°C for 30 minutes; medium for acidophilus JZ6: (NH 4 ) 2 SO 4 3.5, KCl 0.119, K 2 HPO 4 0.58, C...

Embodiment 2

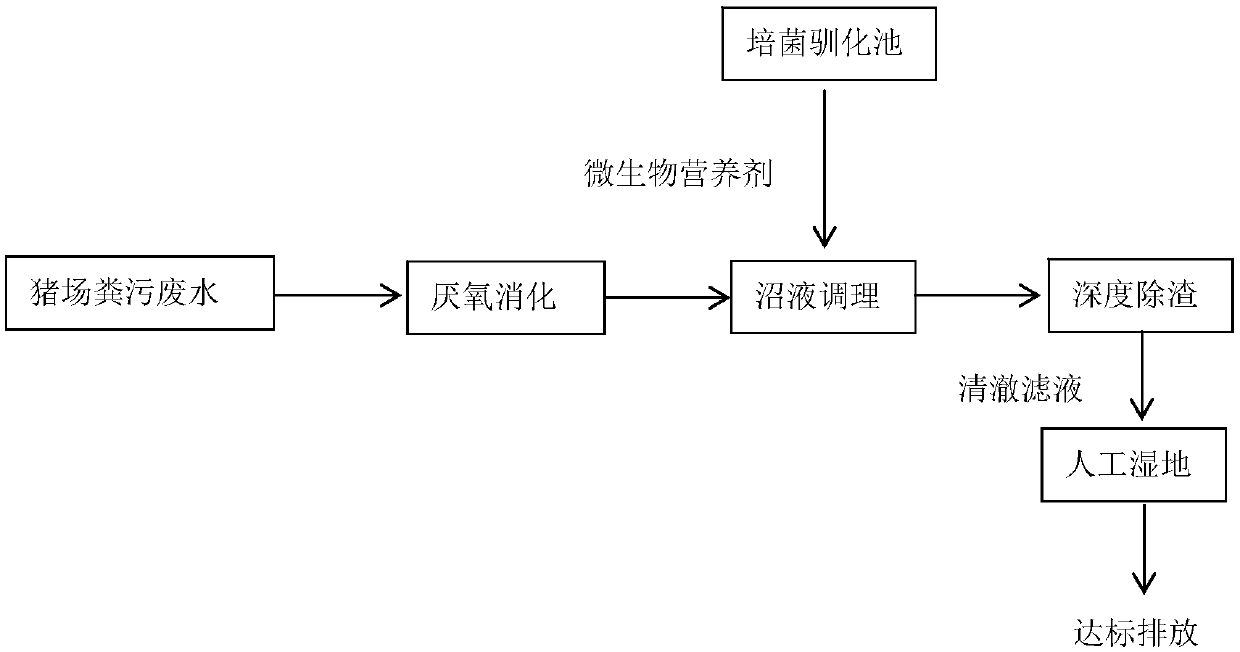

[0064] Advanced slag removal treatment of pig farm manure wastewater by anaerobic digestion biogas slurry

[0065] The pig farm waste water enters the biogas digester after primary solid-liquid separation, and the physicochemical properties of the biogas slurry produced after 3 days of anaerobic fermentation are as follows: COD 11500mg / L, SS 60000mg / L, ammonia nitrogen 850mg / L, total phosphorus 150mg / L . Its deep slag removal treatment such as figure 2 shown, including the following steps:

[0066] (1) Cultivation and domestication of complex microorganisms: inoculate Bacillus F7 and acidophilus JZ6 isolated from sludge into their respective culture media (g / L of Bacillus F7 medium: glucose 20, peptone 0.5, yeast Paste 0.5, (NH 4 ) 2 SO 4 0.2,K 2 HPO 4 5. KH 2 PO 4 2. MgSO 4 0.2, NaCl 0.1, sterilized at 115°C for 30 minutes; medium for acidophilus JZ6: (NH 4 ) 2 SO 4 3.5, KCl 0.119, K 2 HPO 4 0.58, Ca(NO 3 ) 2 4H 2 O 0.168, FeSO 4 ·7H 2 O 4.42, CaCl ...

