Oxidative adsorbent for removing mercury from coal-burning flue gas

A coal-fired flue gas and adsorbent technology, which is applied in other chemical processes, chemical instruments and methods, etc., can solve the problems of large practical amount, high price of activated carbon mercury adsorbent, and degraded quality of fly ash.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

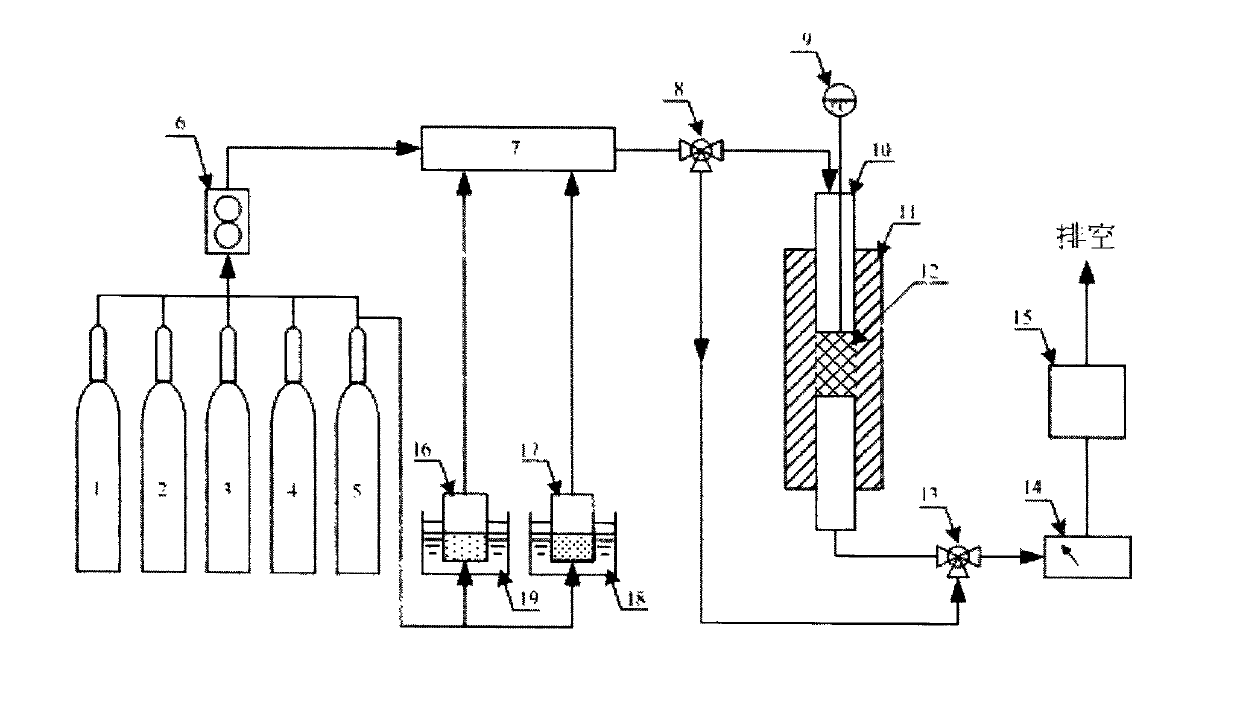

[0020] Embodiment 1: Mix 20 g of 150-mesh activated carbon and 80 g of 150-mesh montmorillonite evenly for later use. Take 50mL of ionized water and 50mL of acetone into a beaker, add 0.3g of MnCl 2 Manganese chloride and 0.7g CuCl 2 Copper chloride powder, stir until completely dissolved to form a solution, add 9.0g of a mixture of activated carbon and montmorillonite to the above solution, stir vigorously for 60 minutes, place in a vacuum rotary dryer and dry at 50°C, and finally in a muffle Activation was carried out at 300° C. for 4 hours in a furnace under the protection of nitrogen, and the obtained product was ground to collect particles of 400-200 mesh, ie, 0.037-0.074 mm, to obtain an oxidized mercury absorbent. The adsorbent can achieve a mercury removal rate of more than 85% in the evaluation device shown in the attached figure.

Embodiment 2

[0021] Embodiment 2: Mix 8 g of 150-mesh activated carbon and 92 g of 150-mesh montmorillonite evenly for later use. Take 20mL of ionized water and 80mL of acetone into a beaker, add 0.06g of MnCl 2 Manganese chloride and 0.54g CuCl 2 Copper chloride powder, stir until it is completely dissolved to form a solution, add 9.4g of a mixture of activated carbon and montmorillonite to the above solution, stir vigorously for 60 minutes, place it in a vacuum rotary dryer and dry it at 50°C, and finally protect it under nitrogen Activation was carried out in a muffle furnace at 300°C for 3 hours, and the obtained product was ground to collect particles of 400-200 mesh, ie, 0.037-0.074mm, to obtain an oxidized mercury absorbent. The adsorbent can achieve a mercury removal rate of more than 80% in the evaluation device shown in the attached figure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com