Thermal desorption remediation device for soil remediation

A soil remediation and thermal desorption technology, which is applied in the field of thermal desorption repair devices for soil remediation, can solve the problems of uneven heat reception by the soil and limited thermal desorption effect, and achieve the effect of high efficiency and avoiding aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

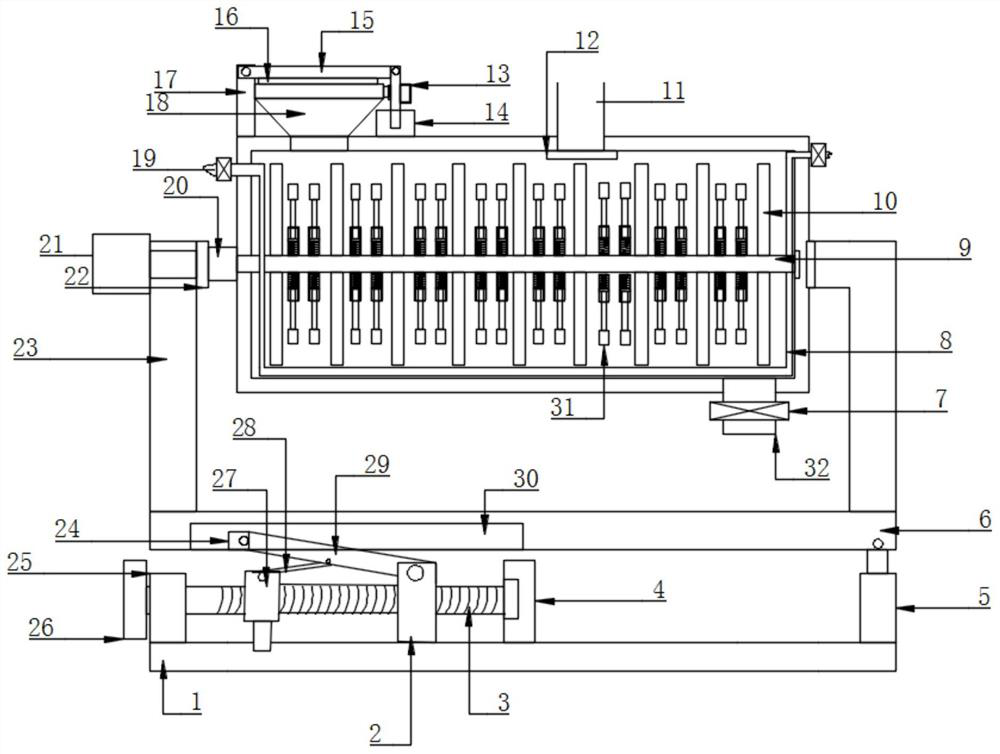

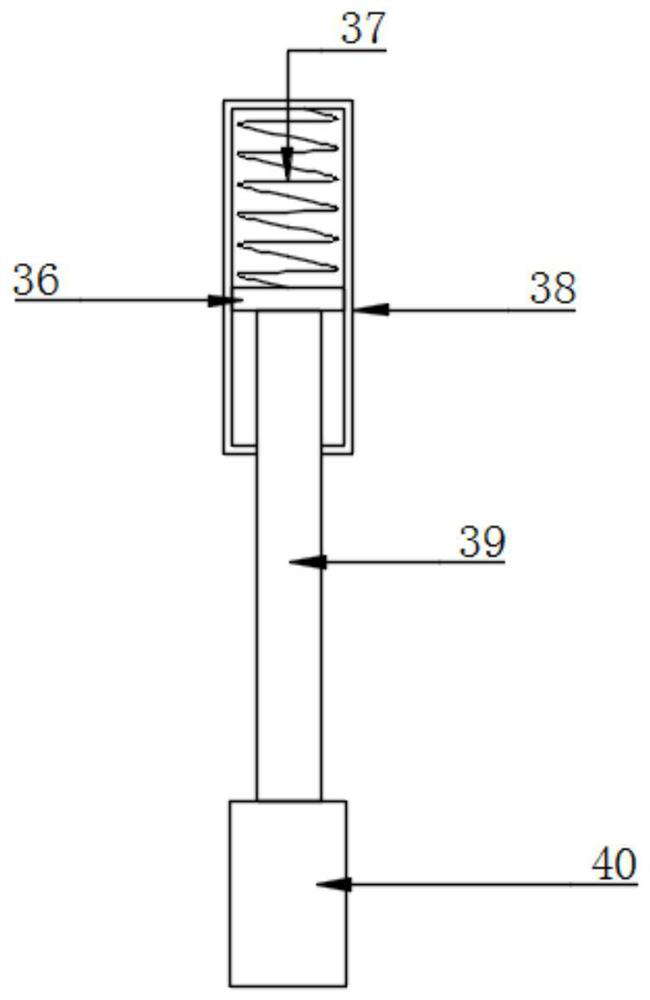

[0020] see Figure 1-4 , a thermal desorption restoration device for soil restoration, comprising a support base 1, a fixed base 6 and a thermal desorption box, the support base 1 is provided with a fixed base 6 through a blanking structure, and the fixed base 6 is provided with There is a thermal desorption box, and a thermal desorption structure is arranged inside the thermal desorption box, and the thermal desorption structure includes an inlet 18, a feeding port 32, an internal stirring structure, an inlet sealing structure, and an outlet control panel 7 , a filter screen 12 and a gas outlet pipeline 11, the inside of the thermal desorption box is rotated to be provided with an internal stirring structure, the thermal desorption box is fixed with an inlet 18, and the inlet 18 is provided