Patents

Literature

153results about How to "Excellent technical indicators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bone porcelain with high resistance of heat shocks and production method thereof

InactiveCN101289307AReduce contentSmall coefficient of thermal expansionClaywaresHigh resistanceSodium Bentonite

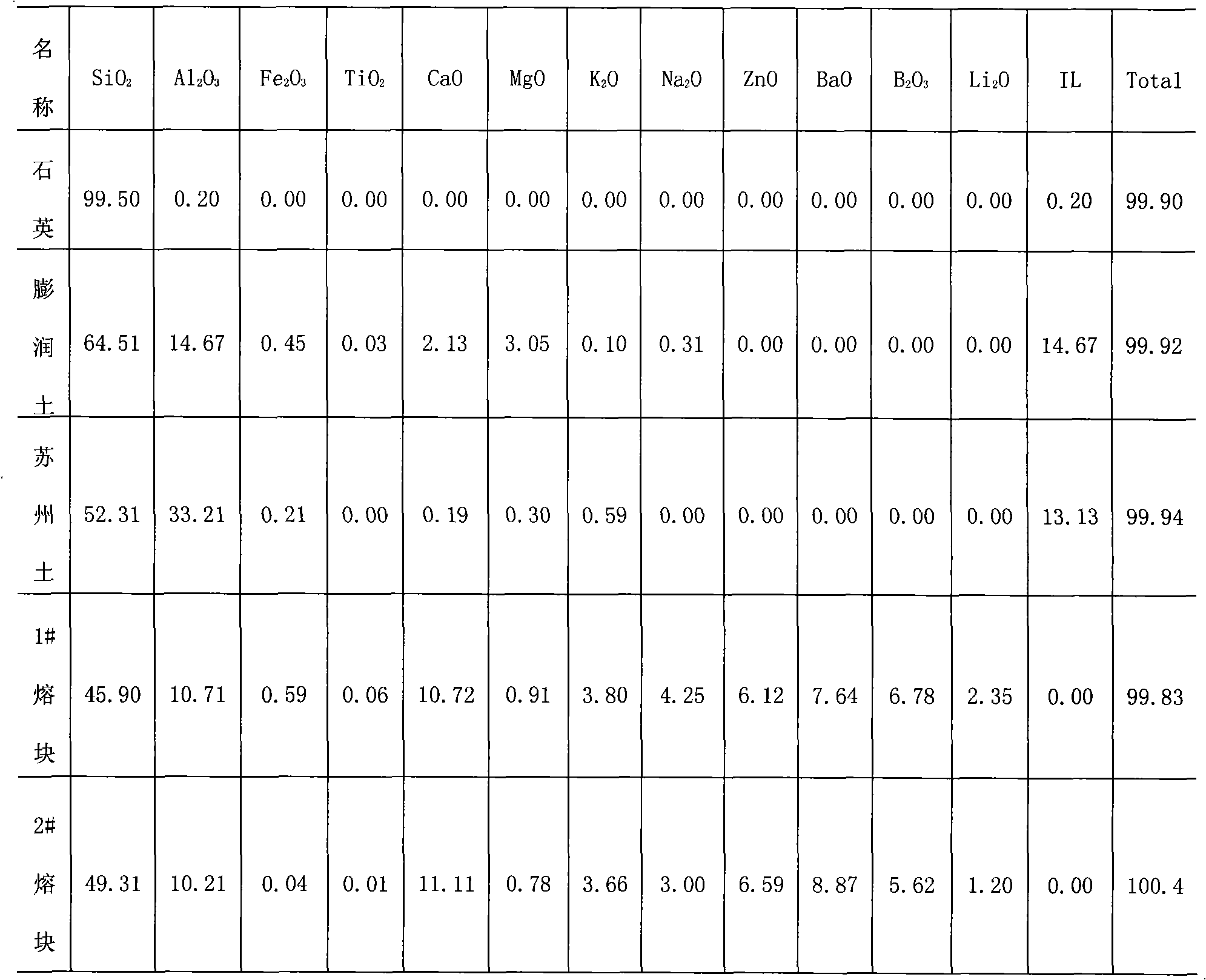

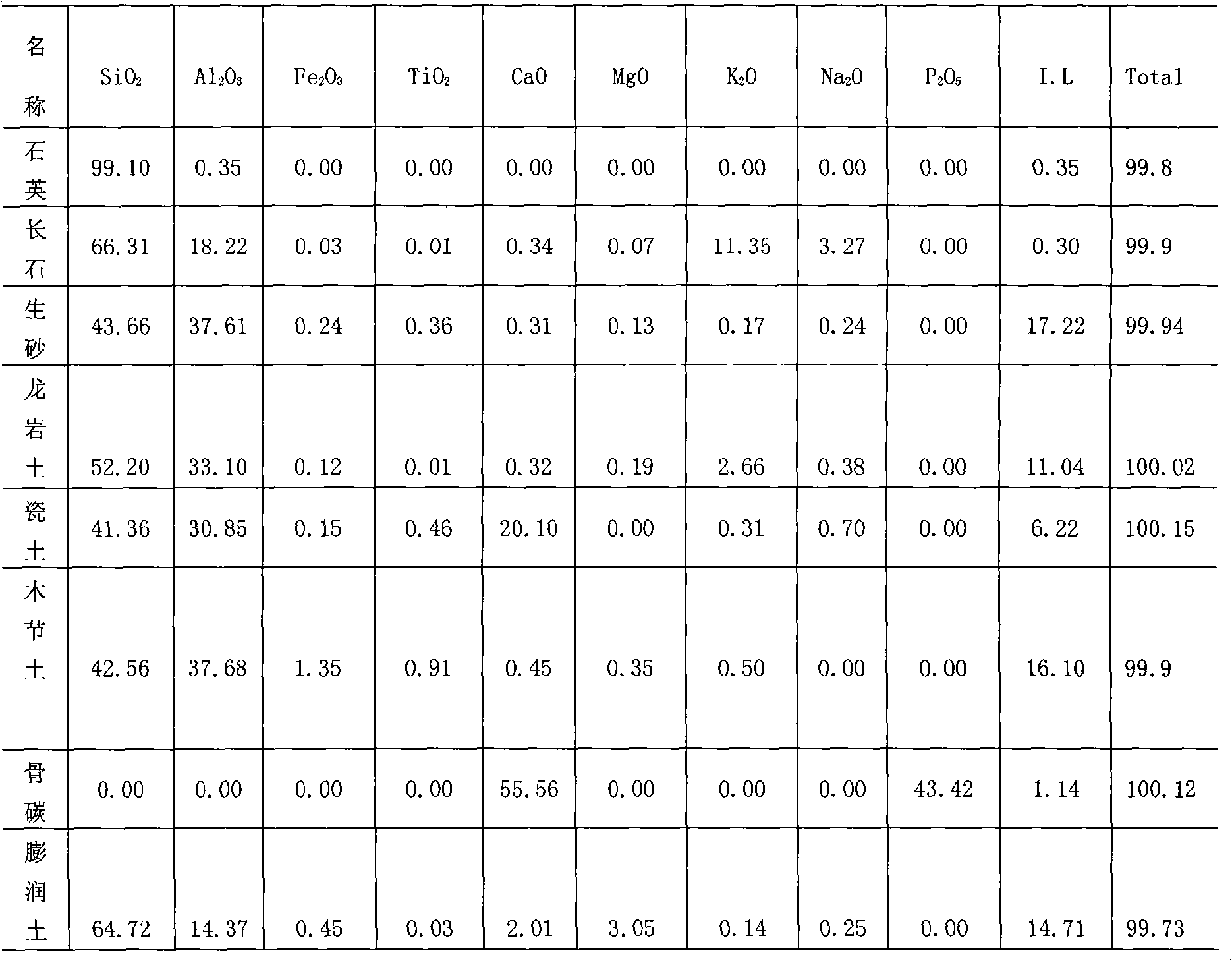

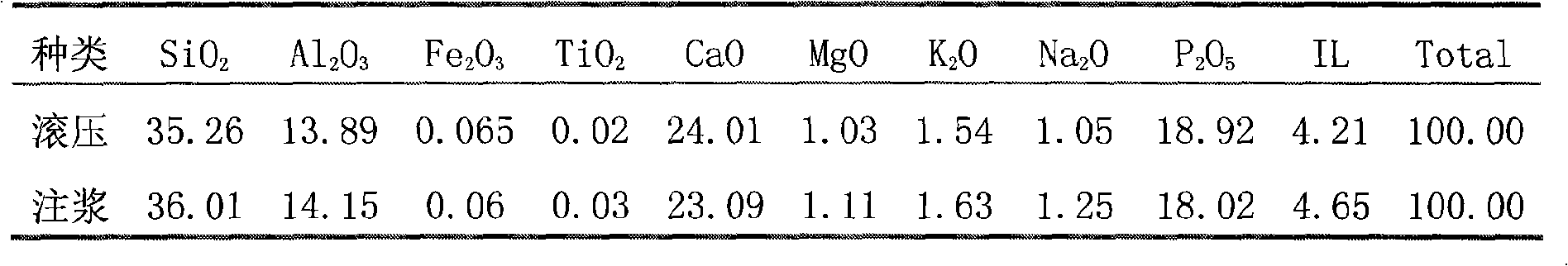

The invention relates to a bone china with high resistance to heat shocks and a manufacture method thereof. The raw material components of the bone china stock and the weight percentages are: 9 to 12 of quartz, 7 to 10 of feldspar, 11 to 14 of greensand, 4 to 7 of Longyan clay, 5 to 8 of china clay, 4 to 7 of kibushi clay, 42 to 46 of bone coal and 7 to 10 of bentonite; the raw material components and the weight percentages of glaze material are: 5 to 8 of the quartz, 2 to 5 of the bentonite, 3 to 6 of Suzhou clay, 50 to 53 of model one fused block and 34 to 37 of model two fused block; the bone china has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C for once. The manufacture steps are as follows: preparing stock paste, preparing glaze paste, roller forming, grouting and forming, biscuit firing, glazing, glaze firing and decorating firing. The enamel layer of the invention has the advantages of large elasticity, good toughness and mechanical property. The raw material ingredients have no lead and zero radioactivity, which are green. The manufacture method is scientific and reasonable, and the product has the resistance to heat shocks that no crack occurs during the heat change in the water with the temperature of 200 to 20 DEG C at one time.

Owner:唐山隆达骨质瓷有限公司

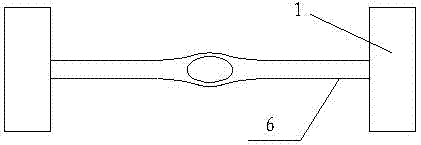

Vanadium titanium cast iron brake drum and preparation method thereof

The invention relates to a manufacturing technique of an automotive vanadium titanium cast iron brake drum with high strength and high abrasive resistance, and particularly relates to a preparation method of a vanadium titanium cast iron brake drum. The preparation method comprises the following steps: melting base iron, namely b y taking vanadium titanium pig iron, steel scrap, foundry returns, a carburant, ferrosilicon, ferromanganese and ferrochrome as furnace charge, adding the carburant to the furnace bottom; smelting the furnace charges by using a medium-frequency induction furnace to prepare the base iron; heating and purifying molten iron in an overheating manner after the molten iron is molten down, and then carrying out heat preservation at 1520-1530 DEG C; and carrying out drossing, adding a slag conglomeration agent to the surface to carry out heat preservation after drossing, and then adding a little of furnace charge, and adjusting the ingredients and the like of the molten iron. A little of furnace charge is added at the later smelting stage to increase the heterogeneous core technology, so that the chilling tendency of the molten iron is relieved, the graphitization ability of the molten iron is improved, and the inoculation effect is improved. A secondary inoculation treatment process of a launder and a pouring cup is adopted, so that the inoculation effect is improved, the graphite form is improved, carbide and ferrite are removed, and the content of pearlite is improved.

Owner:陈国

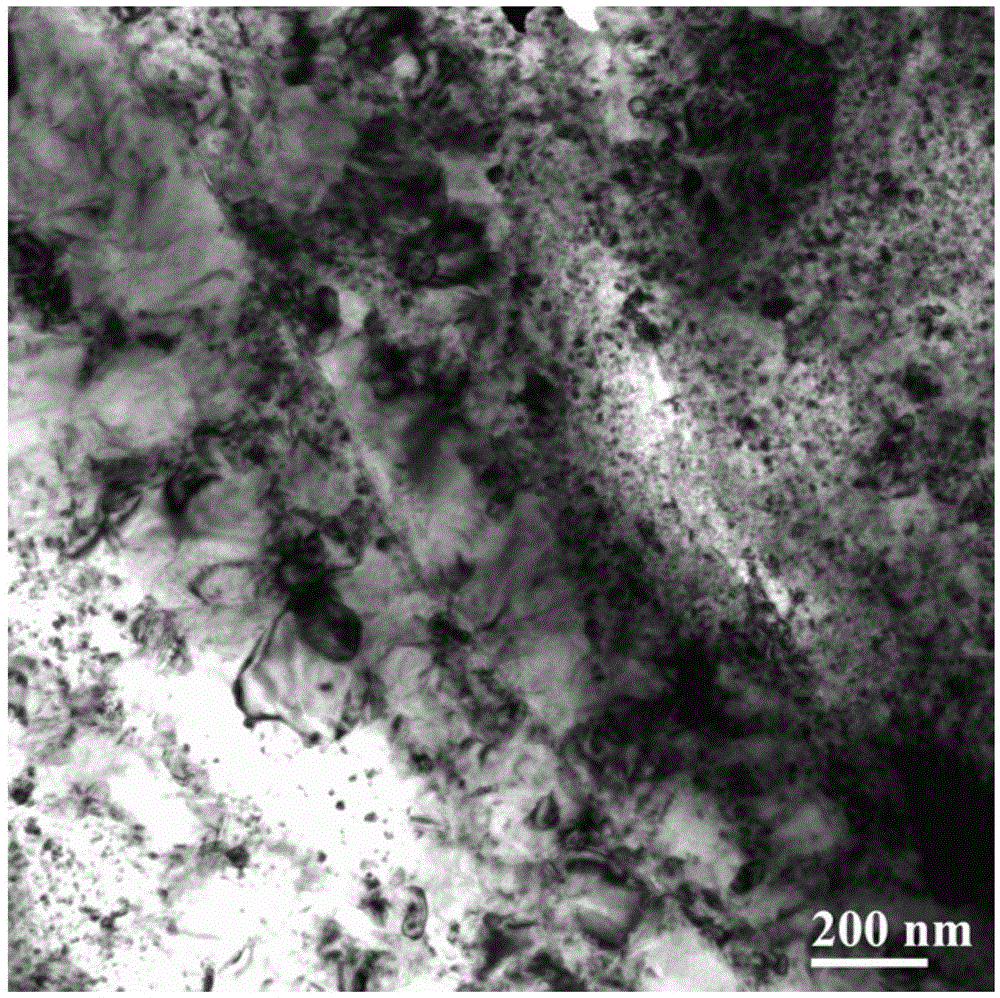

Remanufacturing method for scrap titanium chips through ball milling-equal channel angularpressing

InactiveCN105618501AExcellent technical indicatorsSimple process operationCleaning using liquidsGrain treatmentsScrapSwarf

The invention provides a remanufacturing method for scrap titanium chips through ball milling-equal channel angular pressing. The remanufacturing method sequentially comprises the step of recovering and pretreating titanium chips, the step of performing ball milling treatment on the titanium chips, the step of loading the titanium chips into an equal channel angular pressing mold, the step of performing preprocessing at a room temperature through the equal channel angular pressing, the step of curing and processing at a high temperature, and the step of quenching. The ball milling-equal channel angular pressing composite technique provided by the invention is simple and practical to operate and high in controllability. Through remanufacturing, not only can nanometer block titanium materials (smaller than 200nanometers) with full densification be obtained, but also the metallurgical defect of the continuous distribution and gathering of large sliced oxides can be eliminated. In addition, the shapes of the titanium chips are refined and reformed, and anisotropy caused by deformation texture in hexagonal close packed titanium materials is restrained. The yield strength of the remanufactured nanometer titanium materials reaches to the level of 5-grade titanium, the distribution of nanometer particles of the oxides presents a dispersed uniform state, and through the isotropy of the properties of the materials, the remanufacturing of scrap titanium resources for value increase at low cost is realized.

Owner:SHANGHAI DIANJI UNIV

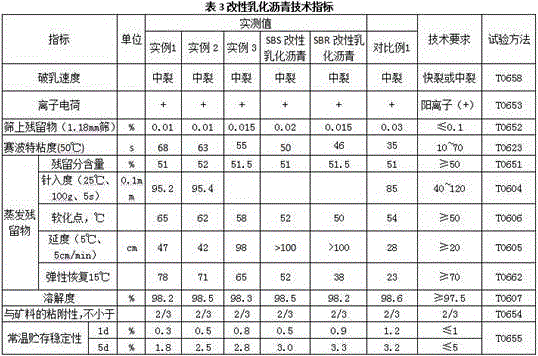

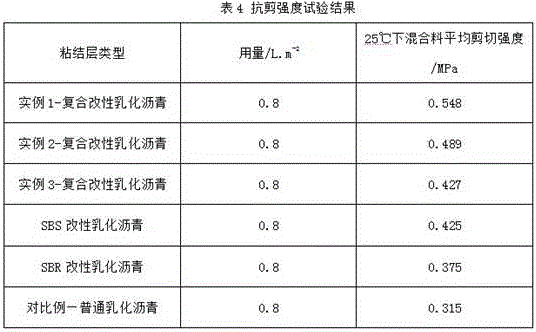

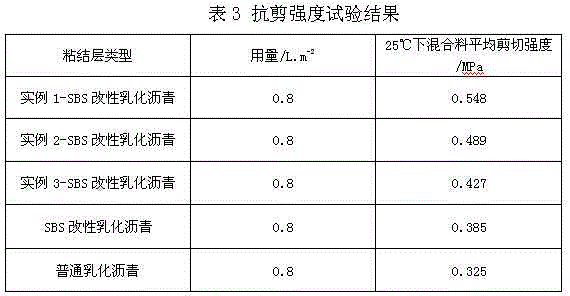

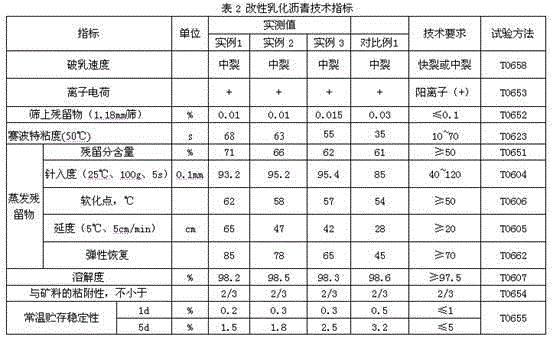

Super-adhesive composite modified emulsified asphalt and preparation method thereof

InactiveCN105482477AGood application prospectSimple production processBuilding insulationsColloid millLiquid soap

Super-adhesive composite modified emulsified asphalt is prepared from matrix asphalt, SBS modifier, viscosity reducer, cationic emulsifier, hydrochloric acid, water and SBR modifier. The method includes the steps of firstly, heating matrix asphalt, adding SBS modifier to be stirred, evenly dispersing SBS modifier in matrix asphalt, and preparing SBS modified asphalt; secondly, heating SBS modified asphalt, adding viscosity reducer, dispersing viscosity reducer to SBS modified asphalt, and preparing SBS modified asphalt used for emulsification; thirdly, placing SBS modified asphalt which is prepared in the second step and used for emulsification in an asphalt tank of an emulsification device to be emulsified; fourthly, adding cationic emulsifier and water into a liquid soap tank of the emulsification device to prepare liquid soap; fifthly, adding concentrated hydrochloric acid to heat liquid soap; sixthly, emulsifying SBS modified asphalt used for emulsification and liquid soap in the liquid soap tank through a colloid mill; seventhly, externally adding SBR modifier to be mixed with emulsification asphalt at a normal temperature for secondary modification. Composite modification is conducted through SBS and SBR modifier, the emulsified asphalt is good in stability, and viscosity of asphalt generated after demulsification is large.

