Strong waterproof ceramic tile gum and preparation and construction method thereof

A ceramic tile and adhesive technology, applied in the direction of adhesive types, adhesive additives, non-polymer adhesive additives, etc., can solve the problem of easy aging, hardening and brittle coating film, poor resistance to tile deformation, water resistance and durability Poor performance and other problems, to achieve the effect of good durability, simple construction, and shorten the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

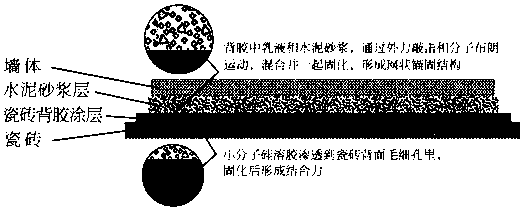

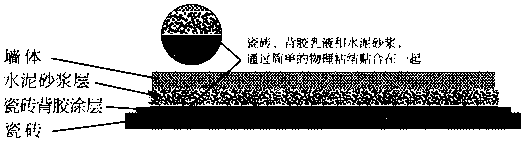

Method used

Image

Examples

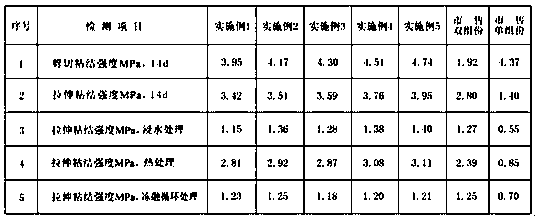

Embodiment 1

[0037] A strong water-resistant tile adhesive, which contains the following components in weight percentage: styrene-butadiene emulsion 25%, nano-silica sol 4%, adhesion promoter 0.25%, filler 48%, silica powder 2.5%, thickener 0.3% , 0.3% cement activator, 0.2% preservative, and the rest is water.

[0038] Wherein said styrene-butadiene emulsion is SD7623 styrene-butadiene emulsion produced by BASF in Germany, said nano-silica sol is TUS-1 silica sol produced by Zhejiang Yuda Chemical Co., Ltd., and said adhesion promoter is KH-450 water-based silane coupling agent, The filler is 70-100 mesh quartz sand, and the silicon micropowder is 2000 mesh powder. The thickener is hydroxyethyl cellulose with a viscosity of 50,000, the cement activator is triethanolamine, and the preservative is Kathon.

[0039] The preparation method of a strong water-resistant ceramic tile adhesive of the present invention comprises the following steps: adding the thickener in the proportion into water...

Embodiment 2

[0043]A strong water-resistant tile adhesive, which contains the following components by weight percentage: styrene-butadiene emulsion 30%, nano-silica sol 4.5%, adhesion promoter 0.3%, filler 47%, silica powder 2.5%, thickener 0.3% , 0.3% cement activator, 0.2% preservative, and the rest is water.

[0044] The materials, preparation method and application method of the ceramic tile adhesive of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0046] A strong water-resistant tile adhesive, which contains the following components in weight percentage: styrene-butadiene emulsion 35%, nano-silica sol 5.5%, adhesion promoter 0.28%, filler 44%, silica powder 2.0%, thickener 0.25% , 0.3% cement activator, 0.1% preservative, and the rest is water.

[0047] The materials, preparation method and application method of the ceramic tile adhesive of this embodiment are the same as those of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com