Pyrolysis desorption reaction kettle and treatment equipment including same for oily sludge of offshore platform

A treatment equipment and reactor technology, which is applied in the field of oily sludge treatment equipment on offshore platforms, can solve the problems of large floor space and achieve the effects of small floor space, high efficiency, and good thermal desorption and desorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

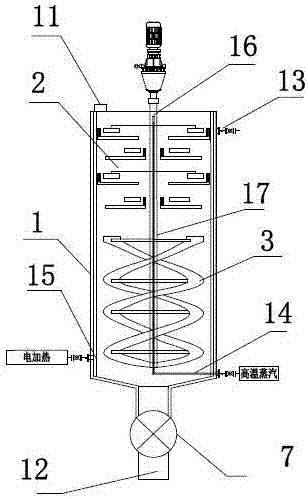

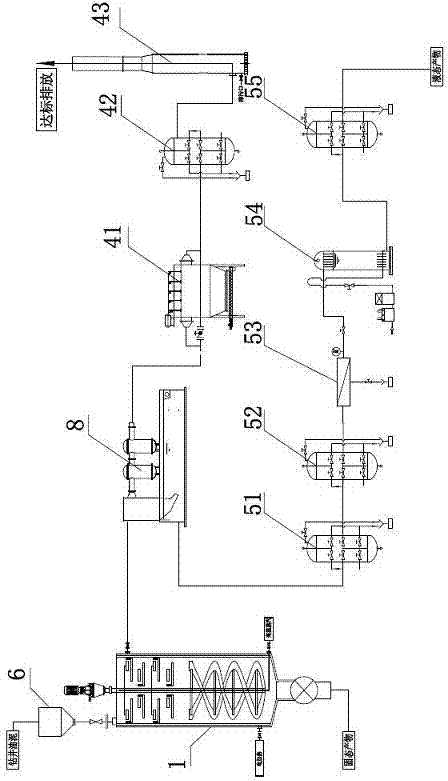

[0029] Such as figure 1 As shown, the thermal desorption and desorption reactor of the present invention includes a body 1, which is generally arranged horizontally with the thermal desorption and desorption reactor in the prior art, while the thermal desorption and desorption reactor of the present application is arranged vertically. The body 1 is provided with a material inlet 11, a material outlet 12, and a pyrolysis gas outlet 13, and the pyrolysis gas outlet 13 is arranged in the upper space of the pyrolysis-desorption reactor. The material outlet 12 is located at the bottom of the thermal desorption reaction kettle, and the material outlet 12 is provided with a gas locker 7 .

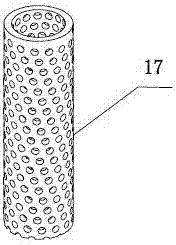

[0030] The body 1 is equipped with a material conveying mechanism, which includes a disc dryer 2 and a single-shaft double-helical mixer 3, and the disc dryer 2 that produces a horizontal centrifugal effect on the material is arranged in the upper space of the thermal desorption reaction kettle. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com