Owner:XIAN HIGHWAY INST

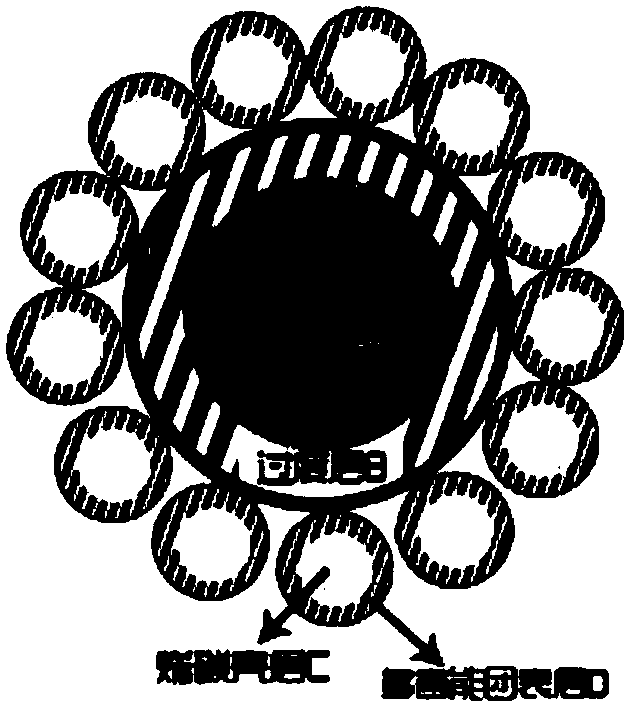

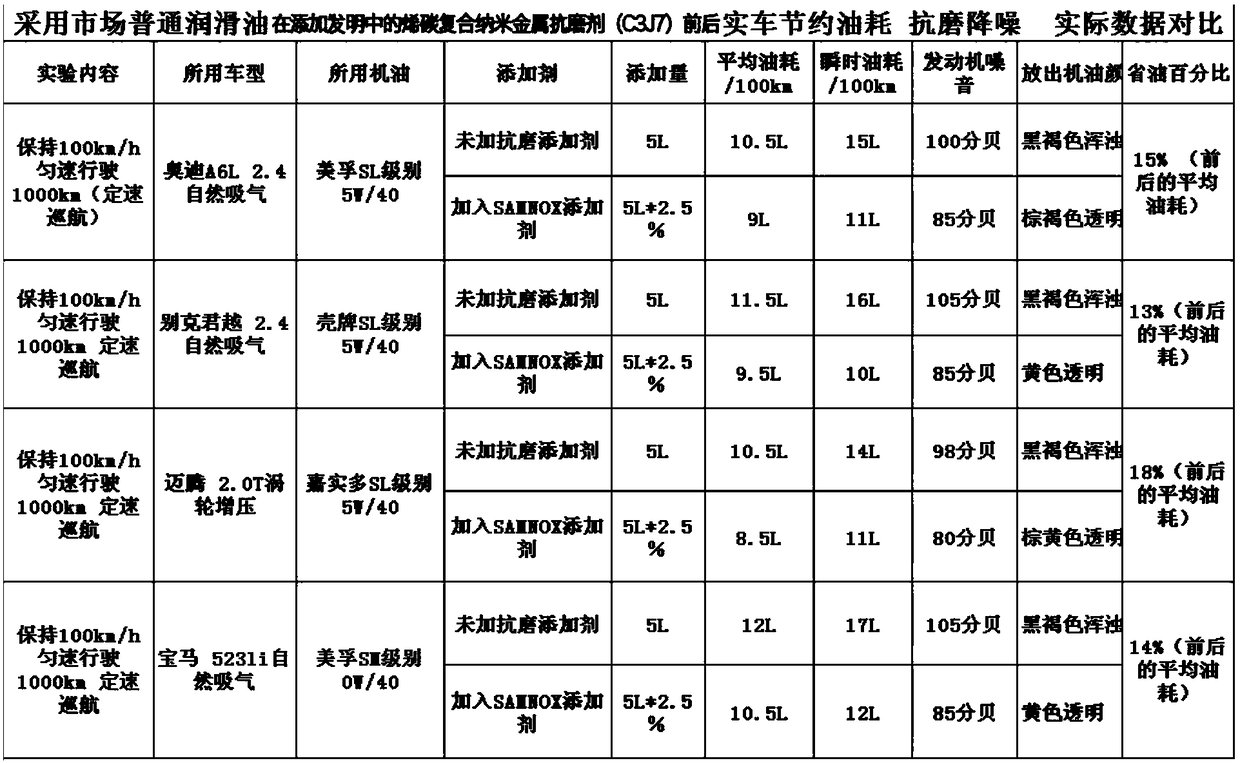

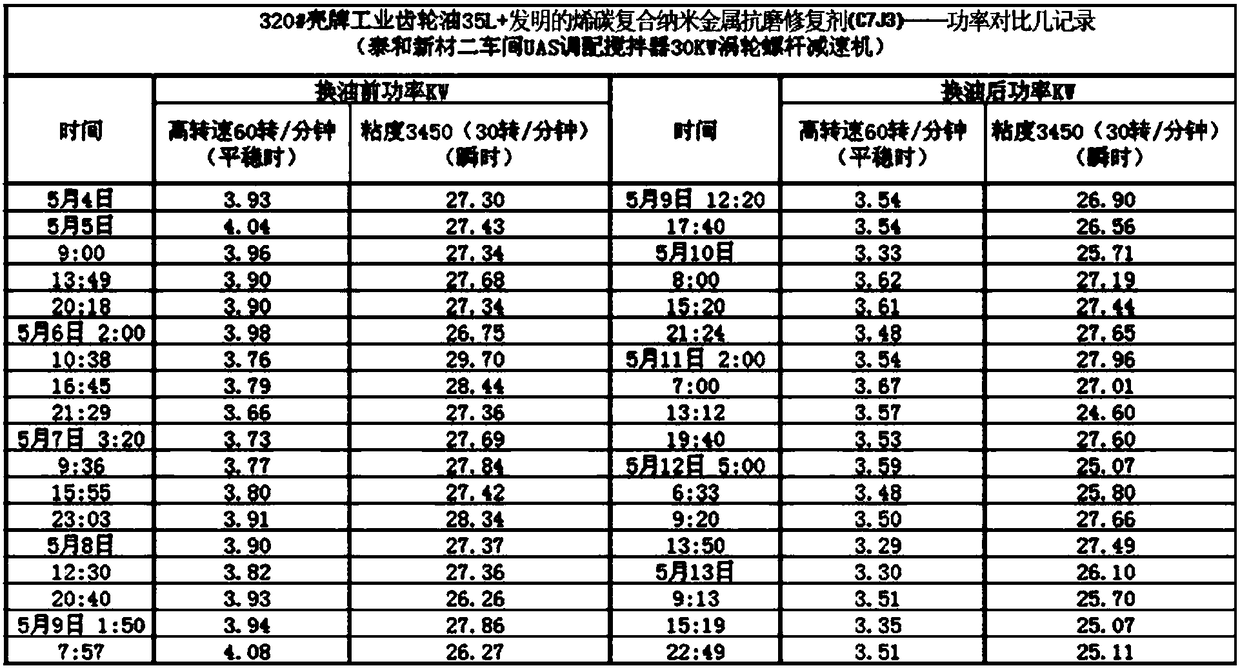

Olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and preparation method thereof

ActiveCN108148652AImprove anti-wear performanceAchieve super lubricityAdditivesWear resistantLubrication

The invention relates to an olefinic carbon compound nanometer soft metal wear-resistant self-repairing material with surface modification, and a preparation method thereof. A nanometer olefinic carbon material with wear-resistant performance and a nanometer metal material with an abrasion repairing function are subjected to in-situ composite preparation with a sol-gel method, so that the materialhas dual functions of abrasion resistance and reduction and abrasion self-repairing, and the advantage complementation mechanism of the synergetic effect and the performance of different types of nanometer materials is performed. The olefinic carbon compound nanometer soft metal wear-resistant self-repairing material prepared with the preparation method can be used for realizing the breakthroughof 'exponential increase of wearing resistance under extreme pressure', 'zero abrasion of metal friction' under an extreme pressure situation is broken through, true super lubrication under the extreme pressure situation is realized, traditional sulfur-phosphorus-containing liquid lubrication performance and application technologies are subjected to revolutionary changes due to the occurrence of olefinic carbon compound wear-resistant energy-saving materials, the material does not contain caustic organic sulfur and phosphorus compound, wear-resistant performance is improved, and wear reductionenergy saving performance is also improved.

Owner:烟台华恒节能科技有限公司

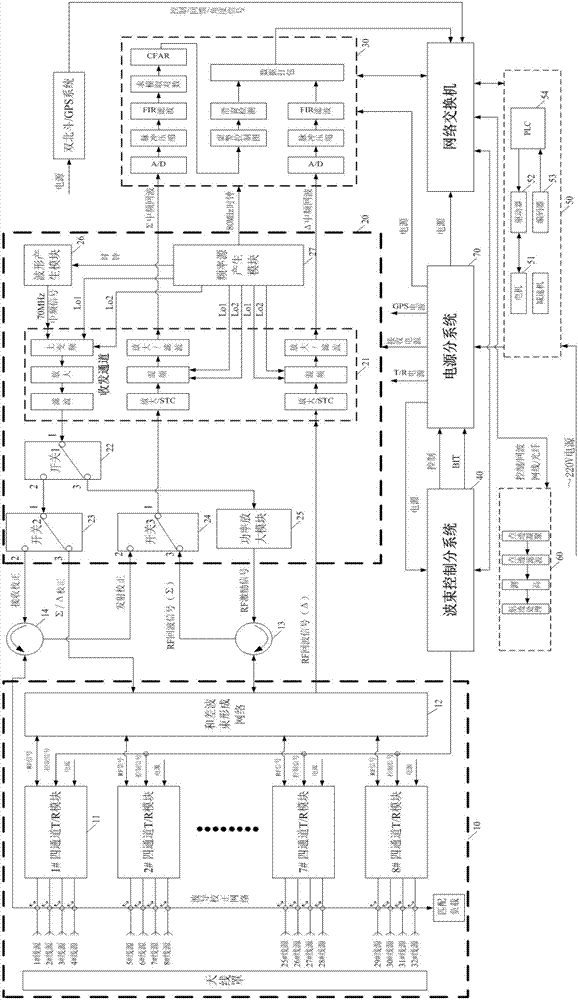

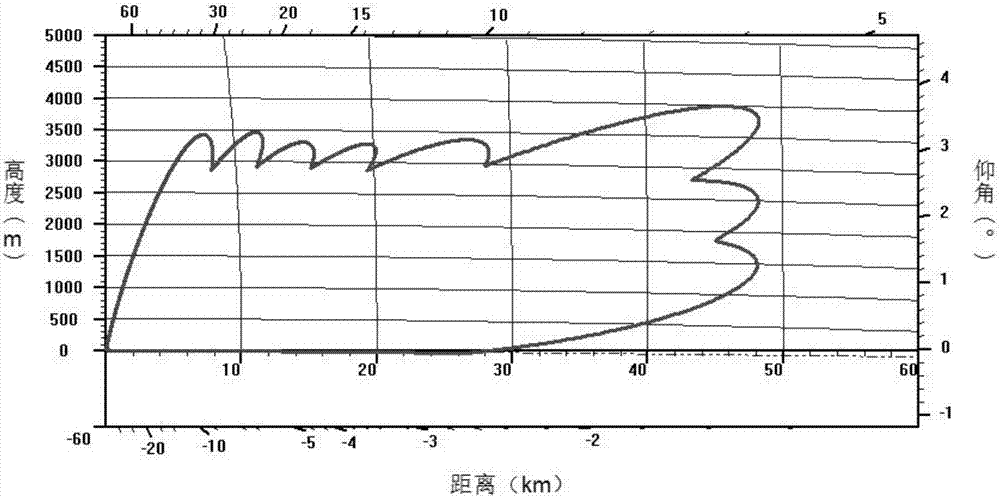

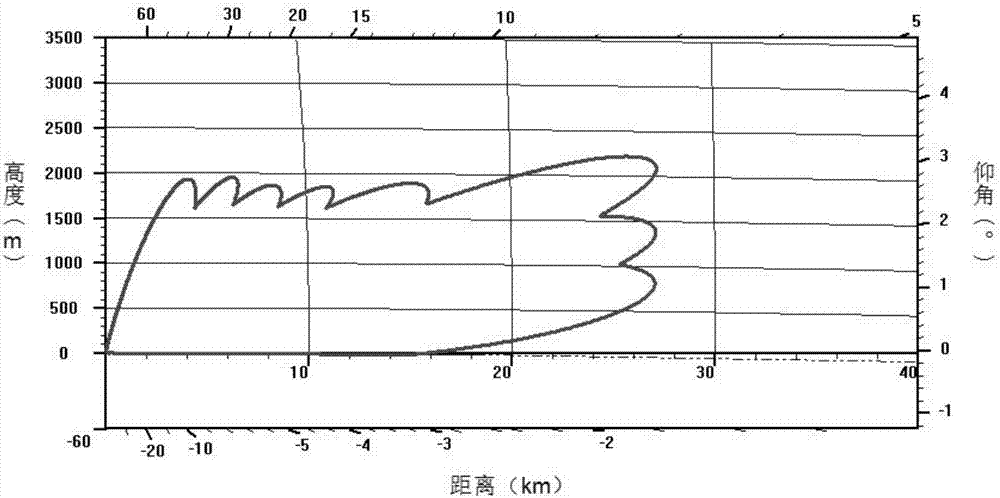

Three-coordinate low-altitude small target radar

ActiveCN107015218AReduce weightReduce volumeRadio wave reradiation/reflectionJet aeroplaneRadar systems

The invention relates to a radar system, specifically to a three-coordinate low-altitude small target radar. The three-coordinate low-altitude small target radar comprises an antenna feeder subsystem, a receiving subsystem, a signal processing subsystem, a wave beam control subsystem, a rotary table servo subsystem, a terminal subsystem and a power supply subsystem, a four-channel T / R module adopts a distributed T / R component, and the component adopts highly integrated design and has the advantages of light weight, small size, good consistency, excellent technical indexes and the like. The three-coordinate low-altitude small target radar provided by the invention can realize search and tracking of an aerodynamic target such as a small airplane, a paraglider and an unmanned aerial vehicle in a low-altitude airspace in a range with a central radius of 45km, precisely monitor the target in the low-altitude area which is low in height, slow in speed and small in size, display and output distance, direction, speed and height information of the flight target, and form a three-coordinate motion situation of the low-altitude target.

Owner:ANHUI SUN CREATE ELECTRONICS

High-viscosity spraying type SBS modified emulsified asphalt and preparing method thereof

InactiveCN104530731ASimple production processGood emulsifying effectBuilding insulationsPolymer scienceBitumen emulsion

High-viscosity spraying type SBS modified emulsified asphalt is made from matrix asphalt, an SBS modifier, a viscosity reducer, a cationic emulsifier, a stabilizer, hydrochloric acid and water according to a certain weight ratio. The method for preparing the high-viscosity spraying type SBS modified emulsified asphalt comprises the steps of (1) heating the matrix asphalt, adding the SBS modifier, stirring the mixture, evenly dispersing the SBS modifier into the matrix asphalt through high-speed shearing, and obtaining SBS modified asphalt; (2) heating the SBS modified asphalt, adding the viscosity reducer, evenly dispersing the viscosity reducer to the SBS modified asphalt through high-speed shearing, and obtaining SBS modified asphalt for emulsification; (3) placing the SBS modified asphalt for emulsification in an asphalt tank of an emulsification device for emulsification; (4) adding the cationic emulsifier, the viscosity reducer and water in a liquid soap tank of the emulsification device to obtain liquid soap; (5) adding hydrochloric acid and heating the liquid soap; (6) conducting colloid mill emulsification and pressure cooling on the SBS modified asphalt for emulsification and liquid soap in the liquid soap tank. The high-viscosity spraying type SBS modified emulsified asphalt is high in asphalt content and stability, and a thick asphalt membrane is generated after demulsification.