with an inlet sealing structure , the bottom of the thermal desorption box is provided with a discharge port 32, the discharge port 32 is provided with an outlet control panel 7, the side ...

Embodiment 2

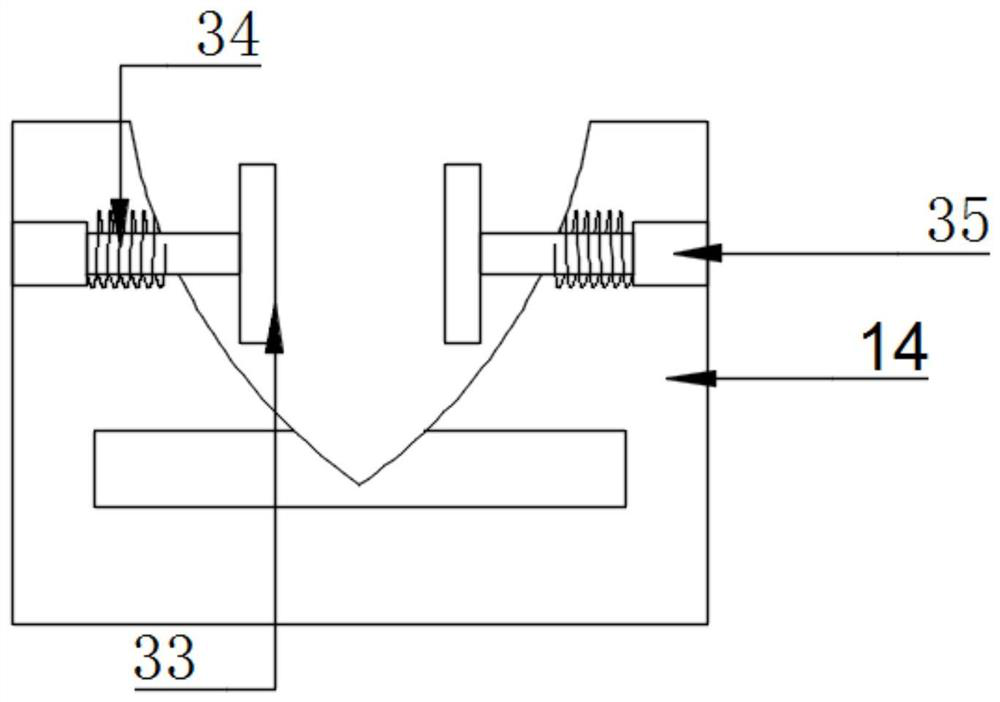

[0027] Compared with Embodiment 1, the improvement of this embodiment is that: a bottom receiving seat 14 is arranged above the thermal desorption box, and a telescopic rod 35 is arranged inside the bottom receiving seat 14, and the end of the telescopic rod 35 A clamping plate 33 is provided, and a clamping spring 34 is provided on the telescopic rod 35 . When the rotating rod rotates to the middle position of the bottom receiving seat 14, first squeeze the clamping plate 33, so that the clamping spring 34 on the telescopic rod 35 is reversely elongated, so that the clamping plate 33 has a clamping force, and the clamping spring 34 is arranged on a fixed position of the output end of the telescopic rod 35, and the other end of the clamping spring 34 is arranged at the inner fixed position of the top receiving seat 14.

[0028] The working principle of the present invention is: at first the soil to be processed enters the inside of the thermal desorption box from the inlet 18,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com