Brick-concrete building waste treatment technology

A technology of construction waste and treatment process, which is applied in the field of environmental protection, can solve the problems that it is difficult to obtain high-efficiency recycled building material products in the treatment of construction waste, and achieve the effects of promoting comprehensive utilization, ensuring removal rate, and avoiding interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

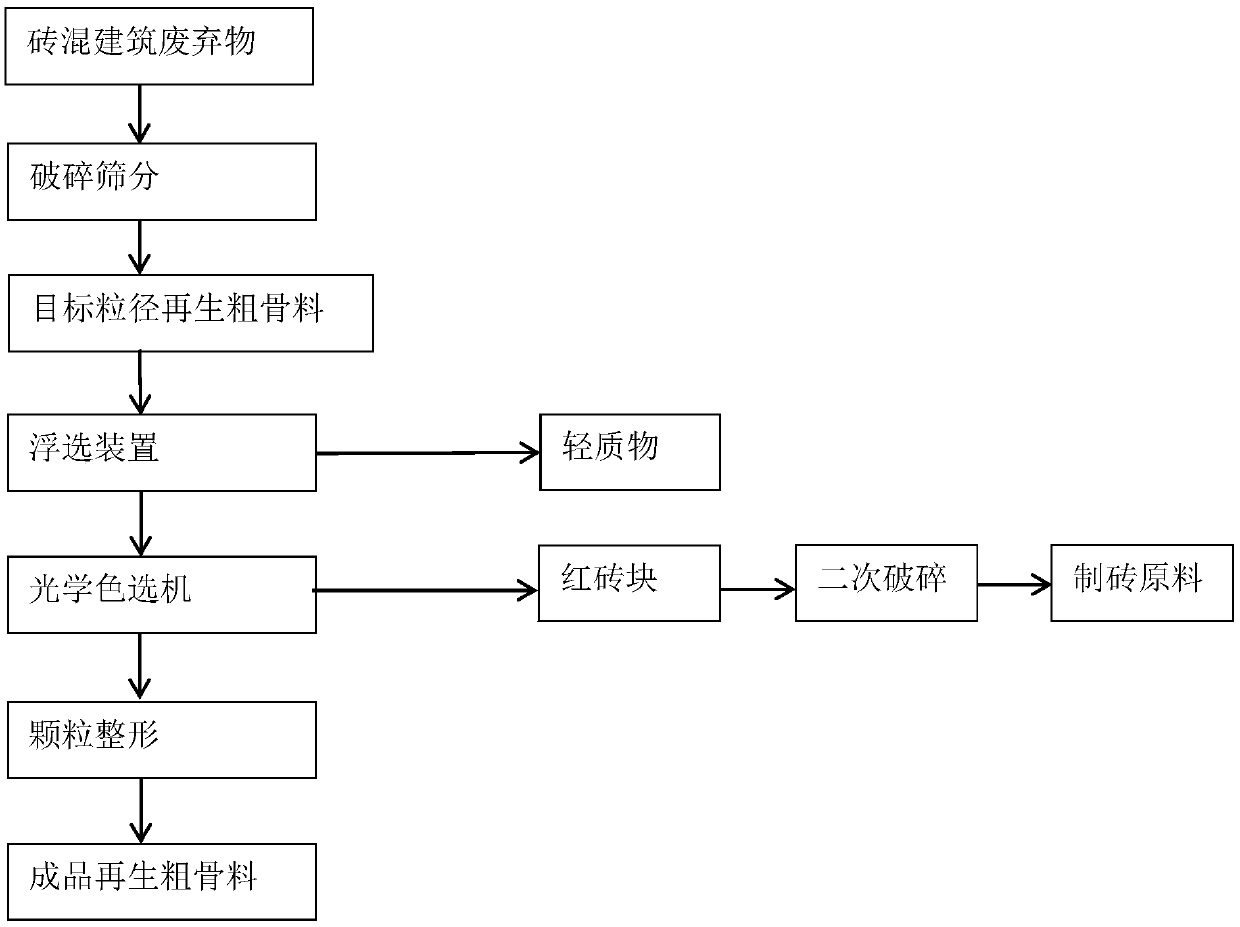

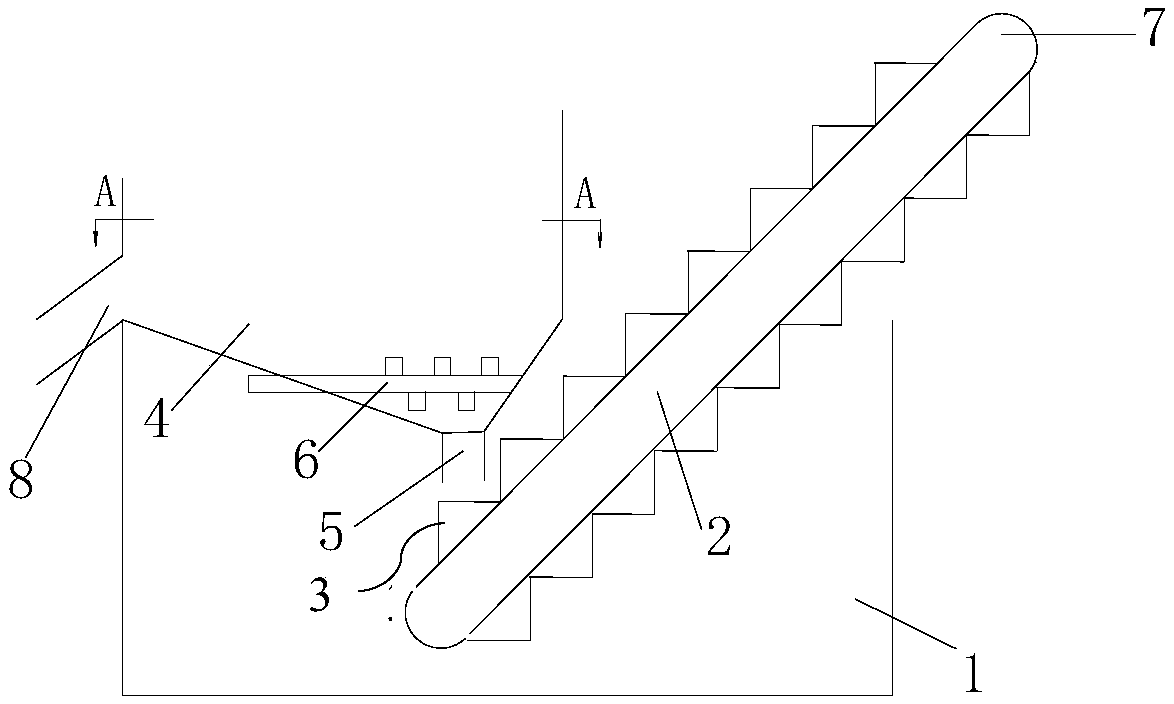

[0023] Below in conjunction with accompanying drawing and embodiment, the treatment process of brick-concrete construction waste of the present invention is described further:

[0024] Such as figure 1 As shown, the invention provides a kind of treatment process of brick-concrete construction waste, comprising:

[0025] A. Crush the brick-concrete construction waste, and sieve to obtain the recycled coarse aggregate in the target particle size range; among them, the brick-concrete construction waste is crushed by a crusher, and the target particle size range is obtained through a screening machine with a pore size of the screen Recycled coarse aggregates inside, such as 5~10mm, 10~20mm, 20~31.5mm, etc.;

[0026] B. Remove the light matter in the recycled coarse aggregate through the flotation device;

[0027] C. Use an optical color sorter to sort out and remove the red bricks in the recycled coarse aggregate; collect the selected and removed red bricks and perform at least ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com