Owner:XIAN HIGHWAY INST +1

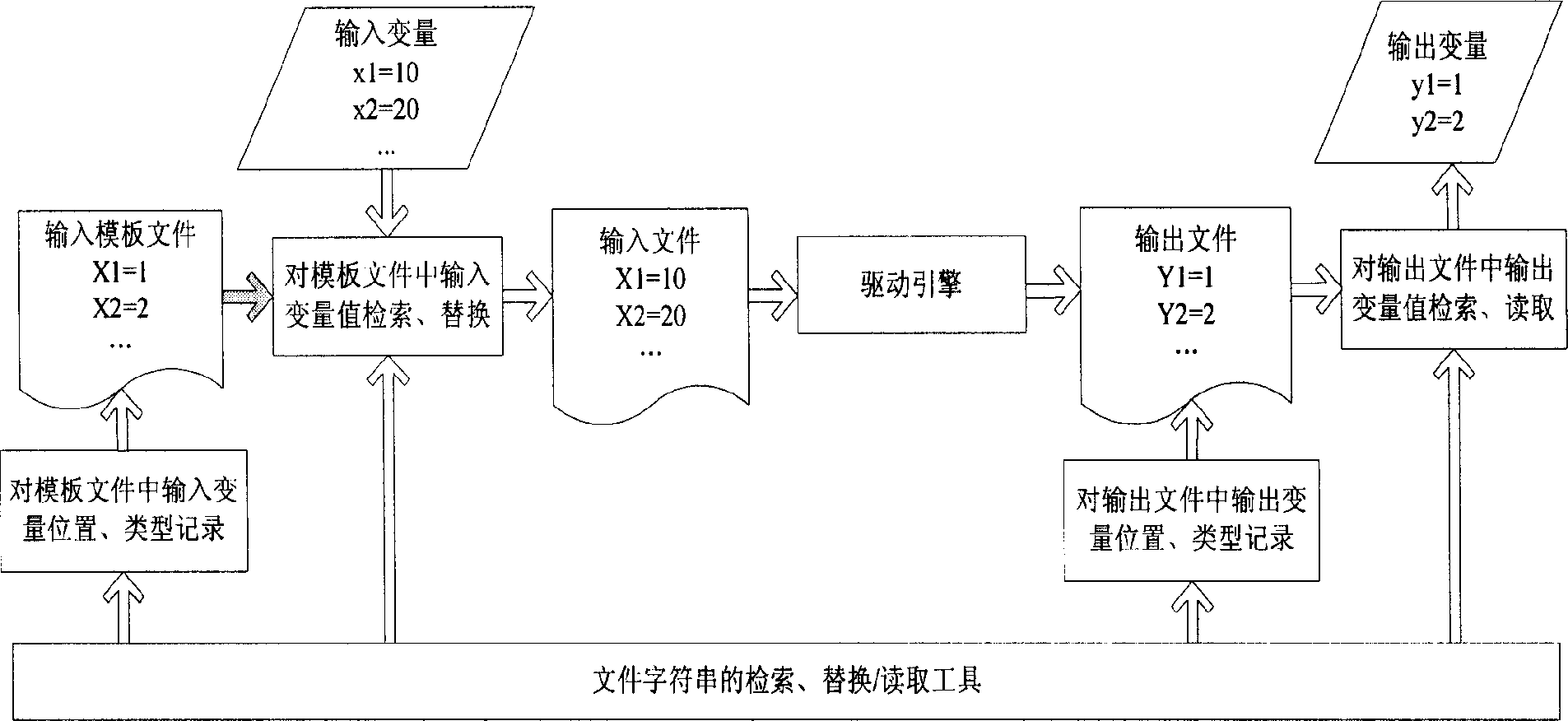

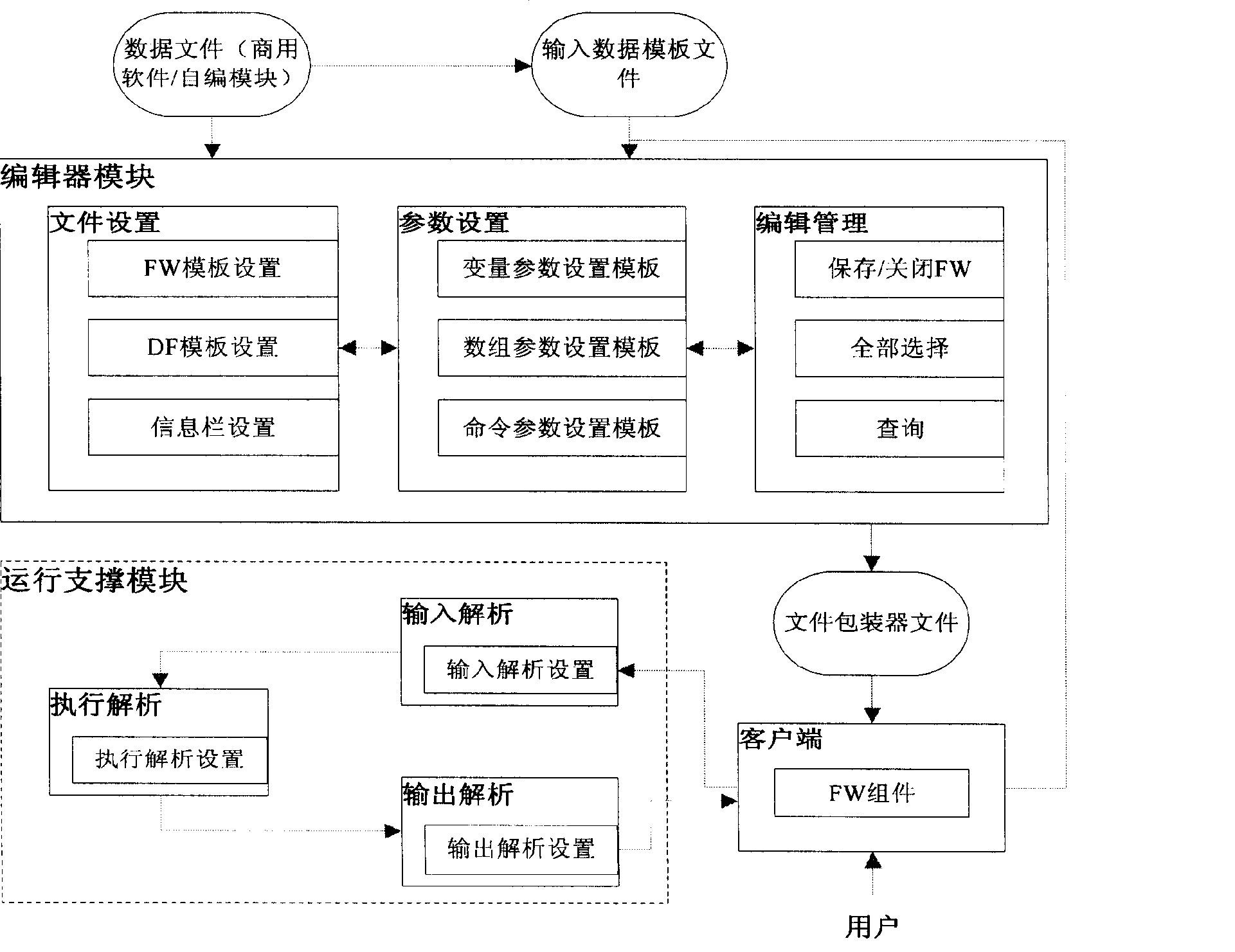

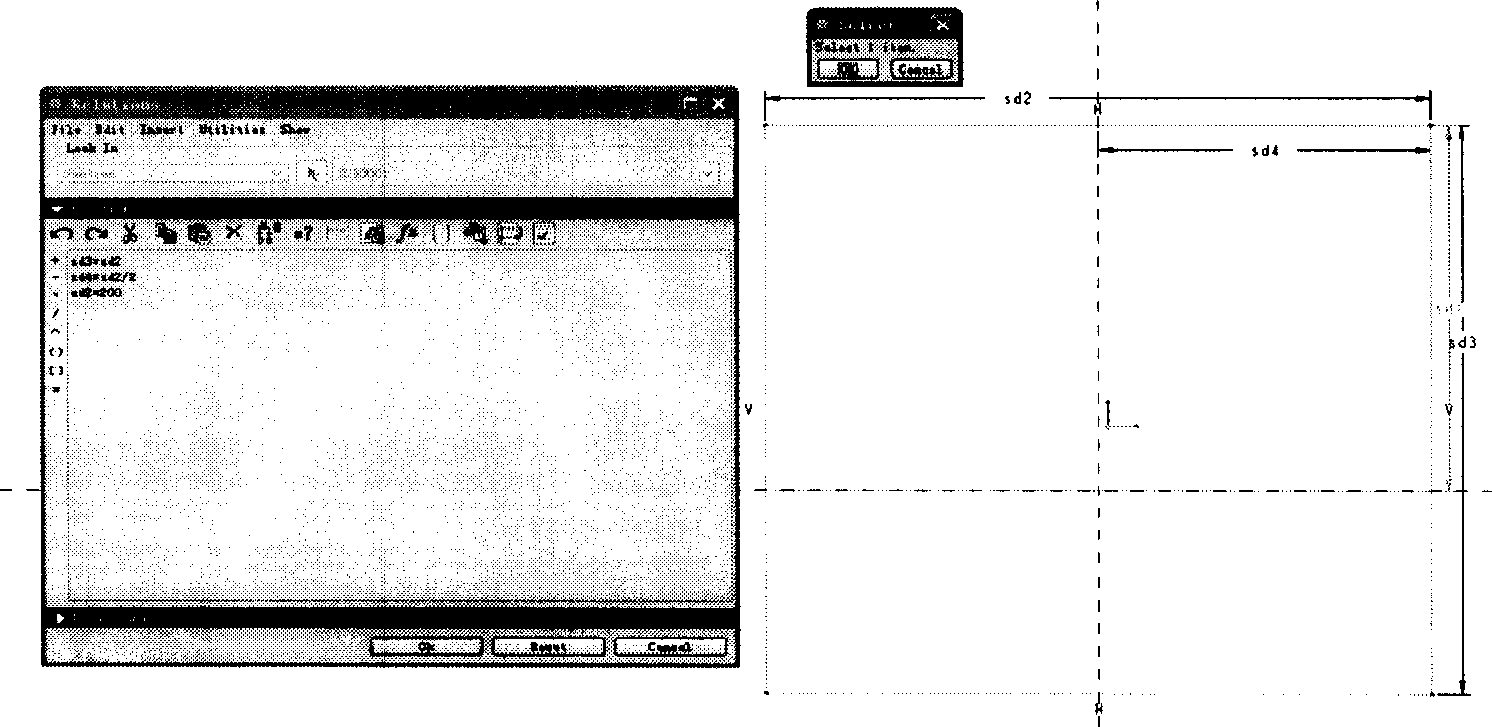

Digital model integral design method of complex product based on file

ActiveCN1758256ASimple designDesign analysis models can be incorporated into unified integrated optimization design optimizationSpecial data processing applicationsAnalytic modelProduct base

This invention relates to an integrated design method for digital models of complicated products based on files, which sets up models of commercial engineering soft and self edited software, determines the input variables to generate input files and templet files used for drive, generates data and files of the analysis results, determining the data format of the output variables and output result files, records the formats, position and the data kinds of the input variables in the templet file by an index tool of a file packaging device and finishes the record of the output variable position, format and data kinds to replace the input variables in the templet file to generate new input files, sets up models to the input files again to compute and generate new output files and carry out searches and fetch to the output variables in the output files to finish automatic integration finally.

Owner:中国航天科技集团公司第一研究院

Preparation method, application and using process of floating agent prepared from drainage oil

The invention relates to a preparation method, application and using process of a floating agent prepared from drainage oil, wherein the preparation method of the floating agent comprises the following steps of: (a) purifying the drainage oil; (b) carrying out hydrolysis reaction on the purified drainage oil obtained from the step (a) to obtain the floating agent used for floating ores. When the floating agent used by the invention and prepared from the drainage oil is used as a collecting agent for floating the ores, the selectivity of the collecting agent can be enhanced, and the technical indicator and the economic indicator of flotation are enhanced favorably; and in addition, because a raw material used for the preparation of the floating agent is the drainage oil, the technical scheme provided by the invention has important significance on the aspects of preventing environmental pollution, simplifying production process, reducing food security threat, and the like.

Owner:鄂尔多斯市君致清环境科技有限公司

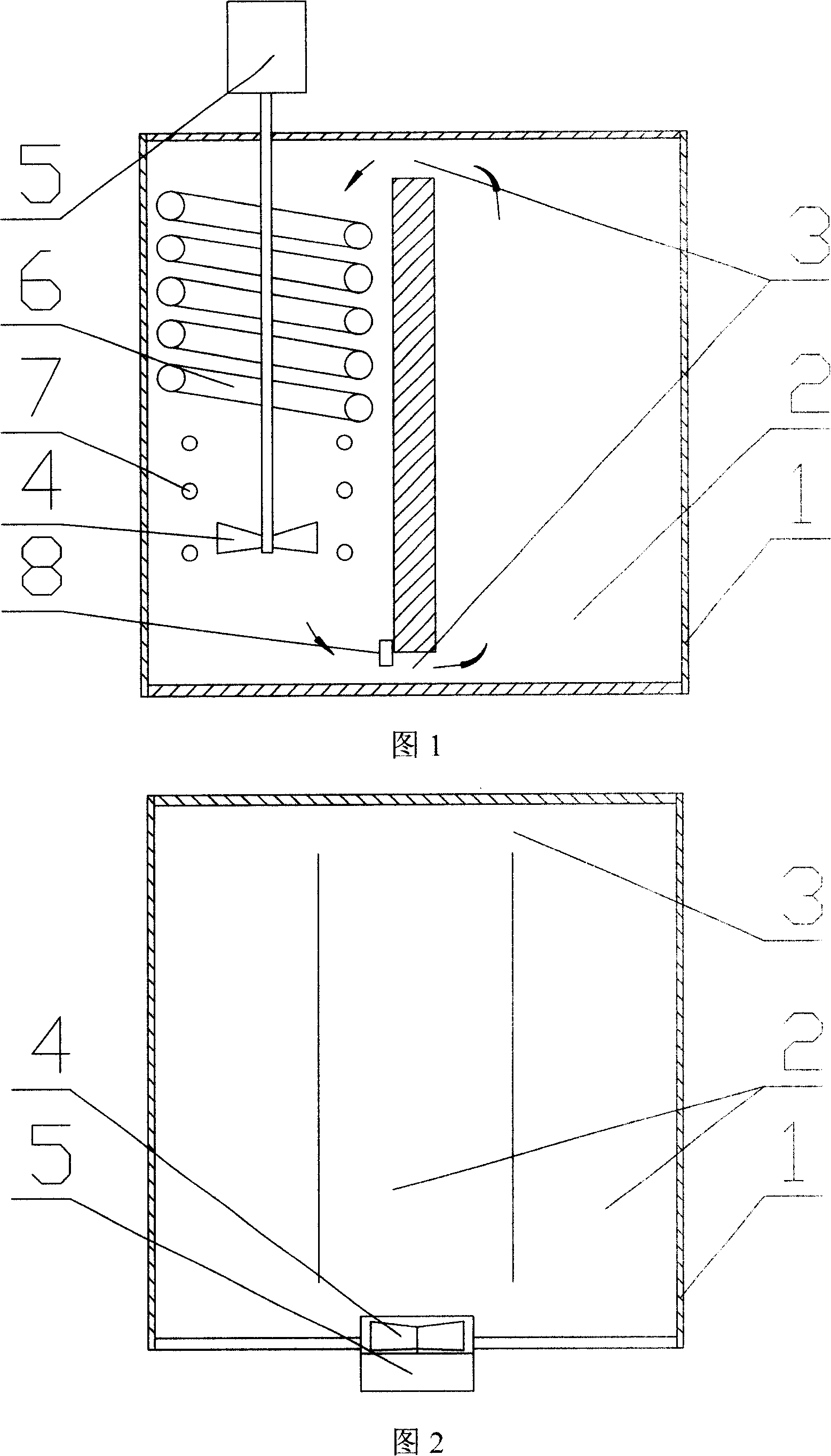

Constant temperature oven

InactiveCN101116835ASimple structureImprove technical indicatorsWater/sand/air bathsMetrologyElectric machinery

The present invention discloses a constant-temperature groove, which comprises a groove body (1) and is characterized in that the groove body (1) is divided into 2 cavities (2) including a left one and a right one, wherein circulation channels (3) are arranged on the upper end and the lower end between the cavities (2), a stirring oar (4) is arranged inside one of the cavities (2) and connected with an electrical machine (5). The groove body provided by the present invention is divided into 2 cavities, one of which is adopted as the working area, and the other is provided with the stirring oar inside to form a single circulation of the medium, thereby having simple structure, higher technical standard, and the temperature which is much more stable and even. As proved by the test carried out by National institute of metrology, the technical index of the present invention is superior to or meet the national standard, meanwhile the present invention adopts the stirring on the lateral of the working area, thereby preventing the stirring oar of the constant-temperature groove from being damaged by the fallen thermometer used to measure the temperature. The present invention has the advantages of a simple structure, small fluctuation of both the temperature and the maximum temperature difference, and the technical index superior to the national standard, etc.

