Iron-aluminum-boron abrasion-resistant alloy and preparation method thereof

A boron wear-resistant and alloy technology, applied in the field of wear-resistant materials, can solve the problems of easy oxidation during heating and heat preservation, easy deformation of workpieces, increased energy consumption, etc., to improve high-temperature oxidation resistance, improve smelting efficiency, and improve wear resistance sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

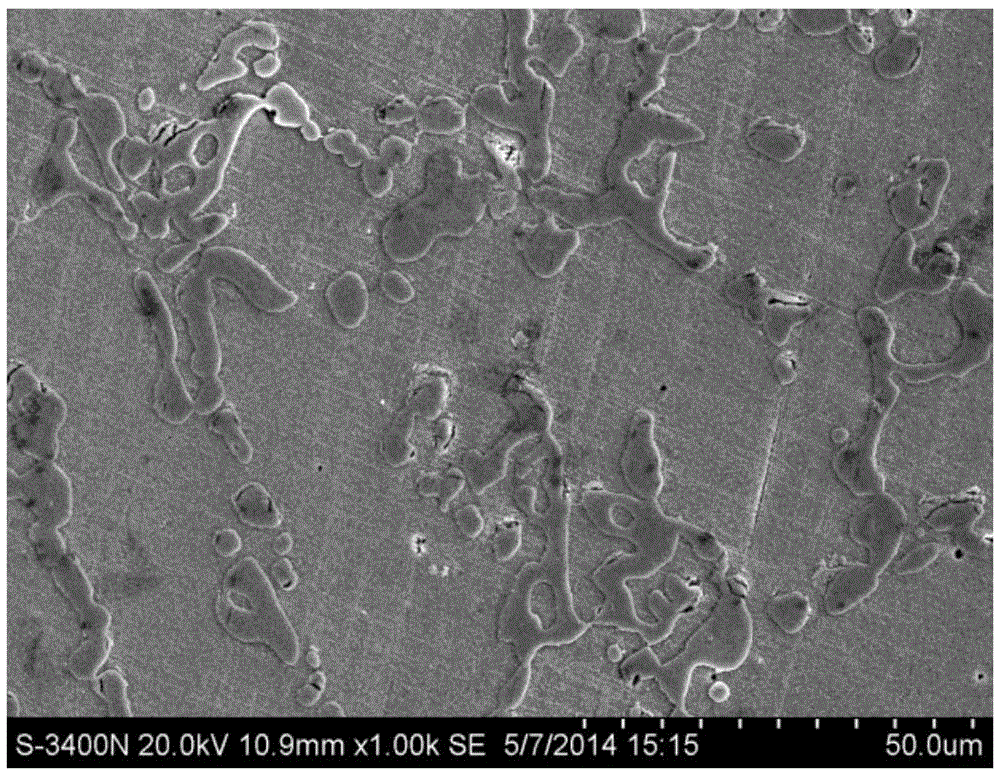

Image

Examples

Embodiment 1

[0023] An iron-aluminum-boron wear-resistant alloy and a preparation method thereof, the manufacturing process steps are:

[0024] ①Use two 500kg medium-frequency induction furnaces to smelt high-boron multi-element alloy melt and aluminum-iron multi-element alloy melt at the same time respectively. The composition and mass fraction of high-boron multi-element alloy melt are: 3.01%B, 0.65%C, 4.13%Si , 1.02% Cr, 0.36% Mn, 0.023% S, 0.045% P, the balance Fe, the aluminum-iron multi-element alloy melt is composed of 60% Q235 scrap steel, 39% aluminum ingot and 1% ZnCl 2 It is smelted. During the smelting process of aluminum-iron multi-element alloy melt, 60% mass fraction of Q235 steel scrap is first added (the chemical composition and mass fraction of Q235 steel scrap are: 0.19%C, 0.47%Mn, 0.21%Si, 0.033%S, 0.040% %P, the balance being Fe), when the steel scrap is completely melted, start to add aluminum ingots with a mass fraction of 39%, and when the aluminum ingots are comple...

Embodiment 2

[0028] An iron-aluminum-boron wear-resistant alloy and a preparation method thereof, the manufacturing process steps are:

[0029] ①Use two 350 kg intermediate frequency induction furnaces to simultaneously melt high-boron multi-element alloy melt and aluminum-iron multi-element alloy melt. The composition and mass fraction of high-boron multi-element alloy melt are: 3.46%B, 0.53%C, 4.49%Si , 1.17% Cr, 0.28% Mn, 0.036% S, 0.041% P, the balance Fe, the aluminum-iron multi-element alloy melt is composed of 64% Q235 scrap steel, 34.5% aluminum ingot and 1.5% ZnCl 2 It is smelted. During the smelting process of aluminum-iron multi-element alloy melt, Q235 steel scrap with a mass fraction of 64% is first added (the chemical composition and mass fraction of Q235 steel scrap are: 0.18%C, 0.62%Mn, 0.18%Si, 0.035%S, 0.038% %P, the balance is Fe), when the steel scrap is completely melted, start to add aluminum ingots with a mass fraction of 34.5%, and when the aluminum ingots are compl...

Embodiment 3

[0033] An iron-aluminum-boron wear-resistant alloy and a preparation method thereof, the manufacturing process steps are:

[0034]①Use two 500 kg intermediate frequency induction furnaces to simultaneously melt high-boron multi-element alloy melt and aluminum-iron multi-element alloy melt. The composition and mass fraction of high-boron multi-element alloy melt are: 3.27%B, 0.59%C, 4.27%Si , 1.06% Cr, 0.42% Mn, 0.035% S, 0.047% P, the balance Fe, the aluminum-iron multi-element alloy melt is composed of 62% Q235 scrap steel, 37% aluminum ingot and 1.0% ZnCl 2 It is smelted. During the smelting process of the aluminum-iron multi-element alloy melt, Q235 steel scrap with a mass fraction of 62% is first added (the chemical composition and mass fraction of Q235 steel scrap are: 0.20%C, 0.43%Mn, 0.25%Si, 0.038%S, 0.039% %P, the balance being Fe), when the steel scrap is completely melted, start to add aluminum ingots with a mass fraction of 37%, and when the aluminum ingots are com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com