Diamond tuned cutting method and equipment for complex optical surfaces of brittle materials

A technology for optical surfaces and brittle materials, applied to stone processing equipment, stone processing tools, work accessories, etc., to achieve the effect of improving cutting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

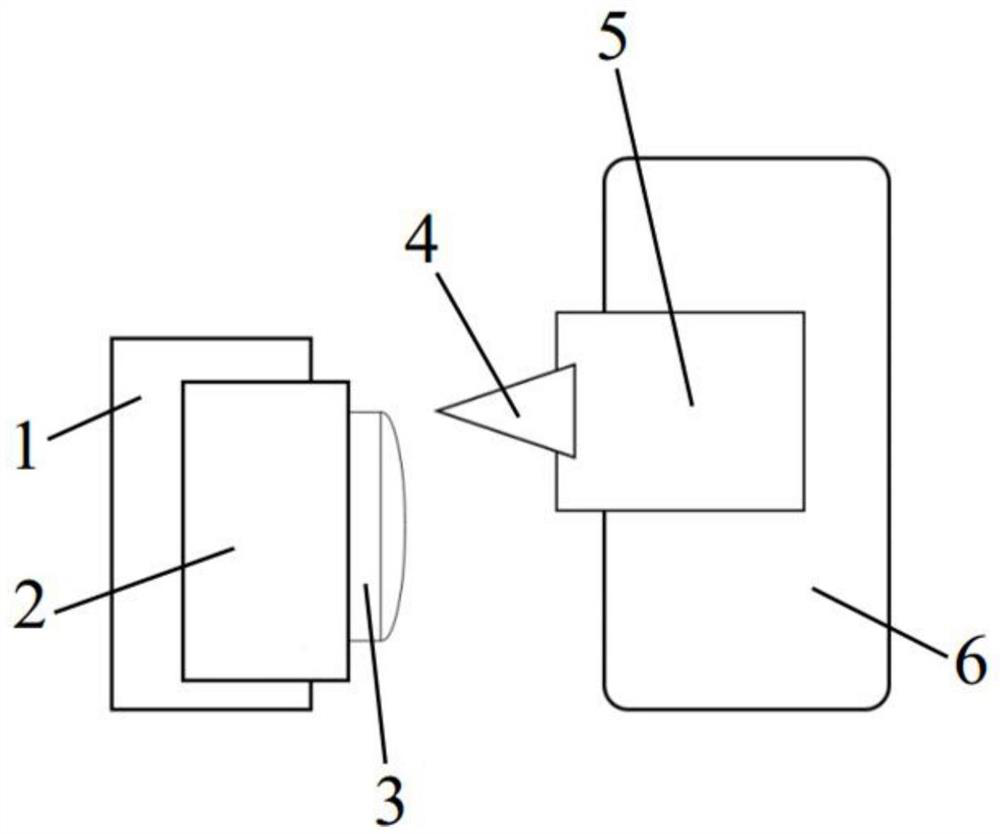

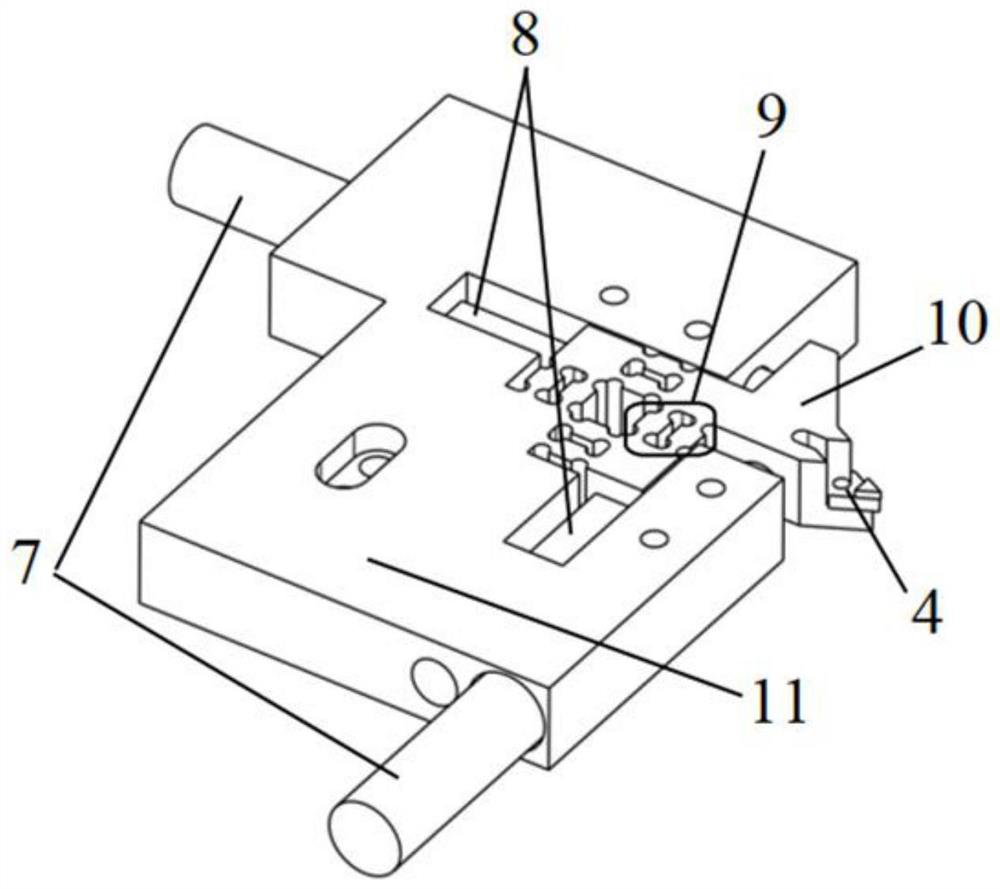

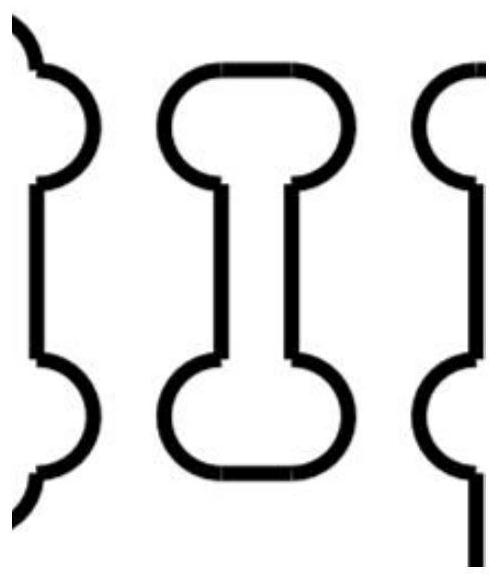

[0046] to combine Figure 1-3 , a diamond-tuned cutting equipment for complex optical surfaces of brittle materials, which improves the efficiency of diamond cutting for complex optical surfaces of brittle materials. The workpiece 3 is installed on the main shaft 2 of a three-axis CNC machine tool and rotates accordingly. Installed on the X-axis guide rail 6 of the machine tool and moving in a straight line at a constant speed; under the dual constraints of plastic domain cutting and surface accuracy, the two-axis tool servo 5 adaptively adjusts the X-axis lateral feed and Z-axis of the tool 4 at any cutting position Axis servo cutting motion to maximize material removal at any cutting position; adaptive lateral feed motion and complex surface creation motion are respectively realized by two-axis tool servo X-axis and Z-axis fast servo motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com