Patents

Literature

37results about How to "Improve thermal desorption efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

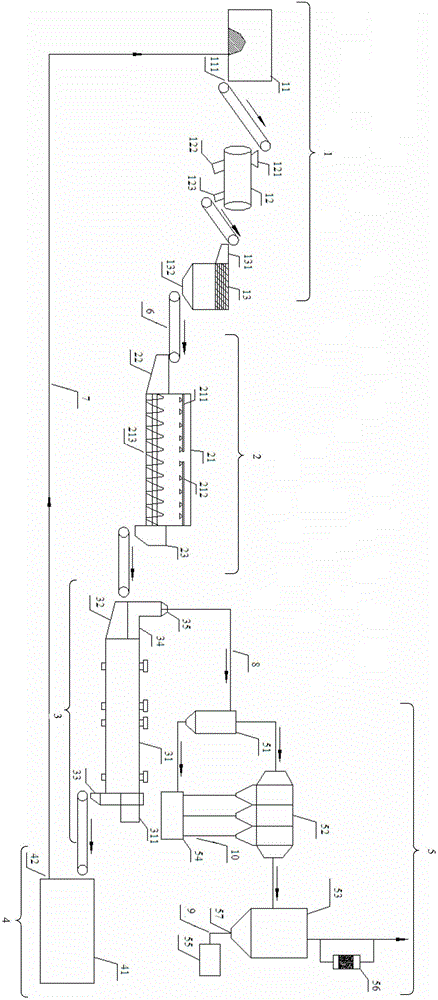

System and method for repairing polycyclic aromatic hydrocarbon contaminated soil

ActiveCN106363017AShorten the timeReduce competition effectContaminated soil reclamationPolycyclic aromatic hydrocarbonFlue gas

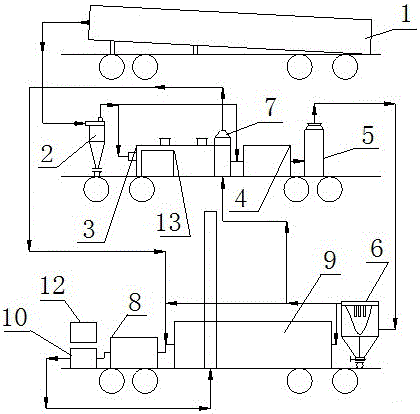

The invention provides a system for repairing polycyclic aromatic hydrocarbon contaminated soil. The system is provided with soil pretreatment equipment, chemical oxidation equipment, thermal desorption equipment, soil accumulation equipment and flue gas dust removal equipment in sequence. Conveying belts are arranged between the soil pretreatment equipment, the chemical oxidation equipment, the thermal desorption equipment and the soil accumulation equipment. The thermal desorption equipment communicates with the flue gas dust removal equipment through a pipeline. The soil accumulation equipment communicates with the soil pretreatment equipment through a pipeline. The invention further provides a method for repairing the polycyclic aromatic hydrocarbon contaminated soil. According to the system and method for repairing the polycyclic aromatic hydrocarbon contaminated soil, chemical oxidation and low-temperature thermal desorption are combined, and therefore the removal rate of polycyclic aromatic hydrocarbon of the soil can reach 99%, the repairing effect of the contaminated soil can be effectively improved, and the repairing period can be effectively shortened.

Owner:TONGJI UNIV +1

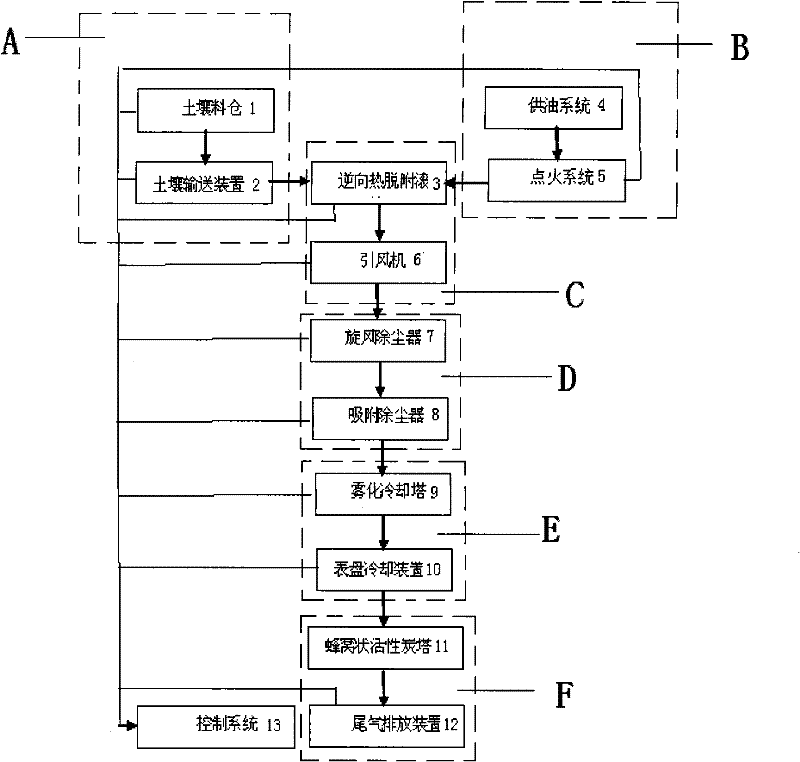

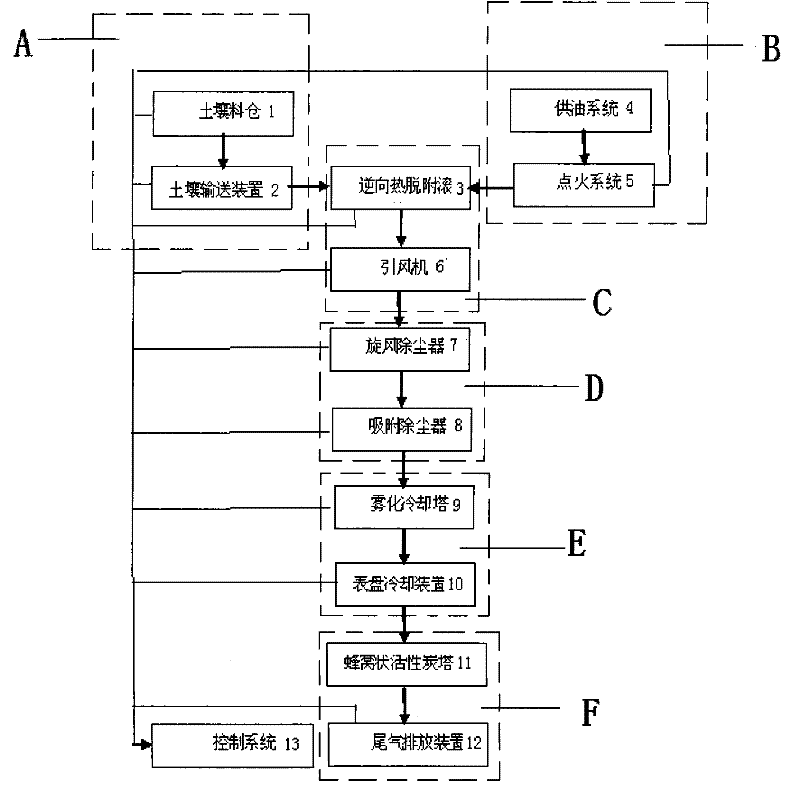

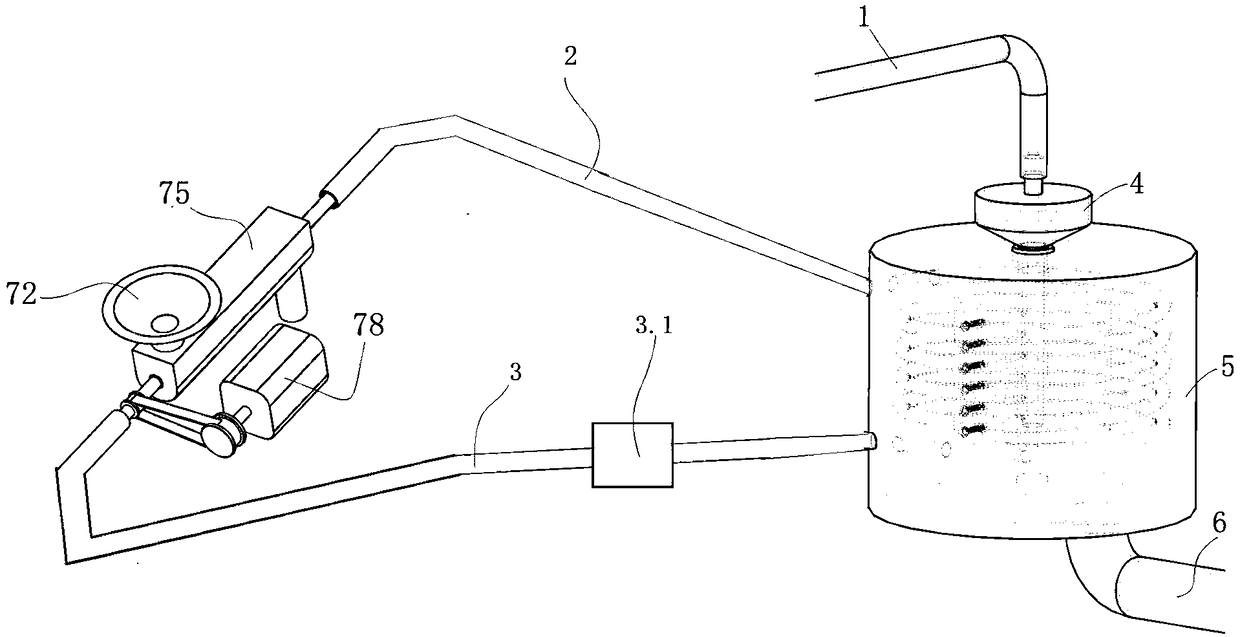

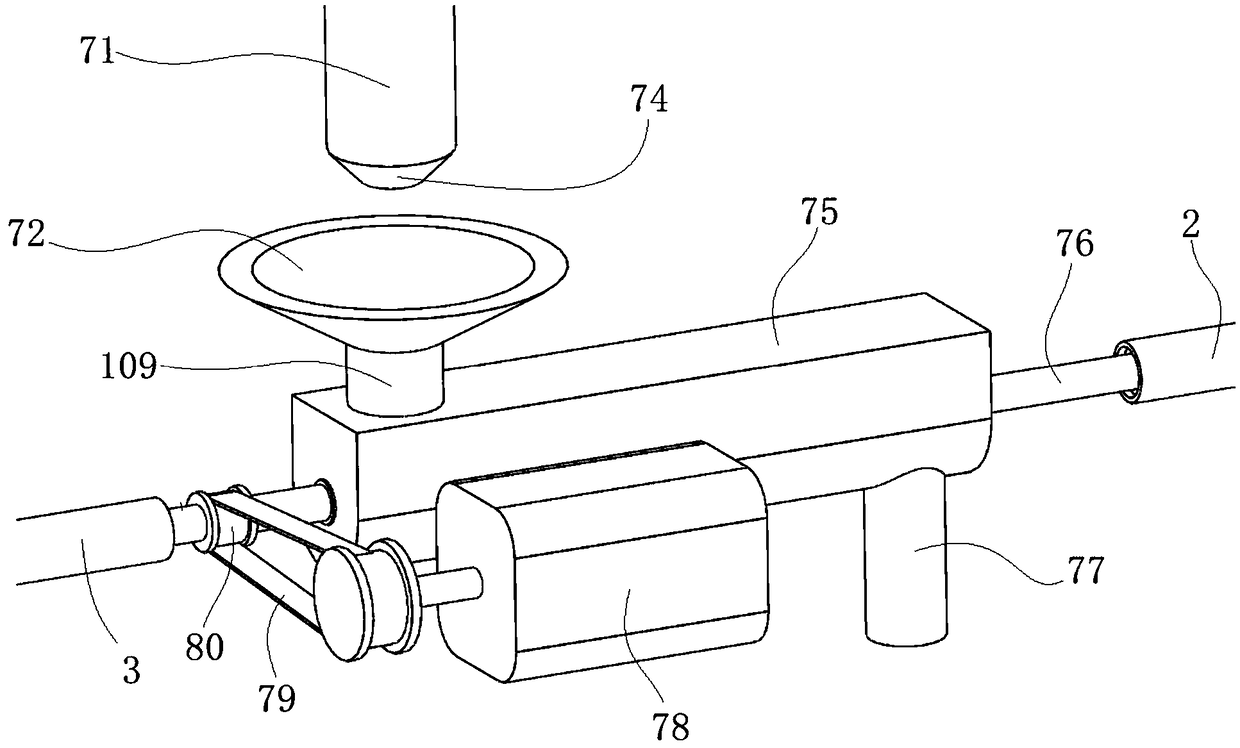

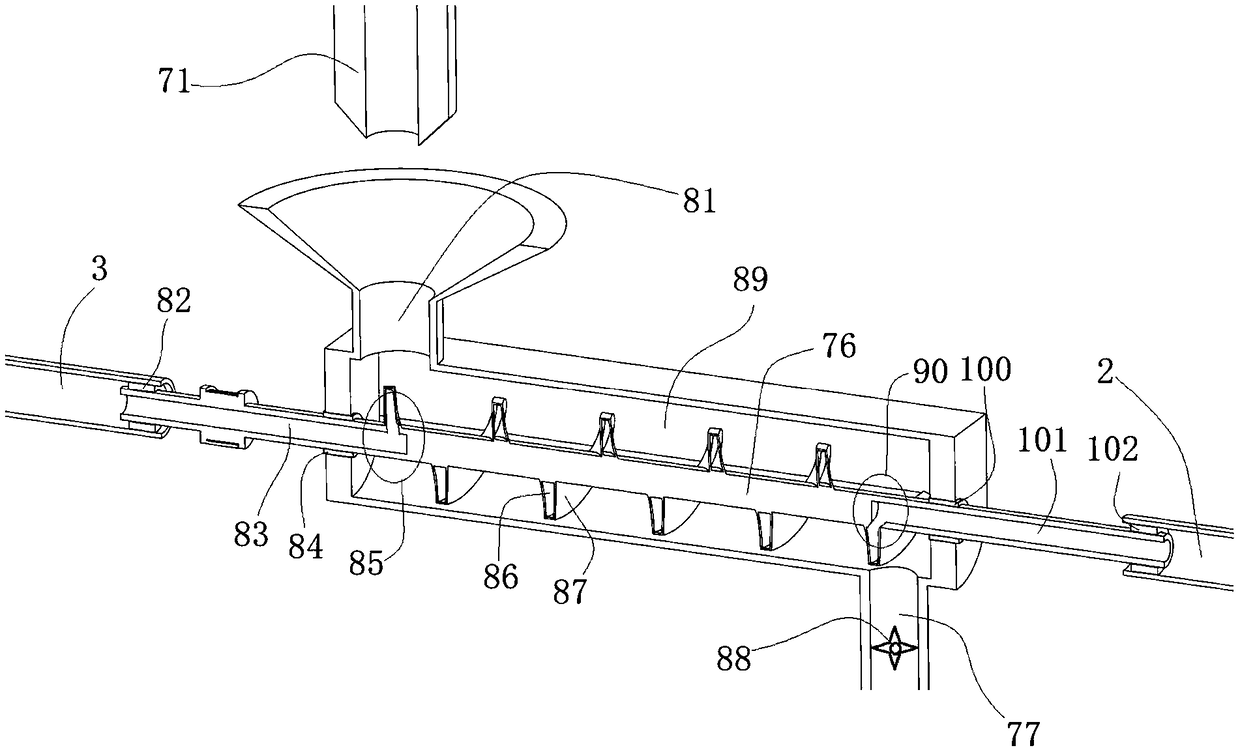

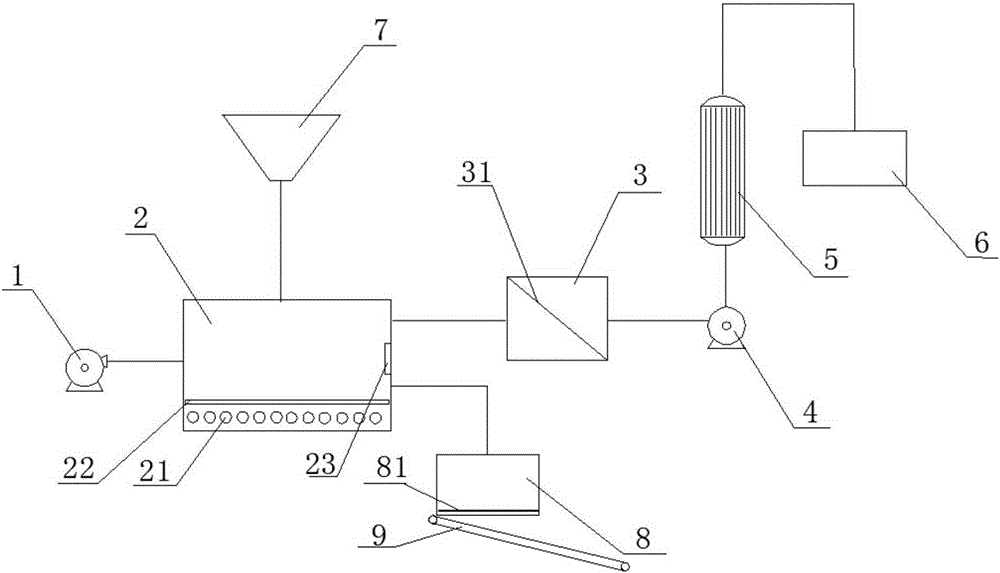

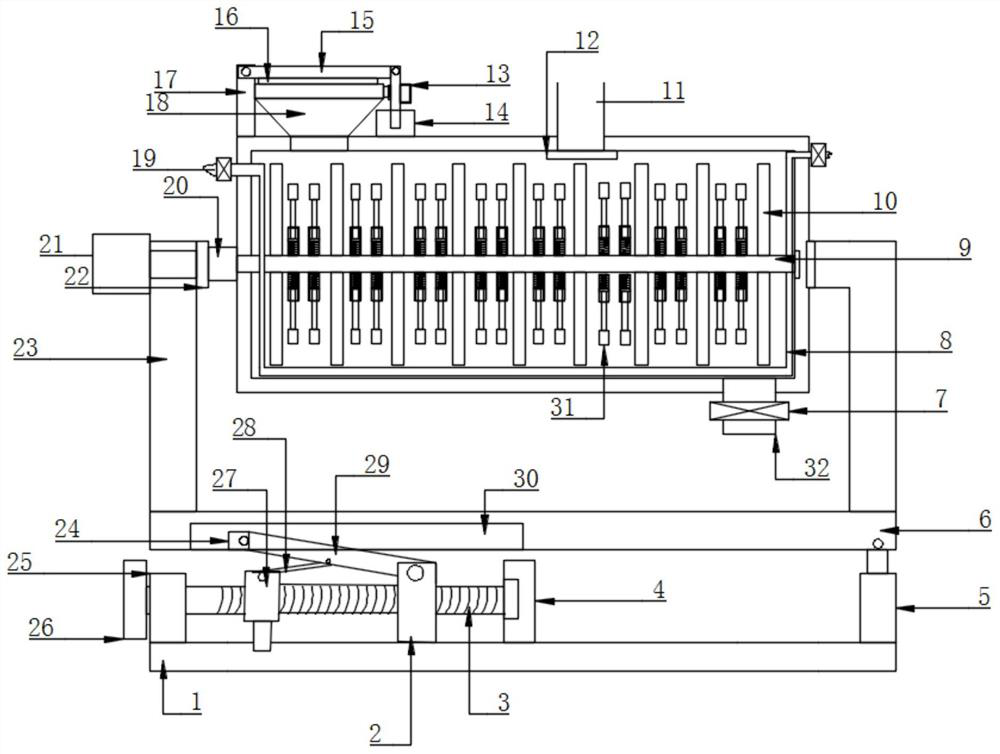

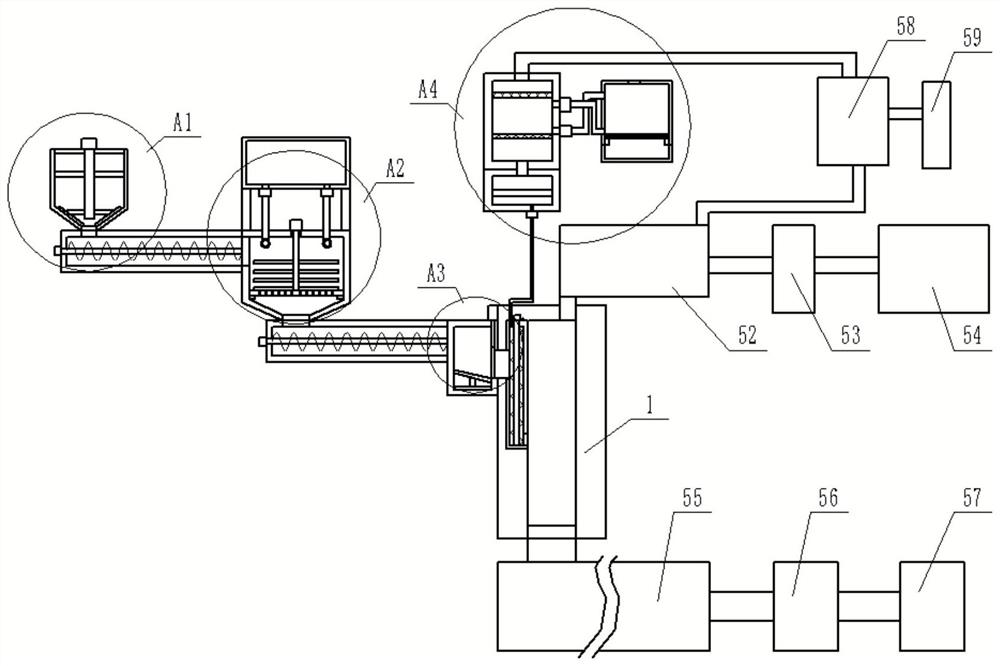

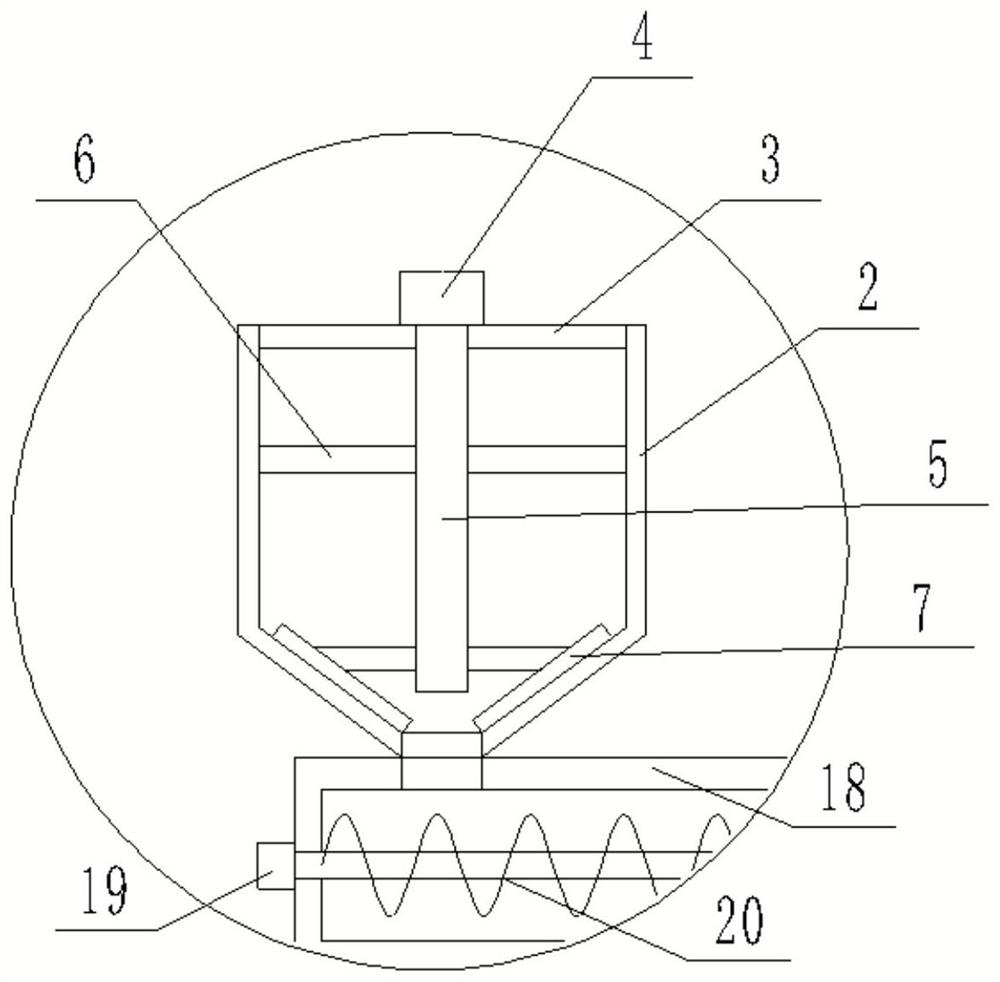

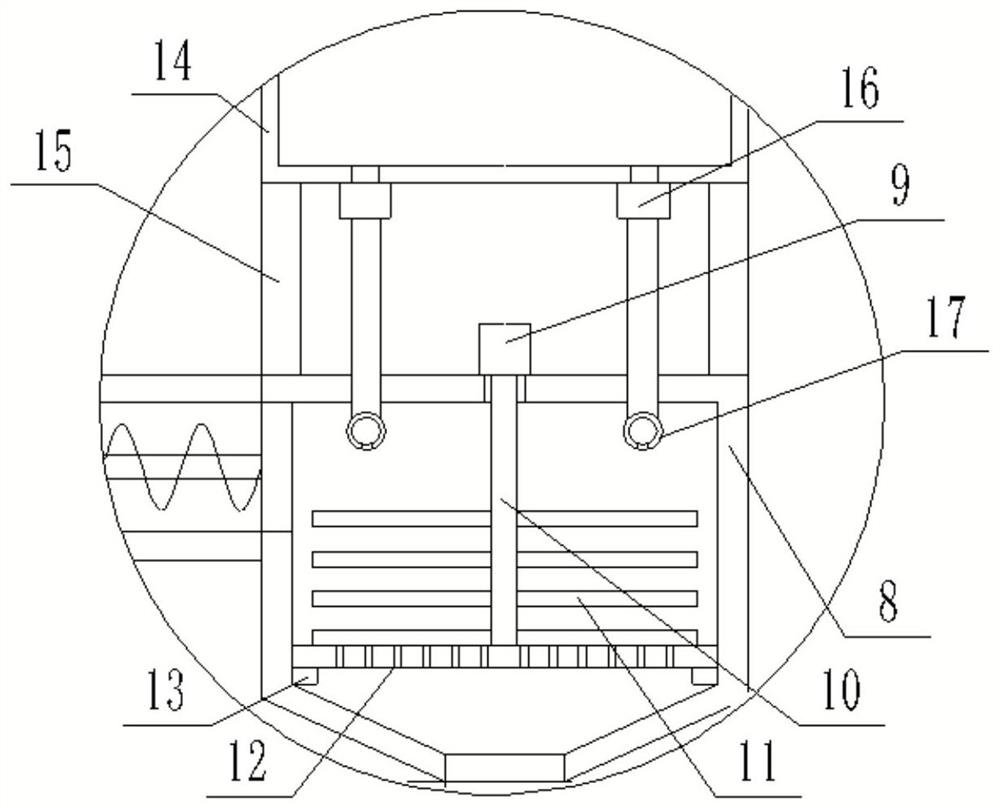

Roller-type reverse thermal desorption system for soil polluted by organic matters