Embodiment 3

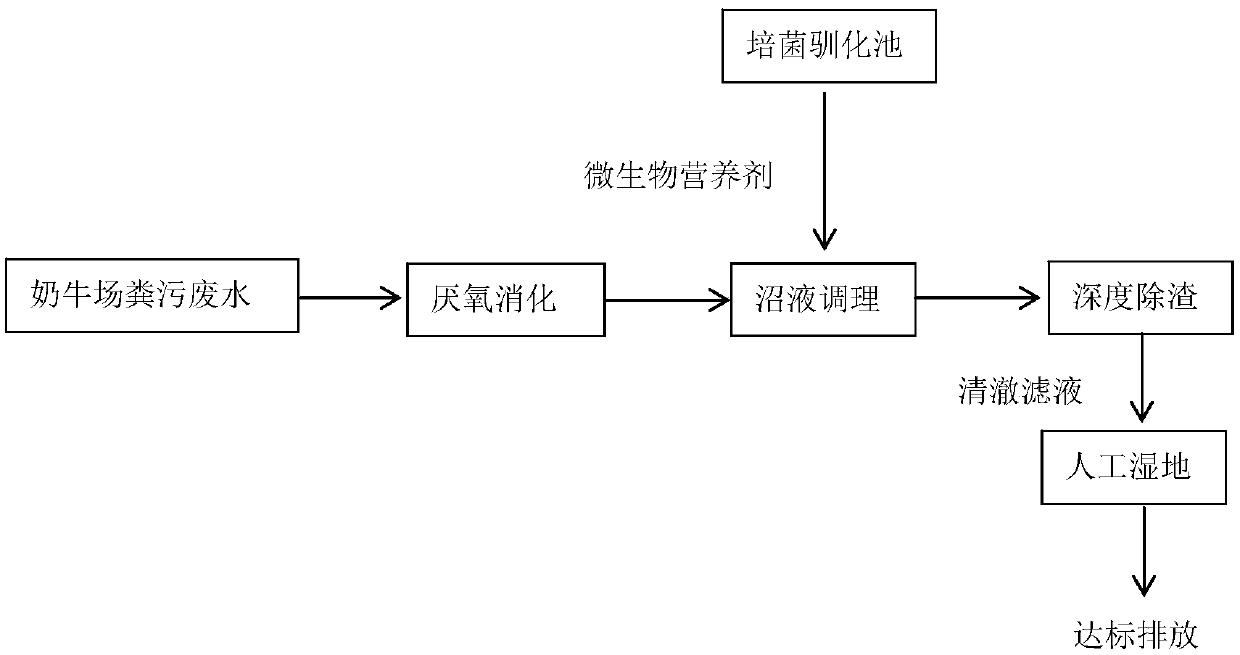

[0070] Anaerobic digestion biogas slurry advanced slag removal treatment of dairy farm manure wastewater

[0071] The manure wastewater from the dairy farm enters the biogas digester after primary solid-liquid separation, and the physicochemical properties of the biogas slurry produced after 5 days of anaerobic fermentation are as follows: COD 45500mg / L, SS 90000mg / L, ammonia nitrogen 1000mg / L, total phosphorus 300mg / L . Its deep slag removal treatment such as image 3 shown, including the following steps:

[0072] (1) Cultivation and domestication of complex microorganisms: inoculate Bacillus F7 and acidophilus JZ6 isolated from sludge into their respective culture media (g / L of Bacillus F7 medium: glucose 20, peptone 0.5, yeast Paste 0.5, (NH 4 ) 2 SO 4 0.2,K 2 HPO 4 5. KH 2 PO 4 2. MgSO 4 0.2, NaCl 0.1, sterilized at 115°C for 30 minutes; medium for acidophilus JZ6: (NH 4 ) 2 SO 4 3.5, KCl 0.119, K 2 HPO 4 0.58, Ca(NO 3 ) 2 4H 2 O 0.168, FeSO 4 ·7H ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com