A method to reduce high oxygen content in rh vacuum chamber

A high oxygen content, vacuum chamber technology, applied in the field of metallurgy, can solve the problems of increased steel oxide inclusions and increased oxygen content, and achieve the effect of improving the purity of molten steel, reducing aluminum loss, and improving pourability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

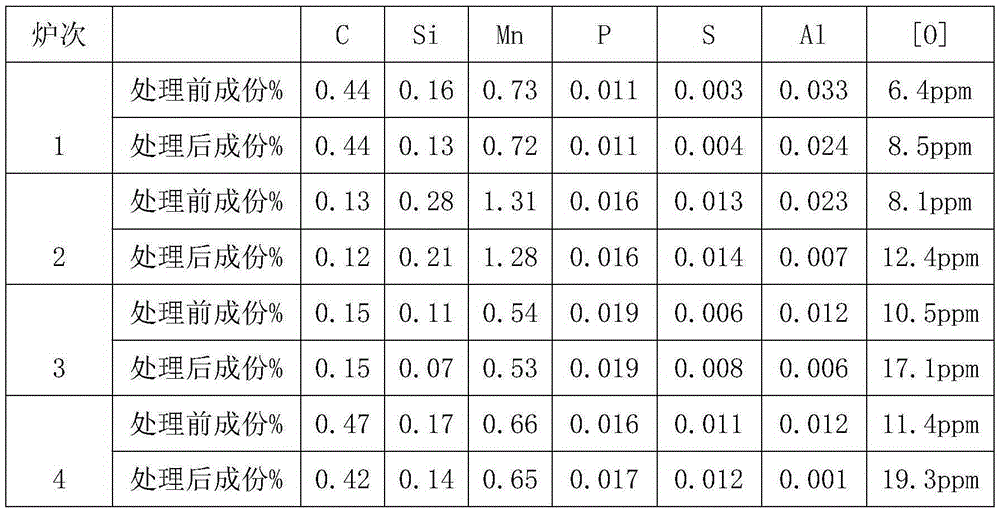

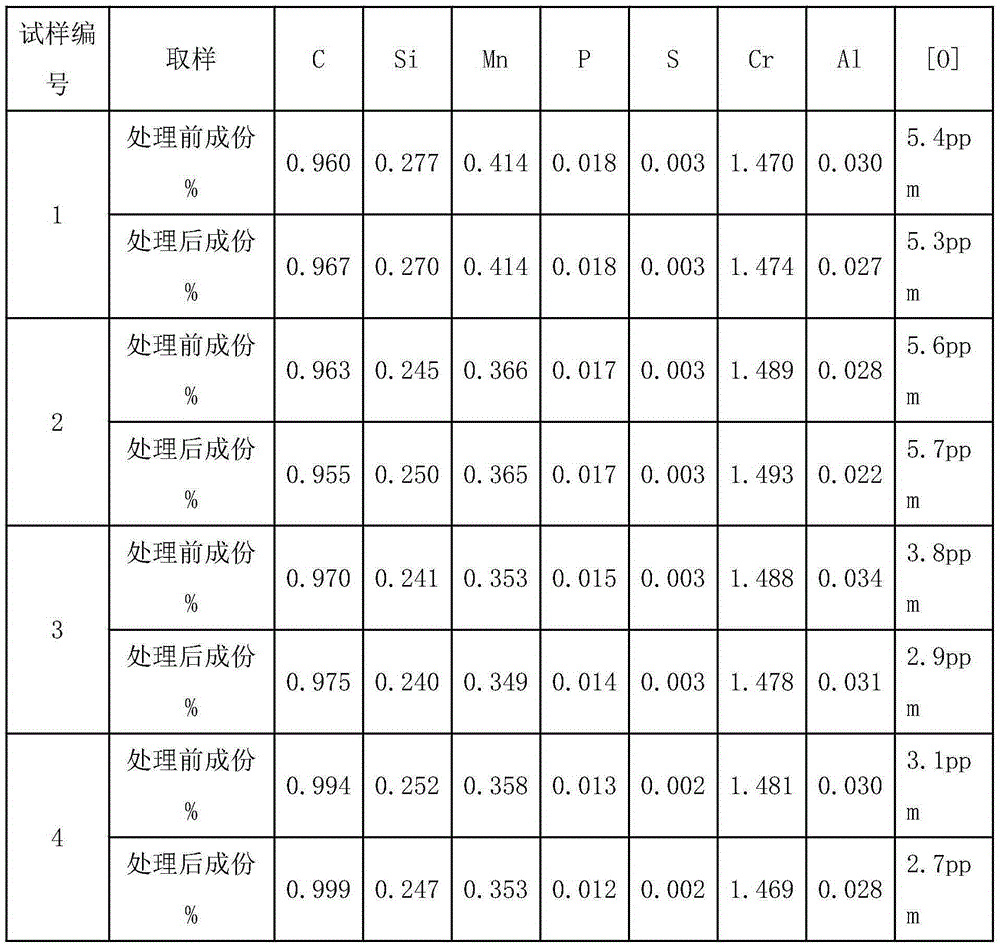

Examples

Embodiment Construction

[0022] A method for reducing the high oxygen content in the RH vacuum chamber. The vacuum chamber is first cleaned before vacuum refining of special steel types. The specific steps are as follows:

[0023] The first step is to hoist the deoxidized and heated ordinary molten steel to the RH vacuum refining furnace;

[0024] In the second step, the ladle car transports the ladle molten steel to the vacuum treatment position to lift the ladle and the ladle car;

[0025] The third step is to turn on the vacuum pump system for vacuum treatment;

[0026] The fourth step is to start the circulation of molten steel by vacuuming. Light treatment is carried out in the early stage of treatment, and the vacuum degree is kept between 10KPa-20KPa; during the treatment process, the residual oxidizing steel slag in the vacuum chamber and the easily oxidizable elements aluminum, carbon, and silicon in the circulating molten steel , manganese, etc. continue to react. At this time, the vacuum c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com