ActiveCN102029287BLarge amount of processingImprove thermal desorption efficiencyContaminated soil reclamationCooling towerEngineering

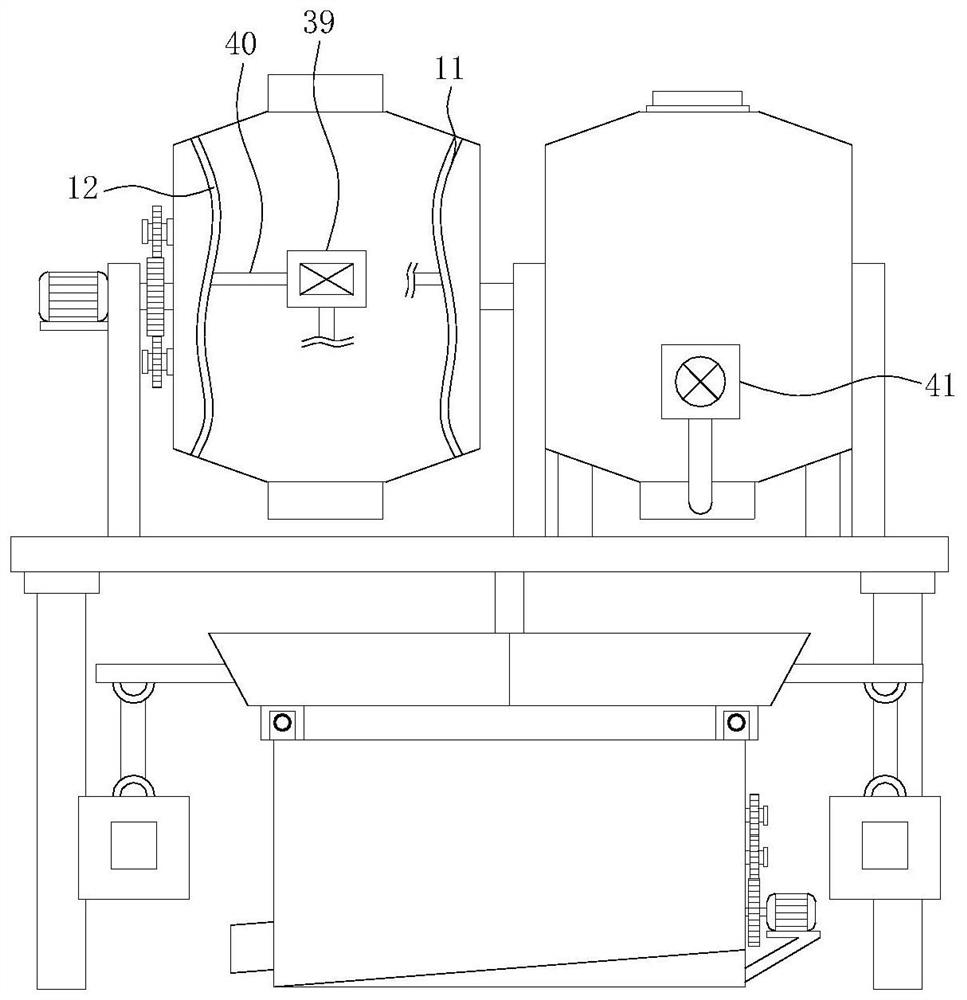

The invention relates to a roller-type reverse thermal desorption system for soil polluted by organic matters. The roller-type reverse thermal desorption system comprises a soil feeding system, wherein the soil feeding system and a heat source system are connected with a reverse thermal desorption system; the reverse thermal desorption system is connected with a dust removing system, a cooling system and an active carbon adsorption system in turn; and control ends of the soil feeding system, the heat source system, the reverse thermal desorption system, the dust removing system, the cooling system and the active carbon adsorption system are connected with a control system. In the roller-type reverse thermal desorption system, hot air is fed into a reverse thermal desorption roller by an ignition system, and polluted soil is fed into the reverse thermal desorption roller by a soil transferring device, wherein the hot air contacts the soil reversely, so that organic pollutants containedin the soil are heated and volatilized; the purified soil is used as backfill soil; and the volatilized tail gas is dedusted by a cyclone dust extractor and an adsorption dust extractor after passingthrough an induced draft fan, and the dedusted volatilized tail gas is absorbed by a honeycomb-shaped active carbon tower after passing through an atomization cooling tower and a dial plate cooling device, and finally is discharged by a tail gas exhaust device on the basis of meeting the national standard. Materials can be fed into the roller-type reverse thermal desorption system continuously and can be heated directly; and the hot air and the polluted soil are fully mixed, and the roller-type reverse thermal desorption system has high thermal desorption efficiency.

Owner:TSINGHUA UNIV +1

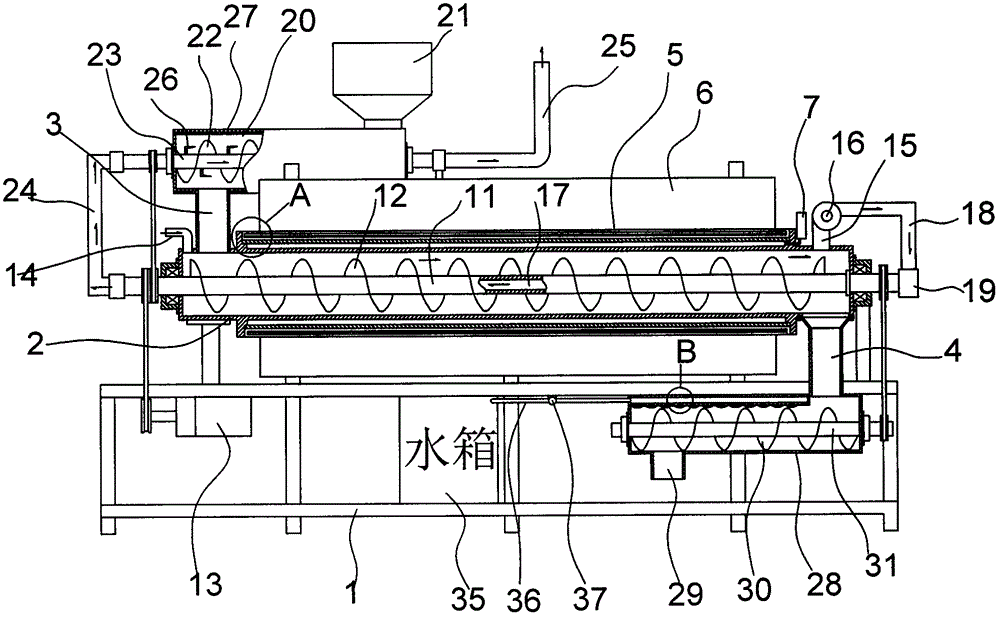

Energy-saving soil contamination thermal desorption device

ActiveCN105750319AReduce thermal desorption costsImprove thermal desorption efficiencyContaminated soil reclamationSoil contaminationConservation energy

The invention relates to the technical field of soil treatment and discloses an energy-saving soil contamination thermal desorption device. The device comprises a support and a horizontal heating barrel arranged on the support, wherein a feeding channel is formed in the upper side of the left end of the heating barrel, a discharging channel is formed in the lower side of the right end of the heating barrel, a solar heat collecting tube is arranged on the outer side of the heating barrel, a solar reflector is arranged on one side of the support, a spindle is arranged in the heating barrel, a screw belt is arranged on the surface of the spindle, a motor for driving the spindle to rotate is arranged on the support, an air inlet pipe is arranged on the upper side of the left end of the heating barrel, an exhaust pipe is arranged on the upper side of the right end of the heating barrel, and an exhaust fan is arranged on the exhaust pipe. The device is heated by solar energy, energy is saved, and the soil thermal desorption cost is reduced.

