Magnesium alloy smelting and casting integrated device

A magnesium alloy and smelting zone technology, applied in the field of magnesium alloy smelting and casting equipment, can solve the problems of energy waste and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

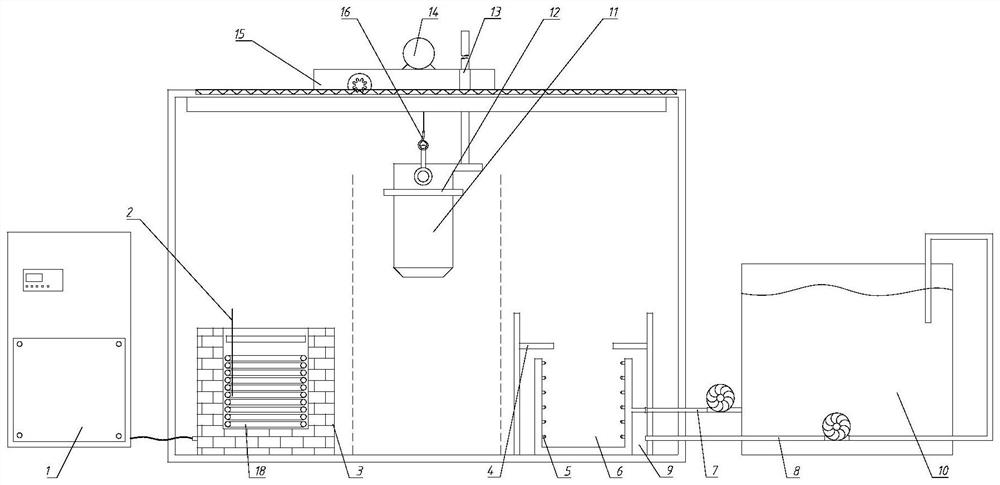

[0011] Specific Embodiment 1: In this embodiment, the magnesium alloy smelting and casting integrated device is composed of a cabinet, a temperature controller 1, a heating furnace 3, a crucible 11, a quenching pool 6 and a pool 10; the temperature controller 1 and the pool 10 are arranged in the cabinet outside the body;

[0012] From left to right in the cabinet, there are smelting area, transfer area and quenching area. The heating furnace 3, the crucible 11 and the quenching pool 6 are arranged in the cabinet, the heating furnace 3 is installed in the melting area, and the quenching pool 6 is installed in the quenching area; The upper surface is provided with a mobile platform 15, and the mobile platform 15 is provided with a lifting mechanism 14 for lifting and lowering the crucible 11. The crucible 11 is hoisted below the mobile platform 15 and connected with the lifting mechanism 14. The crucible 11 is provided on the outer wall near the upper port There is an annular c...

specific Embodiment approach 2

[0014] Embodiment 2: This embodiment is different from Embodiment 1 in that: the upper port of the crucible 11 is provided with lifting lugs.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment is different from Embodiment 1 or 2 in that: the lower end of the wire rope in the hoisting mechanism 14 is provided with a hook 16 , and the hook 16 is connected to the lifting lug provided on the port on the crucible 11 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com