Recovery method for pop-tops made of waste aluminum

A recycling method and technology of pop-top cans, applied in the direction of improving process efficiency, etc., can solve problems such as unsuitable for large-scale application, difficulty in completely removing paint, etc., and achieve stable and reliable paint removal efficiency, low cost, and high-efficiency separation effects

Inactive Publication Date: 2018-12-28

CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

View PDF0 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This method generally adopts manual treatment, and the process operation is flexible, but it is not suitable for large-scale application, and it is difficult to completely remove the paint.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

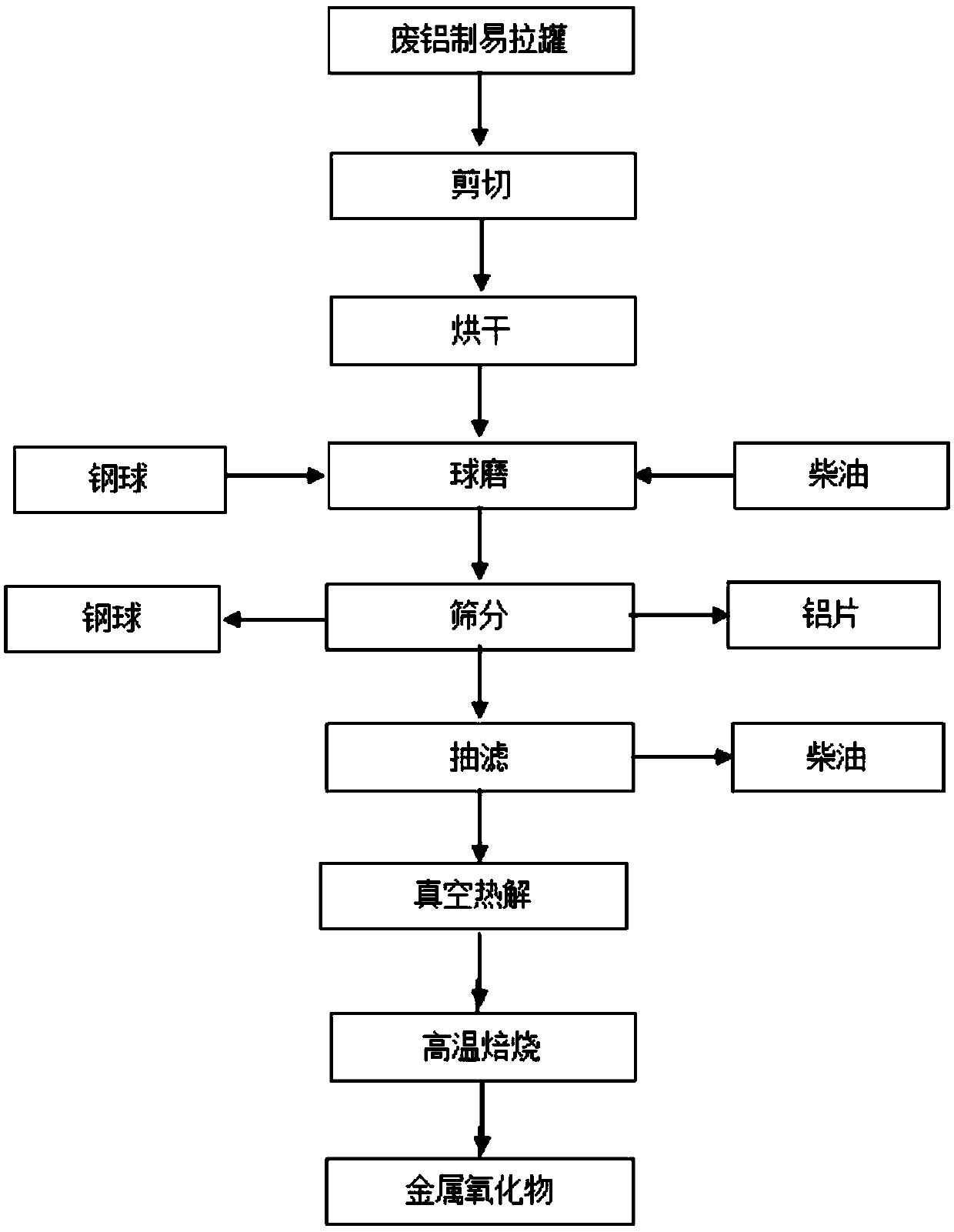

The invention provides a recovery method for pop-tops made of waste aluminum. The recovery method comprises the following steps: firstly cutting out the pop-tops made of waste aluminum into aluminum pieces of which the area is 8-12cm<2> with a cutting machine, conveying the aluminum pieces into a drying machine, and removing water; performing ball milling on the aluminum pieces without water, steel balls and diesel fuel, and performing screening to obtain depainted aluminum pieces, steel balls and diesel fuel infiltrated with come-off paintcoats and aluminum powder; performing sucking filtration on the diesel fuel containing paintcoats and aluminum powder so as to obtain clean diesel fuel as a recycled material; performing vacuum pyrolysis on the paintcoats and the aluminum powder containing a little oil, and through condensation, collecting pyrolytic oil as an available fuel; and then conveying surplus pyrolysis residues in a muffle furnace, and performing high-temperature roasting treatment so as to obtain a mixed metallic oxide powder of which the main components include titanium dioxide and aluminum oxide. Due to the adoption of the recovery method disclosed by the invention, the stripping of the paintcoats of the pop-tops made of waste aluminum can be realized, organic resin and titanium dioxide in the paintcoats can be recovered, and a little scraped-away aluminum powdercan be converted into aluminium oxide to be used as chemical industry raw materials.

Description

Technical field: The invention belongs to the field of recovery and utilization of secondary resources, and in particular relates to a recovery method for pop cans made of waste aluminum. technical background: Aluminum beverage cans first appeared in 1959. By 1963, two-piece DWI cans were officially launched and began to be promoted. It was not until 1968 that several aluminum producers in the United States, especially Reynolds Metals, began to realize the metal value of cans, and did not start the aluminum cans recycling program. In 1973, the American newspaper "Consumption Growth Limit" put forward the idea of recycling cans, which was the first document in the world to formally propose the recycling of cans. The recycling and reuse of cans can save a lot of bauxite resources and make effective use of bauxite resources; second, it can save a lot of energy and alleviate the energy shortage problem; To protect the environment, etc. At present, domestic waste cans resou...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22B21/00C22B7/00

CPCC22B21/0069Y02P10/20

Inventor 张柏林易自希

Owner CHANGSHA HUIJU ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com