Owner:陈坚

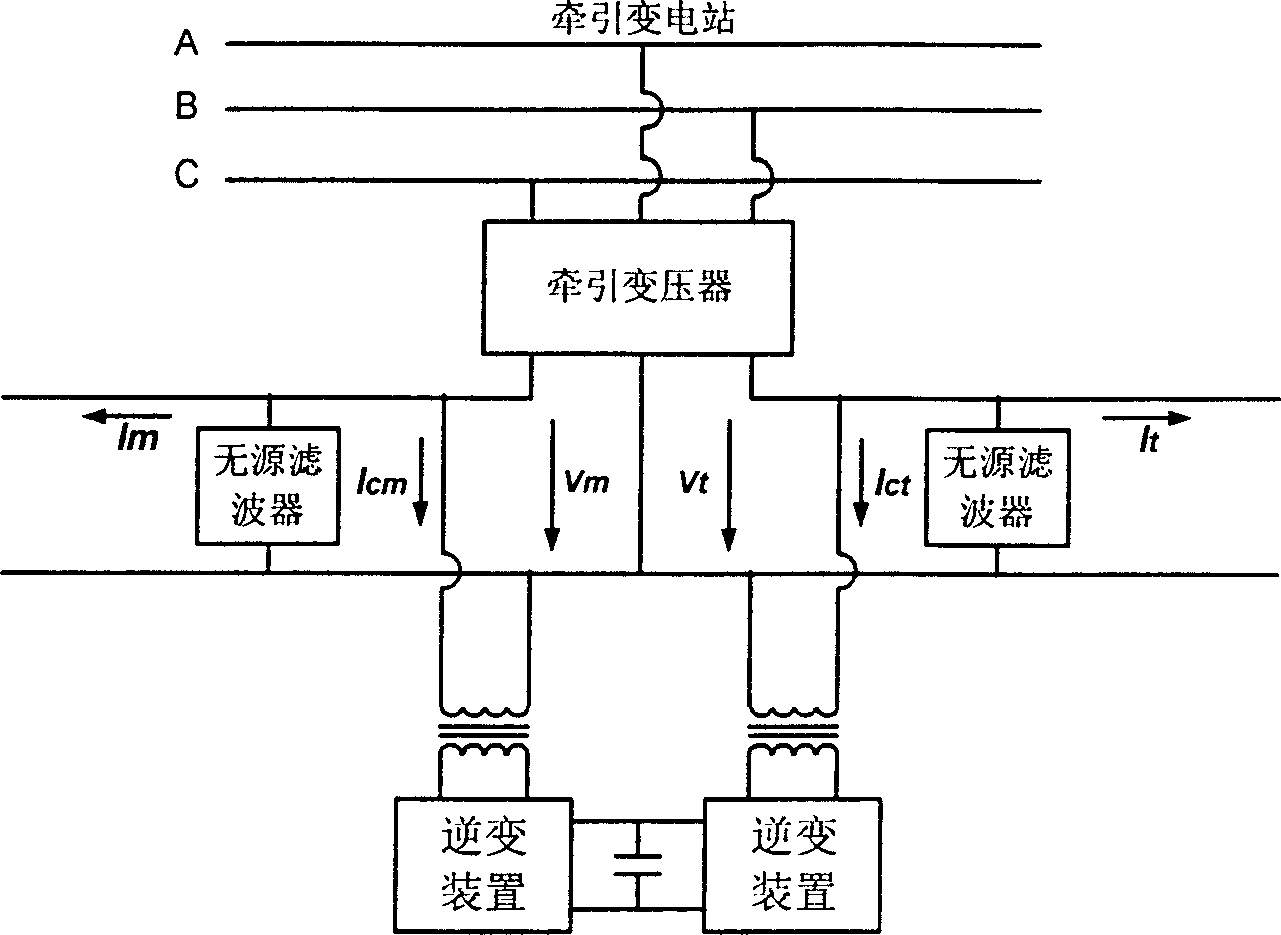

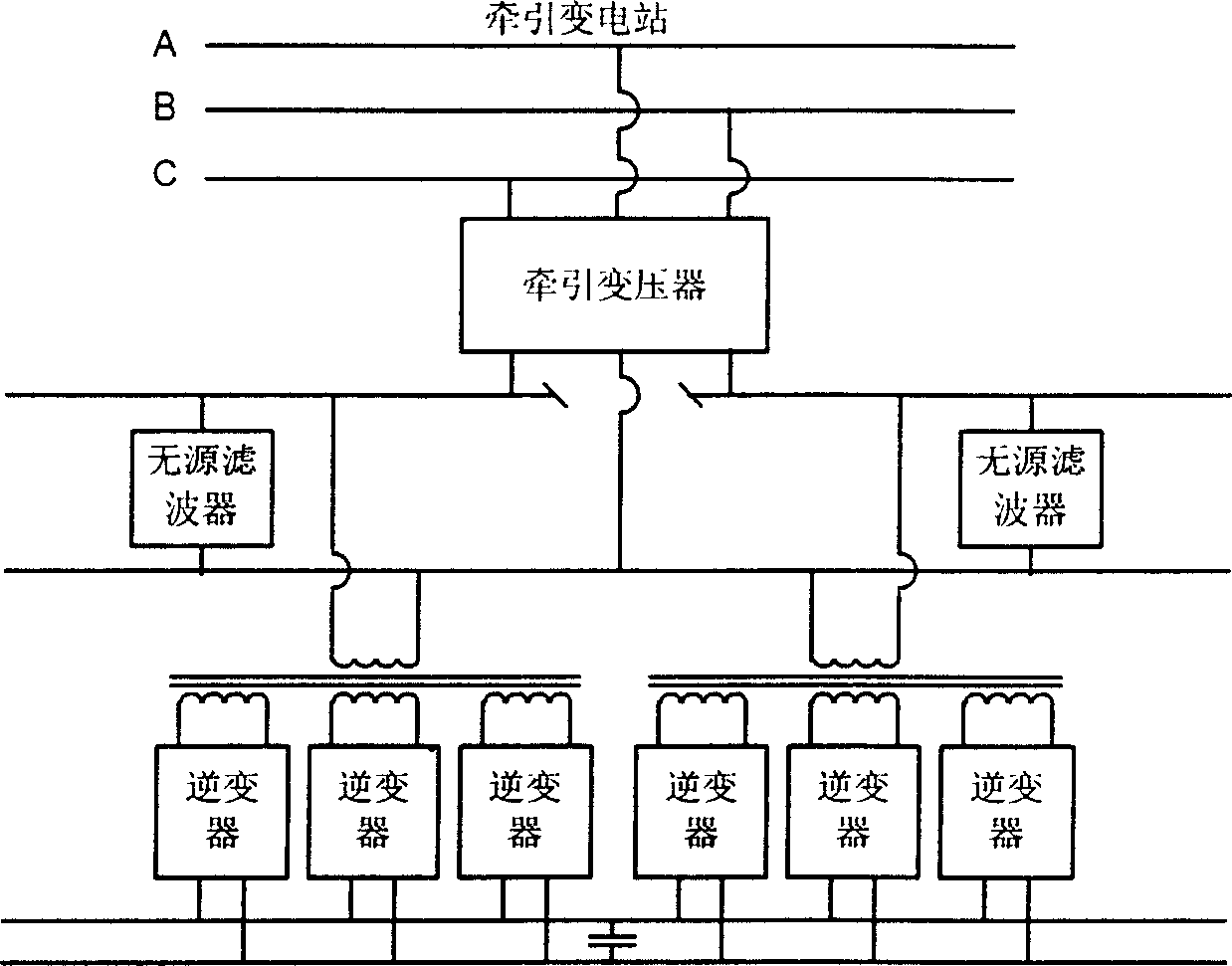

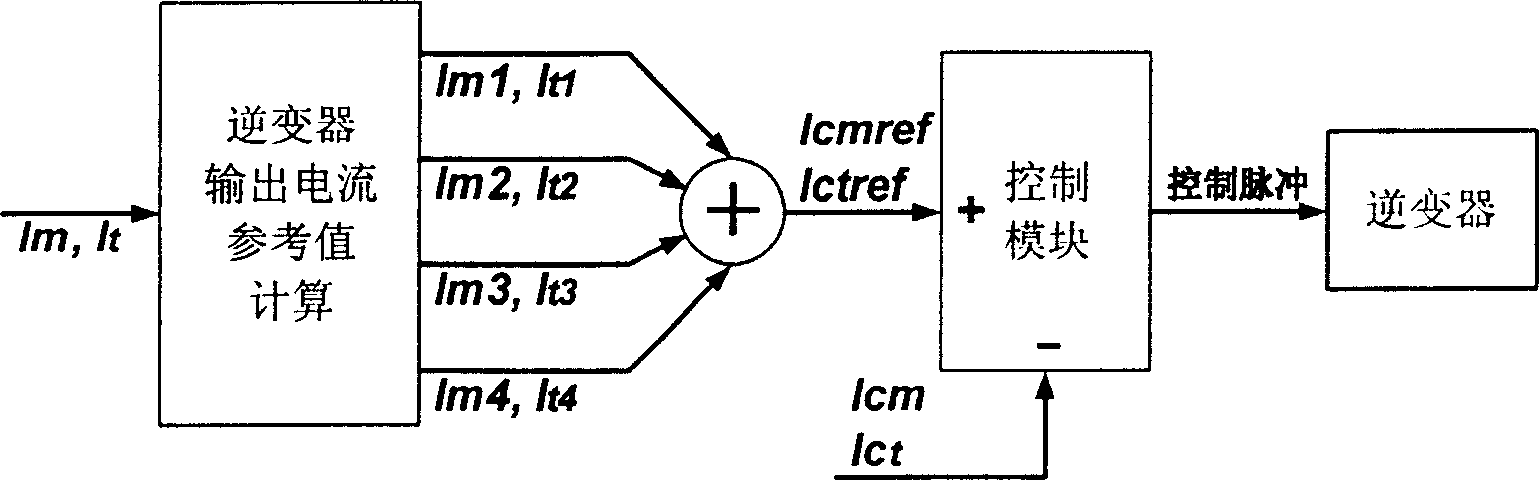

Compensator for electric-railway non-power compensation and electric-energy quality control

InactiveCN1897393ASimple configurationLow costReactive power adjustment/elimination/compensationReactive power compensationTransformerPower factor

The invention is concerned with the compensation equipment that uses for electrification railroad reactive power compensation and the electrical energy quality control, including: two groups of passive filters using to provide reactive power for electrification railroad locomotive and filters the harmonic current of the electrification locomotive; two groups of contravariant equipments using to create current that can control the breadth value, the phase and the frequency; two groups of transformers using to coupling the current from the two contravariant equipments to the supply are of the electrification railroad; the public direct-current unit using to transform the active power between the two groups of contravariant equipments and provide the direct-current to the two groups of contravariant equipments. The invention can process power factor compensation for the electrification railroad supply system, control the quality of the electricity energy.

Owner:北京思源清能电气电子有限公司

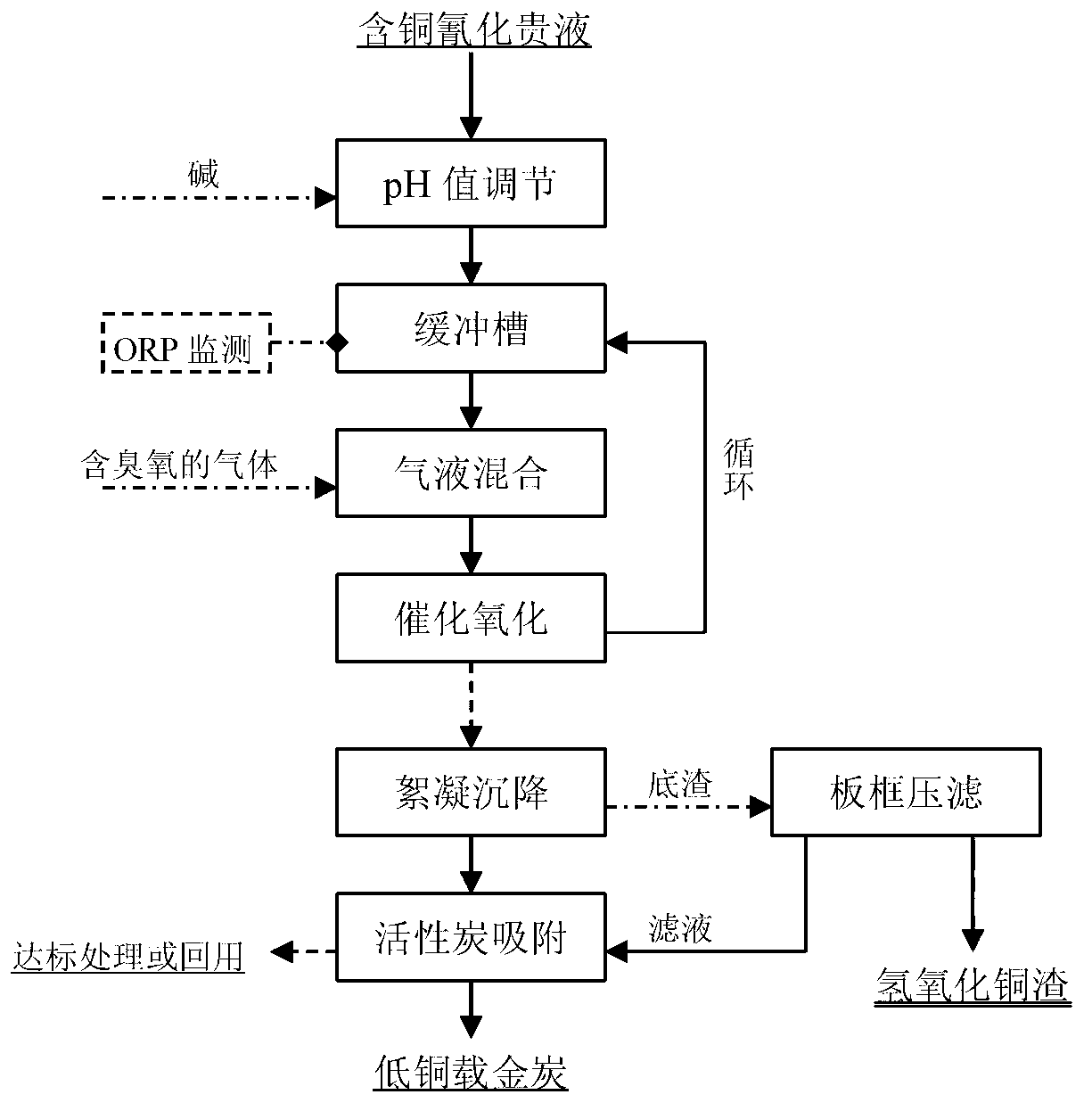

Method for separating and recovering gold and copper from copper-bearing cyanide pregnant solution

The invention relates to a method for separating and recovering gold and copper from a copper-bearing cyanide pregnant solution. A group technology of a catalytic oxidation method, a chemical precipitation method and an active carbon adsorption method is adopted to selectively remove copper from the copper-bearing cyanide pregnant solution, gold and copper in the pregnant solution are separated and recovered to the greatest extent, copper is recovered in a copper hydroxide slag form, and gold is recovered in a low copper gold-loaded carbon form.

Owner:ZIJIN MINING GROUP

Infrared filter with broadband of 3.65 to 5 microns, and manufacturing method for infrared filter

ActiveCN102590917AGood signal to noise ratioMeeting Sensitivity and Accuracy RequirementsLayered productsOptical filtersPhysicsSignal-to-noise ratio (imaging)

The invention discloses an infrared filter with a broadband of 3.65 to 5 microns, and a manufacturing method for the infrared filter. The infrared filter with the broadband of 3.65 to 5 microns is characterized in that: monocrystalline germanium Ge with the size of phi 18*1.0mm is used as a base plate 1, wherein the surface aperture N of the monocrystalline germanium Ge is less than or equal to 5, and the local aperture delta N is less than or equal to 0.5, the depth of parallelism theta is less than or equal to 1', and the surface finish is more than 60 / 40; coating materials are silicon monoxide SiO and the monocrystalline germanium Ge, and multiple layers of interference films are deposited on two surfaces of the base plate; Sub 1.33(.5HL.5H)<5>3.39(.5LH.5L)<5> Air is adopted by the design of a first surface film system interference film 2; Sub 0.92(.5HL.5H)<3> 1.1(.5HL.5L)<4> Air is adopted by the design of a second surface film system interference film 3; and according to the infrared filter with the broadband of 3.65 to 5 microns, gradient of two sides is less than 3 percent, namely the wavelength of a transition area from the transmissivity of 5 percent to the transmissivity of 80 percent is less than 20nm, the transmissivity of a high-transmissivity area is more than or equal to 90 percent, the cut-off depth in a cut-off area is less than or equal to 0.1 percent, the transmissivity reaches more than 92 percent in the range of thermal imager wavelength of 3.7 to 4.9mu m, excellent signal-to-noise ratio is achieved, and the requirements of sensitivity and accuracy of a high-performance thermal imager can be met.

Owner:MULTI IR OPTOELECTRONICS

Method for low-grade magnesite flotation

InactiveCN103212486ALarge resource reservesAchieve scaleFlotationMining engineeringReverse flotation

The invention relates to a method for low-grade magnesite flotation. The method includes the following steps: carrying out ore grinding on magnesite lean ore after the magnesite lean ore is smashed, and selecting 200-mesh screen underflow to obtain magnesite lean ore powder; taking reverse flotation reagents and the magnesite lean ore powder according to the liquid-solid ratio of 1-2:1, stirring the reverse flotation reagents and the magnesite lean ore powder for 3-5 minutes at an environment temperature, filling air into the reverse flotation reagents and the magnesite lean ore powder, removing foam on the upper layer, and keeping material on the bottom layer; taking direct flotation reagents and the material on the bottom layer in the step 2) according to the liquid-solid ratio of 2-4:1, stirring the direct flotation reagents and the material on the bottom layer for 3-5 minutes at the environment temperature, carrying out air filling and the flotation, and taking the foam material on the upper layer; and carrying out the process on the material on the upper layer again, taking the material on the upper layer again, and drying the material on the upper layer. According to the method for the low-grade magnesite flotation, the MgO content in low-grade magnesite can be effectively improved, the impurity content can be reduced, existing magnesite resources can be fully used, and both energy saving and environment protection are achieved.

Owner:辽宁省地质矿产研究院

Visible near-infrared spectrum band reflection and infrared multispectral band transmission color separation filter and preparation method

The invention relates to a visible near-infrared spectrum band reflection and infrared multispectral band transmission color separation filter and a preparation method, and belongs to the field of surface technology. The color separation filter comprises a zinc selenide base and a film system on one side of the base; the structure of the film system is (0.3h 0.6l0.3 h) ^ 10 (0.38h 0.76 l0.38 h) ^ 10 (0.5 h l0.5 h) ^ 12, and the central wavelength is 890 nm, wherein h and l refer to zinc sulfide and yttrium fluoride film respectively; and the color separation filter is prepared through the following steps: heating the base in vacuum, using ion beam to bombard the base, using ion beam to assist electronic gun evaporation to deposit the film system on two sides of the base, and cooling. The reflectivity of the color separation filter is high at 0.43-0.90 micron; the transmittance of the color separation filter is high at 1.55-1.75 microns, 2.08-2.35 microns, 3.5-5.5 microns, 7.8-10 microns, and 11.08-12.55 microns; and the color separation filter meets beam split operating requirement of a remote sensing detection system.

Owner:LANZHOU INST OF PHYSICS CHINESE ACADEMY OF SPACE TECH

Polyurethane modified unsaturated polyester varnish

InactiveCN1821328AImprove scratch resistanceGood temperature resistancePolyurea/polyurethane coatingsPolyester coatingsDiluentHardness

The present invention discloses a kind of polyurethane modified unsaturated polyester varnish. The varnish is compounded with polyurethane and unsaturated polyester in the ratio of 1 to 0.3-5. The polyurethane consists of polyurethane paint, curing agent and diluent in the ratio of 1 to 1 to 0.6-1; and the polyurethane paint consists of alkyd resin 80-93 wt%, xylene 5-10 wt%, leveling agent 0.3-0.5 wt% and defoaming agent 0.1-0.3 wt%. The unsaturated polyester consists of unsaturated polyester paint, promoter and initiator in the ratio of 100 to 0.8-1.2 to 1-1.5, and the unsaturated polyester paint consists of unsaturated resin 80-90 wt%, styrene 9-18 wt%, leveling agent 0.3-0.5 wt% and defoaming agent 0.2-0.3 wt%. The present invention has the advantages of high hardness, good fullness, high adhesion, high flexibility, etc.