Owner:江苏普泽环境工程有限公司

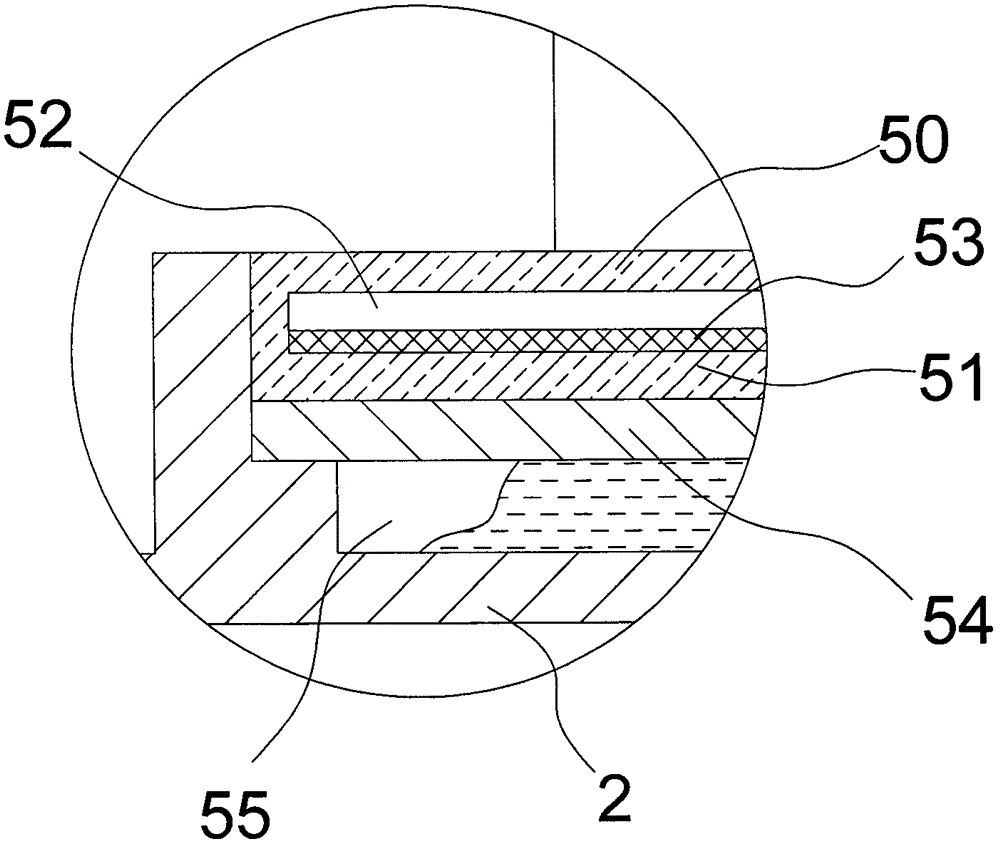

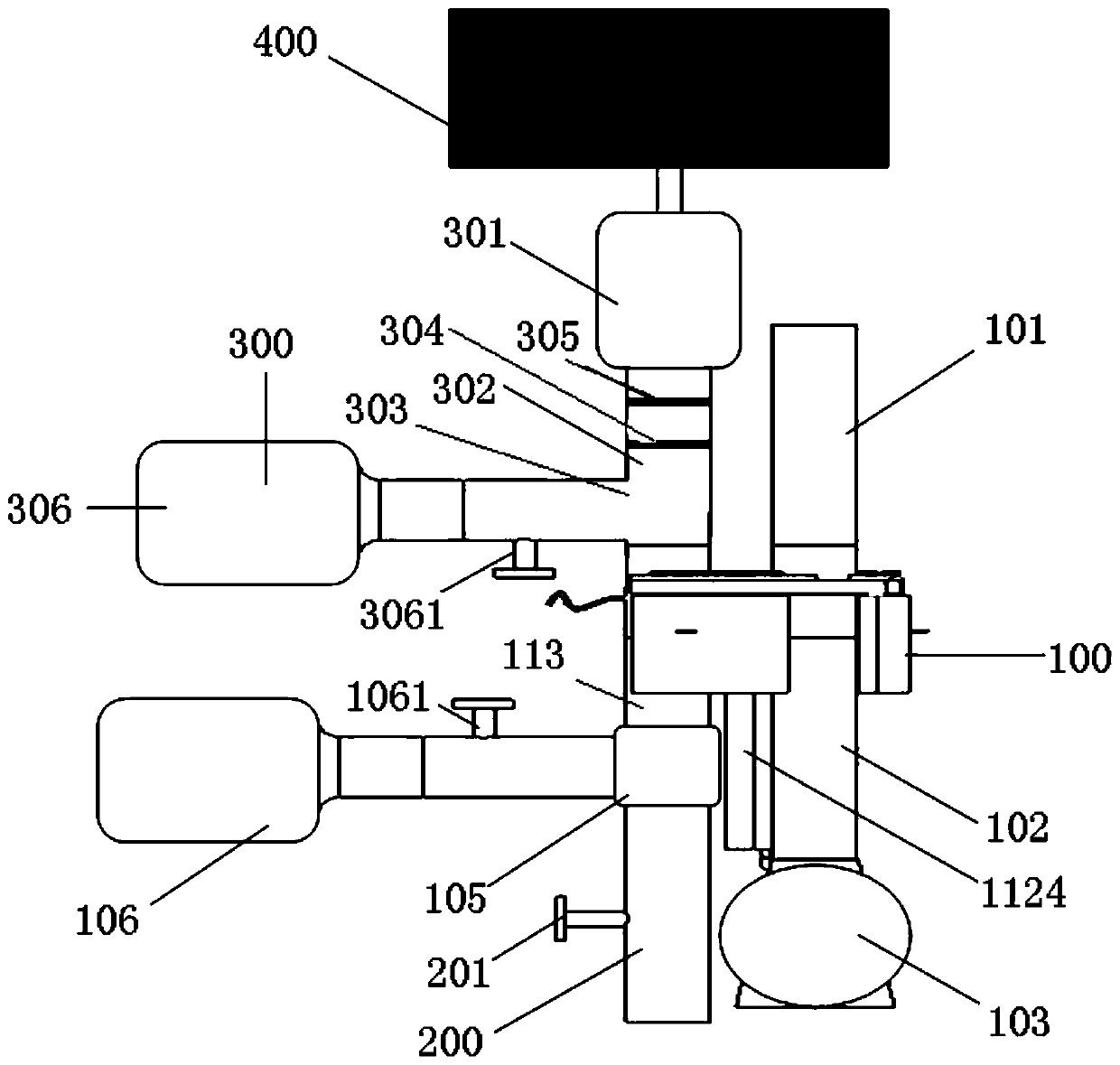

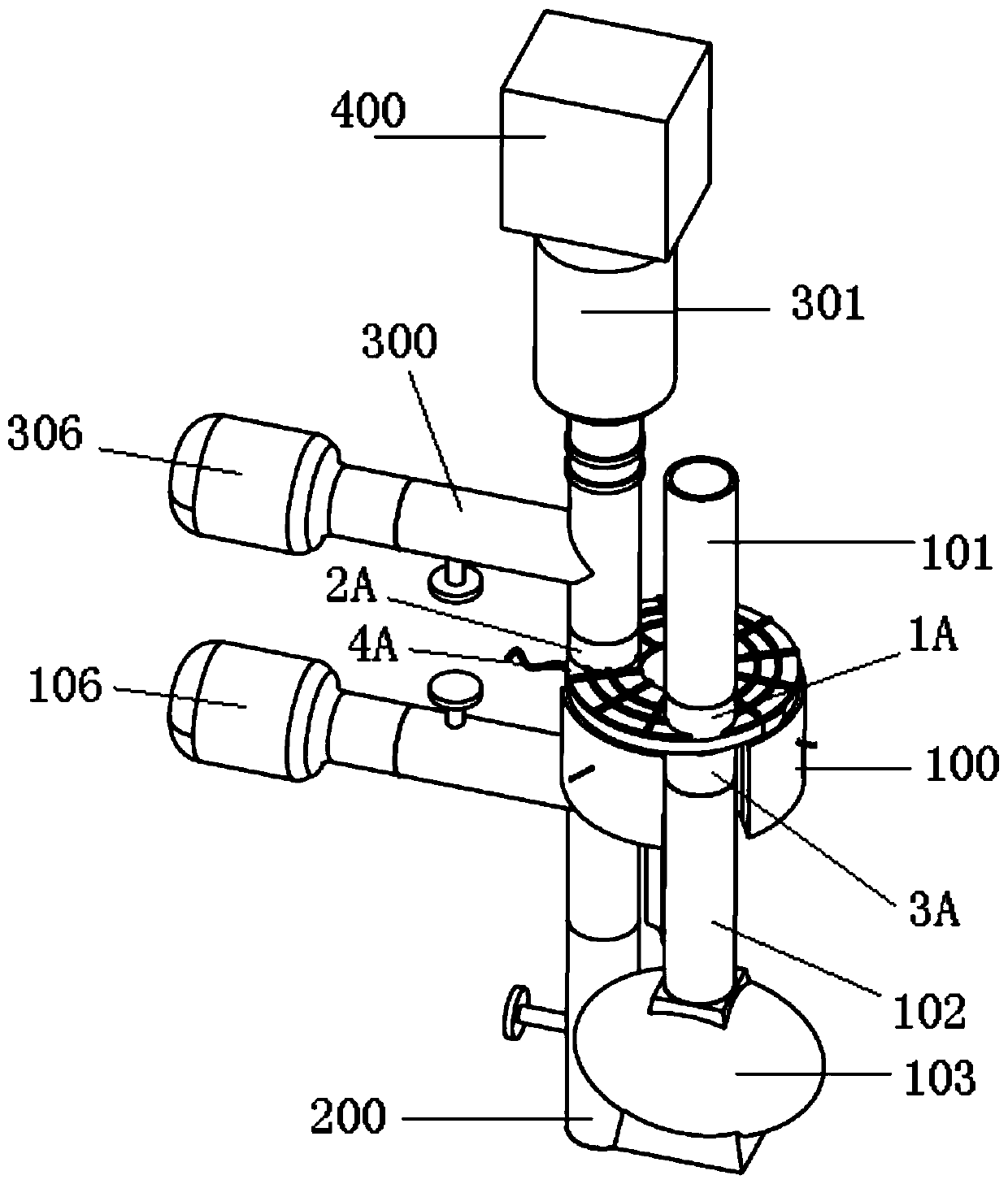

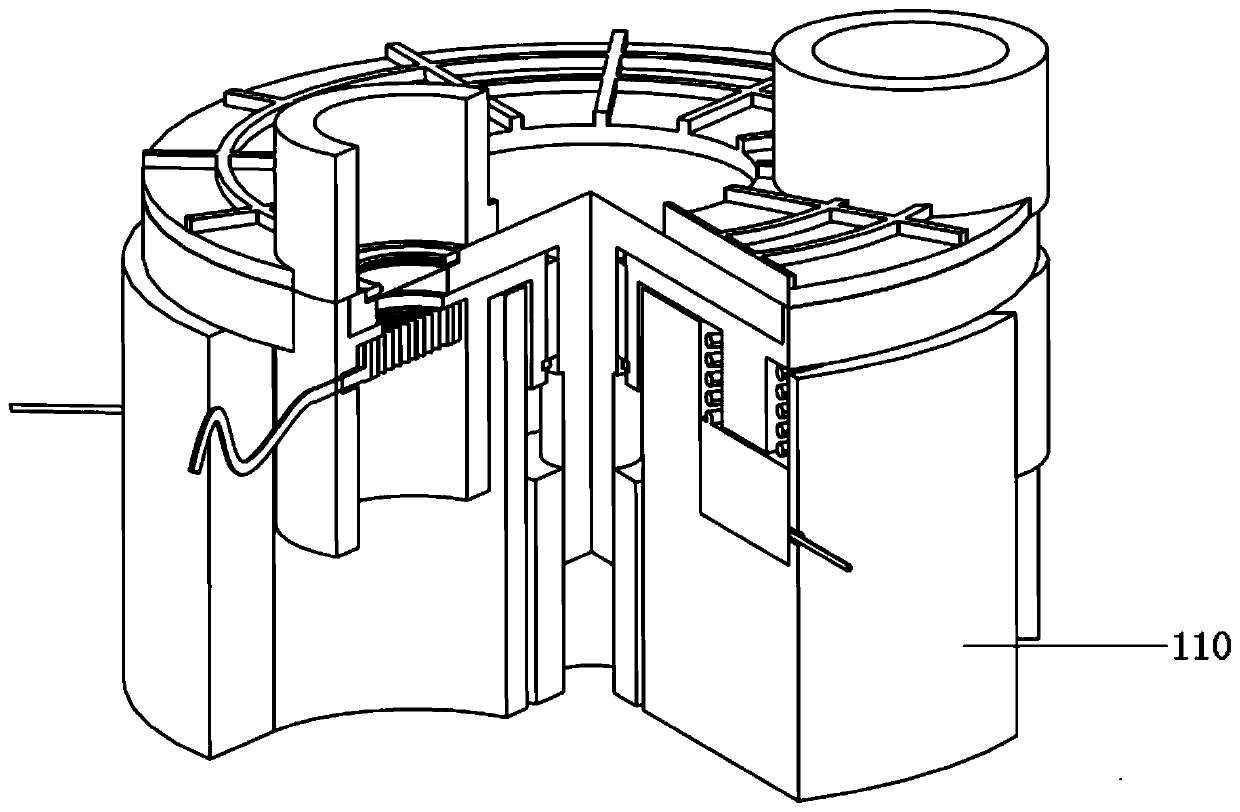

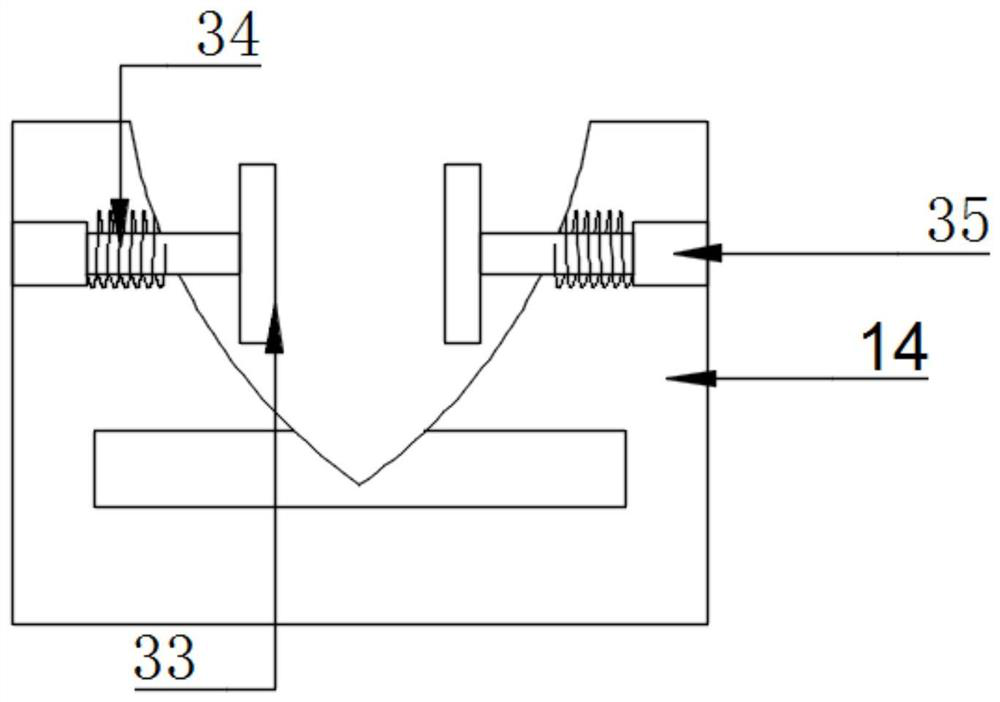

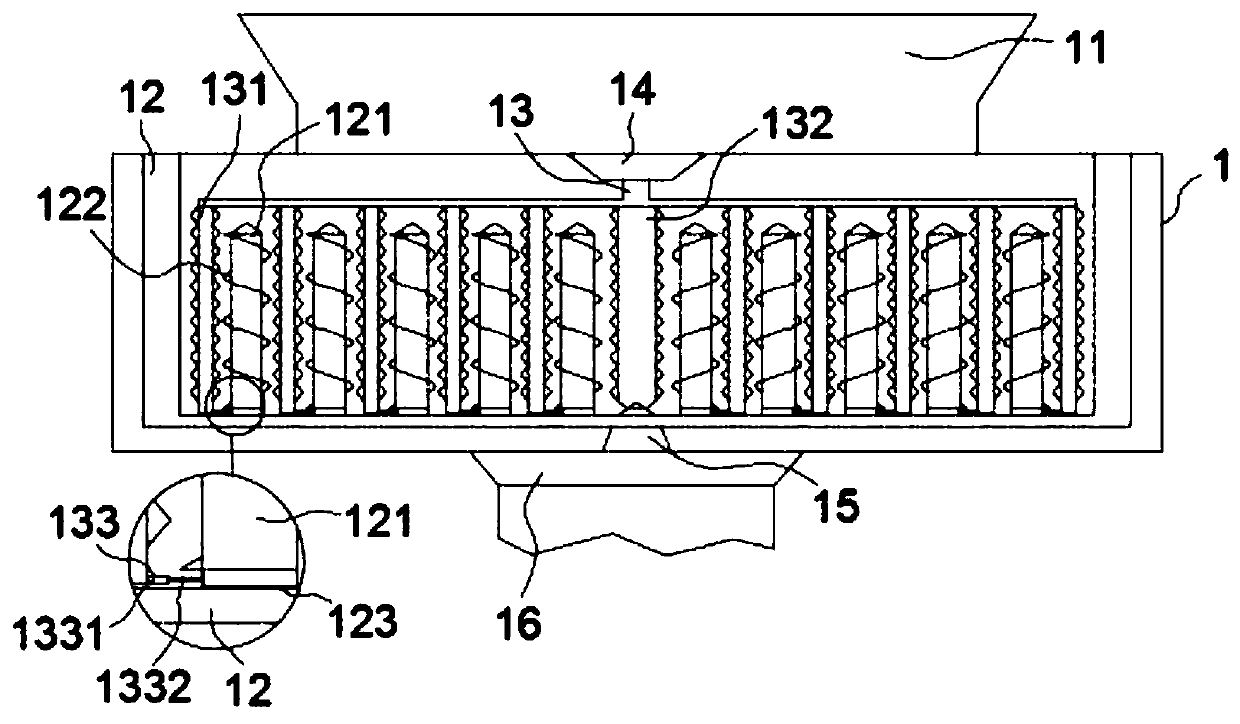

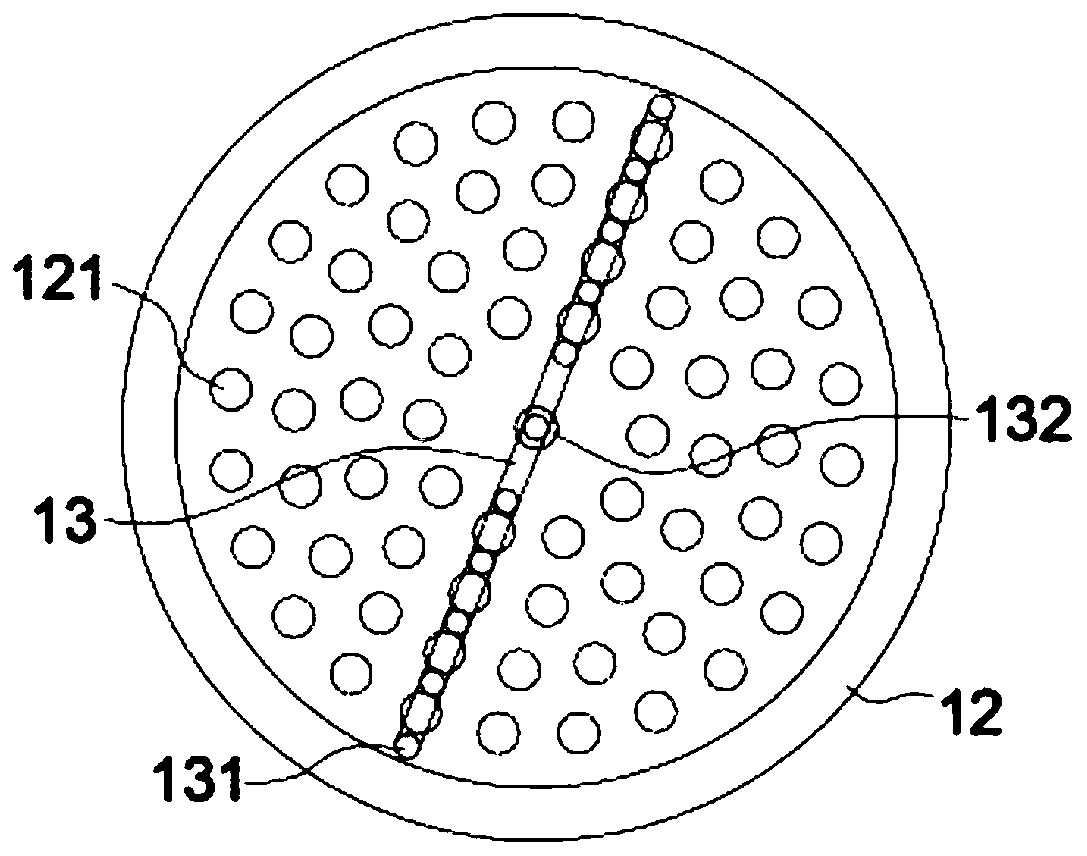

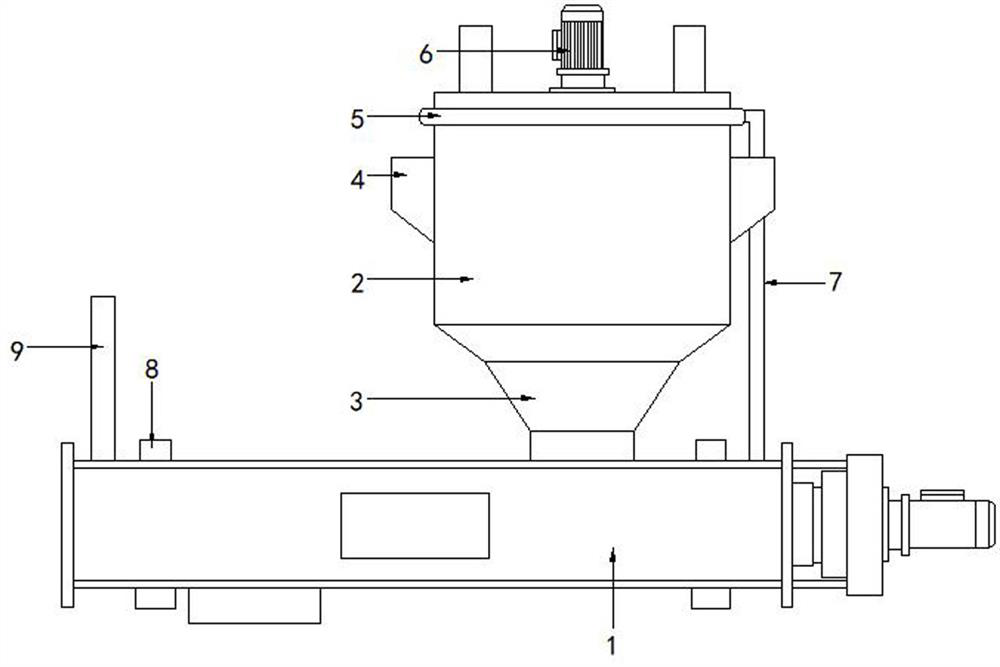

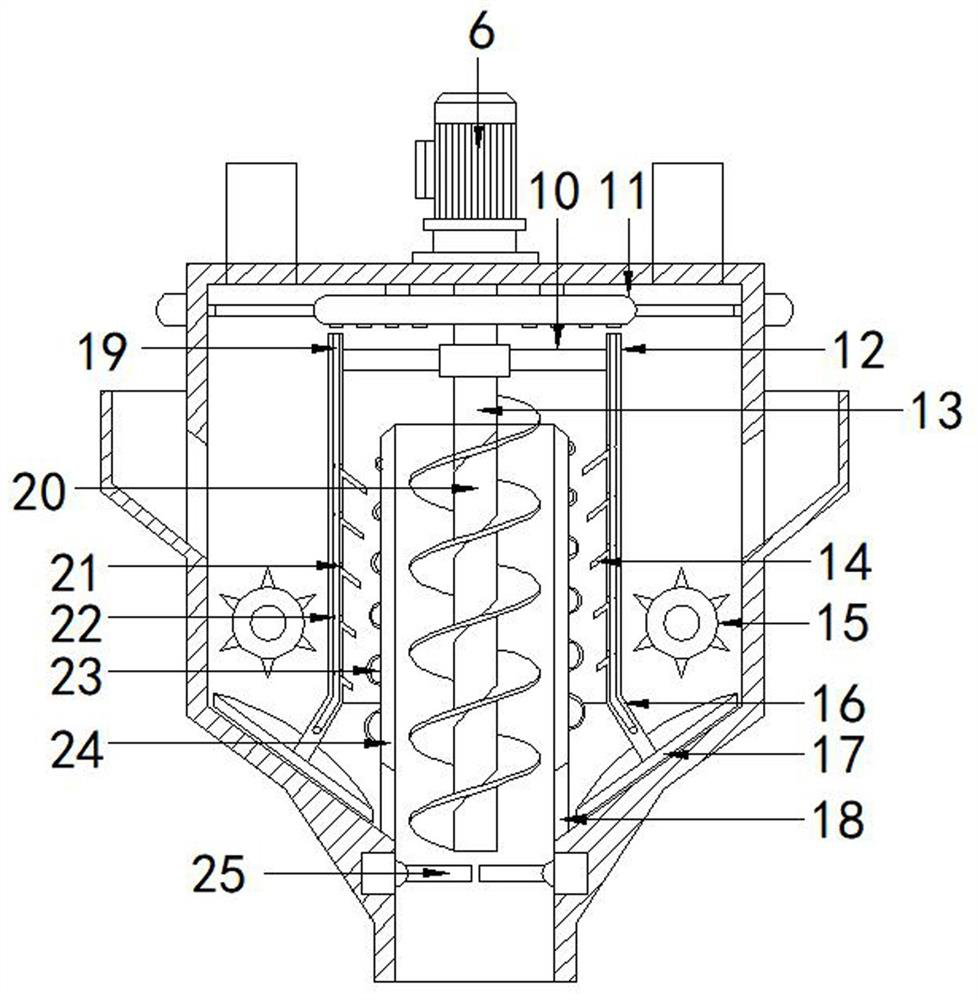

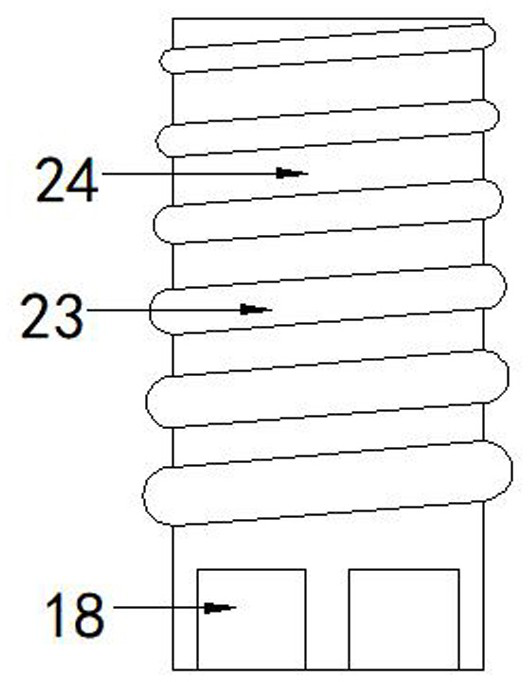

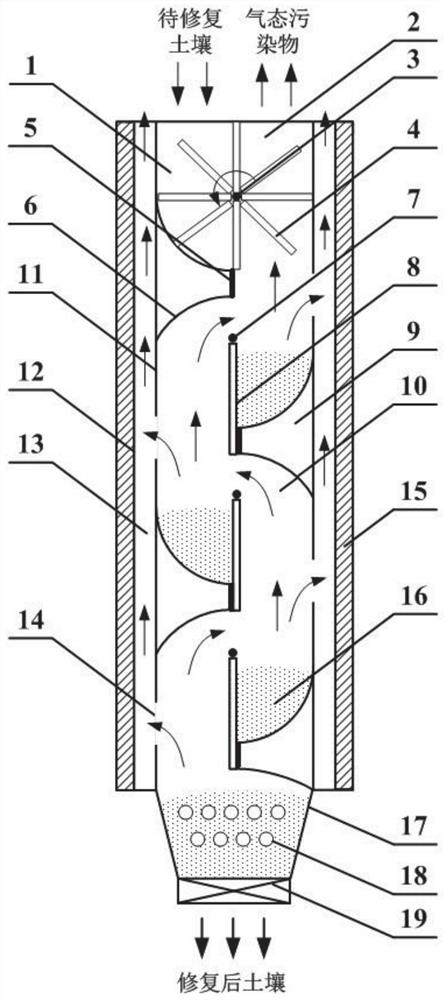

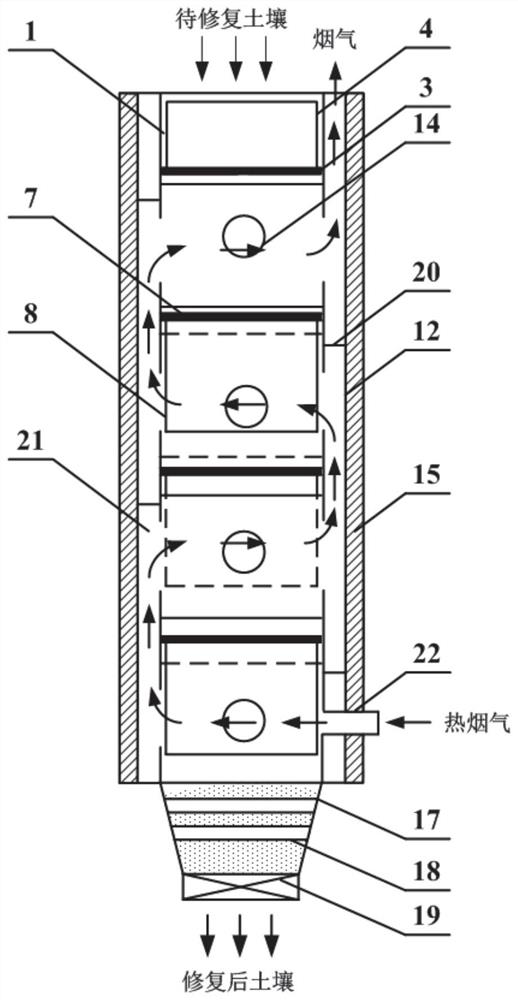

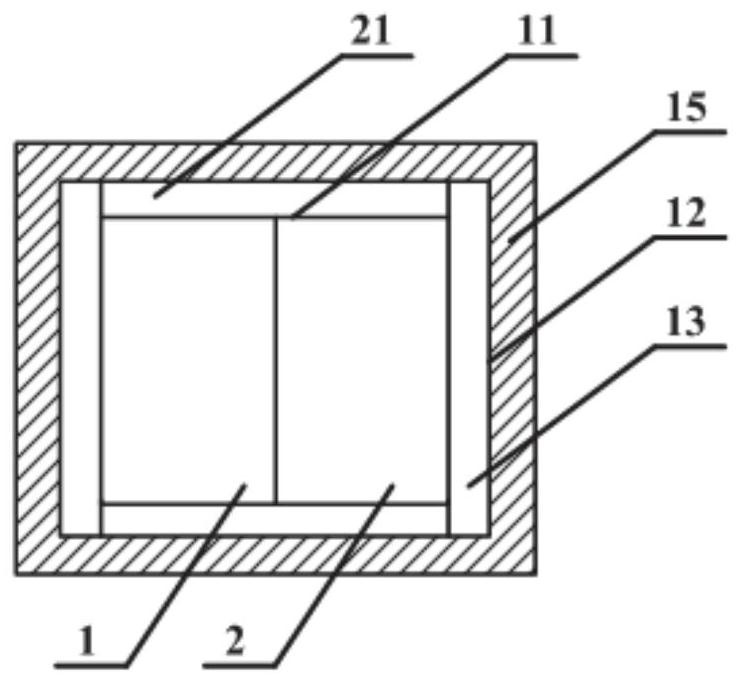

Pyrolysis desorption reaction kettle and treatment equipment including same for oily sludge of offshore platform

ActiveCN107176779ASmall footprintReduce occupancyElectrical coke oven heatingSludge treatment by pyrolysisPyrolysisEngineering

The invention belongs to the technical field of oily sludge treatment and particularly relates to a pyrolysis desorption reaction kettle and treatment equipment including the same for oily sludge of an offshore platform. The pyrolysis desorption reaction kettle comprises a body (1), wherein a material inlet (11), a material outlet (12) and a pyrolysis gas outlet (13) are formed in the body (1), a material conveying mechanism is arranged in the body (1), and the pyrolysis desorption reaction kettle is vertically distributed; and the material conveying mechanism comprises a disc dryer (2) and a single-shaft double-helix stirrer (3), the disc dryer (2) for generating a transverse centrifuging effect to materials is arranged in an upper space in the pyrolysis desorption reaction kettle, and the single-shaft double-helix stirrer (3) for generating a vertical rolling effect to the materials is arranged in a lower space in the pyrolysis desorption reaction kettle. According to the treatment equipment including the pyrolysis desorption reaction kettle for the oily sludge of the offshore platform, the occupied area of the equipment is reduced, and meanwhile, the treatment efficiency of the oily sludge is improved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

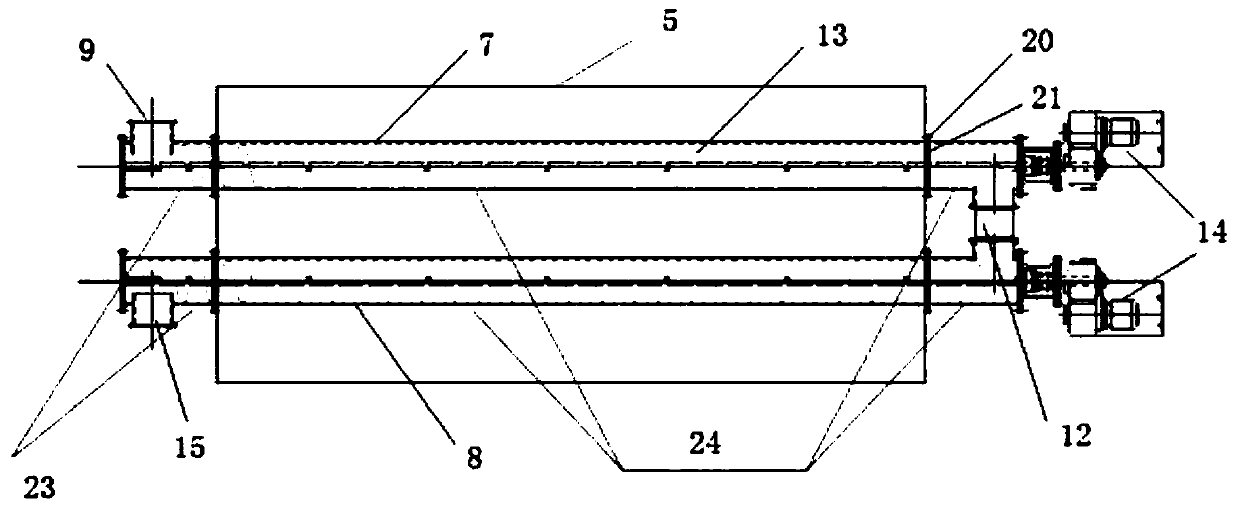

Hollow packing auger blade-type soil remediation device and method

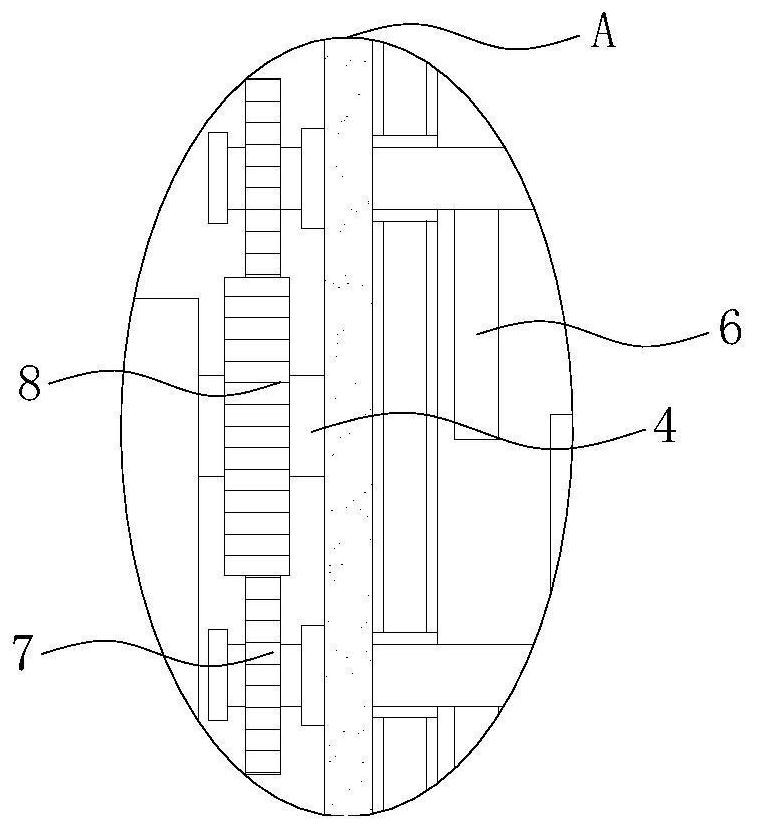

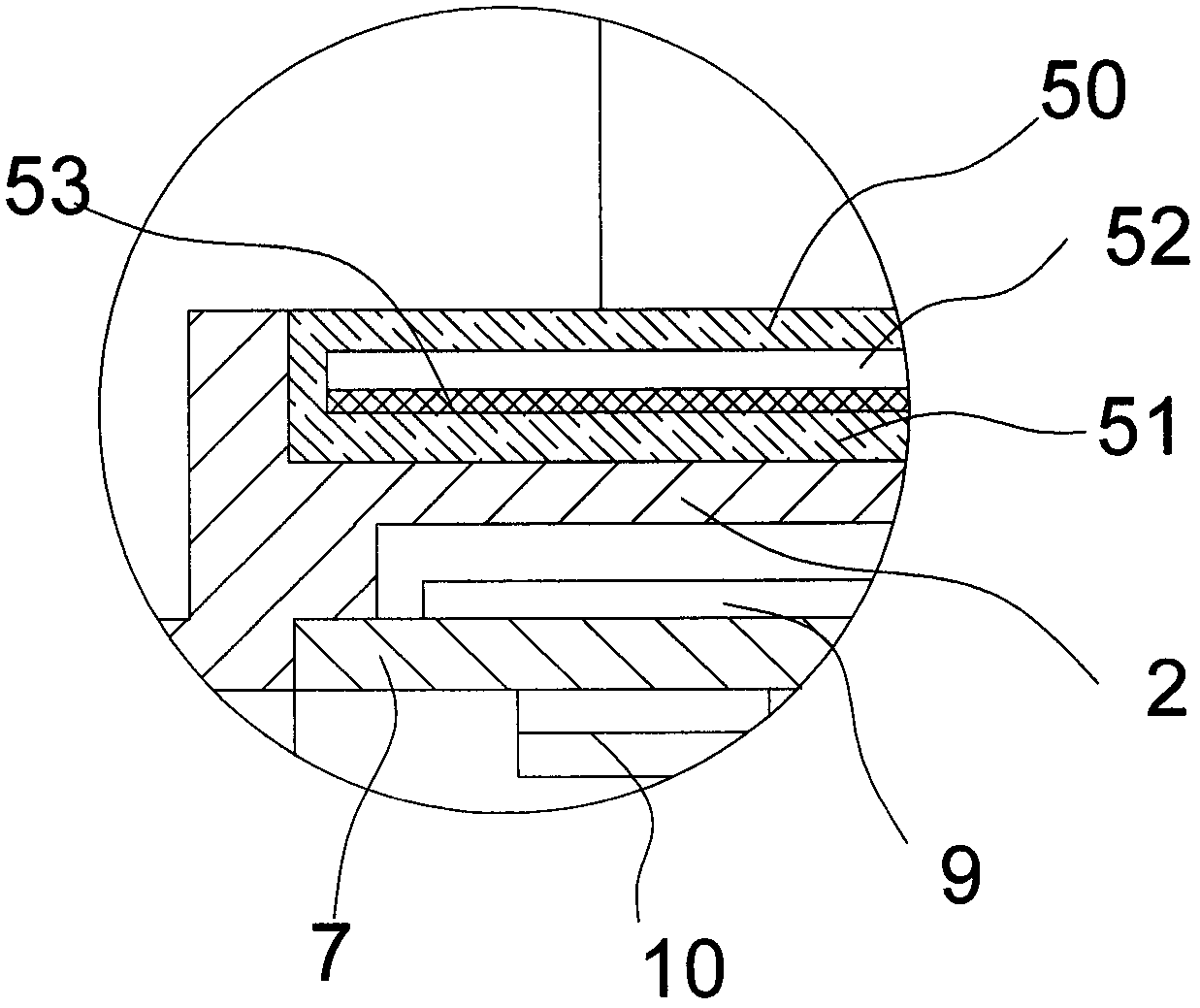

ActiveCN108817064AImprove thermal desorption efficiencyReduce generationContaminated soil reclamationSoil remediationHeat conducting

The invention discloses a hollow packing auger blade-type soil remediation device. The device comprises a soil thermal desorption transmission shell. A soil thermal desorption chamber is arranged in the soil thermal desorption transmission shell along the length direction. A packing auger blade shaft extends along the length direction in the soil thermal desorption chamber. Two ends of the packingauger blade shaft respectively pass through the two end walls of the soil thermal desorption transmission shell. The shaft walls of the packing auger blade shaft are rotatingly arranged on the two end walls of the soil thermal desorption transmission shell through a first seal bearing and a second seal bearing. The device has a simple structure. A spiral liquid guiding channel is filled with flowing high-temperature heat-conducting oil, so that the packing auger blade is always in a heating state and the packing auger blade continuously agitates the soil in the soil thermal desorption chamberand gently heats the soil turned in the soil thermal desorption chamber.

