Ag+-Fe2+ activated persulfate, method for degrading pollutants and application

A technology for activating persulfate and persulfate, applied in the field of pollutant treatment, can solve the problems of high cost and easy inactivation, and achieve the effects of complete degradation, saving operation time and avoiding side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Selection of iron ion source:

[0044] The source of ferrous iron selected in this embodiment is ferrous sulfate heptahydrate.

[0045] 2) Selection of persulfate:

[0046] The persulfate selected in this embodiment is sodium persulfate.

[0047] 3) Choice of silver ion source: silver nitrate.

[0048] 4) The specific degradation process is implemented according to the following steps:

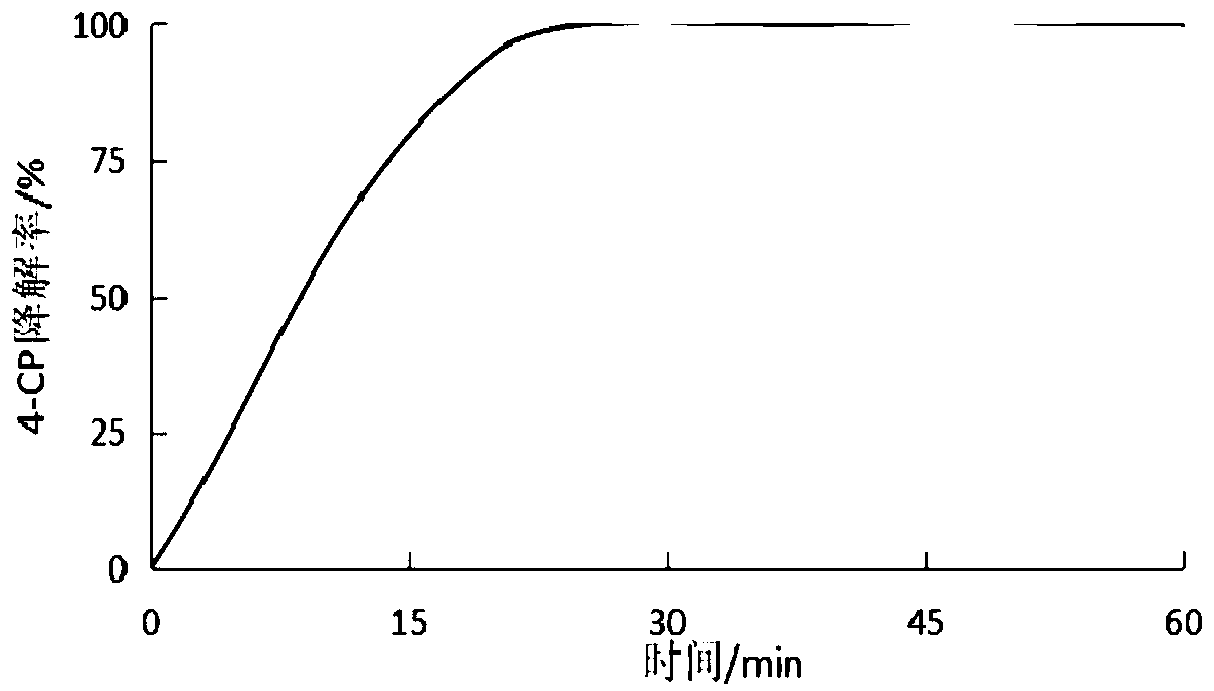

[0049] Get p-chlorophenol aqueous solution (concentration is 20mg / L), add Ag+, Fe 2+ and sodium persulfate, and make Ag + : Fe 2+ : The molar ratio of sodium persulfate is 9:8:3, the pH value is adjusted to 3, the total volume is 50ml, and the shaker is shaken at 10°C and 200rpm for 10-20min;

[0050] Get 3ml of the treated solution in a 10ml centrifuge tube, extract it with an equal volume of ethyl acetate, pass through a 0.22 μm water filter, measure the concentration of p-chlorophenol (4-CP) in the system by high performance liquid chromatography, and calculate The degradat...

Embodiment 2

[0052] 1) Selection of iron ion source:

[0053] The source of ferrous iron selected in this embodiment is ferrous acetate and ferrous sulfate heptahydrate.

[0054] 2) Selection of persulfate:

[0055] The persulfate selected in this embodiment is sodium persulfate.

[0056] 3) Choice of silver ion source: silver nitrate.

[0057] 4) The specific degradation process is implemented according to the following steps:

