Improvement of production method of activating and modifying sodium bisulfoxylate formaldehyde

A technology of sodium formaldehyde sulfoxylate and production method, applied in chemical instruments and methods, sulfur compounds, inorganic chemistry and other directions, can solve problems such as poor stability and decreased activity, and achieve improved stability, simplified process and guaranteed purity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

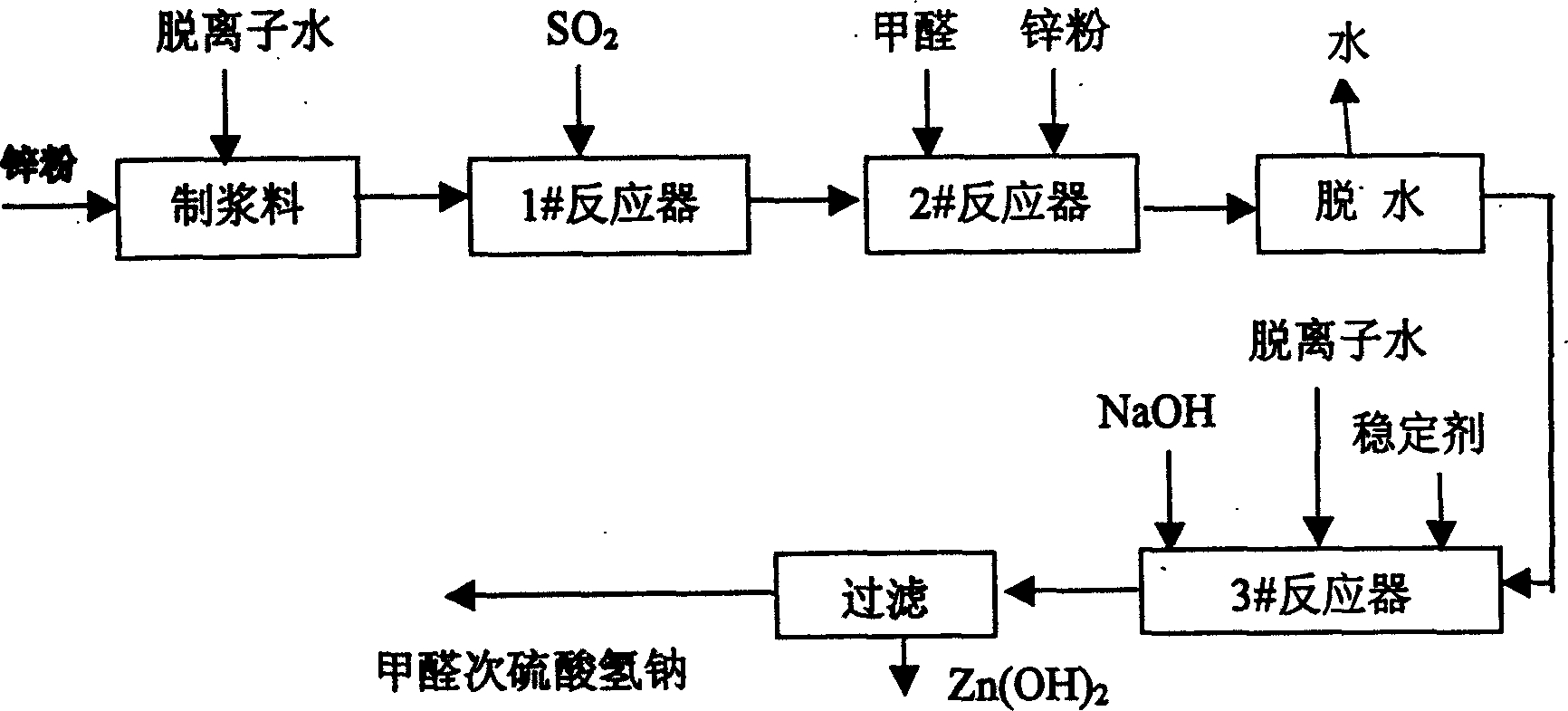

[0019] With reference to the drawings and specific implementation methods, the present invention is further described as follows:

[0020] See Figure 2 After 110kg of zinc powder and 500kg of deionized water are made into a slurry, it is pumped into the 1# reactor, the circulation pump is started, and SO is introduced into the reactor 2 For gas, use cooling water to control the temperature to 55±5℃, and stop entering SO when the material turns yellow 2 Analyze the zinc disulfite content ≥400g / L to obtain qualified ZnS 2 O 4 .

[0021] Add 165kg of formaldehyde solution (content 37%) to the 2# reactor, and then add the ZnS in the above 1# reactor 2 O 4 Add it to the reactor, heat with steam, start stirring and control the temperature to 100±5℃, and add zinc powder in batches. The amount is 0.82 times the original amount of zinc powder mentioned above. Add 2kg per batch until the addition After the heating is stopped, when the temperature reaches 70°C, the material is sent to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com