Owner:大庆中环评价检测有限公司

Organic matter soil restoration device

InactiveCN106799392ALarge amount of processingImprove thermal desorption efficiencyMembranesDispersed particle separationDirect heatingSoil remediation

The invention discloses an organic matter soil restoration device. The device is characterized by comprising a blower, a soil restoration box, a membrane separation system, a vacuum pump, a condenser and an organic matter collection tank, wherein a soil feed opening is formed in the upper part of the soil restoration box; a soil discharge opening is formed in the side face of the soil restoration box; the soil feed opening is connected with a soil breaking box; the soil discharge opening is connected with a soil cooling box; the soil cooling box is externally provided with a discharge device. The device has the benefits that the device can achieve continuous feeding, has high polluted soil treatment capacity, adopts a direct heating manner, has high heat desorption efficiency, employs the membrane separation system to treat exhaust gas and does not generate secondary pollution.

Owner:CHENGDU KECHUANGCHENG TECH

Atmospheric pollutant real-time sampling and analysis device and method

PendingCN110186998AImprove ionization reaction efficiencyThe method has high sensitivityWithdrawing sample devicesMaterial analysis by electric/magnetic meansParticulatesNitrogen

The invention provides an atmospheric pollutant real-time sampling and analysis device and a method. The device comprises a particulate matters online sampling unit, an environment gas component sampling unit, a soft ionization device and a mass spectrometer; the particulate matters online sampling unit comprises an atmosphere intake pipeline, a rotary table component, a first gas guiding flexiblepipe, a sucking pump, a film heating component, a first three-way valve and a nitrogen high pressure bottle. The device and the method provided by the invention have the following advantages: (1) reactive ions with relatively high reaction activity are generated through plasmas, the reactive ions react with a compound desorbed from a sampling film, thus, analyzable sample range of the device is expanded, and method sensitivity is improved; a sample is enabled to pass through a plasma generation device, contact area and time between the sample and the plasmas can be improved, and efficiency isimproved; (2) a plurality of particulate matters sampling films are mounted on the rotary table, thus, frequency of halting and changing the films is reduced, sample collection efficiency is improved, and operation steps are simplified; (3) the particulate matters sampling films are directly heated through a honeycomb window, and particulate state sample thermal desorption efficiency is improved.