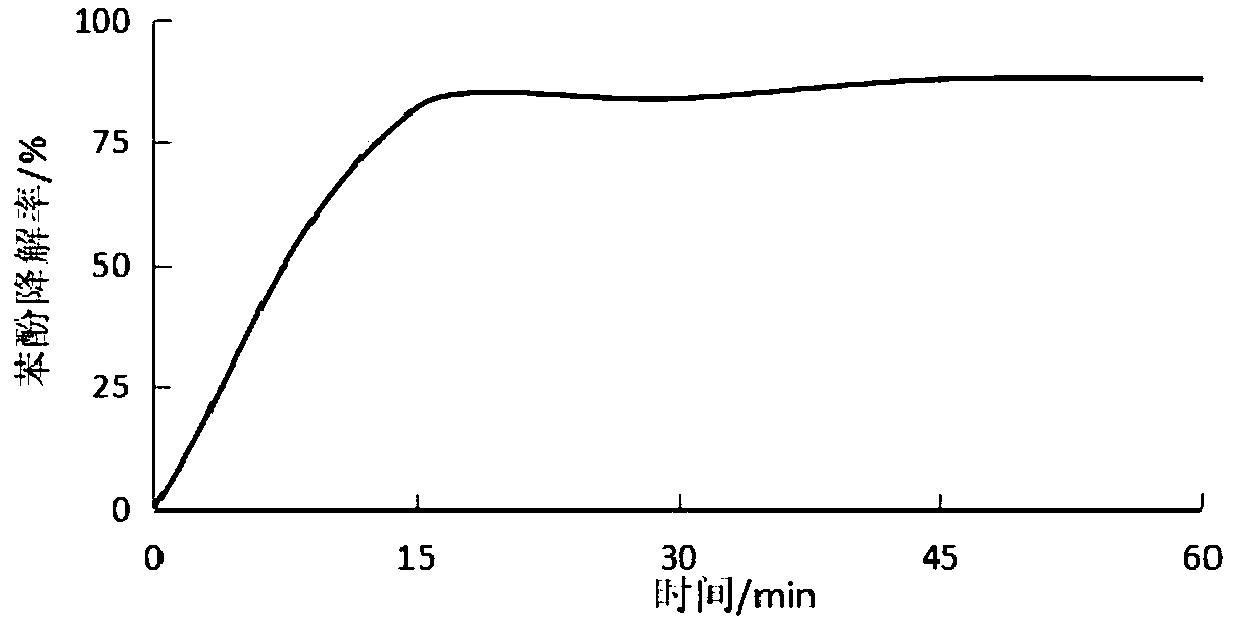

[0058] Get p-chlorophenol aqueous solution (concentration is 20mg / L), add Ag+, Fe 2+ and sodium persulfate, and make Ag + : Fe 2+ : The molar ratio of sodium persulfate is 1:1:10, the pH value is adjusted to 6, the total volume is 50ml, and the shaker is shaken at 45°C and 250rpm for 50-60min;

[0059] Get 3ml of the treated solution in a 10ml centrifuge tube, extract it with an equal volume of ethyl acetate, pass through a 0.22 μm water filter, measure the concentration of p-chlorophenol (4-CP) in the system by high performance liquid chromatography, and ca...

Embodiment 3

[0061] 1) Selection of iron ion source:

[0062] The source of ferrous iron selected in this embodiment is ferrous chloride tetrahydrate.

[0063] 2) Selection of persulfate:

[0064] The persulfates selected in this embodiment are potassium persulfate and sodium persulfate.

[0065] 3) Choice of silver ion source: silver nitrate.

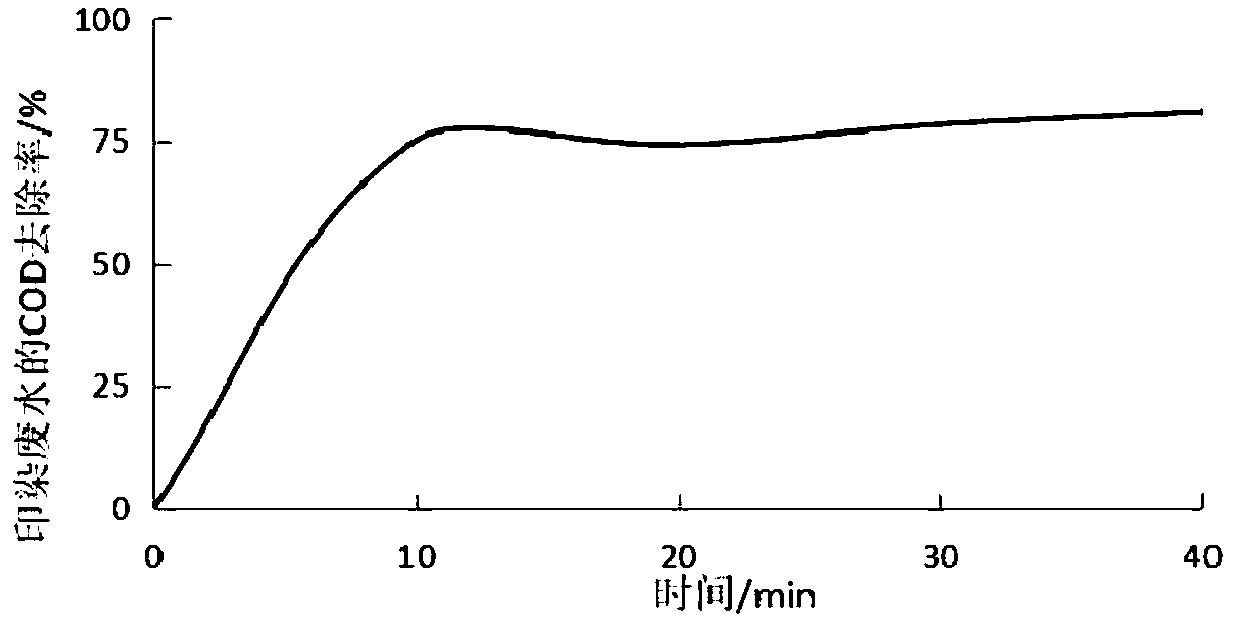

[0066] 4) The specific degradation process is implemented according to the following steps:

[0067] Get p-chlorophenol aqueous solution (concentration is 20mg / L), add Ag+, Fe 2+ and sodium persulfate, and make Ag + : Fe 2+ : The molar ratio of sodium persulfate is 2:2:9, the pH value is adjusted to 4-5, the total volume is 50ml, and the shaker is shaken at 40°C and 210rpm for 30-40min;

[0068] Get 3ml of the treated solution in a 10ml centrifuge tube, extract it with an equal volume of ethyl acetate, pass through a 0.22 μm water filter, measure the concentration of p-chlorophenol (4-CP) in the system by high performance liquid chromatograph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com