Compensator for electric-railway non-power compensation and electric-energy quality control

An electrified railway and compensation device technology, applied in reactive power adjustment/elimination/compensation, reactive power compensation, etc. Resonance or harmonic current amplification is reduced, harmonic suppression is achieved, and service life is shortened

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

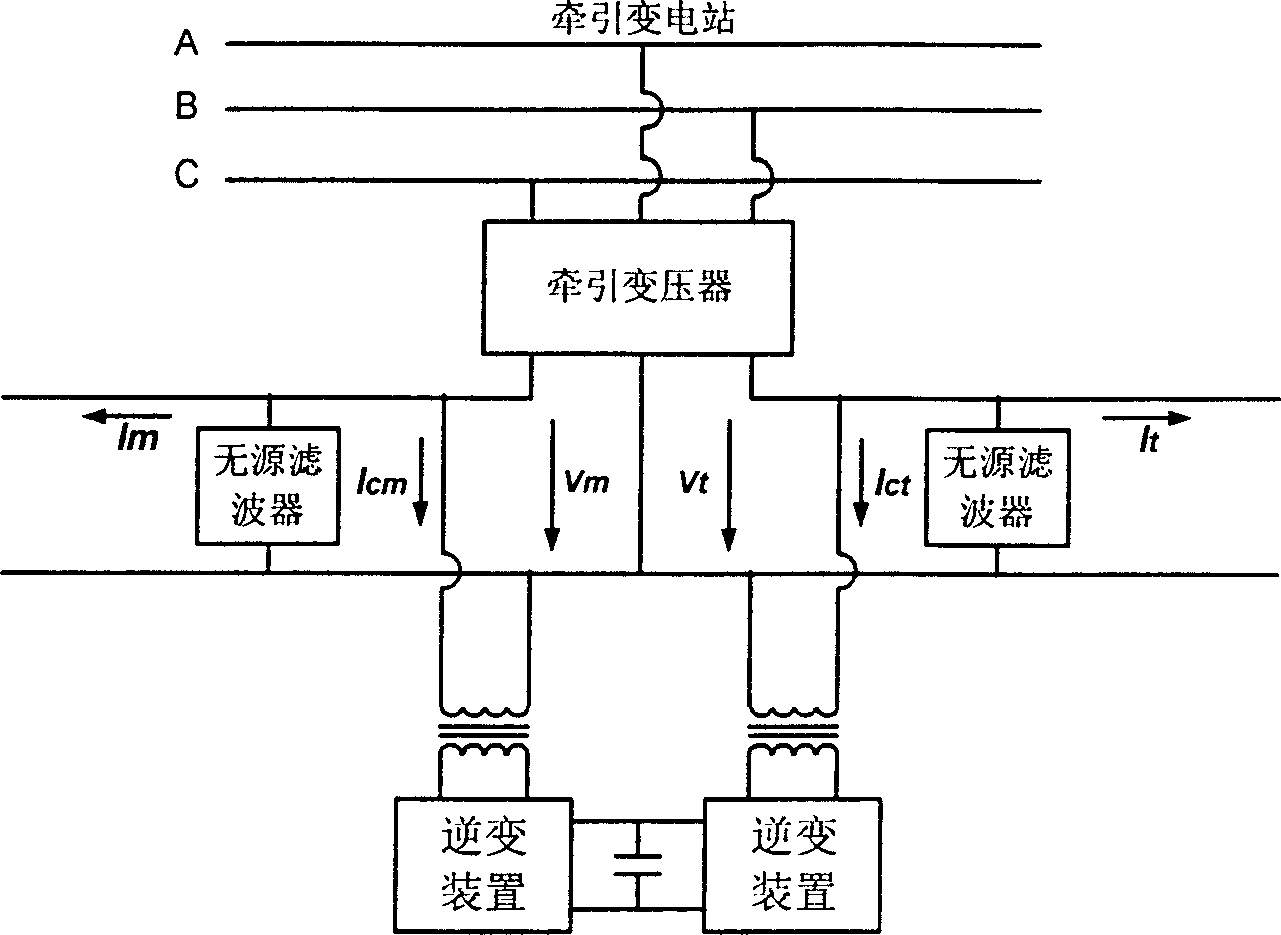

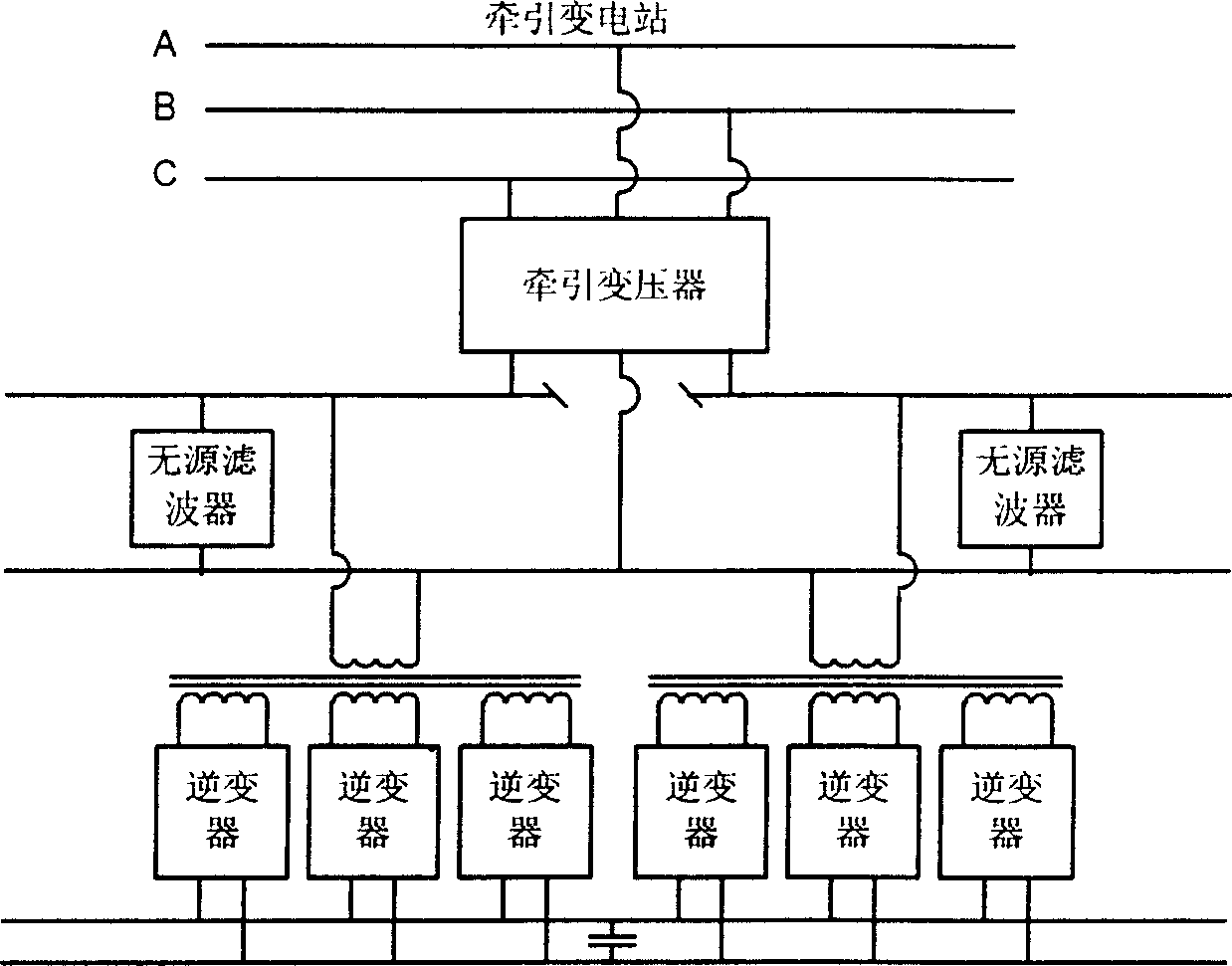

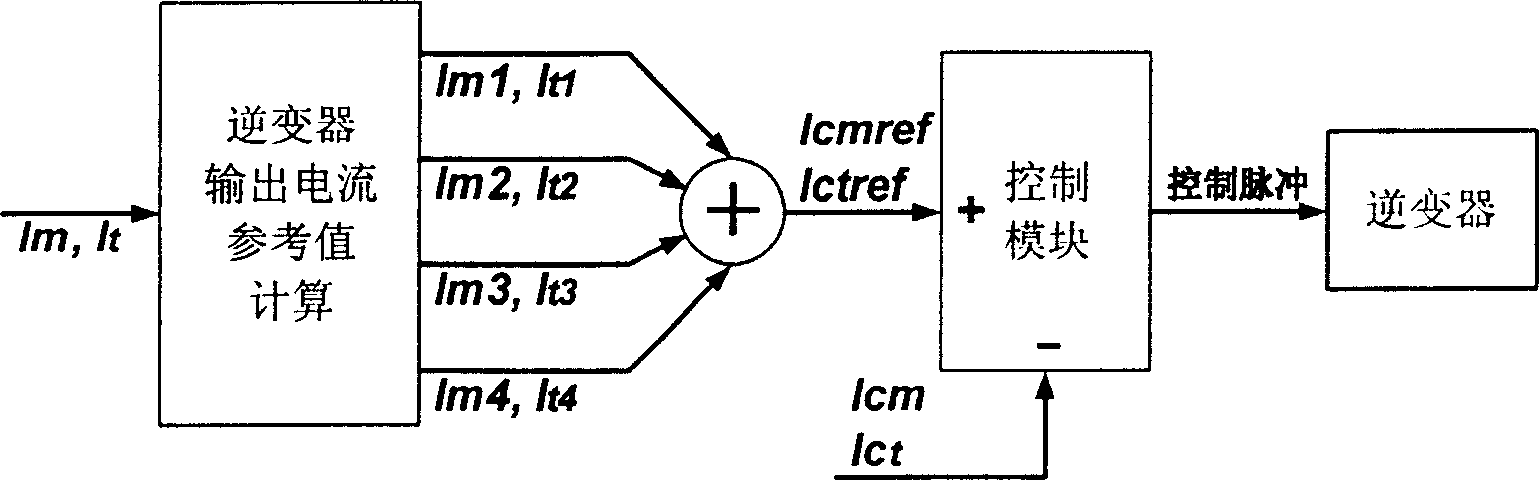

[0024] The compensation device for reactive power compensation and power quality control of electrified railways proposed by the present invention has a structure such as figure 1 As shown, it includes: two sets of passive filters, used to provide reactive power for electrified railway electric locomotives and filter out harmonic currents generated by electric locomotives, the passive filters are connected in parallel on the power supply arms of electrified railways; two sets of An inverter device consisting of one or more single-phase inverters is used to generate current with controllable amplitude, phase and frequency; two sets of transformers are used to couple the current generated by the above two groups of inverter devices to the electrified On the power supply arm of the railway, the primary side of the transformer is connected in parallel to the power supply arm of the electrified railway, and the secondary side is connected to the inverter device; Active power is tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com