Owner:INST OF ATMOSPHERIC PHYSICS CHINESE ACADEMY SCI

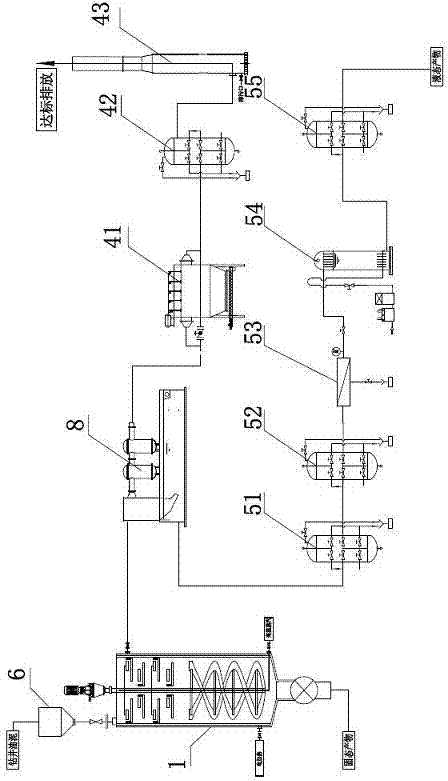

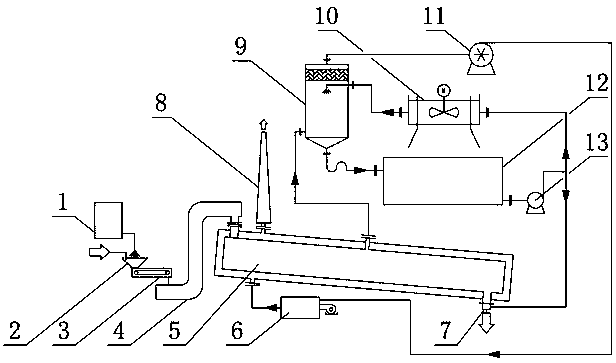

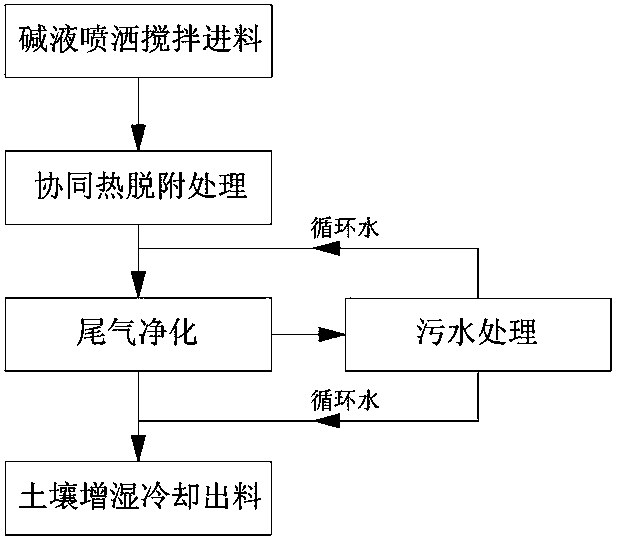

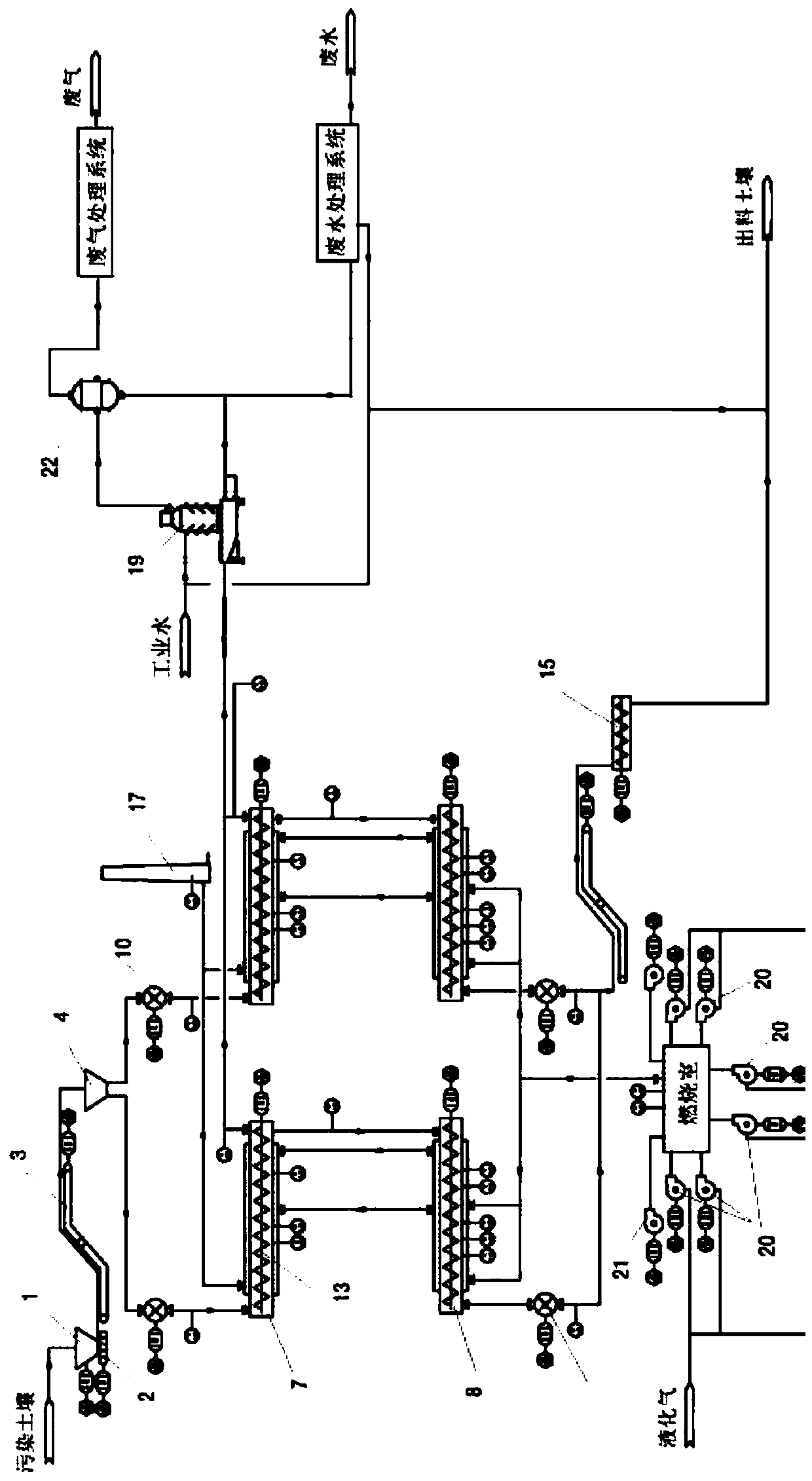

Synergistic indirect thermal desorption soil remediation system and remediation method thereof

PendingCN110180881ASolve the problem of small thermal desorption treatment capacityImprove thermal desorption efficiencyContaminated soil reclamationCombustion chamberSoil treatment

The invention relates to a synergistic indirect thermal desorption soil remediation system and a remediation method thereof. The system comprises an alkali liquor spray feeding system, fed soil is sent to a rotary kiln type thermal desorption chamber after alkali liquor spray stirring, a combustion chamber produces high-temperature flue gas to provide heat to indirectly heat a rotary kiln, and organic matter is degraded to be desorbed from polluted soil under the synergistic effect of heating and alkali liquor catalysis; the thermal desorption chamber is provided with a desorption gas outlet connected with a tail gas treatment system, the tail gas treatment system performs spray cooling on thermal desorption gas to condensate and transfer organic matter to sewage, and one part of producedsewage is recycled and the other part is used for humidifying discharged materials after the sewage is sent to a sewage treatment purification system for purification. The synergistic indirect thermaldesorption soil remediation system can significantly improve the soil treatment capacity, effectively reduce thermal adsorption temperature of organic matter polluted soil and save energy consumption.

Owner:CSSC NANJING LUZHOU ENVIRONMENT PROTECTION CO LTD

Movable multifunctional module thermal desorption system

InactiveCN106077068AEasy to automate managementAdjust equipment parameters in timeCombination devicesGas treatmentHigh concentrationOrganic sulfide compound

The invention relates to a movable multifunctional module thermal desorption system. Equipment of the system is divided into three modules; the module I comprises a thermal desorption rotary kiln 1; the module II comprises a cyclone dust collector 2, a secondary combustion chamber 3, a heat exchanger 4, a spray cooling tower 5, an alkali absorption tower 7, an automatic control system 13 and a steam-water separator 14; the module III comprises a bag type dust collector 6, an activated carbon absorber 8, a biofilter 9, an induced draft fan 10, an exhaust device 11 and a booster fan 12; the equipment of the module I, the module II and the module III are respectively arranged on movable equipment. The system is suitable for four process routes including high-concentration and high-toxicity organic compound contaminated sites, general volatile / semi-volatile organic compound contaminated sites, acidic organic compound contaminated sites and organic sulfide and ammonia-nitrogen organic compound contaminated sites; different process routes and equipment can be accurately and effectively provided according to different organic compound contaminated sites, so that the time for designing a technical route is reduced, and the transportation and onsite loading and unloading are convenient.

Owner:中钢集团天澄环保科技股份有限公司

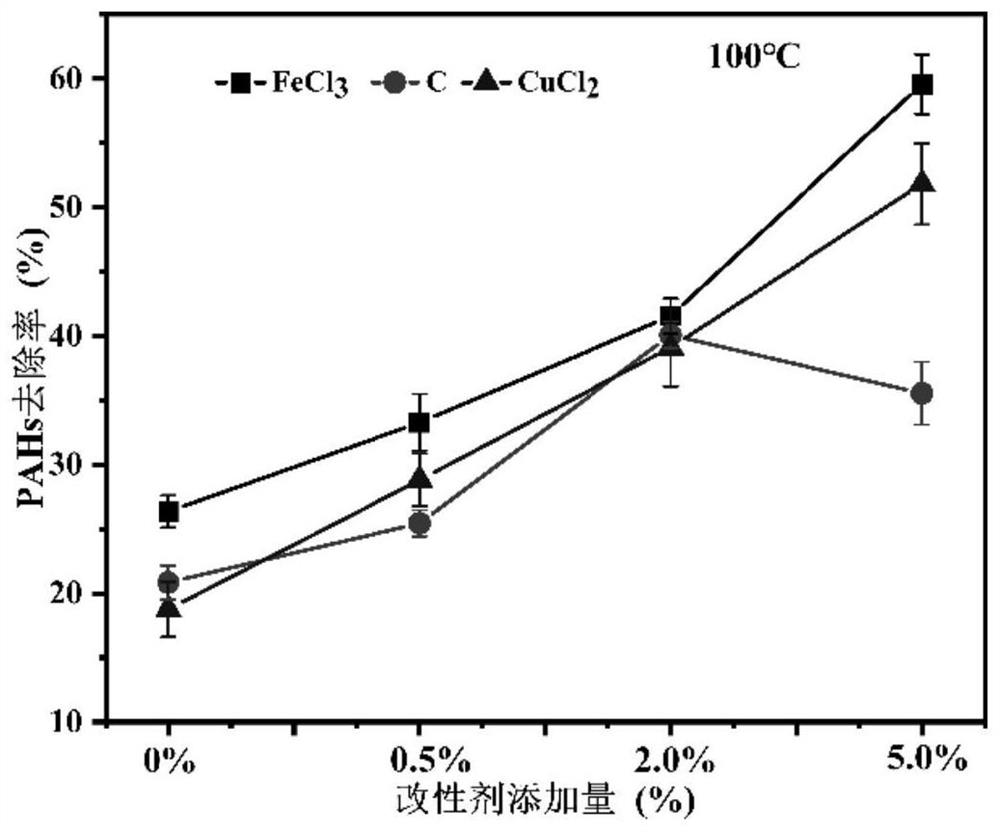

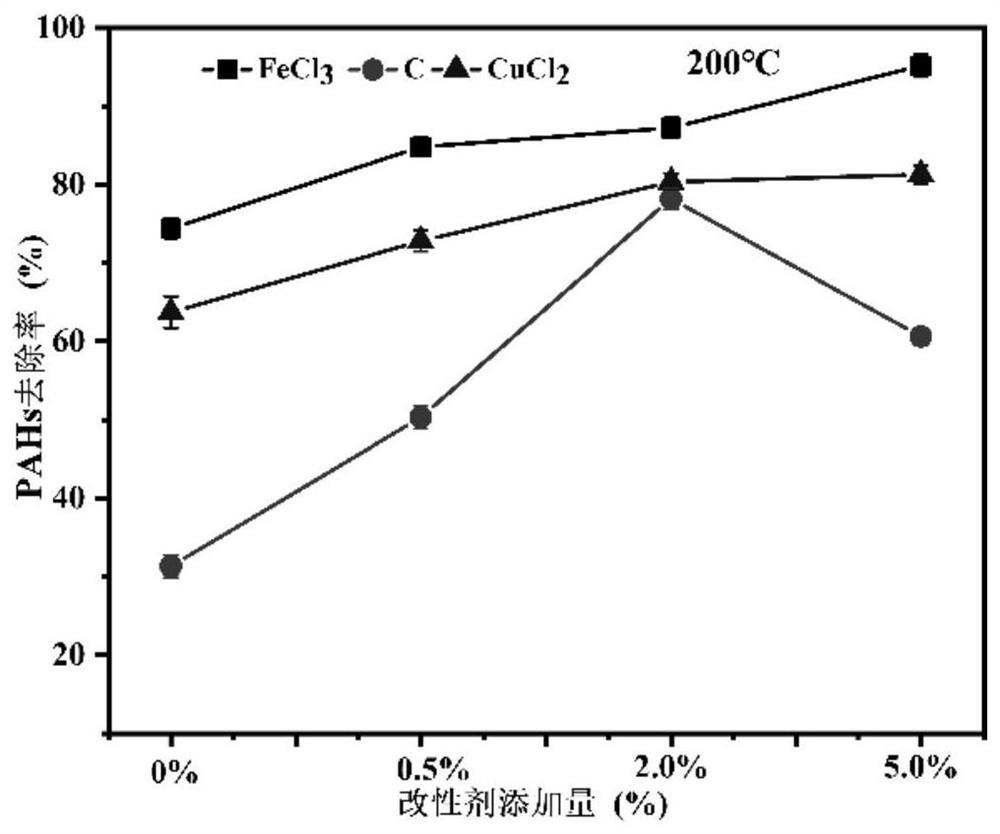

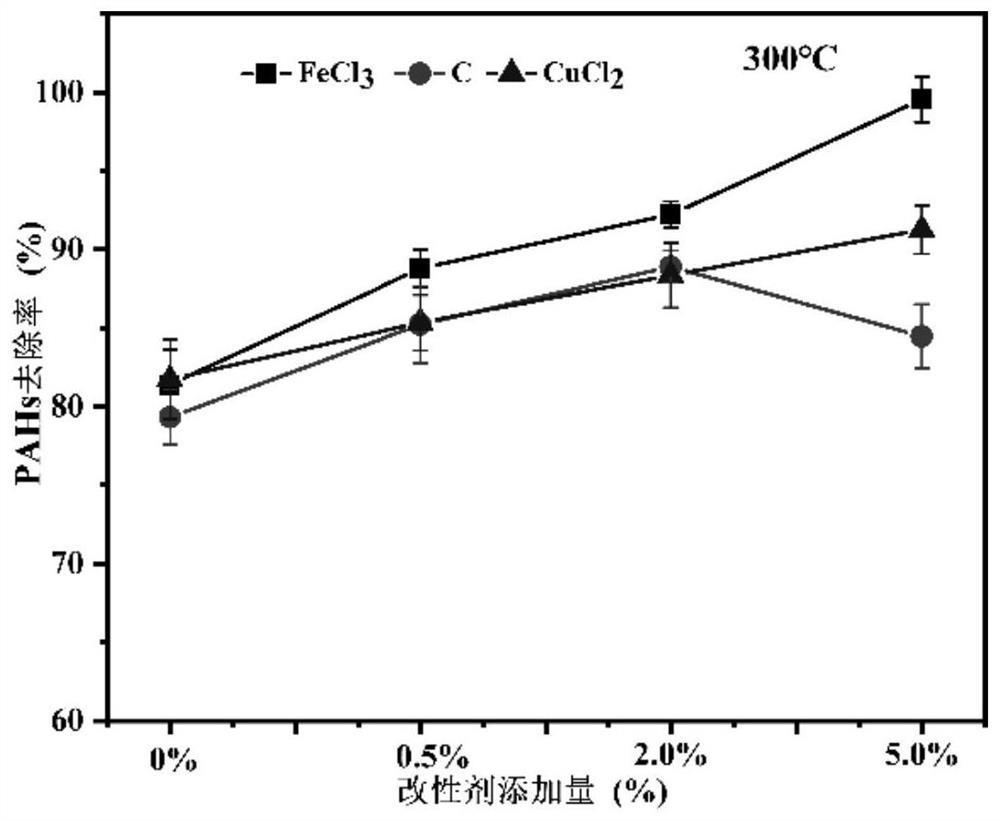

Modifier enhanced thermal desorption remediation method for polycyclic aromatic hydrocarbon contaminated site

ActiveCN113275372AReduce repair costsImprove removal efficiencyContaminated soil reclamationOrganic fertilisersPolycyclic aromatic hydrocarbonSoil science

The invention relates to a modifier enhanced thermal desorption remediation method for a polycyclic aromatic hydrocarbon (PAHs) contaminated site, which comprises the steps of (1) pretreating contaminated soil, crushing, grinding, screening, and adjusting the moisture content of the PAHs contaminated soil to obtain a standby soil sample; (2) adding a modifier into the standby soil sample by adopting a dry mixing method, and carrying out modification treatment for 24 hours to obtain modified soil; and (3) carrying out modifier enhanced thermal desorption treatment on the modified soil at the temperature of 100-300 DEG C for a certain time, and cooling after thermal desorption treatment to obtain the remediated soil. According to the method, the PAHs contaminated soil is modified through the modifier to strengthen the thermal desorption process of the PAHs, so that the desorption efficiency of the whole thermal desorption process is improved, the remediation cost is reduced, the cost effectiveness of the thermal desorption technology is also improved, and the method has a good application prospect.