Owner:GUANGDONG LANYANG SCI & TECH

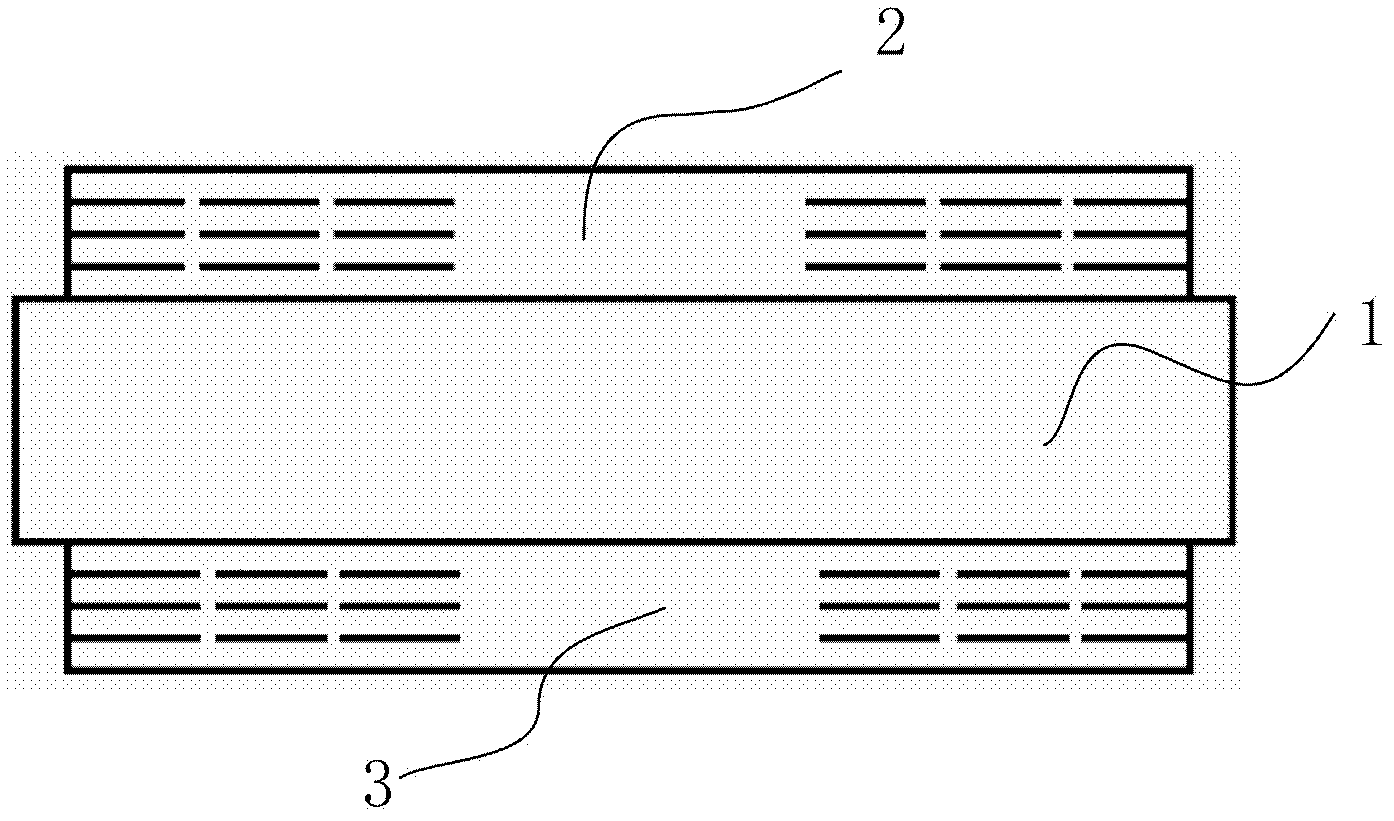

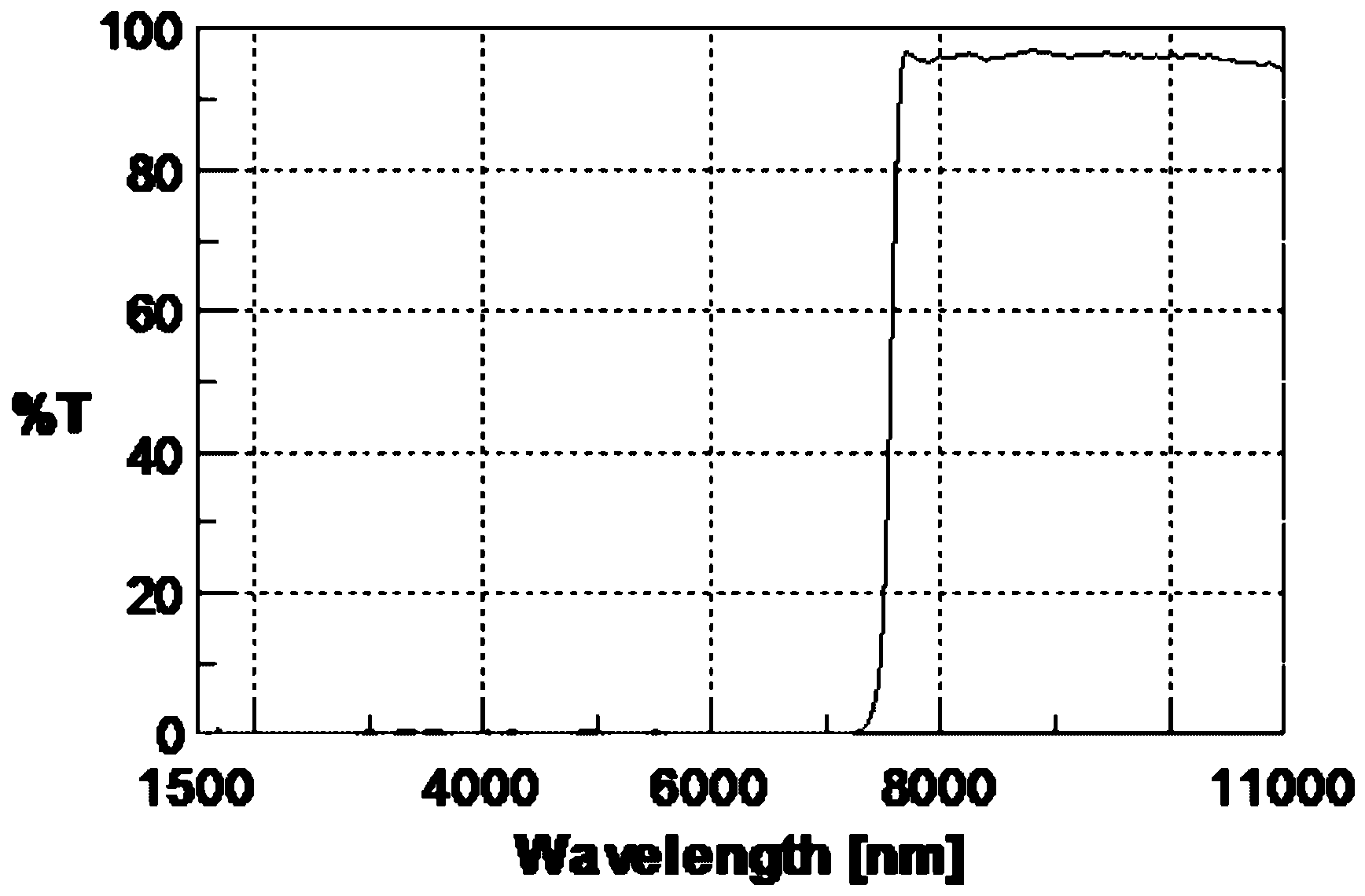

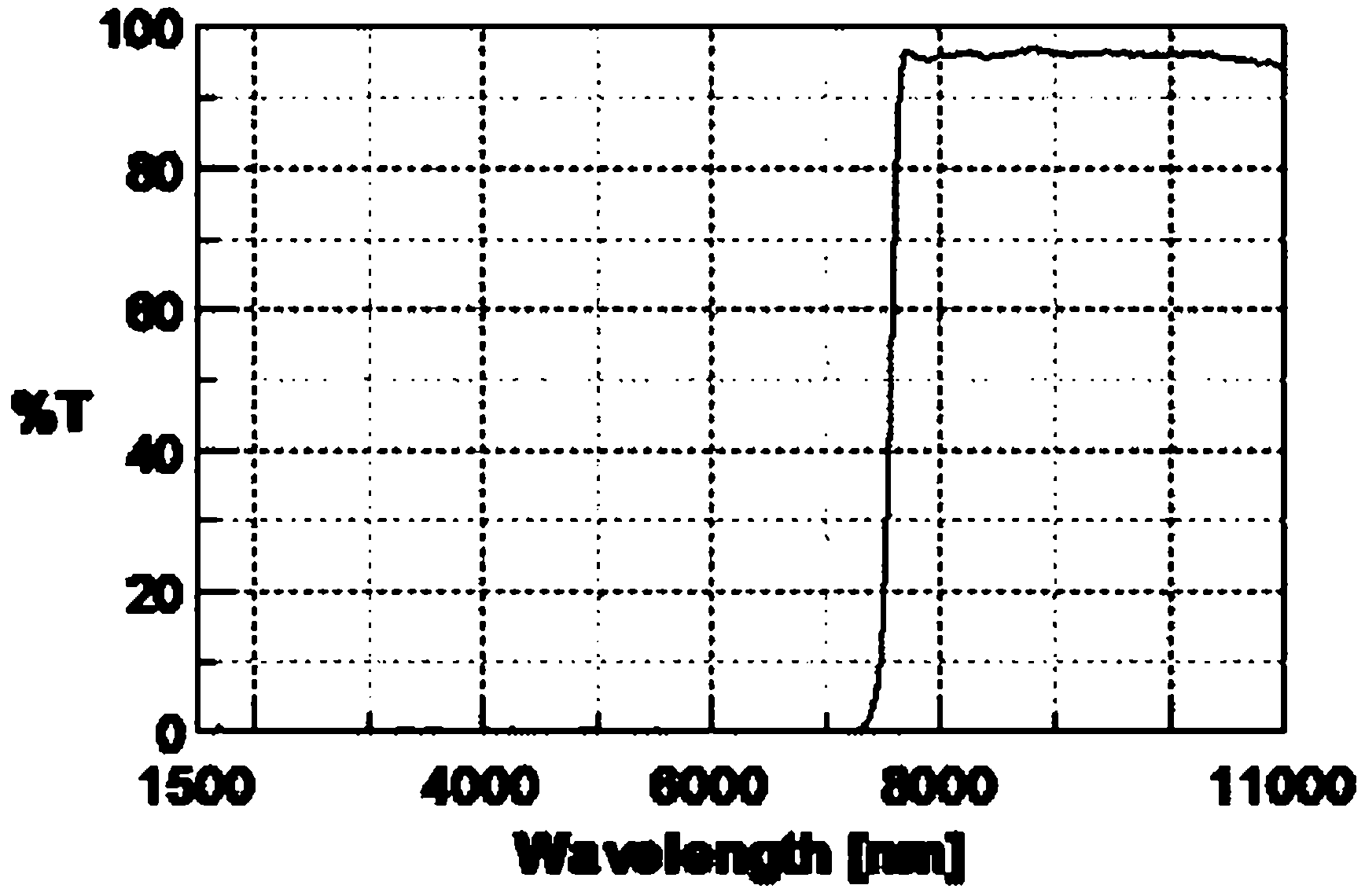

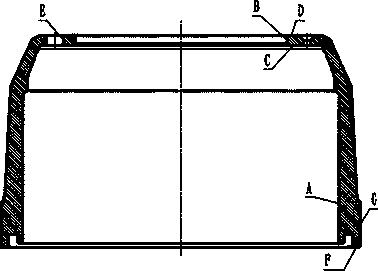

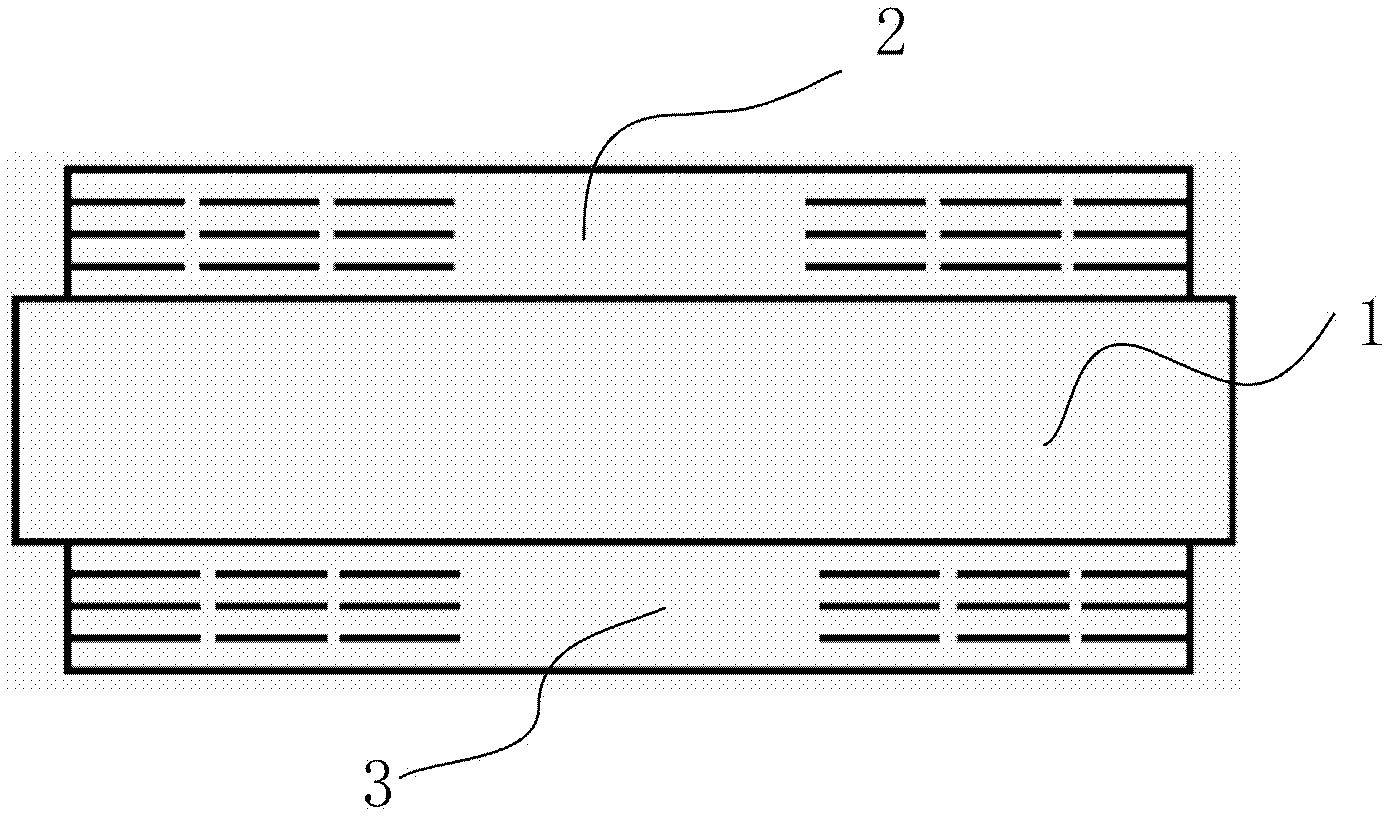

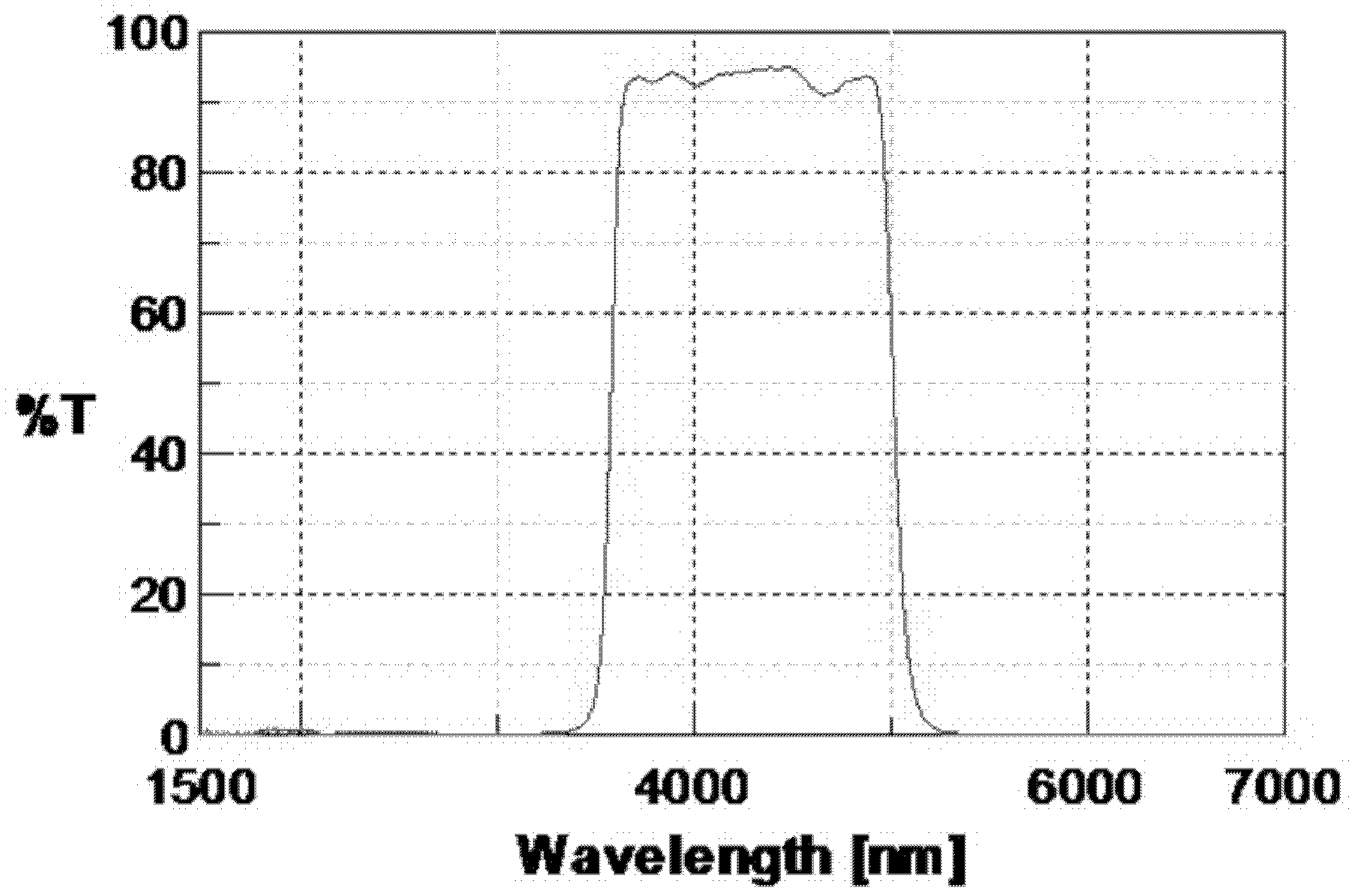

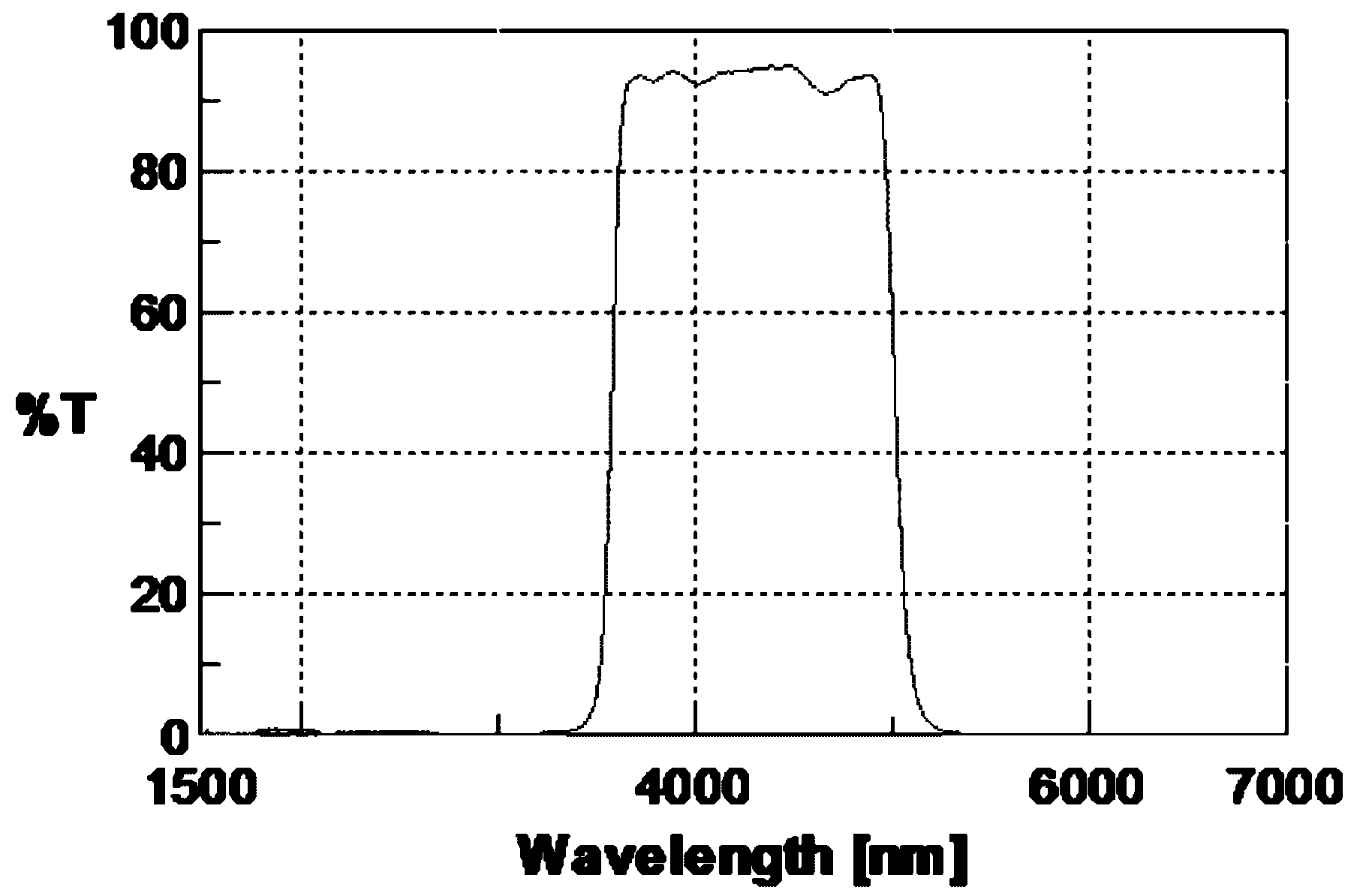

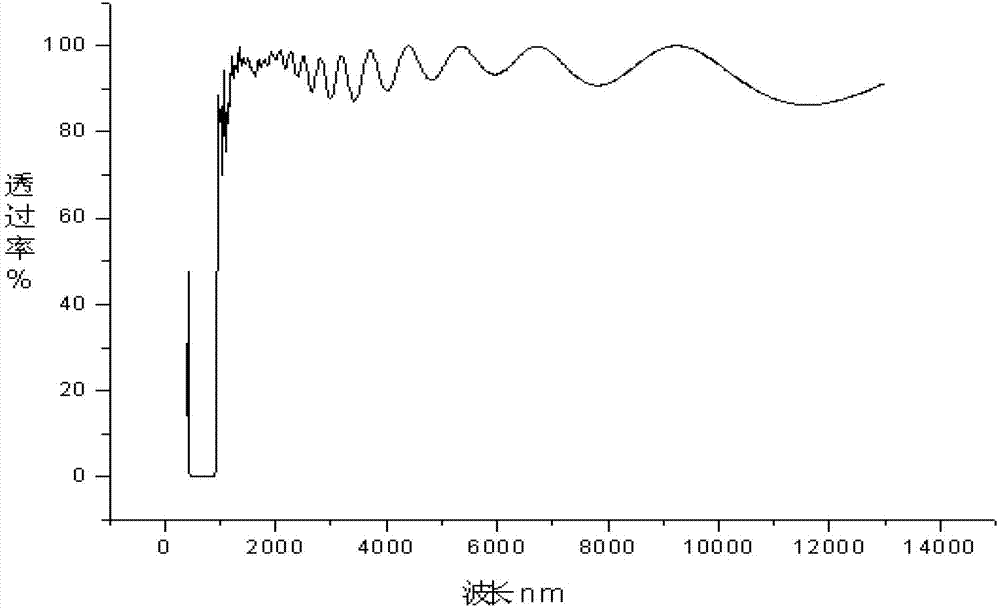

3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof

The present invention belongs to the technical field of surfaces, and especially relates to a 3.5-3.9[Mu]m medium wave infrared mini-type optical filter and a preparation method thereof. The optical filter comprises a silicon substrate and long-wave and medium-wave through film systems; the long-wave through film system structure is (0.35H0.7L0.35H)^9(0.5HL0.5H)^13, and the central wavelength is 2800nm; a short-wave through film system structure is (0.5LH0.5L)^13, and the central wavelength is 4650nm; H and L are a germanium film layer and a zinc sulfide film layer; the silicon substrate is heated in the vacuum, an electronic gun evaporation method assistant by an ion beam is employed to deposit long-wave and short-wave through film systems at the two sides of the substrate, and the optical filter is prepared after cooling. The optical filter has high transmittance at the 3.5-3.9[Mu]m spectrum band, and is cut off at the 0.80-3.3[Mu]m spectrum band width and 4.1-5.5[Mu]m spectrum bandwidth, and the optical filter can be used in the low temperature of (80K) and can meet the splicing requirement in the space mini-type combined optical filter.

