High-viscosity spraying type SBS modified emulsified asphalt and preparing method thereof

A technology for emulsified asphalt and modified asphalt, applied in building components, building insulation materials, construction and other directions, can solve the problems of high production cost, inability to apply upgrade and maintenance requirements, and high cost, and achieve good emulsification effect, good application prospects, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

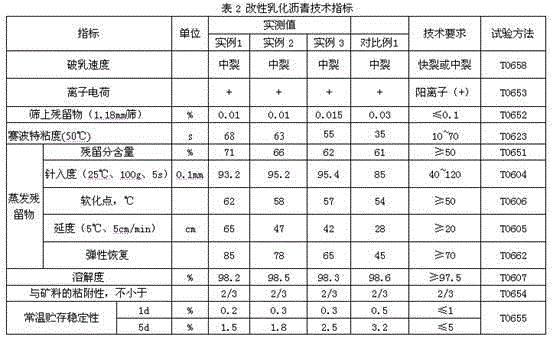

[0030] A high-viscosity spray-type SBS modified emulsified asphalt, including the following components by weight percentage: 63.7% of base asphalt, 0.24% of SBS modifier, 0.06% of viscosity reducer, 1% of cationic emulsifier, 1% of stabilizer, Hydrochloric acid 0.5%, water 33.5%;

[0031] The base asphalt is one or more mixtures of road petroleum asphalts with a penetration of 60-150 mm;

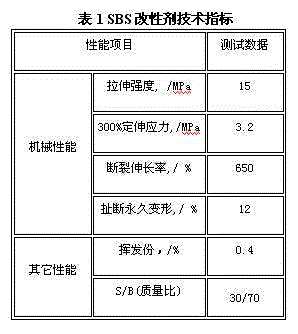

[0032] The SBS is a linear structure with a weight average molecular weight of 80,000 to 150,000;

[0033] The viscosity reducer is lignosulfonate.

[0034] The cationic emulsifier is BE-2.

Embodiment 2

[0037] A high-viscosity spray-type SBS modified emulsified asphalt, including the following components by weight percentage: 60.61% of base asphalt, 0.18% of SBS modifier, 0.21% of viscosity reducer, 2% of cationic emulsifier, 2% of stabilizer, 1% hydrochloric acid, 34% water;

[0038] The base asphalt is No. 70 asphalt with a penetration of 70 to 80 mm or No. 90 asphalt with a penetration of 90 to 100 mm;

[0039] The SBS is a linear structure with a weight average molecular weight of 90,000 to 100,000;

[0040] Described viscosity reducer is GGX-1.

[0041] The cationic emulsifier is MQK-1M.

Embodiment 3

[0044] A high-viscosity spraying type SBS modified emulsified asphalt, comprising the following components by weight percentage: base asphalt 68%, SBS modifier 0.18%, viscosity reducer 0.06%, cationic emulsifier 1%, stabilizer 0.1%, Hydrochloric acid 0.5%, water 30.16%;

[0045] The base asphalt is No. 70 bitumen with a penetration of 60-80 mm or No. 90 bitumen with a penetration of 80-100 mm;

[0046] The SBS is a linear structure with a weight average molecular weight of 100,000 to 150,000;

[0047] Described cationic emulsifier is GNN-R;

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com