Owner:江苏南京地质工程勘察院 +1

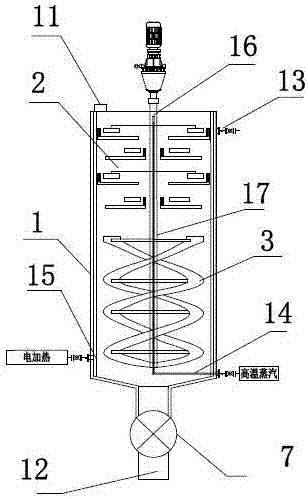

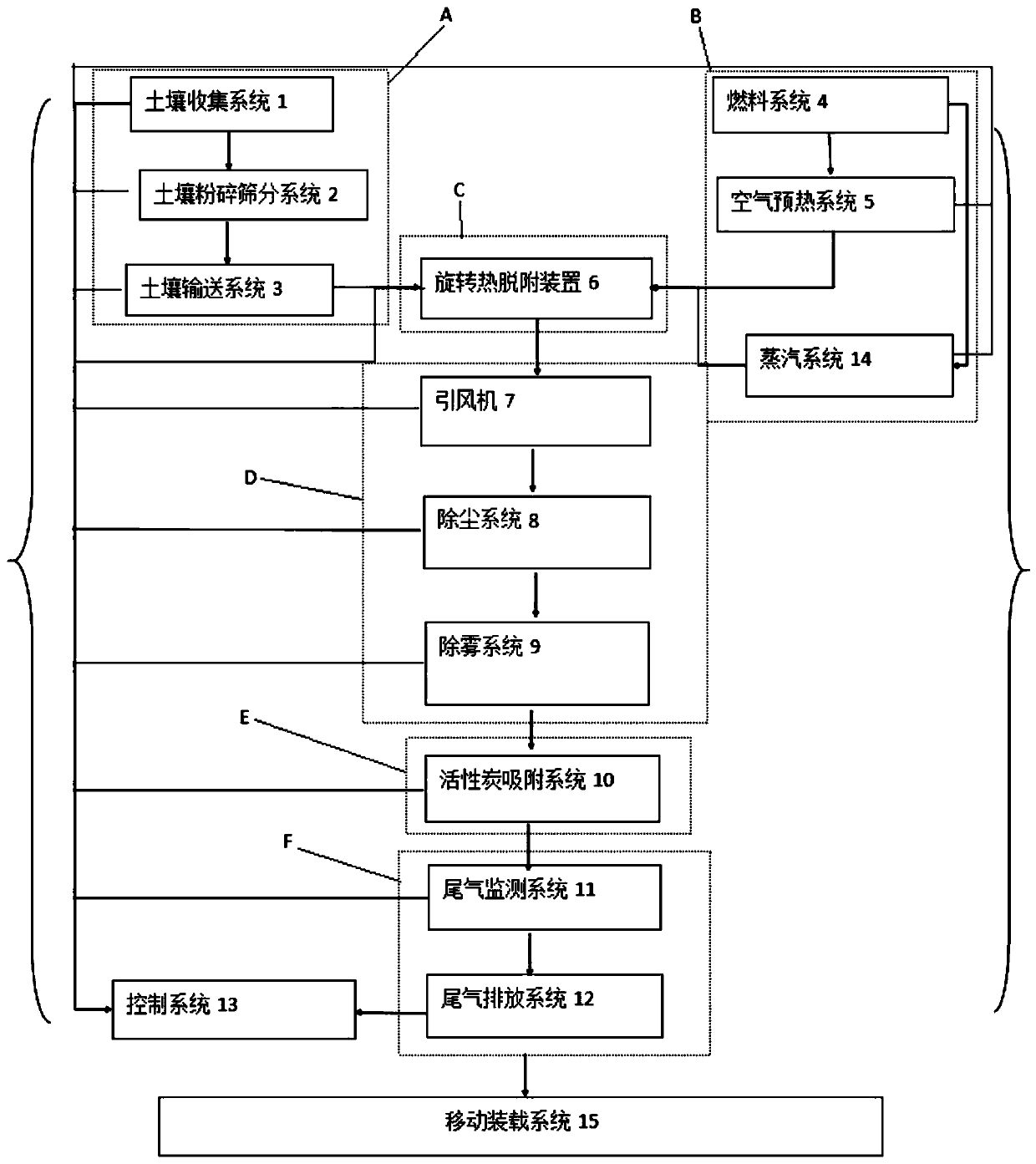

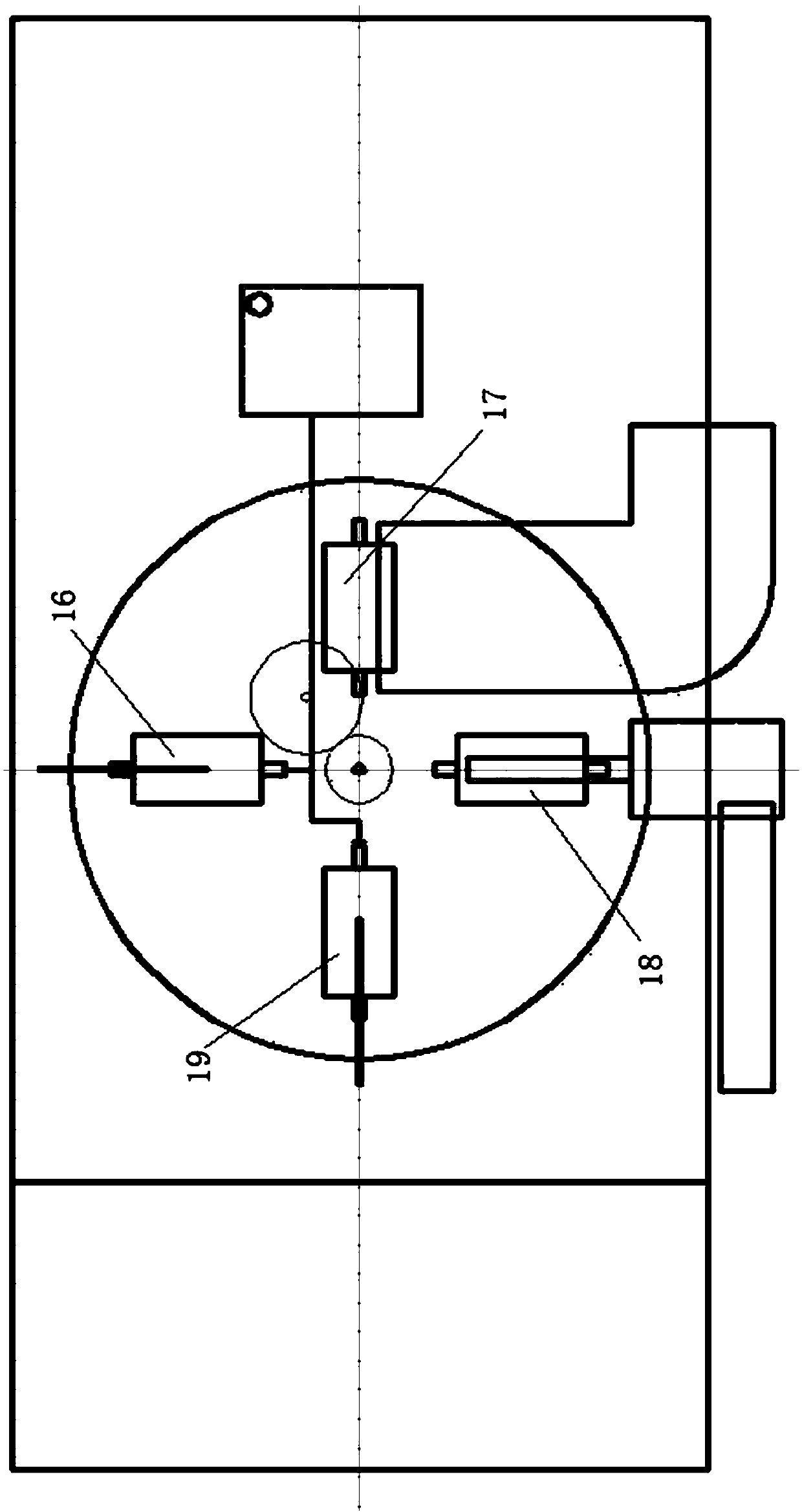

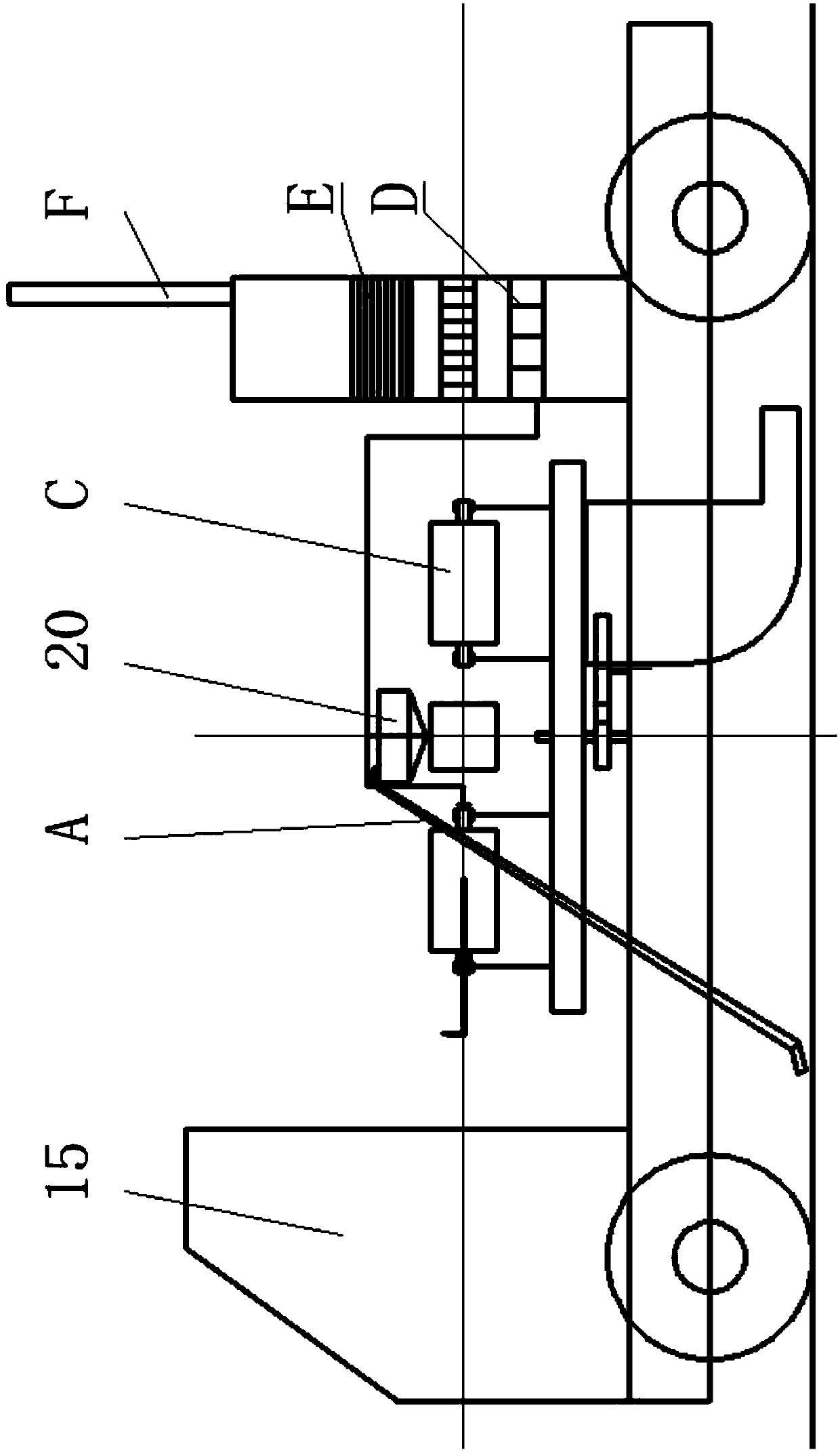

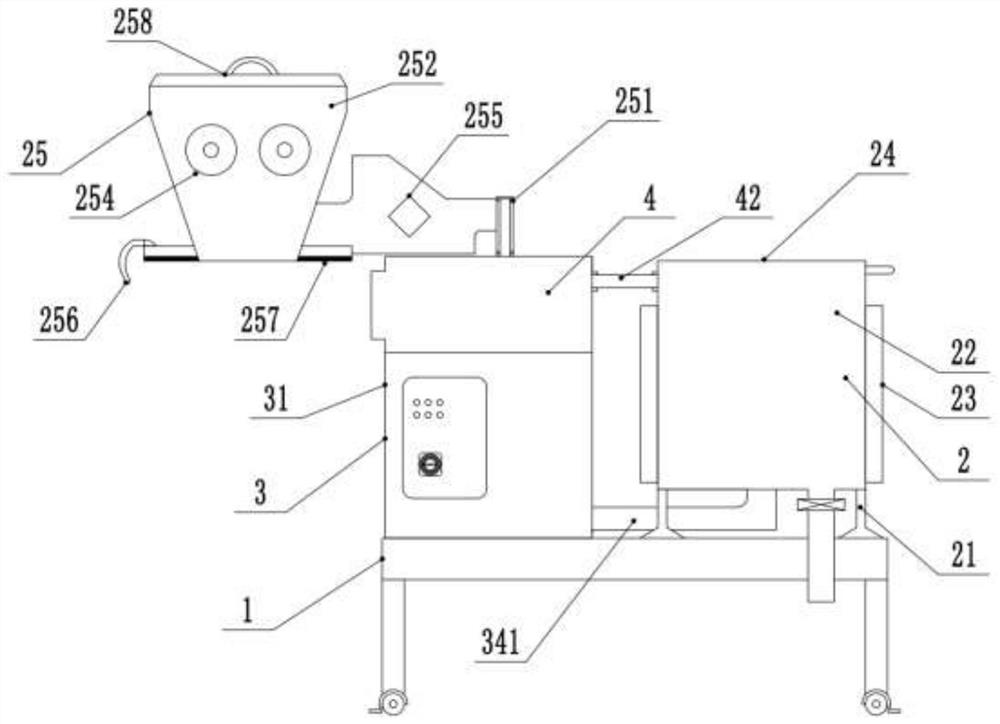

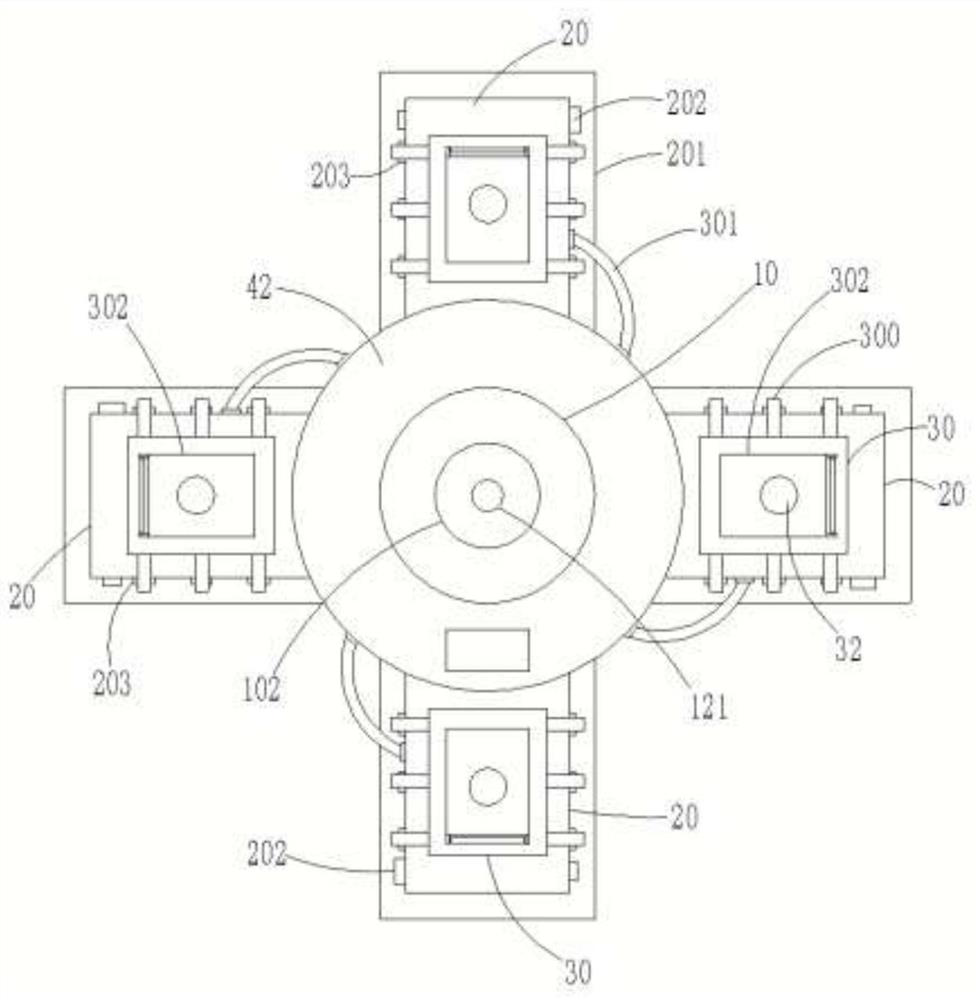

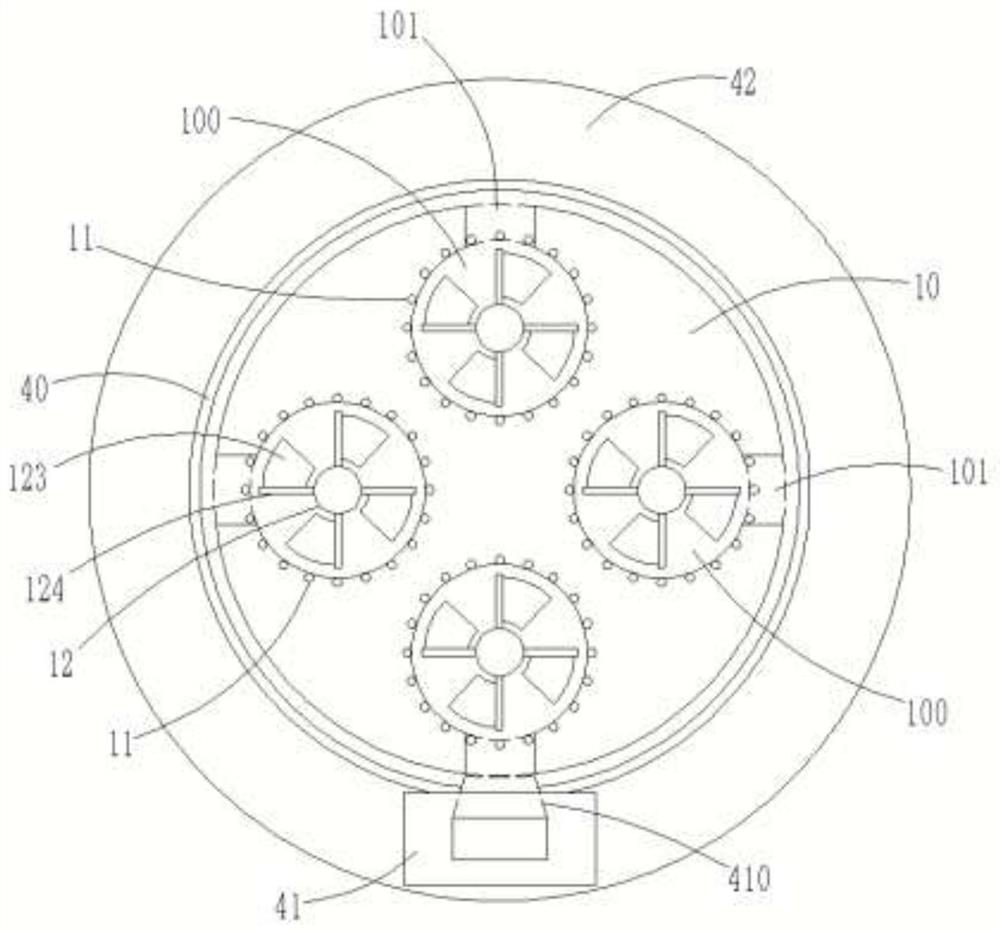

Organic matter contaminated soil movable four-roller continuous rotation thermal desorption treatment system and application

PendingCN107597830ALarge amount of processingImprove thermal desorption efficiencyContaminated soil reclamationEnvironmental resistanceAutomatic control

The invention relates to an organic matter contaminated soil movable four-roller continuous rotation thermal desorption treatment system. The treatment system comprises a soil feeding system, a heating system, a rotation thermal desorption system, a dust and mist removing system, an activated carbon adsorption system, a tail gas treatment system and a control system. The system can achieve continuous feeding, the contaminated soil treatment amount is large, and automatic control is achieved; the direct heating manner is adopted, the high-temperature steam makes sufficient contact with contaminated soil in the rotation thermal desorption system, and the thermal desorption efficiency is extremely high; and the adsorption manner is adopted for tail gas treatment, secondary pollution cannot begenerated, and environment protection is facilitated.

Owner:AEROSPACE ENVIRONMENTAL ENG

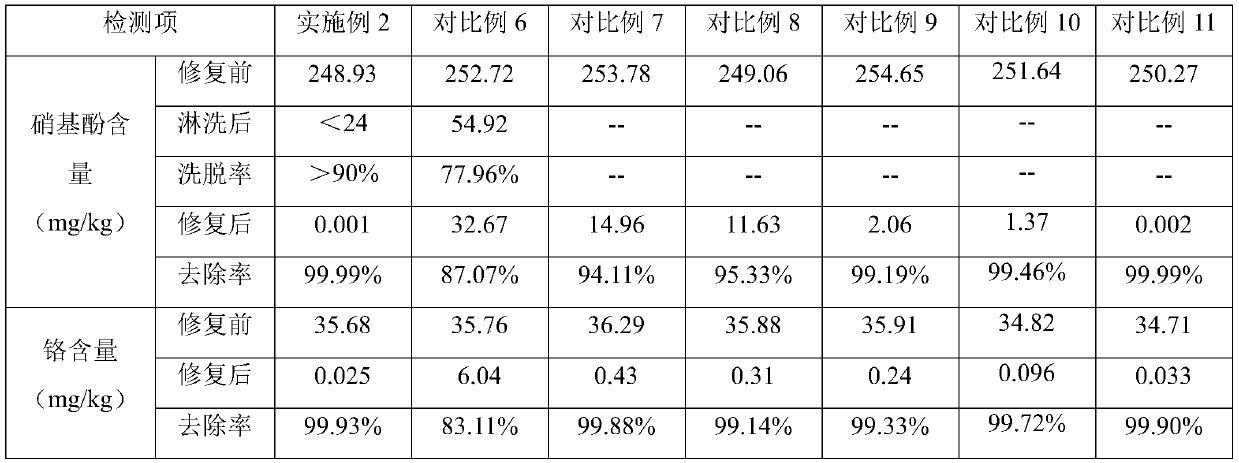

Method for removing persistent organic pollutants in soil

ActiveCN110743906AHigh mechanical strengthEvenly dispersedContaminated soil reclamationMembrane filtersSoil scienceDecomposition

The invention provides a method for removing persistent organic pollutants in soil. The method includes the following steps that step one, soil pretreatment is performed; step two, continuous soil leaching is performed; step three, degradation of the persistent organic pollutants and heavy metal recovery are performed; and step four, pyrolysis and high-voltage pulse discharge oxidation are performed. A soil loosening agent is mixed with the soil first to avoid the aggregation of the soil due to the effects of ultrasound, leaching pressure and leaching agent components in the leaching process,and can further solubilize in synergy with the cavitation effect of ultrasound, and most of the persistent organic pollutants are removed by leaching; and then in the pyrolysis-high-voltage pulse discharge oxidation process, heating and temperature rising are performed first, the desorption and decomposition of the persistent organic pollutants can be promoted, and the high-temperature environmentimproves the use ratio of high-voltage pulse energy. The method is simple in process and mature in equipment, saves manpower and material resources, is high in removal rate of the persistent organicpollutants and heavy metal in soil and thorough in removal, and has no secondary pollution.

Owner:河南省环境保护科学研究院

An energy-saving soil pollution thermal desorption device

ActiveCN105750319BReduce thermal desorption costsImprove thermal desorption efficiencyContaminated soil reclamationSoil treatmentSoil contamination

The invention relates to the technical field of soil treatment and discloses an energy-saving soil contamination thermal desorption device. The device comprises a support and a horizontal heating barrel arranged on the support, wherein a feeding channel is formed in the upper side of the left end of the heating barrel, a discharging channel is formed in the lower side of the right end of the heating barrel, a solar heat collecting tube is arranged on the outer side of the heating barrel, a solar reflector is arranged on one side of the support, a spindle is arranged in the heating barrel, a screw belt is arranged on the surface of the spindle, a motor for driving the spindle to rotate is arranged on the support, an air inlet pipe is arranged on the upper side of the left end of the heating barrel, an exhaust pipe is arranged on the upper side of the right end of the heating barrel, and an exhaust fan is arranged on the exhaust pipe. The device is heated by solar energy, energy is saved, and the soil thermal desorption cost is reduced.

Owner:江苏普泽环境工程有限公司

External-heating double-position spiral drying roasting kiln for ex-situ remediation of soil

ActiveCN111266398AAdjustable heating temperatureAdjustable capacityContaminated soil reclamationCharge manipulationThermodynamicsCombustor

The invention discloses an external-heating double-position spiral drying roasting kiln for ex-situ remediation of soil. The furnace comprises upper and lower furnace bodies, wherein two furnace tubesare arranged in each of the upper and lower furnace bodies; a feeding bin is connected with a feeding hole of the upper furnace tube through a rotary vane type feeder; a rotary vane feeder is connected with a driving motor with a frequency converter; spiral conveying augers are arranged in the upper furnace tube and the lower furnace tube and are connected with a transmission speed reducer with afrequency converter; the working frequency of the rotary vane feeder is equal to the spiral conveying frequency of the spiral conveying auger, so that the consistency of front and back feeding speedsis ensured; the right sides of the upper furnace tube and the lower furnace tube are vertically communicated; a discharge conveyor is arranged at a discharge hole in the bottom of the lower furnace tube; a water spraying humidifier is arranged at the top of the upper furnace tube; and a combustor is arranged at bottom of furnace body. The spiral drying roasting kiln is small in size, low in siterequirement, high in thermal desorption efficiency, low in equipment failure rate and low in energy consumption; in the spiral drying roasting kiln, the furnace tube adopts a segmented flange connection mode, so that the service life of the furnace tube can be prolonged, the furnace tube replacement cost is reduced, gaps between the furnace tube and a hearth can be eliminated, and heat dissipationis reduced.

Owner:上海吾励环境技术有限公司

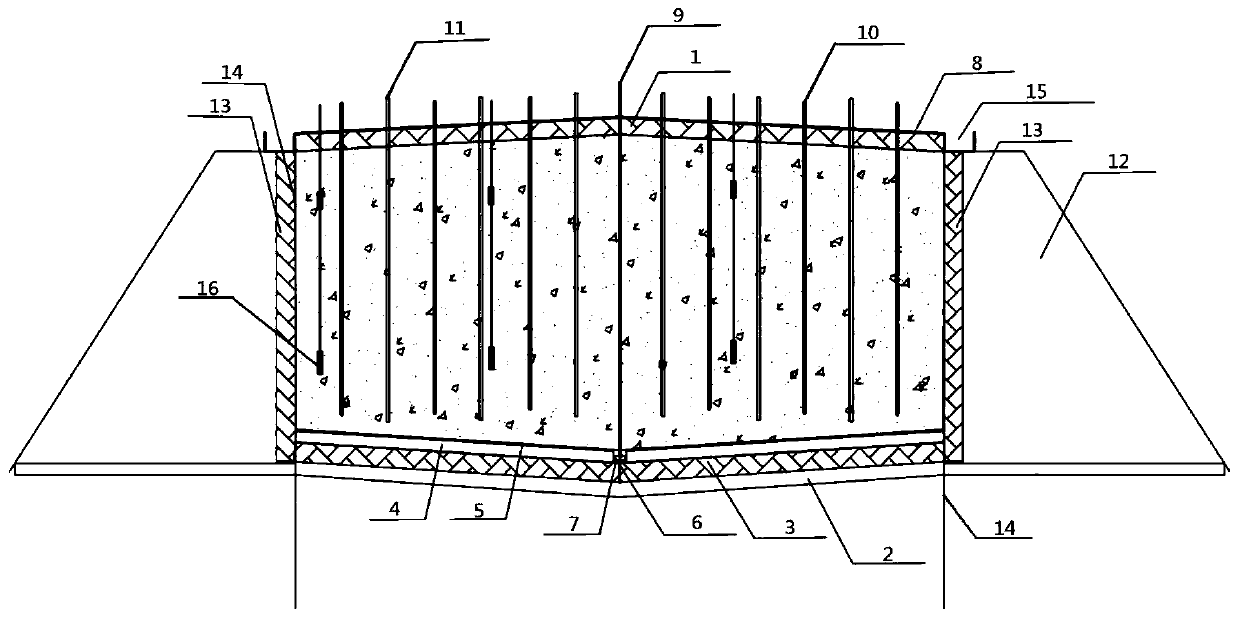

Ex-situ thermal desorption remediation device and remediation method for soil

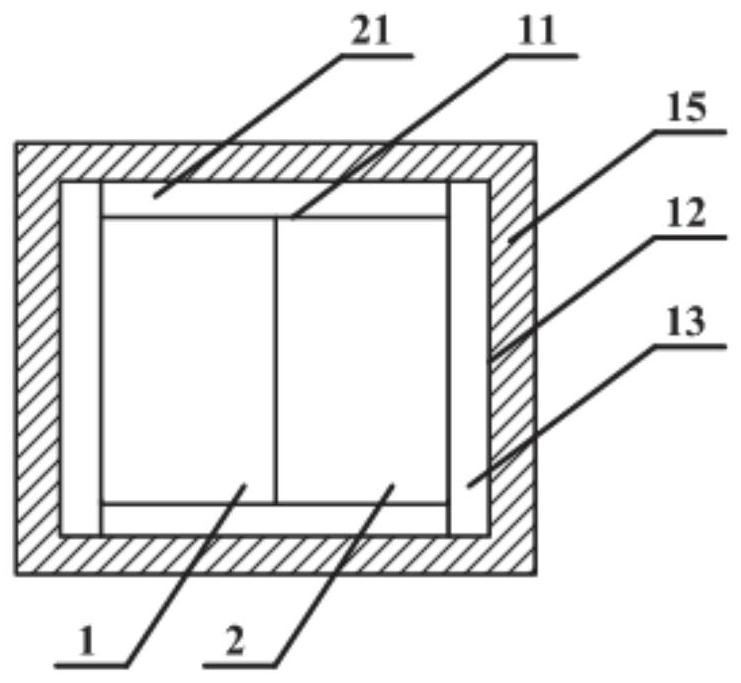

PendingCN110523760AImprove repair efficiencyEasy to install and removeContaminated soil reclamationGeotextileThermal insulation

The invention relates to an ex-situ thermal desorption remediation device and remediation method for soil. The device includes a construction platform for stacking polluted soil piles to be treated and a thermal insulation layer which is spread on the tops of the polluted soil piles to be treated; the construction platform is provided with a concrete layer, a heat insulation layer, a water filterlayer and a geotextile in sequence from the bottom to the top; the interior of the water filter layer is provided with a water collection cavity, and the interior of the water collection cavity is provided with a submersible pump for discharging water; an anti-seepage film is spread on the thermal insulation layer; and water suction pipes, heating pipes and gas suction pipes which are inserted into the polluted soil piles to be treated are also arranged. The device provided by the invention has the beneficial effects of a large treatment amount of polluted soil, high efficiency of thermal desorption, convenient reutilization of equipment and high cost performance.

Owner:上海环境绿色生态修复科技有限公司

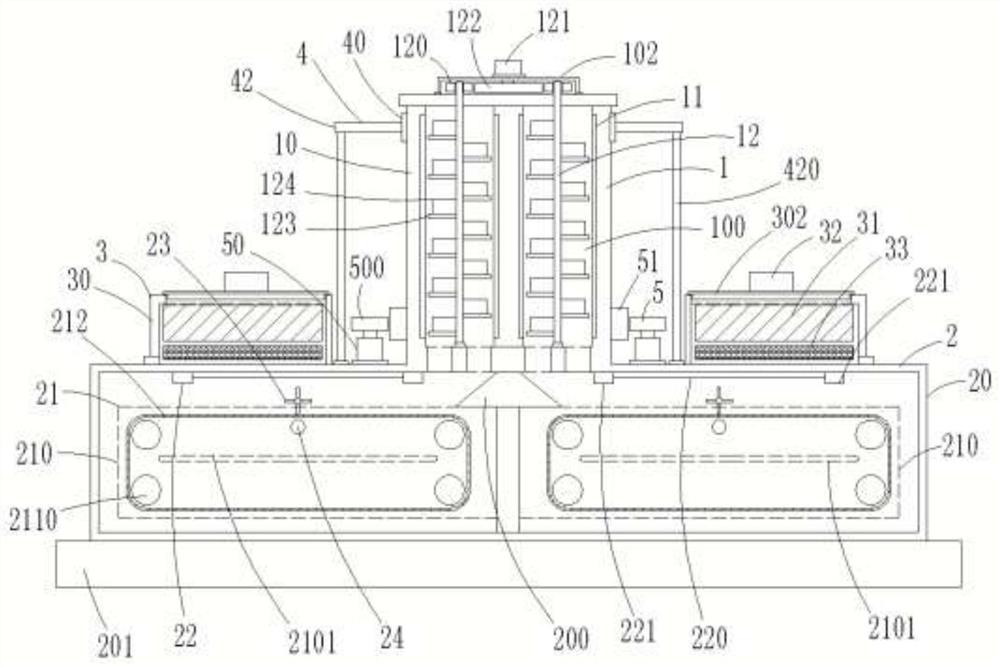

Tank-type thermal desorption device based on thermal desorption additive filling and desorption method

ActiveCN112058892AEvenly dispersedImprove thermal desorption efficiencyContaminated soil reclamationGrain treatmentsElectric machineLow-temperature thermal desorption

The invention discloses a tank type thermal desorption device based on thermal desorption additive filling and a desorption method thereof. The device comprises a supporting frame, a thermal desorption unit, a drive control unit and a tail gas treatment unit, the thermal desorption unit, the drive control unit and the tail gas treatment unit are at the upper part of the supporting frame, and the thermal desorption unit comprises a thermal desorption tank sleeved with an electric heating sleeve; the bottom of the thermal desorption tank is rotationally connected with a rotating poking wheel filled with a thermal desorption additive through a rotating shaft; the driving control unit comprises an electric box, a motor and a transmission assembly connected with the rotating shaft; and the tailgas treatment unit comprises an adsorption box body filled with an adsorption filler. According to the invention, alumina balls adsorbed with a hydrogen peroxide solution are used as a low-temperature thermal desorption auxiliary agent, calcium peroxide is used as a high-temperature thermal desorption auxiliary agent, and the soil is fully distributed in two poking pieces filled with the thermaldesorption auxiliary agents by virtue of centrifugal rotation of the rotary poking wheel, so that oxygen decomposed by heating can be uniformly dispersed into the soil, and the thermal desorption efficiency is improved.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

Chemical-thermal desorption combined remediation method for polycyclic aromatic hydrocarbon contaminated soil

InactiveCN113732045AImprove heat transfer performanceEnhanced mass transferContaminated soil reclamationPolycyclic aromatic hydrocarbonSoil science

The invention relates to a chemical-thermal desorption combined remediation method for polycyclic aromatic hydrocarbon contaminated soil. The method comprises the following steps: 1, pretreatment of the contaminated soil: sequentially crushing, grinding and screening the polycyclic aromatic hydrocarbon contaminated soil, and then adjusting the moisture content of the soil to obtain a soil sample for later use; 2, chemical pre-oxidation treatment: adding an oxidizing agent into the soil sample by adopting a dry mixing method to carry out chemical pre-oxidation treatment; and 3, thermal desorption: performing thermal desorption treatment on the soil subjected to pre-oxidation treatment under a medium-temperature condition, and then cooling to room temperature. According to the method, the contaminated soil is pre-oxidized through the oxidizing agent containing benzoyl peroxide, then the PAHs contaminated soil is subjected to thermal desorption treatment, the PAHs removal efficiency can be improved, meanwhile, the remediation temperature can be reduced, and therefore the purposes of reducing remediation energy consumption and remediation cost are achieved.

Owner:SOUTHEAST UNIV +1

Thermal desorption remediation device for soil remediation

InactiveCN112872006AAvoid gatheringAbsorbs heat and emits vaporized impurities quicklyContaminated soil reclamationThermodynamicsSoil science

The invention discloses a thermal desorption remediation device for soil remediation. The thermal desorption remediation device for soil remediation comprises a supporting base, a fixed base and a thermal desorption box body, wherein a thermal desorption structure is arranged in the thermal desorption box body, and the thermal desorption structure comprises an inlet, a discharging opening, an internal stirring structure, an inlet sealing structure, an outlet control plate, a filter screen and a gas outlet pipeline; and a box body rotating structure comprises a side supporting rod, a rotating motor, a rotating plate and an end bearing seat. According to the invention, the thermal desorption box body capable of rotating and an internal stirring structure are arranged, so the rotating direction of the thermal desorption box body is opposite to the rotating direction of the internal stirring structure, the speed that soil absorbs heat, dissipates and vaporizes impurities during thermal desorption is increased, and thermal desorption efficiency is improved; and meanwhile, a discharging structure is arranged on the device, so the soil is prevented from being gathered in the thermal desorption box body.