Owner:WUXI HONGRUI AEROSPACE MECHANICAL & ELECTRICAL EQUIP CO LTD

Method for using collector prepared from illegal cooking oil in fluorite flotation

The invention relates to a method for using a collector prepared from illegal cooking oil in fluorite flotation. The collector is prepared by the following steps: (a) purifying and extracting illegal cooking oil; and (b) subjecting the purified and extracted illegal cooking oil obtained by the step (a) to a hydrolysis reaction and thus obtaining the collector for use in ore floatation. When the collector prepared from the illegal cooking oil, which is used in the invention, is used in fluorite flotation, the selectivity of the collector is improved, and the technical index and economic index of the flotation can be improved. As the illegal cooking oil is used as the raw material for preparing the collector, the technical scheme adopted by the invention has a great significance for avoiding environment pollution, simplifying production process, reducing food safety threats and the like.

Owner:BEIJING JUNZHIQING SCI & TECH

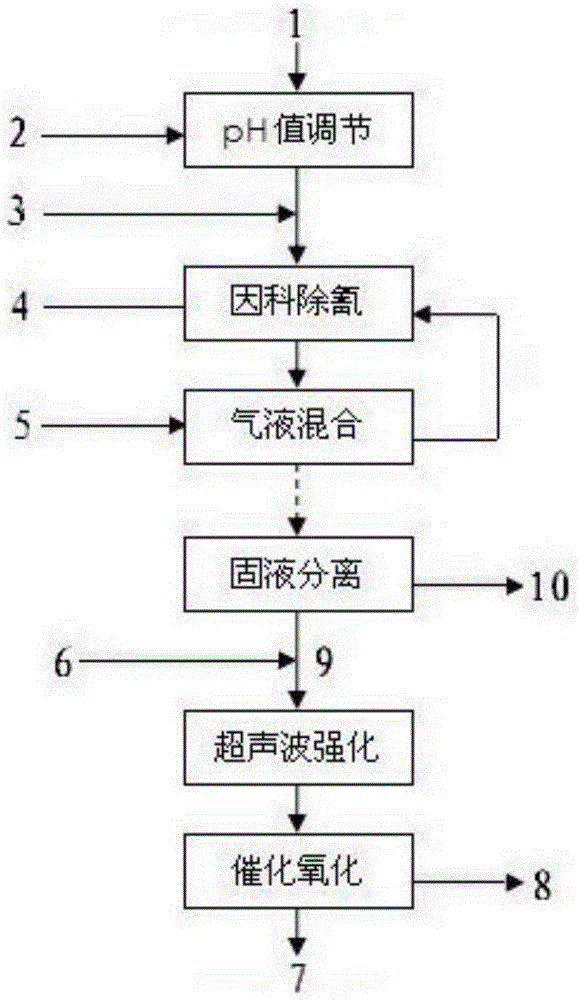

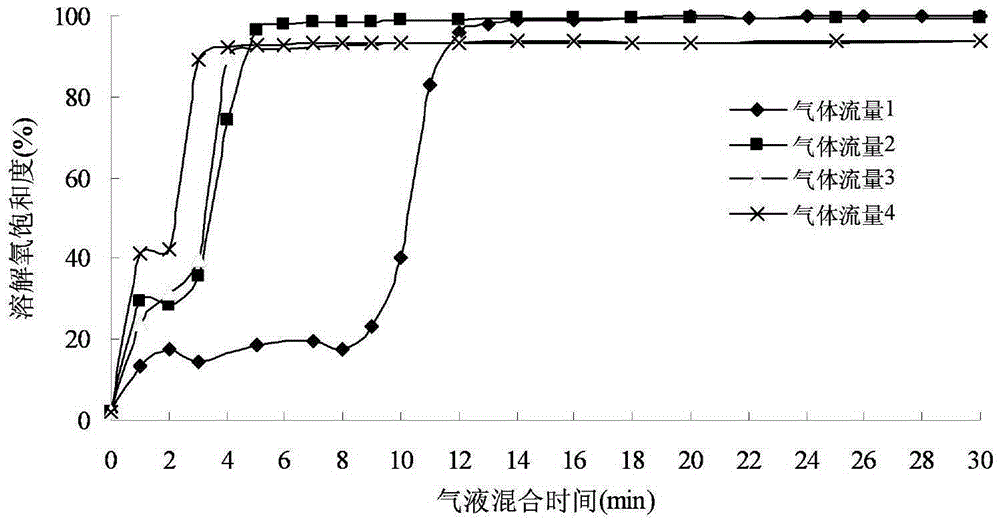

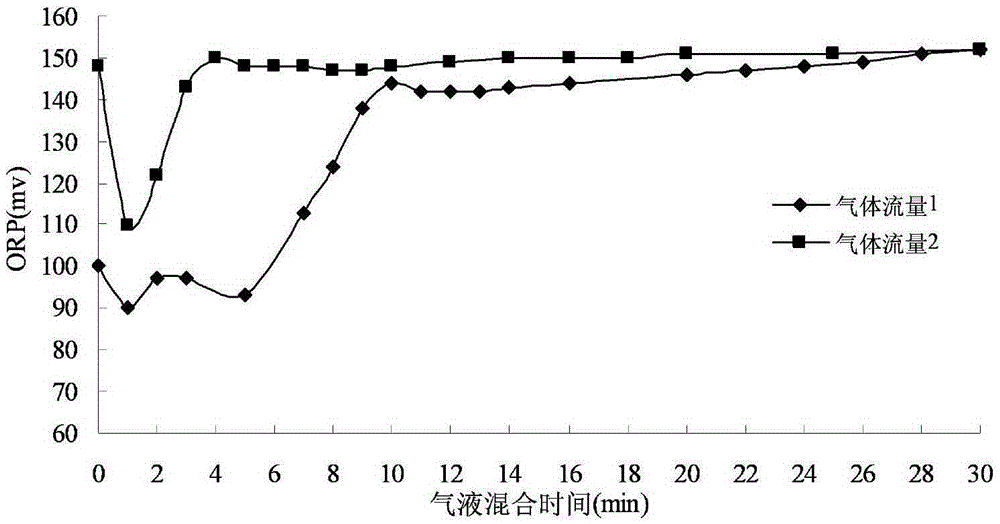

Treatment method for copper-containing gold ore cyaniding waste water

ActiveCN105399237AReaction is easy to controlStrong resistance to hydraulic shock loadWaste water treatment from quariesWater contaminantsChemical reactionSulfite salt

The invention relates to a treatment method for copper-containing gold ore cyaniding waste water. The treatment method comprises the following steps under the following conditions: pH value adjustment: adjusting the pH value of the cyaniding waste water to 8.0 to 11.5; cyanogen removal in an INCO method (sulfur dioxide-air oxidation method): adding sodium sulfite into the cyaniding waste water with pH value well adjusted, uniformly mixing, mixing air and the cyaniding mixed solution, and monitoring the value by using a DO or ORP monitor; solid-liquid separation: performing solid-liquid separation for the waste water reaching a set value by adopting a coagulating sedimentation method, and separating a precipitate product dominant on copper hydroxide and supernatant; oxidation strengthening: adding an oxidant into the supernatant, and carrying out ultrasonic strengthening and induced oxidization; and catalytic oxidation: performing active carbon physical and chemical reactions for the ultrasonically-strengthened solution to obtain pure water and gold-loaded carbon. The method has the advantages that technological advantages are complementary and unified, the reaction is relatively easy to control, the hydraulic impact load resistant capability is high, the pH value of water is not required to be maintained, the operation is simple, the power consumption is small, the consumption of the oxidant and the expense of chemicals are low, the purified water quality is good, the recovery rate of valuable metals is high, and the like; and the method is suitable for treating the copper-containing gold ore cyaniding waste water.

Owner:ZIJIN MINING GROUP

Method for preparing high-quality strontium carbonate

InactiveCN101070177AReduce sulfur contentImprove qualityCalcium/strontium/barium carbonatesStrontium carbonateStrontium sulfide

The invention offers a new kind of method producing strontium carbonate using lazurite mineral as raw material. Mix lazurite breeze with reduced iron powders in certain proportion to get black ash, dip black ash in water of opposite flow and get strontium carbonate solution; regard calcined soda as carburizer, make them reactivate at temperature of 90-100deg.C under mixing to form slurry including deposition of strontium carbonate and sodium sulfide solution of low iron, and get deposition of strontium carbonate and sodium sulfide solution of low iron through separating solid and liquid, absterge strontium carbonate with water of opposite flow for 3-5 times, dry it and get product of strontium carbonate of high quality; Mother liquor absterging strontium carbonate for the first time mixes with centrifugal mother liquor of slurry of strontium carbonate and the mixed solution is vaporized by cold boiler which regards heat transfer oil as medium, get byproduct of sodium sulfide of low iron. The producing craft of the invention is simple, the procedure is short with low cost, the investment of equipment is small, quality of main product and byproduct is high, it has a good economical effect.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

7.6-micron front cut-off infrared optical filter and making method thereof

InactiveCN102540313AGood signal to noise ratioSuppress background distractionsVacuum evaporation coatingSputtering coatingCooking & bakingGas phase

The invention discloses a 7.6-micron front cut-off infrared optical filter and a making method thereof. The optical filter is characterized in that: single crystal germanium (Ge) with the size of phi 25.4*1.0mm is used as a substrate, the surface aperture N of the substrate is less than or equal to 5, the local aperture delta N is less than or equal to 0.5, the parallelism theta is less than or equal to 1', and the surface finishment is superior to 60 / 40; zinc sulfide (ZnS) and single crystal germanium (Ge) are used as coating materials, and a plurality of layers of interference films are respectively deposited on two surfaces of the single crystal Ge substrate; Sub absolute value 2.42(0.5HL0.5H)<8>3.0(0.5HL0.5H)<7> Air is adopted in the design of a first side film system; Sub absolute value 1.2(0.5HL0.5H)<6>1.6(0.5HL0.5H)<7>2.32(0.5HL0.5H)<6> Air is adopted in the design of a second side film system; according to the adopted evaporation process conditions, heating and baking of below 300 DEG C are performed in a vacuum environment with the vacuum degree of less than or equal to 10<-3>Pa, and a physical vapor deposition mode and ion source aided coating are adopted; and the 7.6-micron front cut-off infrared optical filter has excellent signal-to-noise ratio and good background interference suppression. The optical filter can be widely used for detecting the temperature of a far infrared object.

Owner:MULTI IR OPTOELECTRONICS

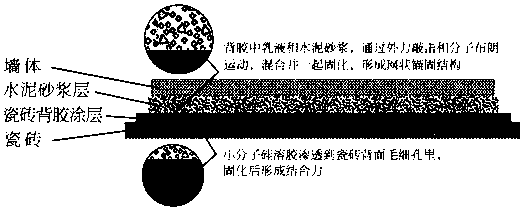

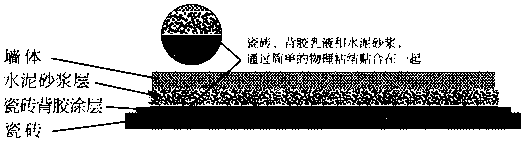

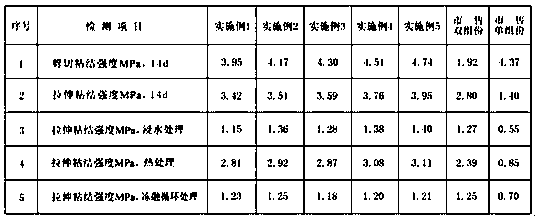

Strong waterproof ceramic tile gum and preparation and construction method thereof

PendingCN109370483AGood water resistanceLow water absorption of coating filmNon-macromolecular adhesive additivesMacromolecular adhesive additivesCeramic tilesButadiene-styrene rubber

The invention relates to the technical field of chemical construction materials, and particularly relates to preparation of a strong waterproof ceramic tile gum and a using method of the gum. The gumis prepared from styrene-butadiene rubber latex, nano-silica gel, adhesion promoter, packing, silica powder, a thickening agent, cement activator, preservative and water. The ceramic tile gum has super-strong adhesive force of double-component gum and flexible ceramic tile deformation resistance of single-component gum, has excellent waterproofing performance and durability, is simple and quick inconstruction, and can be applied to pavement of various construction environments and various ceramic tiles.

Owner:杭州古邦建材科技有限公司

Nano coating

ActiveCN101597447AReduce pollutionGood stain resistanceAntifouling/underwater paintsPaints with biocidesEmulsionMicrostructure

A nano coating is prepared by nano-composite size added with fillers and various auxiliary agents; wherein, the average grain size of the nano powder formed by covering in the nano coating is 35 nanometers; the spherical nano powder has ends with surfaces closed and lotus leaf-like surface microstructure; the nano powder also has tap density of 0.15-0.5g / cm and specific surface area of 125-180 / g; the nano coating comprises the following materials by weight percent: 3.8% of ionized water, 10-12% of nano size, 2.5-2.8% of glycol, 5.3-5.7% of hydroxyethyl cellulose, 1.4-1.7% of film forming auxiliary agent, 28-29% of titanium dioxide, 2-3% of calcined kaolin, 2-3% of heavy calcium carbonate, 39-40% of phenylethylene-propyl ethylene acid ester emulsion, 0.5-0.6% of propylene glycol, 0.1-0.2% of bactericide, 0.2-2% of thickener, 0.1% of defoamer, 0.27% of dispersant, 0.06% of wetting agent and 0.2% of pH value regulator. The coating is bactericidal, nontoxic, tasteless and resistant to 300000 times of washing.

