Simple steel mould trolley

A steel formwork trolley, a simple technology, applied in the direction of shaft lining, tunnel lining, underground chamber, etc., can solve the problems of low cost performance, low secondary utilization rate, high transfer cost and transformation cost of steel formwork trolley, and achieve construction Low cost, fast construction progress, and the effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

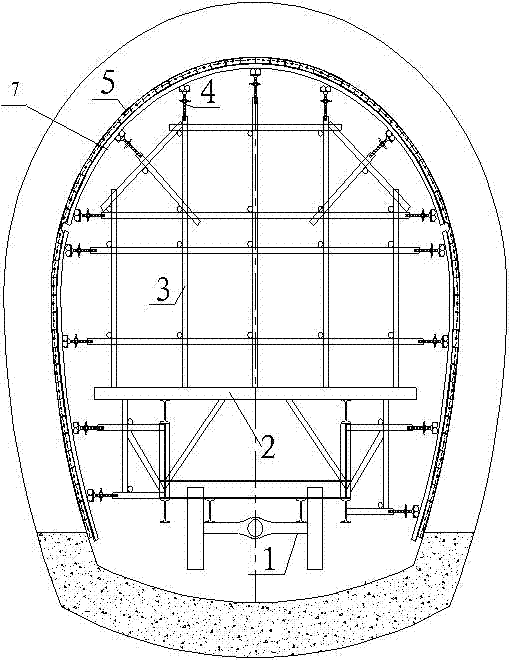

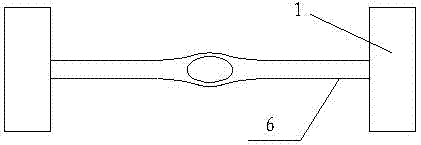

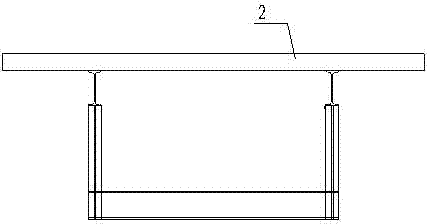

[0015] The simple steel mold trolley of the present invention is composed of a walking wheel (automobile rear axle) 1, a platform 2, a load-bearing scaffold 3 (Φ48 steel pipe), a template 5, an arch 8, and the like. The platform 2 is placed on the walking wheel 1, and the load-bearing scaffold 3 is installed on the platform. The arch frame 8 is an arc-shaped structural frame made of steel pipes. The arch frame is composed of a top arch and two side arches, and the side arches are hinged to the top arch. , formwork 5 is the side formwork and the top formwork, the top arch formwork is placed above the load-bearing scaffold, the side arch formwork is placed on both sides of the load-bearing scaffold, the side formwork and top formwork are fixed on the arch frame, the load-bearing scaffold is installed on the platform 2, the top The arch frame is placed above the load-bearing scaffold 3, the arch frames on both sides are placed on both sides of the load-bearing scaffold, and the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com