Owner:郭文静

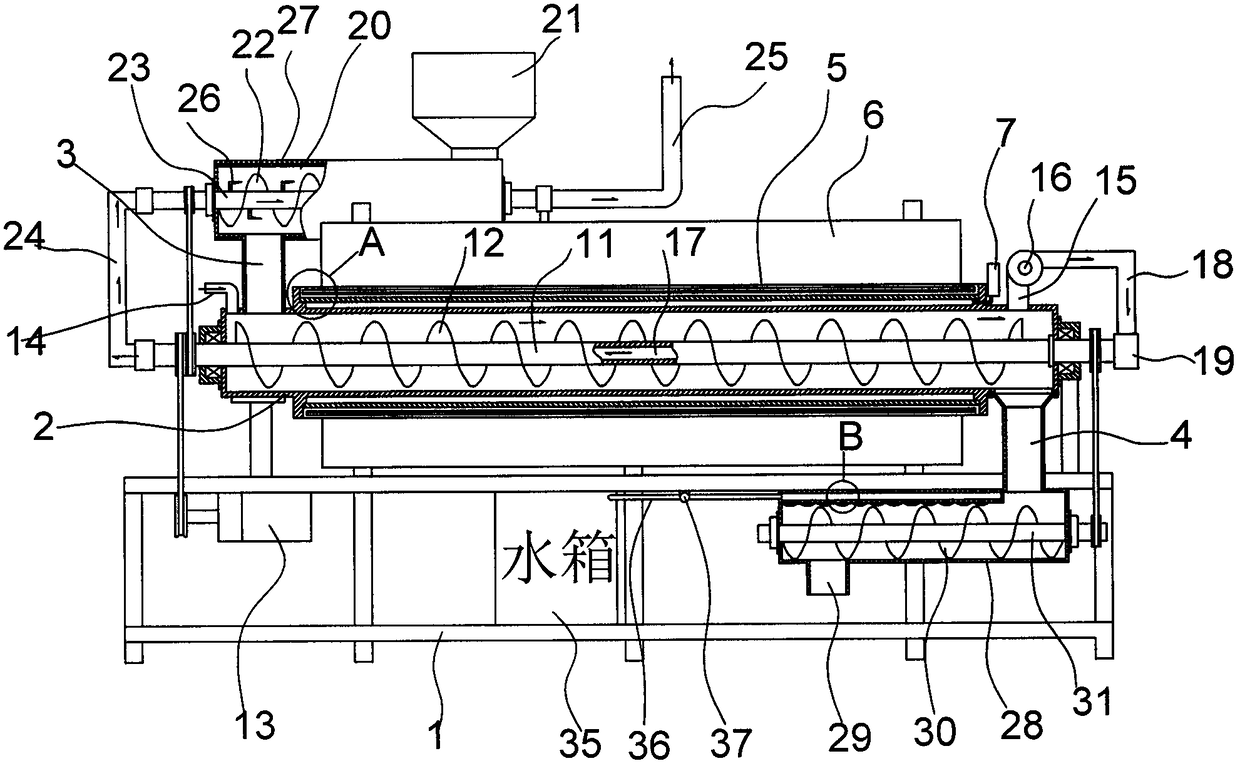

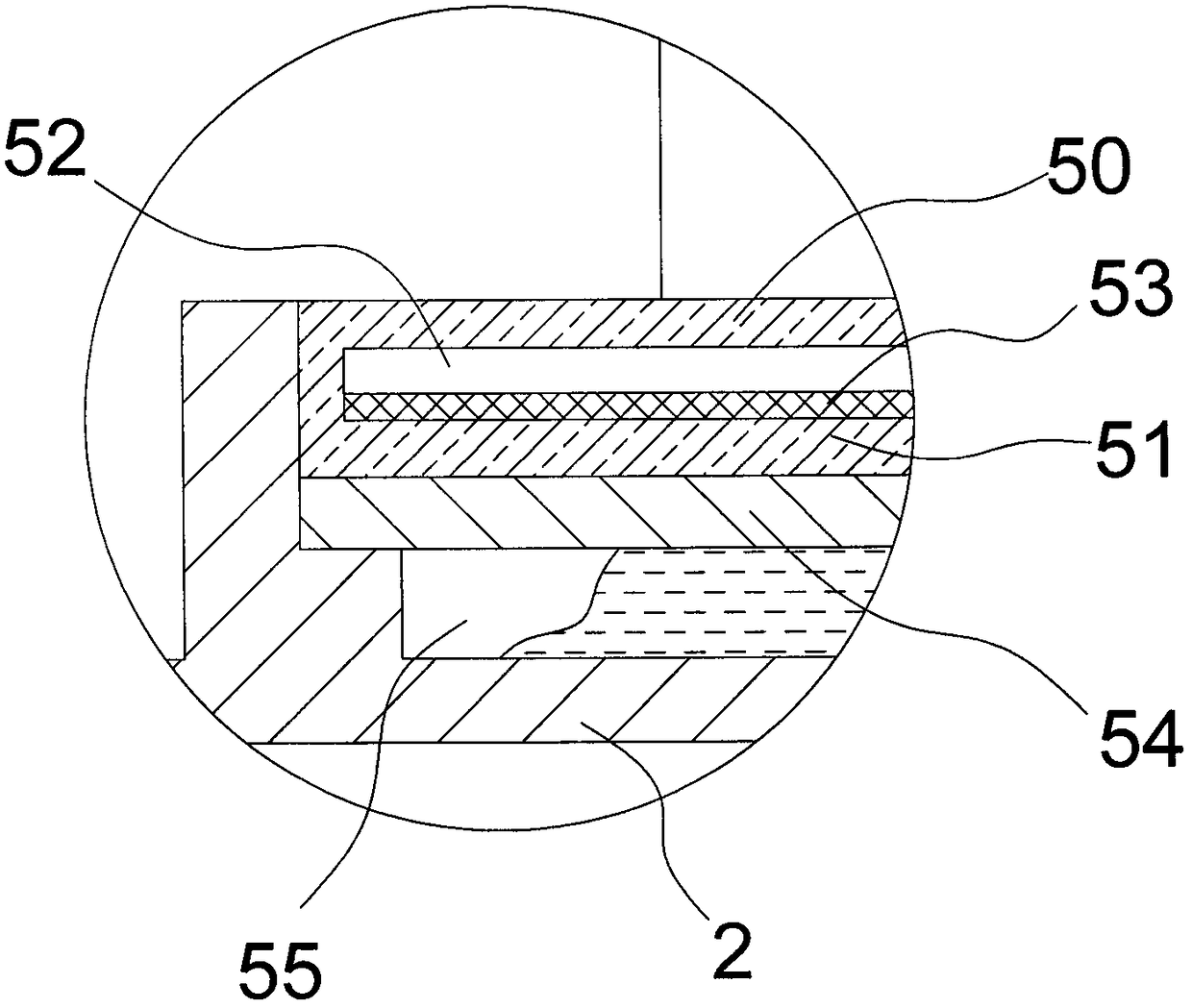

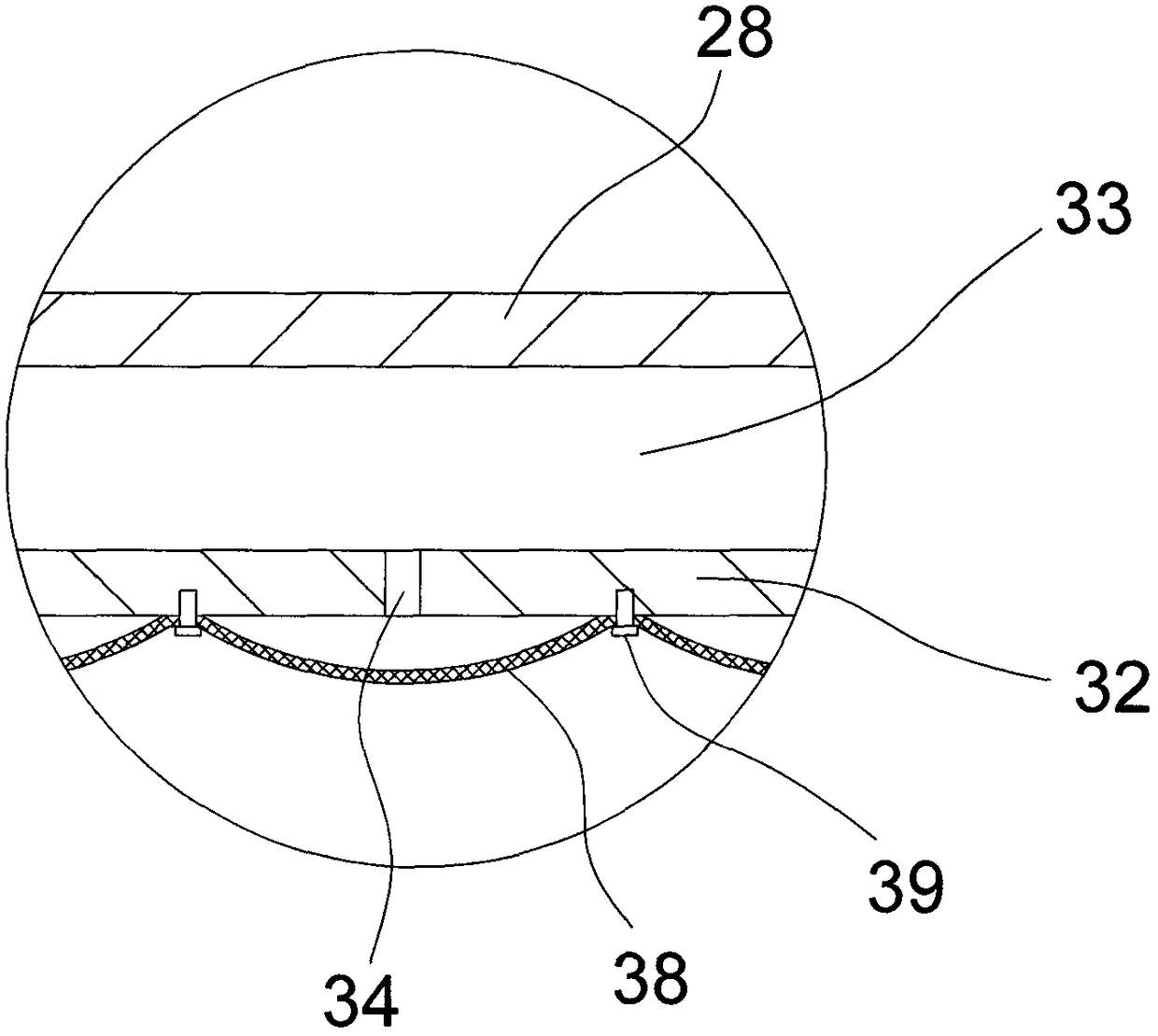

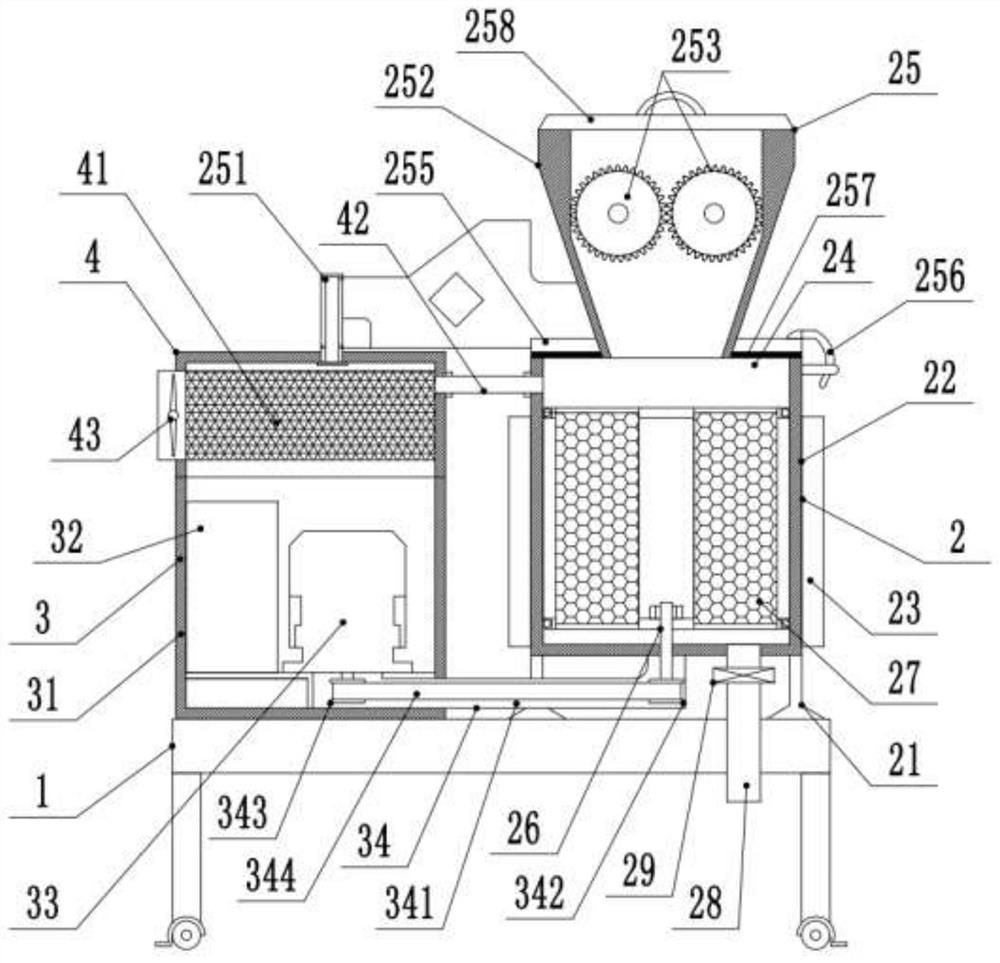

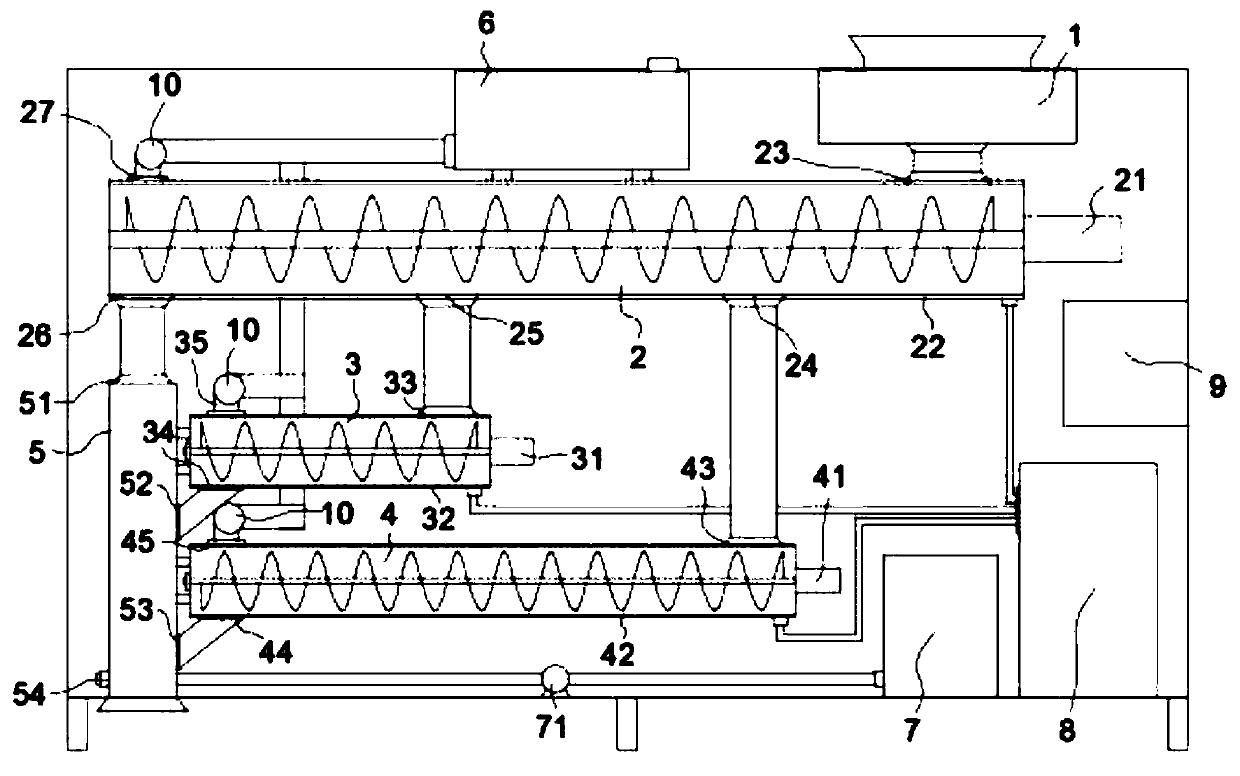

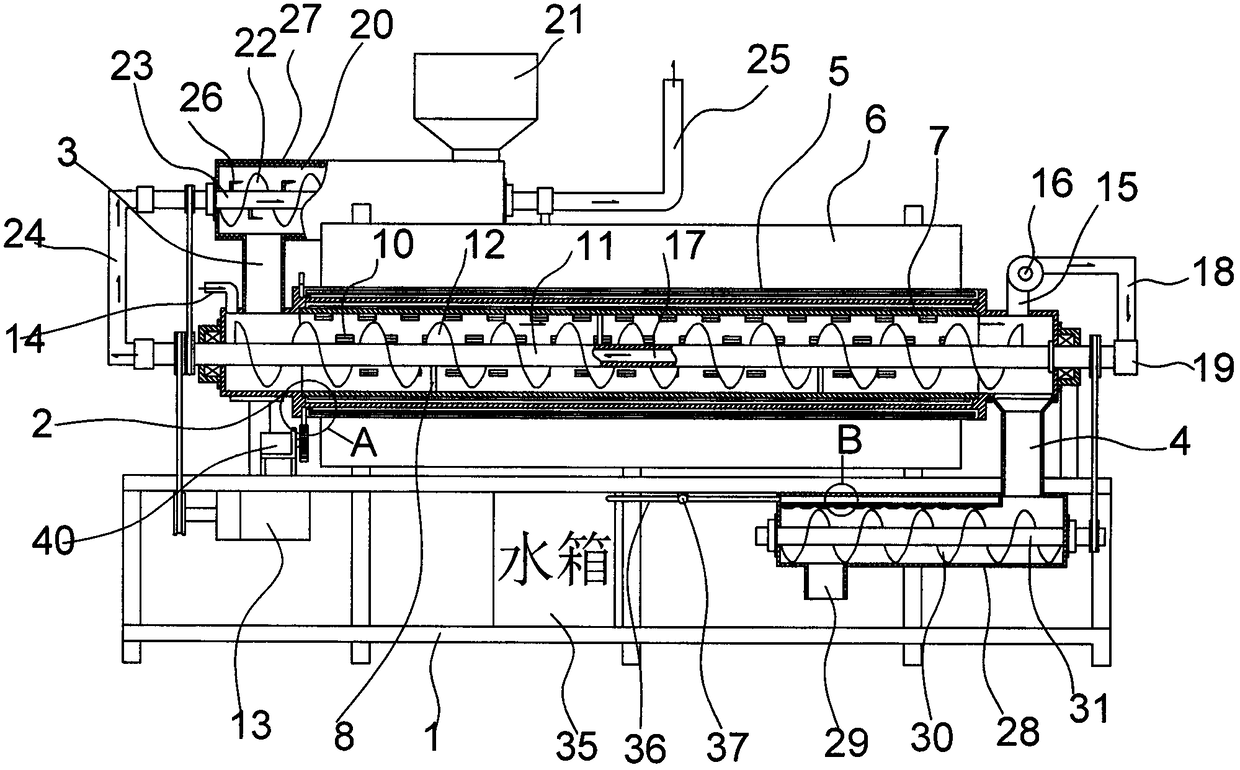

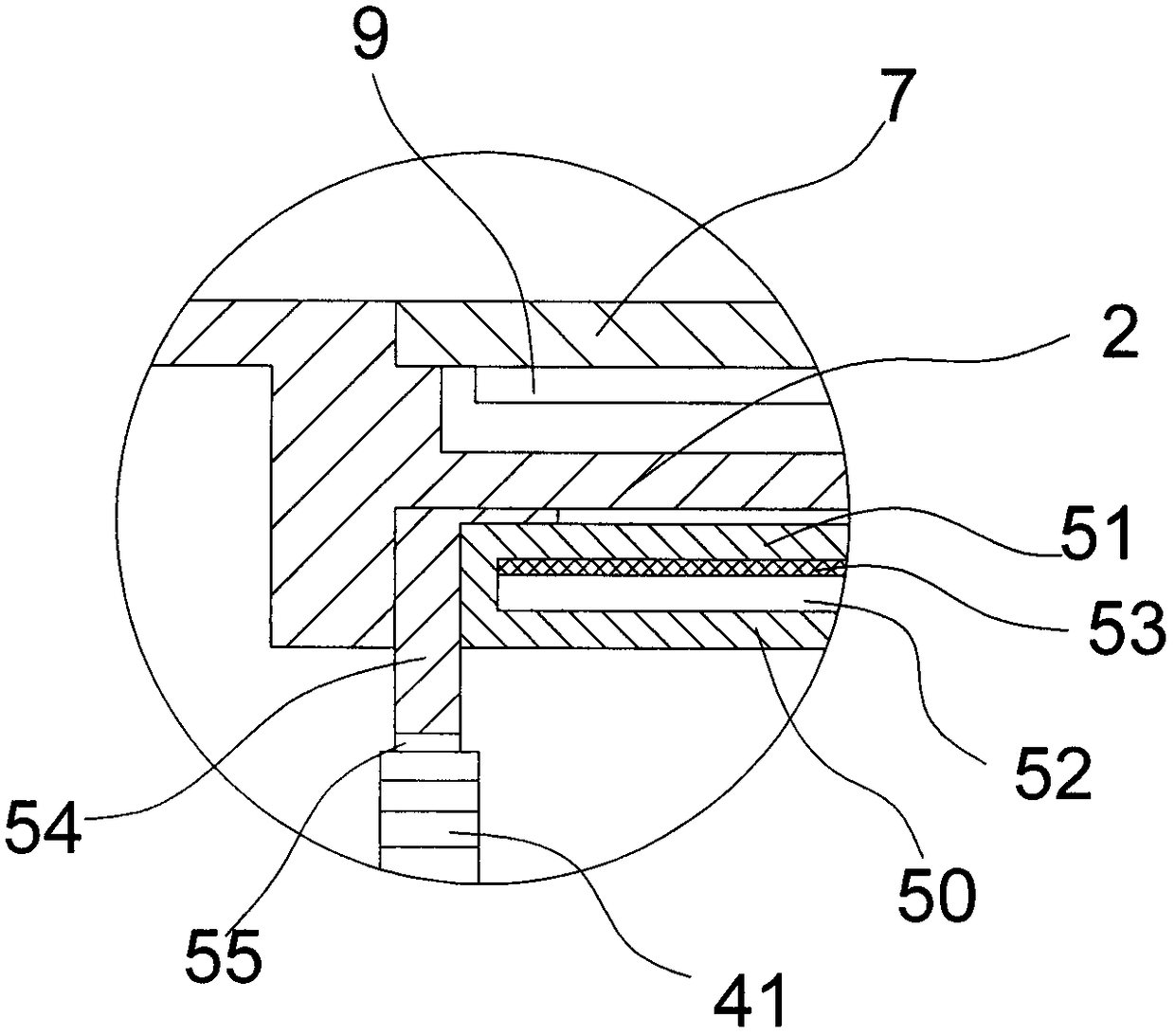

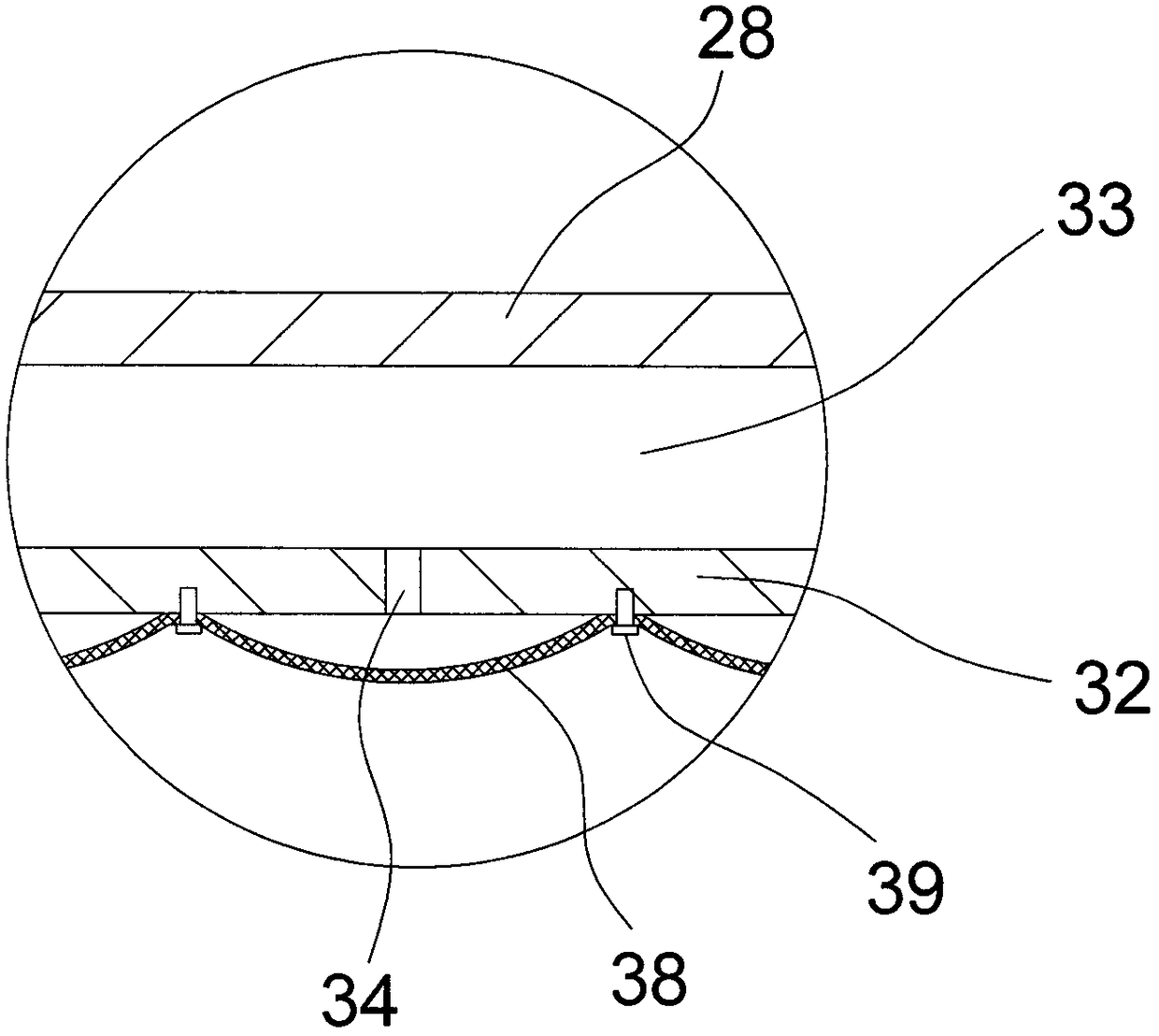

A thermal desorption device for remediation of organically polluted soil

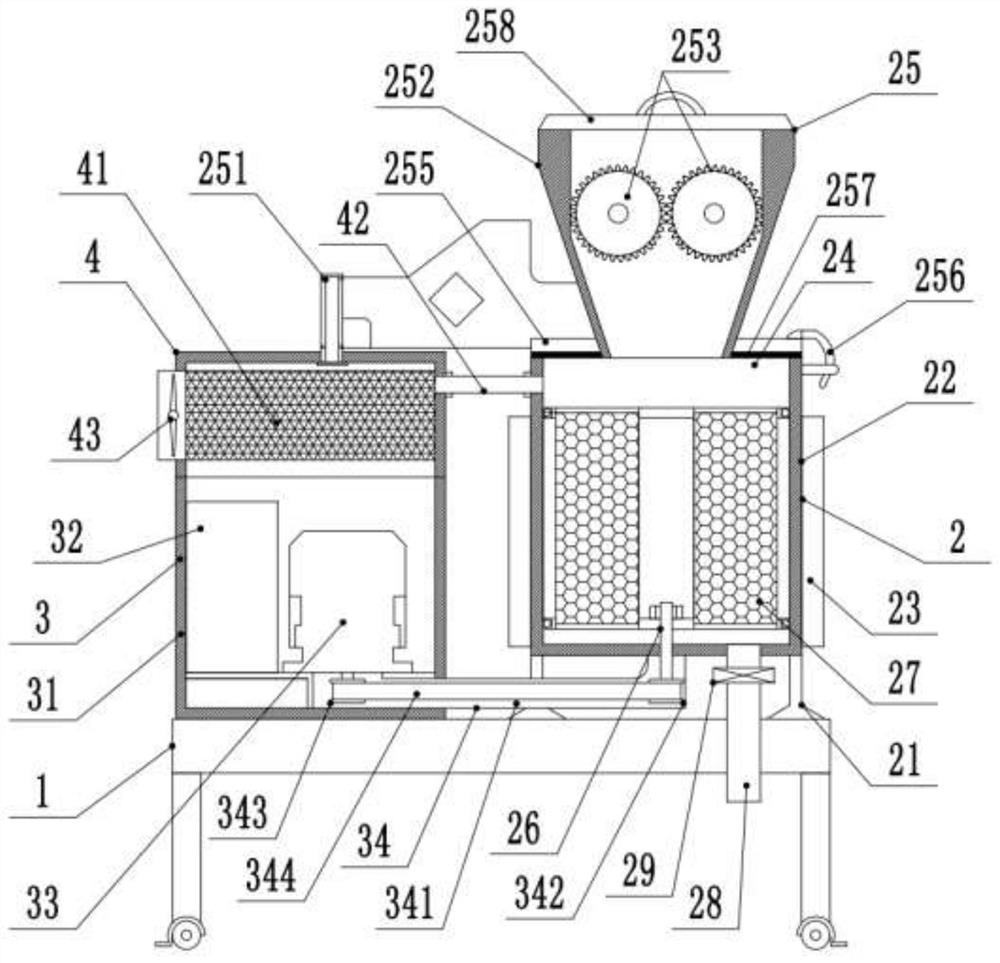

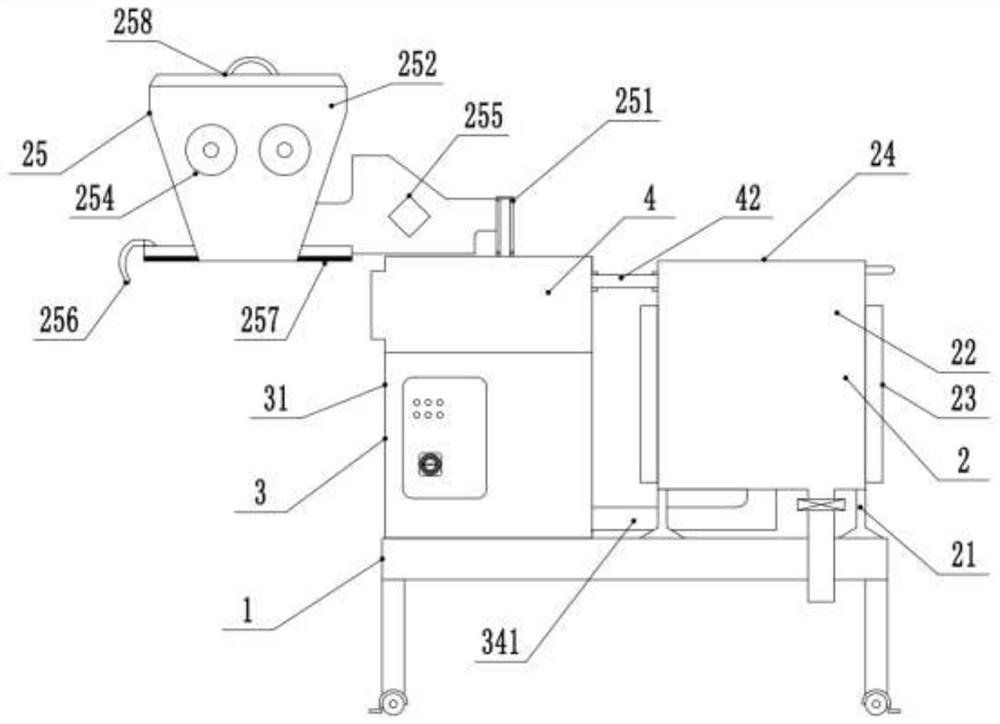

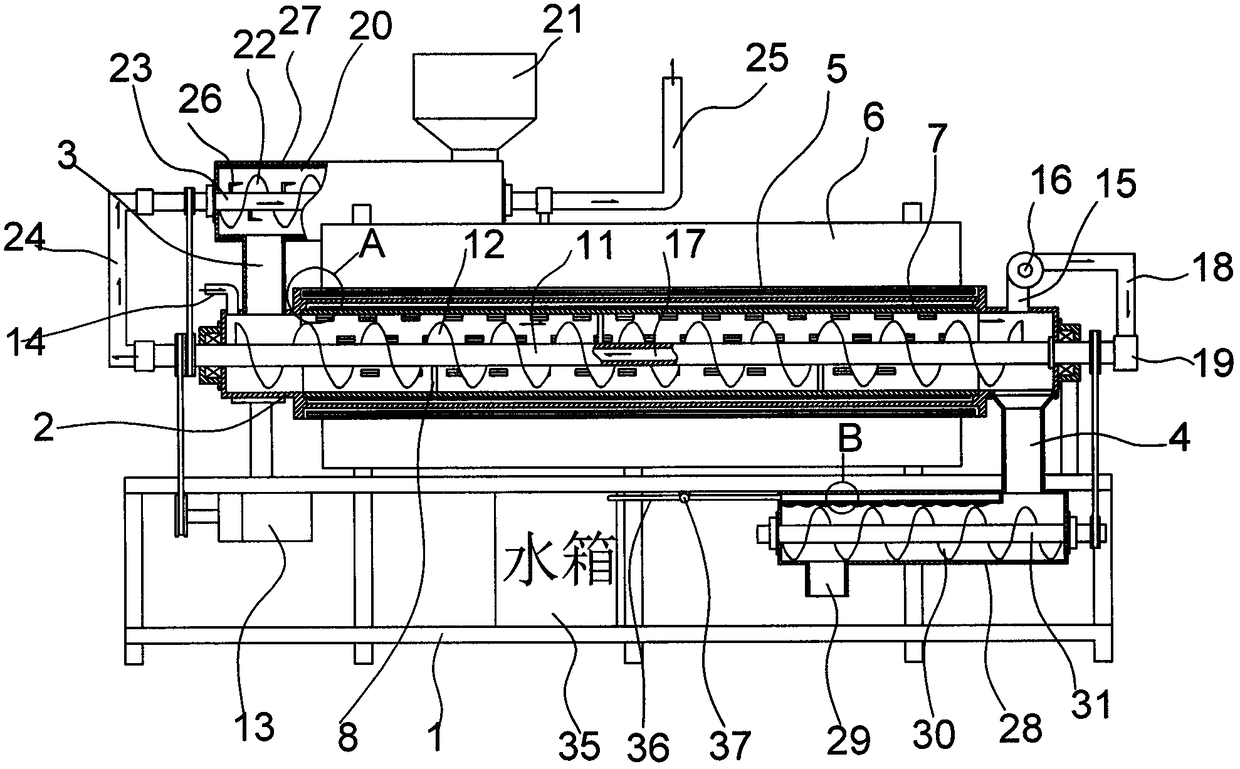

InactiveCN109550775BThermal analysis is goodOptimization of thermal desorption effectCombination devicesLiquid fertiliser distributionWater storageCombustion chamber

The invention discloses a thermal desorption apparatus for repairing organic polluted soil. The thermal desorption apparatus comprises a crushing device, a thermal desorption screw propulsion device,a first-stage auxiliary screw propulsion device, a second-stage auxiliary screw propulsion device, a humidifying device, a gas treatment device, a water storage box, a combustion chamber and a power supply, wherein the upper end of the thermal desorption screw propulsion device is sequentially provided with the gas treatment device and the crushing device from left to right, the lower end of the thermal desorption screw propulsion device is sequentially provided with the first-stage auxiliary screw propulsion device and the second-stage auxiliary screw propulsion device from top to bottom, theleft side of the first-stage auxiliary screw propulsion device and the second-stage auxiliary screw propulsion device is provided with the humidifying device, the right side of the first-stage auxiliary screw propulsion device and the second-stage auxiliary screw propulsion device is provided with the water storage box, the right side of the water storage box is provided with the combustion chamber, and the power supply is arranged above the combustion chamber. The thermal desorption apparatus of the invention is convenient to operate, has remarkable thermal desorption treatment effect on polluted soil, and further has high thermal desorption efficiency.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

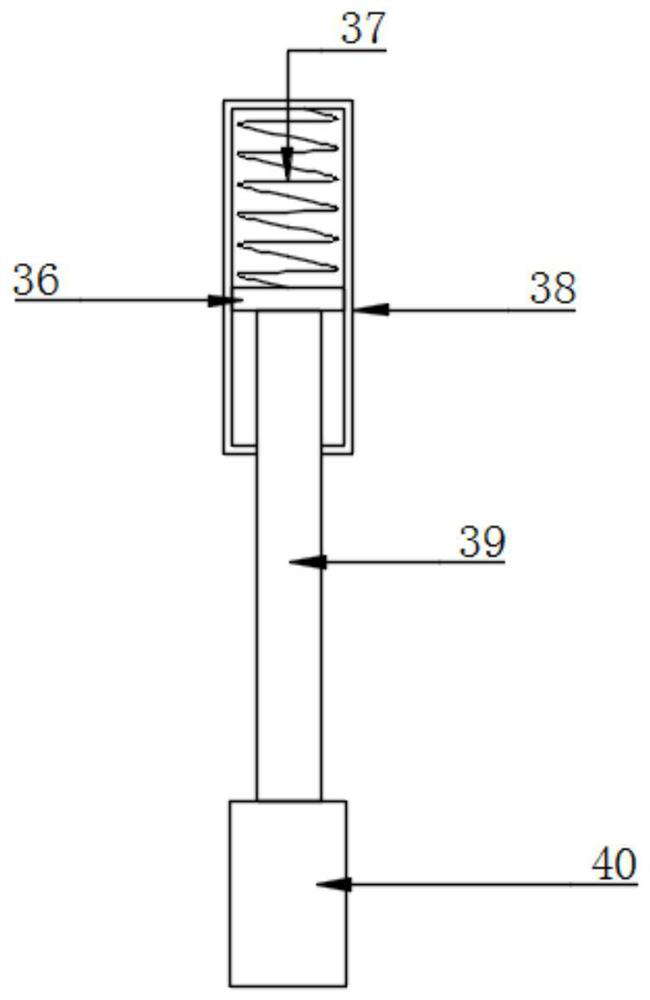

Thermal desorption remediation device for polluted soil

ActiveCN113182342AExtended stayIncrease contact timeContaminated soil reclamationGrain treatmentsBuffer stripSoil treatment

The invention relates to the technical field of soil treatment, in particular to a thermal desorption remediation device for polluted soil. The device comprises a treatment device, a material guide pipe and a spiral conveyor which are sequentially connected together from top to bottom, inner cavities of the treatment device, the material guide pipe and the spiral conveyor are communicated, and the spiral conveyor and the material guide pipe are located on one side of the top of the spiral conveyor; and a fixed pipe with the same inner diameter as the material guide pipe is installed in the middle of the inner bottom of the treatment device, the fixed pipe is sleeved with a movable pipe, a transmission column is further vertically installed in the treatment device, the tail end of the transmission column extends into the fixed pipe, and spiral blades are installed on the outer wall of the transmission column. The retention time of soil between the movable pipe and the fixed pipe is prolonged through a guide plate and a buffer strip, the heating efficiency is improved, the treated soil enters the spiral conveyor through the material guide pipe to be conveyed, the treated soil makes contact with inlet air in the reverse convection direction in the conveying process, secondary thermal desorption is conducted, the contact time between the soil and hot air is prolonged, and through two times of thermal desorption, the thermal desorption efficiency is improved.

Owner:SHANXI NO 8 CONSTR GRP

Equipment for fertility-increasing thermal desorption soil remediation

InactiveCN112317526AImprove thermal desorption efficiencyImprove uniformityTransportation and packagingContaminated soil reclamationSoil scienceSoil remediation

The invention discloses equipment for fertility-increasing thermal desorption soil remediation, and relates to the technical field of soil remediation. The equipment for fertility increasing type thermal desorption soil remediation comprises a bearing plate, three sets of bearing columns are fixedly installed at the top of the bearing plate, two sets of discharging openings are formed in the bearing plate, a thermal desorption box is arranged at the top of the bearing plate, a fermentation manure tank is welded to the outer surface of the top of the bearing plate, and rotating columns are rotatably installed on the adjacent side walls of the two sets of bearing columns. According to the equipment, soil subjected to thermal desorption and a fertilizer can be added into a mixing box according to a certain proportion, the situation that the fertilizer increasing effect is poor or excessive due to proportion imbalance is avoided, the follow-up soil fertilizer increasing effect is effectively guaranteed, the quantitative proportion is adjustable, and the diversity of the fertilizer increasing proportion is enhanced. Loss caused by the fact that the quantitative proportion cannot be adjusted due to different properties of soil in all places is avoided, the error-tolerant rate of the equipment is increased, and a foundation is effectively laid for next-step mixed fertilization.

Owner:湖州桑农生态农业有限公司

A tank-type thermal desorption device and desorption method based on thermal desorption additive filling

ActiveCN112058892BEvenly dispersedImprove thermal desorption efficiencyContaminated soil reclamationGrain treatmentsLow-temperature thermal desorptionControl cell

The invention discloses a tank-type thermal desorption device based on thermal desorption auxiliary agent filling and a desorption method thereof. The device includes a support frame, a thermal desorption unit located above the support frame, a drive control unit and an exhaust gas The processing unit, the thermal desorption unit includes a thermal desorption tank with an electric heating jacket on the outside, the bottom of the thermal desorption tank is connected to the rotary dial filled with thermal desorption aids through a rotating shaft, and the drive control unit includes an electric box and The motor and the transmission assembly connected with the rotating shaft; the tail gas treatment unit includes an adsorption box filled with adsorption filler. The present invention uses aluminum oxide balls with adsorbed hydrogen peroxide solution as a low-temperature thermal desorption aid, calcium peroxide as a high-temperature thermal desorption aid, and the soil is fully distributed between two thermal desorption aids by means of the centrifugal rotation of the rotating dial wheel. The paddle of the desorption aid can evenly disperse the oxygen decomposed by heat into the soil, improving the thermal desorption efficiency.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