Owner:赵青山

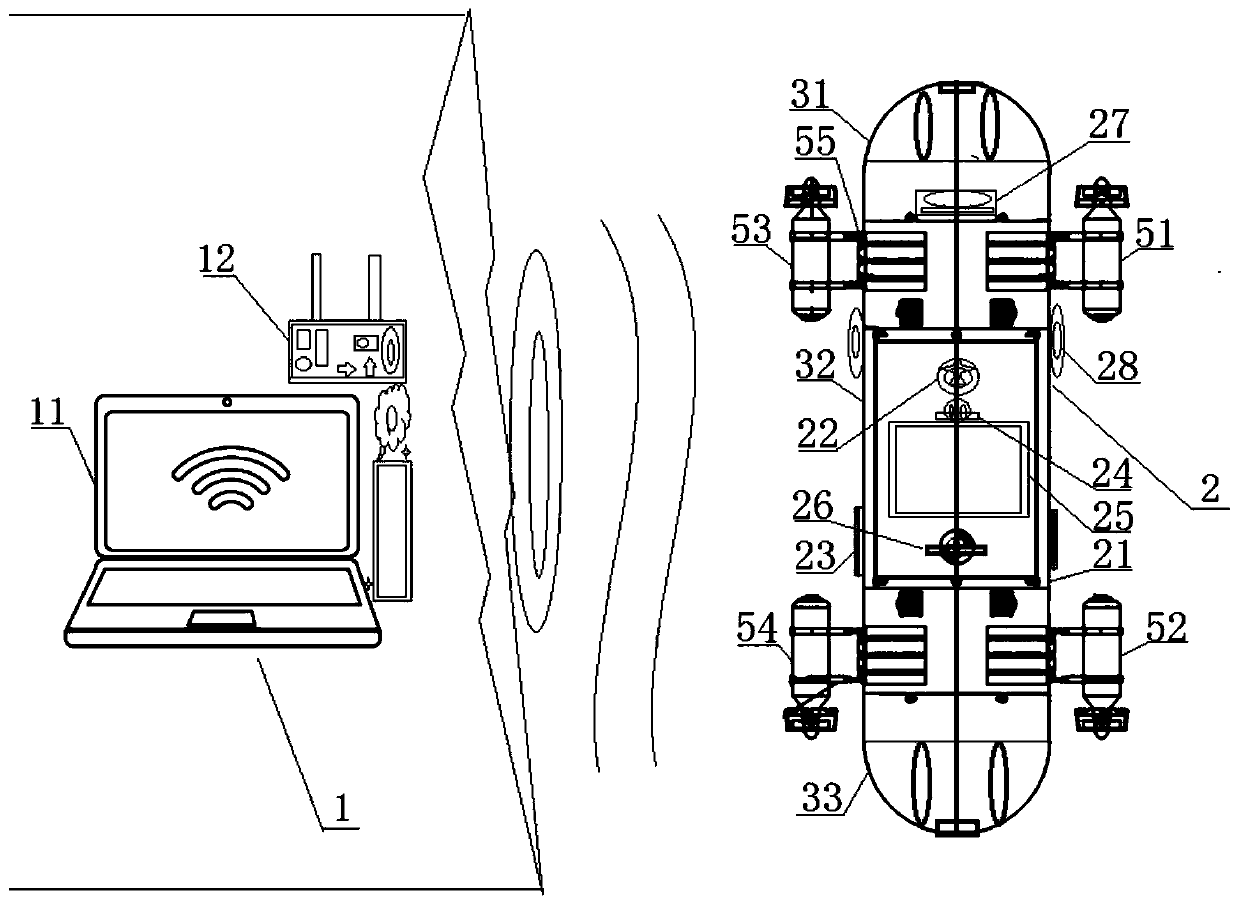

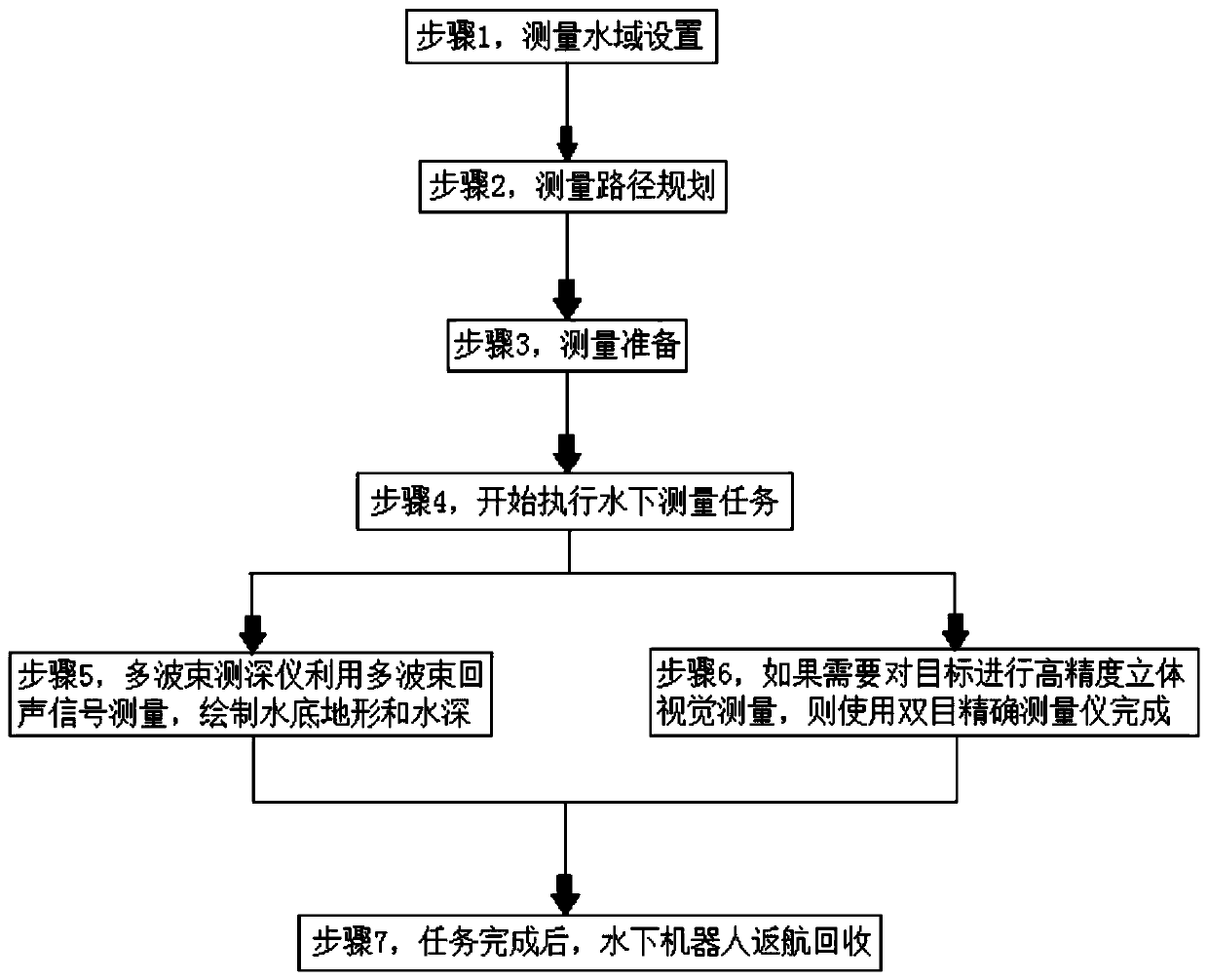

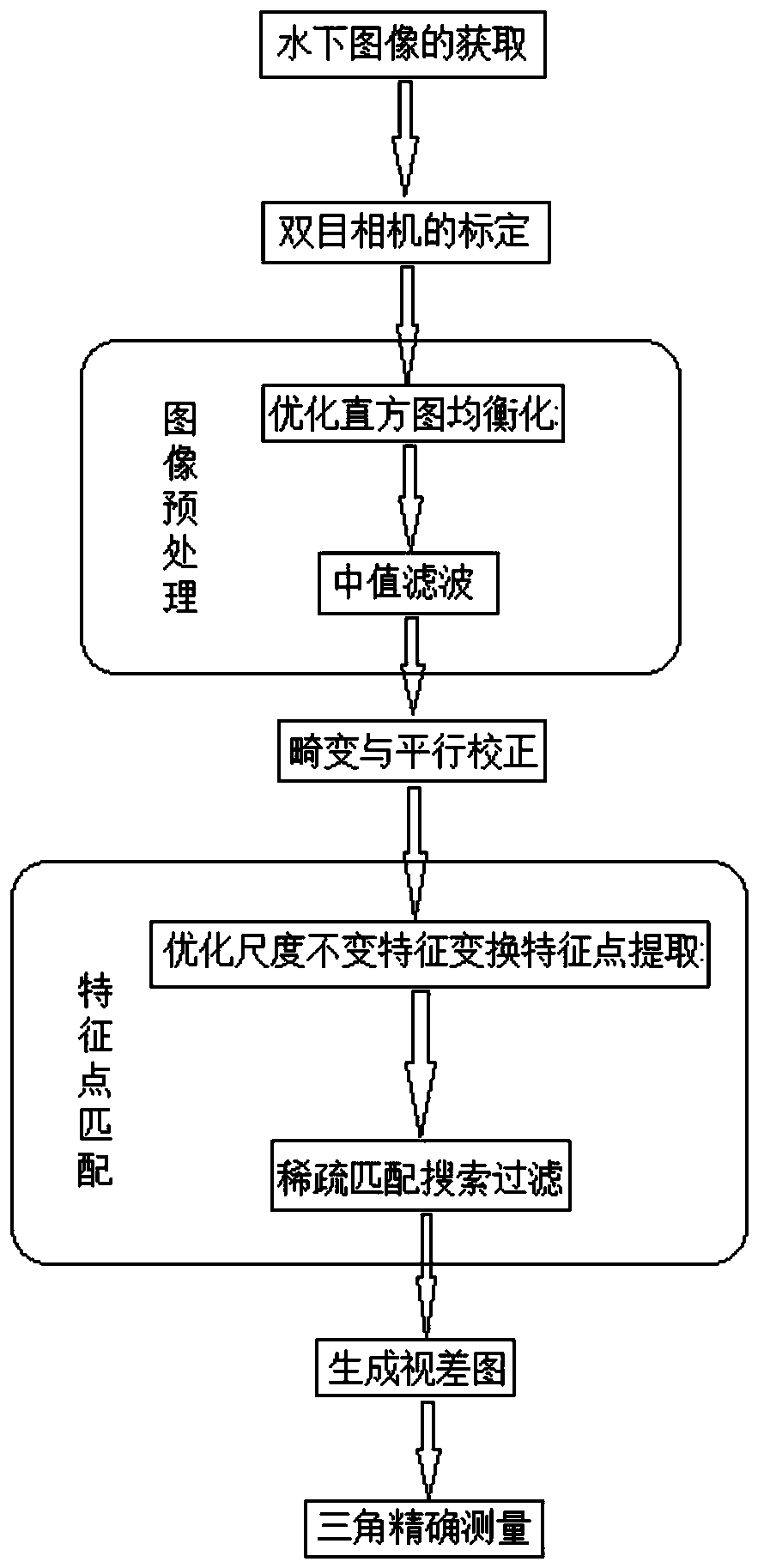

Remote control robot for underwater precise measurement

InactiveCN110053743AReasonable arrangementAchieve acquisitionImage enhancementImage analysisHigh densityMeasuring instrument

The invention provides a remote control robot for underwater precise measurement. Motion of four or more degrees of freedom of the underwater robot is achieved, the underwater robot has the capabilityof depth keeping hover, direct movement, rotation and lateral movement, and can maintain good communication with land control equipment, electronic components are all subjected to watertight pressure-resisting protection, and the remote control robot is suitable for passing through an underwater narrow area to conduct underwater detection and underwater measurement operation; the precise measurement underwater robot specially plans a path to improve the cruise and measurement efficiency; a multi-beam depth finder and a binocular precision measuring instrument are utilized to synergistically carry out underwater measurement, high-precision and high-density measurement of underwater detection targets is achieved through a multi-beam depth measuring technology, binocular precision measurement helps the underwater robot to execute certain complex underwater operation tasks, and two measurement methods synergistically complete high-quality underwater precision measurement; and the relativeerror of underwater measurement is small, and the operating requirements of the underwater robot for underwater target grabbing and the like are met.

Owner:扆亮海

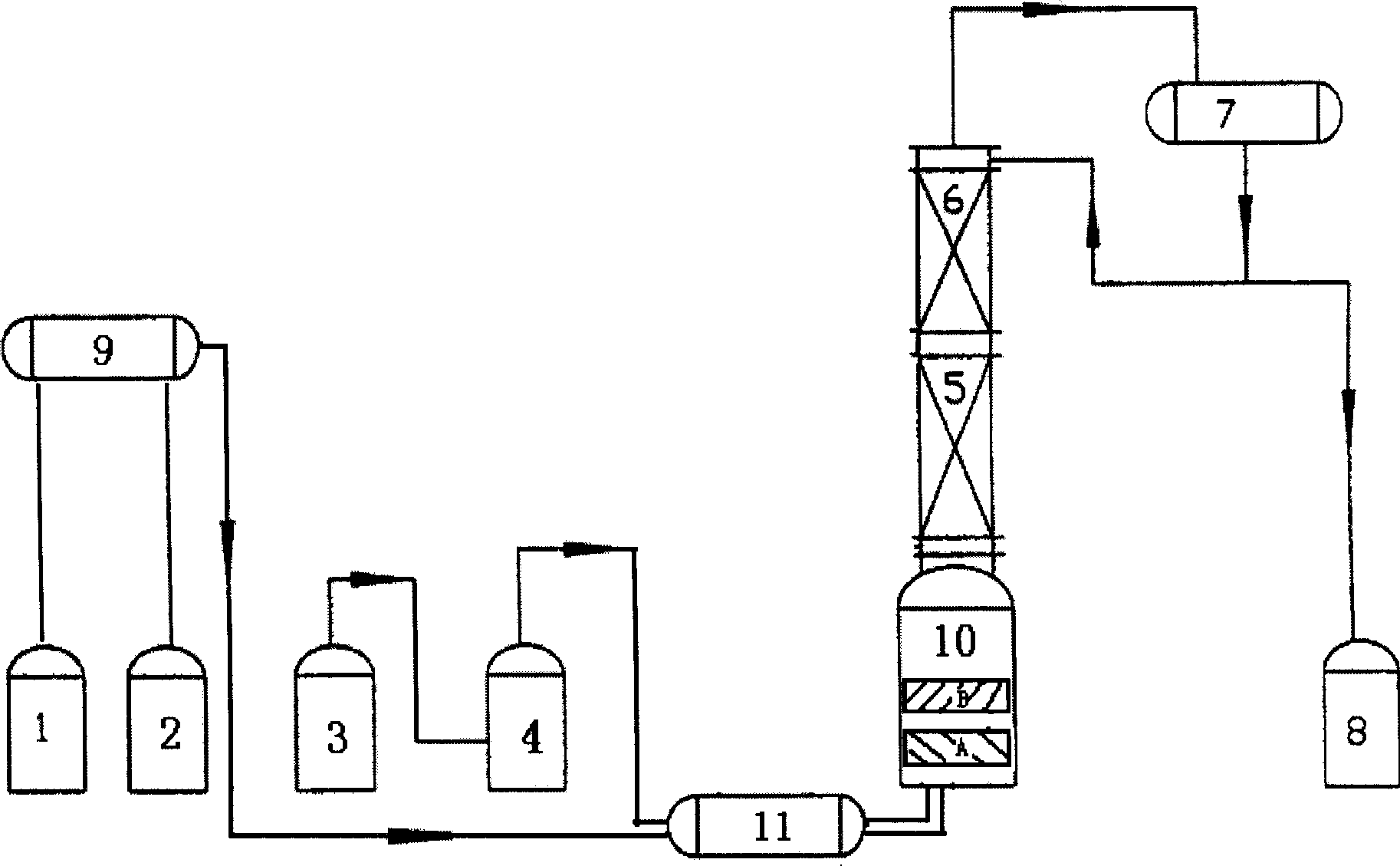

Process of preparing dimethyl dichloro silicane by organosilicon high and low boiling matter

InactiveCN100999530AIncrease profitLoose requirementsGroup 4/14 element organic compoundsSilanesHydrogen chloride

The process of preparing dimethyl dichloro silane with organosilicon high and low boiler includes a two-section catalytic reaction of the mixture of organosilicon high boiler and organosilicon low boiler and preheated hydrogen chloride or chloromethane cracking gas with active carbon and gamma-Al2O3 as catalyst at the reaction pressure not higher than 0.2MPa and temperature of 200-400 deg.c, rectification, stripping and condensation to collect product. The present invention features the weight ratio between the catalyst and the mixture material of 1-10 %, the volume ratio between organosilicon high boiler and organosilicon low boiler of 1.2-1.5 to 1, and the molar ratio between the mixture and the hydrogen chloride or chloromethane cracking gas of 1 / 1.5-2, high boiler cracking rate higher than 85 %, total yield as high as 80 %, and M2 selectivity higher than 40 %.

Owner:NANCHANG UNIV

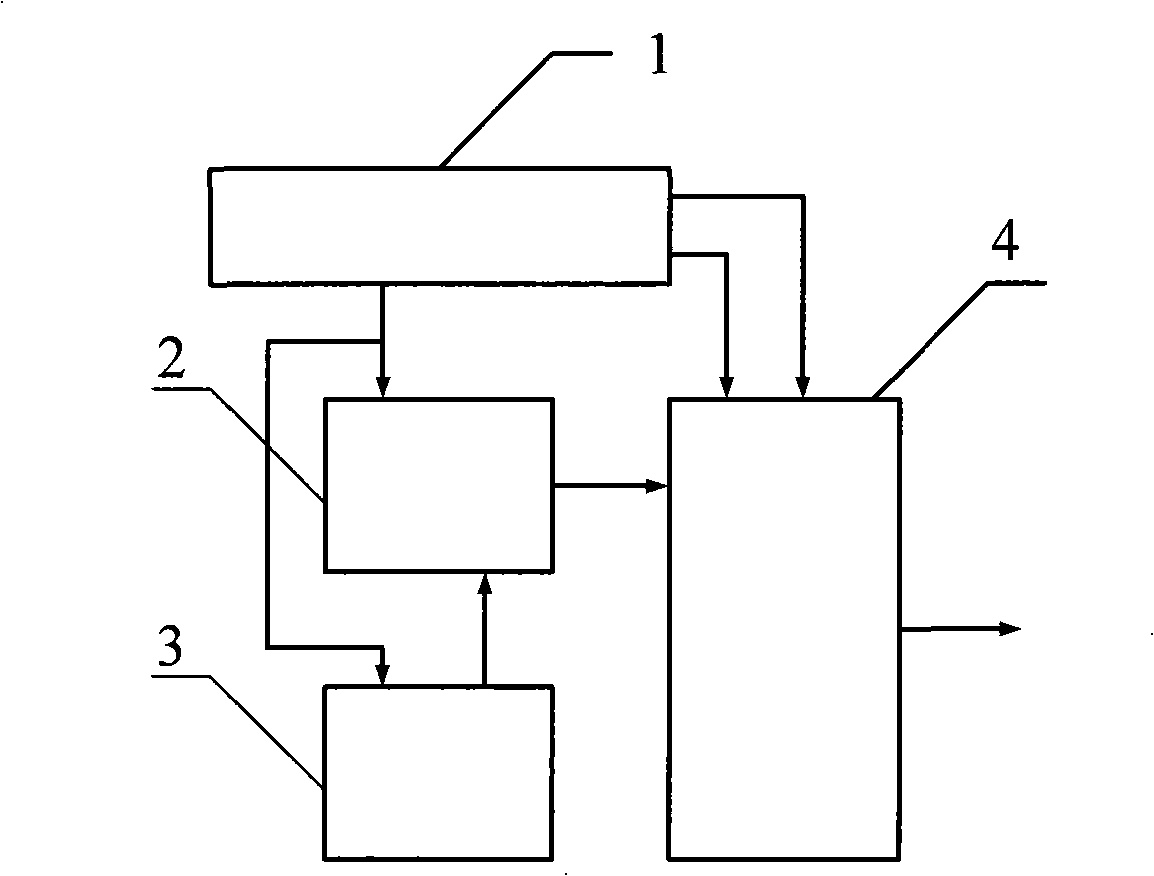

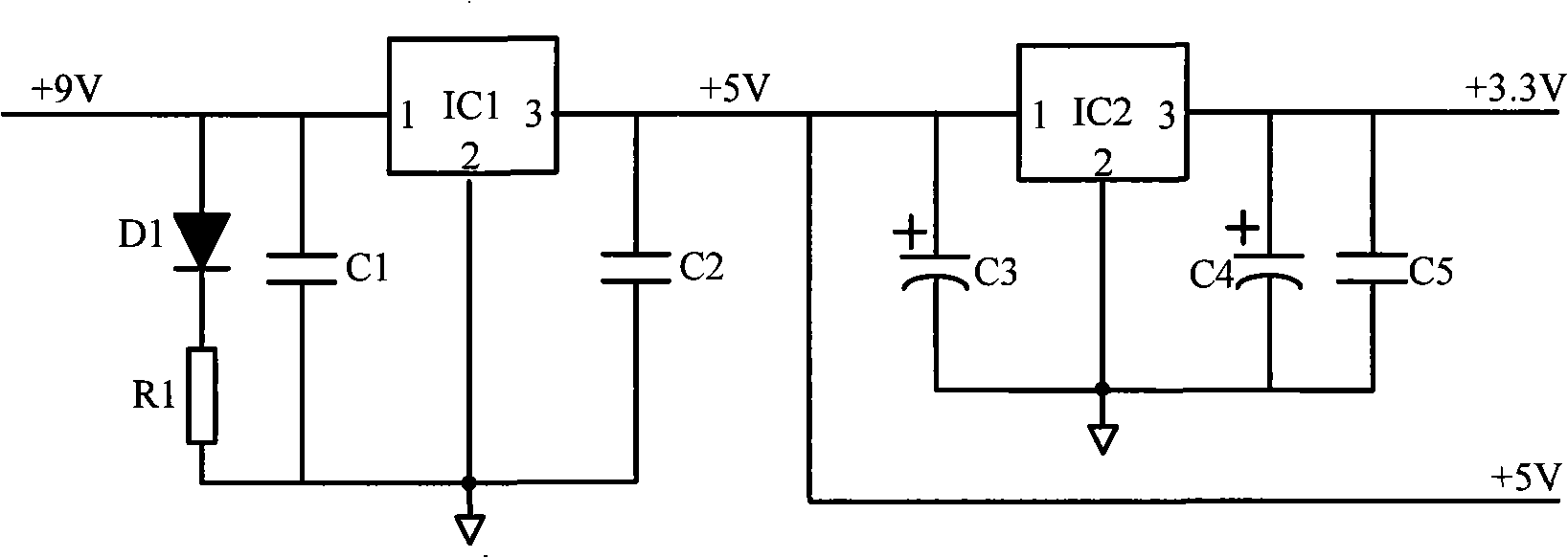

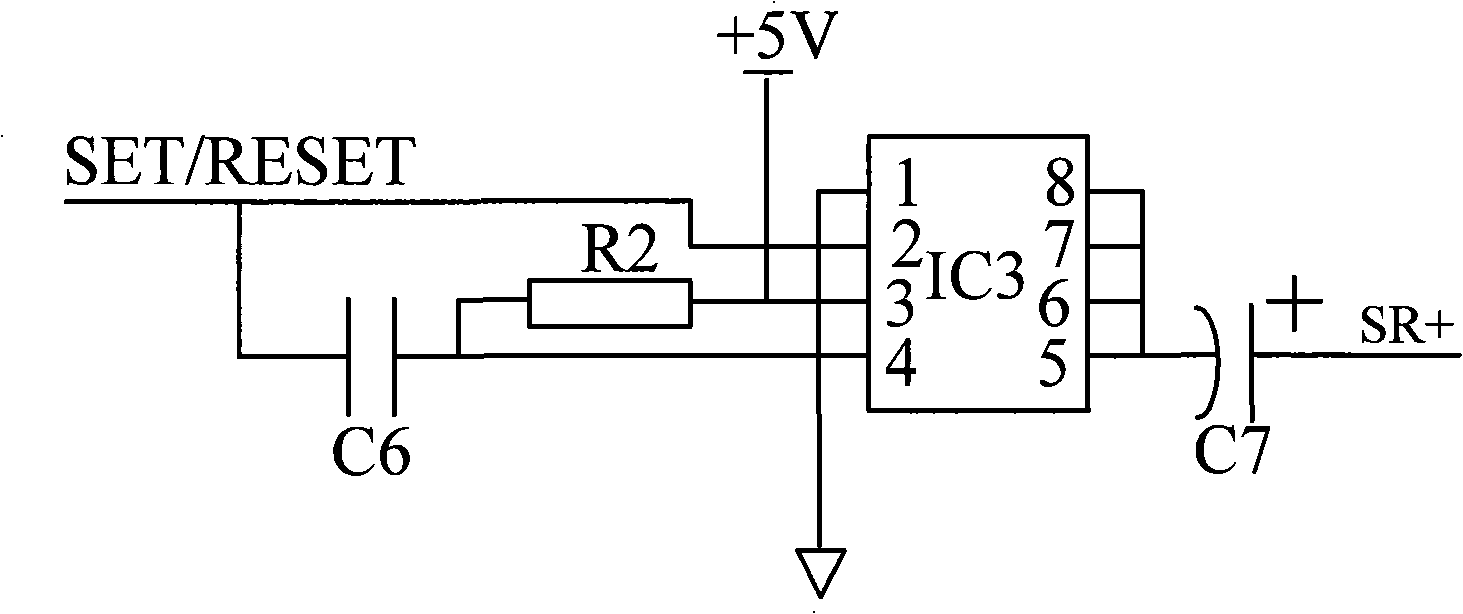

Deep sea geomagnetic field survey instrument circuit

InactiveCN101329410AFirmly connectedReduce power consumptionElectric/magnetic detectionAcoustic wave reradiationOcean bottomGyroscope

