A kind of preparation method of aluminum strip for high-speed rail sound barrier

A sound barrier and aluminum strip technology, applied in metal rolling, manufacturing tools, metal rolling, etc., can solve the problems of high cost and long production cycle, and achieve energy saving, increase of standing time, obvious economic benefits and social benefits benefit effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

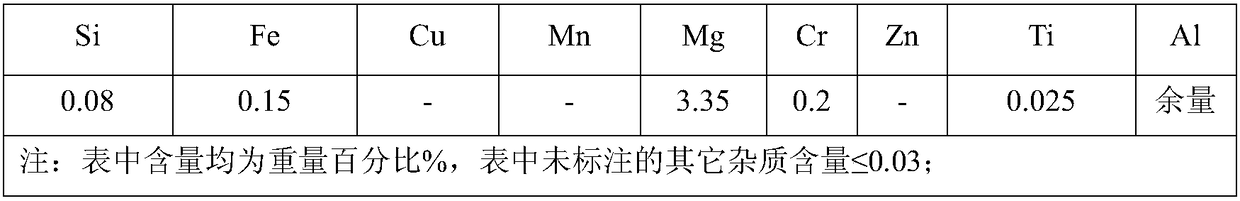

[0039] The invention relates to a method for preparing aluminum strips for high-speed rail sound barriers. In the invention, electrolytic aluminum liquid, aluminum ingots, and aluminum alloy solid waste are smelted into aluminum melts, and then 3-5 mm thick aluminum is prepared by continuous casting and rolling processes. Finally, through reasonable setting of process technical parameters such as cold rolling, tension leveling cleaning and finished product annealing, the process flow is shortened and the production cost is reduced.

[0040]The general preparation method of the present invention is: smelting electrolytic aluminum liquid, aluminum ingots, and aluminum alloy solid waste into aluminum melt → continuous casting and rolling to prepare 3-5mm thick aluminum coils → cold rolling → cleaning and trimming → finished product annealing → Slitting and rewinding → inspection and packaging Prepare the aluminum strip for high-speed rail sound barriers, where cleaning and trimmin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com