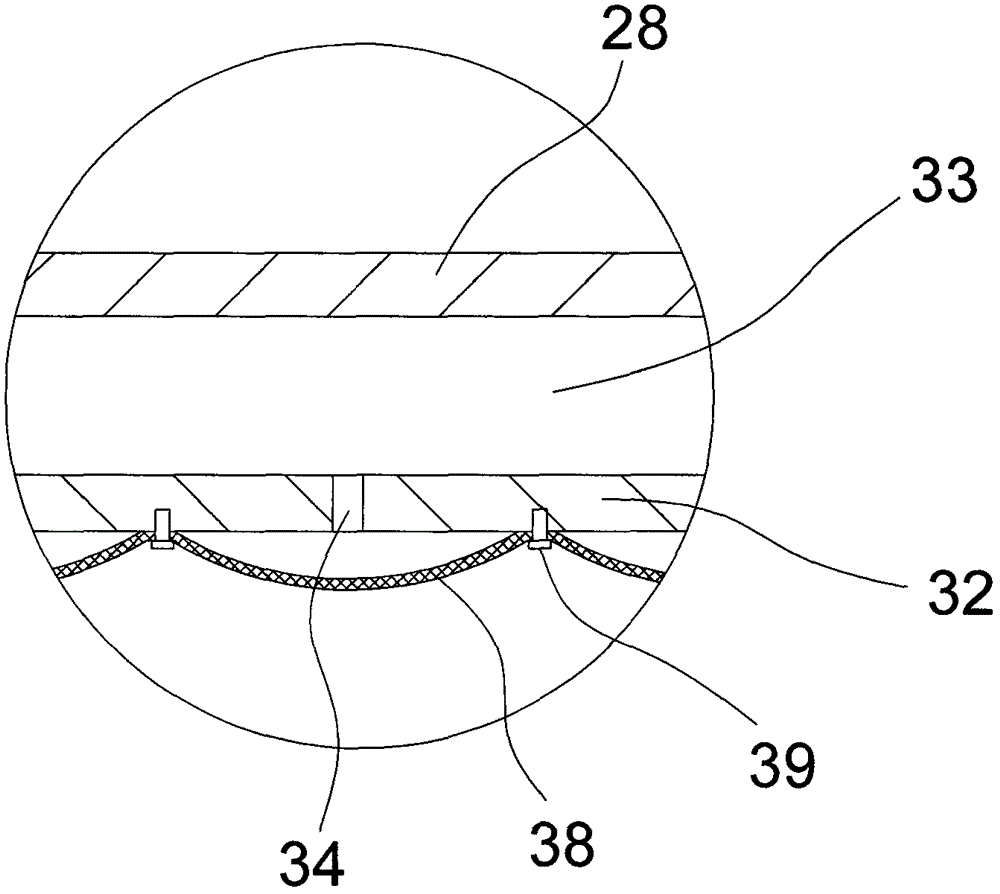

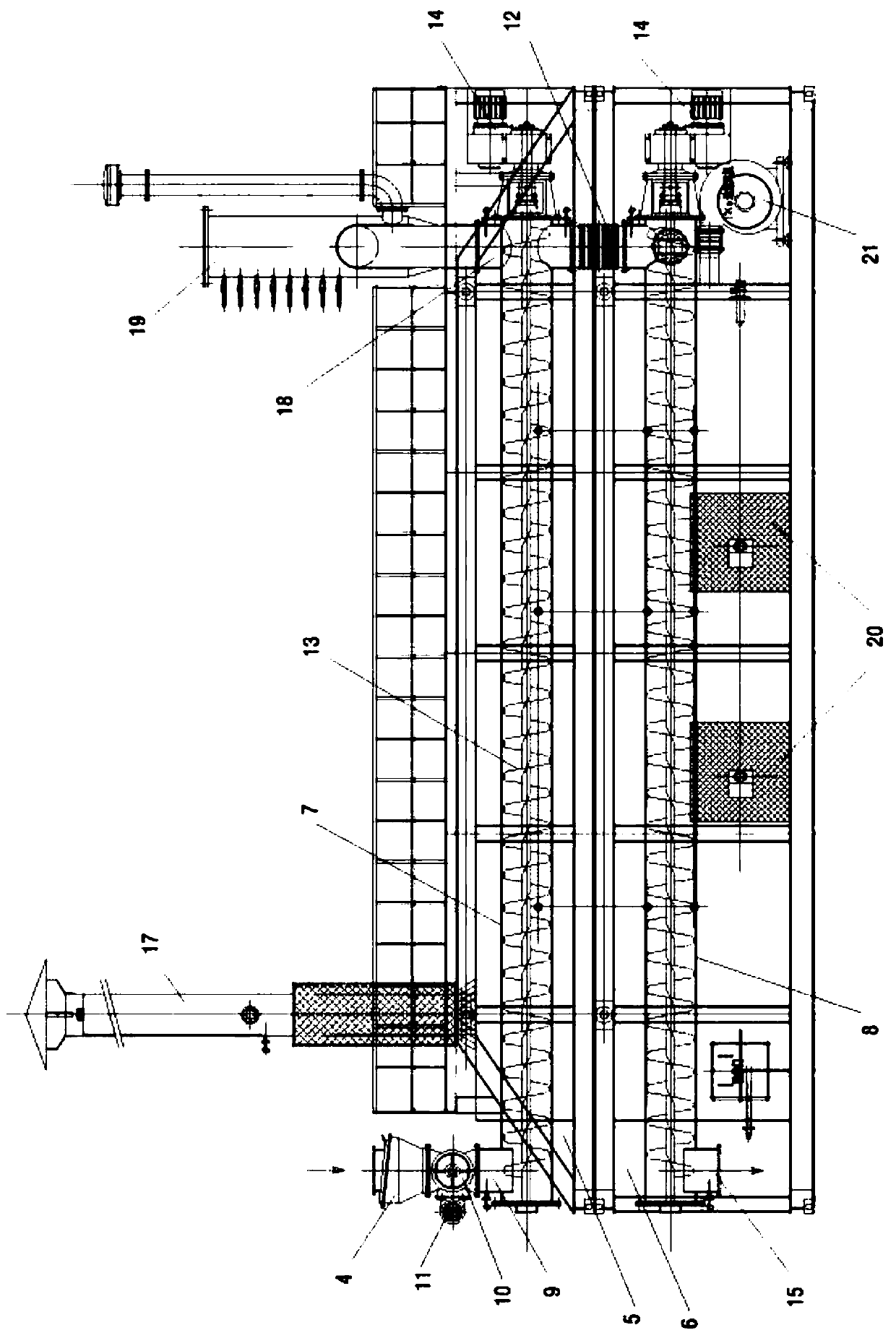

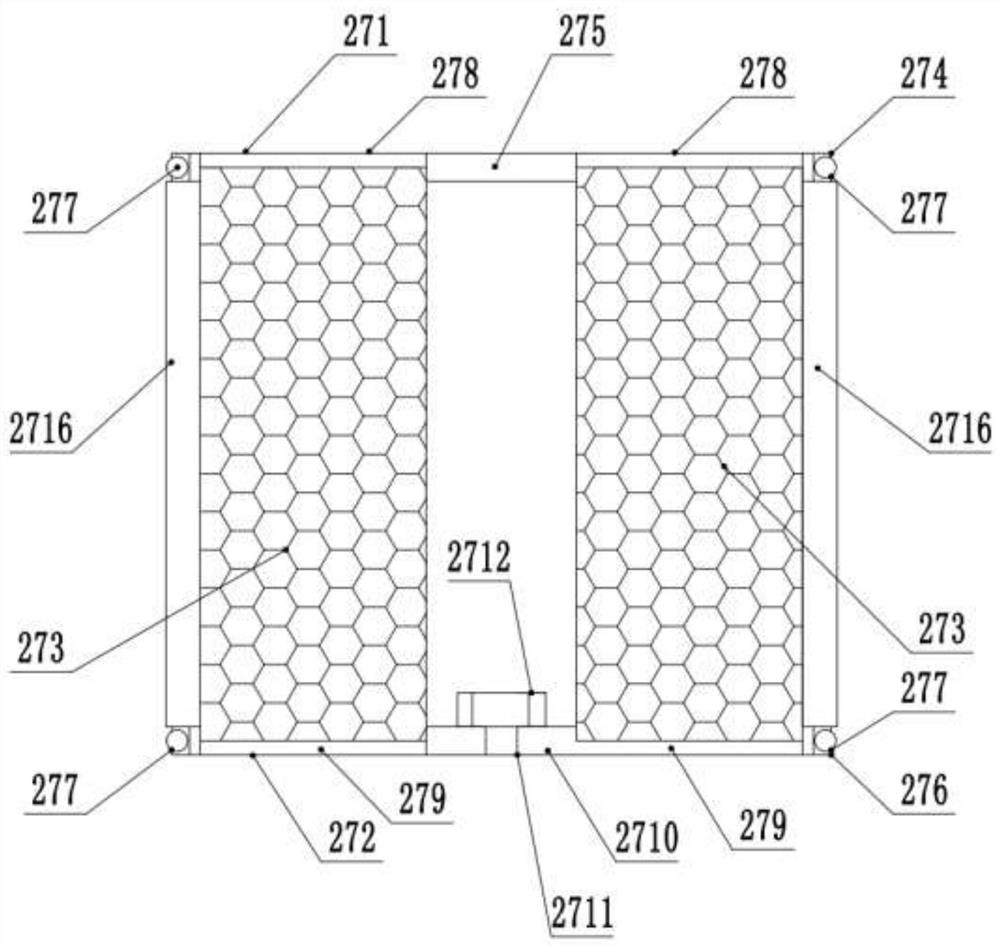

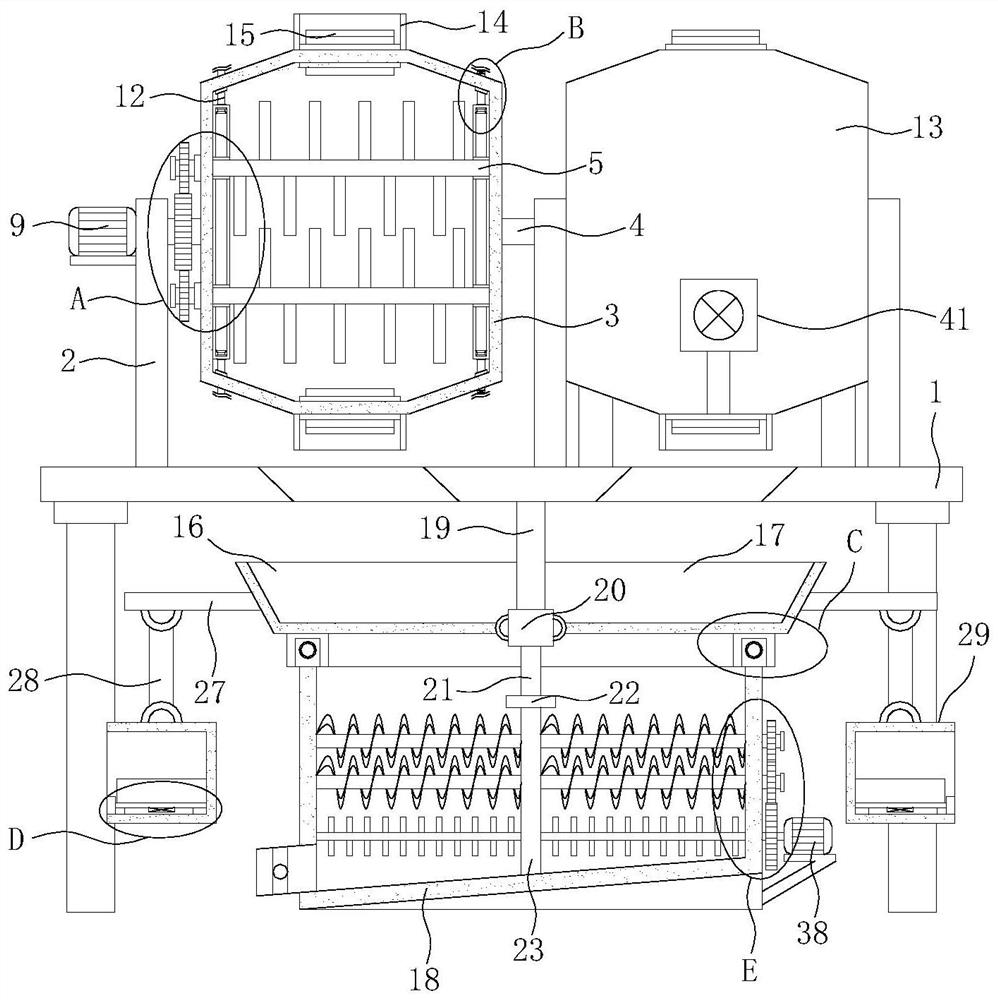

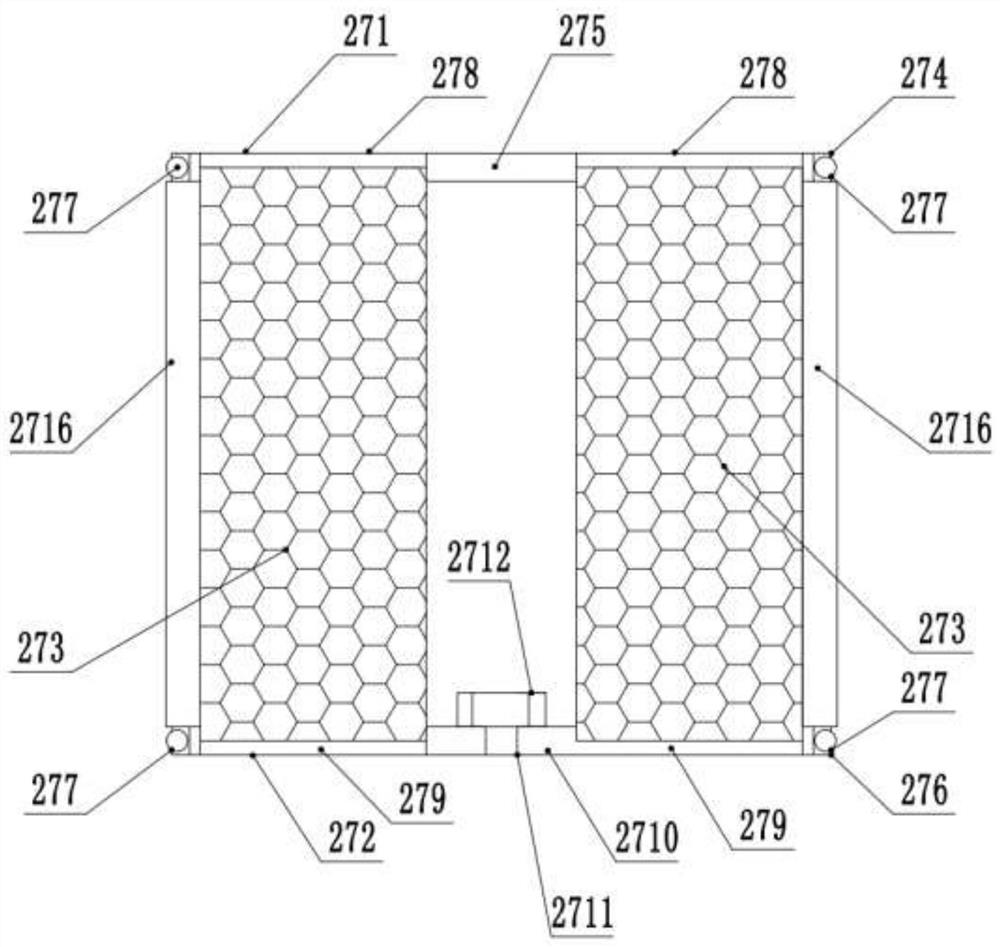

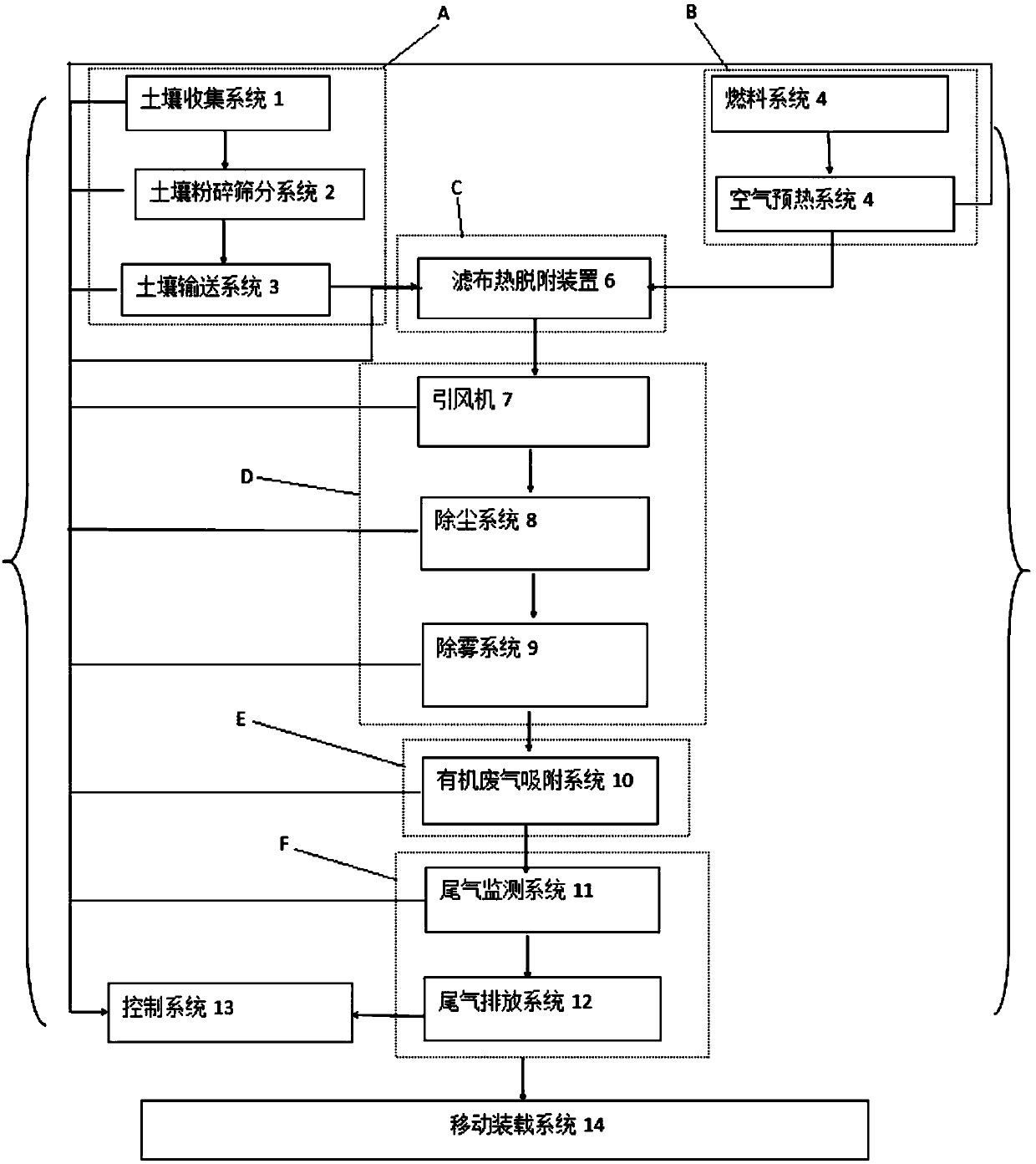

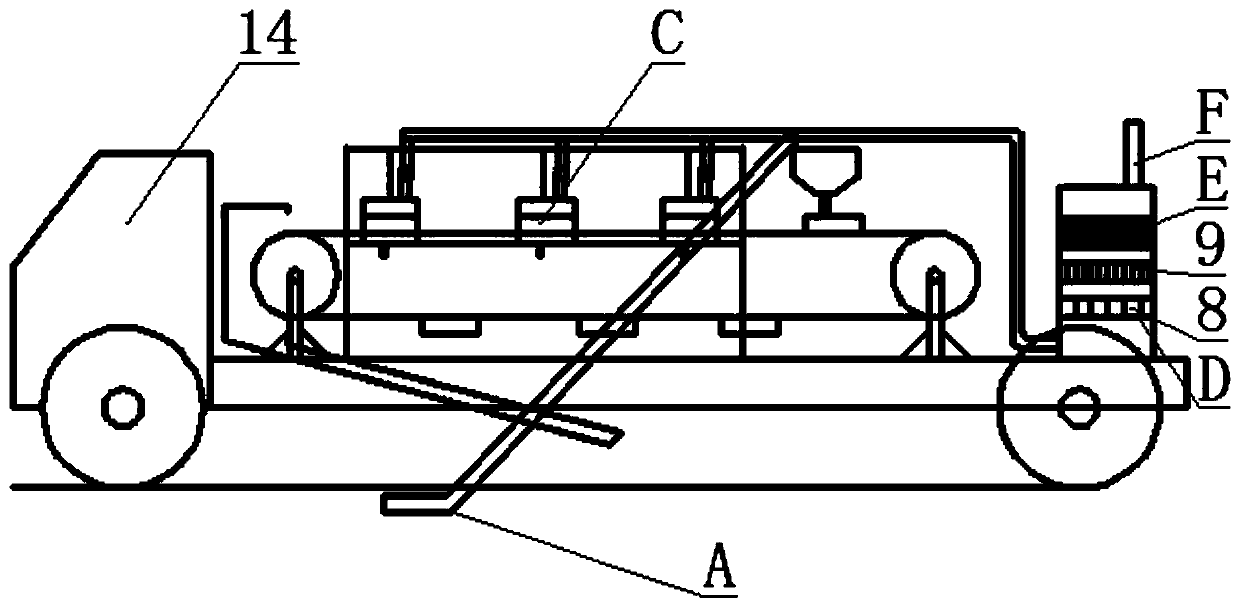

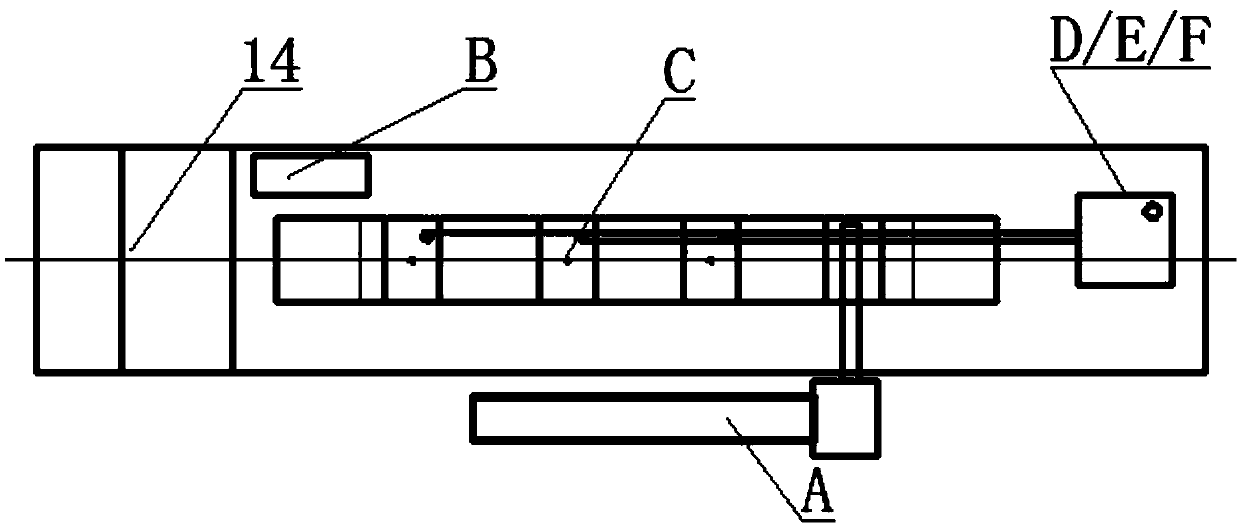

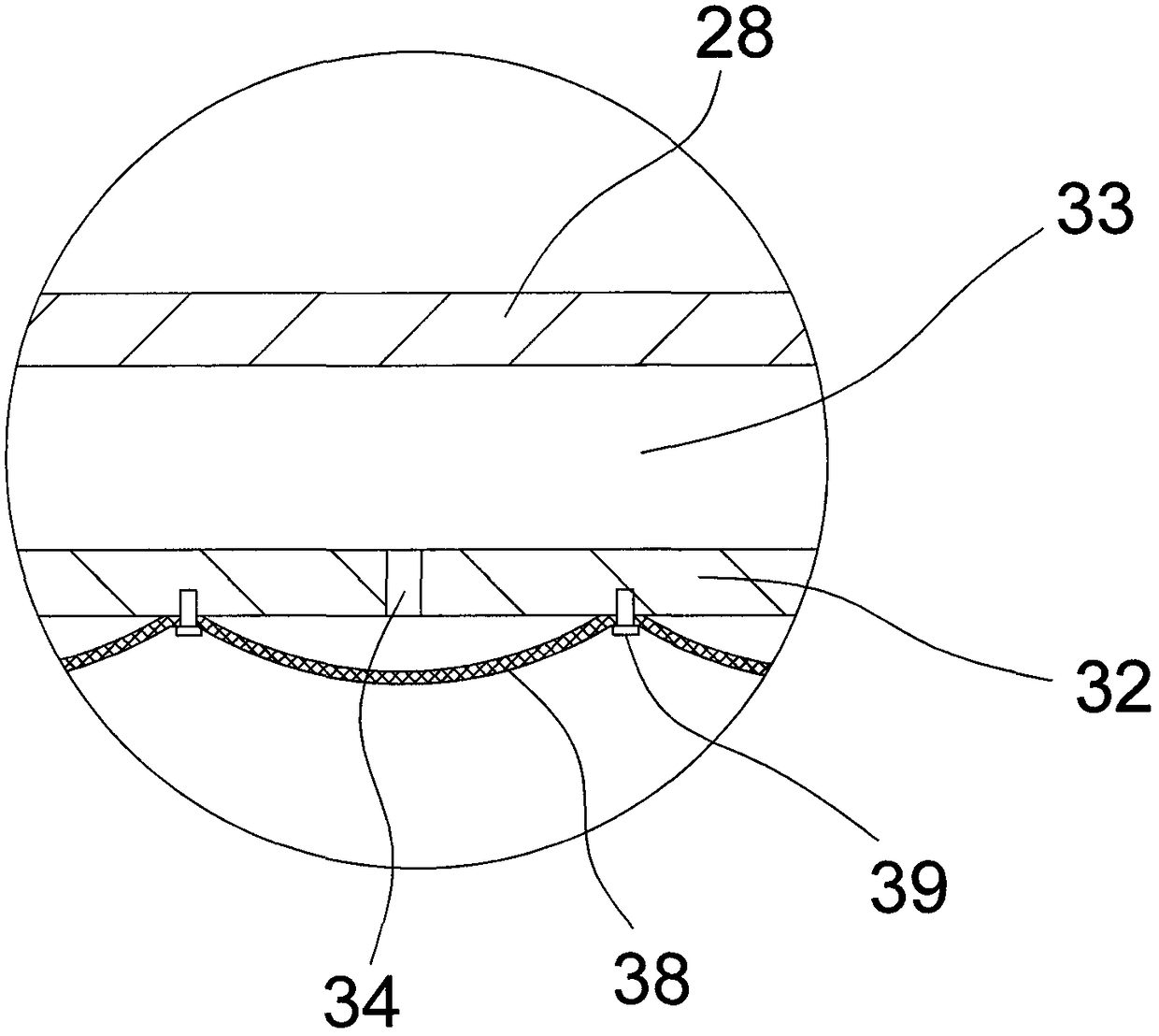

Movable type continuous filter cloth thermal desorption treatment system for soil polluted by organic matter and application

PendingCN107617631ALarge amount of processingLarge desorption capacityContaminated soil reclamationEnvironmental resistanceAutomatic control

The invention relates to a movable type continuous filter cloth thermal desorption treatment system for soil polluted by organic matter. The movable type continuous filter cloth thermal desorption treatment system comprises a soil feeding system, a hot-air system, a filter cloth thermal desorption system, a dedusting and demisting system, an organic waste gas adsorption system, a tail gas treatment system and a control system. The movable type continuous filter cloth thermal desorption treatment system can feed the soil continuously and can be controlled automatically; the treatment amount ofthe polluted soil is large, hot air and the polluted soil are fully mixed on a filter cloth, thus the thermal desorption efficiency is quite high, and the thermal desorption amount is large; and tailgas is treated in an adsorption mode, thus secondary pollution is avoided, environmental protection can be achieved easily, and the cost is low.

Owner:AEROSPACE ENVIRONMENTAL ENG

Low-carbon environment-friendly resource utilization process and system for high-mercury cyanogen-containing gold separation waste residues

ActiveCN114425555AAchieve recyclingHarmlessTransportation and packagingSolid waste disposalProcess engineeringEnvironmental engineering

The system comprises a rotary kiln and a treatment device communicated with the rotary kiln, the treatment device comprises a raw material storage mechanism, a crushing and screening mechanism and a metering mechanism, and a decomposing furnace of the rotary kiln is arranged on the side face of the metering mechanism; a mercury removal mechanism is embedded in one side of an inner cavity of the decomposing furnace, the side face of the mercury removal mechanism communicates with a metering mechanism, a detection mechanism is arranged on one side of the mercury removal mechanism, the top face of the mercury removal mechanism communicates with an adsorption mechanism, and the bottom of the decomposing furnace communicates with a cement preparation mechanism of a rotary kiln; and the top of the decomposing furnace is communicated with a raw material adding mechanism of the rotary kiln, so that harmless treatment and resource utilization of the hazardous wastes can be realized at the same time. The system can realize the following processes in sequence: high-mercury cyanogen-containing gold separation waste residue storage and crushing and screening pretreatment, mercury removal and mercury product recovery, and decyanation production of cement through collaborative treatment of the rotary kiln.

Owner:山西丽浦创新科技有限公司

A thermal desorption remediation device for pops pesticide-contaminated soil

ActiveCN113145628BEvenly heatedFully heatedContaminated soil reclamationHeater RodEnvironmental engineering

The invention discloses a thermal desorption repairing device for soil contaminated by POPs pesticides, comprising a primary thermal desorption component, a secondary thermal desorption component, a gas collection component, a feeding component and a driving component; a primary thermal desorption component Attached components include pyrolysis cylinder, electric heating rod and stirrer, electric heating rod and stirrer are located inside the pyrolysis cylinder, secondary thermal desorption components include pyrolysis box, soil transmission mechanism and infrared heating mechanism, soil transmission mechanism It is installed inside the pyrolysis box and is used to transport the soil entering the pyrolysis box out of the pyrolysis box. The infrared heating mechanism is used to heat the soil on the transmission mechanism. The volatilized organic gas in the box is collected and purified, the feed assembly is used to put contaminated soil into the pyrolysis cylinder, and the drive assembly is used to drive the pyrolysis cylinder to rotate; the structure design of the invention is reasonable, and the thermal desorption efficiency of POPs pesticide-contaminated soil is high. High, suitable for mass promotion.

Owner:NANJING INST OF ENVIRONMENTAL SCI MINIST OF ECOLOGY & ENVIRONMENT OF THE PEOPLES REPUBLIC OF CHINA

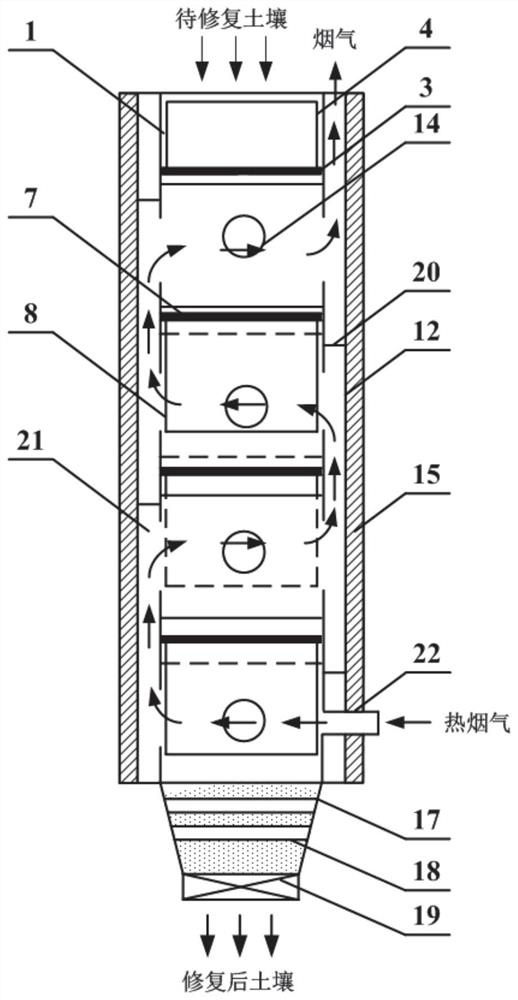

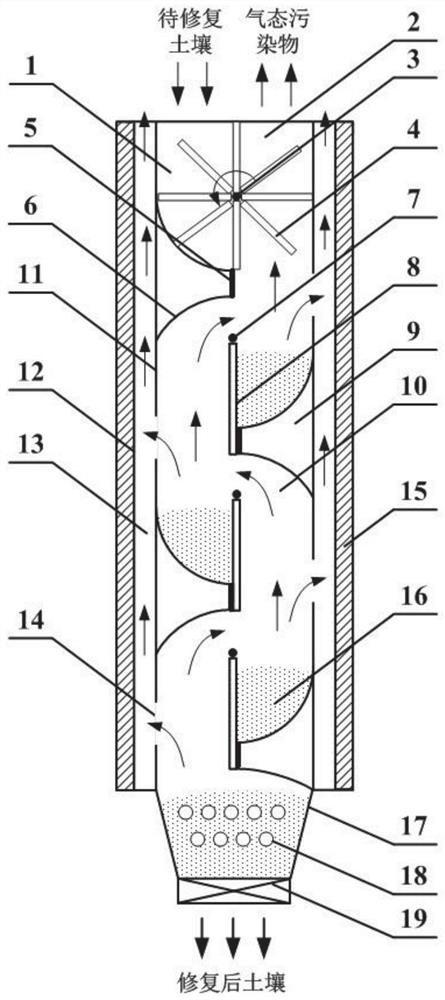

Vertical soil thermal desorption device with internal and external heating and self-weight blanking functions

ActiveCN112916600AHeating evenlyImprove desorption efficiencyHeat storage plantsContaminated soil reclamationThermodynamicsFlue gas

The invention relates to a vertical soil thermal desorption device with internal and external heating and self-weight discharging functions. The device comprises an inner channel and an outer channel arranged outside the inner channel in a sleeving mode, and a gas channel and a flue which are independent of each other are formed in a gap between the inner channel and the outer channel; a plurality of thermal desorption units are arranged in the inner channel, each thermal desorption unit structurally comprises a movable baffle and a heating cavity, and a flue gas inlet and a flue gas outlet which are communicated with the flue are formed in the two ends of each heating cavity respectively; each heating cavity is provided with at least one arc plate, the arc plate and the movable baffle form a soil heating area, and the movable baffle rotates around a rotating shaft at the top of the movable baffle under the action of soil pressure, so that soil slides into the soil heating area of the next thermal desorption unit along the arc plate; and a snakelike heating chamber is formed between each heating cavity and the wall surface of the inner channel, and the heating chamber is communicated with the gas channel and is used for discharging gaseous pollutants separated out during desorption. The technical problems of uneven heating and low heating rate are solved.

Owner:SOUTHEAST UNIV

A soil thermal desorption repairing device

ActiveCN105598151BReduce thermal desorption costsImprove thermal desorption efficiencyContaminated soil reclamationSoil treatmentEngineering

The invention relates to the technical field of soil treatment and discloses a thermal-desorption soil restoring device. The thermal-desorption soil restoring device comprises a support and a horizontal heating cylinder arranged on the support, wherein a feeding channel is arranged at the upper side of the left end of the heating cylinder, a discharging channel is arranged at the lower side of the right end of the heating cylinder, a solar heat collecting pipe is arranged at the outer side of the heating cylinder, a solar reflector is arranged at one side of the support, a main shaft is arranged in the heating cylinder, a spiral band is arranged on the surface of the main shaft, a motor for driving the main shaft to rotate is arranged on the support, an air inlet pipe is arranged at the upper side of the left end of the heating cylinder, an exhaust pipe is arranged at the upper side of the right end of the heating cylinder, an exhaust fan is arranged on the exhaust pipe, a rotary drum is arranged at the inner side of the heating cylinder, an annular space is formed between the rotary drum and the heating cylinder, and a plurality of connecting rods are arranged between the inside of the rotary drum and the main shaft. According to the thermal-desorption soil restoring device, solar heating is utilized, energy is saved and the soil thermal-desorption cost is reduced.

Owner:南京中清环境发展有限公司

A Soil Thermal Desorption Restoration Device Based on Solar Energy

ActiveCN105618476BReduce thermal desorption costsImprove thermal desorption efficiencyContaminated soil reclamationMotor driveSoil treatment

The invention relates to the technical field of soil treatment and discloses a thermal desorption remediation device based on solar energy for soil. The thermal desorption remediation device comprises a support and a horizontal heating cylinder arranged on the support, a feed channel is formed in the upper side of the left end of the heating cylinder, a discharge channel is formed in the lower side of the right end of the heating cylinder, a solar thermal collection pipe is arranged on the outer side of the heating cylinder, a solar reflection plate is arranged on one side of the support, a main shaft is arranged inside the heating cylinder, a spiral band is arranged on the surface of the main shaft, a motor driving the main shaft to rotate is arranged on the support, an air inlet pipe is arranged on the upper side of the left end of the heating cylinder, an exhaust pipe is arranged on the upper side of the right end of the heating cylinder, an exhaust fan is arranged on the exhaust pipe, rotating sleeves are fixed to the two ends of the solar thermal collection pipe and are connected to the heating cylinder in a rotating mode, outer teeth are arranged on the outer side of the rotating sleeve at the left end of the solar thermal collection pipe, an auxiliary motor is arranged on the support, and a gear meshed with the outer teeth is arranged at the shaft end of the auxiliary motor. The thermal desorption remediation device has the beneficial effect of greatly lowering the thermal desorption cost of the soil by utilizing the solar energy for heating.

Owner:重庆昆顶环保科技有限公司

A vertical soil thermal desorption device with internal and external heating and self-weight unloading

ActiveCN112916600BHeating evenlyImprove desorption efficiencyHeat storage plantsContaminated soil reclamationThermodynamicsFlue gas

The invention relates to a vertical soil heat desorption device with internal and external heating and self-weight cutting, which includes an inner channel and an outer channel sleeved outside the inner channel, and the gap between the inner channel and the outer channel forms mutually independent air channels and the flue; the inner passage is provided with a plurality of thermal desorption units, and the structure of each thermal desorption unit includes a movable baffle and a heating chamber, and the two ends of the heating chamber are respectively provided with flue gas inlets and outlets connected with the flue; Each heating chamber has at least one arc plate, and the arc plate and the movable baffle form a soil heating area. The movable baffle rotates around its top shaft under the action of soil pressure, so that the soil slides along the arc plate to the next thermal desorption In the soil heating area of the unit; a serpentine heating chamber is formed between each heating chamber and the wall of the inner channel, and the heating chamber is connected with the air passage for discharging gaseous pollutants precipitated during desorption. The invention solves the technical problems of uneven heating and low heating rate.

Owner:SOUTHEAST UNIV

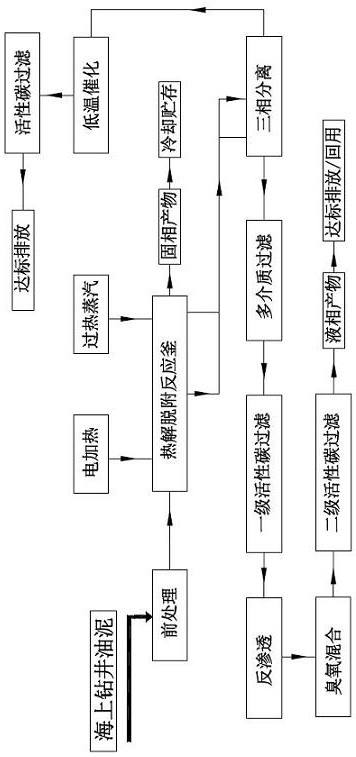

Treatment method of oily sludge on offshore platform

ActiveCN107151088BReduce occupancySmall footprintGas treatmentSludge treatment by pyrolysisSludgeCentrifugation

The invention belongs to the technical field of processing of oily sludge and particularly relates to a processing method of oily sludge on an offshore platform. The processing method of the oily sludge on the offshore platform comprises pyrolysis desorption processing, tail gas processing and waste water processing; the pyrolysis desorption processing is completed in a pyrolysis desorption reaction kettle, the inner wall of the pyrolysis desorption reaction kettle and the inside of the pyrolysis desorption reaction kettle are simultaneously heated, the pyrolysis desorption reaction kettle is vertically arranged, and the oily sludge is discharged from the pyrolysis desorption reaction kettle after being subjected to transverse centrifugation and vertical rollover in the pyrolysis desorption reaction kettle; the tail gas processing is used for processing tail gas obtained after a pyrolysis product generated in the pyrolysis desorption reaction kettle is subjected to three-phase separation; the waste water processing is used for processing waste water obtained after the pyrolysis product generated in the pyrolysis desorption reaction kettle is subjected to three-phase separation. According to the processing method of the oily sludge on the offshore platform, when an occupied area of equipment is reduced, processing efficiency of the oily sludge can be improved.

Owner:ZHE JIANG ECO ENVIRONMENTAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com