The invention relates to a circuit of a deep-sea geomagnetic measuring instrument. The precision of the existing device is too low, thereby being lack of practical significance in the application of analyzing the geomagnetic micro-change of a small ocean bottom region. The circuit comprises a power supply circuit, a setting / resetting circuit, a sensing measuring circuit and a main control circuit, wherein, the sensing measuring circuit comprises a single-axis magnetoresistive sensor chip IC4, a dual-axis magnetoresistive sensor chip IC5, three same operational amplifier circuits 5, a high-precision AC chip IC6 and a voltage reference chip IC7. The main control circuit comprises a main control chip IC8, a gyroscope chip IC9, a level conversion chip IC10 and a reading / writing interface J1 of an SD card. The circuit adopts the magnetoresistive sensing technology to constitute a deep-sea geomagnetic measuring circuit and utilizes the characteristics of high sensitivity and low power consumption of the magnetoresistive sensors, thereby having simple circuit connection, reducing the noise by 1 / f and improving the effective resolution.

Owner:HANGZHOU DIANZI UNIV

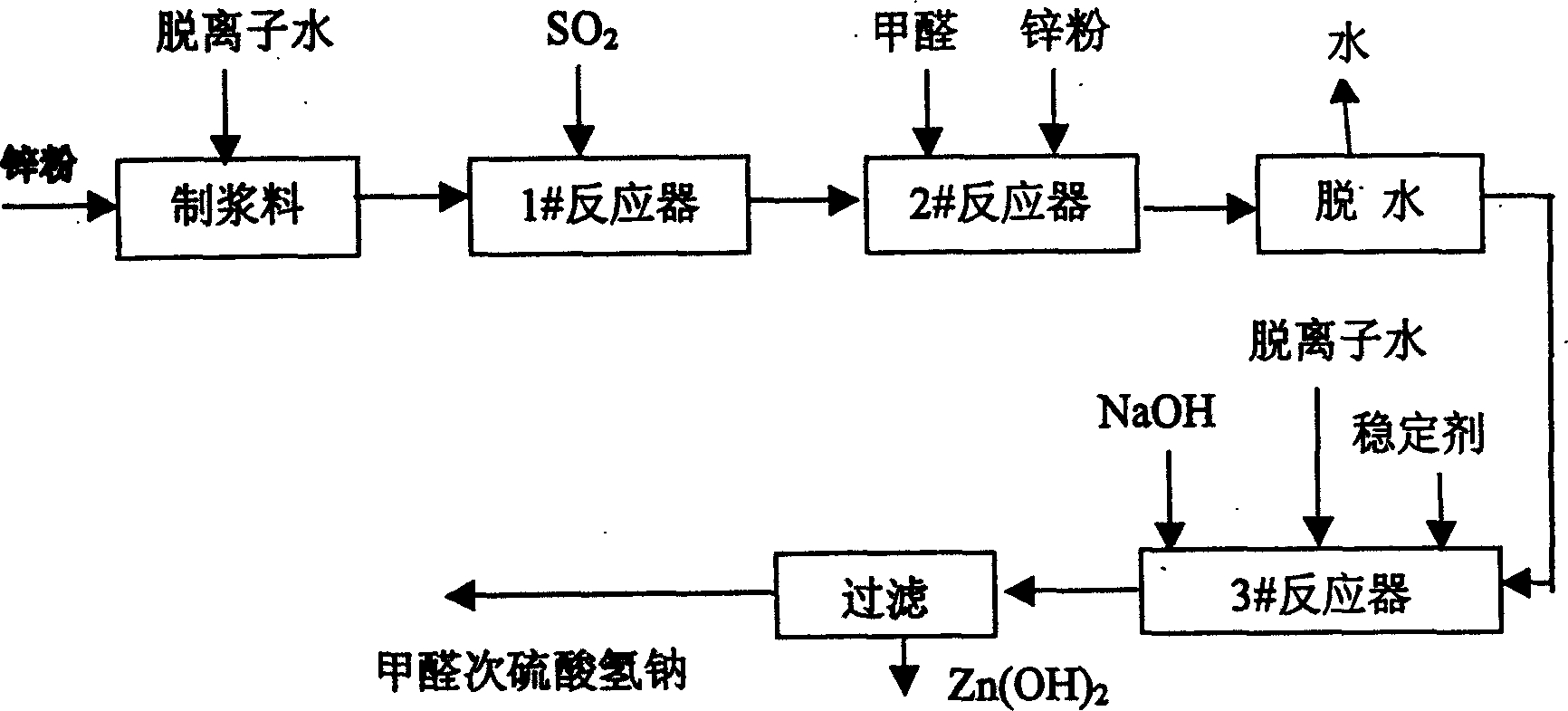

Improvement of production method of activating and modifying sodium bisulfoxylate formaldehyde

InactiveCN1557695ASignificant positive effectImprove stabilityOrganic chemistrySulfur compoundsSlurrySodium bisulfate

The improved production process of formaldehyde sodium sulfoxylate activator includes making slurry with zinc powder and deionized water in the weight ratio of 1 to 4.545; pumping the slurry into the first reactor and introducing SO2 gas at 55 deg.c until the material becomes yellow; adding formaldehyde in 1.65 times the initial zinc powder weight into the second reactor, adding the material from the first reactor, heating to 100 deg.c while stirring, adding zinc powder of 0.82 time the initial amount, lowering the temperature to 70 deg.c, said vacuum dewatering to water content of not more than 20 %; adding deionized water in the amount of 1.3 times the initial water weight to the third reactor, adding the dewatered material, heating to 70 deg.c under stirring, adding EAC stabilizer in the amount of 1 % of zinc powder weight slowly, adding NaOH after 10 min to pH 11, filtering and collecting product.

Owner:吉林市大宇化工有限公司

Method for floatation of apatite using collector prepared from illegal cooking oils

The invention relates to a method for the floatation of apatite using a collector prepared from illegal cooking oils, wherein the preparation of the collector comprises the following steps of: (a) cleansing and purifying the illegal cooking oils; and (b) performing a hydrolysis reaction on the illegal cooking oils cleansed and purified in the step a, thereby obtaining the collector for the floatation of minerals. The collector prepared from the illegal cooking oils in the invention, if used for the floatation of apatite, is capable of improving the selectivity of the collector and advantageous to increasing the technique indexes and the economic indexes of the floatation; as the raw materials for preparing the collector in the invention are the illegal cooking oils, the technical solution of the invention plays an important role in avoiding environmental pollution, simplifying production process and reducing food safety threats and the like.

Owner:鄂尔多斯市君致清环境科技有限公司

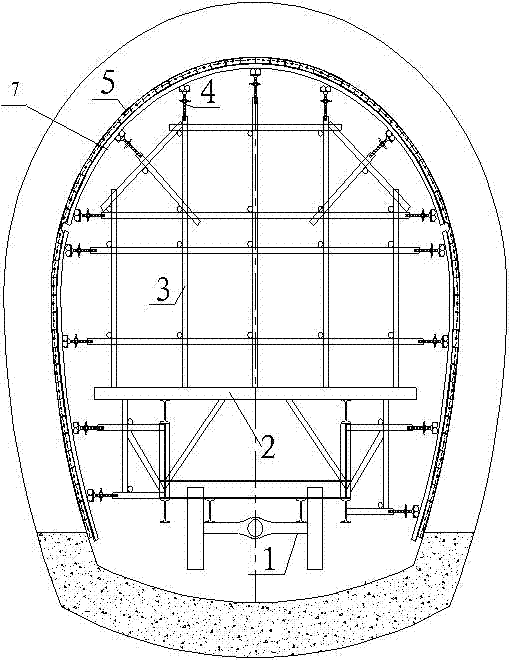

Simple steel mould trolley

InactiveCN102777192ASolve difficultySolve space problemsUnderground chambersTunnel liningSteel tubeBuilding construction

The invention discloses a simple steel mould trolley which is mainly composed of a running wheel, a platform, a load bearing scaffold, a lagging jack and a moldboard, wherein the platform is arranged on the running wheel, the load bearing scaffold is arranged on the platform, and the lagging jack is an arc-like structure frame made of a steel pipe; the lagging jack is composed of a top arch and two side arches, the side arches are articulated with the top arch, and the moldboard is composed of a side module and a top module; and the lagging jack of the top module is placed above the load bearing scaffold, the lagging jacks of the side arches are placed on the two sides of the load bearing scaffold, and the side module and the top module are fixed on the lagging jack. Compared with the traditional steel mould trolley, the manufacturing cost is low, the performance is high, the operation is simple and convenient, the installation is rapid, the processing and manufacturing material can be totally utilized and recycled basically, the construction process is simple, and the building workers can master the simple steel mould trolley conveniently.

Owner:SINOHYDRO BUREAU 14 CO LTD

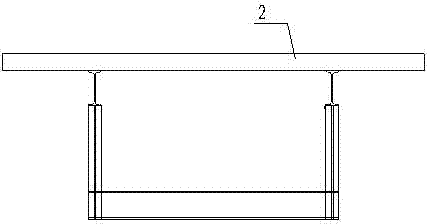

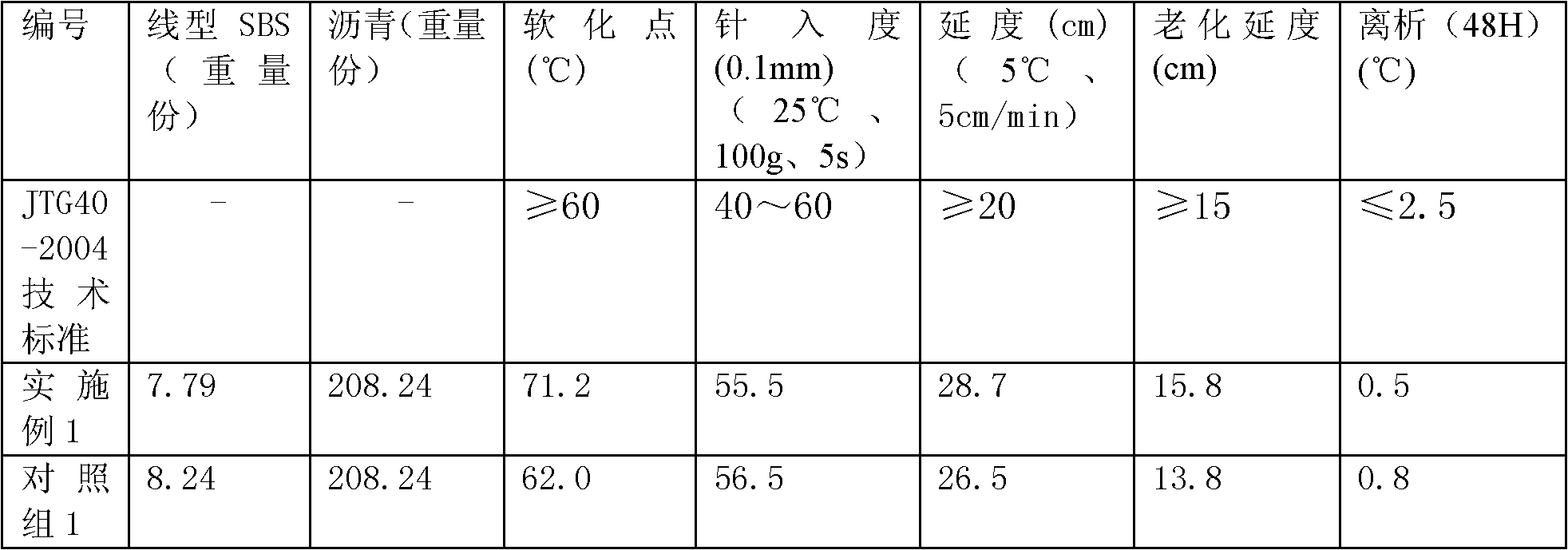

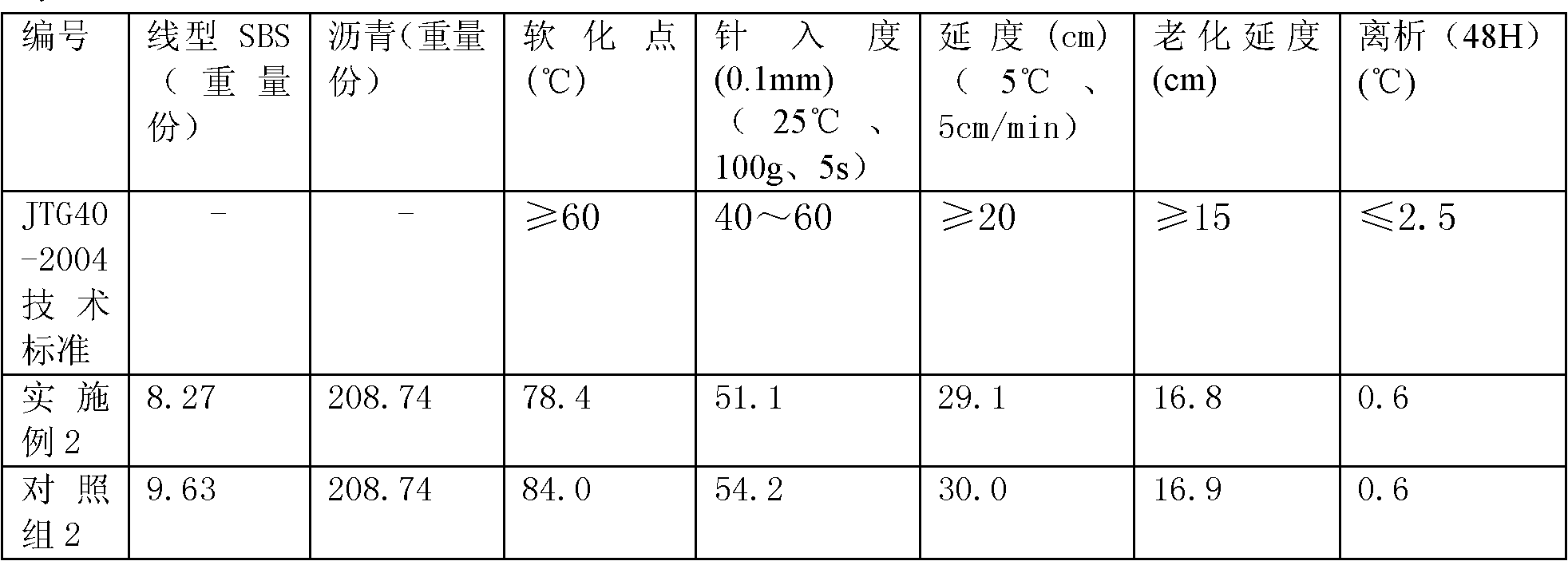

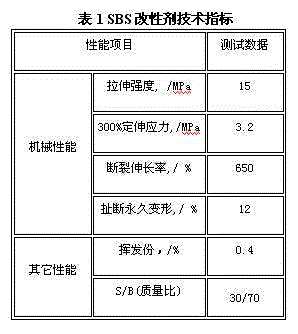

Process for producing styrene-butadiene-styrene block copolymer (SBS) modified asphalt

ActiveCN102643555AIncrease costExcellent technical indicatorsBuilding insulationsMolten stateHighway engineering

The invention discloses a process for producing styrene-butadiene-styrene block copolymer (SBS) modified asphalt, which includes the following steps of a swelling, a shearing, a primary development, a secondary development and an obtainment of a finished product of the SBS modified asphalt, wherein the swelling includes that base asphalt is heated to be in a molten state, the shearing includes that the base asphalt after being subjected to the swelling is mixed with a SBS modifier to be subjected to shearing and grinding to form a mixture, the primary development comprises that a portion of the base asphalt subjected to the swelling and a stabilizing agent are added into the mixture after shearing to develop and a semi-finished product of the SBS modified asphalt is obtained after the primary development is completed, the secondary development comprises that the base asphalt subjected to the swelling is further added into the semi-finished product of the SBS modified asphalt obtained in the primary development to develop, and the finished product of the SBS modified asphalt is obtained after the secondary development is completed. By means of the process for producing the styrene-butadiene-styrene block copolymer (SBS) modified asphalt, the asphalt is subjected to developing for two times, and a full development is achieved by adding a portion of the base asphalt subjected to swelling in each time of developing, thereby the content of the SBS modifier in the finished product is equal to or larger than 3.6% and simultaneously the technical index of the finished product can meet the requirements of highway engineering asphalt of industry standard of People' Republic of China.

Owner:HUBEI GUOCHUANG HI TECH MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof 3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof](https://images-eureka.patsnap.com/patent_img/49991abd-a492-4cc4-b108-b0b4c8a83786/HDA0001854376810000011.png)

![3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof 3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof](https://images-eureka.patsnap.com/patent_img/49991abd-a492-4cc4-b108-b0b4c8a83786/HDA0001854376810000021.png)

![3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof 3.5-3.9[Mu]m medium wave infrared mini-type optical filter and preparation method thereof](https://images-eureka.patsnap.com/patent_img/49991abd-a492-4cc4-b108-b0b4c8a83786/HDA0001854376810000031.png)